Preparation and wide temperature range tribological behavior of VN-Ag-MoO3 composites

-

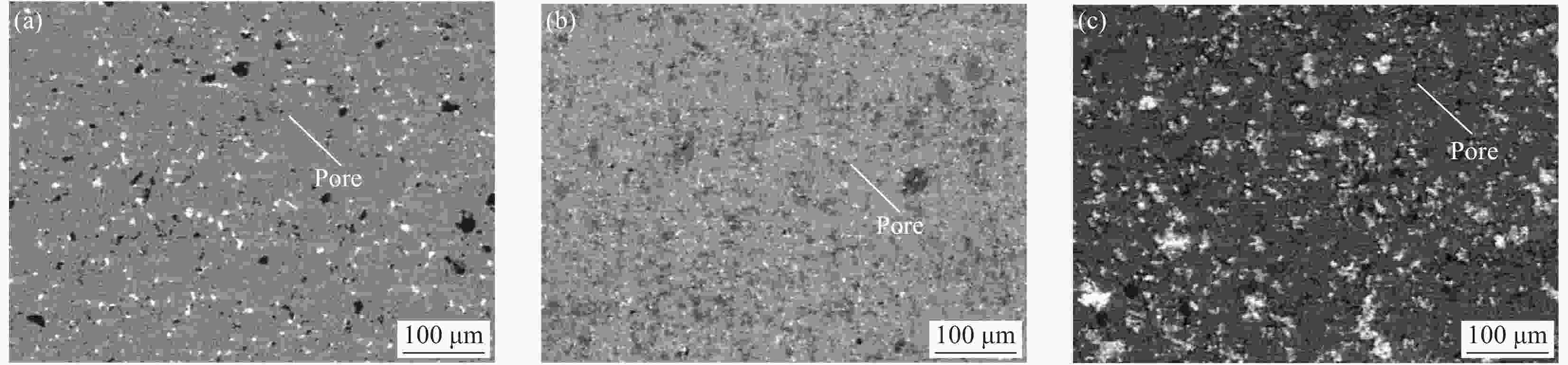

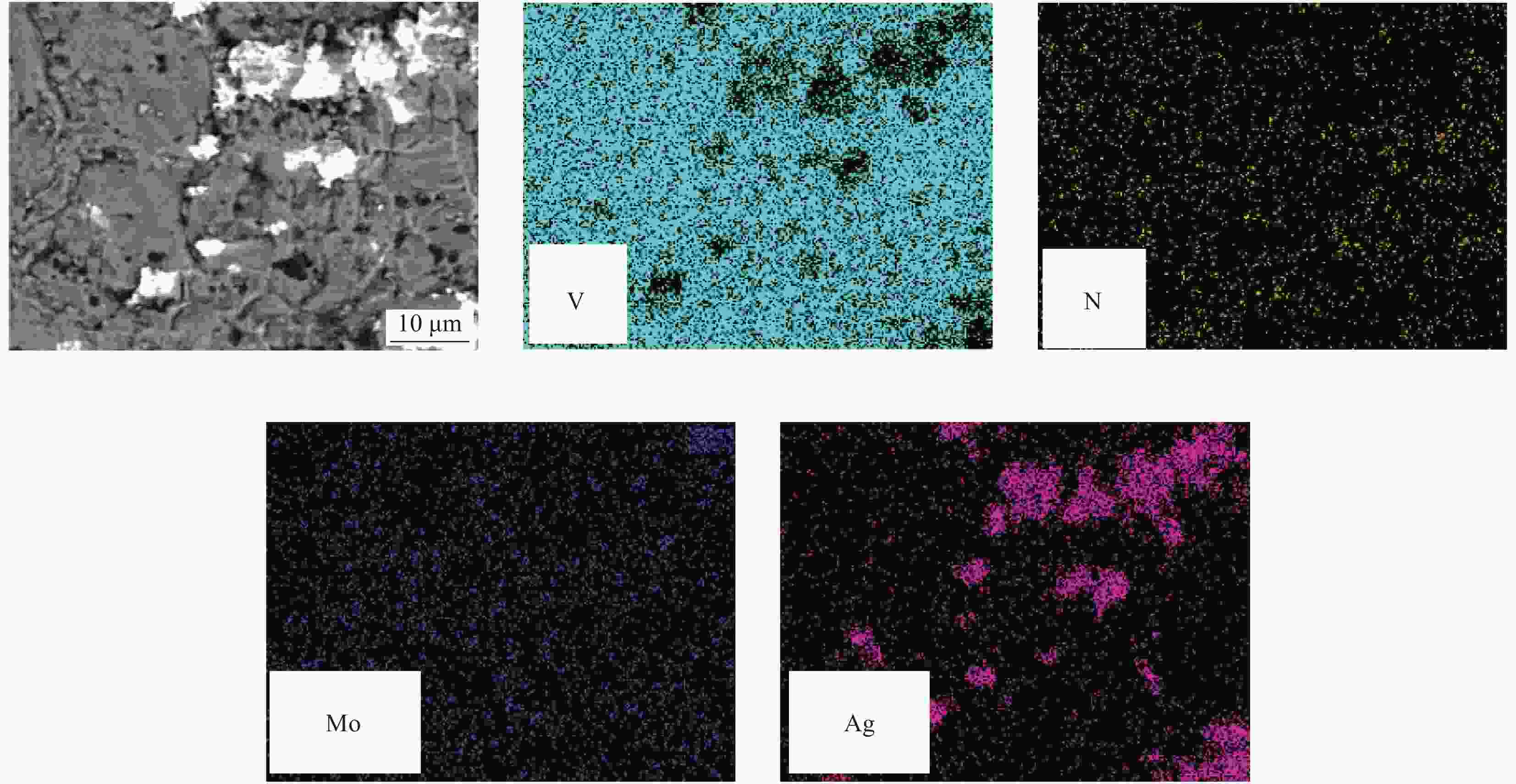

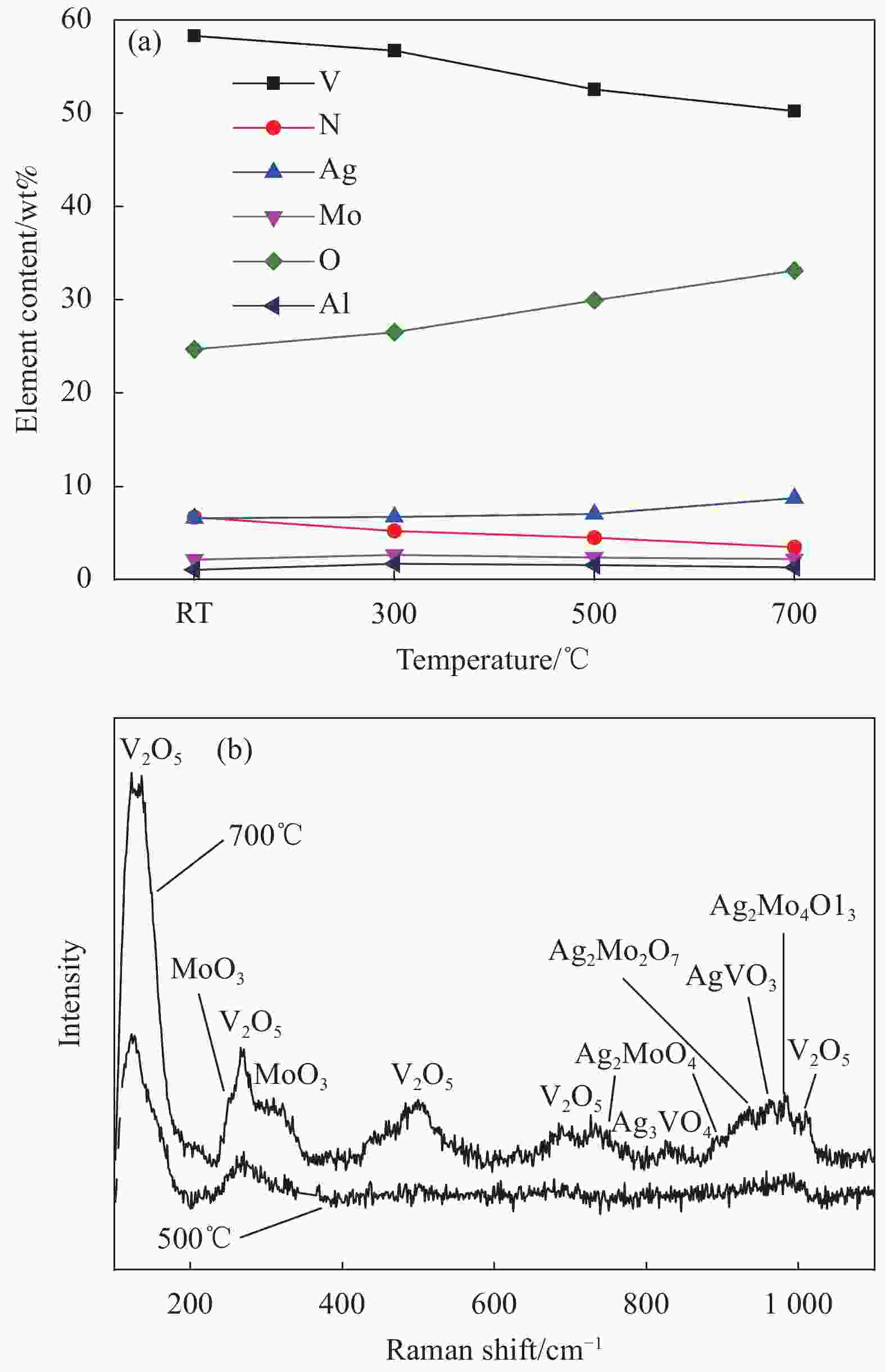

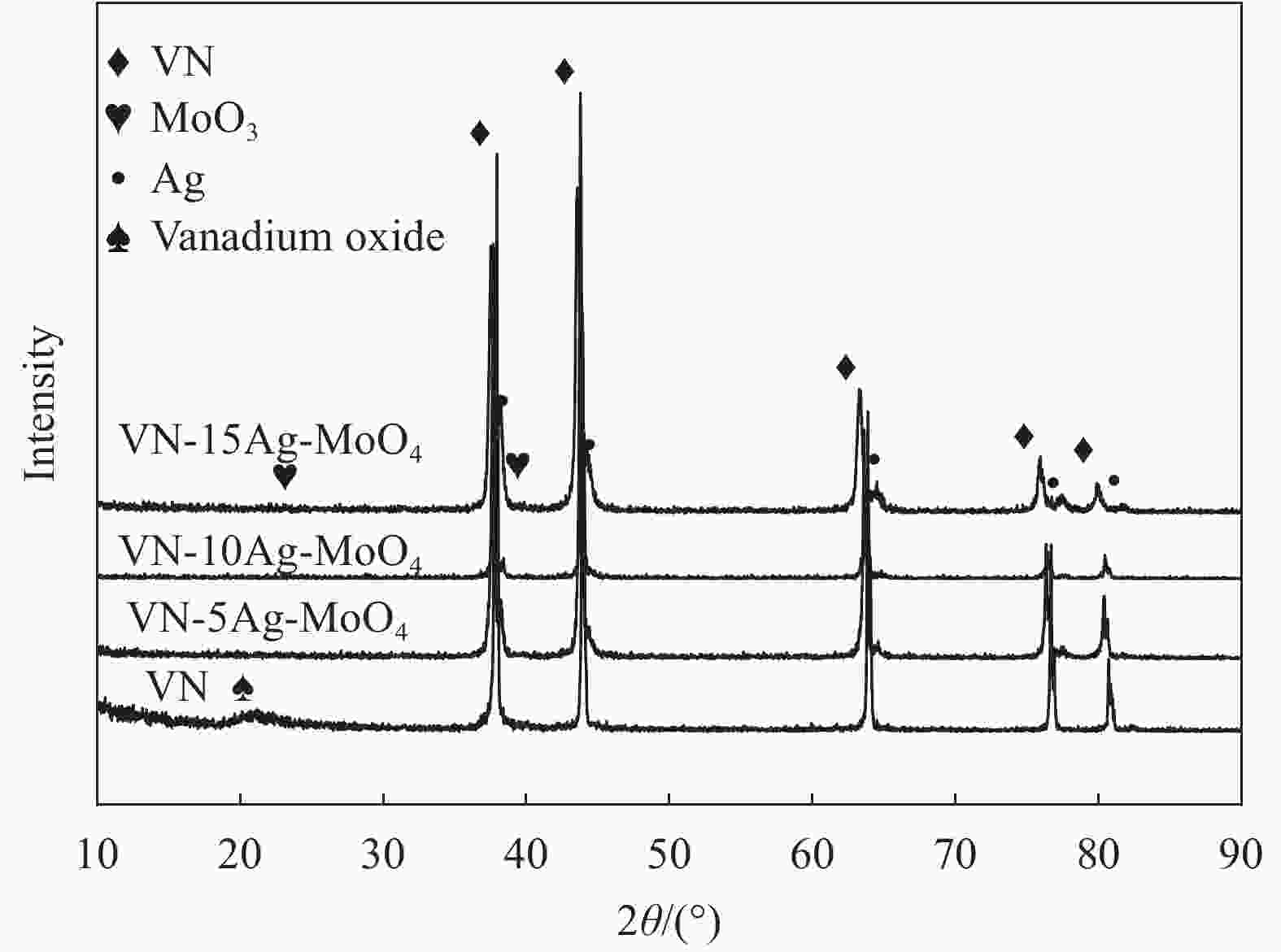

摘要: 利用真空热压烧结技术制备了VN-Ag-MoO3复合材料,研究了Ag2MoO4对VN基复合材料组织结构及宽温域摩擦磨损性能的影响。结果表明:VN-Ag-MoO3复合材料组织较致密,主要由VN、MoO3和Ag组成,其中均匀分布于VN基体的MoO3和Ag由Ag2MoO4经高温分解形成。宽温域摩擦磨损测试表明,Ag2MoO4的添加有效改善了室温(RT)~700℃温域范围VN陶瓷的摩擦磨损性能。其中,700℃时Ag2MoO4含量为10wt%的VN-10Ag-MoO3的摩擦系数(0.285)和磨损率(1.37×10−5 mm3/(N·m))分别较VN降低了23%和72%,这归因于磨损表面的氧化钒、钒酸银和钼酸银等高温润滑相起到了优异的润滑及减磨作用。Abstract: VN-Ag-MoO3 composites were prepared by vacuum hot pressing sintering. The effects of Ag2MoO4 on the microstructure and wide temperature range friction and wear properties of VN matrix composites were investigated. The results show that the structure of VN-Ag-MoO3 composite is relatively compact, mainly composed of VN, MoO3 and Ag, and the MoO3 and Ag distributed evenly in VN matrix are formed by the decomposition of Ag2MoO4 at high temperature. Friction and wear tests in a wide temperature range show that the addition of Ag2MoO4 can effectively improve the friction and wear properties of VN ceramics in the temperature range of room temperature (RT)-700℃. The friction coefficient (0.285) and wear rate (1.37×10−5 mm3/(N·m)) of VN-10Ag-MoO3 with 10wt% Ag2MoO4 at 700℃ are 23% and 72% lower than those of VN, respectively, which are attributed to the excellent lubrication and wear reduction effects of high temperature lubrication phases such as vanadium oxide, silver vanadate and silver molybdate on the wear surface.

-

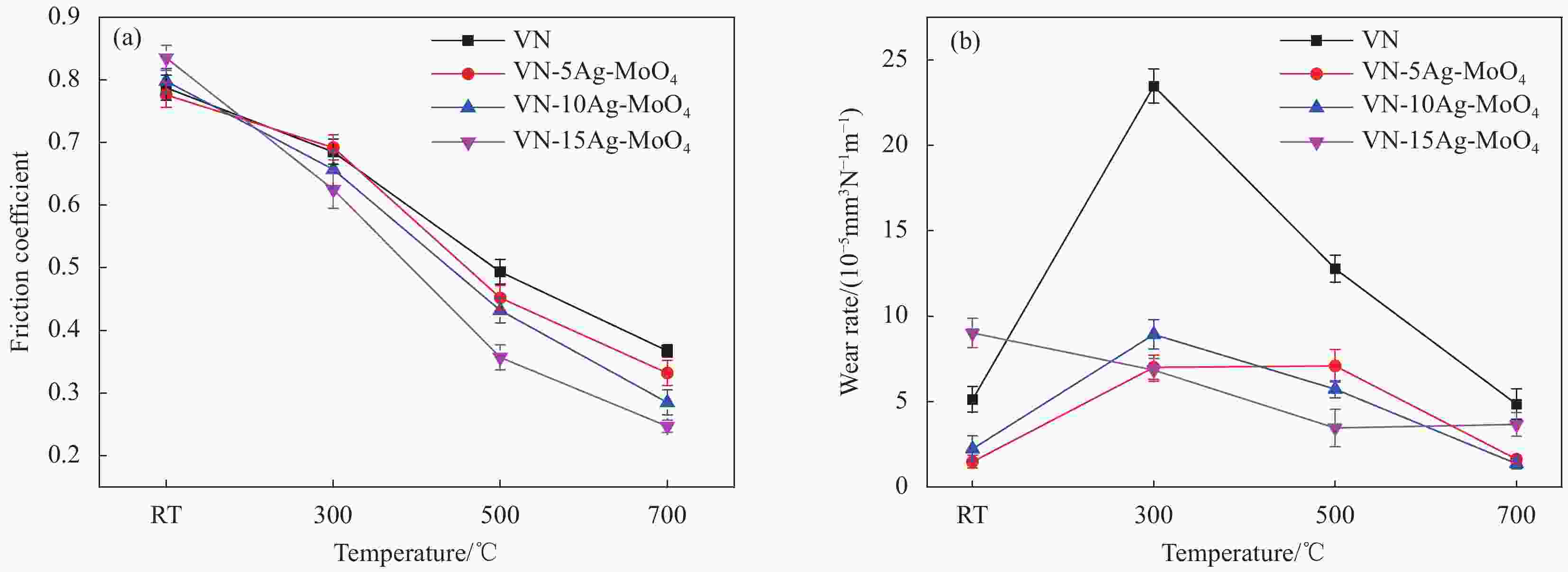

图 5 不同温度时VN-Ag-MoO3复合材料的磨损形貌

Figure 5. SEM morphologies of worn surfaces of VN-Ag-MoO3 composites at different temperatures ((a) VN- 5Ag-MoO3, RT; (b) VN-10Ag-MoO3, RT; (c) VN-15Ag-MoO3, RT; (d) VN-5Ag-MoO3, 300℃; (e) VN-10Ag-MoO3, 300℃; (f) VN-15Ag-MoO3, 300℃; (g) VN-5Ag-MoO3, 500℃; (h) VN-10Ag-MoO3, 500℃; (i) VN-15Ag-MoO3, 500℃; (j) VN-5Ag-MoO3, 700℃; (k) VN-10Ag-MoO3, 700℃; (l) VN-15Ag-MoO3, 700℃)

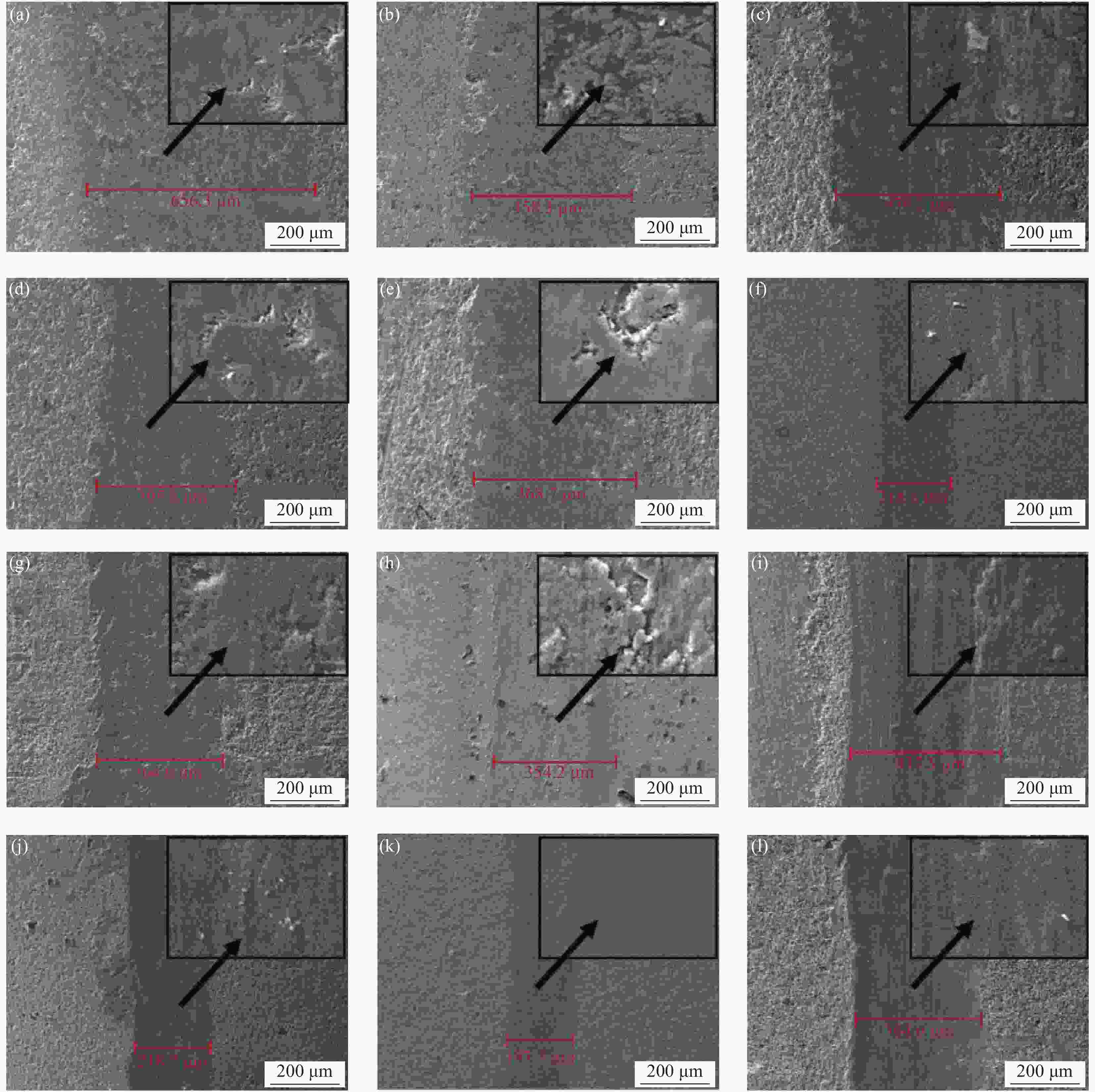

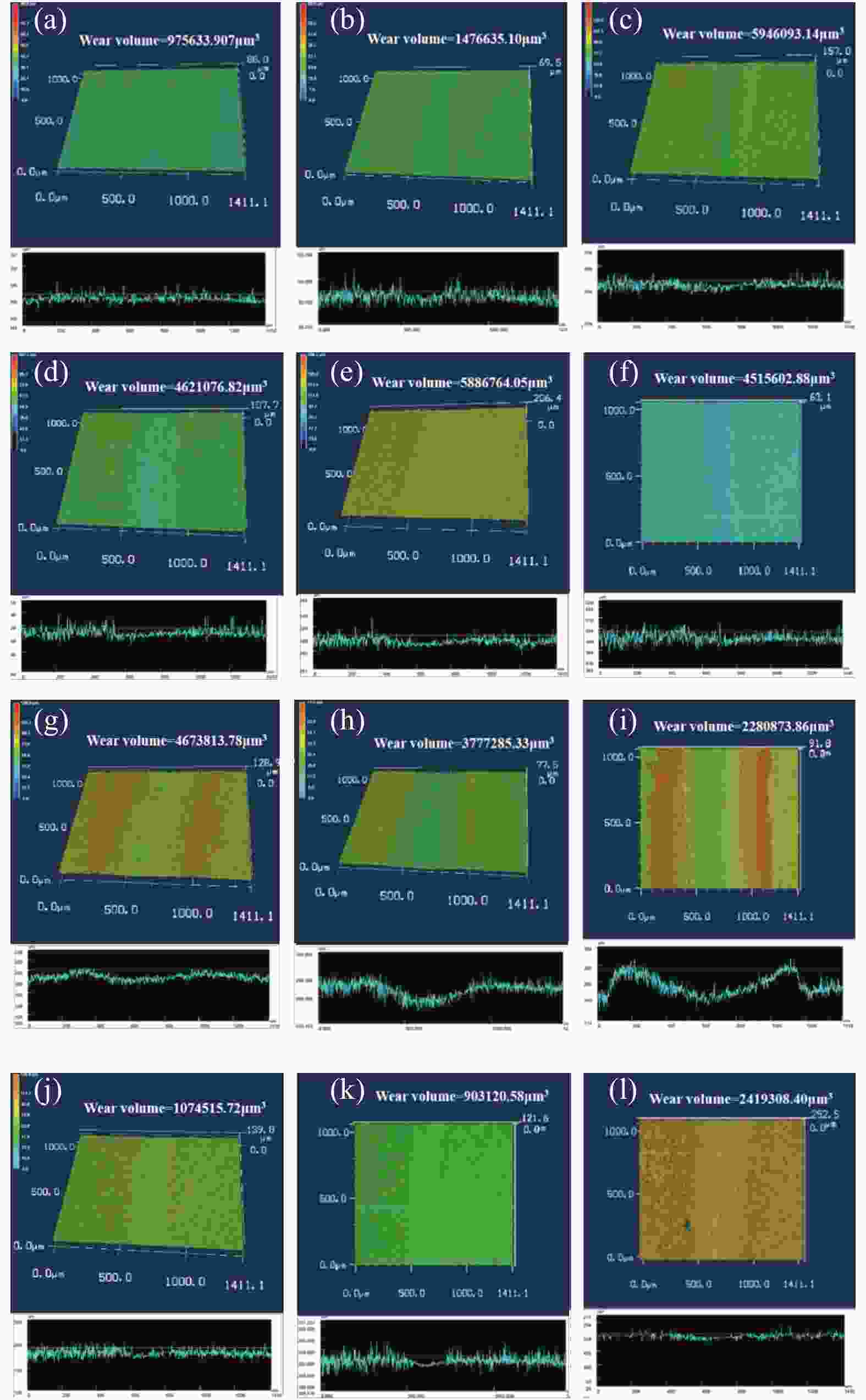

图 6 不同温度时VN-Ag-MoO3复合材料的磨痕三维轮廓图

Figure 6. Three-dimensional wear profiles of worn surfaces of VN-Ag-MoO3 composites at different temperatures((a) VN- 5Ag-MoO3, RT; (b) VN-10Ag-MoO3, RT; (c) VN-15Ag-MoO3, RT; (d) VN-5Ag-MoO3, 300℃; (e) VN-10Ag-MoO3, 300℃; (f) VN-15Ag-MoO3, 300℃; (g) VN-5Ag-MoO3, 500℃; (h) VN-10Ag-MoO3, 500℃; (i) VN-15Ag-MoO3, 500℃; (j) VN-5Ag-MoO3, 700℃; (k) VN-10Ag-MoO3, 700℃; (l) VN-15Ag-MoO3, 700℃)

表 1 VN-Ag-MoO3复合材料的命名

Table 1. Naming of VN-Ag-MoO3 composites

Sample Ag2MoO4/wt% VN 0 VN-5Ag-MoO3 5 VN-10Ag-MoO3 10 VN-15Ag-MoO3 15 表 2 各元素在VN-Ag-MoO3系复合材料中的含量

Table 2. Element content of VN-Ag-MoO3 composites

wt% Sample Chemical composition V N Ag Mo O VN 77.45 16.50 − − 4.41 VN-5Ag-MoO3 78.08 12.60 3.32 1.58 3.75 VN-10Ag-MoO3 76.15 10.35 5.54 2.48 4.82 VN-15Ag-MoO3 73.75 9.26 7.09 2.75 6.32 表 3 VN-Ag-MoO3系复合材料的硬度及密度

Table 3. Hardness and density of VN-Ag-MoO3 composites

Composition Hardness/HV Density/(g·cm−3) VN-5Ag-MoO4 1189.45 5.81 VN-10Ag-MoO4 1226.50 5.92 VN-15Ag-MoO4 1170.40 6.10 -

[1] 刘二勇, 贾均红, 高义民, 等. 宽温域连续润滑材料的研究进展[J]. 中国表面工程, 2015, 28(4):1-13. doi: 10.11933/j.issn.1007-9289.2015.04.001LIU E Y, JIA J H, GAO Y M, et al. Research progress of continuous lubricating materials with wide temperature range[J]. China Surface Engineering,2015,28(4):1-13(in Chinese). doi: 10.11933/j.issn.1007-9289.2015.04.001 [2] ZHU S Y, CHENG J, QIU Z H, et al. High temperature solid-lubricating materials: A review[J]. Tribology International,2019,133:206-223. doi: 10.1016/j.triboint.2018.12.037 [3] 国洪建, 贾均红, 张振宇, 等. 脉冲激光沉积VN/Ag复合薄膜的组织及摩擦学性能研究[J]. 材料导报, 2017, 31(2):55-59. doi: 10.11896/j.issn.1005-023X.2017.02.012GUO H J, JIA J H, ZHANG Z Y, et al. Microstructure and tribological properties of VN/Ag composite films deposited by pulsed laser deposition[J]. Materials Reports,2017,31(2):55-59(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.02.012 [4] 刘可心, 王蕾, 杨晨, 等. Ti3SiC2/Cu复合材料的制备与摩擦磨损性能[J]. 复合材料学报, 2020, 37(11):2844-2852.LIU K X, WANG L, YANG C, et al. Fabrication and friction and wear properties of Ti3SiC2/Cu composites[J]. Acta Materiae Compositae Sinica,2020,37(11):2844-2852(in Chinese). [5] SONG J J, ZHANG Y S, LI T, et al. Tribological behavior and lubrication mechanism of self-lubricating ceramic/metal composites: The effect of matrix type on the friction and wear properties[J]. Wear,2017,372–373:130-138. [6] TORRES H, SLAWIK S, GACHOT C, et al. Microstructural design of self-lubricating laser claddings for use in high temperature sliding applications[J]. Surface and Coatings Technology,2018,337:24-34. doi: 10.1016/j.surfcoat.2017.12.060 [7] 章小峰, 王爱华, 张祥林, 等. 激光熔覆Ni45-CaF2-WS2自润滑涂层组织与性能[J]. 中国有色金属学报, 2008, 18(2):215-220. doi: 10.3321/j.issn:1004-0609.2008.02.004ZHANG X F, WANG A H, ZHANG X L, et al. Microstructure and properties of laser cladding Ni45-CaF2-WS2 self-lubricating coating[J]. The Chinese Journal of Nonferrous Metals,2008,18(2):215-220(in Chinese). doi: 10.3321/j.issn:1004-0609.2008.02.004 [8] 荆阳, 庞思勤, 张学恒, 等. TiAlN-MoS/TiAlN硬质润滑膜研究[J]. 北京理工大学学报, 2002, 22(4):457-459. doi: 10.3969/j.issn.1001-0645.2002.04.015JING Y, PANG S Q, ZHANG X H, et al. TiAlN-MoS/TiAlN hard lubricating film research[J]. Journal of Beijing Institute of Technology,2002,22(4):457-459(in Chinese). doi: 10.3969/j.issn.1001-0645.2002.04.015 [9] 杜之明, 费岩晗, 孙永根, 等. 陶瓷-金属双连续相复合材料的发展现状与未来[J]. 复合材料学报, 2021, 38(2):315-338.DU Z M, FEI Y H, SUN Y G, et al. The development and future of ceramic-metal duplex continuous phase compo-sites[J]. Acta Materiae Compositae Sinica,2021,38(2):315-338(in Chinese). [10] TAN H, WANG S, YU Y, et al. Friction and wear properties of Al-20Si-5Fe-2Ni-Graphite solid-lubricating composite at elevated temperatures[J]. Tribology International,2018,122:228-235. doi: 10.1016/j.triboint.2018.02.037 [11] TORRES H, VUCHKOV T, RODRÍGUEZ RIPOLL M, et al. Tribological behaviour of MoS2-based self-lubricating laser cladding for use in high temperature applications[J]. Tribology International,2018,126:153-165. doi: 10.1016/j.triboint.2018.05.015 [12] AOUADI S M, PAUDEL Y, LUSTER B, et al. Adaptive Mo2N/MoS2/Ag tribological nanocomposite coatings for aerospace applications[J]. Tribology Letters,2008,29(2):95-103. doi: 10.1007/s11249-007-9286-x [13] 陕钰, 刘峰, 汪建义, 等. NiCrW-Al2O3-SrCO3-Ag金属陶瓷复合材料的高温摩擦学性能研究[J]. 摩擦学学报, 2015, 35(6):707-713.SHAN Y, LIU F, WANG J Y, et al. Study on high temperature tribological properties of NiCrW-Al2O3-SrCO3-Ag cermet composites[J]. Tribology,2015,35(6):707-713(in Chinese). [14] AOUADI S M, PAUDEL Y, SIMONSON W J, et al. Tribological investigation of adaptive Mo2N/MoS2/Ag coatings with high sulfur content[J]. Surface & Coatings Technology,2009,203(10):1304-1309. [15] LI J, XIONG D, HUANG Z, et al. Effect of Ag and CeO2 on friction and wear properties of Ni-base compo-site at high temperature[J]. Wear,2009,267(1-4):576-584. doi: 10.1016/j.wear.2008.12.050 [16] YANG J H, LIANG X S, LIU Z G, et al. Friction and wear properties of hot-pressed NiCr-BaCr2O4 high temperature self-lubricating composites[J]. Wear,2013,301(1-2):820-827. doi: 10.1016/j.wear.2013.02.004 [17] ZHAO Y Q, MU Y T, LIU M. Mechanical properties and frictionwear characteristics of VN/Ag multilayer coatings with heterogeneous and transition interfaces[J]. Transactions of Nonferrous Metals Society of China,2020,30(2):472-483. doi: 10.1016/S1003-6326(20)65227-X [18] GE F, ZHU P, MENG F, et al. Achieving very low wear rates in binary transition-metal nitrides: The case of magnetron sputtered dense and highly oriented VN coatings[J]. Surface & Coatings Technology,2014,248:81-90. [19] GASSNER G, MAYRHOFER P H, KUTSCHEJ K, et al. A new low friction concept for high temperatures: Lu-bricious oxide formation on sputtered VN coatings[J]. Tribology Letters,2004,17(4):751-756. doi: 10.1007/s11249-004-8083-z [20] AOUADI S M, SINGH D P, STONE D S, et al. Adaptive VN/Ag nanocomposite coatings with lubricious behavior from 25 to 1 000℃[J]. Acta Materialia,2010,58(16):5326-5331. doi: 10.1016/j.actamat.2010.06.006 [21] LIU E Y, WANG W Z, GAO Y M, et al. Tribological properties of adaptive Ni-based composites with addition of lubricious Ag2MoO4 at elevated temperatures[J]. Tribology Letters,2012,47(1):21-30. doi: 10.1007/s11249-012-9958-z [22] 慕永涛. 自润滑氮化钒基复合涂层制备及宽温域摩擦磨损特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.MU Y T. Preparation of self-lubricating VN based compo-site coating and study on friction and wear characteristics in wide temperature range[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [23] 董丽荣, 李长生, 王旻璐, 等. Ag/Bi2Sr2CaCu2Ox复合材料摩擦学特性[J]. 复合材料学报, 2009, 26(2):125-130. doi: 10.3321/j.issn:1000-3851.2009.02.022DONG L R, LI C S, WANG M L, et al. Tribological properties of Ag/Bi2Sr2CaCu2Ox composites[J]. Acta Materiae Compositae Sinica,2009,26(2):125-130(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.02.022 -

下载:

下载: