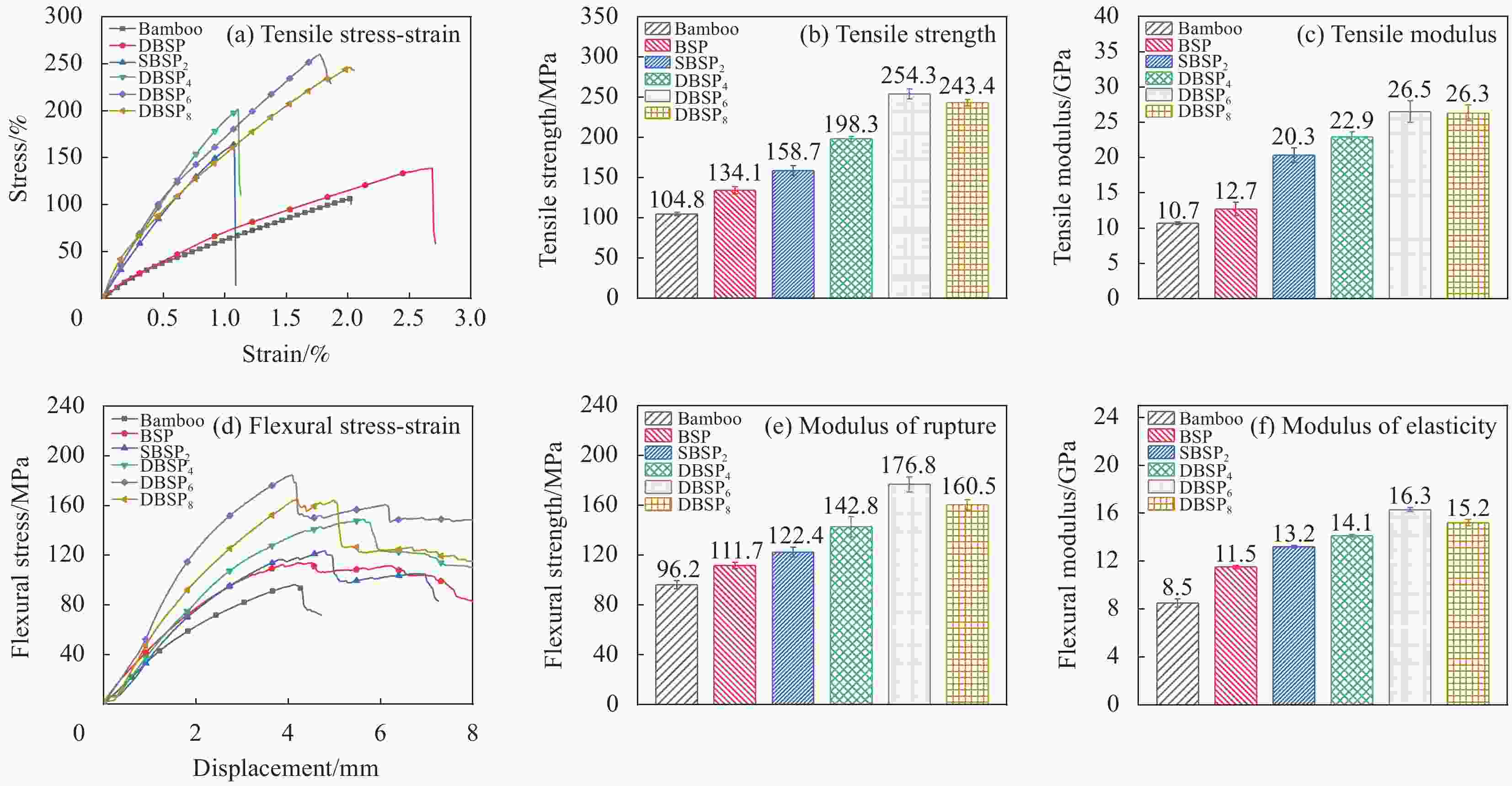

Preparation and properties of directionally reconstituted bamboo cellulose fiber/phenolic resin composites

-

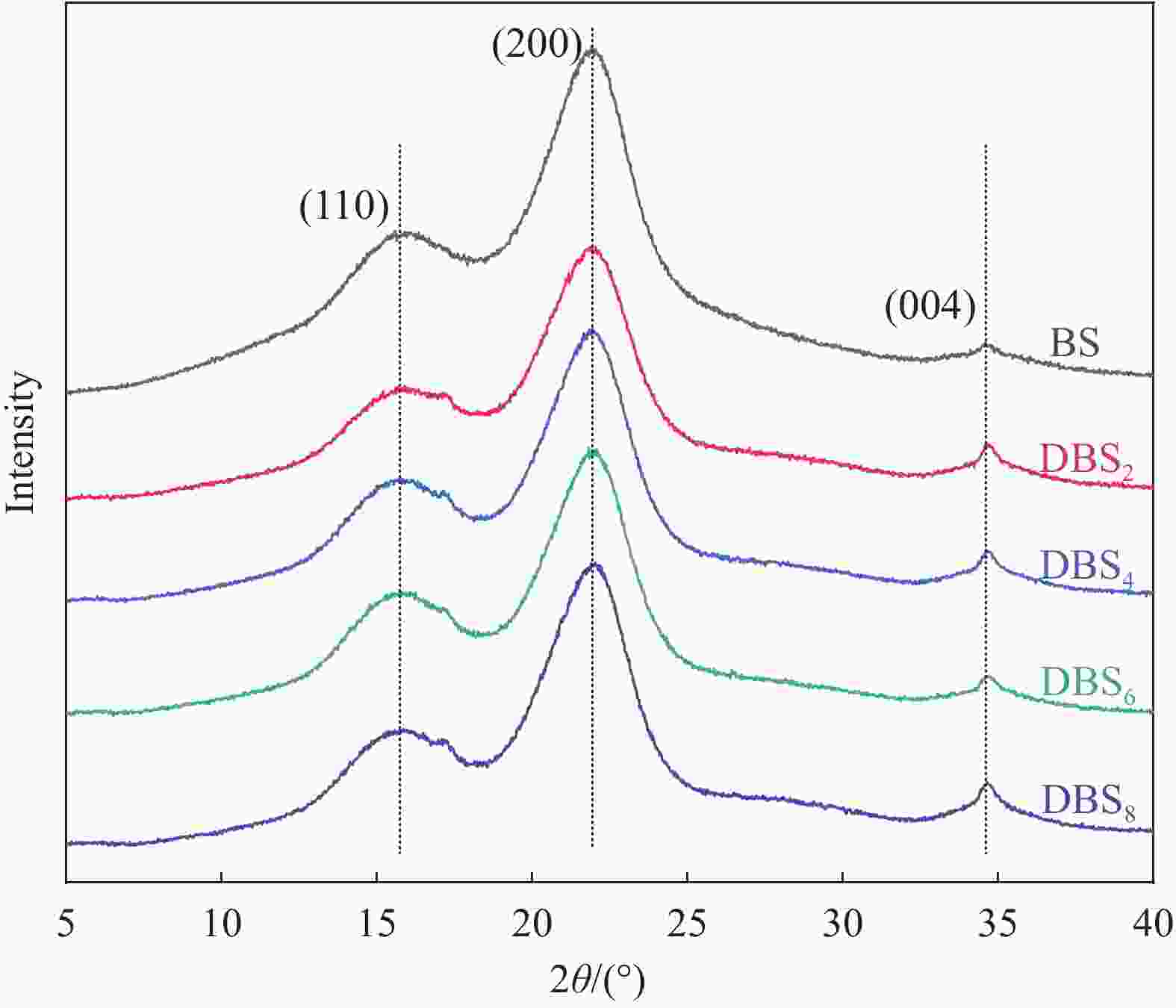

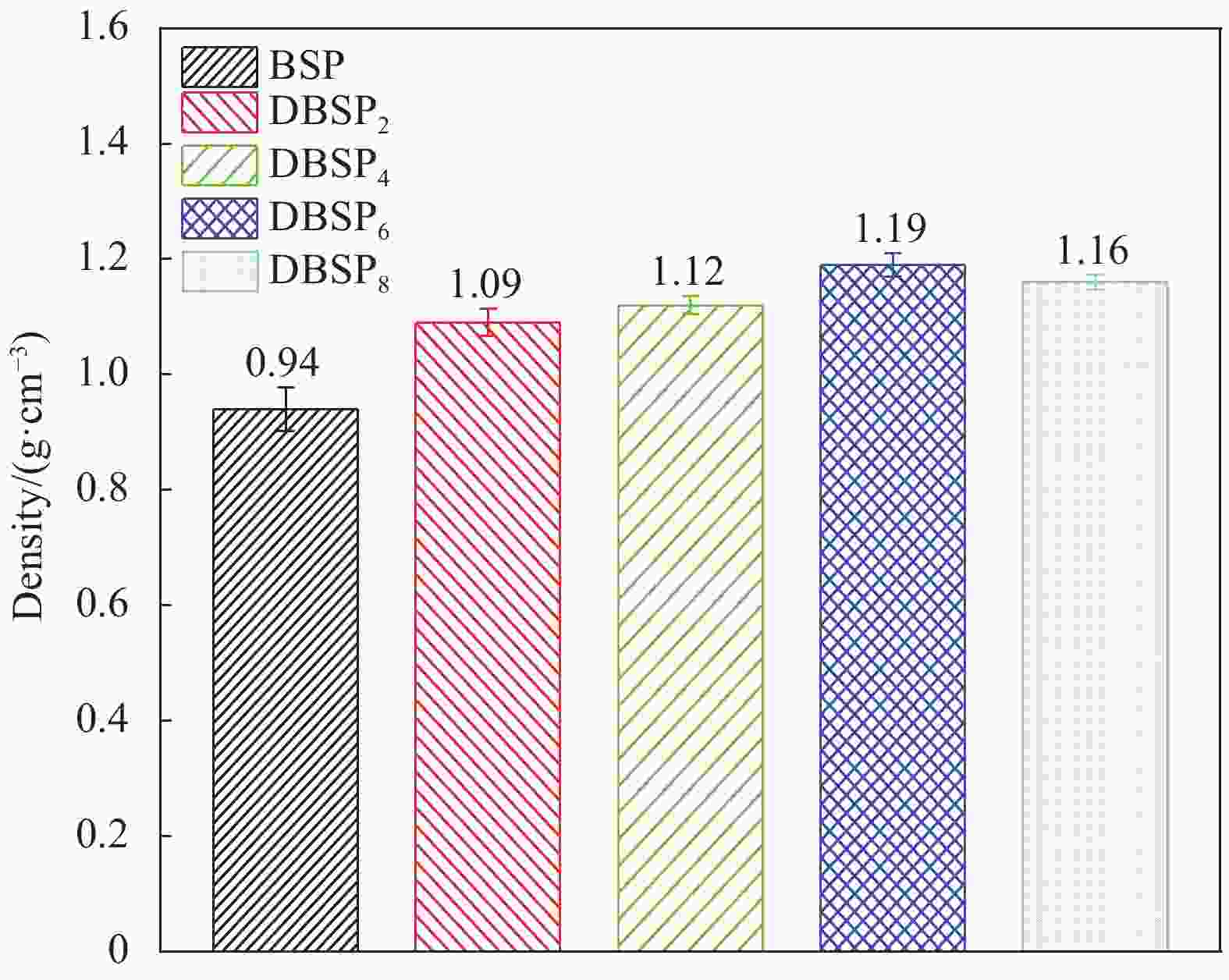

摘要: 研究以毛竹为原料,首先通过不同程度的脱木素处理制备成块状的定向竹纤维素纤维,然后进行酚醛树脂浸渍,最后高温热压成定向重组竹纤维素纤维/酚醛树脂复合材料(DBSP)。SEM、FTIR、XRD等检测显示随着脱木素时间的增加,木素含量逐渐降低,纤维素结晶度逐渐增加,竹材细胞壁变薄,并逐步被分离成微米级的定向竹材纤维素纤维。同时,研究指出随着脱木素处理时间的增加,DBSP的力学性能被显著提高,吸水率、尺寸稳定性均得到明显的改善。其中,脱木素处理6 h后的竹纤维素纤维制备的DBSP表现出优异的综合性能,其拉伸强度和静曲强度分别达到254.3 MPa 和176.8 MPa,24 h吸水率为5.83%,24 h吸水厚度和宽度膨胀率分别为2.28%和0.76%,因此,作为一种高性能的竹重组复合材料,可广泛应用于风力发电机叶片、汽车车身制造等领域。Abstract: Bamboo cellulose fiber was prepared via deligninfied treatment at different times, then was impregnated with phenolic resin, finally was fabricated into the directionally reconstituted bamboo cellulose fiber/phenolic resin composites (DBSP) under hot pressing. SEM, FTIR, and XRD tests indicate that with the increase of deligninfication time, the lignin content gradually decreases, the crystallinity of cellulose gradually increases, and the bamboo cell wall also becomes thinner, finally the bamboo cell wall is separated into micron-scale oriented bamboo cellulose fibers. Moreover, the performance tests display that the mechanical strength, water absorption and dimensional stability of DBSP are significantly improved with the increase of deligninfication time. Among them, DBSP (6 h) shows excellent comprehensive performance, in which the tensile strength and modulus of rapture are up to 254.3 MPa and 176.8 MPa, respectively; the water absorption of 24 h is decreased to 5.83%, and the absorbing water thickness and width expansion rate are 2.28% and 0.76%, respectively. Therefore, as a kind of high-performance bamboo orientation recombined composites, it could be widely used in wind tur-bine blades, automotive body and other fields.

-

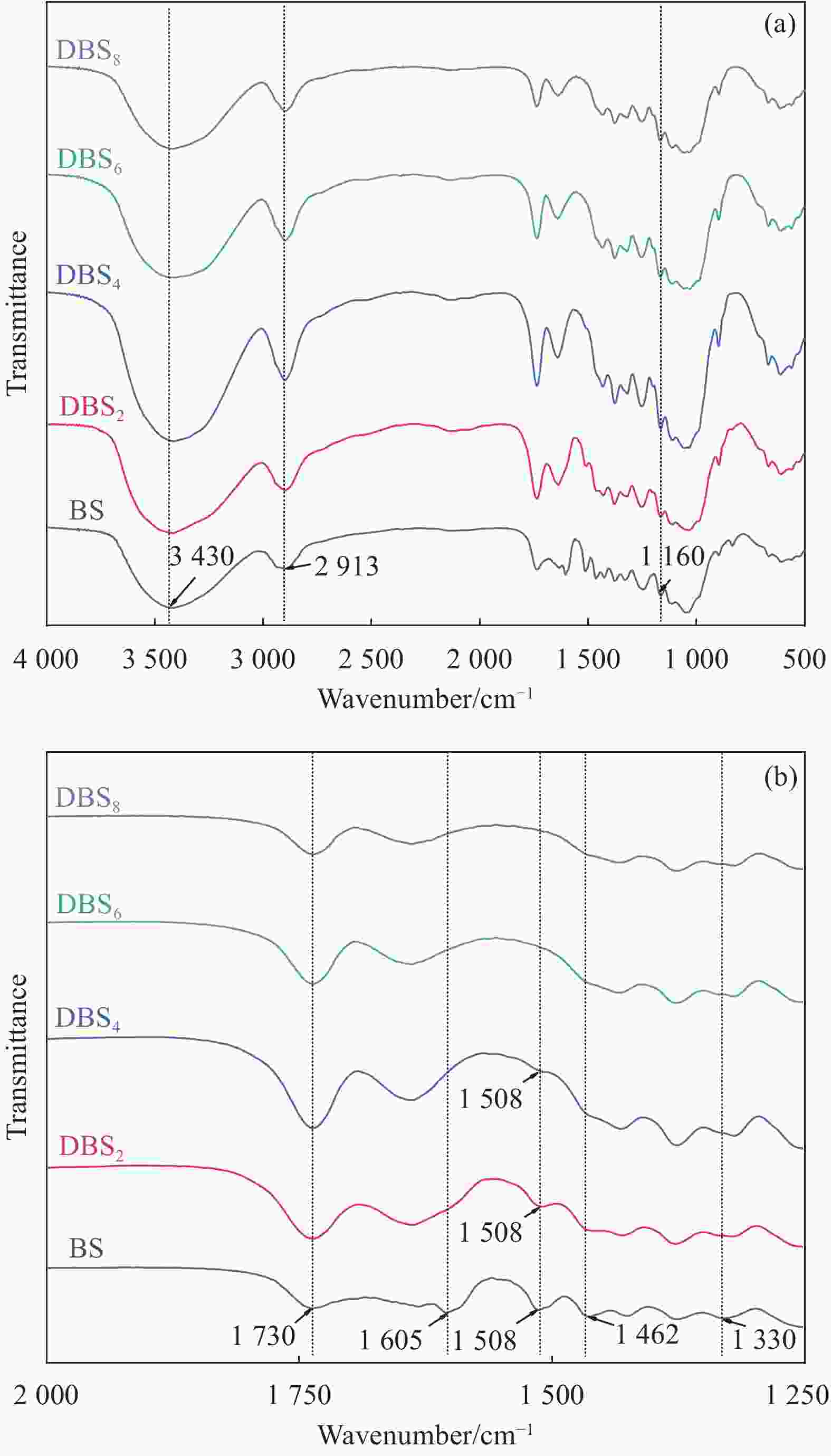

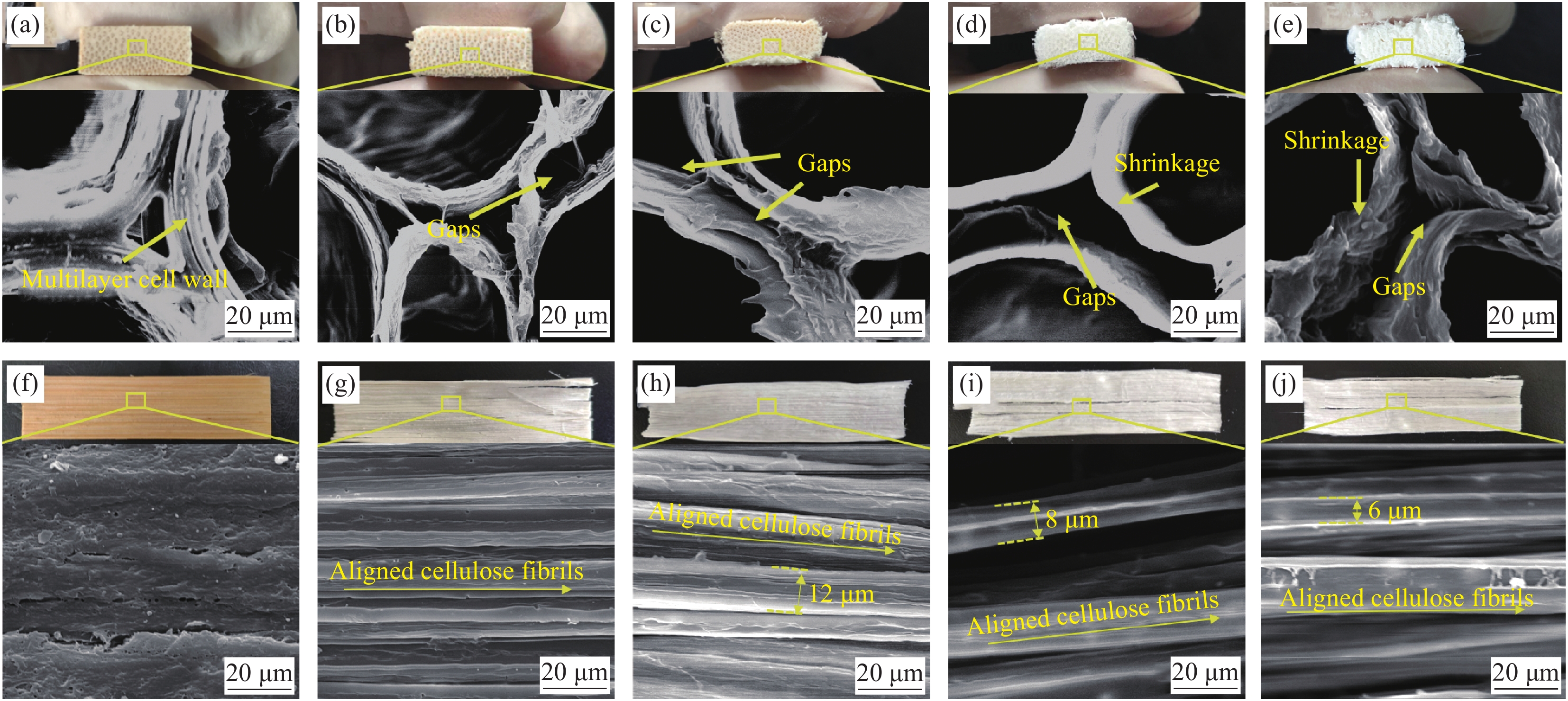

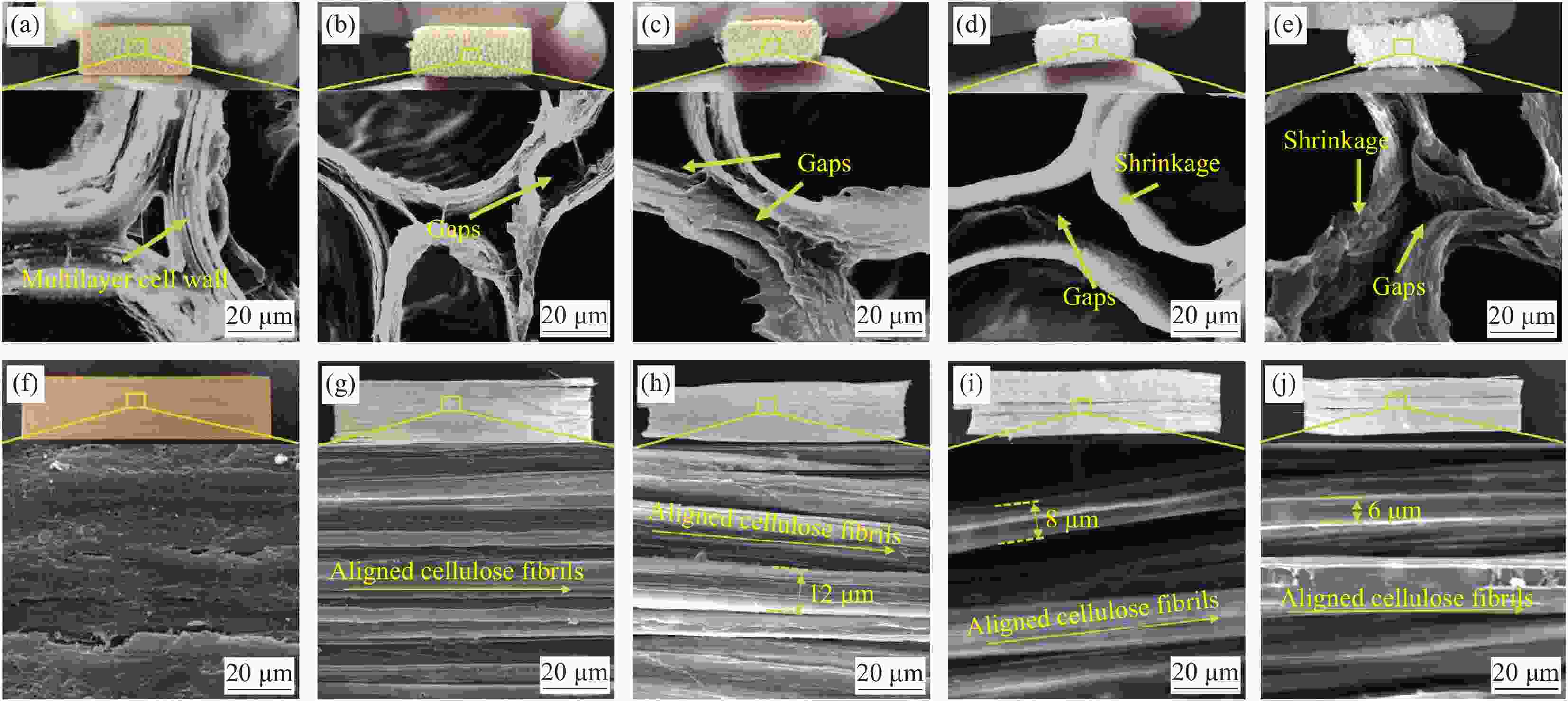

图 1 竹条(BS)和所有脱木素竹条(DBS)的实物、横截面及纵向微观结构((a)、(f) BS的实物、横截面和纵向微观结构;(b)~(e) DBS2、DBS4、DBS6、DBS8的实物和横截面微观结构; (g)~(j) DBS2、DBS4、DBS6、DBS8的实物和纵切面的微观结构)

Figure 1. SEM micrographs of bamboo splint (BS) and all decanted bamboo strip (DBS) specimens on the cross sections and longitudinal sections((a), (f) SEM micrographs of BS on the cross sections and longitudinal sections; (b)-(e) SEM micrographs of DBS2, DBS4, DBS6 and DBS8 on the cross sections; (g)-(j) DBS2, DBS4, DBS6 and DBS8 on the longitudinal sections)

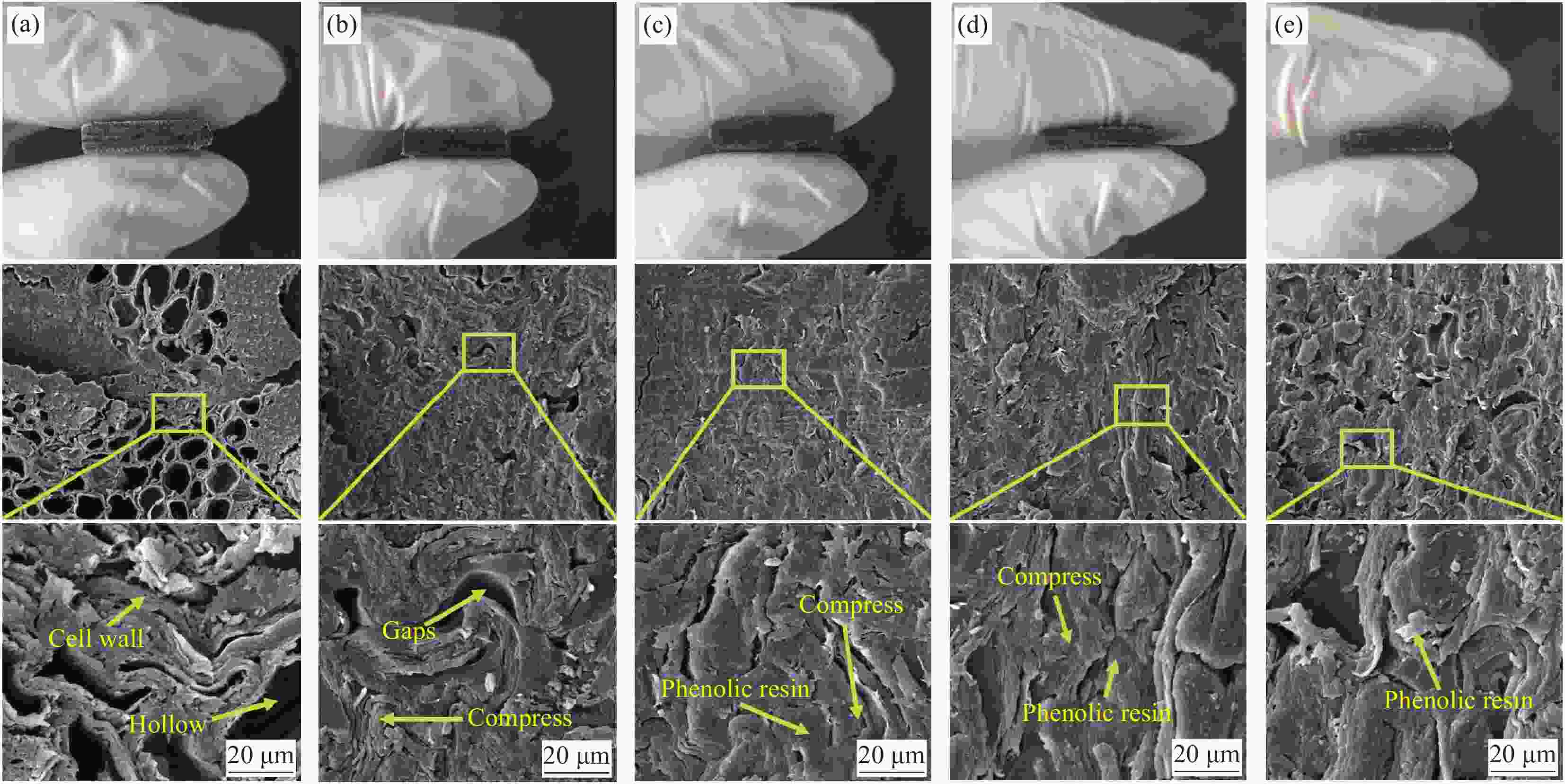

图 4 竹条/酚醛树脂复合材料(BSP)与所有DBSP样品的横截面微观结构((a)BSP的实物和微观结构; (b~(e) DBSP2、DBSP4、DBSP6、DBSP8的实物、放大400倍和放大2000倍的微观结构)

Figure 4. Microstructures of the cross section of the bamboo splint/phenolic resin composites (BSP) and DBSP specimens((a) Microstructure of the BSP specimen on the cross section; (b)-(e) Physical pictures and the microstructures of DBSP2, DBSP4, DBSP6 and DBSP8 with the magnification of 400 times and 2000 times)

图 7 BSP和DBSP样品的吸水率和尺寸稳定性((a) BSP和所有DBSP的24 h吸水率;(b) BSP和所有DBSP的24 h吸水厚度膨胀率;(c) BSP和所有DBSP的24 h吸水宽度膨胀率)

Figure 7. 24 h water absorption and dimensional stability of BSP and DBSP specimens((a) 24 h water absorption of the BSP and DBSP specimens; (b) Thickness expansion rate of 24 h water absorbing of the BSP and DBSP specimens; (c) Width expansion rate of 24 h water absorbing of the BSP and DBSP specimens)

表 1 竹纤维素纤维(DBS)和定向重组竹纤维素纤维/酚醛树脂复合材料(DBSP)的样品名称

Table 1. Directionally reconstituted bamboo cellulose fiber (DBS) and directionally reconstituted bamboo cellulose fiber/phenolic resin composites (DBSP) sample name

Deligninfication time/h DBS DBSP 0 — DBSP 2 DBS2 DBSP2 4 DBS4 DBSP4 6 DBS6 DBSP6 8 DBS8 DBSP8 表 2 脱木素处理对竹条化学组分的影响

Table 2. Effect of delignification treatment of bamboo strips on chemical composition

Sample Hemicellulose/wt% Cellulose/wt% Lignin/wt% BS 20.56 55.85 22.27 DBS2 16.98 70.08 11.32 DBS4 11.33 78.47 8.28 DBS6 10.63 85.48 1.02 DBS8 9.16 89.66 0.05 表 3 BS和DBS的结晶度

Table 3. Crystallinity of BS and DBS

Sample Relative crystallinity/% BS 53.99 DBS2 54.64 DBS4 57.88 DBS6 58.22 DBS8 57.66 -

[1] KU H, WANG H, PATTARACHAIYAKOOP N, et al. A review on the tensile properties of natural fiber reinforced polymer composites[J]. Composites Part B: Engineering,2011,42(4):856-873. doi: 10.1016/j.compositesb.2011.01.010 [2] UNTERWEGER C, BRÜGGEMANN O, FÜRST C. Synthetic fibers and thermoplastic short-fiber-reinforced polymers: Properties and characterization[J]. Polymer Composites,2014,35(2):227-236. doi: 10.1002/pc.22654 [3] UMAMHESHWAR RAO R S, MAHENDER T. Mechanical properties and optimization of processing parameters for epoxy/glass fiber reinforced composites[J]. Materials Today: Proceedings,2019,19:489-492. doi: 10.1016/j.matpr.2019.07.641 [4] 水兴瑶, 刘猛, 朱曜峰, 等. 水性上浆剂对碳纤维表面及碳纤维/环氧树脂复合材料界面性能的影响[J]. 复合材料学报, 2016, 33(2):273-279.SHUI Xingyao, LIU Meng, ZHU Yaofeng, et al. Effect of waterborne sizing agent on carbon fiber surface and properties of carbon fiber/epoxy composites interface[J]. Acta Materiae Compositae Sinica,2016,33(2):273-279(in Chinese). [5] PATTERSON B A, MALAKOOTI M H, LIN J, et al. Aramid nanofibers for multiscale fiber reinforcement of polymer composites[J]. Composites Science and Technology,2018,161:92-99. doi: 10.1016/j.compscitech.2018.04.005 [6] WEI J, MEYER C. Degradation mechanisms of natural fiber in the matrix of cement composites[J]. Cement and Concrete Research,2015,73:1-16. doi: 10.1016/j.cemconres.2015.02.019 [7] PICKERING K L, EFENDY M G A, LE T M. A review of recent developments in natural fibre composites and their mechanical performance[J]. Composites Part A: Applied Science and Manufacturing,2016,83:98-112. doi: 10.1016/j.compositesa.2015.08.038 [8] SCURLOCK J M O, DAYTON D C, HAMES B. Bamboo: An overlooked biomass resource[J]. Biomass and Bioenergy,2000,19(4):229-244. [9] 张玉红, 蔡基伟, 李珍. 竹材力学性能及阻燃性能的改善[J]. 化学研究, 2018, 29(2):197-201.ZHANG Yuhong, CAI Jiwei, LI Zhen. Research on improving mechanical and flame retardant properties of bamboo[J]. Chemical Research,2018,29(2):197-201(in Chinese). [10] 陈复明, 王戈, 程海涛,等. 新型竹纤维复合材料的研发[J]. 东北林业大学学报, 2016, 44(2):80-85. doi: 10.3969/j.issn.1000-5382.2016.02.019CHEN Fuming, WAGN Ge, CHENG Haitao, et al. Development of advanced bamboo fiber based composites material[J]. Journal of Northeast Forestry University,2016,44(2):80-85(in Chinese). doi: 10.3969/j.issn.1000-5382.2016.02.019 [11] 罗蓓, 何蕊, 杨燕, 等. 竹材资源分布及其在建筑中的应用[J]. 西南林业大学学报(社会科学), 2019, 3(5):44-47.LUO Bei, HE Rui, YANG Yan, et al. Distribution of bamboo resource and its application in architecture[J]. Journal of Southwest Forestry University(Social Sciences),2019,3(5):44-47(in Chinese). [12] OKUBO K, FUJII T, YAMAMOTO Y. Development of bamboo-based polymer composites and their mechanical properties[J]. Composites Part A: Applied Science and Manufacturing,2004,35(3):377-383. doi: 10.1016/j.compositesa.2003.09.017 [13] 李文豪, 吴义强, 李萍, 等. 竹纤维/聚乳酸可降解复合材料相容界面构建进展[J]. 材料导报, 2018, 32(17):3076-3082. doi: 10.11896/j.issn.1005-023X.2018.17.021LI Wenhao, WU Yiqiang, LI Ping, et al. Construction of compatible interfaces for BF/PLA biodegradable compo-sites: A review[J]. Materials Review,2018,32(17):3076-3082(in Chinese). doi: 10.11896/j.issn.1005-023X.2018.17.021 [14] 何文, 宋剑刚, 汪涛, 等. 热油处理对重组竹性能的影响[J]. 林业工程学报, 2017, 2(5):15-19.HE Wen, SONG Jiangang, WANG Tao, et al. Effect of heat oil treatment on bamboo scrimber properties[J]. Journal of Forestry Engineering,2017,2(5):15-19(in Chinese). [15] 中国国家标准化管理委员会. 塑料 拉伸性能的测定: GB/T 1040—2018[S]. 北京: 中国标准出版社, 2019.Standardization Administration of the People’s Republic of China. Plastics—Determination of tensile properties: GB/T 1040—2018[S]. Beijing: China Standards Press, 2019(in Chinese). [16] 中国国家标准化管理委员会. 人造板及饰面人造板理化性能试验方法: GB/T 17657—2013[S]. 北京: 中国标准出版社, 2014Standardization Administration of the People’s Republic of China. Test methods of evaluating the properties of wood-based panels and surface decorated wood based panels: GB/T 17657—2013[S]. Beijing: China Standards Press, 2014(in Chinese). [17] LI Z, CHEN C, MI R, et al. A Strong, tough, and scalable structural material from fast-growing bamboo[J]. Advanced Materials,2020,32(10):1906308. doi: 10.1002/adma.201906308 [18] HE W, ZHANG X, YU C, et al. Synthesis of bamboo/polyaniline composites by in situ polymerization and their characteristics[J]. Bioresources,2015,10(2):2969-2981. [19] NISHIDA M, TANAKA T, MIKI T, et al. Multi-scale instrumental analyses for structural changes in steam-treated bamboo using a combination of several solid-state NMR methods[J]. Industrial Crops and Products,2017,103:89-98. doi: 10.1016/j.indcrop.2017.03.041 [20] GAO K, SHAO Z, WU X, et al. Cellulose nanofibers/reduced graphene oxide flexible transparent conductive paper[J]. Carbohydrate Polymers,2013,97(1):243-251. doi: 10.1016/j.carbpol.2013.03.067 [21] 吴波, 陈梦唯, 吴永亮, 等. 纳米纤维素/还原氧化石墨烯透明导电薄膜的制备及表征[J]. 林业工程学报, 2019, 4(2):106-112.WU Bo, CHEN Mengwei, WU Yongliang, et al. Fabrication and characteristics of cellulose nano-fibrils/reduced graphene oxide transparent conductive films[J]. Journal of Forestry Engineering,2019,4(2):106-112(in Chinese). [22] KALALI E N, HU Y, WANG X, et al. Highly-aligned cellulose fibers reinforced epoxy composites derived from bulk natural bamboo[J]. Industrial Crops and Products,2019,129:434-439. doi: 10.1016/j.indcrop.2018.11.063 [23] 李朝英, 郑路, 杨文娟, 等. 用范氏法测定多类植物中酸性洗涤木质素的影响因素研究[J]. 江西农业学报, 2019, 31(3):61-64.LI Chaoying, ZHENG Lu, YANG Wenjuan, et al. Research on factors affecting determination of acid detergent lignin in many types of plants by using van soest method[J]. Acta Agriculturae Jiangxi,2019,31(3):61-64(in Chinese). [24] FRENCH A D. Idealized powder diffraction patterns for cellulose polymorphs[J]. Cellulose,2014,21(2):885-896. doi: 10.1007/s10570-013-0030-4 [25] 马晓娟, 黄六莲, 陈礼辉, 等. 纤维素结晶度的测定方法[J]. 造纸科学与技术, 2012(2):75-78.MA Xiaojuan, HUANG Liulian, CHEN Lihui, et al. Determination methods for crystallinity of cellulose[J]. Paper Science & Technology,2012(2):75-78(in Chinese). -

下载:

下载: