Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns

-

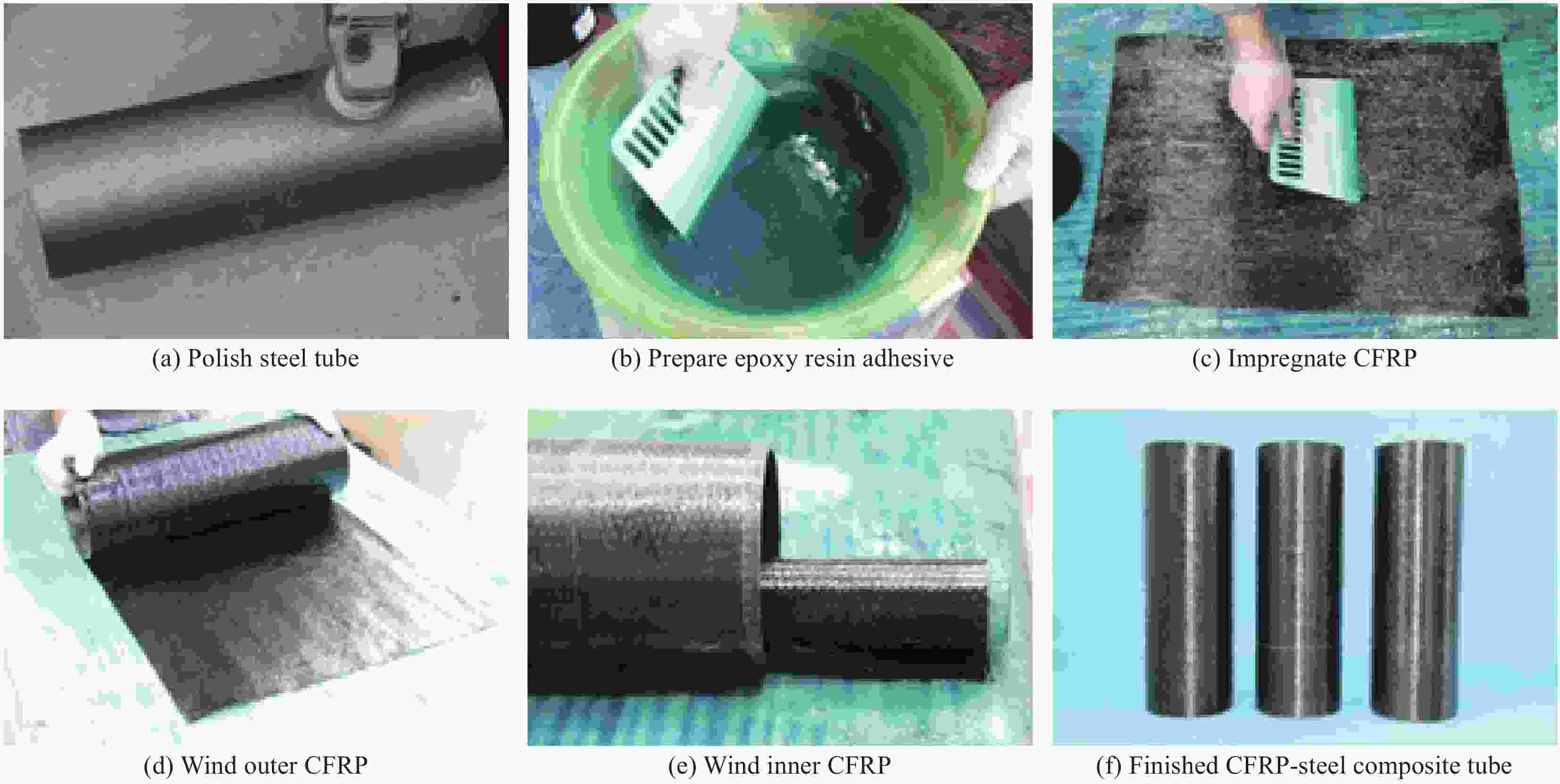

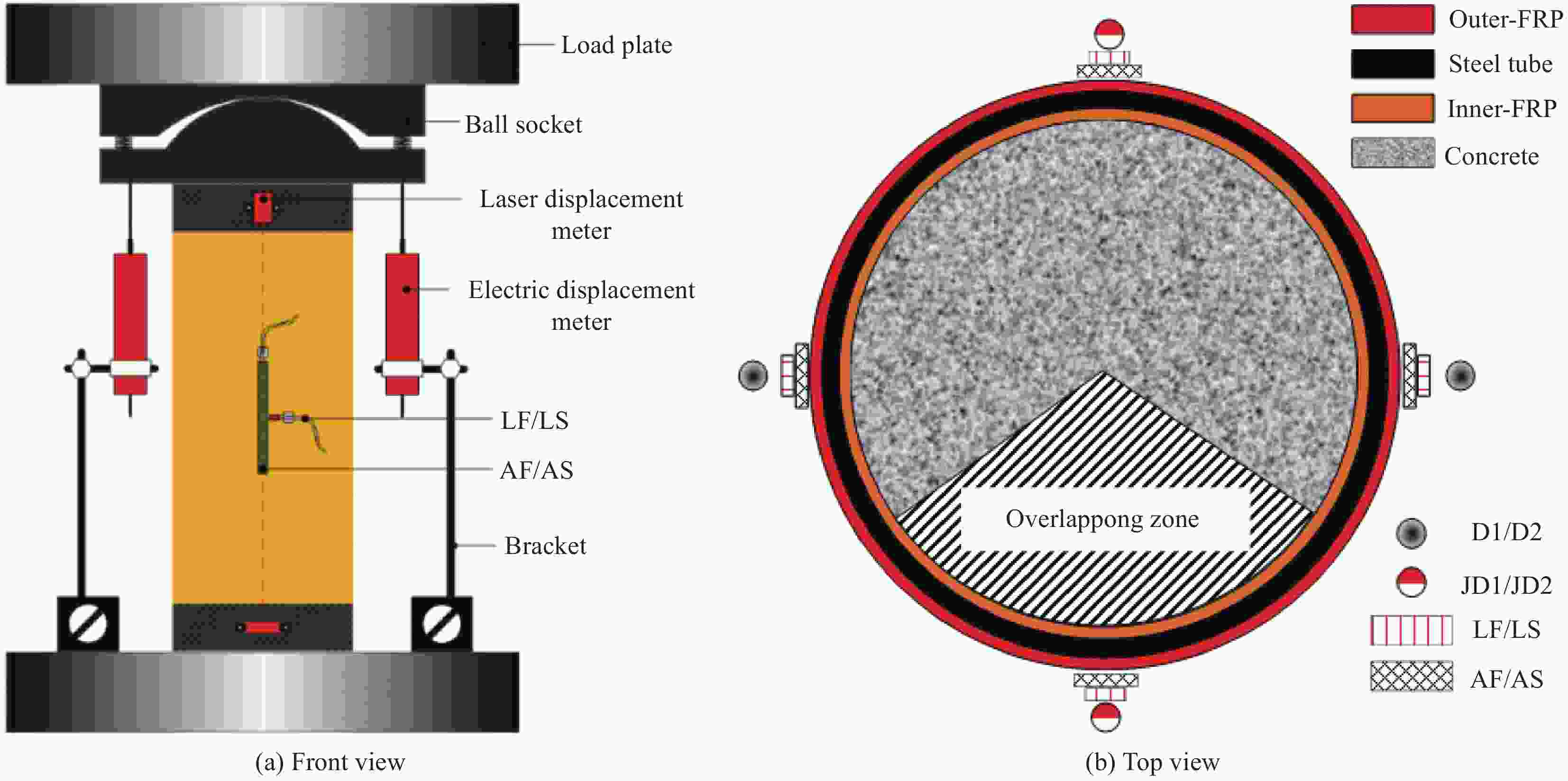

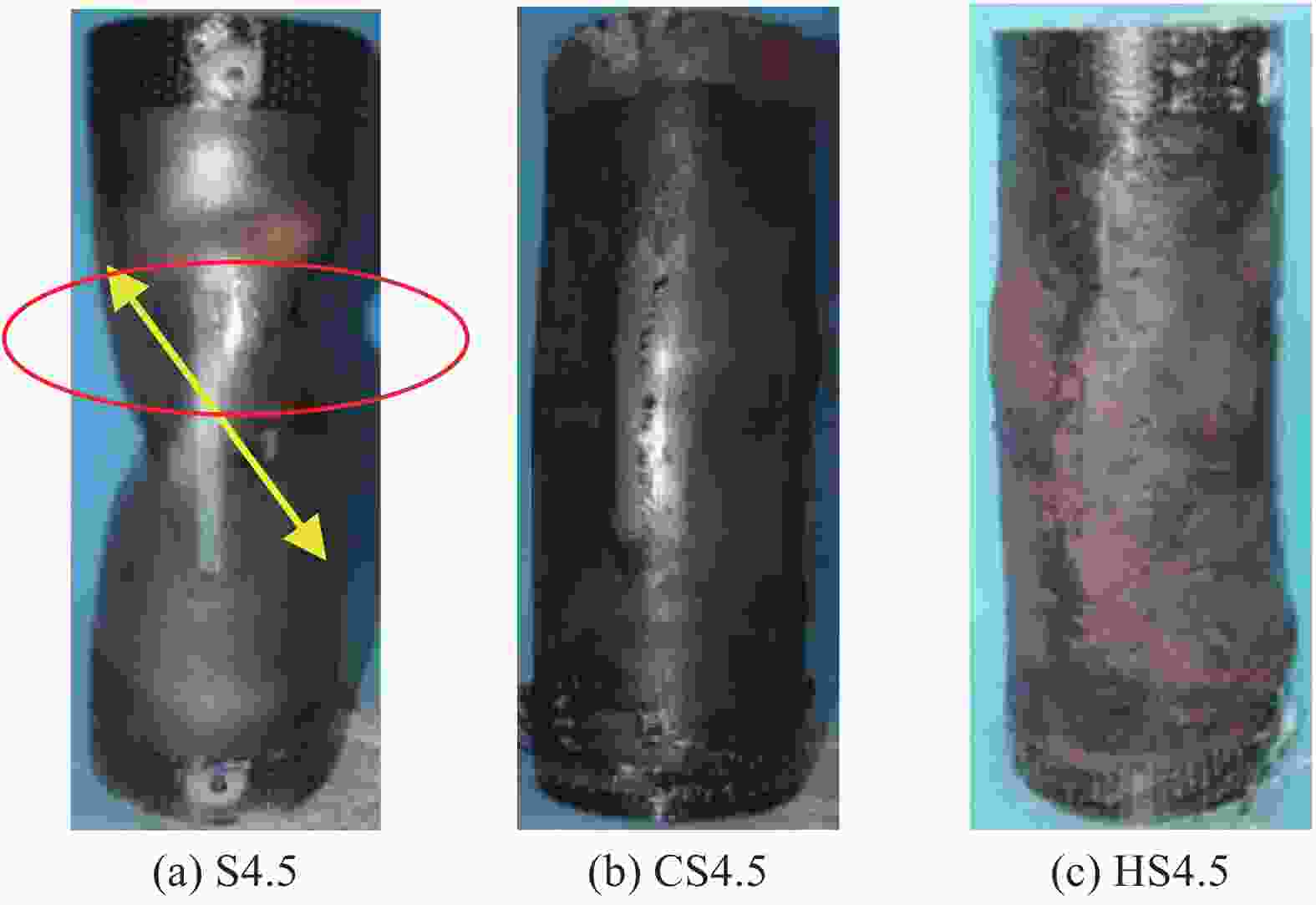

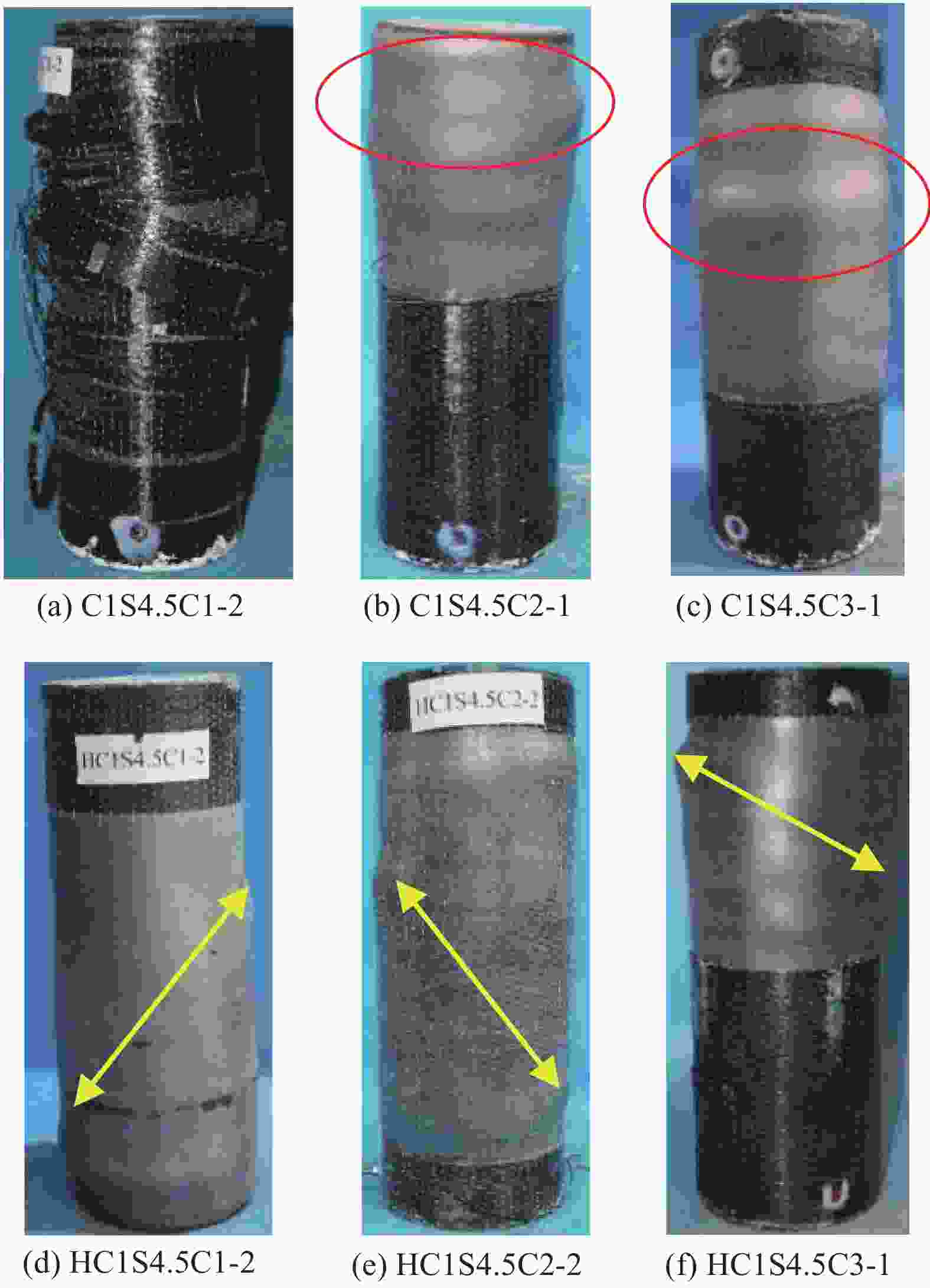

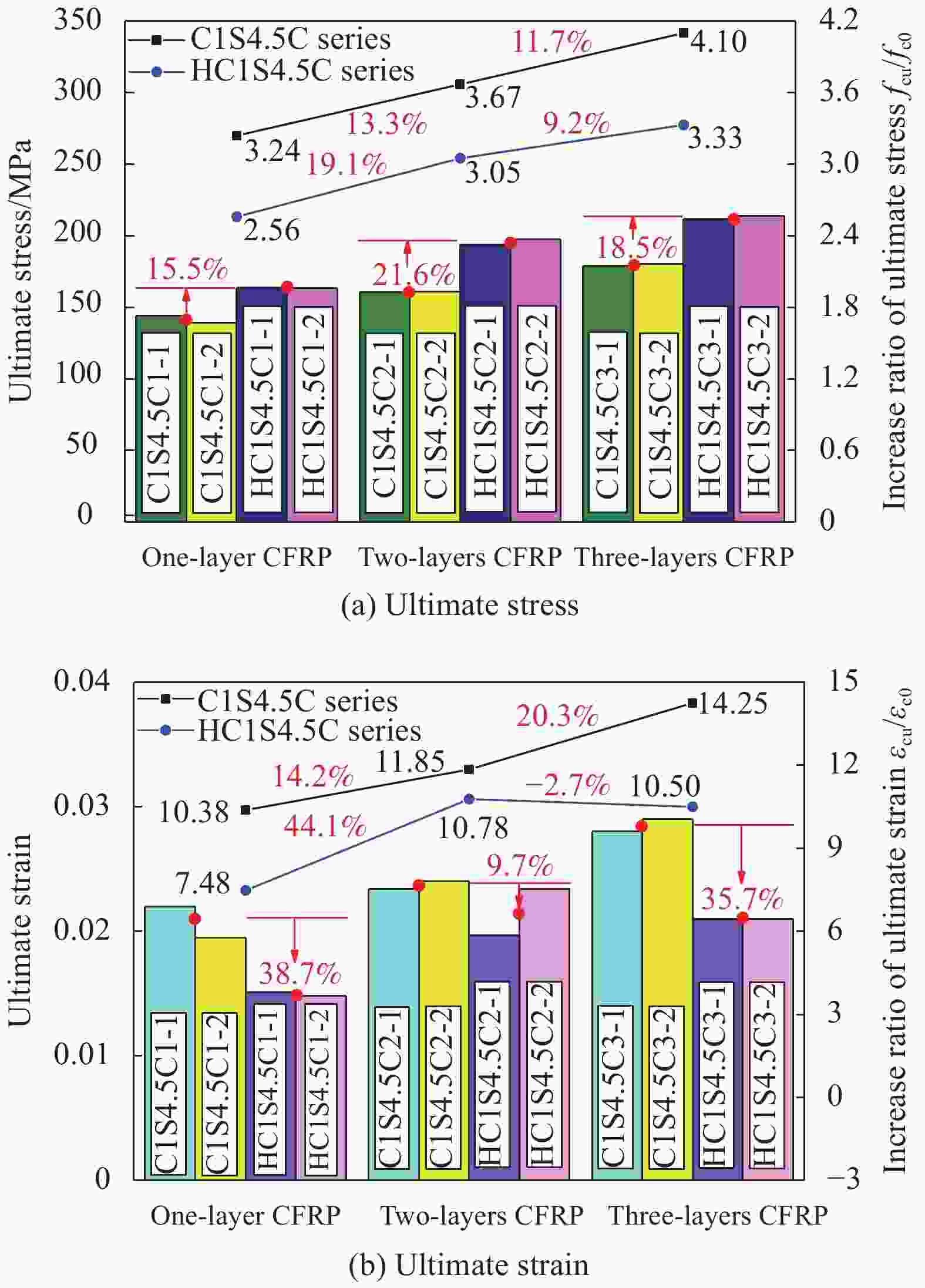

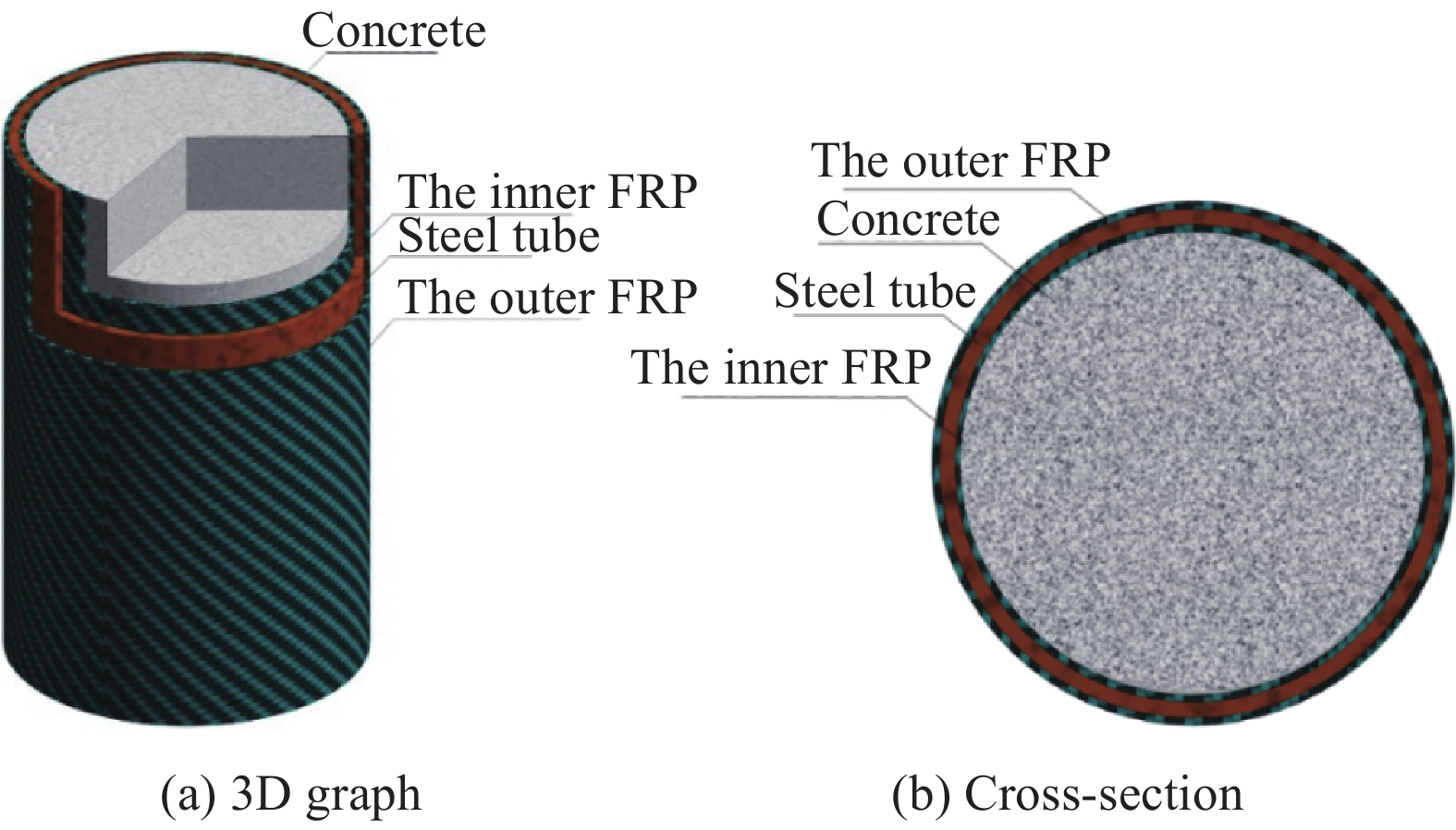

摘要: 为研究原状海水海砂混凝土在复合管混凝土中的应用可行性,提出一种新型由内外壁纤维增强复合材料(FRP)和夹心钢管复合的碳纤维增强复合材料(CFRP)-钢复合管海水海砂混凝土柱结构。对12个新型CFRP-钢复合管海水海砂混凝土圆柱试件进行了轴压试验,研究了CFRP层数和核心混凝土强度等级变化对其轴压性能的影响。试验结果表明,内外壁CFRP的包裹能够有效地提高结构承载力和变形能力;CFRP-钢复合管海水海砂普通混凝土圆柱破坏形态为混凝土压溃,而CFRP-钢复合管海水海砂高强混凝土圆柱破坏形态为剪切破坏;结构的极限应力与CFRP层数、混凝土强度呈正相关,而极限应变随着CFRP层数增加而提高,却随着混凝土强度提高而减小;核心混凝土和钢管对极限应力的贡献随着CFRP层数增加基本不变,且当包裹两层及以上CFRP时,CFRP对试件极限应力的贡献占主导地位。Abstract: In order to study the feasibility of applying the original seawater and sea sand concrete directly to the concrete filled composite tube, a new structure of seawater and sea sand concrete filled carbon fiber reinforced polymer (CFRP) -steel composite tube composed of internal and external fiber reinforced polymer (FRP) and sandwich steel tube was proposed. Twelve new seawater and sea sand concrete filled circular CFRP-steel composite tube columns were tested under axial compression, and the influence of the number of CFRP layers and the strength grade of core concrete on the axial compression performance was studied. The test results show that the wrapping of inner and outer CFRP can effectively improve the bearing capacity and deformation capacity of the structure. The failure mode of common strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns is concrete crushing, while that of high strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns is shear failure. The ultimate stress of the structure is positively correlated with the number of CFRP layers and the strength of concrete. However, the ultimate strain only increases with the number of CFRP layers, but decreases with the strength of concrete. The contribution of core concrete and steel tube to the ultimate stress almost does not change with the increase of the number of layers of CFRP, and the contribution of CFRP to the ultimate stress of specimens is dominant when two or more layers of CFRP are wrapped.

-

Key words:

- FRP /

- steel tube /

- seawater and sea sand concrete /

- confinement /

- axial compression behavior

-

表 1 CFRP-钢复合管海水海砂混凝土轴压试验结果

Table 1. Test result of seawater and sea sand concrete filled circular CFRP-steel composite tube columns under axial compression

Specimen

numberH/mm D/mm ts/mm Inner-FRP layers Outer-FRP layers fc0/MPa fcu/MPa εcu Failure mode S4.5 400 133 4.5 0 0 — — — Local buckling CS4.5 400 133 4.5 0 0 43.8 — — Concrete crushing HS4.5 400 133 4.5 0 0 64.0 — — Shear failure C1S4.5C1-1 400 133 4.5 1 1 43.8 144.2 0.0220 Concrete crushing C1S4.5C1-2 400 133 4.5 1 1 43.8 139.2 0.0195 Concrete crushing C1S4.5C2-1 400 133 4.5 1 2 43.8 160.4 0.0234 Concrete crushing C1S4.5C2-2 400 133 4.5 1 2 43.8 161.0 0.0240 Concrete crushing C1S4.5C3-1 400 133 4.5 1 3 43.8 179.0 0.0280 Concrete crushing C1S4.5C3-2 400 133 4.5 1 3 43.8 180.4 0.0290 Concrete crushing HC1S4.5C1-1 400 133 4.5 1 1 64.0 163.7 0.0151 Shear failure HC1S4.5C1-2 400 133 4.5 1 1 64.0 163.6 0.0148 Shear failure HC1S4.5C2-1 400 133 4.5 1 2 64.0 193.3 0.0197 Shear failure HC1S4.5C2-2 400 133 4.5 1 2 64.0 197.4 0.0234 Shear failure HC1S4.5C3-1 400 133 4.5 1 3 64.0 211.9 0.0210 Shear failure HC1S4.5C3-2 400 133 4.5 1 3 64.0 213.9 0.0210 Shear failure Notes: H—Height of all specimens; D—Outer diameter of all specimens; ts—Thickness of steel tube; fc0—Cylinder concrete strength; fcu—Ultimate stress of specimen; εcu—Ultimate strain of specimen. The specimens were numbered according to the different parameters of the specimens, and two specimens with the same parameters were prepared, which were distinguished by “−1” and “−2”. S4.5—Hollow steel tube specimen with a thickness of 4.5 mm; CS4.5—Common strength seawater and sea sand concrete filled circular steel tube columns with 4.5 mm steel tube thickness; HS4.5—High strength seawater and sea sand concrete filled circular steel tube columns with 4.5 mm steel tube thickness; C1S4.5C1-1—Common strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns with 4.5 mm steel tube thickness, one-layer inner-FRP and one-layer outer-FRP; HC1S4.5C2-1—High strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns with 4.5 mm steel tube thickness, one-layer inner-FRP and two-layer outer-FRP. 表 2 CFRP和钢管力学性能

Table 2. Mechanical properties of CFRP and steel tube

Material fy/MPa ff/MPa εf Modulus of elasticity/GPa CFRP — 3331.7 0.0139 239.8 Steel tube 328.8 486.2 — 206.2 Notes: fy—Yield stress of material; ff—Ultimate tensile stress of material; εf—Ultimate tensile strain of material. 表 3 普通FRP-钢复合管约束混凝土承载力计算模型

Table 3. Calculation model of confined concrete bearing capacity of concrete filled FRP-steel composite tube

Source of the model Calculation formula Zhang et al[17] $\dfrac{{{f_{{\rm{cu}}}}}}{{{f_{{\rm{c0}}}}}} = 1 + 1.27{\xi _{\rm{s}}} + 1.28{\xi _{\rm{f}}}$ Tang et al[25] ${N_{\rm{u}}} = \left( {1 + {\eta _{{\rm{cap}}}}} \right)\left( {1.27F{A_{\rm{s}}} + 0.85{f_{{\rm{c0}}}}{A_{\rm{c}}}} \right)$ Dong et al[26] ${N_{\rm{u}}} = \left[ {0.95 + {f_{\rm{1}}} + \min \left( {{f_{\rm{2}}}{\rm{ }},{f_{\rm{3}}}} \right)} \right]{A_{\rm{c}}}{f_{{\rm{c0}}}} + {A_{\rm{s}}}{f_{\rm{y}}}$ Lu et al[27] ${N_{\rm{u}}} = \left( {1 + 1.8{\xi _{\rm{s}}} + 1.15{\xi _{\rm{f}}}} \right){A_{\rm{c}}}{f_{{\rm{c0}}}}$ Ding et al[18] ${N_{\rm{u}}} = \left( {1 + 1.7{\xi _{\rm{s}}} + 1.7{\xi _{\rm{f}}}} \right){f_{{\rm{c0}}}}{A_{\rm{c}}}$ Tao et al[28] ${N_{\rm{u}}} = \left( {1 + 1.02{\xi _{\rm{s}}}} \right){f_{{\rm{c0}}}}{A_{\rm{s}}} + 1.15{\xi _{\rm{f}}}{f_{{\rm{c0}}}}{A_{\rm{c}}}$ Notes: fcu—Ultimate stress of specimen; fc0—Cylinder concrete strength; ξs—Effective constraint coefficient of steel tube; ξf—Effective constraint coefficient of FRP; Nu—Bearing capacity of specimen; ηcap—Increase index of capacity; F—Minimum between yield strength and 0.7 tensile strength of carbon steel; As—Cross-sectional area of steel tube; Ac—Cross-sectional area of concrete; f1, f2, f3—Three factors of the steel tube, FRP and concrete characteristics, respectively. -

[1] ZHANG Q T, XIAO J Z, ZHANG P, et al. Mechanical behaviour of seawater sea-sand recycled coarse aggregate concrete columns under axial compressive loading[J]. Construction and Building Materials,2019,229:117050. doi: 10.1016/j.conbuildmat.2019.117050 [2] TENG J G, XIANG Y, YU T, et al. Development and mechanical behaviour of ultra-high-performance seawater sea-sand concrete[J]. Advances in Structural Engineering,2019(6):1-21. [3] QIN R, LAU D, TAM L, et al. Experimental investigation on interfacial defect criticality of frp-confined concrete columns[J]. Sensors,2019,19(3):468. [4] GHARACHORLOU A, RAMEZANIANPOUR A A. Durability of concrete cylinder specimens strengthened with FRP laminates under penetration of chloride ions[J]. International Journal of Civil Engineering,2010,8(4):327-336. [5] MOHAMMEDAMEEN A, EVIK A, ALZEEBAREE R, et al. Performance of FRP confined and unconfined engineered cementitious composite exposed to seawater[J]. Journal of Composite Materials,2019,53(28-30):4285-4304. [6] GUO F, AL-SAADI S, SINGH RAMAN R K, et al. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment[J]. Corrosion Science,2018,141:1-13. doi: 10.1016/j.corsci.2018.06.022 [7] DONG Z Q, WU G, ZHAO Xi L, et al. Mechanical properties of discrete BFRP needles reinforced seawater sea-sand concrete-filled GFRP tubular stub columns[J]. Construction and Building Materials,2020,244:118330. [8] WANG J, FENG P, HAO T Y, et al. Axial compressive behavior of seawater coral aggregate concrete-filled FRP tubes[J]. Construction and Building Materials,2017,147:272-285. doi: 10.1016/j.conbuildmat.2017.04.169 [9] ZHANG T, NIU D T, RONG C. GFRP-confined coral aggregate concrete cylinders: The experimental and theoretical analysis[J]. Construction and Building Materials,2019,218:206-213. doi: 10.1016/j.conbuildmat.2019.05.052 [10] ZHOU A, QIN R Y, CHOW C L, et al. Structural performance of FRP confined seawater concrete columns under chloride environment[J]. Composite Structures,2019,216:12-19. doi: 10.1016/j.compstruct.2019.02.058 [11] ZENG J J, GAO W Y, DUAN Z J, et al. Axial compressive behavior of polyethylene terephthalate/carbon FRP-confined seawater sea-sand concrete in circular columns[J]. Construction and Building Materials,2020,234:117383. doi: 10.1016/j.conbuildmat.2019.117383 [12] JIANG T, TENG J G. Analysis-oriented stress-strain models for FRP-confined concrete[J]. Engineering Structures,2007,29(11):2968-2986. doi: 10.1016/j.engstruct.2007.01.010 [13] LI Y L, ZHAO X L, RAMAN SINGH R K, et al. Tests on seawater and sea sand concrete-filled CFRP, BFRP and stainless steel tubular stub columns[J]. Thin-Walled Structures,2016,108:163-184. doi: 10.1016/j.tws.2016.08.016 [14] LI Y L, ZHAO X L, SINGH R K R, et al. Experimental study on seawater and sea sand concrete filled GFRP and stainless steel tubular stub columns[J]. Thin-Walled Structures,2016,106:390-406. doi: 10.1016/j.tws.2016.05.014 [15] WEI Y, WU G, LI G F. Performance of circular concrete-filled fiber-reinforced polymer-steel composite tube columns under axial compression[J]. Journal of Reinforced Plastics & Composites,2014,33(20):1911-1928. [16] WEI Y, ZHANG Y R, CHAI J L, et al. Experimental investigation of rectangular concrete-filled fiber reinforced polymer (FRP)-steel composite tube columns for various corner radii[J]. Composite Structures,2020,244:112311. doi: 10.1016/j.compstruct.2020.112311 [17] ZHANG Y R, WEI Y, BAI J W, et al. Stress-strain model of an FRP-confined concrete filled steel tube under axial compression[J]. Thin-Walled Structures,2019,142:149-159. doi: 10.1016/j.tws.2019.05.009 [18] DING F X, LU D R, BAI Y, et al. Behaviour of CFRP-confined concrete-filled circular steel tube stub columns under axial loading[J]. Thin-Walled Structures,2018,125:107-118. doi: 10.1016/j.tws.2018.01.015 [19] HU H S, XU L, GUO Z X, et al. Behavior of eccentrically loaded square spiral-confined high-strength concrete-filled steel tube columns[J]. Engineering Structures,2020,216:110743. doi: 10.1016/j.engstruct.2020.110743 [20] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485.ZHANG Y R, WEI Y, BAI J W, et al. Models for predicting axial compression behavior of fiber reinforced polymer-steel composite circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2478-2485(in Chinese). [21] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of China. Test method for tensile properties of directional fiber reinforced polymer matrix composites: GB/T 3354—2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [22] 中国国家标准化管理委员会. 金属材料拉伸试验: 第一部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of China. Tensile test of metallic materials: Part 1: Test method at room tempera-ture: GB/T 228.1—2010[S]. Beijing: Standards Press of China, 2010(in Chinese). [23] 张素梅, 刘界鹏, 马乐, 等. 圆钢管约束高强混凝土轴压短柱的试验研究与承载力分析[J]. 土木工程学报, 2007, 40(3):24-31. doi: 10.3321/j.issn:1000-131X.2007.03.005ZHANG S M, LIU J P, MA L, et al. Axial compression test and analysis of circular tube confined HSC stub columns[J]. China Civil Engineering Journal,2007,40(3):24-31(in Chinese). doi: 10.3321/j.issn:1000-131X.2007.03.005 [24] 郭莹, 许天祥, 刘界鹏. 圆CFRP-钢复合管约束高强混凝土短柱轴压试验研究[J]. 建筑结构学报, 2019, 40(5):124-131.GUO Y, XU T X, LIU J P. Experimental study on axial behavior of circular CFRP-steel composite tubed high-strength concrete stub columns[J]. Journal of Building Structures,2019,40(5):124-131(in Chinese). [25] TANG H Y, CHEN J L, FAN L Y, et al. Experimental investigation of FRP-confined concrete-filled stainless steel tube stub columns under axial compression[J]. Thin-Walled Structures, 2020, 146(10): 106483. [26] DONG C X, KWAN A K H, HO J C M. Effects of external confinement on structural performance of concrete-filled steel tubes[J]. Journal of Constructional Steel Research,2017,132:72-82. doi: 10.1016/j.jcsr.2016.12.024 [27] LU Y Y, LI N, LI S. Behavior of FRP-confined concrete-filled steel tube columns[J]. Polymers,2014,6(5):1333-1349. doi: 10.3390/polym6051333 [28] TAO Z, HAN L H, ZHUANG J P. Axial loading behavior of CFRP strengthened concrete-filled steel tubular stub columns[J]. Advances in Structural Engineering,2007,10(1):37-46. doi: 10.1260/136943307780150814 -

下载:

下载: