Preparation and pyrolysis kinetics of melamine phytates/rigid polyurethane foam composites

-

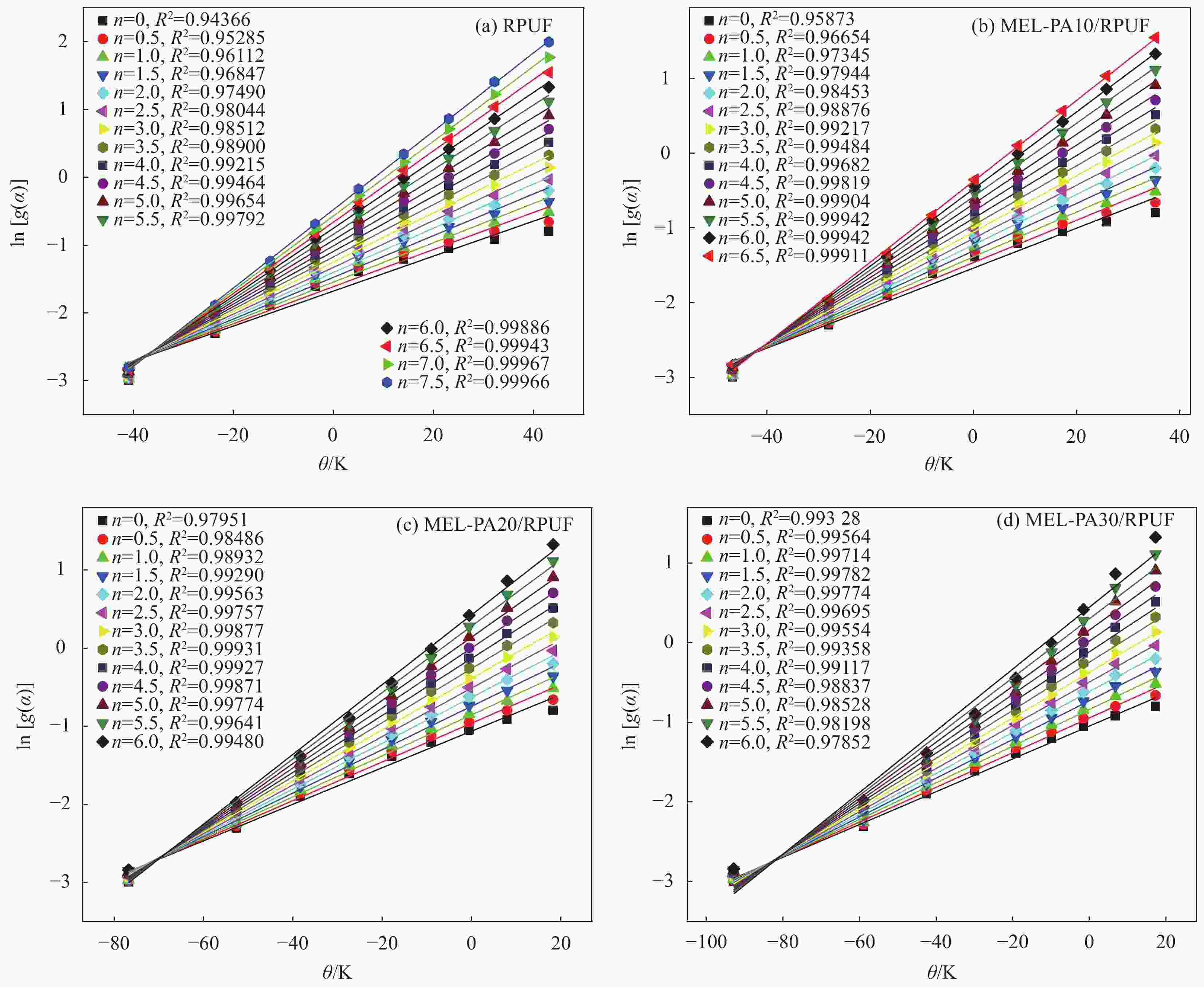

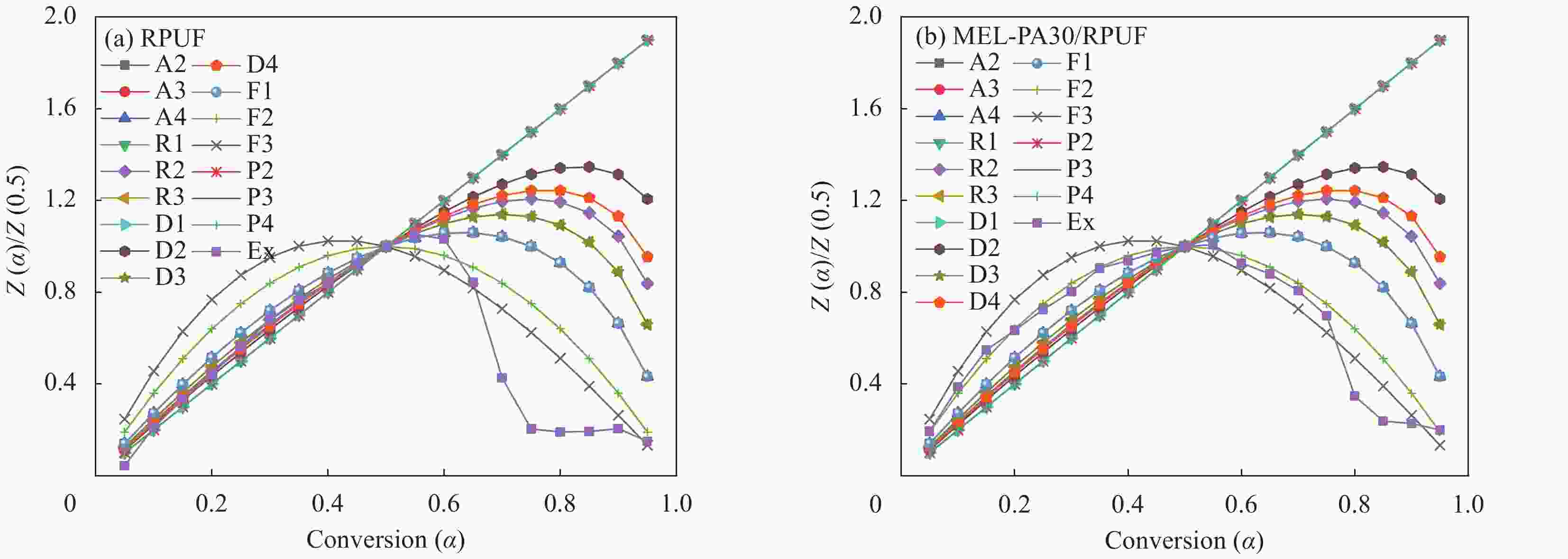

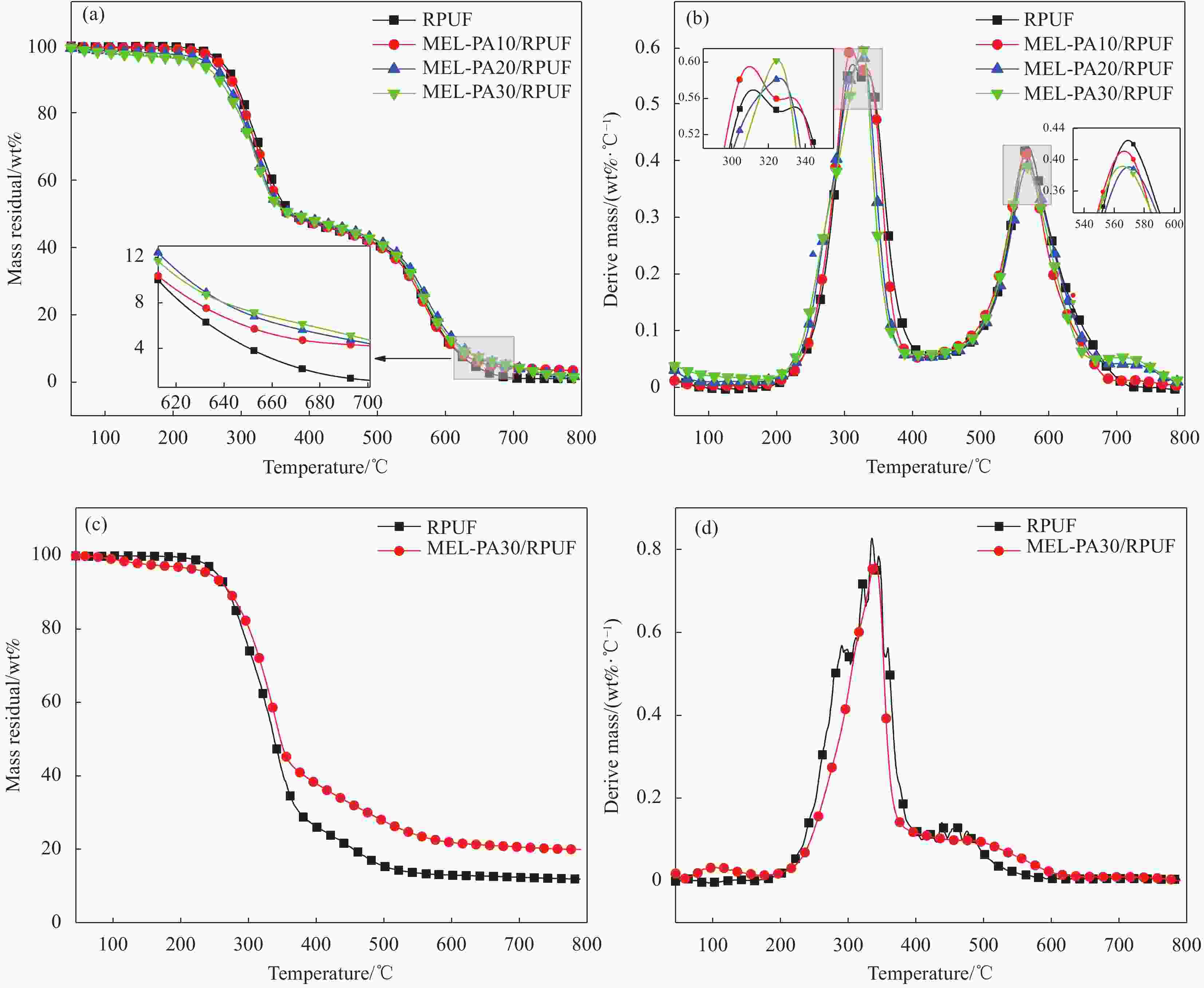

摘要: 以实验室自制的三聚氰胺植酸(MEL-PA)为阻燃剂,采用一步法全水发泡工艺制备一系列三聚氰胺植酸/硬质聚氨酯泡沫(MEL-PA/RPUF)复合材料。采用热重分析(TG)与热分析动力学研究复合材料热稳定性,揭示其降解机制。研究表明,随着MEL-PA负载量的增加,MEL-PA/RPUF在700 ℃的残炭率逐渐提升。结合TGA数据,通过Coats-Redfern和Horowitz-Metzger积分法计算复合材料主要降解阶段的反应等级n、活化能E及指前因子A。结果表明,空气氛围中MEL-PA促进了复合材料的初始降解,而在高温阶段使复合材料具有更高的热稳定性,并且两种计算方法具有相同规律。N2氛围中,MEL-PA30/RPUF(MEL-PA质量分数为10.3wt%)与RPUF相比,n增大,E升高。表明MEL-PA30/RPUF的反应更为复杂,热稳定性更高。通过Criado法进行数学模型与实验分析,验证了Coats-Redfern法的可行性。MEL-PA/RPUF复合材料的热氧化降解动力学研究结果为分析不同阻燃体系的RPUF的阻燃性能提供参考依据。Abstract: A series of melamine phytates/rigid polyurethane foam (MEL-PA/RPUF) composites were prepared by one-step water-blown method with MEL-PA as flame retardant. Thermogravimetric analysis (TG) and thermal analysis kinetics were used to study the thermal stability of the composites and reveal its degradation mechanism. The results show that the char residues of MEL-PA/RPUF gradually increases at 700℃ with the increase of MEL-PA loading. Based on TGA data, the reaction grade n, activation energy E and pre exponential factor A of the main degradation stage for the composites were calculated by the Coats-Redfern and Horowitz-Metzger integration methods. The results show that MEL-PA promotes the initial degradation of the composites in air atmosphere, while the MEL-PA/RPUF composites have higher thermal stability in the high temperature stage, and the two calculation methods have the same law. In N2 atmosphere, MEL-PA30/RPUF (mass fraction of MEL-PA is 10.3wt%) has higher n and E compared with RPUF. The results indicate that the reaction of MEL-PA30/RPUF is more complex and the thermal stability is higher. The mathematical model and experimental analysis by Criado method verify the feasibility of the Coats-Redfern method. The results of thermal degradation kinetics of MEL-PA/RPUF composites provide reference for the analysis of flame retardation performance of RPUF with different flame retardation systems.

-

Key words:

- rigid polyurethane foam /

- melamine phytates /

- composites /

- thermal stability /

- pyrolysis kinetics

-

表 1 硬质聚氨酯泡沫(RPUF)及三聚氰胺植酸/硬质聚氨酯泡沫(MEL-PA/RPUF)复合材料组成

Table 1. Composition of rigid polyurethane foam (RPUF) and melamine phytates/rigid polyurethane foam (MEL-PA/RPUF) composites

Sample LY-4110/g PM-200/g A33/g AK-8805/g LC/g TEOA/g Water/g MEL-PA/g MEL-PA/wt% RPUF 100 150 1 2 0.5 3 2 0 0 MEL-PA10/RPUF 100 150 1 2 0.5 3 2 10 3.7 MEL-PA20/RPUF 100 150 1 2 0.5 3 2 20 7.1 MEL-PA30/RPUF 100 150 1 2 0.5 3 2 30 10.3 Notes: LY-4110—Polyether polyol; PM-200—Polyaryl polymethylene isocyanate; A33—Triethylene diamine; AK-8805—Silicone surfactant; LC—Dibutyltin dilaurate; TEOA—Triethanolamine. 表 2 RPUF和MEL-PA/RPUF在空气条件下的TGA结果

Table 2. TGA results of RPUF and MEL-PA/RPUF under air condition

Sample T−5%/℃ T−50%/℃ Tmax/℃ Vmax/(%·℃−1) Char residueat

700℃/wt%Step 1 Step 2 Step 1 Step 2 RPUF 271 376 312 569 0.569 0.425 1.2 MEL-PA10/RPUF 266 370 310 567 0.595 0.411 4.2 MEL-PA20/RPUF 250 373 326 570 0.582 0.391 4.4 MEL-PA30/RPUF 233 375 325 566 0.602 0.392 4.8 Notes: T−5%—Onset degradation temperature; T−50%—Midpoint temperature of the degradation; Tmax—Maximum decomposition temperature; Vmax—Maximum decomposition rate. 表 3 RPUF和MEL-PA/RPUF30在N2条件下的TGA结果

Table 3. TGA results of RPUF and MEL-PA/RPUF30 under N2 condition

Sample T−5%/℃ T−50%/℃ Tmax/℃ Char residueat

700℃/wt%Step 1 Step 2 RPUF 254 338 335 463 12.4 MEL-PA30/

RPUF242 347 340 487 20.6 表 4 Criado法的积分机理函数

$ g\left(\alpha \right) $ 和微分机制函数$ f\left(\alpha \right) $ 表达式Table 4. Expressions of integral mechanism function

$ g\left(\alpha \right) $ and differential mechanism function$ f\left(\alpha \right) $ of Criado methodReaction mechanism Code $ f\left(\alpha \right) $ $ g\left(\alpha \right) $ Random nucleation and nuclei growth Two-dimensional A2 2(1−$ \alpha $)[−ln(1−$ \alpha $)]1/2 [−ln(1−$ \alpha $)]1/2 Three-dimensional A3 3(1−$ \alpha $)[−ln(1−$ \alpha $)]2/3 [−ln(1−$ \alpha $)]1/3 Four-dimensional A4 4(1−$ \alpha $)[−ln(1−$ \alpha $)]3/4 [−ln(1−$ \alpha $)]1/4 Limiting surface reaction between both phases One-dimensional R1 1 $ \alpha $ Contracting sphere R2 2(1−$ \alpha $)1/2 1−(1−a)1/2 Contracting cylinder R3 3(1−$ \alpha $)2/3 1−(1−a)1/3 Diffusion One-way transport D1 1/(2$ \alpha $) $ \alpha $2 Two-way transport D2 [−ln(1−a)]−1 (1−$ \alpha $) ln(1−$ \alpha $)+$ \alpha $ Three-way transport D3 3/2[1−(1−$ \alpha $)1/3]−1(1−$ \alpha $)2/3 [1−(1−$ \alpha $)1/3]2 Ginstling-Brounshtein equation D4 3/2[(1−$ \alpha $)−1/3−1]−1 (1−2/3$ \alpha $)− (1−$ \alpha $)2/3 Order of reaction First order F1 1−$ \alpha $ −ln(1−$ \alpha $) Second order F2 (1−$ \alpha $)2 (1−$ \alpha $)−1−1 Third order F3 (1−$ \alpha $)3 [(1−$ \alpha $)−2−1]/2 Exponential nucleation Power law, n = 1/2 P2 2$ \alpha $1/2 $ \alpha $1/2 Power law, n = 1/2 P3 3$ \alpha $2/3 $ \alpha $1/3 Power law, n = 1/4 P4 4$ \alpha $3/4 $ \alpha $1/4 表 5 空气氛围下加热速率为20℃/min的Coats-Redfern法获得的RPUF及MEL-PA/RPUF复合材料动力学参数

Table 5. Kinetic parameters of RPUF and MEL-PA/RPUF composites obtained by Coats-Redfern method with heating rates of 20℃/min in air atmosphere

α Sample n E/(kJ·mol−1) lnA R2 0.05-0.45 RPUF 5.5 126.15 25.03 0.99963 MEL-PA10/RPUF 4 107.65 21.02 0.99915 MEL-PA20/RPUF 2.5 70.07 13.66 0.99867 MEL-PA30/RPUF 0.2 45.45 6.94 0.99526 0.65-0.90 RPUF 0.4 25.33 1.13 0.98784 MEL-PA10/RPUF 0.2 17.30 −0.47 0.97172 MEL-PA20/RPUF 0.6 30.36 2.13 0.99286 MEL-PA30/RPUF 0.8 38.00 3.61 0.99332 Notes: α—Conversion rate; n—Reaction grade; E—Activation energy; A—Pre exponential factor. 表 6 空气氛围下加热速率为20℃/min的Horowitz-Metzger法获得的RPUF及MEL-PA/RPUF复合材料动力学参数

Table 6. Kinetic parameters of RPUF and MEL-PA/RPUF composites obtained by Horowitz-Metzger method with heating rates of 20℃/min in air atmosphere

α Sample n E/(kJ·mol−1) lnA R2 0.05-0.45 RPUF 7 157.06 31.82 0.99967 MEL-PA10/RPUF 5.5 139.87 28.16 0.99942 MEL-PA20/RPUF 3.5 103.21 20.09 0.99931 MEL-PA30/RPUF 1.5 72.35 13.10 0.99782 0.65-0.90 RPUF 0.4 39.22 3.55 0.99552 MEL-PA10/RPUF 0.1 28.85 1.63 0.99345 MEL-PA20/RPUF 0.8 51.83 5.86 0.99703 MEL-PA30/RPUF 1 60.01 7.36 0.99695 表 7 N2氛围下加热速率为20℃/min的Coats-Redfern和Horowitz-Metzger法获得的RPUF及MEL-PA30/RPUF复合材料动力学参数

Table 7. Kinetic parameters of RPUF and MEL-PA30/RPUF composites obtained by Coats-Redfern and Horowitz-Metzger methods with heating rate of 20℃/min in N2 atmosphere

Method Sample n E/(kJ·mol−1) lnA R2 Coats-Redfern RPUF 0.8 61.14 10.75 0.99820 MEL-PA30/RPUF 1.8 80.93 15.46 0.99752 Horowitz-Metzger RPUF 1.4 89.13 16.86 0.99891 MEL-PA30/RPUF 2.3 109.66 21.67 0.99766 -

[1] AKDOGAN E, ERDEM M, UREYEN M E, et al. Rigid polyurethane foams with halogen-free flame retardants: Thermal insulation, mechanical, and flame retardant properties[J]. Journal of Applied Polymer Science,2020,137(1):47611. [2] XU W Z, WANG G S, XU J Y, et al. Modification of diatomite with melamine coated zeolitic imidazolate framework-8 as an effective flame retardant to enhance flame retardancy and smoke suppression of rigid polyurethane foam[J]. Journal of Hazardous Materials,2019,379:120819. [3] LIU X, HAO J W, GAAN S, et al. Recent studies on the decomposition and strategies of smoke and toxicity suppression for polyurethane based materials[J]. RSC Advances,2016,6(78):74742-74756. doi: 10.1039/C6RA14345H [4] 韦兴文, 李明, 周筱雨, 等. 湿度对玻璃微珠增强硬质聚氨酯复合泡沫塑料黏弹力学性能影响[J]. 复合材料学报, 2013, 30(1):218-222.WEI X W, LI M, ZHOU X Y, et al. Influence of humidity on viscoelastic behavior of glass microsphere reinforced rigid polyurethane syntactic foams[J]. Acta Materiae Compositae Sinica,2013,30(1):218-222(in Chinese). [5] YUAN Y, WANG W, SHI Y Q, et al. The influence of highly dispersed Cu2O-anchored MoS2 hybrids on reducing smoke toxicity and fire hazards for rigid polyurethane foam[J]. Journal of Hazardous Materials,2020,382:121028. [6] CHEN Y H, WANG Q. Thermal oxidative degradation kinetics of flame-retarded polypropylene with intumescent flame-retardant master batches in situ prepared in twin-screw extruder[J]. Polymer Degradation and Stability,2007,92(2):280-291. doi: 10.1016/j.polymdegradstab.2006.11.004 [7] NIE S B, ZHOU C, PENG C, et al. Thermal oxidative degradation kinetics of novel intumescent flame-retardant polypropylene composites[J]. Journal of Thermal Analysis and Calorimetry,2015,120(2):1183-1191. doi: 10.1007/s10973-015-4393-7 [8] MENG X Y, YE L, ZHANG X G, et al. Effects of expandable graphite and ammonium polyphosphate on the flame-retardant and mechanical properties of rigid polyurethane foams[J]. Journal of Applied Polymer Science,2009,114(2):853-863. doi: 10.1002/app.30485 [9] GAO L P, ZHENG G Y, ZHONG Y H, et al. Synergistic effect of expandable graphite, melamine polyphosphate and layered double hydroxide on improving the fire behavior of rosin-based rigid polyurethane foam[J]. Industrial Crops and Products,2013,50:638-647. doi: 10.1016/j.indcrop.2013.07.050 [10] DENG H W, ZHAO P H, LIU Y Q, et al. Halogen Free flame retardant rigid polyurethane foam with a novel phosphorus-nitrogen intumescent flame retardant[J]. Journal of Applied Polymer Science,2014,131(11):39581. [11] ZHANG M, ZHANG J W, CHEN S G, et al. Synthesis and fire properties of rigid polyurethane foams made from a polyol derived from melamine and cardanol[J]. Polymer Degradation and Stability,2014,110:27-34. [12] YANG H Y, WANG X, SONG L, et al. Aluminum hypophosphite in combination with expandable graphite as a novel flame retardant system for rigid polyurethane foams[J]. Polymers for Advanced Technologies,2014,25(9):1034-1043. doi: 10.1002/pat.3348 [13] WU D H, ZHAO P H, ZHANG M, et al. Preparation and properties of flame retardant rigid polyurethane foam with phosphorus–nitrogen intumescent flame retardant[J]. High Performance Polymers,2013,25(7):868-875. doi: 10.1177/0954008313489997 [14] THIRUMAL M, KHASTGIR D, NANDO G B, et al. Halogen-free flame retardant PUF: Effect of melamine compounds on mechanical, thermal and flame retardant properties[J]. Polymer Degradation and Stability,2010,95(6):1138-1145. doi: 10.1016/j.polymdegradstab.2010.01.035 [15] WANG C, WU Y C, LI Y C, et al. Flame-retardant rigid polyurethane foam with a phosphorus-nitrogen single intumescent flame retardant[J]. Polymers for Advanced Technologies,2018,29(1):668-676. doi: 10.1002/pat.4105 [16] TANG G, ZHOU L, ZHANG P, et al. Effect of aluminum diethylphosphinate on flame retardant and thermal properties of rigid polyurethane foam composites[J]. Journal of Thermal Analysis and Calorimetry,2020,140(2):625-636. doi: 10.1007/s10973-019-08897-z [17] XU F F, WANG B, YANG D, et al. Thermal degradation of typical plastics under high heating rate conditions by TG-FTIR: Pyrolysis behaviors and kinetic analysis[J]. Energy Conversion and Management,2018,171:1106-1115. doi: 10.1016/j.enconman.2018.06.047 [18] MISHRA R K, MOHANTY K. Kinetic analysis and pyrolysis behaviour of waste biomass towards its bioenergy potential[J]. Bioresource Technology,2020,311:123480. [19] WANG J, CAI X F. Kinetics study of thermal oxidative degradation of ABS containing flame retardant components[J]. Journal of Thermal Analysis and Calorimetry,2012,107(2):725-732. doi: 10.1007/s10973-011-1704-5 [20] LIN H J, HAN L J, DONG, L S. Thermal degradation behavior and gas phase flame-retardant mechanism of polylactide/PCPP blends[J]. Journal of Applied Polymer Science,2014,131(13):378-387. [21] SHANG S, YUAN B H, SUN Y R, et al. Facile preparation of layered melamine-phytate flame retardant via supramolecular self-assembly technology[J]. Journal of Colloid and Interface Science,2019,553:364-371. doi: 10.1016/j.jcis.2019.06.015 [22] CHEN G Q, YUAN B H, WANG Y, et al. Inhibited combustion of graphene paper by in situ phosphorus doping and its application for fire early-warning sensor[J]. Sensors and Actuators A: Physical,2020,312:112111. [23] XU, Z M, DUAN L Q, HOU Y B, et al. The influence of carbon-encapsulated transition metal oxide microparticles on reducing toxic gases release and smoke suppression of rigid polyurethane foam composites[J]. Composites Part A: Applied Science and Manufacturing,2020,131:105815. [24] WANG S H, WANG X G, WANG X, et al. Surface coated rigid polyurethane foam with durable flame retardancy and improved mechanical property[J]. Chemical Engineering Journal,2020:385: 123755. [25] JIANG Z L, WANG C S, FANG S Y, et al. Durable flame-retardant and antidroplet finishing of polyester fabrics with flexible polysiloxane and phytic acid through layer-by-layer assembly and sol-gel process[J]. Journal of Applied Polymer Science,2018,135(27):46414. [26] 袁尧. 反应型磷氮化合物及其阻燃硬质聚氨酯泡沫设计与抑烟减毒的研究[D]. 合肥: 中国科学技术大学, 2019.YUAN Y. Design of reactive-type phosphorus and nitrogen-containing compounds and study on the smoke toxicity suppression of rigid polyurethane foam[D]. Hefei: University of Science and Technology of China, 2019(in Chinese). [27] LI W X, LI S X, CHENG Z, et al. The effect of flame retardant-modified sepiolite nanofibers on thermal degradation and fire retardancy of low-density polyethylene[J]. Journal of Thermal Analysis and Calorimetry,2019,138(2):1011-1019. doi: 10.1007/s10973-019-08162-3 [28] 李紫璇, 丁克, 郝留成, 等. 特高压气体绝缘金属封闭开关设备用Al2O3/环氧树脂复合材料的非等温固化动力学及蠕变性能[J]. 复合材料学报, 2020, 37(3):562-572.LI Z X, DING K, HAO L C, et al. Non-isothermal curing kinetics and creep behavior of Al2O3/epoxy composites for extra-high vlotage gvlotage gas insulated switchgear[J]. Acta Materiae Compositae Sinica,2020,37(3):562-572(in Chinese). [29] HOROWITZ H H, METEGER G. A new analysis of thermogravimetric traces[J]. Analytical Chemistry,1963,35(10):1464-1468. doi: 10.1021/ac60203a013 -

下载:

下载: