Tensile and compressive properties and crack distribution of polyethylene fiber reinforced high ductile alkali-activated slag composites

-

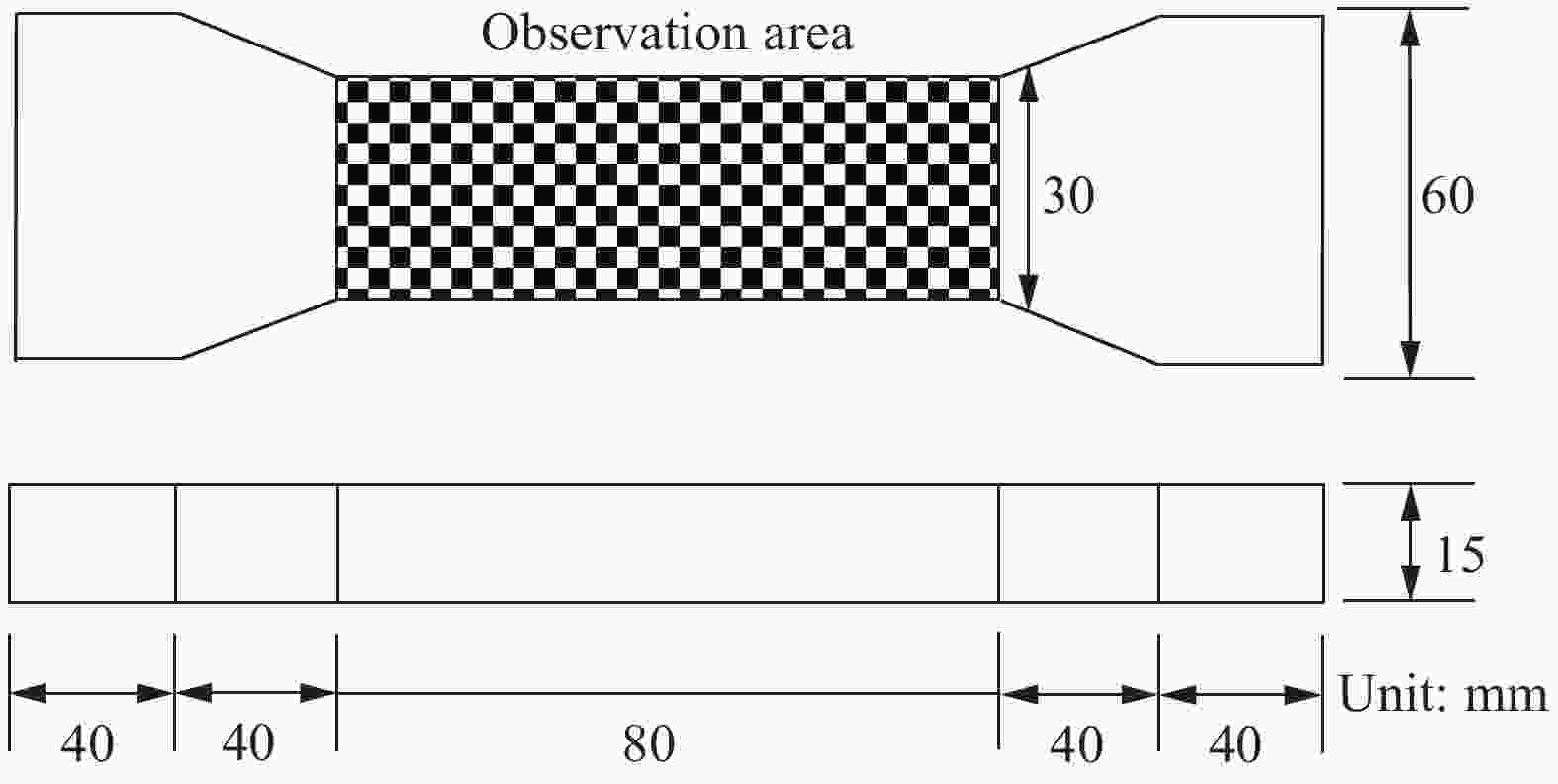

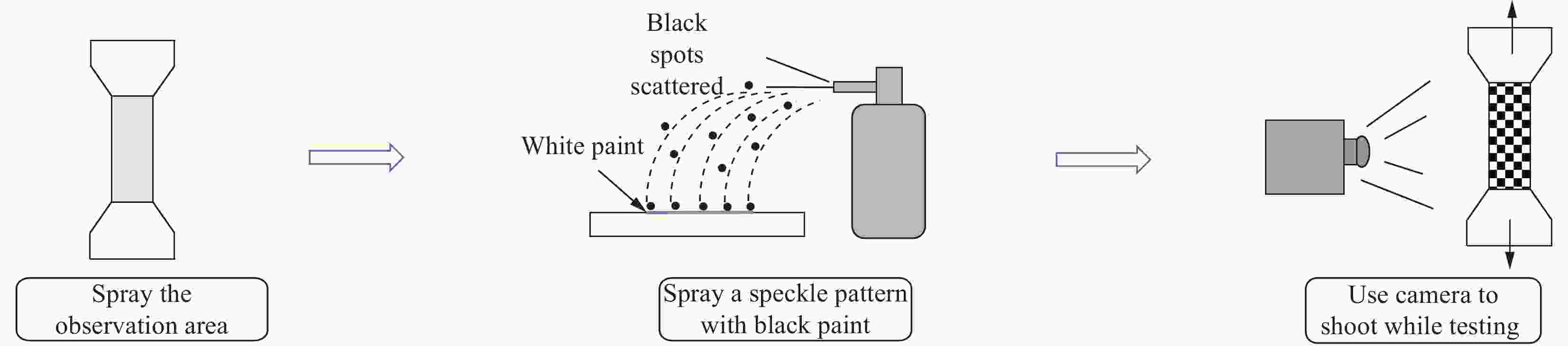

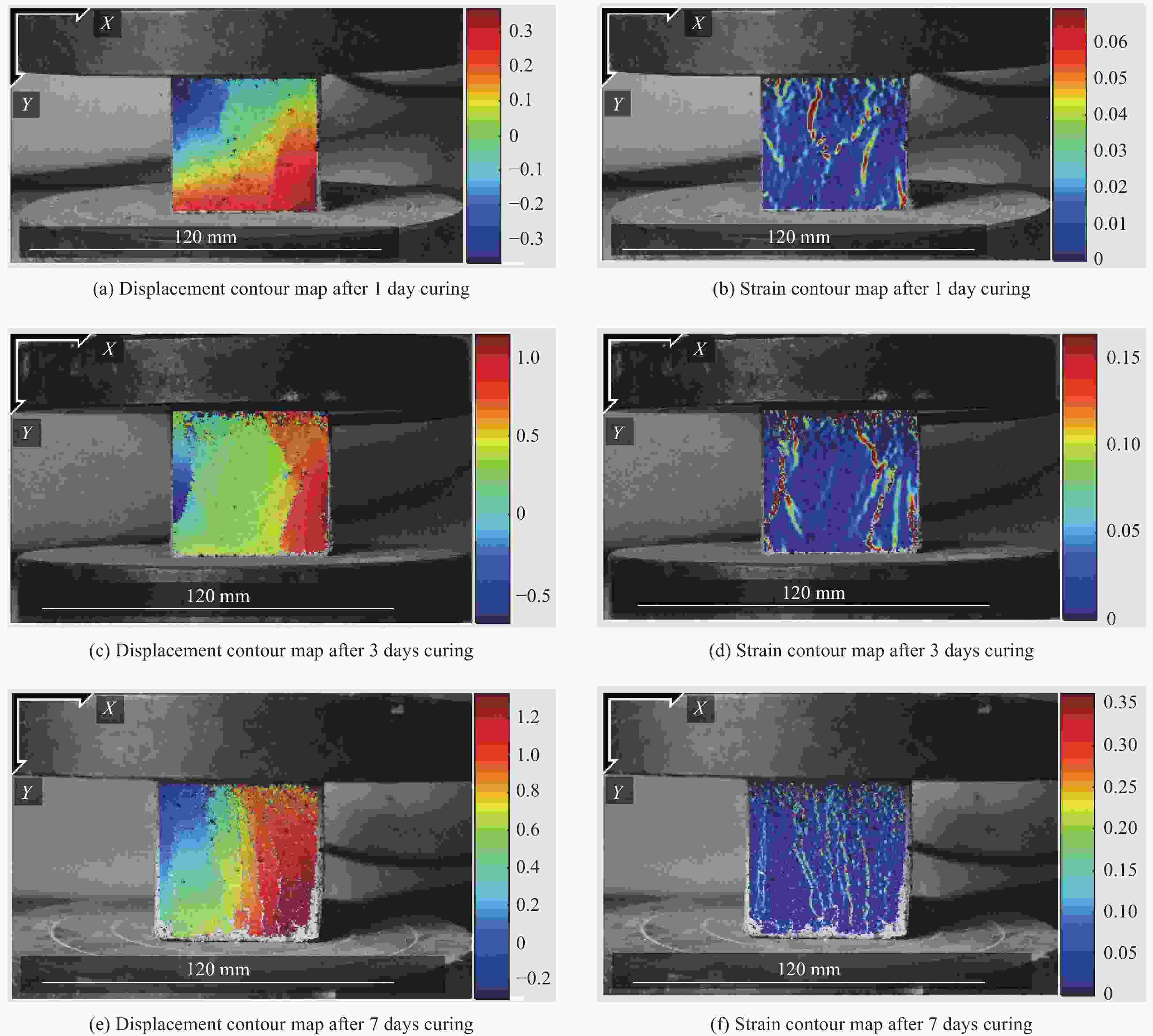

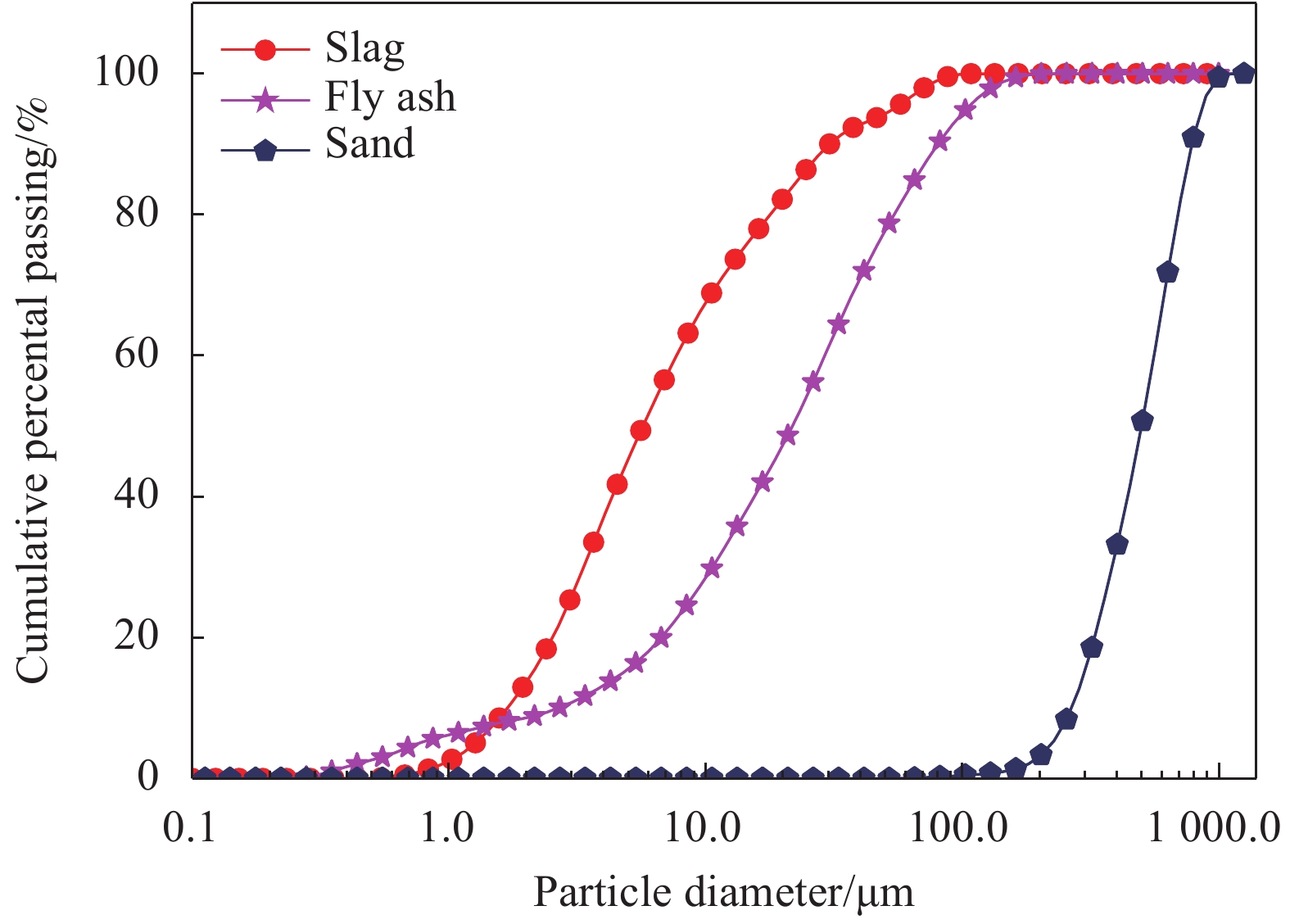

摘要: 在碱激发作用下,以矿粉为主要原材料,粉煤灰为辅助材料,共同制备聚乙烯(PE)纤维增强高延性碱矿渣复合材料。通过轴向拉、压实验,研究不同养护龄期(1天、3天、7天、28天、56天、120天)下材料的拉压性能,并借助数字图像技术(DIC)对裂缝进行了表征。结果表明:高延性碱矿渣表现出较好的延性,具有早强特征。7天强度值可达极限强度的84%以上(极限拉压强度分别为5.05 MPa、91.24 MPa),拉伸应变可达5.74%,多缝开裂基本饱和;28天后拉压性能趋于稳定(拉压强度、拉伸应变分别保持在6 MPa、100 MPa、6%);DIC数字分析云图直观地描述了裂缝的形成及发展过程,可从一定程度上对开裂破坏方向及位置进行可靠预判。Abstract: Activated by alkaline activator, polyethylene (PE) fiber reinforced high ductile alkali-activated slag composites were prepared using slag as the main raw material and fly ash as auxiliary material. The tensile and compressive properties of the composites under different curing ages (1 day, 3 days, 7 days, 28 days, 56 days and 120 days) were studied through uniaxial tensile and compressive tests, and the cracks were characterized by a digital image correlation technology (DIC). The results show that the alkali-activated slag owns a good high ductility and early strength. The strength value at 7 days can reach more than 84% of the ultimate strengths (the ultimate tensile and compressive strengths are 5.05 MPa and 91.24 MPa, respectively), 5.74% for the tensile strain, and the multi-cracking is basically saturated. After 28 days, the tensile and compressive properties become stable (tensile and compressive strengths and tensile strain keep around 6 MPa, 100 MPa and 6%, respectively). DIC analysis cloud maps visually describe the formation and propagation of cracks, which can be applied to predict reliably the direction and location of cracks to a certain extent.

-

表 1 矿粉和粉煤灰的主要化学组成

Table 1. Main chemical composition of slag and fly ash

wt% Oxide CaO SiO2 Al2O3 Fe2O3 MgO SO3 K2O Na2O TiO2 Slag 42.6 35.2 10.4 0.51 4.95 2.0 0.40 0.31 0.53 Fly ash 16.4 35.4 27.8 2.4 0.75 5.66 0.59 0.16 1.55 表 2 聚乙烯(PE)纤维增强高延性碱矿渣复合材料配合比

Table 2. Mix design proportion of polyethylene (PE) fiber reinforced high ductile alkali-activated slag composites

Slag/wt% Fly ash/wt% Sand/wt% Na2SiO3/wt% NaOH/wt% Water/wt% PE fiber/vol% 48.46 5.38 16.15 13.21 2.94 12.92 2 表 3 不同龄期下PE纤维增强高延性碱矿渣试件裂缝的特性

Table 3. Crack characteristics of the PE fiber reinforced alkali-activated slag composite specimens at different ages

Curing age/day Number of crack Average crack width/μm Average crack spacing/mm 1 9±1 229.21±23.62 8.59±0.42 3 17±2 175.74±29.33 4.78±0.57 7 29±2 160.81±12.22 2.80±0.16 28 34±1 147.34±4.33 2.35±0.07 56 31±1 158.41±9.65 2.58±0.07 120 33±2 145.20±1.92 2.43±0.12 表 4 PE纤维增强高延性碱矿渣在不同龄期下的抗压强度

Table 4. Compressive strength of PE fiber reinforced high ductile alkali-activated slag composites at different ages

Curing age/day 1 3 7 28 56 120 Compressive strength/MPa 69.7±4.8 80.51±2.0 91.24±2.1 100.69±3.7 99.39±4.3 97.6±4.9 -

[1] PROVIS J L, PALOMO A, SHI C. Advances in understanding alkali-activated materials[J]. Cement and Concrete Research,2015,78:110-125. doi: 10.1016/j.cemconres.2015.04.013 [2] 陈硕, 王立久. 活性MgO改性流化床炉底渣-硅灰复合材料的力学性能及产物[J]. 复合材料学报, 2018, 35(5):1288-1297.CHEN Shuo, WANG Lijiu. Mechanical properties and reaction products of reactive MgO modified circulating fluidized bed combustion slag-silica fume composites[J]. Acta Materiae Compositae Sinica,2018,35(5):1288-1297(in Chinese). [3] LING Y, WANG K. Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites[J]. Composites Part B: Engineering,2019,164:747-757. doi: 10.1016/j.compositesb.2019.01.092 [4] KOSHY N, DONDORB K. Synthesis and characterization of geopolymers derived from coal gangue, fly ash and red mud[J]. Construction and Building Materials,2019,206:287-296. doi: 10.1016/j.conbuildmat.2019.02.076 [5] SCRIVENER K L, JOHN V M, GARTNER E M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry[J]. Cement and Concrete Research,2018,114:2-26. doi: 10.1016/j.cemconres.2018.03.015 [6] 曹明莉, 许玲, 张聪. 高延性纤维增强水泥基复合材料的微观力学设计、性能及发展趋势[J]. 硅酸盐学报, 2015, 43(5):632-642.CAO Mingli, XU Ling, ZHANG Cong. Review on micromechanical design, performance and development tendency of engineered cementitious composite[J]. Journal of the Chinese Ceramic Society,2015,43(5):632-642(in Chinese). [7] 阚黎黎, 段贝贝, 闫涛. 高延性纤维增强偏高岭土-粉煤灰基地聚合物在不同环境下的自愈合性能[J]. 复合材料学报, 2018, 35(10):2841-2850.KAN Lili, DUAN Beibei, YAN Tao. Self-healing characteristics of engineered geopolymer composites incorporating metakaolin and fly ash under different environments[J]. Acta Materiae Compositae Sinica,2018,35(10):2841-2850(in Chinese). [8] ZHANG Z G, ZHANG Q, LI V C. Multiple-scale investigations on self-healing induced mechanical property recovery of ECC[J]. Cement and Concrete Composites,2019,103:293-302. doi: 10.1016/j.cemconcomp.2019.05.014 [9] LI V C. On engineered cementitious composites (ECC)—A review of the material and its applications[J]. Advanced Concrete Technology,2003(3):215-230. [10] ZHOU J, QIAN S Z, YE G, et al. Improved fiber distribution and mechanical properties of engineered cementitious composites by adjusting the mixing sequence[J]. Cement and Concrete Composites,2012,34(3):342-348. doi: 10.1016/j.cemconcomp.2011.11.019 [11] VICTOR C LI. Tailoring ECC for special attributes: A review[J]. International Journal of Concrete Structures and Materials,2012(6):135-144. [12] 林建辉, 余江滔, VICTOR C LI. PVA纤维增强水泥基复合材料热处理后的力学性能[J]. 复合材料学报, 2016, 33(1):116-122.LIN Jianhui, YU Jiangtao, VICTOR C LI. Mechanical properties of PVA fiber reinforced cementitious composites after thermal treatment[J]. Acta Materiae Compositae Sinica,2016,33(1):116-122(in Chinese). [13] NOWELL D. Application of digital image correlation to the investigation of crack closure following overloads[J]. Procedia Engineering,2010(2):1035-1043. [14] 卿龙邦, 曹国瑞, 管俊峰. 基于DIC方法的混凝土允许损伤尺度试验研究[J]. 工程力学, 2019, 36(10):115-121.QING Longbang, CAO Guorui, GUAN Junfeng. Experimental investigation of the concrete permissible damage scale based on the digital image correlation method[J]. Engineering Mechanics,2019,36(10):115-121(in Chinese). [15] 赵燕茹, 邢永明, 黄建永, 等. 数字图像相关方法在纤维混凝土拉拔试验中的应用[J]. 工程力学, 2010, 27(6):169-175.ZHAO Yanru, XING Yongming, HUANG Jianyong, et al. Study on the fiber-reinforced concrete pull-out test using digital image correlation method[J]. Engineering Mechanics,2010,27(6):169-175(in Chinese). [16] 赵燕茹, 郝松, 王磊, 等. 基于数字图像相关的钢纤维增强水泥基复合材料的冲击损伤特性[J]. 复合材料学报, 2018, 35(5):1325-1331.ZHAO Yanru, HAO Song, WANG Lei, et al. Impact damage characteristics of steel fiber reinforced cement matrix composites based on digital image correlation[J]. Acta Materiae Compositae Sinica,2018,35(5):1325-1331(in Chinese). [17] 俞鑫炉, 付应乾, 董新龙, 等. 轴向钢筋增强混凝土一维应力层裂实验研究[J]. 工程力学, 2020, 37(1):80-87.YU Xinlu, FU Yingqian, DONG Xinlong, et al. Experimental study on one-dimensional stress spall of unidirectional reinforced concrete[J]. Engineering Mechanics,2020,37(1):80-87(in Chinese). [18] KAN L L, SHI R X, ZHAO Y J, et al. Feasibility study on using incineration fly ash from municipal solid waste to develop high ductile alkali-activated composites[J]. Journal of Cleaner Production,2020,254:120168. doi: 10.1016/j.jclepro.2020.120168 [19] COLLINS F G, SANJAYAN J G. Microcracking and strength development of alkali activated slag concrete[J]. Cement and Concrete Composites,2001,23:345-352. doi: 10.1016/S0958-9465(01)00003-8 [20] NUNES L C, REIS J M L. Estimation of crack-tip-opening displacement and crack extension of glass fiber reinforced polymer mortars using digital image correlation method[J]. Materials and Design,2012,33(1):248-253. [21] MOHAMMED F, AMER B, NEMKUMER B, et al. Tensile performance of eco-friendly ductile geopolymer compo-sites (EDGC) incorporating different micro-fibers[J]. Cement and Concrete Composites,2019,103:183-192. doi: 10.1016/j.cemconcomp.2019.05.004 -

下载:

下载: