Low-speed collision optimization design of composite bumper

-

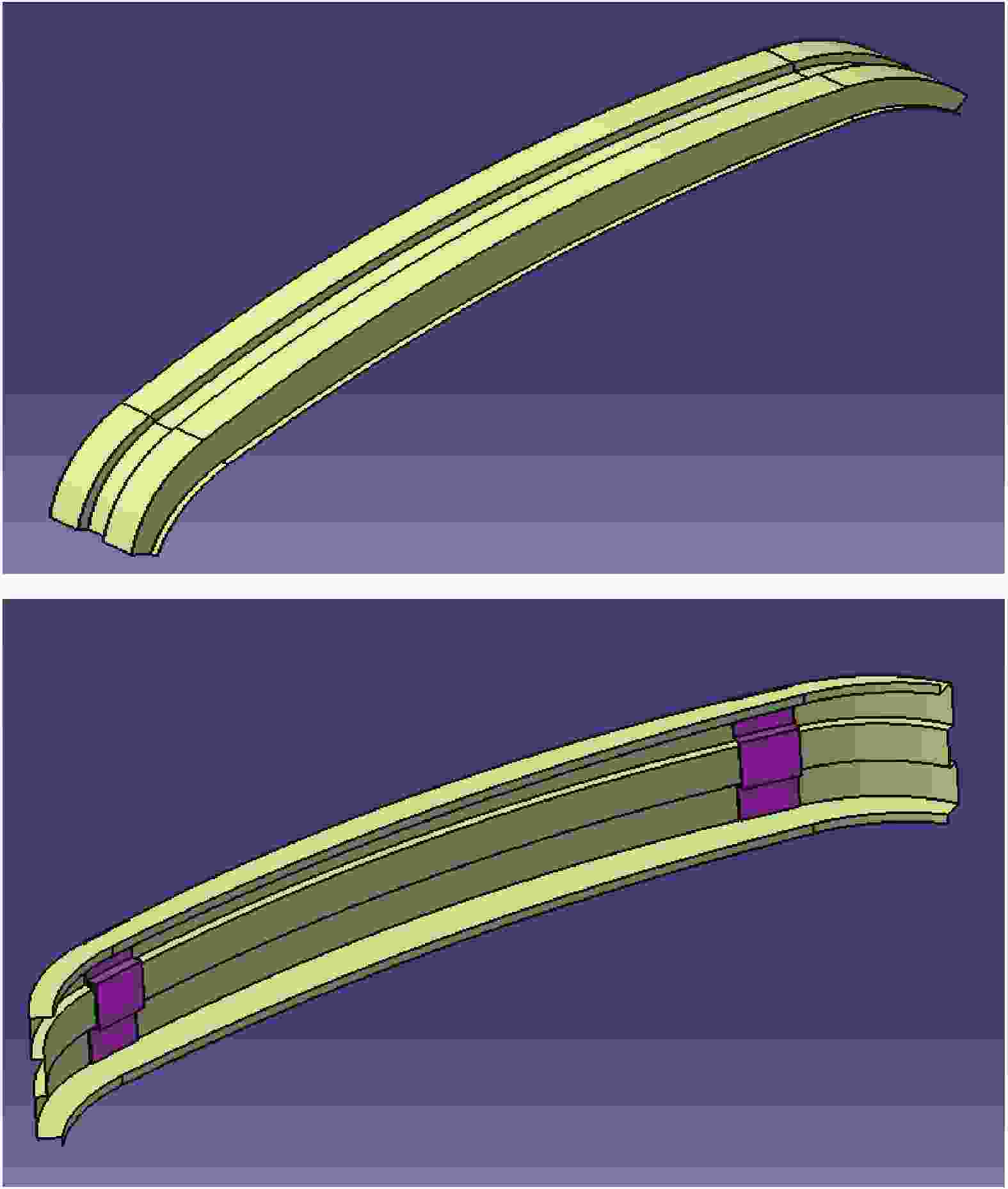

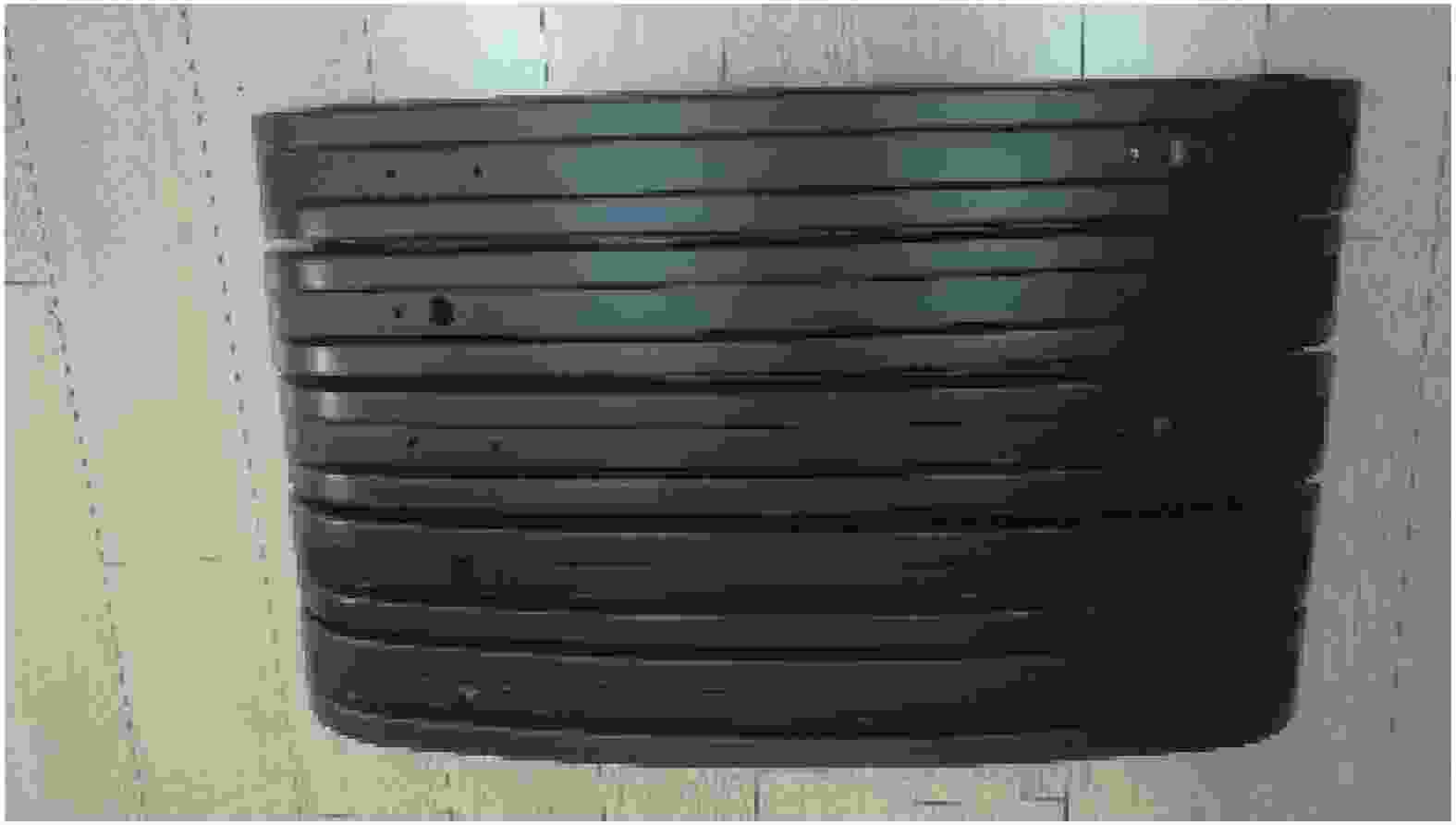

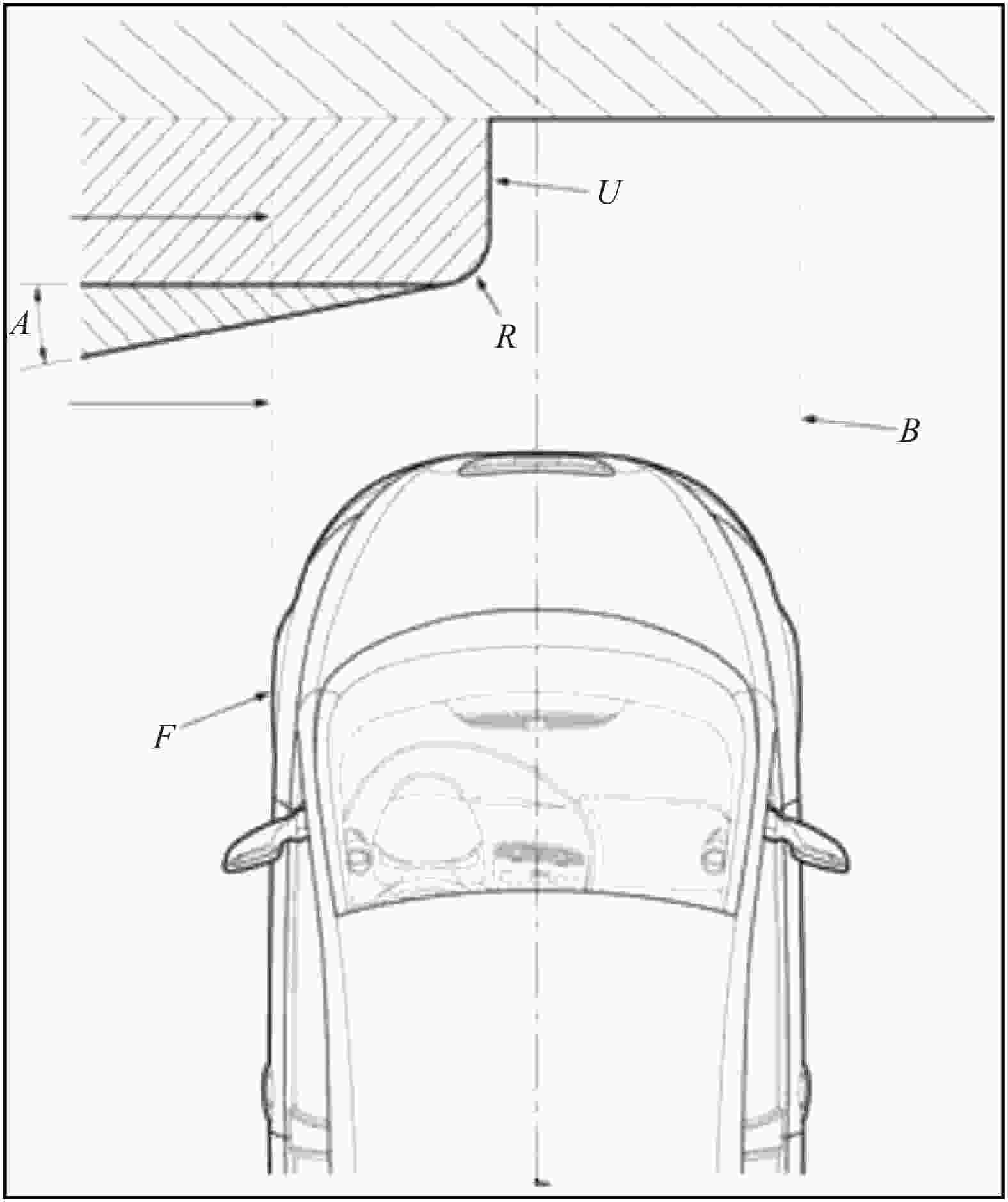

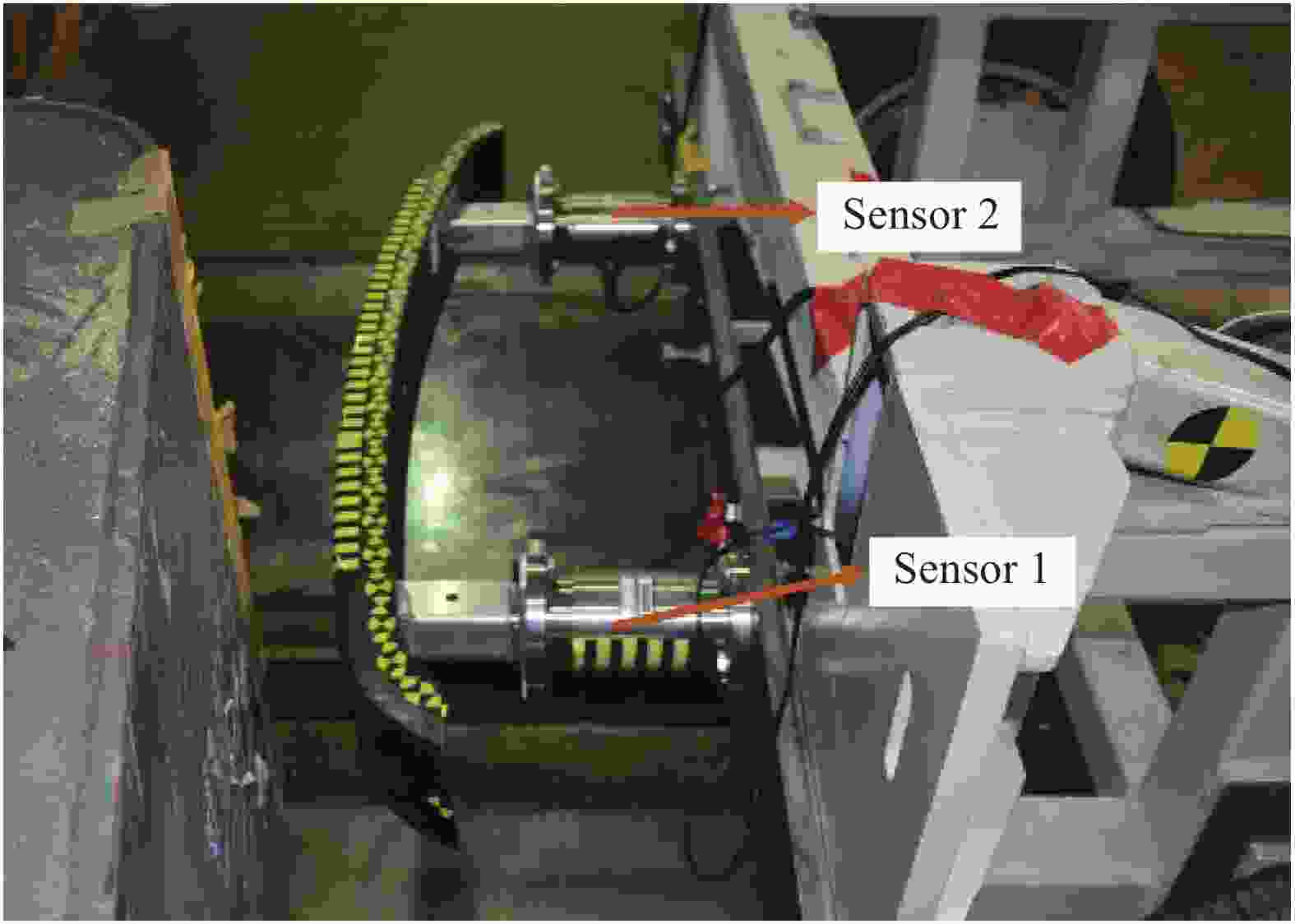

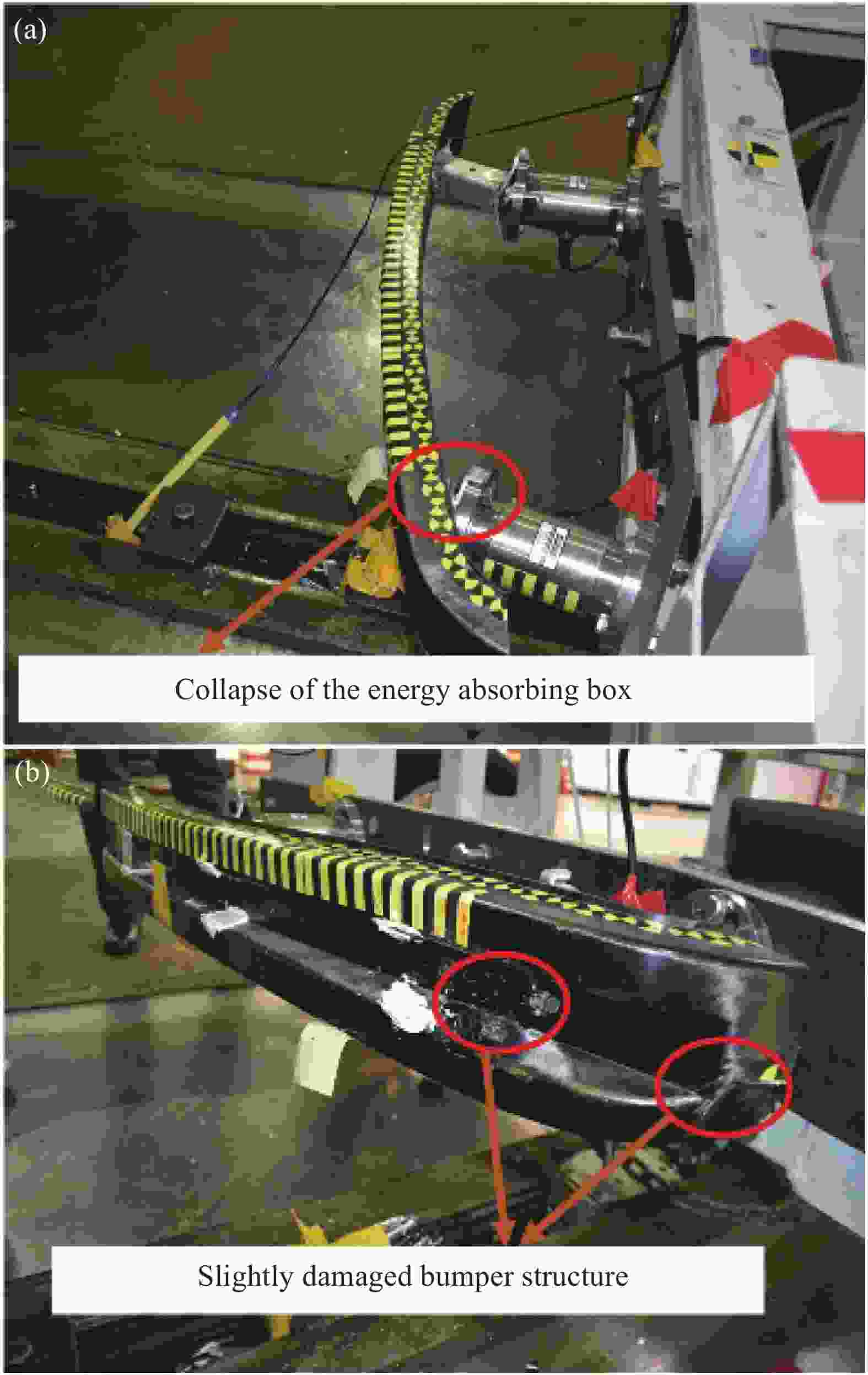

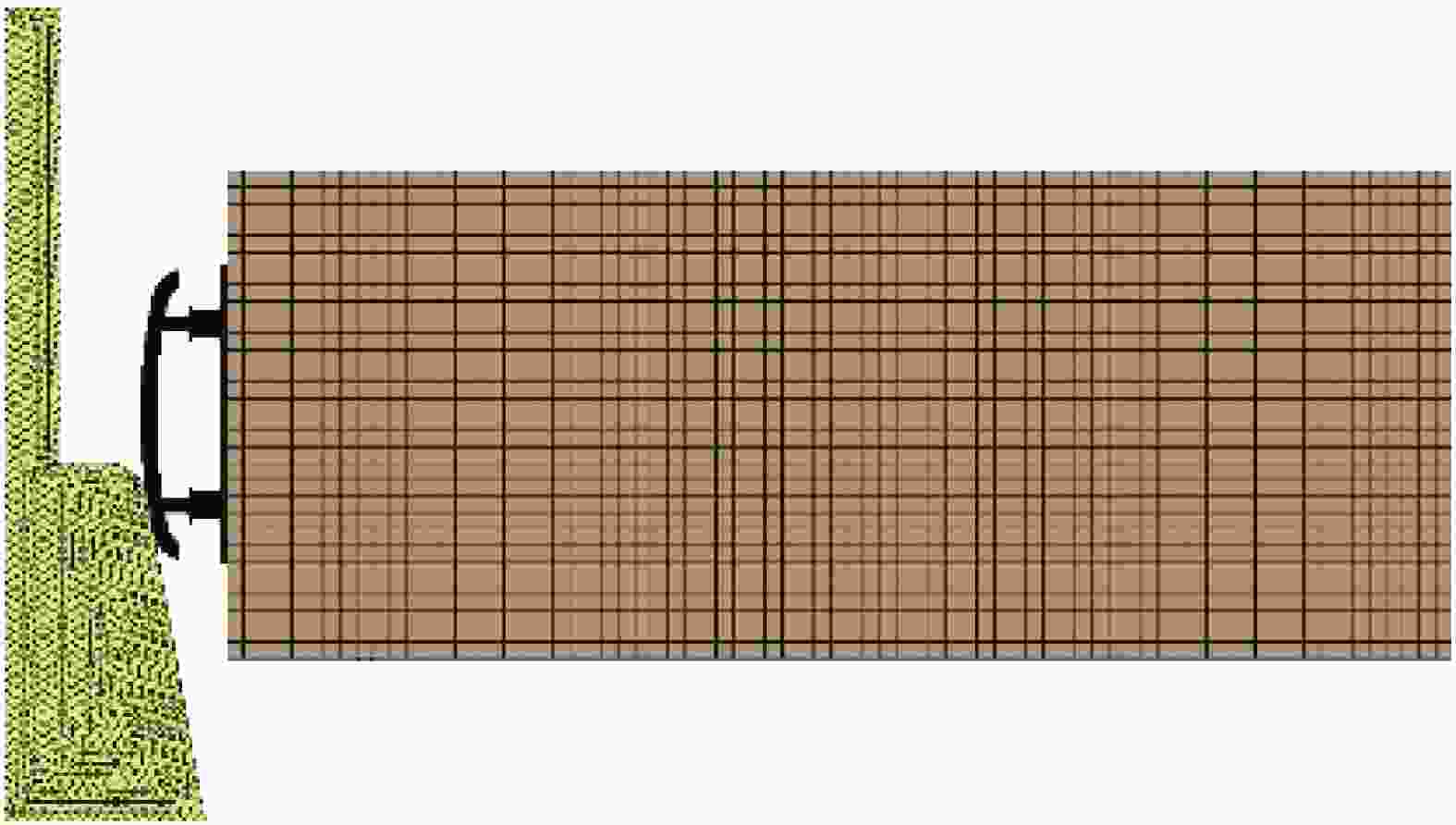

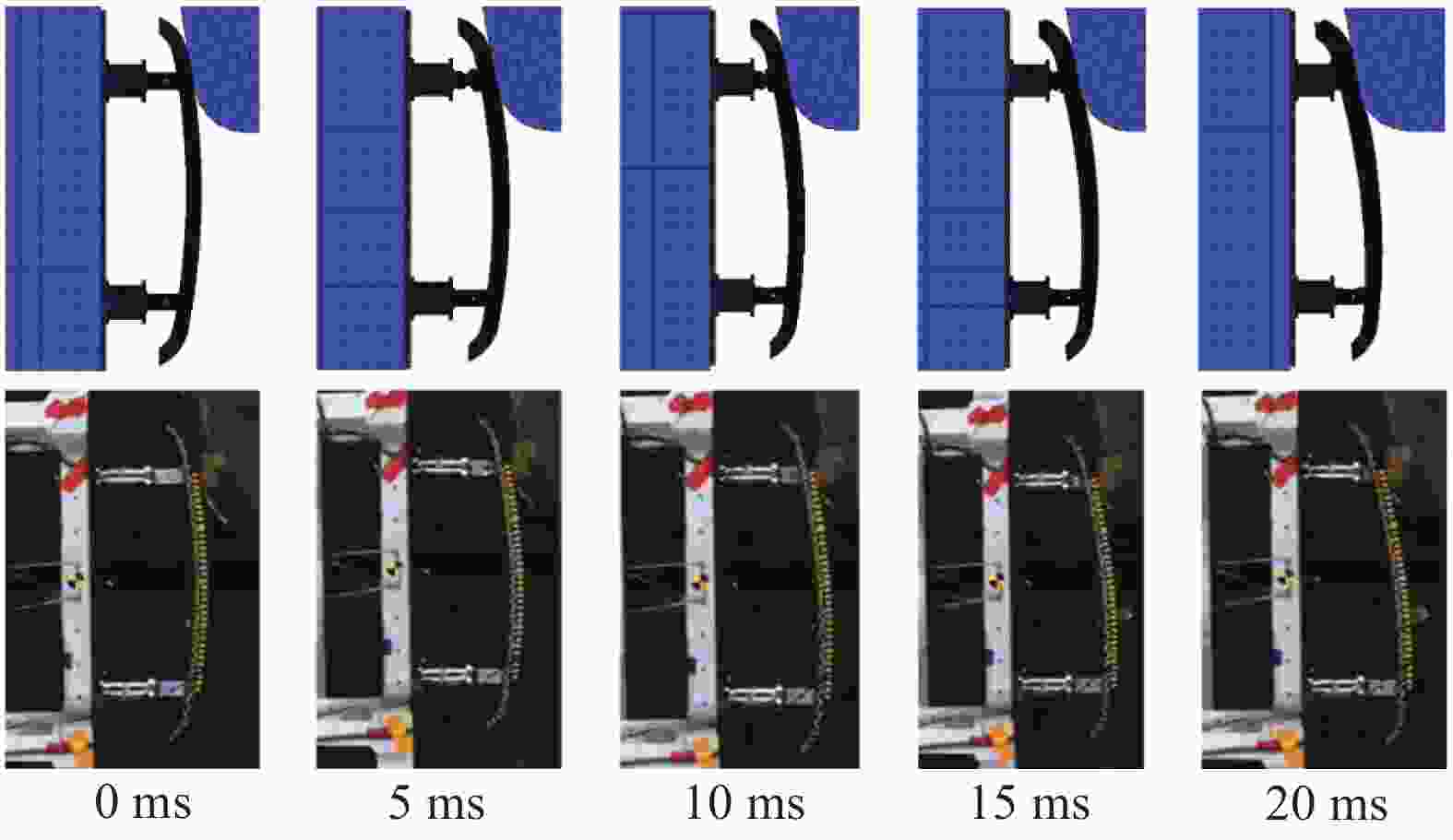

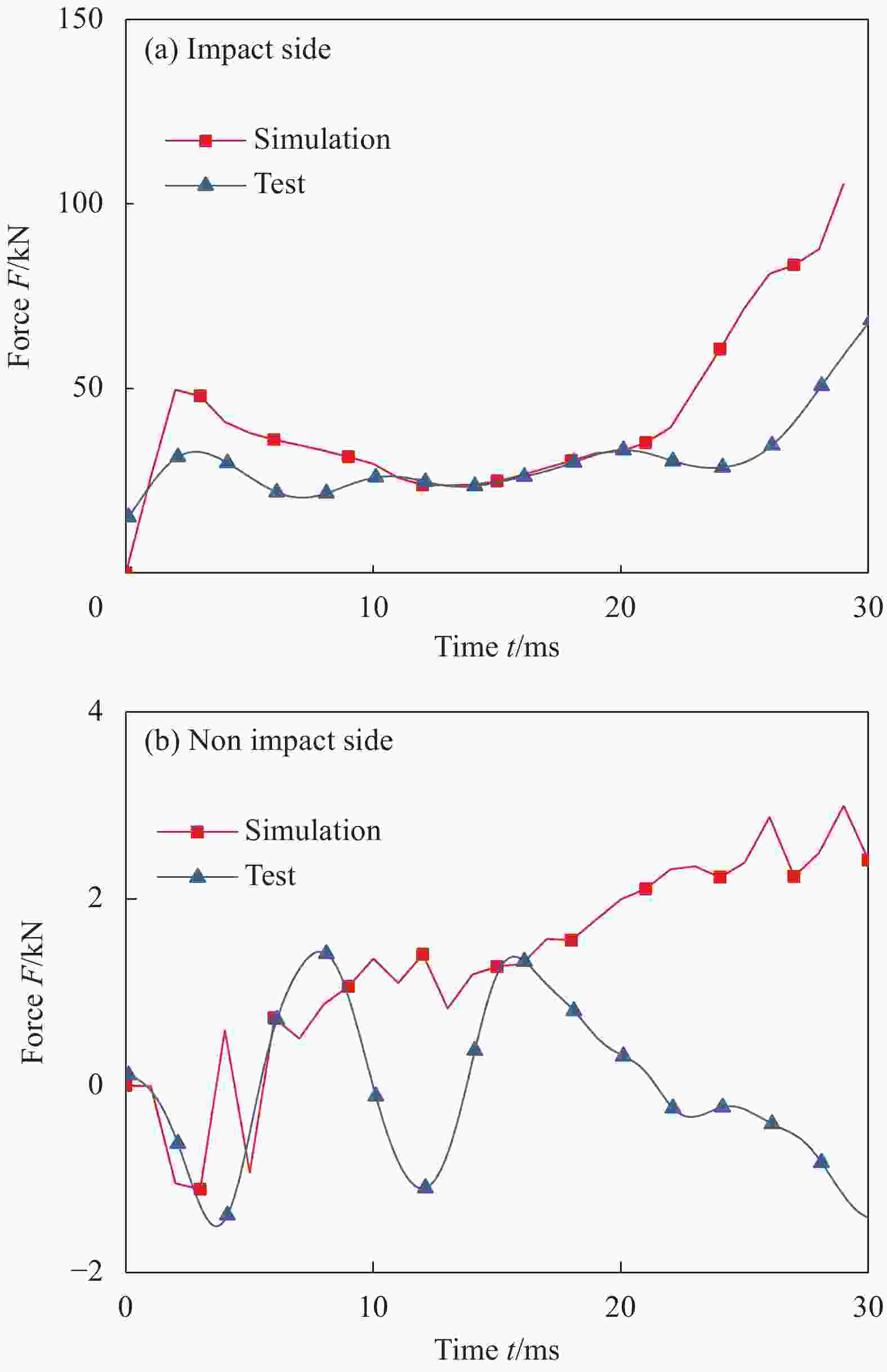

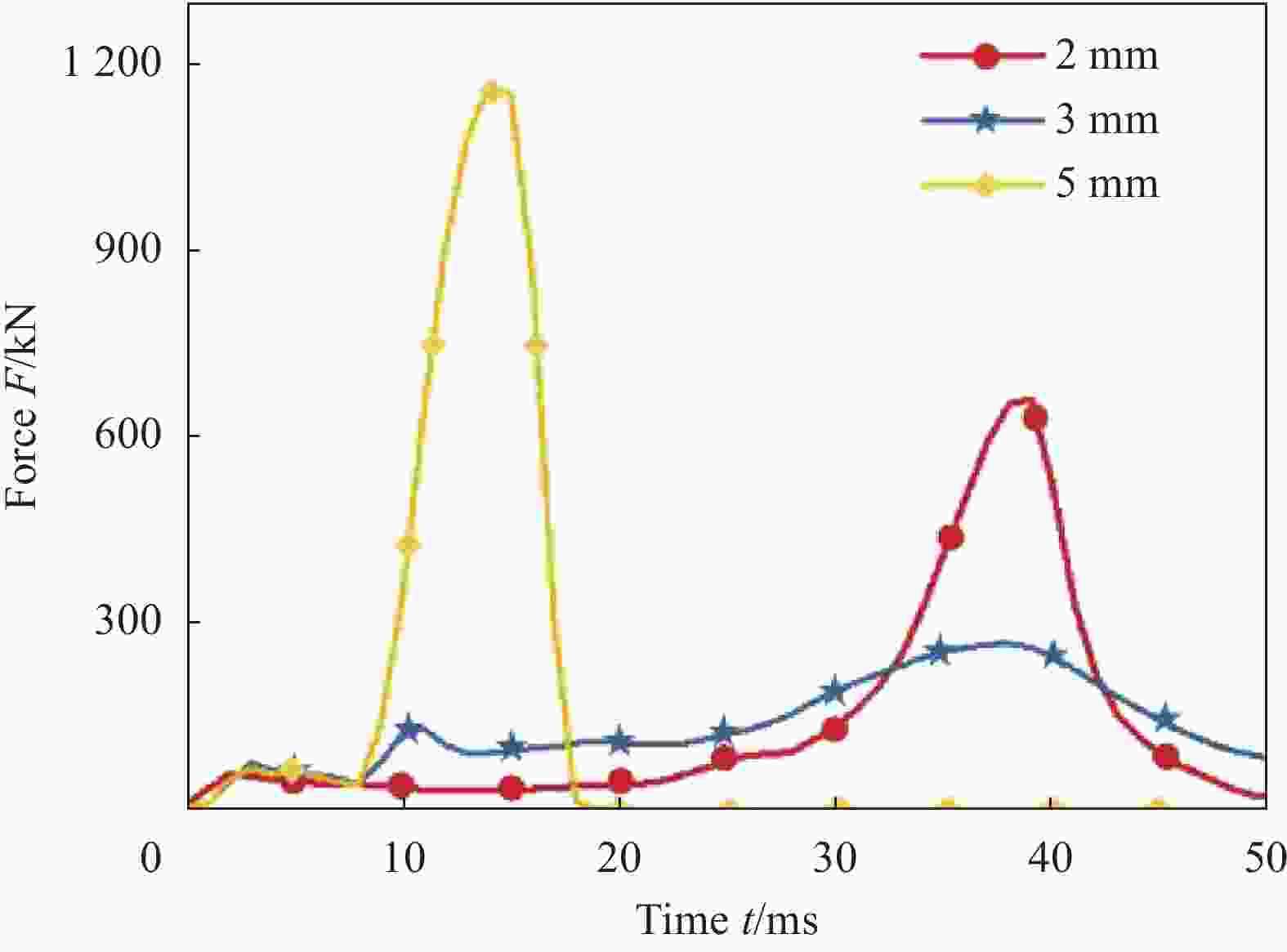

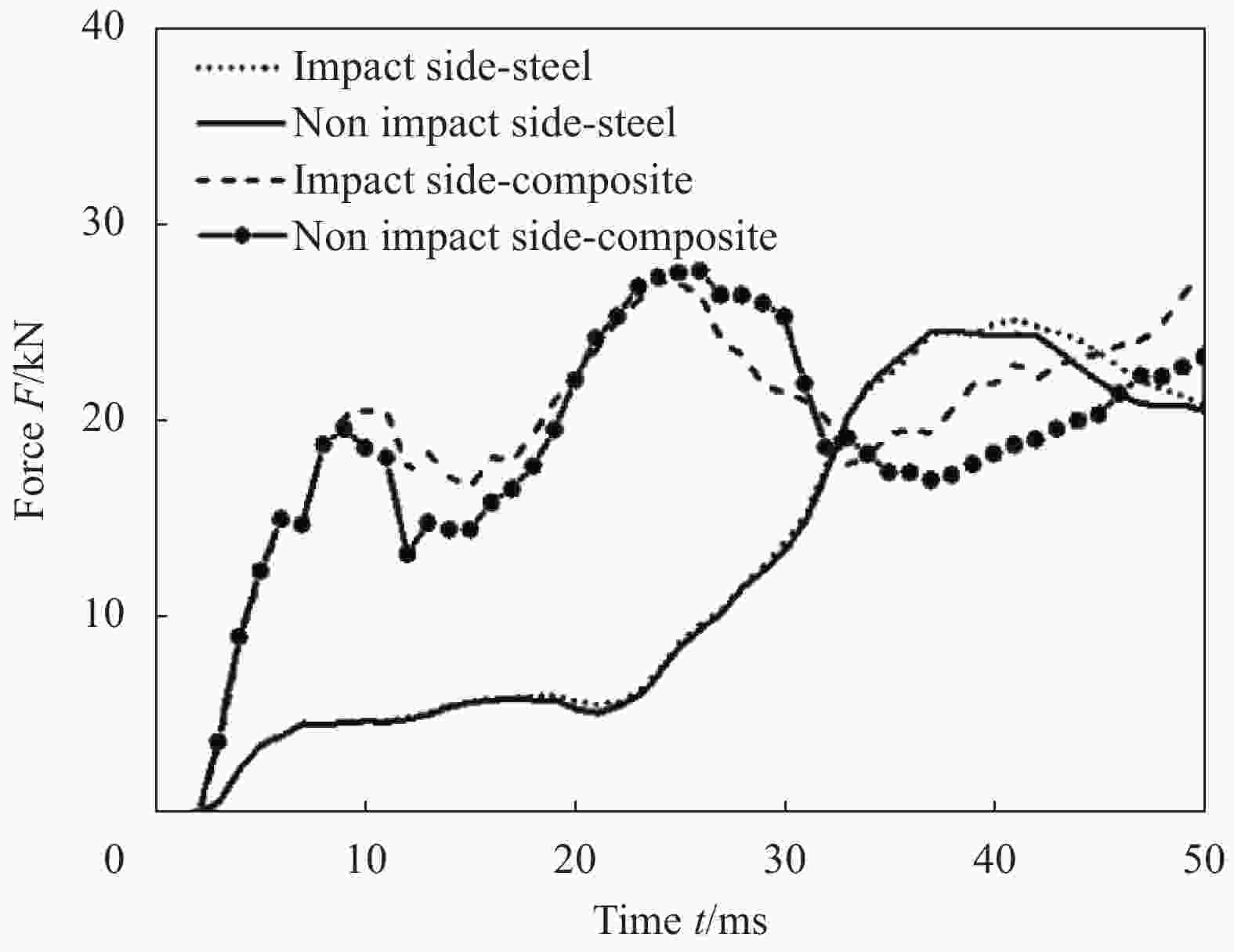

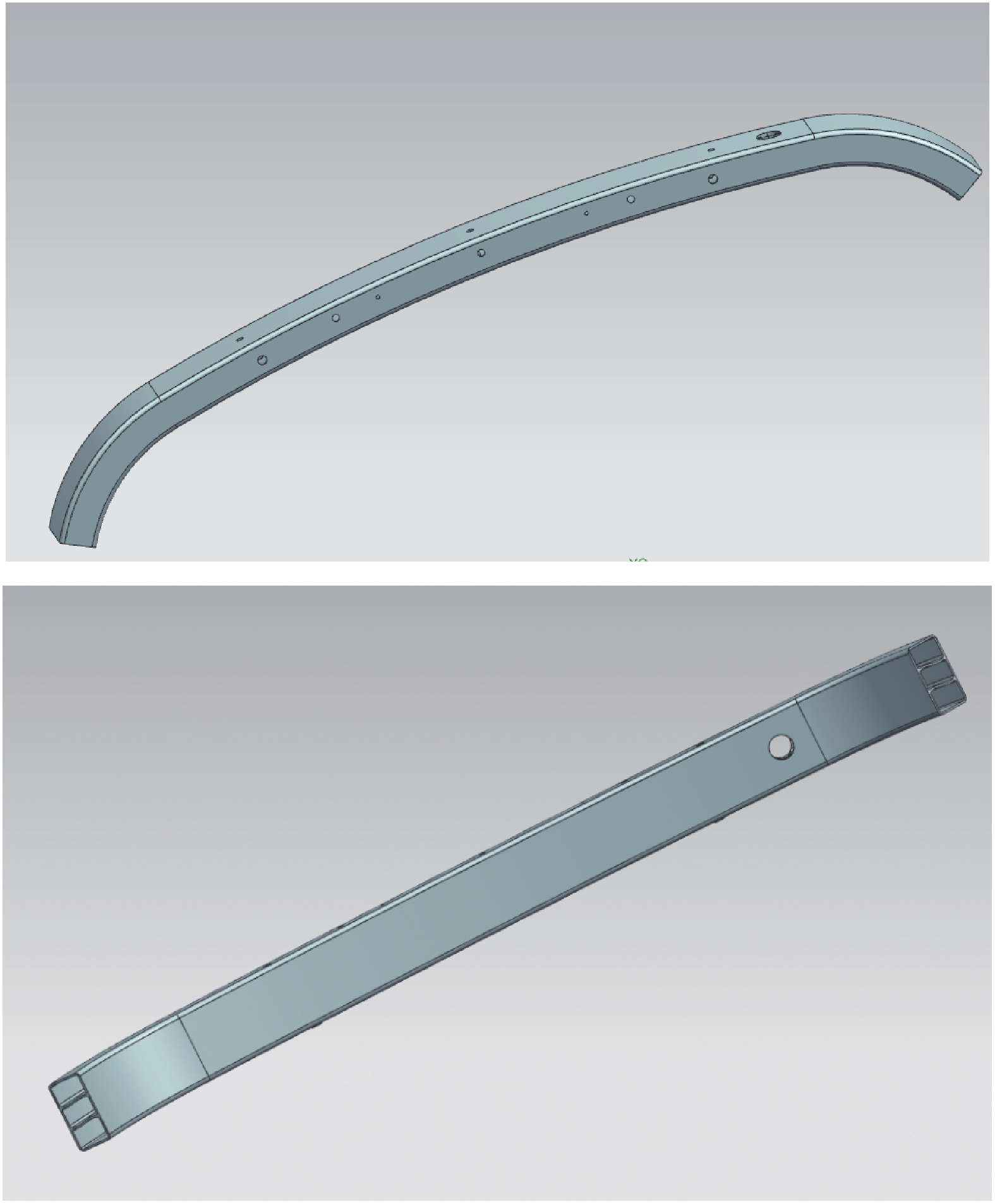

摘要: 复合材料由于其较高的比刚度、比强度而成为重要的轻量化材料,推广其在汽车上的应用可有效缓解当前人类面临的环境污染和能源短缺问题。基于某款汽车铝合金前防撞梁,开展了复合材料替代设计,可实现减重27%,并采用碳纤维湿法模压成型工艺进行制备后,进行了RCAR标准下正面40%重叠碰撞实验;同时,利用有限元软件LS-DYNA构建了复合材料前防撞梁数值模型,验证后基于该模型进一步对吸能盒壁厚、复合材料梁铺层厚度、铺层方式等参数进了探讨,发现吸能盒壁厚对于防撞梁的耐撞性较关键,而引入仿生螺旋铺层设计可进一步提升能量吸收特性。此外,同等质量下的复合材料防撞梁综合性能被证明较金属防撞梁更加优异。Abstract: Composites are termed as important lightweight materials because of their high specific stiffness and strength. The application of composites in automotive industry can be one effective way to reduce environmental pollution and energy shortages. A composites bumper, which is 27% lighter than the aluminum counterpart, was designed and fabricated using wet compression molding with carbon fiber. Then, 40% frontal collision following RCAR standard were performed on these bumpers. Meanwhile, the finite element models were built up in LS-DYNA and used for parameter discussion after validation. The thickness of energy absorption box can increase the crashworthiness of the bumper, while the energy absorption capability can be enhanced after introducing a bioinspired helicoidal fiber arrangement. Also, the composites bumper is demonstrated to outperform the metal one under the same weight.

-

Key words:

- composites /

- lightweight /

- bumper /

- wet compression molding /

- low-speed collision

-

表 1 碰撞器和车身材料参数

Table 1. Parameters of impactor and car

Parameter Collision Car Density ρ/(g·cm−3) 7.85 1.036 Modulus E/GPa 210 210 Poisson’s ratio 0.3 0.3 表 2 吸能盒和传感器参数

Table 2. Parameters of crash box and sensor

Parameter Crash box Sensor Density ρ/(g·cm−3) 2.70 7.85 Modulus E/GPa 69 210 Poisson’s ratio 0.33 0.3 Yield stress σ/MPa 105 355 表 3 碳纤维增强环氧树脂复合材料的力学性能

Table 3. Mechanical properties of carbon fiber reinforced epoxy composites

Parameter Value Density ρ/(g·cm−3) 1.5×10−6 Longitudinal tensile modulus Ea/GPa 127 Transverse tensile modulus Eb /GPa 8.41 In-plane shear modulus Gab/GPa 4.21 Principal Poisson’s ratio 0.309 Sub Poisson’s ratio 0.0205 Longitudinal tensile strength Xt/GPa 2.2 Longitudinal compressive strength Xc/GPa 1.47 Transverse tensile strength Yt/GPa 0.049 Transverse compressive strength Yc/GPa 0.199 In-plane shear strength Sc/GPa 0.154 表 4 三种铺层数的复合材料防撞梁关键参数仿真结果对比

Table 4. Comparison of simulation results of key parameters of composite bumpers with three laying methods

Number of layer Maximum force/kN Maximum displacement/mm Energy absorption/J Specific energy absorption/(J·kg−1) 12 27.8 78.9 4462 2617 24 47.9 49.0 5850 2145 36 92.4 40.1 6732 1795 表 5 四种铺层方式的复合材料防撞梁关键参数仿真结果对比

Table 5. Comparison of simulation results of key parameters of composite bumpers with four laying methods

Stacking mode Maximum force/kN Maximum displacement/mm Energy absorption/J Specific energy absorption/(J·kg−1) Case I 27.8 78.9 4462 2617 Case II 26.3 84.6 2597 1523 Case III 23.7 94.8 3105 1821 Case IV 39.1 78.1 4573 2682 Notes: Case I—[45/0/0/0/−45/0/0/−45/0/0/0/45]; Case II—[0]12; Case III—[90]12; Case IV—[0/36/72/−72/−36/0/0/−36/−72/72/36/0]. 表 6 钢制梁与复合材料梁的关键参数仿真结果对比

Table 6. Comparison of simulation results of key parameters between steel bumper and composite bumper

Material Maximum force/kN Maximum displacement/mm Energy absorption/J Specific energy absorption/(J·kg−1) Steel 25.2 92.2 2843 1667 Composite 27.8 78.9 4462 2617 -

[1] 杨旭静, 张振明, 郑娟, 等. 复合材料前防撞梁变截面多工况多目标优化设计[J]. 汽车工程, 2015, 37(10):1130-1137, 1143. doi: 10.3969/j.issn.1000-680X.2015.10.005YANG Xujing, ZHANG Zhenming, ZHENG Juan, et al. Multi-condition/multi-object optimization design of the variable cross-section of composite front bumper[J]. Automotive Engineering,2015,37(10):1130-1137, 1143(in Chinese). doi: 10.3969/j.issn.1000-680X.2015.10.005 [2] 段书用. 面向车身应用的 LGFRP 复合材料制备工艺及力学性能研究[D]. 长沙: 湖南大学, 2016.DUAN Shuyong. The research on the preparation technology and mechanical properties of LGFPR composite for application in vechicle body[D]. Changsha: Hunan University, 2016(in Chinese). [3] 肖永清. 轻量化材料驱动汽车的未来[J]. 汽车工程师, 2010(12):14-16. doi: 10.3969/j.issn.1674-6546.2010.12.002XIAO Yongqing. Lightweight materials guiding the future of automobile[J]. Auto Engineer,2010(12):14-16(in Chinese). doi: 10.3969/j.issn.1674-6546.2010.12.002 [4] 吴尘瑾, 祖磊, 李书欣, 等. 变刚度复合材料层合板的纤维铺放路径设计及屈曲分析[J]. 玻璃钢/复合材料, 2018(4):5-10.WU Chenjin, ZU Lei, LI Shuxin, et al. Design of fiber placement path and bucking analysis of variable stiffness composite laminates[J]. FRP/Composites,2018(4):5-10(in Chinese). [5] 刘昌. 复合材料变刚度铺层优化设计方法研究[D]. 太原: 中北大学, 2016.LIU Chang. Stacking sequence optimization research of variable stiffness composite laminates[D]. Taiyuan: North University of China, 2016(in Chinese). [6] 张宇, 郑升伟. 基于某轿车RCAR低速后碰分析及优化设计[J]. 机械强度, 2016, 38(6):1356-1360.ZHANG Yu, ZHEN Shengwei. Analysis and optimization on vehicle low speed back-crash design based on RCAR tests[J]. Journal of Mechanical Strength,2016,38(6):1356-1360(in Chinese). [7] 孙晴, 高保才, 陈现岭, 等. 基于RCAR的保险杠低速碰撞的分析与应对措施[J]. 汽车安全与节能学报, 2012, 3(4):332-338. doi: 10.3969/j.issn.1676-8484.2012.04.006SUN Qing, GAO Baicai, CHEN Xianling, et al. Analysis and its solution for bumper low-speed structural crash based on RCAR[J]. Journal of Automotive Safety and Energy,2012,3(4):332-338(in Chinese). doi: 10.3969/j.issn.1676-8484.2012.04.006 [8] 都雪静, 陈占丽. 基于RCAR试验的电动SUV低速保险杠耐撞性研究[J]. 交通科技与经济, 2020, 22(3):35-41.DU Xuejing, CHEN Zhanli. Research on crash resistance of electric SUV low speed bumper based on RCAR test[J]. Technology & Economy in Areas of Communication,2020,22(3):35-41(in Chinese). [9] 王镇江, 何造, 林广谊, 等. 基于模态分析的汽车塑料保险杠拓扑优化[J]. 塑料, 2017, 46(5):9-12.WANG Zhenjiang, HE Zao, LIN Guangyi, et al. Topology optimization of automobile plastic bumper based on modal analysis[J]. Plastics,2017,46(5):9-12(in Chinese). [10] 陈静, 唐傲天, 田凯, 等. 碳纤维复合材料防撞梁轻量化设计[J]. 汽车工程, 2020, 42(3):390-395.CHEN Jing, TANG Aotian, TIAN Kai, et al. Multi-condition/multi-object optimization design of the variable cross-section of composite front bumper[J]. Automotive Engineering,2020,42(3):390-395(in Chinese). [11] 仲伟东, 王东方, 李静. 复合材料防撞梁低速碰撞的研究与多目标优化[J]. 南京工业大学学报(自然科学版), 2019, 41(4):463-471.ZHONG Weidong, WANG Dongfang, LI Jing. Research and multi-objective optimization for low speed collision of composite bumper beam[J]. Journal of Nanjing Tech Univesity (Natural Science Edition),2019,41(4):463-471(in Chinese). [12] KIM K J, GER K M. Effect of structural variables on automotive body bumper impact beam[J]. International Journal of Automotive Technology,2008,9(6):713-717. doi: 10.1007/s12239-008-0084-8 [13] ZAREI H R, GER K M. Bending behavior of empty and foam-filled beams: Structural optimization[J]. International Journal of Impact Engineering,2008,35:521-529. doi: 10.1016/j.ijimpeng.2007.05.003 [14] SHOJAEIFARD M H, ZAREI H R, TALEBITOOTI M M. Bending behavior of empty and form filled aluminum tubes with different cross-section[J]. Acta Mechanica Solida Sinica,2012,25(6):616-626. doi: 10.1016/S0894-9166(12)60057-3 [15] TANLAK N, SONMEZ F O, SENALTUN M. Shape optimization of bumper beams under high -velocity impact loads[J]. Engineering Structures,2015,95(7):49-60. [16] KUMAR S A J, BALA B R. Structural analysis of bumper beam with different alloys[J]. International Journal & Magazine of Engineering, Technology, Management and Research,2018,5(7):6-16. [17] YIN S, YANG R, HUANG Y, et al. Toughening mechanism of coelacanth-fish-inspired double-helicoidal composites[J]. Composites Science and Technology,2021,205:108650. [18] WEAVER J C, MILLIRON G W, MISEREZ A, et al. The stomatopod dactyl club: A formidable damage-tolerant biological hammer[J]. Science,2012,336:1275-1280. doi: 10.1126/science.1218764 [19] GRUNENFELDER L K, SUKSANGPANYA N , SALINAS C, et al. Bio-inspired impact resistant composites[J]. Acta Biomaterialia,2014,10:3997-4008. doi: 10.1016/j.actbio.2014.03.022 [20] YIN S, CHEN H, YANG R, et al. Tough nature-inspired helicoidal composites with printing-induced voids[J]. Cell Reports Physical Science,2020,1:1-18. [21] 全国汽车标准化委员会. 汽车前、后端保护装置: GB 17354—1998[S]. 北京: 中国标准出版社, 1998.National Technical Committee of Auto Standardization. Front and rear protective devices for passenger cars: GB 17354—1998[S]. Beijing: China Standards Press, 1998(in Chinese). -

下载:

下载: