Polyimide nanofiber self-reinforced film with high transparency and low thermal expansion coefficient

-

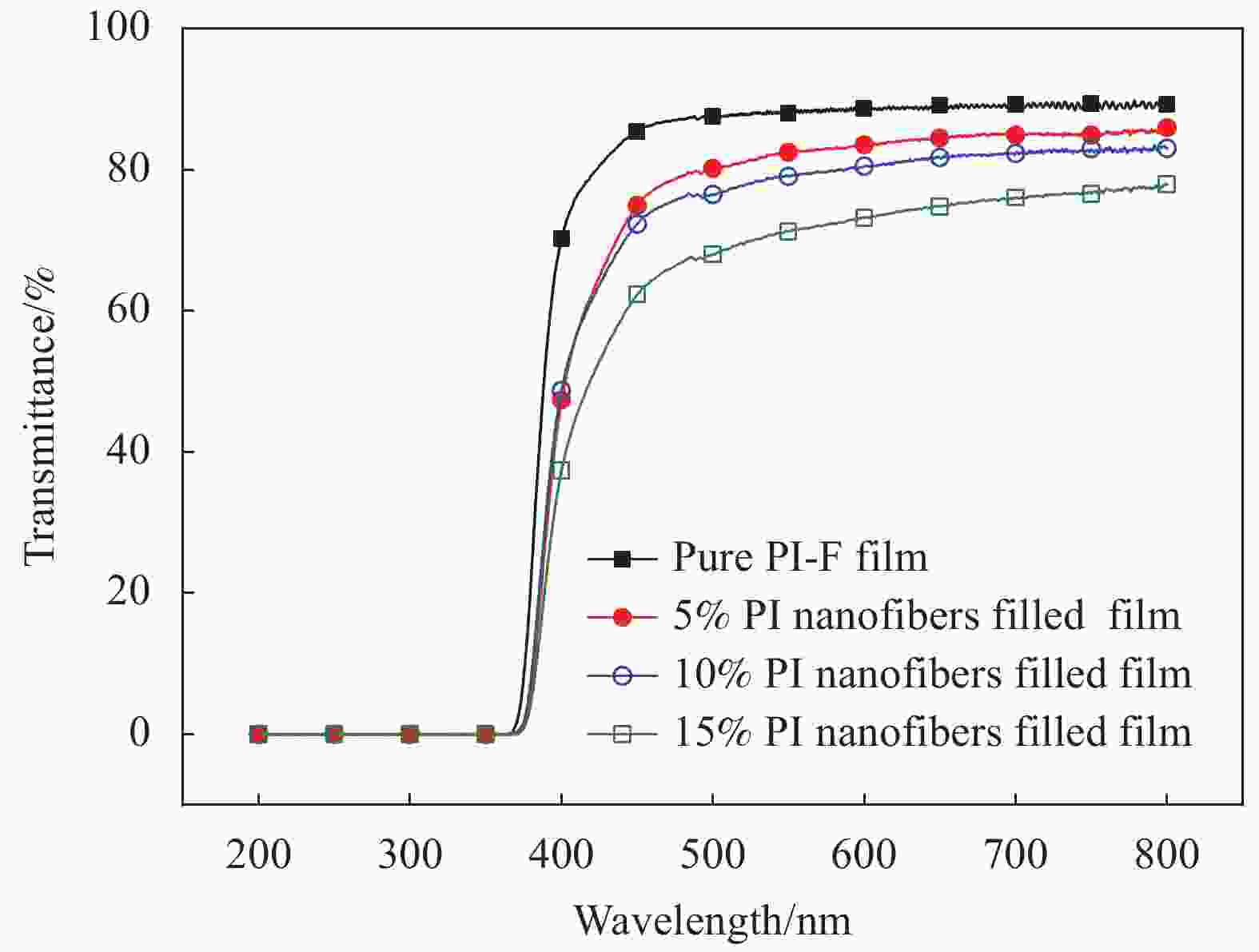

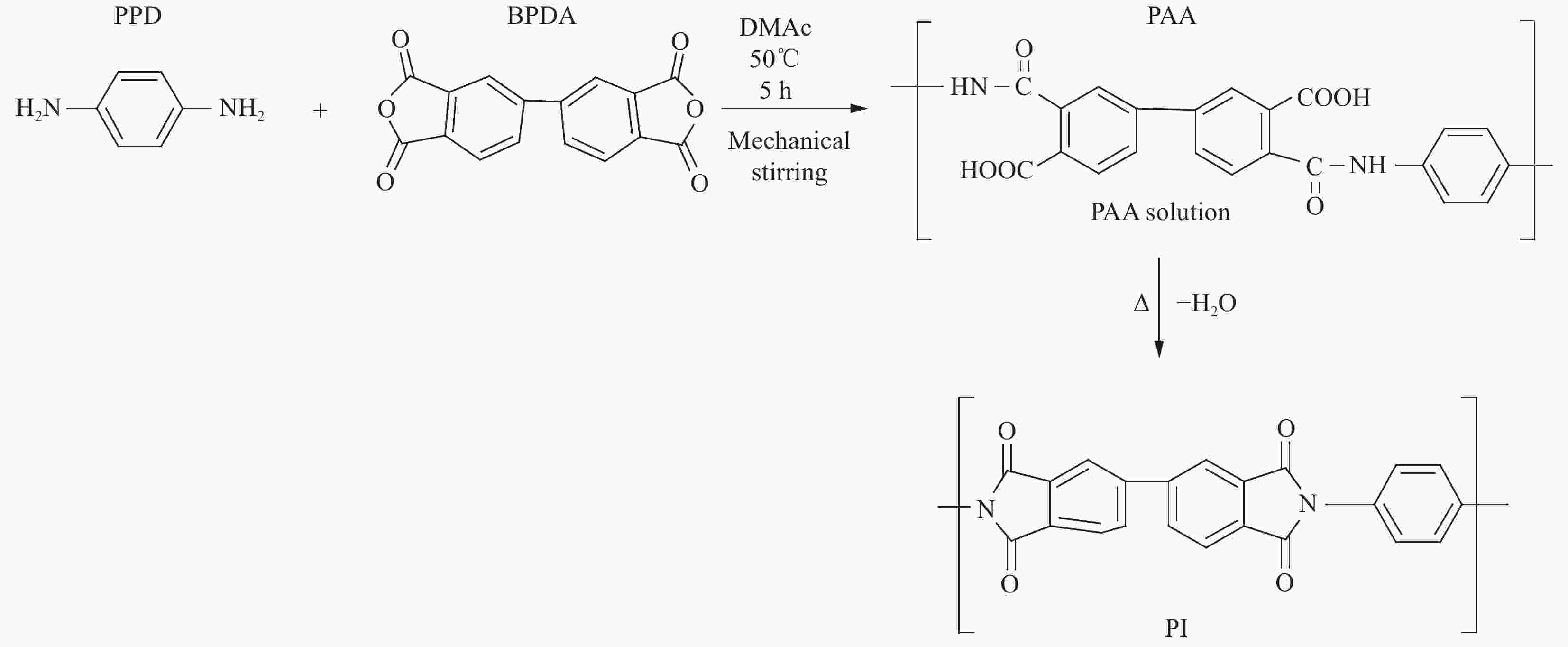

摘要: 应用于柔性显示的聚酰亚胺(Polyimide,PI)膜要求高透明性和低热膨胀系数CTE,而目前高透明聚酰亚胺的CTE普遍高于40×10−6/℃。本研究采用同质增强法,将高强度的纳米PI纤维与无色透明热塑性含氟聚酰亚胺(PI-F)复合,得到的纳米PI纤维增强PI-F基复合薄膜不仅保持PI-F的高透明,同时具有更低的CTE和优异的拉伸性能。研究结果表明:纳米尺寸的纤维可减少光透过时发生的散射,使复合薄膜维持了较高的透明性。当纳米PI纤维质量分数为10%时,在可见光区其透光率达到80.5%,与纯PI-F薄膜相比,复合薄膜的CTE值降低了40.3%,为28.3×10−6/℃。其拉伸强度提高了132.9%,达到107.6 MPa,拉伸模量增大了89.5%,达到1152.2 MPa。Abstract: The colorless polyimide (PI) used for the flexible display field is required to have high transparency and low thermal expansion coefficient CTE. However, the CTE value of commercial colorless PI film is above 40×10−6/℃. In the study, nanofiber self-filled PI film was prepared by embedding the PI nanofiber-net in thermoplastic fluorinated polyimide solution (PI-F). The nanofiber-net self-filled PI film demonstrates high transparency retention, much CTE and excellent tensile property. The results show that the fiber of nanosize avoids light scattering, therefore the high transparency of the film is retained. When the PI fiber mass fraction is 10%, the transparency of the film is 80.5%. In comparison to the pure PI-F film, the CTE of composite film is reduced by 40.3% and reaches 28.3×10−6/℃; The tensile strength and the tensile modulus of the composite film are increased by 132.9% and 89.5%, respectively and are 107.6 MPa and 1152.2 MPa correspondingly.

-

Key words:

- polyimide /

- nanofibers /

- micro-structure /

- self enhancement /

- thermal expansion coefficient

-

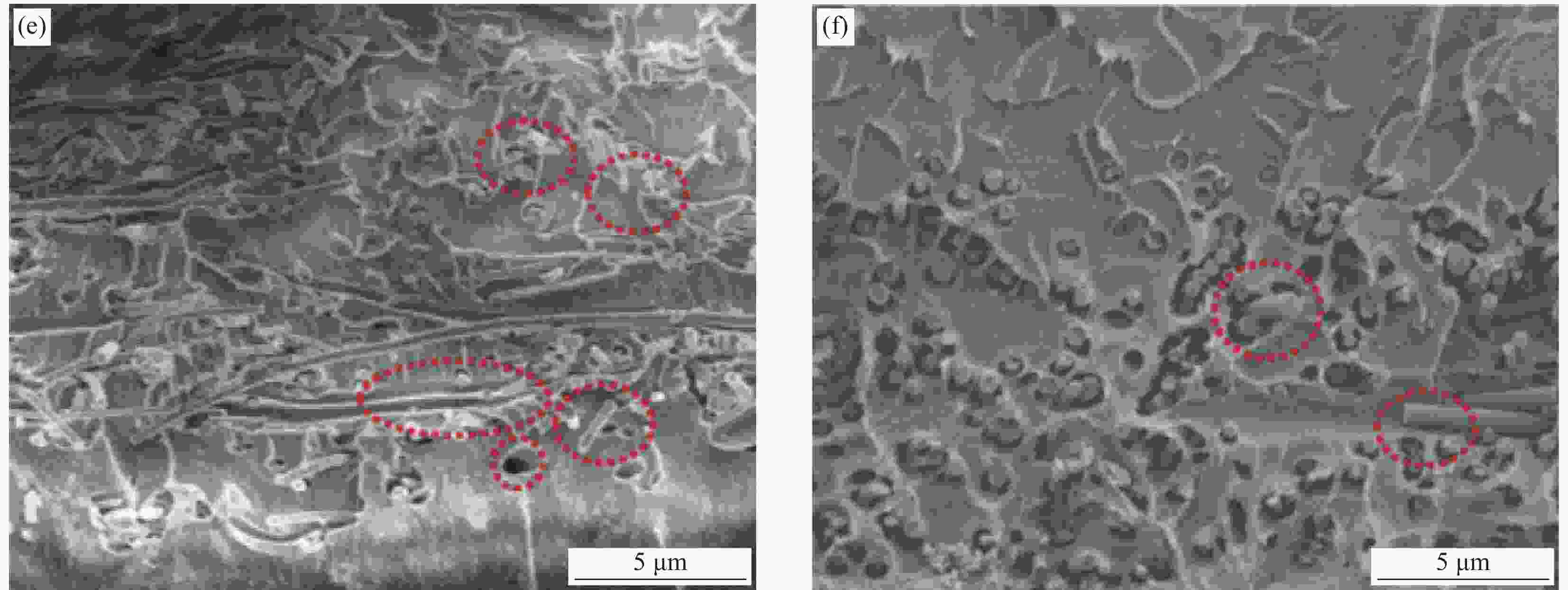

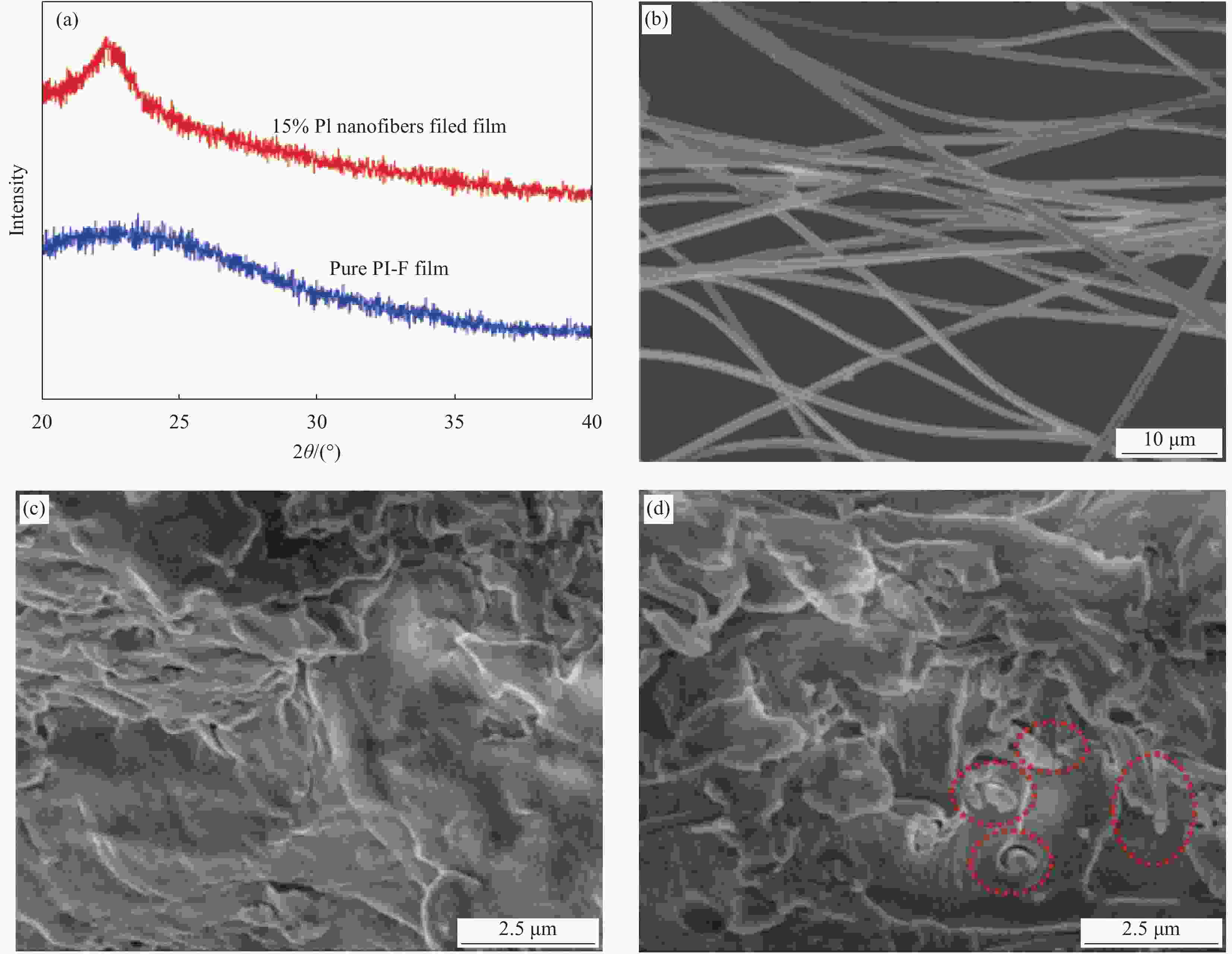

图 7 纳米PI纤维及其增强PI-F基复合薄膜的XRD图谱 (a);纳米PI纤维的SEM图像 (b);纳米PI纤维增强PI-F基复合薄膜横截面图 ((c)~(f)) (纤维含量: (d) 5%; (e) 10%; (f) 15%)

Figure 7. XRD spectra of PI nanofibers and PI nanofibers filled PI-F films (a); SEM image of PI nanofibers (b); SEM images of the cross-section morphology of PI nanofibers filled PI-F films ((c)-(f)) (Fiber content: (d) 5%; (e) 10%; (f) 15%)

表 1 纳米PI纤维增强PI-F基复合薄膜的组分质量含量(干膜)

Table 1. Composition of the PI nanofiber filled PI-F films (mass ratio based on dry film)

Sample PI nanofibers/% PI-F/% Pure PI-F film 0 100 5% PI nanofibers filled film 5 95 10% PI nanofibers filled film 10 90 15% PI nanofibers filled film 15 85 表 2 纳米PI纤维增强PI-F基复合薄膜的热膨胀系数CTE值及拉伸性能

Table 2. Thermal expansion coefficient CTE and tensile properties of PI nanofibers filled PI-F films

Sample CTE/(10−6℃−1) Tensile modulus/MPa Elongation at break/% Tensile strength/MPa Pure PI-F film 47.2 608.1±3.7 26.3±0.1 46.2±7.6 5% PI nanofibers filled film 34.4 987.0±1.9 18.6±0.1 73.8±5.7 10% PI nanofibers filled film 28.3 1152.2±2.5 15.9±0.1 107.6±6.5 15% PI nanofibers filled film 27.2 1388.9±3.2 15.2±0.1 122.4±7.1 -

[1] TONG Yuejin, LI Yuesheng. XIE Fengchao, et al. Preparation and characteristics of polyimide–TiO2 nanocomposite film[J]. Polymer International,2015,49(11):1543-1547. [2] QIAN Chao, ZHU Tianwen, ZHENG Weiwen, et al. Improving dielectric properties and thermostability of CaCu3Ti4O12/polyimide composites by employing surface hydroxylated CaCu3Ti4O12 particles[J]. ACS Applied Polymer Materials,2019,1(6):1263-1271. doi: 10.1021/acsapm.9b00010 [3] JUNG Youngsuk, BYUN Sunjung, PARK Sungjun, et al. Polyimide-organosilicate hybrids with improved thermal and optical properties[J]. ACS Applied Materials & Interfaces,2014,6(9):6054-6061. [4] 戴俊燕, 刘德山. 含氟聚酰亚胺的研究进展[J]. 功能高分子学报, 1999, 12(3):337-344.DAI Junyan, LIU Deshan. Structure and properties of fluoro-containing polyimides[J]. Journal of Functional Polymers,1999,12(3):337-344(in Chinese). [5] 张玲, 徐瑛, 陈妤红, 等. 可溶性透明聚酰亚胺薄膜的合成及性能研究[J]. 绝缘材料, 2016(4):14-18.ZHANG Ling, XU Ying, CHEN Shuhong, et al. Synthesis and properties of soluble and transparent polyimide films[J]. Insulation Materials,2016(4):14-18(in Chinese). [6] CHEN Chunkai, LIN Yancheng, MIYANE Satoshi, et al. Thermally and mechanically stable polyimides as flexible substrates for organic field-effect transistors[J]. ACS Applied Polymer Materials,2020,2(8):3422-3432. doi: 10.1021/acsapm.0c00488 [7] JIANG Ganglan, WANG Dongyang, DU Haopeng, et al. Reduced coefficients of linear thermal expansion of colorless and transparent semi-alicyclic polyimide films via incorporation of rigid-rod amide moiety: Preparation and properties[J]. Polymers,2020,12(2):413. doi: 10.3390/polym12020413 [8] TAN Yaoyao, ZHANG Yan, JIANG Ganglan, et al. Preparation and properties of inherently black polyimide films with extremely low coefficients of thermal expansion and potential applications for black flexible copper clad laminates[J]. Polymers,2020,12(3):576. doi: 10.3390/polym12030576 [9] LU Zheng, HU Jianghuai, CHEN Chang, et al. Preparation and characterization of adenine-based polyimide/nano-silica hybrid films[J]. European Polymer Journal,2018,102:209-218. doi: 10.1016/j.eurpolymj.2018.03.019 [10] ZHAO Yuanliang, QI Xiaowen, DONG Yu, et al. Mechanical, thermal and tribological properties of polyimide/nano-SiO2 composites synthesized using an in-situ polymerization[J]. Tribology International,2016,103:599-608. doi: 10.1016/j.triboint.2016.08.018 [11] CHEN Minghua, QI Meili, YAO Lei, et al. Effect of surface charged SiO2 nanoparticles on the microstructure and properties of polyimide/SiO2 nanocomposite films[J]. Surface and Coatings Technology,2017,320:59-64. doi: 10.1016/j.surfcoat.2017.01.120 [12] 李亮荣, 丁永红, 齐海霞, 等. 表面改性纳米TiO2粒子杂化PI薄膜的制备与性能研究[J]. 化工新型材料, 2012, 40(1):57-61.LI Liangrong, DING Yonghong, QI Haixia, et al. Preparation and properties investigations of hybrid films of polyimide (PI) doped with surface modified nano-TiO2 particles[J]. New Chemical Materials,2012,40(1):57-61(in Chinese). [13] JEON Hyungjoon, YOON Cheolsang, SONG Younggeon, et al. Reducing the coefficient of thermal expansion of polyimide films in microelectronics processing using ZnS particles at low concentrations[J]. ACS Applied Nano Materials,2018,1(3):1076-1082. doi: 10.1021/acsanm.7b00259 [14] PHAN Hoangphuong, ZHONG Yishan, NGUYEN Tuankhoa, et al. Long-lived, transferred crystalline silicon carbide nanomembranes for implantable flexible electronics[J]. ACS Nano,2019,13(10):11572-11581. doi: 10.1021/acsnano.9b05168 [15] LUO Jiangbo, WU Yongpeng, SUN Yunna, et al. Preparation and characterization of high thermal conductivity and low CET polyimide composite reinforced with diamond nanoparticles/SiC whiskers for 3D IC interposer RDL dielectric[J]. Applied Sciences,2019,9(9):1962. doi: 10.3390/app9091962 [16] JEON Hyungjoon, LEE Kangtaek. Effect of gold nanoparticle morphology on thermal properties of polyimide nanocomposite films[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2019,579:123651. doi: 10.1016/j.colsurfa.2019.123651 [17] TANG J C, LIN G L, YANG H C, et al. Polyimide-silica nanocomposites exhibiting low thermal expansion coefficient and water absorption from surface-modified silica[J]. Journal of Applied Polymer Science,2007,104(6):4096-4105. doi: 10.1002/app.26041 [18] REN Liyun, PASHAYI Kamyar, FARD Hafezraeisi, et al. Engineering the coefficient of thermal expansion and thermal conductivity of polymers filled with high aspect ratio silica nanofibers[J]. Composites Part B: Engineering,2014,58:228-234. doi: 10.1016/j.compositesb.2013.10.049 [19] MALLICK Kaushik, CRONIN John, ARZBERGER Steven. Effect of inclusion morphology on the coefficient of thermal expansion in filled polymer matrix[C]//47thAIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 14th AIAA/ASME/AHS Adaptive Structures Conference 7th. 2006: 2098. [20] 唐欣磊, 谭洪生, 谭浩, 等. 长芳纶纤维增强抗冲共聚聚丙烯复合材料的研究[J]. 工程塑料应用, 2013(2):8-12.TANG Xinlei, TAN Hongsheng, TAN Hao, et al. Long aramid fiber reinforced impact polypropylene copolymer composites[J]. Application of Engineering Plastics,2013(2):8-12(in Chinese). [21] 全国塑料标准化技术委员会. 塑料薄膜力学性能测试方法: GB 13022—1991[S]. 北京: 中国标准出版社, 1991.National Technical Committee on Plastic Products of Standardization Administration of China. Plastics Determination of tensile properies of films: GB 13022—1991[S]. Beijing: Standards Press of China, 1991(in Chinese). [22] 李洪峰, 刘仲良, 白雪峰, 等. 多壁碳纳米管-丙烯酸酯嵌段共聚物共改性环氧树脂三元复合材料性能[J]. 复合材料学报, 2020, 37(4):741-748.LI Hongfeng, LIU Zhonglian, BAI Xuefeng, et al. Properties of multi-walled carbon nanotubes-acrylate block copolymers/epoxy resin ternary composites[J]. Acta Materiae Compositae Sinica,2020,37(4):741-748(in Chinese). [23] 王晓龙, 王李波, 宋艺赫, 等. Ti3C2Tx/聚酰亚胺复合材料的制备及性能[J]. 复合材料学报, 2019, 36(7):1575-1582.WANG Xiaolong, WANG Libo, SONG Yihe, et al. Preparation and performances of Ti3C2Tx/polyimide composutes[J]. Acta Materiae Compositae Sinica,2019,36(7):1575-1582(in Chinese). [24] 胡永彬, 王帆, 朱亚平, 等. SiO2中空微球改性含硅芳炔树脂及其复合材料的结构与性能[J]. 复合材料学报, 2019, 36(3):592-601.HU Yongbin, WANG Fan, ZHU Yapping, et al. Structure and properties of SiO2 hollow microspheres modified Si-containing arylacetylene resin and their composites[J]. Acta Materiae Compositae Sinica,2019,36(3):592-601(in Chinese). -

下载:

下载: