Modeling of reinforcing effects of three kinds of typical nanophases on interfacial bonding in multiscale composites

-

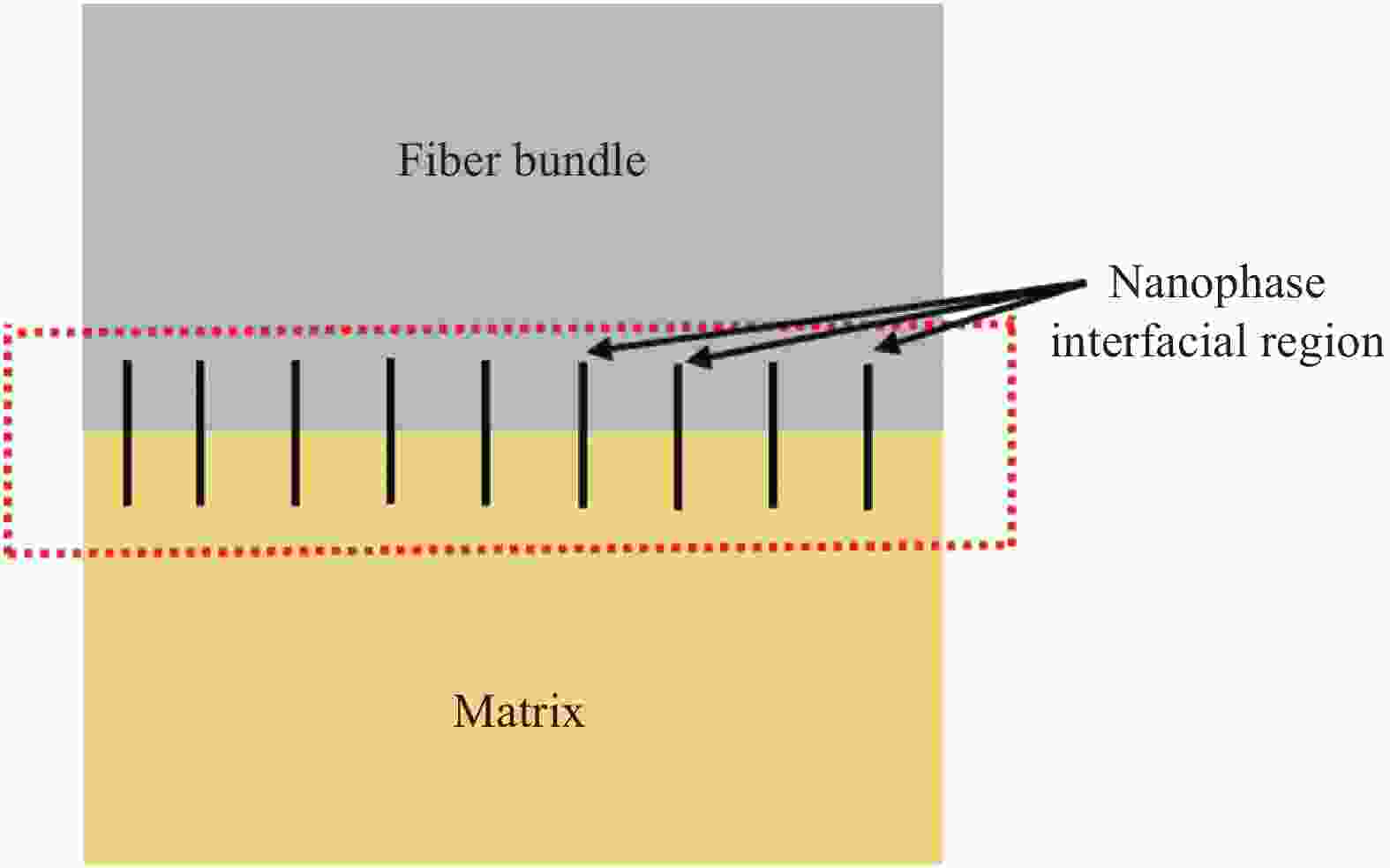

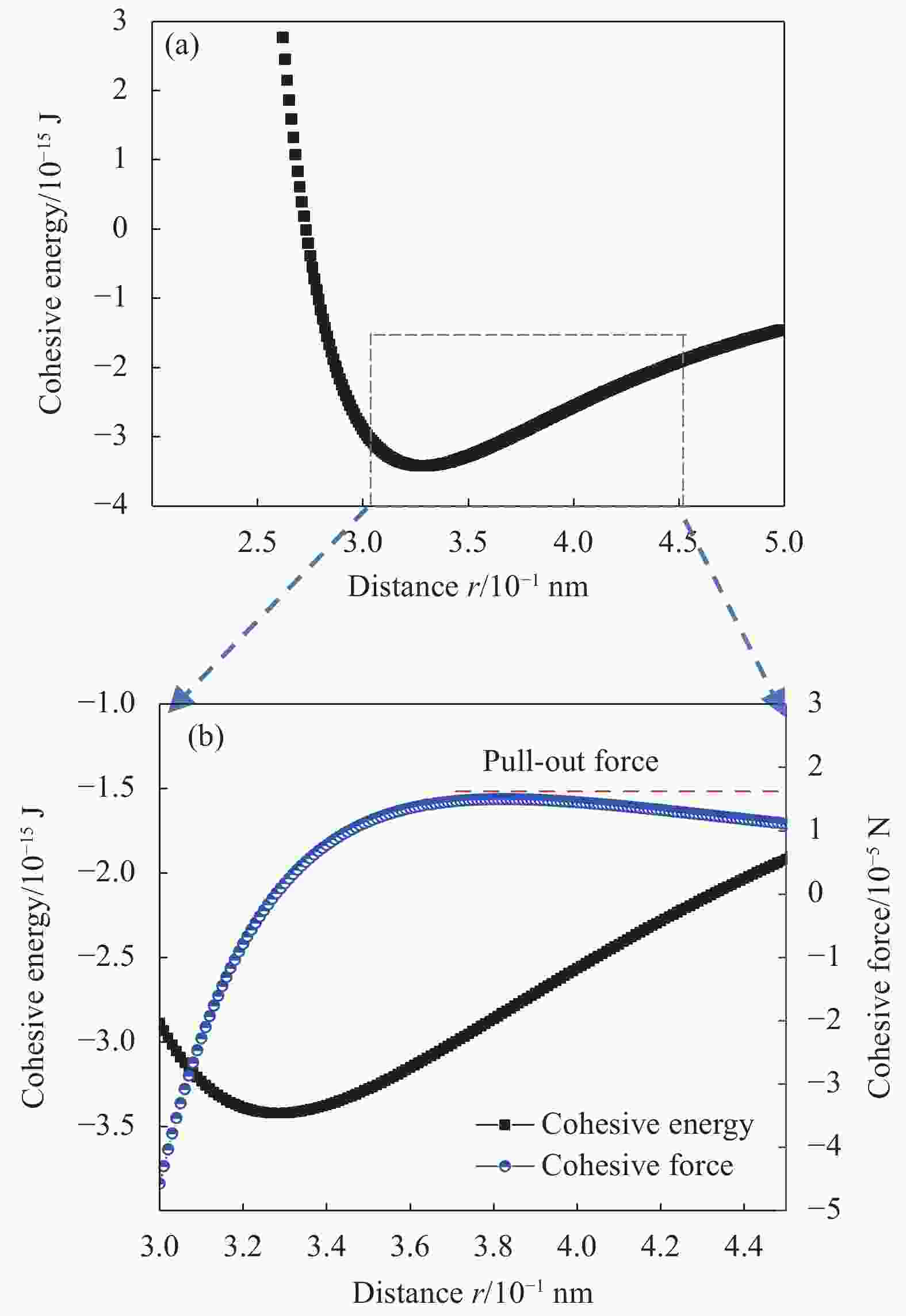

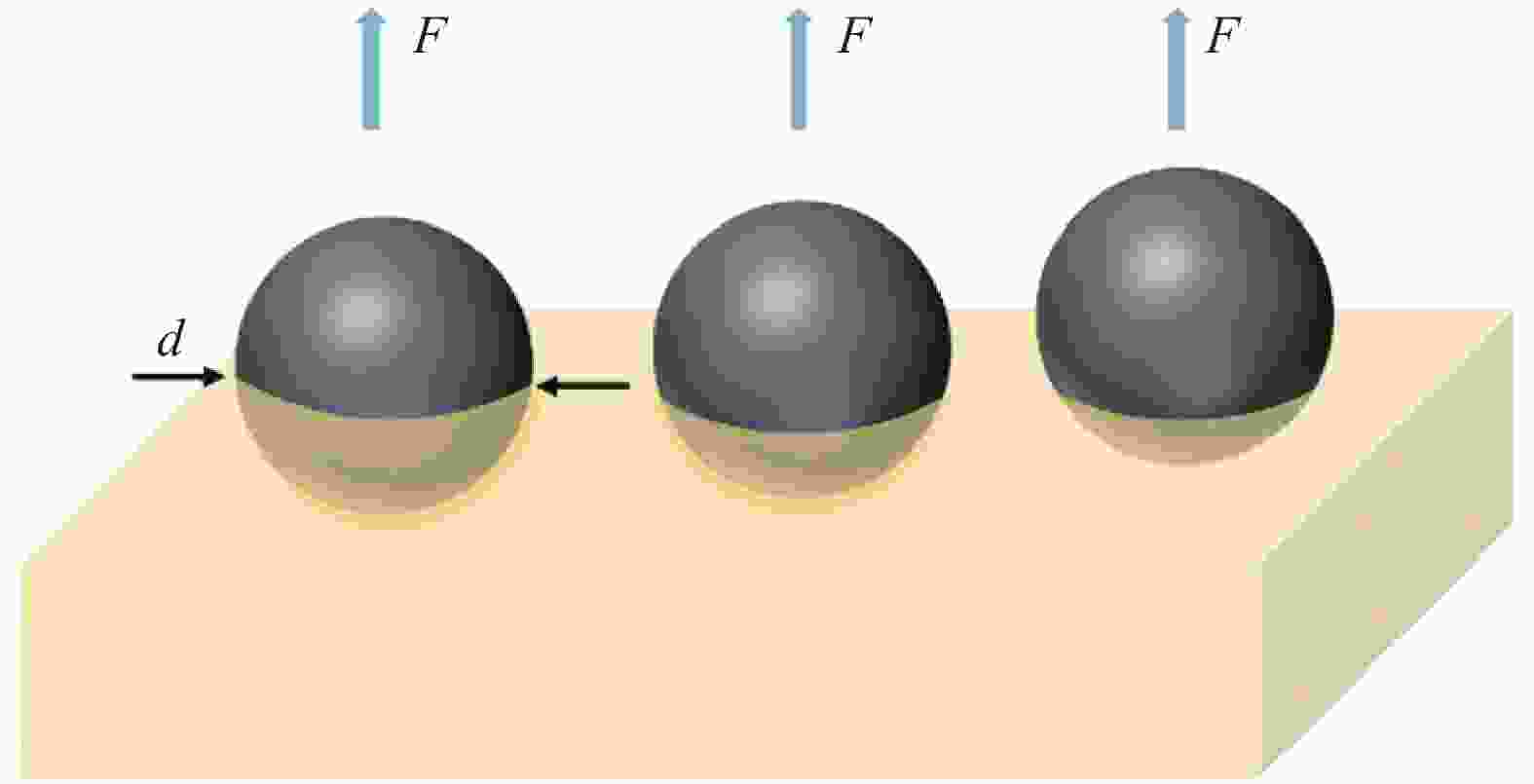

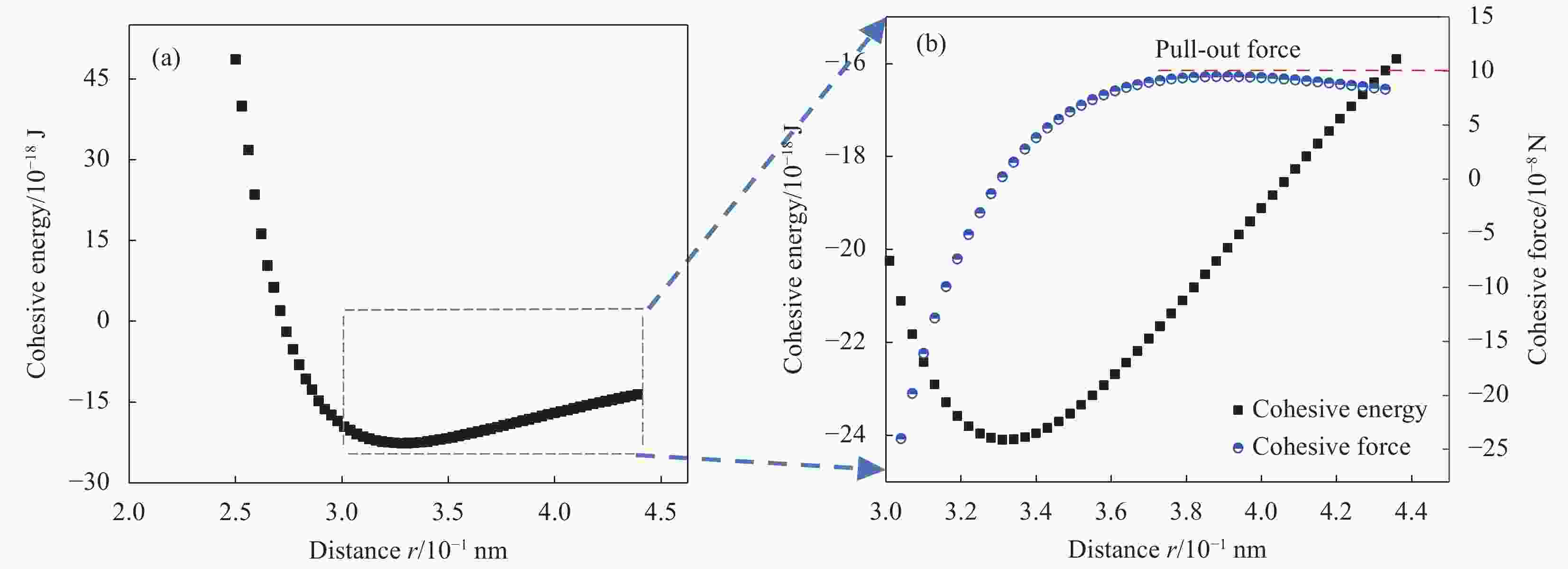

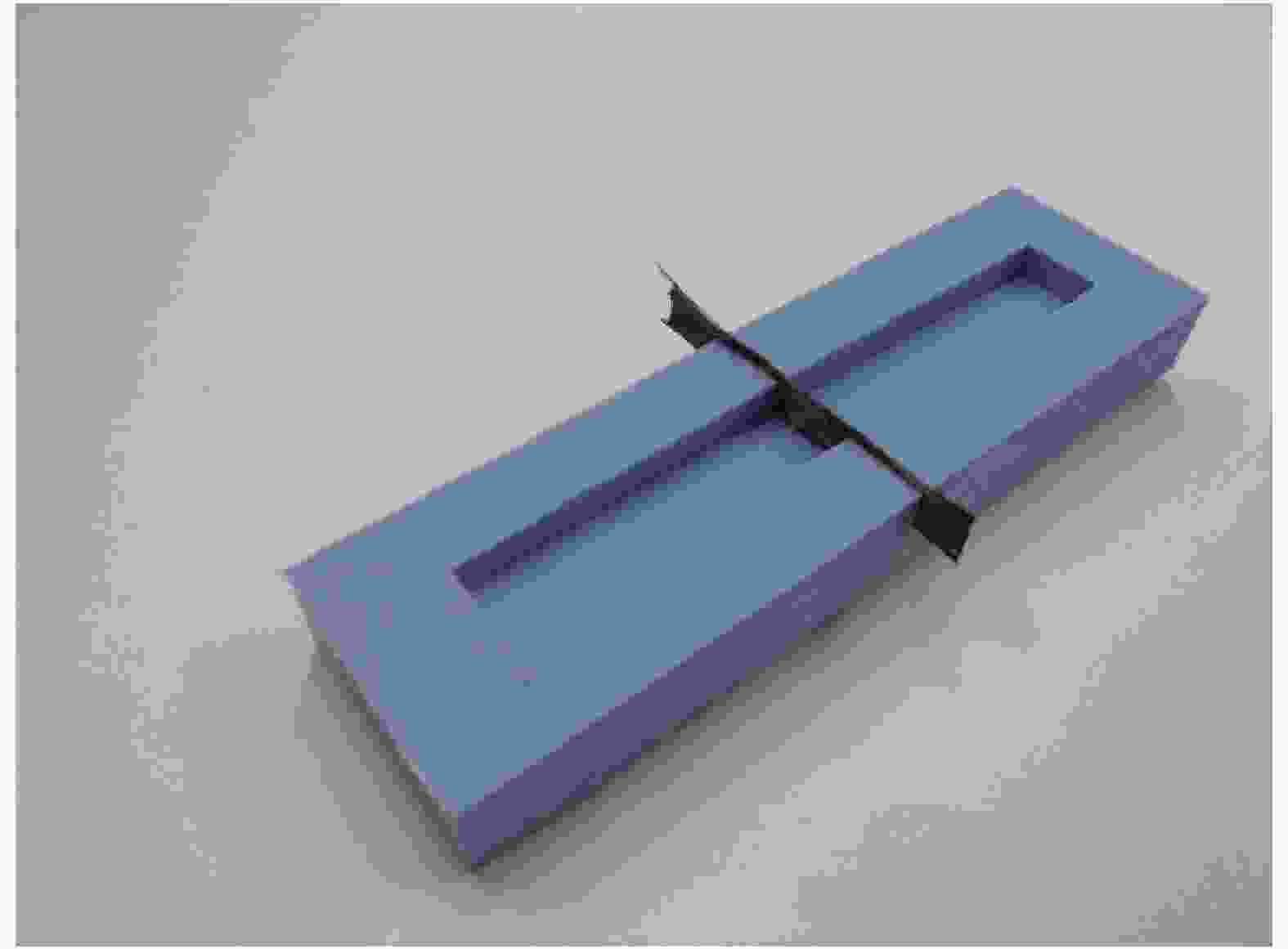

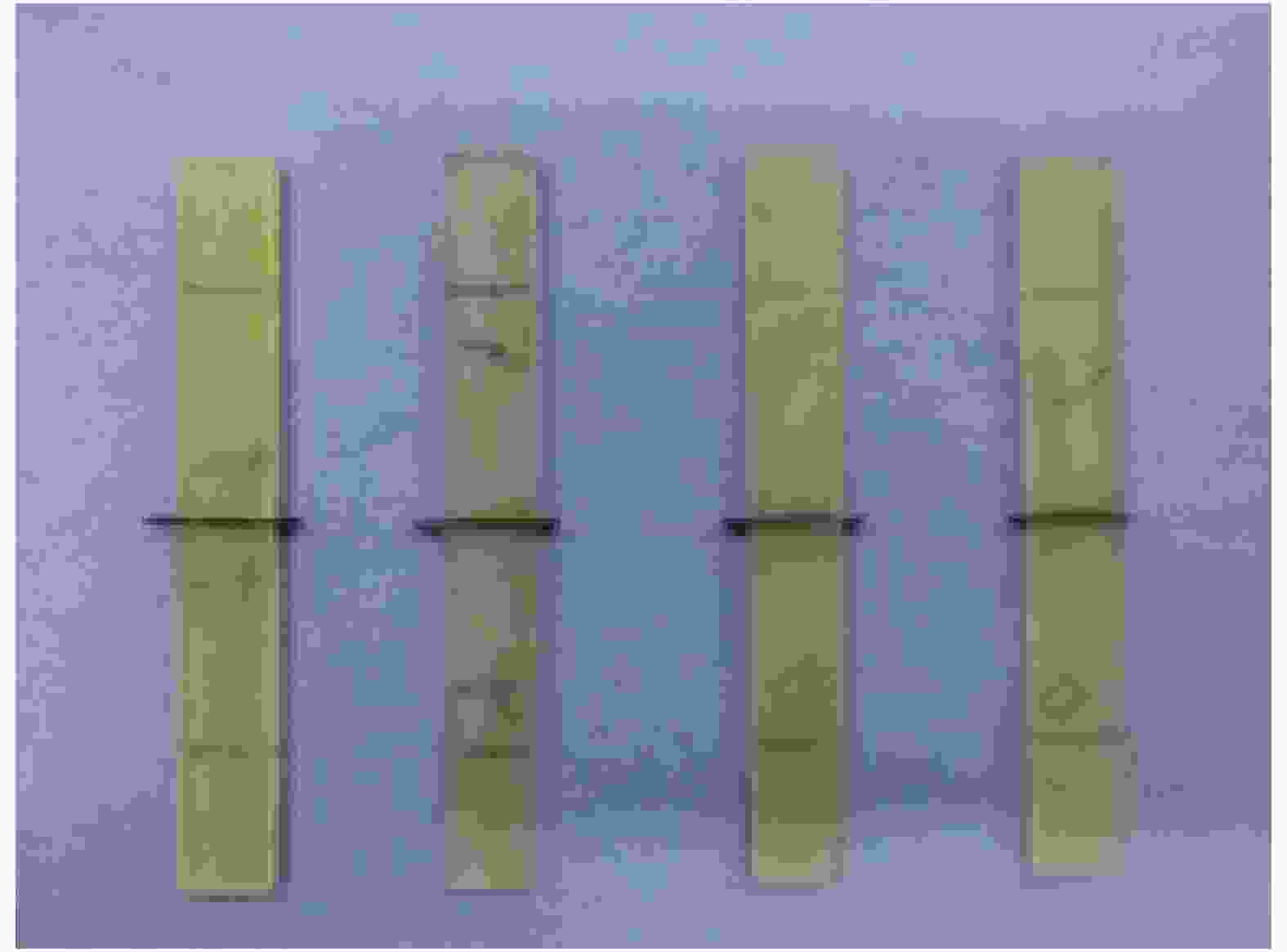

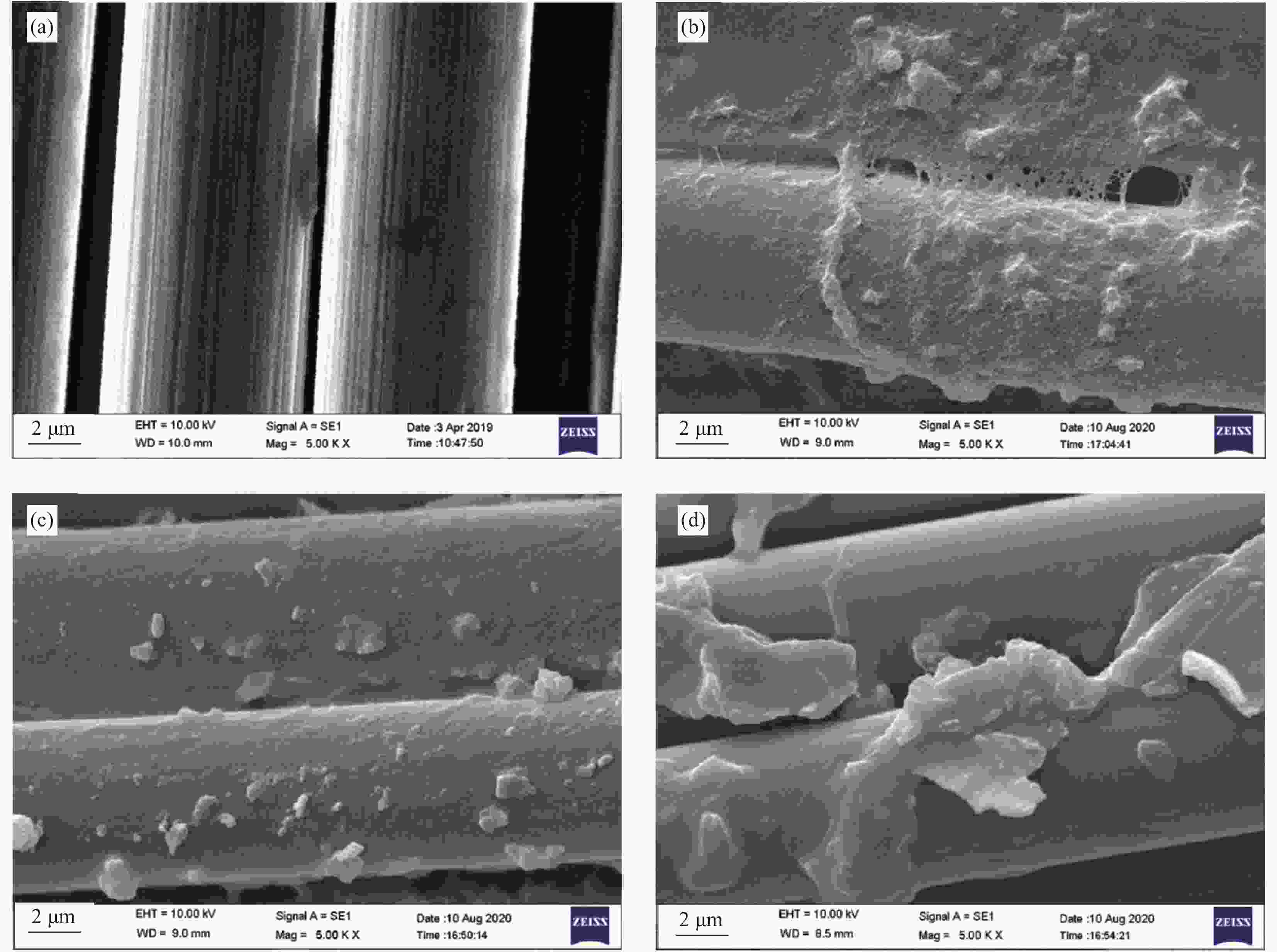

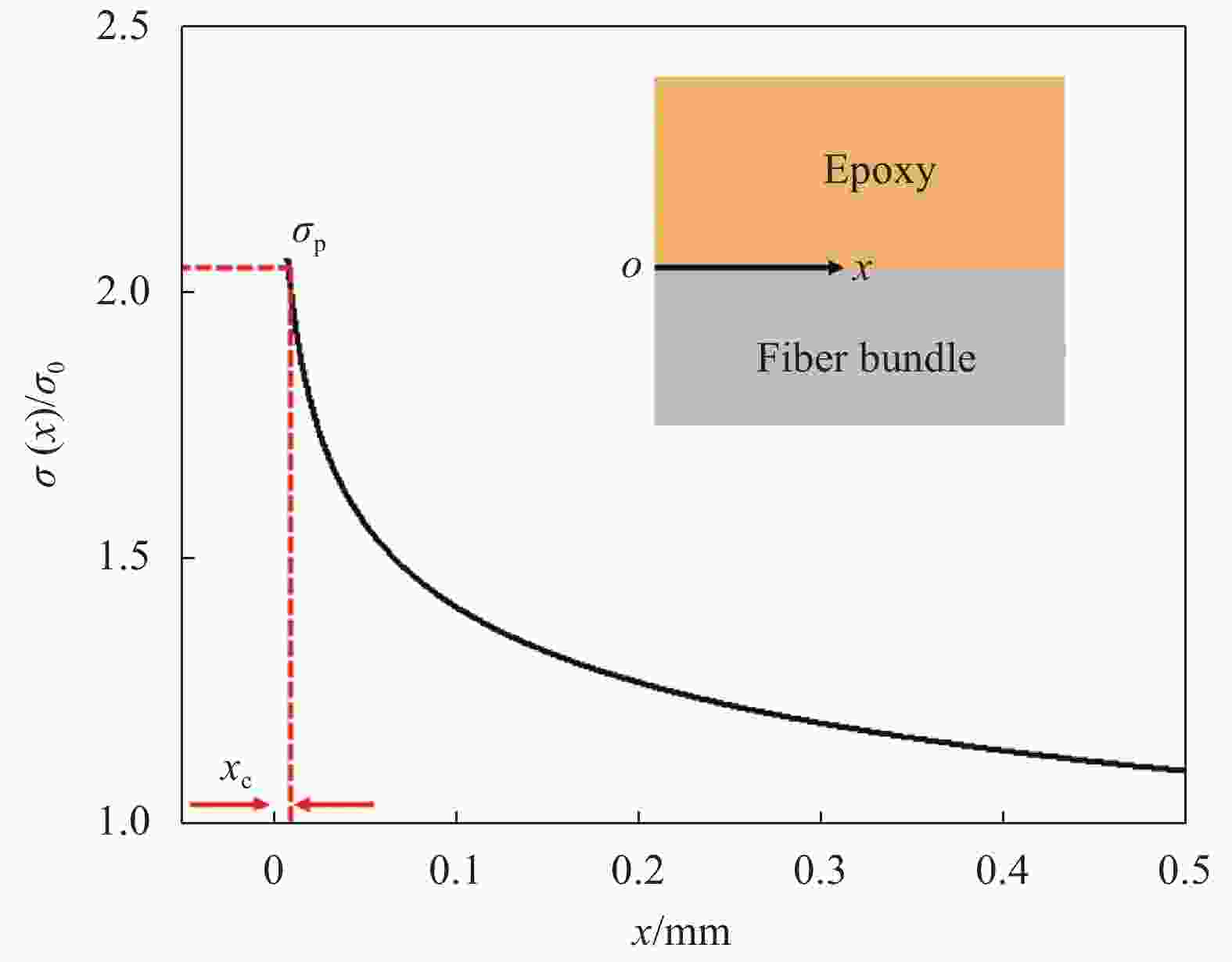

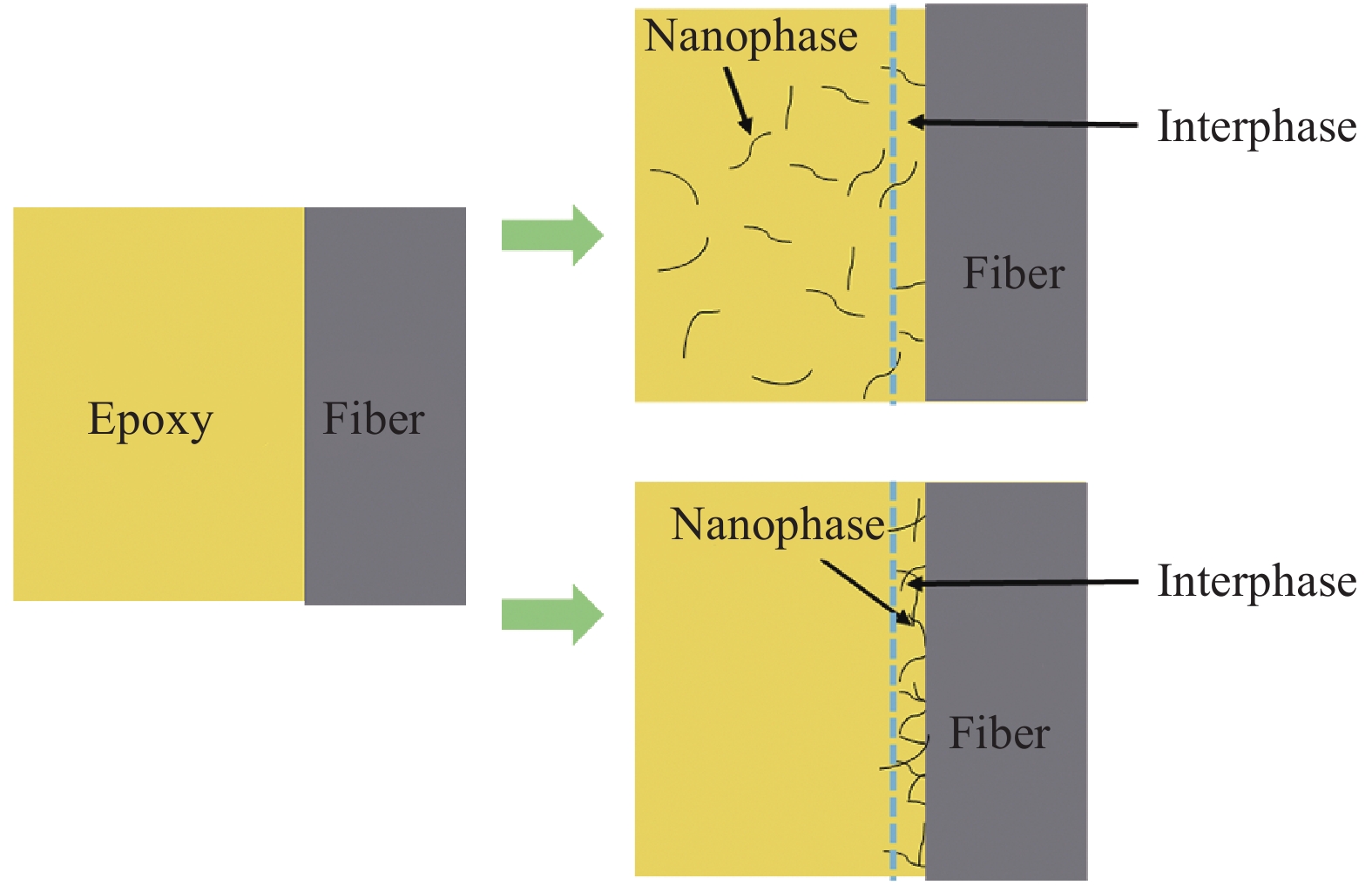

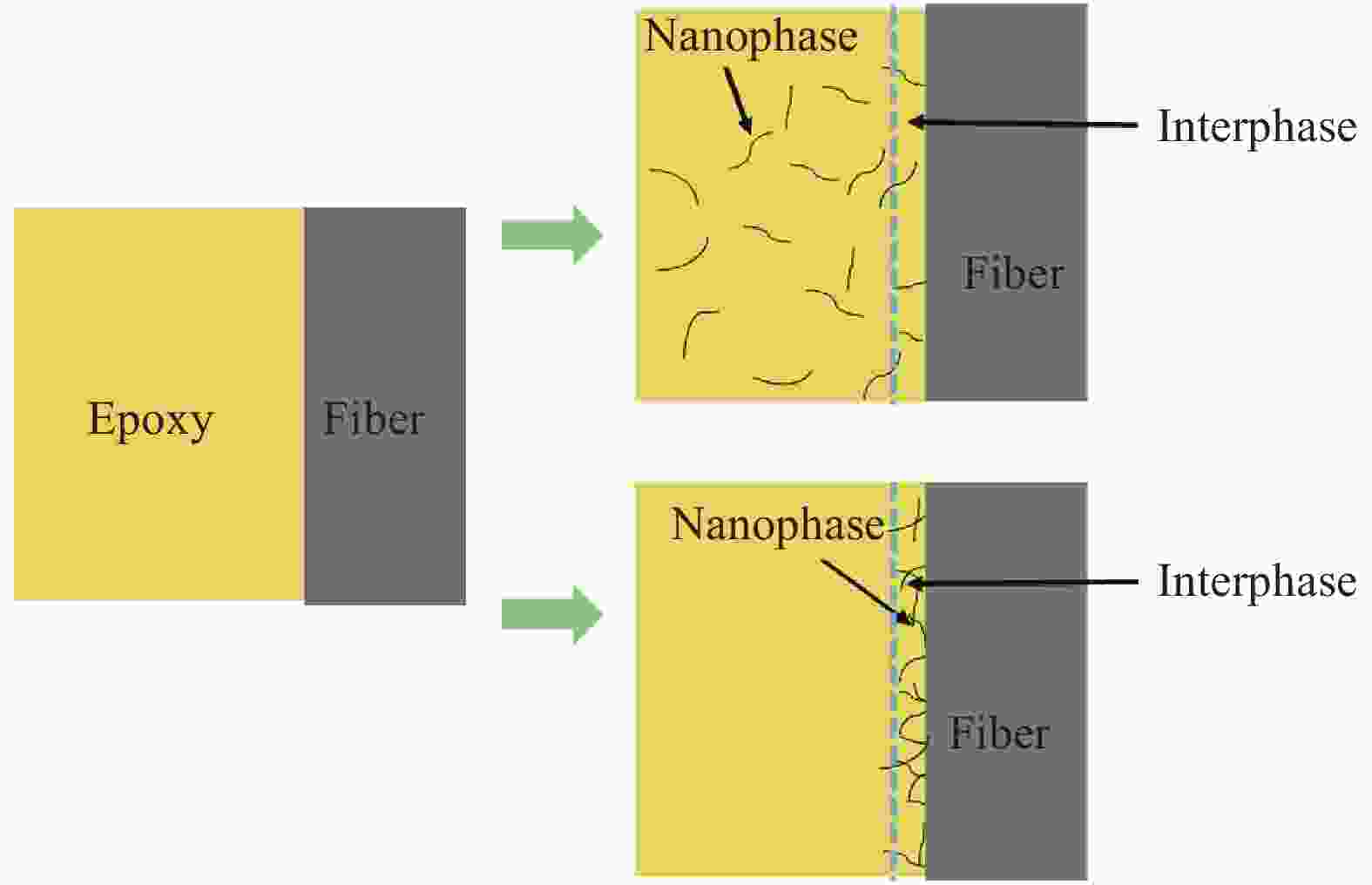

摘要: 实验研究表明,将纳米增强相引入纤维增强树脂复合材料界面构成多尺度复合材料,能够显著改善复合材料中纤维与基体之间的黏结性能,而且不同形态的纳米相在多尺度复合材料中发挥的增强效应有明显差异。本文基于内聚能模型探讨了三种典型形态的纳米增强相(包括高长径比碳纳米管、球状富勒烯纳米颗粒、片层状氧化石墨烯)对碳纤维与环氧树脂基体之间黏结强度的影响,建立了纳米增强相的形态和数量参数如何影响界面黏结强度的力学模型。利用纤维束复合材料横向拉伸测试方法评估了三种多尺度复合材料的界面黏结性能,通过理论预测结果与实测数据的对比验证了模型的合理性。Abstract: Experimental study has shown that the interfacial bonding between fibers and matrix can be significantly improved by introducing nanophases into fiber reinforced polymer composites. The reinforcing effects of various nanophases on the obtained multi-scale composites were found different, which were associated with the shape and dimension of the nanophases. In this paper, a multiscale model was proposed based on the cohesive energy model to explore the source of the difference in reinforcing efficiency introduced by the three kinds of typical nanophases, i.e., carbon nanotubes, spherical fullerene nanoparticles and graphene nanoplates. The model elucidates how the shape and quantity of nanophases influence the strength of interfacial bonding in multiscale composites. The proposed model was verified according to the experimental results obtained through transverse tension tests of fiber bundle composites. The theoretical prediction shows a good agreement with the measured data.

-

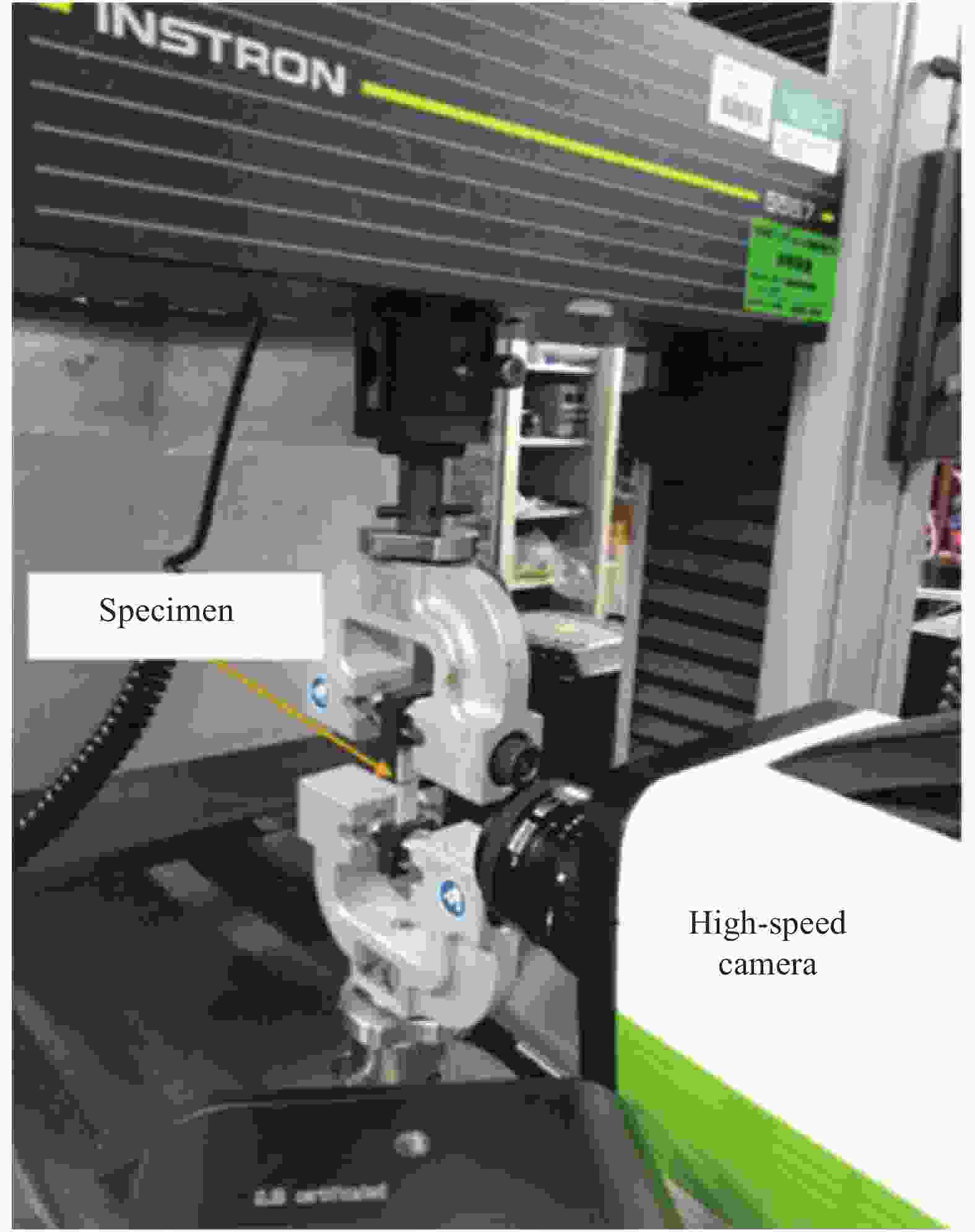

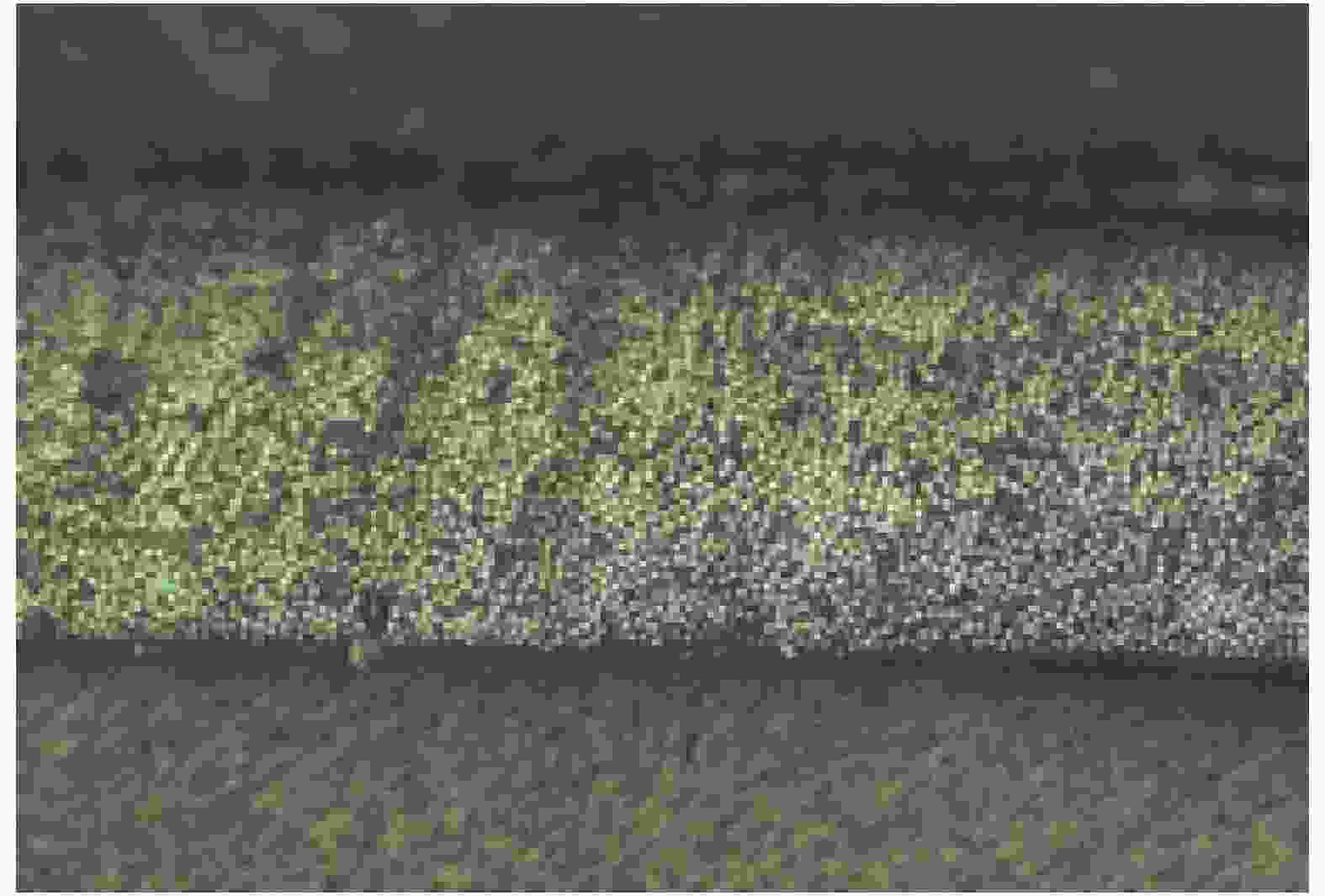

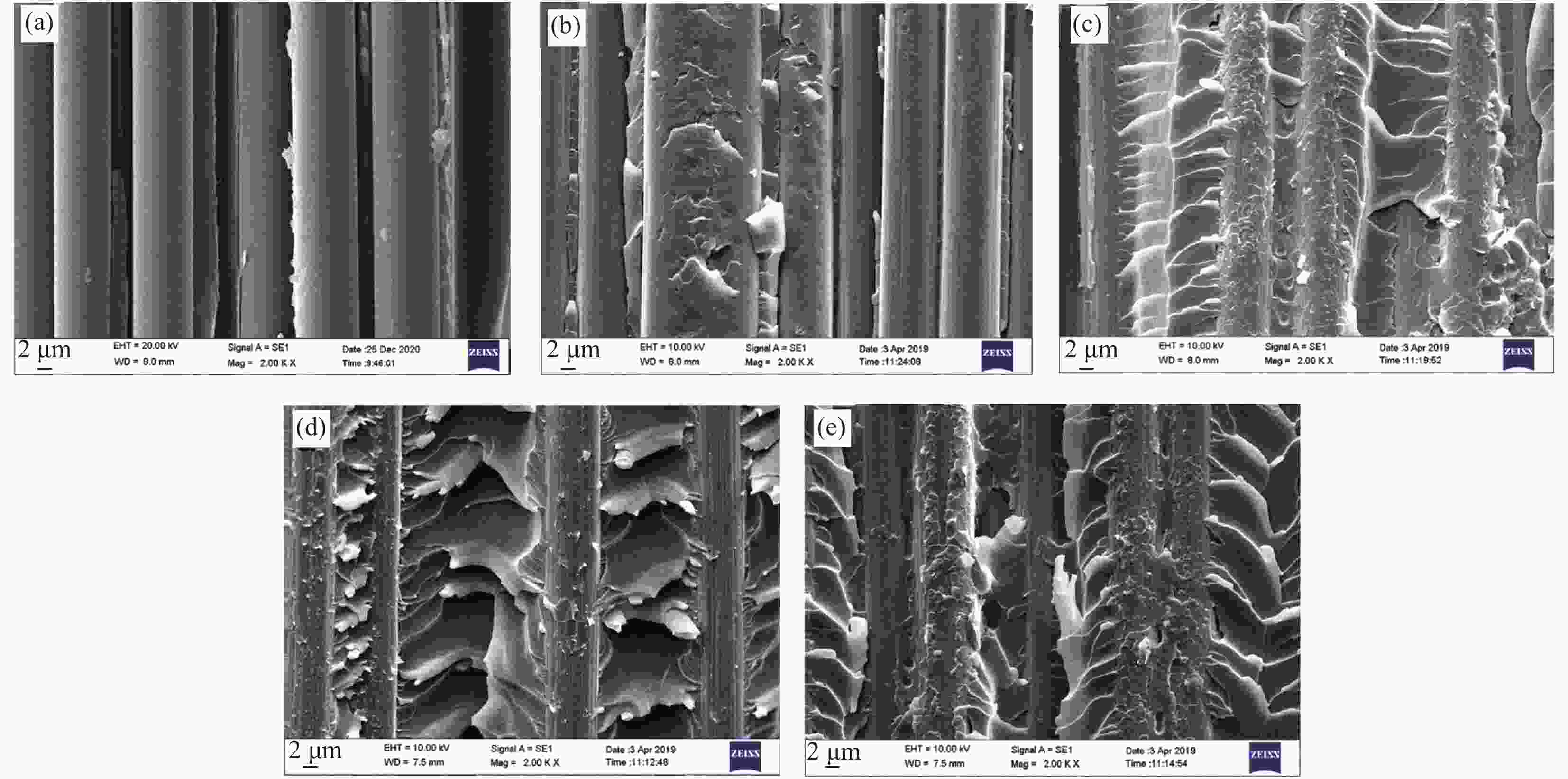

图 17 碳纤维束增强环氧树脂复合材料试样的典型横向拉伸应力-位移曲线 (a)、CF-SC/EP试样的断口形态 (b) 以及高速摄像机捕捉的界面破坏过程 (c)

Figure 17. Transverse tensile stress-displacement curves of carbon fiber bundle reinforced epoxy composite specimens (a), as well as fracture surfaces (b) and the crack development captured by high-speed camera (c) of CF-SC/EP specimen

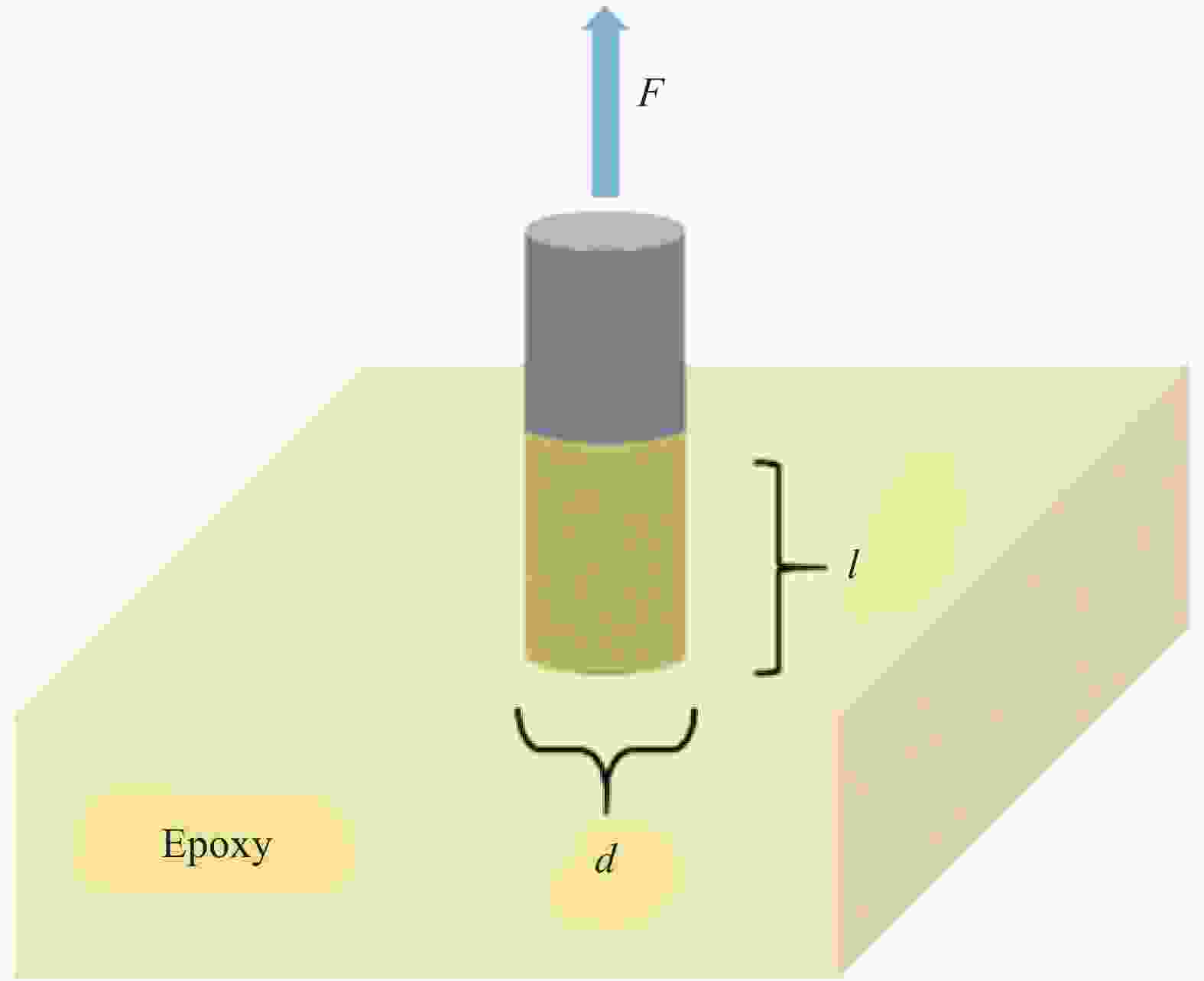

表 1 文献[26]报道的拔出实验中的CNT几何参数

Table 1. Geometric parameters of CNT reported in the pull-out test in Ref. [26]

Specimen No. 1 2 3 Diameter/nm 8.2 11.0 11.6 Embedded length/nm 484 256 193 表 3 碳纤维束增强环氧树脂复合材料横向拉伸实测强度与预测结果

Table 3. Measured transverse tensile strength of carbon fiber bundle reinforced epoxy composites and predicted values

Composite CF/EP CF-SC/EP CF-SC-CNT/EP CF-SC-C60/EP CF-SC-GO/EP Measured value/MPa 8.47 ± 1.01 9.49 ± 1.28 11.80 ± 1.48 14.34 ± 1.12 11.39 ± 1.40 Predicted value/MPa - - 12.06 15.63 13.70 表 4 根据实验估算的三类纳米增强相的埋入长度/深度和临界拔出力

Table 4. Embedded length/depth and pull-out force of the three types of nanophases estimated according to the experiments

Nanophase CNT C60 GO Embedded length/depth/nm 300 1 200 Pull-out of force/N 4.51×10−6 1.25×10−10 9.68×10−5 表 2 三类纳米增强相的实验参数及其在界面上的单位面积数量

Table 2. Experimental parameters of the three types of nanophases and their numbers per unit area on interface

CNT C60 GO Mass fraction of nanophase ${w_0}/\% $ 0.06 0.13 0.09 Mass of solution on the slide ${m_1}/{\rm{mg}}$ 10481 8497 2859 Mass of dried solution on the slide ${m_2}/{\rm{mg}}$ 174 302 72 Mass of sliane coating and nanophase attached to carbon fiber $M/{\rm{mg}}$ 47.1 50.4 48.3 Area of carbon fiber bundle ${S_0}/{\rm{c}}{{\rm{m}}^2}$ 354.03 311.17 363.07 Average volume of individual nanophase ${V_{\rm{n}}}/{\rm{n}}{{\rm{m}}^3}$ 1.1×105 4.19 2.6×107 Density of nanophase ${\rho _{\rm{n} } }/\left( { {\rm{g} }\cdot{\rm{c} }{ {\rm{m} }^{-3}} } \right)$ 1.5 3.4 2.2 Number of nanophases per unit area on carbon fiber bundle $n/{\rm{c}}{{\rm{m}}^{ - 2}}$ 1.55×1010 2.50×1013 2.83×107 -

[1] 曹莹, 吴林志, 张博明. 碳纤维复合材料界面性能研究[J]. 复合材料学报, 2000, 17(2):89-93. doi: 10.3321/j.issn:1000-3851.2000.02.020CAO Ying, WU Linzhi, ZHANG Boming. Investigation of interfacial properties of composites reinforced by carbon fiber[J]. Acta Materiae Compositae Sinica,2000,17(2):89-93(in Chinese). doi: 10.3321/j.issn:1000-3851.2000.02.020 [2] RENNHOFER H, PUCHEGGER S, PABISCH S, et al. The structural evolution of multi-layer graphene stacks in carbon fibers under load at high temperature–A synchrotron radiation study[J]. Carbon,2014,80:373-381. doi: 10.1016/j.carbon.2014.08.076 [3] LIANG Y L, PEARSON R A. Toughening mechanisms in epoxy–silica nanocomposites[J]. Polymer,2009,50(20):4895-4905. doi: 10.1016/j.polymer.2009.08.014 [4] BEKYAROVA E, THOSTENSON E T, YU A, et al. Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites[J]. Langmuir: the Acs Journal of Surfaces and Colloids,2007,23(7):3970. doi: 10.1021/la062743p [5] ZHAO Z, TENG K, LI N, et al. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface[J]. Composite Structures,2017,159:761-772. doi: 10.1016/j.compstruct.2016.10.022 [6] WANG K, CHEN L, WU J, et al. Epoxy nanocomposites with highly exfoliated clay: Mechanical properties and fracture mechanisms[J]. Macromolecules,2005,38(3):788-800. doi: 10.1021/ma048465n [7] GOJNY F H, WICHMANN M H G, FIEDLER B, et al. Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites–A comparative study[J]. Compo-sites Science and Technology,2005,65(15-16):2300-2313. doi: 10.1016/j.compscitech.2005.04.021 [8] THOSTENSON E T, LI W Z, WANG D Z, et al. Carbon nanotube/carbon fiber hybrid multiscale composites[J]. Journal of Applied Physics,2002,91(9):6034-6037. doi: 10.1063/1.1466880 [9] YAO H, SUI X, ZHAO Z, et al. Optimization of interfacial microstructure and mechanical properties of carbon fiber/epoxy composites via carbon nanotube sizing[J]. Applied Surface Science,2015,347(AUG. 30):583-590. [10] WU G, MA L, LIU L, et al. Interfacially reinforced methylphenylsilicone resin composites by chemically grafting multiwall carbon nanotubes onto carbon fibers[J]. Composites Part B: Engineering,2015,82:50-58. doi: 10.1016/j.compositesb.2015.08.012 [11] JIANG Z, ZHANG H, ZHANG Z, et al. Improved bonding between PAN-based carbon fibers and fullerene-modified epoxy matrix[J]. Composites Part A: Applied Science and Manufacturing,2008,39(11):1762-1767. doi: 10.1016/j.compositesa.2008.08.005 [12] SUBHANKAR D, SUDIPTA H, ARIJIT S, et al. Assessing nano scratch behavior of epoxy nanocomposite toughened with silanized fullerene[J]. ACS Applied Nano Materials,2018,1(7):3653-3662. doi: 10.1021/acsanm.8b00763 [13] ZHANG X, FAN X, YAN C, et al. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials and Interfaces,2012,4(3):1543. doi: 10.1021/am201757v [14] CHEN L, JIN H, XU Z, et al. A design of gradient interphase reinforced by silanized graphene oxide and its effect on carbon fiber/epoxy interface[J]. Materials Chemistry and Physics,2014,145(1-2):186-196. doi: 10.1016/j.matchemphys.2014.02.001 [15] CHEN L, JIN H, XU Z, et al. Role of a gradient interface layer in interfacial enhancement of carbon fiber/epoxy hierarchical composites[J]. Journal of Materials Science,2015,50(1):112-121. doi: 10.1007/s10853-014-8571-y [16] ROSEN B W. Tensile failure of fibrous composites[J]. AIAA Journal,2013,2(11):1985-1991. [17] GAO X L, LI K. A shear-lag model for carbon nanotube-reinforced polymer composites[J]. International Journal of Solids and Structures,2005,42(5):1649-1667. [18] DUGDALE D S. Yielding of steel sheets containing slits[J]. Journal of the Mechanics and Physics of Solids,1960,8(2):100-104. doi: 10.1016/0022-5096(60)90013-2 [19] BARENBLATT G I. The formation of equilibrium cracks during brittle fracture. General ideas and hypotheses. Axially-symmetric cracks[J]. Journal of Applied Mathematics and Mechanics,1959,23(3):622-636. doi: 10.1016/0021-8928(59)90157-1 [20] XIA W, SONG J, MENG Z, et al. Designing multi-layer graphene-based assemblies for enhanced toughness in nacre-inspired nanocomposites[J]. Molecular Systems Design and Engineering,2016,1(1):40-47. doi: 10.1039/C6ME00022C [21] ZHAO J, JIANG J W, JIA Y, et al. A theoretical analysis of cohesive energy between carbon nanotubes, graphene and substrates[J]. Carbon,2013,57(3):108-119. [22] JIANG L Y, HUANG Y, JIANG H, et al. A cohesive law for carbon nanotube/polymer interfaces based on the van der Waals force[J]. Journal of the Mechanics and Physics of Solids,2006,54(11):2436-2452. doi: 10.1016/j.jmps.2006.04.009 [23] FRANKLAND S J V, HARIK V M, ODEGARD G M, et al. The stress–strain behavior of polymer–nanotube composites from molecular dynamics simulation[J]. Composites Science and Technology,2003,63(11):1655-1661. doi: 10.1016/S0266-3538(03)00059-9 [24] TAN H, JIANG L Y, HUANG Y, et al. The effect of van der Waals-based interface cohesive law on carbon nanotube-reinforced composite materials[J]. Composites Science and Technology,2007,67(14):2941-2946. doi: 10.1016/j.compscitech.2007.05.016 [25] HE X, WANG C, TONG L, et al. A pullout model for inclined carbon nanotube[J]. Mechanics of Materials,2012,52(10):28-39. [26] COOPER C A, COHEN S R, BARBER A H, et al. Detachment of nanotubes from a polymer matrix[J]. Applied Physics Letters,2002,81(20):3873-3875. doi: 10.1063/1.1521585 [27] YU B, JIANG Z Y, TANG X Z, et al. Enhanced interphase between epoxy matrix and carbon fiber with carbon nanotube-modified silane coating[J]. Composites Science and Technology,2014,99:131-140. doi: 10.1016/j.compscitech.2014.05.021 [28] SHOKOOHI S, AREFAZAR A, KHOSROKHAVAR R. Silane coupling agents in polymer-based reinforced composites: A review[J]. Journal of Reinforced Plastics and Composites,2008,27(5):473-485. doi: 10.1177/0731684407081391 [29] VAST L, PHILIPPIN G, DESTRÉE A, et al. Chemical functionalization by a fluorinated trichlorosilane of multi-walled carbon nanotubes[J]. Nanotechnology,2004,15(7):781. doi: 10.1088/0957-4484/15/7/011 [30] MA P C, KIM J K, TANG B Z. Functionalization of carbon nanotubes using a silane coupling agent[J]. Carbon,2006,44(15):3232-3238. doi: 10.1016/j.carbon.2006.06.032 [31] KATHI J, RHEE K Y. Surface modification of multi-walled carbon nanotubes using 3-aminopropyltriethoxysilane[J]. Journal of Materials Science,2008,43(1):33-37. doi: 10.1007/s10853-007-2209-2 [32] 李稳, 陈蔚, 汤立群, 等. 基于纤维束/环氧树脂复合材料试验的单向层合板横向拉伸强度预测方法[J]. 复合材料学报, 2018, 35(2):340-346.LI Wen, CHEN Wei, TANG Liqun, et al. A Prediction method of transverse tensile strength of unidirectional laminates based on test of fiber bundle composites[J]. Acta Materiae Compositae Sinica,2018,35(2):340-346(in Chinese). [33] International Organization for Standardization. Plastics-Determination of tensile properties-Part 2: Test conditions for moulding and extrusion plastics: ISO 527-2[S]. Switzerland: International Organization for Standardization, 1993. [34] LI W, CHEN W, TANG L Q, et al. A general strength model for fiber bundle composites under transverse tension or interlaminar shear[J]. Composites Part A: Applied Science and Manufacturing,2019,121:45-55. doi: 10.1016/j.compositesa.2019.03.009 [35] WAN Y J, GONG L X, TANG L C, et al. Mechanical properties of epoxy composites filled with silane-functionalized graphene oxide[J]. Composites Part A: Applied Science and Manufacturing,2014,64:79-89. doi: 10.1016/j.compositesa.2014.04.023 [36] CHEN L, WEI F, LIU L, et al. Grafting of silane and graphene oxide onto PBO fibers: Multifunctional interphase for fiber/polymer matrix composites with simultaneously improved interfacial and atomic oxygen resistant properties[J]. Composites Science and Technology,2015,106:32-38. doi: 10.1016/j.compscitech.2014.10.021 -

下载:

下载: