Flatwise compression properties of trapezoidal lattice-web reinforced foam core sandwich composites

-

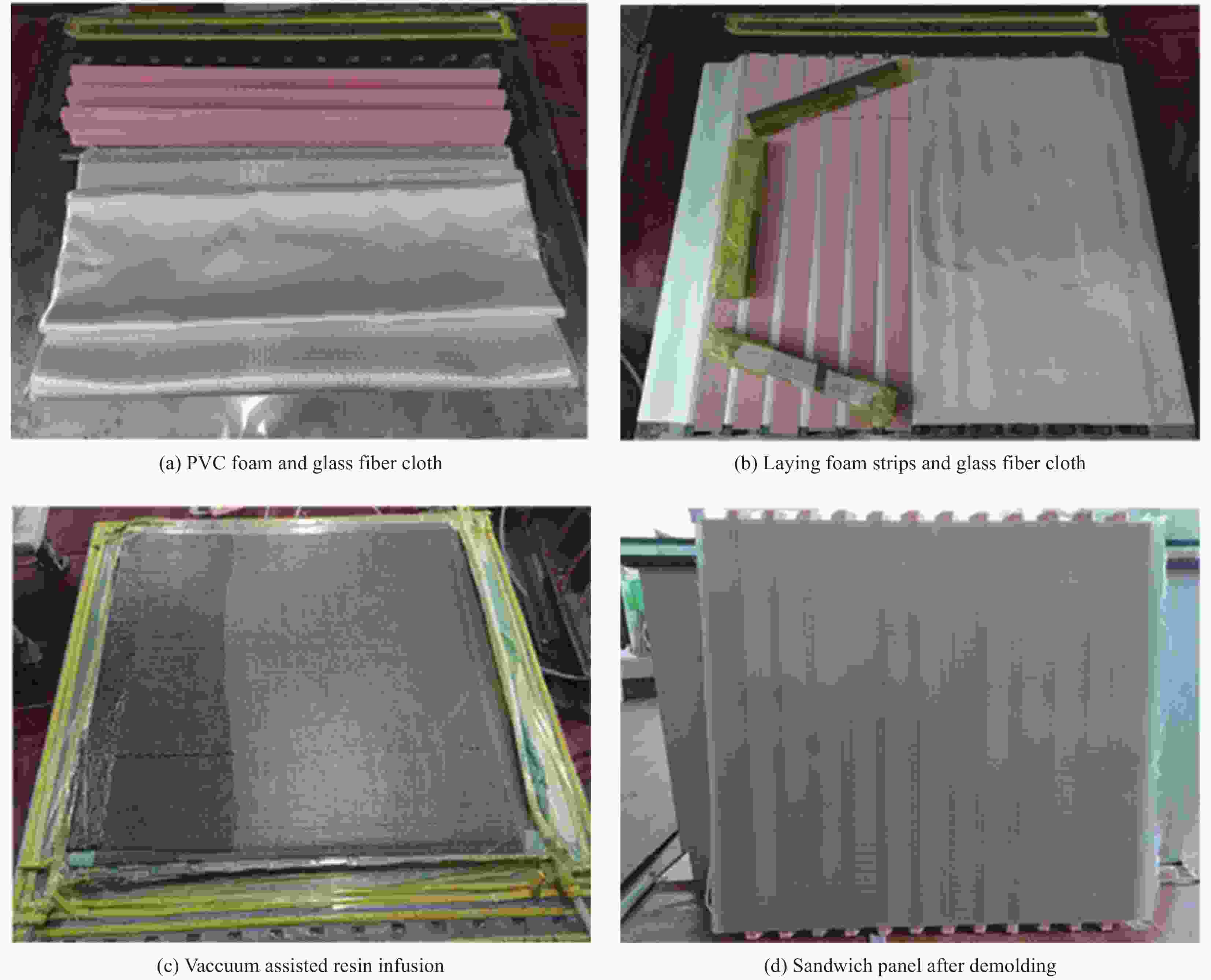

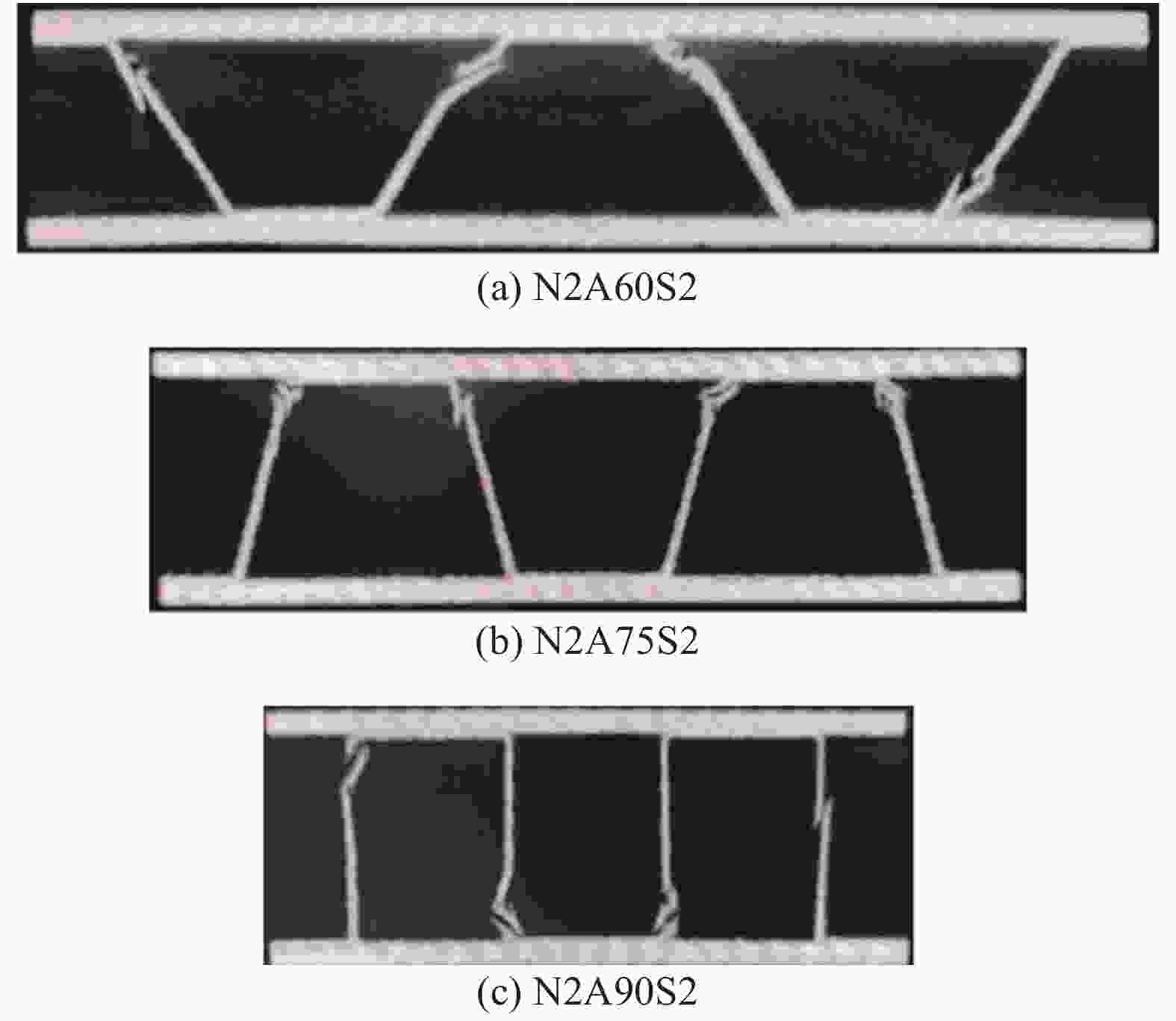

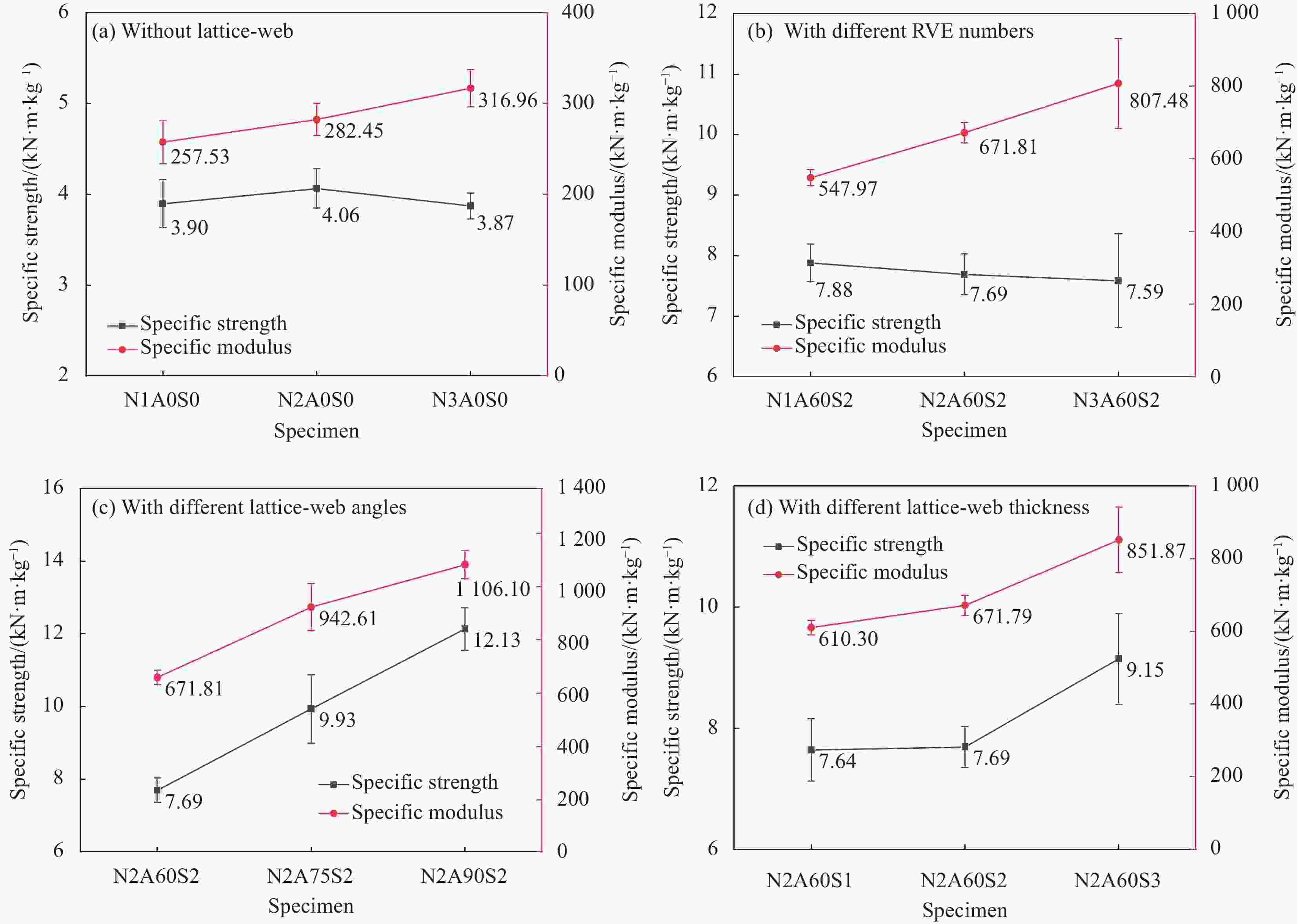

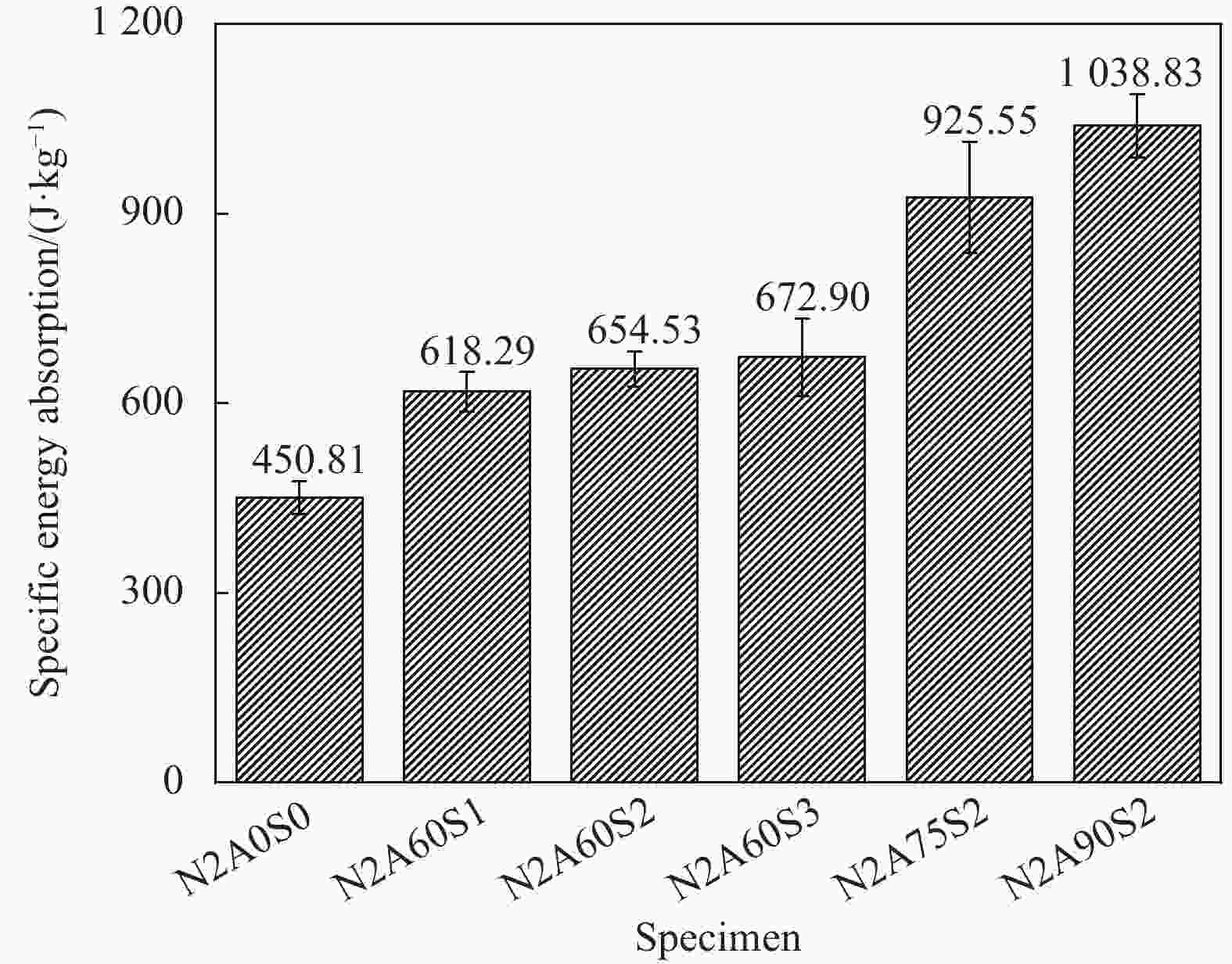

摘要: 设计了一种梯形格构增强泡沫夹芯板,并采用真空辅助树脂灌注(VARI)工艺制备了多种不同结构参数的格构增强泡沫夹芯板。实验研究了夹芯板在平面压缩载荷下的失效模式与力学性能,考察了夹芯板结构参数(试样尺寸、格构腹板角度、格构腹板厚度)对夹芯板比压缩强度、比压缩模量与比吸能的影响规律。结果表明:格构增强泡沫夹芯板主要破坏模式为格构腹板的断裂与屈曲;夹芯板中泡沫芯材与格构腹板协同增强;60°夹角格构增强夹芯板相对于无格构增强夹芯板的比压缩强度、比压缩模量和比吸能分别提高了89.4%、137.9%、45.2%;格构增强泡沫夹芯板压缩性能随着格构腹板角度、格构腹板厚度的增加而提高。这类夹芯板的设计为船舶与海洋工程领域轻质夹芯复合材料的应用提供了指导。Abstract: Trapezoidal lattice-web reinforced foam core sandwich composites with different structural parameters were designed and manufactured by the vacuum assisted resin infusion (VARI) process. The failure modes and mechanical properties of the sandwich panels in flatwise compression loading were studied experimentally. Also, the effects of structural parameters (specimen size, lattice-web angle, lattice-web thickness) on specific compression strength, specific compression modulus and specific energy absorption were investigated. The results show that the main failure modes of the lattice-web reinforced sandwich panels are the fracture and buckling of lattice-web, and the synergistic enhancement effect between foam core and lattice-web is revealed. Compared with the control specimen, the specific compression strength, specific compression modulus and specific energy absorption of the sandwich panel with 60° lattice-web increase by 89.4%, 137.9% and 45.2%, respectively. The compression properties increase with the increase of the angle and thickness of lattice-web. The conclusions above provide reference for the design and application of lightweight sandwich composites in the ship and ocean engineering.

-

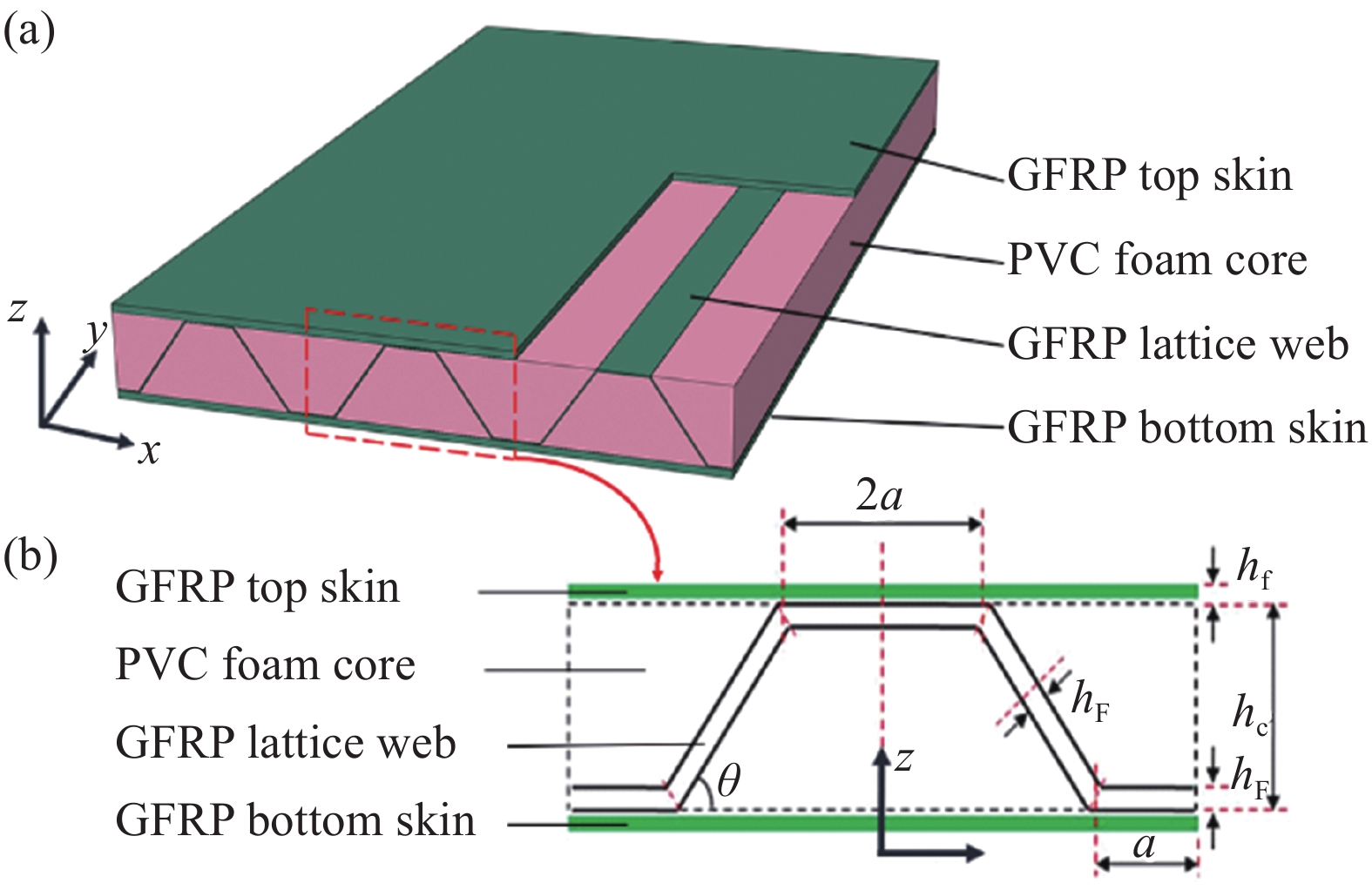

图 1 梯形格栅结构增强泡沫夹芯板示意图

Figure 1. Schematic diagram of trapezoidal lattice-web reinforced foam core sandwich panels

PVC—Polyvinyl chloride; hc, hf, hF, a and θ—Thickness of foam core, face sheets and lattice-web, half of the span length and the angel between the lattice-web and the face sheet, respectively

表 1 梯形格栅结构增强泡沫夹芯板试样信息表

Table 1. Details of trapezoidal lattice-web reinforced foam core sandwich panels specimens

Specimen N A/(°) S L/mm W/mm H/mm N1A0S0 1 – – 76 76 36 N2A0S0 2 – – 152 152 36 N3A0S0 3 – – 228 228 36 N1A60S2 1 60 2 76 76 36 N2A60S2 2 60 2 152 152 36 N3A60S2 3 60 2 228 228 36 N2A75S2 2 75 2 116 116 36 N2A90S2 2 90 2 84 84 36 N2A60S1 2 60 1 152 152 36 N2A60S3 2 60 3 152 152 36 Notes: N—Number of RVEs of the specimen; A—Angle between the lattice-web and the lower face sheet; S—Number of layers of S-glass cloth laid on the lattice-web; L—Length of the specimen; W—Width of the specimen; H—Thickness of the specimen. 表 2 梯形格栅结构增强泡沫夹芯板试样面密度

Table 2. Area density of trapezoidal lattice-web reinforced foam core sandwich panels specimens

Specimen N2A0S0 N2A60S1 N2A60S2 N2A60S3 N2A75S2 N2A90S2 Area density/(kg·m−2) 14.97 16.12 17.18 18.22 17.69 17.98 -

[1] BIRMAN V, KARDOMATEAS G A. Review of current trends in research and applications of sandwich structures[J]. Composites Part B: Engineering,2018,142:221-240. doi: 10.1016/j.compositesb.2018.01.027 [2] 杜善义, 章继峰, 张博明. 先进复合材料格栅结构(AGS)应用与研究进展[J]. 航空学报, 2007(2):419-424. doi: 10.3321/j.issn:1000-6893.2007.02.033DU Shanyi, ZHANG Jifeng, ZHANG Boming. Overview of application and research on advanced composite grid structures[J]. Acta Aeronautica et Astronautica Sinica,2007(2):419-424(in Chinese). doi: 10.3321/j.issn:1000-6893.2007.02.033 [3] 朱子旭, 朱锡, 李永清, 等. 复合材料夹芯结构研究现状及其在船舶工程的应用[J]. 舰船科学技术, 2018, 40(2):1-7. doi: 10.3404/j.issn.1672-7649.2018.02.001ZHU Zixu, ZHU Xi, LI Yongqing, et al. Present researches about sandwich composite structures and its applies in ship industry[J]. Ship Science and Technology,2018,40(2):1-7(in Chinese). doi: 10.3404/j.issn.1672-7649.2018.02.001 [4] FANG H, MAO Y, LIU W, et al. Manufacturing and evaluation of large-scale composite bumper system for bridge pier protection against ship collision[J]. Composite Structures,2016,158:187-198. doi: 10.1016/j.compstruct.2016.09.013 [5] ZHU D, SHI H, FANG H, et al. Fiber reinforced composites sandwich panels with web reinforced wood core for building floor applications[J]. Composites Part B: Engineering,2018,150:196-211. doi: 10.1016/j.compositesb.2018.05.048 [6] 王显峰, 高天成, 肖军. 复合材料缝合技术的研究进展[J]. 纺织学报, 2019, 40(12):169-177.WANG Xianfeng, GAO Tiancheng, XIAO Jun. Research progress of stitching technology of composite materials[J]. Journal of Textile Research,2019,40(12):169-177(in Chinese). [7] 徐学宏, 郑义珠, 陈晨, 等. 缝合泡沫夹层复合材料力学性能研究进展[J]. 复合材料科学与工程, 2020(9):118-122. doi: 10.3969/j.issn.1003-0999.2020.09.019XU Xuehong, ZHENG Yizhu, CHEN Chen, et al. Research progress on the mechanical properties of stitched foam-core sandwich composites[J]. Composites Science and Engineering,2020(9):118-122(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.09.019 [8] 马元春, 韩海涛, 卢子兴, 等. 缝纫泡沫夹芯复合材料失效强度的理论预测与试验验证[J]. 复合材料学报, 2010, 27(5):108-115.MA Yuanchun, HAN Haitao, LU Zixing, et al. Theoretical prediction and experimental study of the failure strength of stitched foam-core sandwich composites[J]. Acta Materiae Compositae Sinica,2010,27(5):108-115(in Chinese). [9] 王裕龙, 许希武, 毛春见. 缝合复合材料层板低速冲击损伤数值模拟[J]. 复合材料学报, 2014, 31(3):715-724.WANG Yulong, XU Xiwu, MAO Chunjian. Numerical simulation of low-velocity impact damage on stitched compo-site laminates[J]. Acta Materiae Compositae Sinica,2014,31(3):715-724(in Chinese). [10] MOURITZ A P. Review of z-pinned laminates and sandwich composites[J]. Composites Part A: Applied Science and Manufacturing,2020,139:106-128. [11] BI J P, DANG X D, WANG X L, et al. Experimental study on mechanical properties of X-Cor sandwich[J]. Materials Science Forum,2011,686:411-418. doi: 10.4028/www.scientific.net/MSF.686.411 [12] 郑锡涛, 孙秦, 李野, 等. 全厚度缝合复合材料泡沫芯夹层结构力学性能研究与损伤容限评定[J]. 复合材料学报, 2006, 23(6):29-36. doi: 10.3321/j.issn:1000-3851.2006.06.005ZHENG Xitao, SUN Qin, LI Ye, et al. Mechanical behavior and damage tolerance tests of composites through-thickness stitched foam sandwich panels[J]. Acta Materiae Compositae Sinica,2006,23(6):29-36(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.06.005 [13] 魏凯耀, 曾竟成, 杜刚, 等. 整体缝合夹芯结构复合材料压缩性能[J]. 复合材料学报, 2016, 33(6):1234-1241.WEI Kaiyao, ZENG Jingcheng, DU Gang, et al. Compression performance of integrated stitched sandwich structure composites[J]. Acta Materiae Compositae Sinica,2016,33(6):1234-1241(in Chinese). [14] 仇艳慧, 徐庆林, 尹昌平, 等. 缝合增强泡沫夹芯结构复合材料力学性能研究[J]. 玻璃钢/复合材料, 2017(10):46-52.CHOU Yanhui, XU Qinglin, YIIN Changping, et al. Mechanical properties of suturing reinforced foam sandwich structure composites[J]. Fiber Reinforced Plastics/Composites,2017(10):46-52(in Chinese). [15] RAEISI S, KADKHODAPOUR J, TOVAR A. Mechanical properties and energy absorbing capabilities of Z-pinned aluminum foam sandwich[J]. Composite Structures,2019,214:34-46. doi: 10.1016/j.compstruct.2019.01.095 [16] NANAYAKKARA A, FEIH S, MOURITZ A P. Experimental analysis of the through-thickness compression properties of z-pinned sandwich composites[J]. Composites Part A: Applied Science and Manufacturing,2011,42(11):1673-1680. doi: 10.1016/j.compositesa.2011.07.020 [17] 史慧媛, 刘伟庆, 方海, 等. GFRP复合材料-轻木夹芯梁弯曲疲劳性能试验[J]. 复合材料学报, 2018, 35(5):1114-1122.SHI Huiyuan, LIU Weiqing, FANG Hai, et al. Experimental research on flexural fatigue behavior of GFRP-balsa sandwich beams[J]. Acta Materiae Compositae Sinica,2018,35(5):1114-1122(in Chinese). [18] WANG L, LIU W, WAN L, et al. Mechanical performance of foam-filled lattice composite panels in four-point bending: Experimental investigation and analytical modeling[J]. Composites Part B: Engineering,2014,67:270-279. doi: 10.1016/j.compositesb.2014.07.003 [19] ZHAO T, JIANG Y, ZHU Y, et al. An experimental investigation on low-velocity impact response of a novel corrugated sandwiched composite structure[J]. Composite Structures,2020,252:112676. doi: 10.1016/j.compstruct.2020.112676 [20] BAHABADI H M, FARROKHABADI A, RAHIMI G H. Investigation of debonding growth between composite skins and corrugated foam-composite core in sandwich panels under bending loading[J]. Engineering Fracture Mechanics,2020,230:106987. doi: 10.1016/j.engfracmech.2020.106987 [21] WU Z, LIU W, WANG L, et al. Theoretical and experimental study of foam-filled lattice composite panels under quasi-static compression loading[J]. Composites Part B: Engineering,2014,60:329-340. doi: 10.1016/j.compositesb.2013.12.078 [22] CHEN J, FANG H, LIU W, et al. Energy absorption of foam-filled multi-cell composite panels under quasi-static compression[J]. Composites Part B: Engineering,2018,153:295-305. doi: 10.1016/j.compositesb.2018.08.122 [23] TAGHIZADEH S A, FARROKHABADI A, LIAGHAT G, et al. Characterization of compressive behavior of PVC foam infilled composite sandwich panels with different corrugated core shapes[J]. Thin-Walled Structures,2019,135:160-172. doi: 10.1016/j.tws.2018.11.019 [24] LIU Y, ZHOU C, CEN B, et al. Compression property of a novel lattice sandwich structure[J]. Composites Part B: Engineering,2017,117:130-137. doi: 10.1016/j.compositesb.2017.02.036 [25] 中国国家标准化管理委员会. 夹层结构或芯子平压性能试验方法: GB/T 1453—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for flatwise compression of sandwich constructions or cores: GB/T 1453—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [26] WANG L, LIU W, FANG H, et al. Behavior of sandwich wall panels with GFRP face sheets and a foam-GFRP web core loaded under four-point bending[J]. Journal of Compo-site Materials,2014,49(22):2765-2778. -

下载:

下载: