Experimental and numerical simulation of permeability variation induced by nesting effect in resin transfer molding

-

摘要: 树脂传递模塑成型工艺(RTM)中最重要的变形模式之一是厚度方向压缩。厚度方向压缩减小了织物预成型体的厚度,使织物预成型体局部结构形式发生改变从而引起嵌套效应。嵌套效应不仅会减少织物预成型体的厚度,增加纤维的体积分数并改变孔隙率,而且相邻织物层嵌套效应具有一定的空间分散性,从而使得织物预成型体渗透率具有变异性。本文针对低黏度树脂设计了一种实验装置用以测量局部渗透率的空间分散性,随后建立了随机嵌套单胞模型,利用ANSYS/CFX有限元软件实现了单胞填充浸润的数值模拟,通过流量分析获得局部渗透率,并研究了渗透率的统计分布。通过实验结果与数值模拟结果相对比,验证数值模拟结果的可靠性。最后,基于渗透率的统计分布建立了随机渗透率场,并进行填充浸润的数值模拟,通过与传统恒定渗透率的方法进行比较,证明该方法具有更高的先进性。研究结果可以对未来RTM工艺的稳健性优化提供依据。

-

关键词:

- 树脂传递模塑成型工艺(RTM) /

- 嵌套 /

- 渗透率变异性 /

- 压缩 /

- 数值模拟

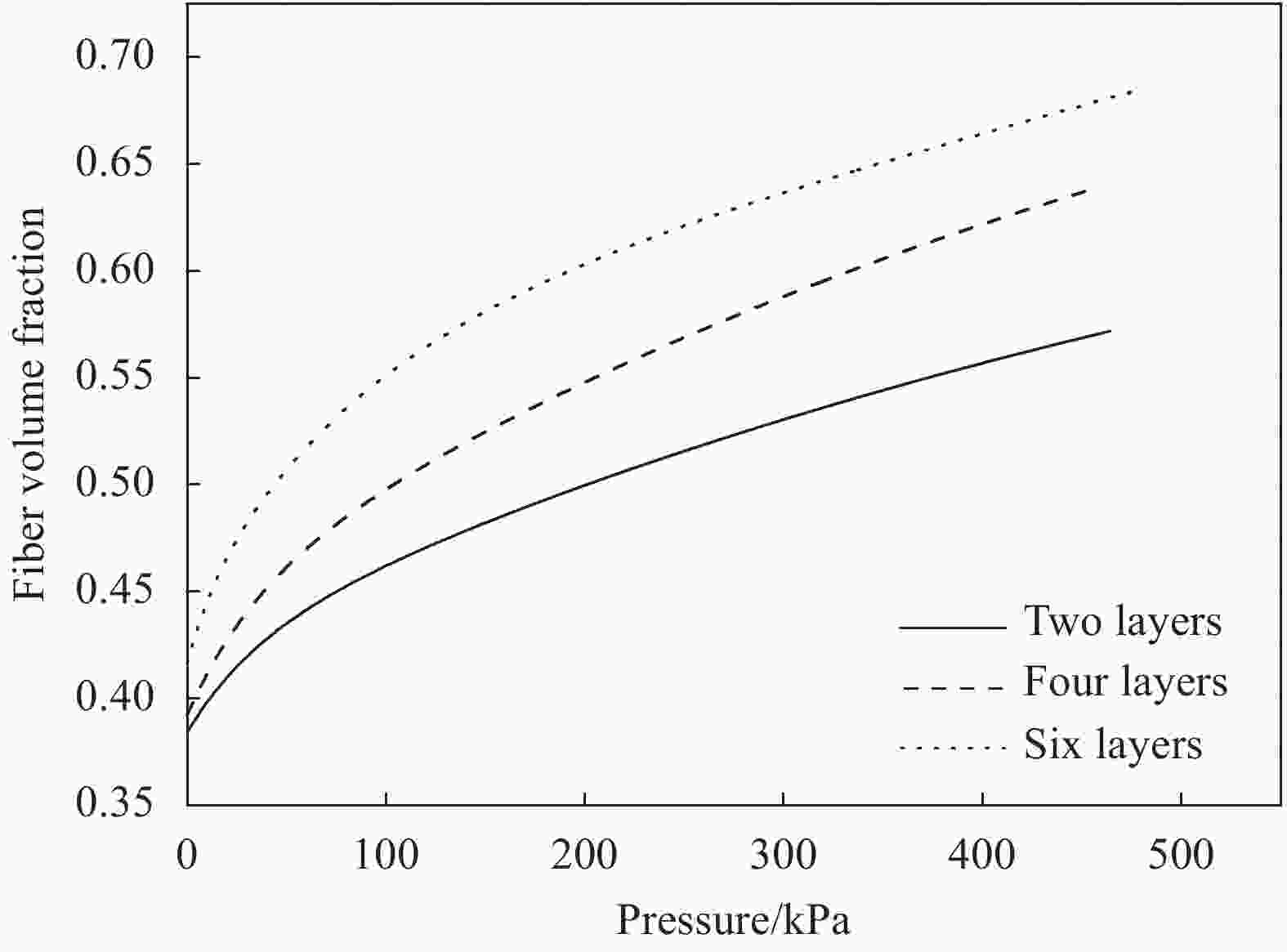

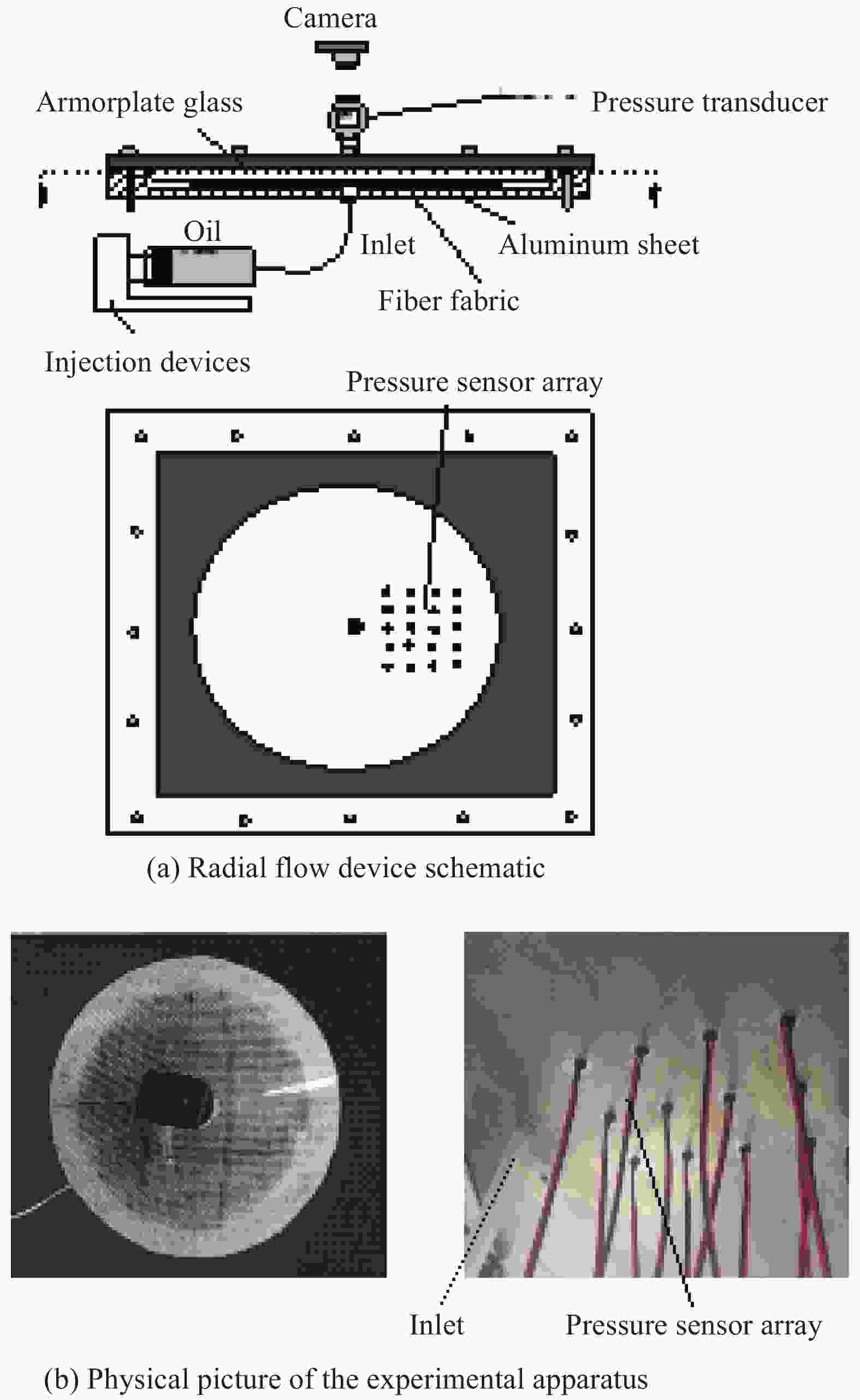

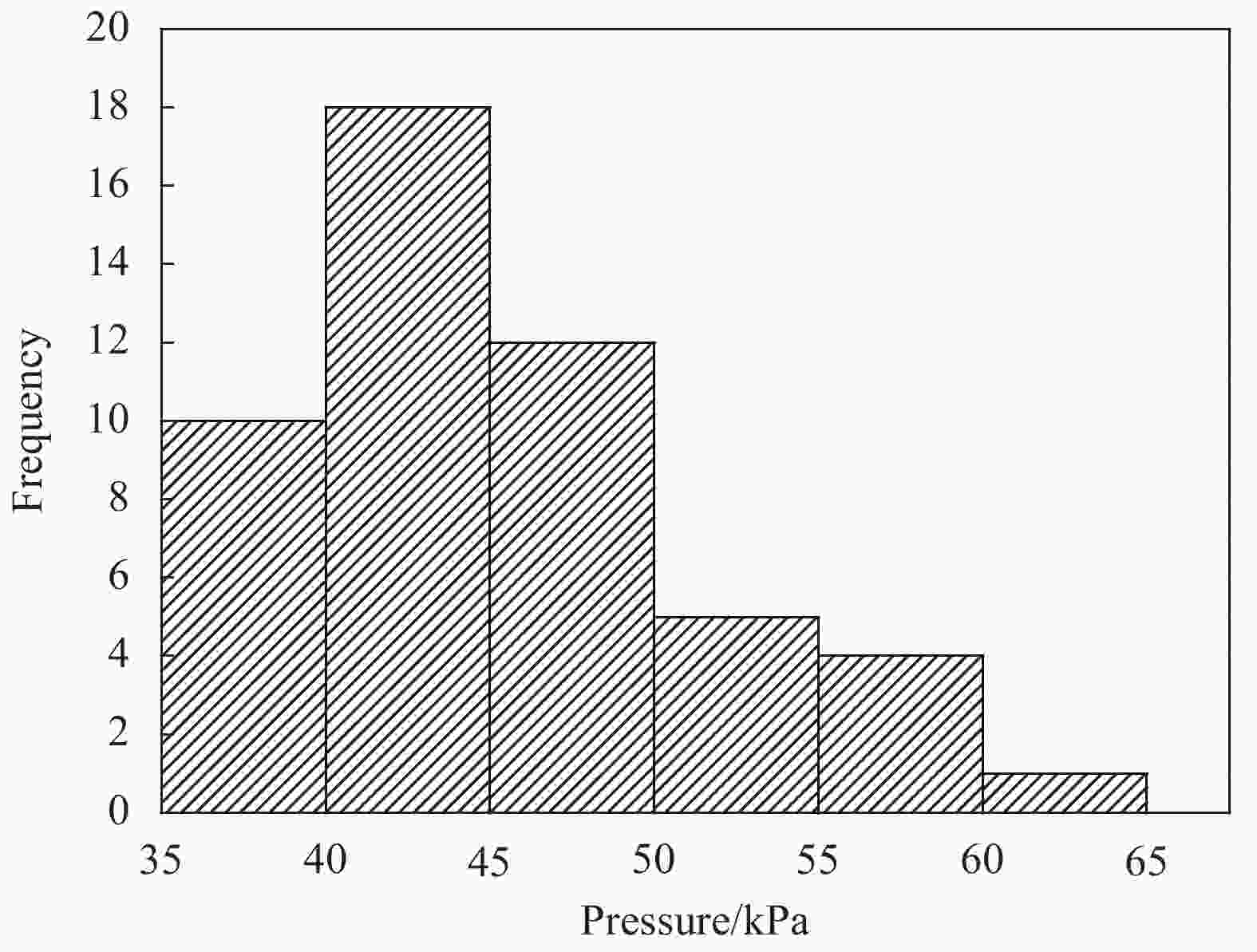

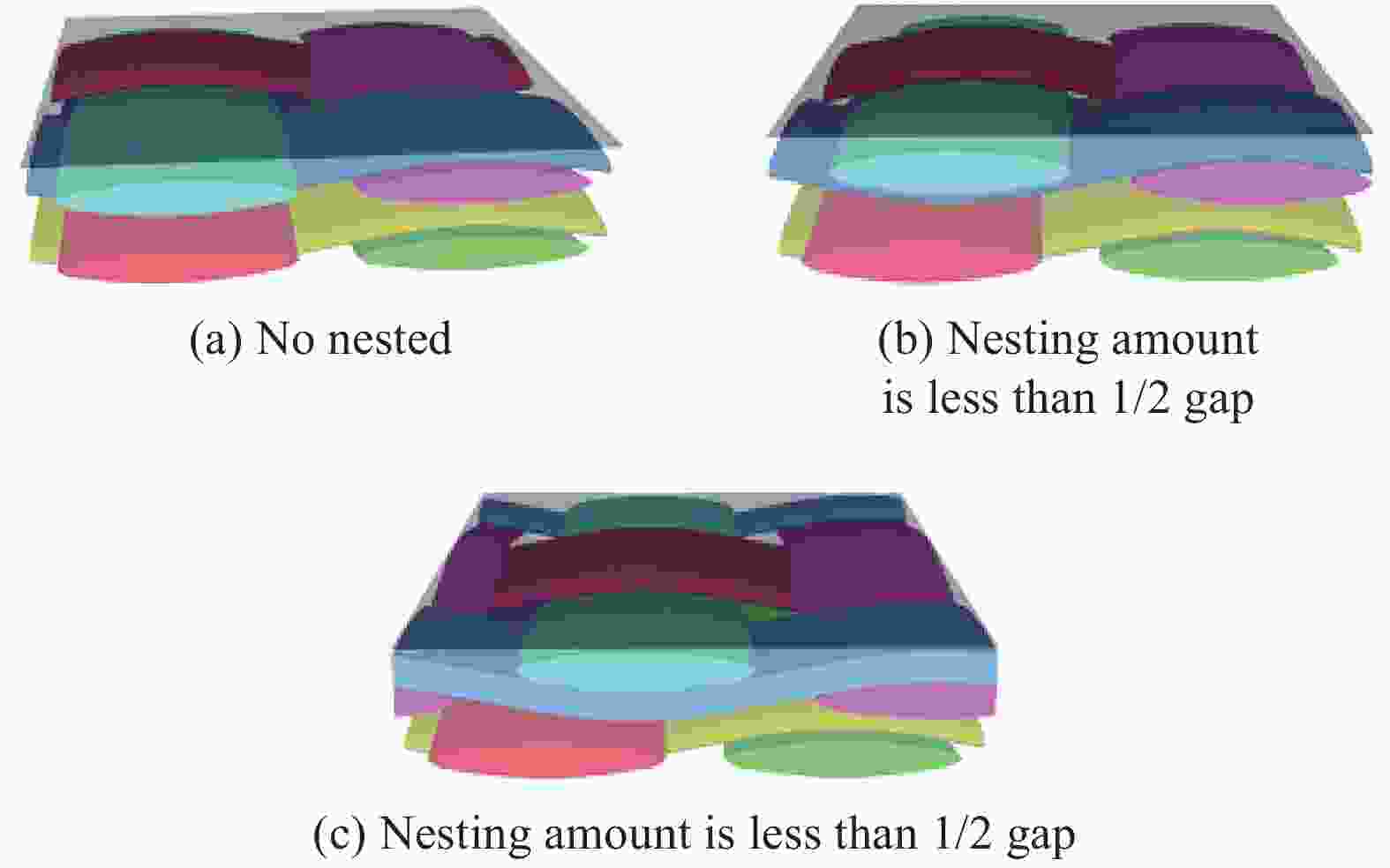

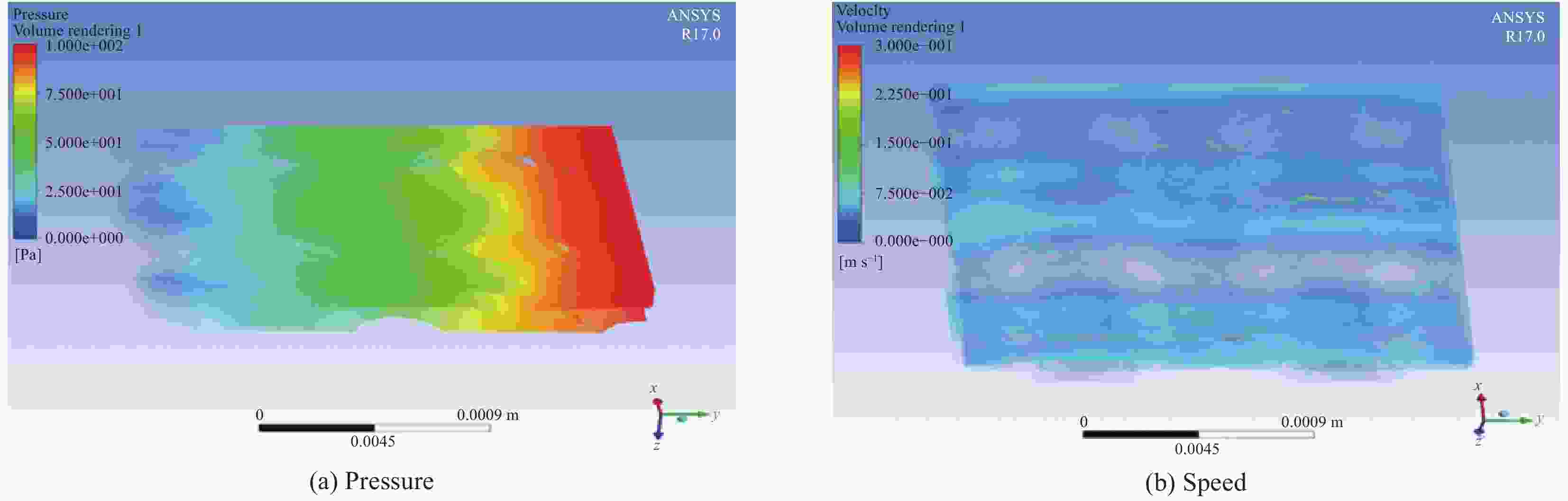

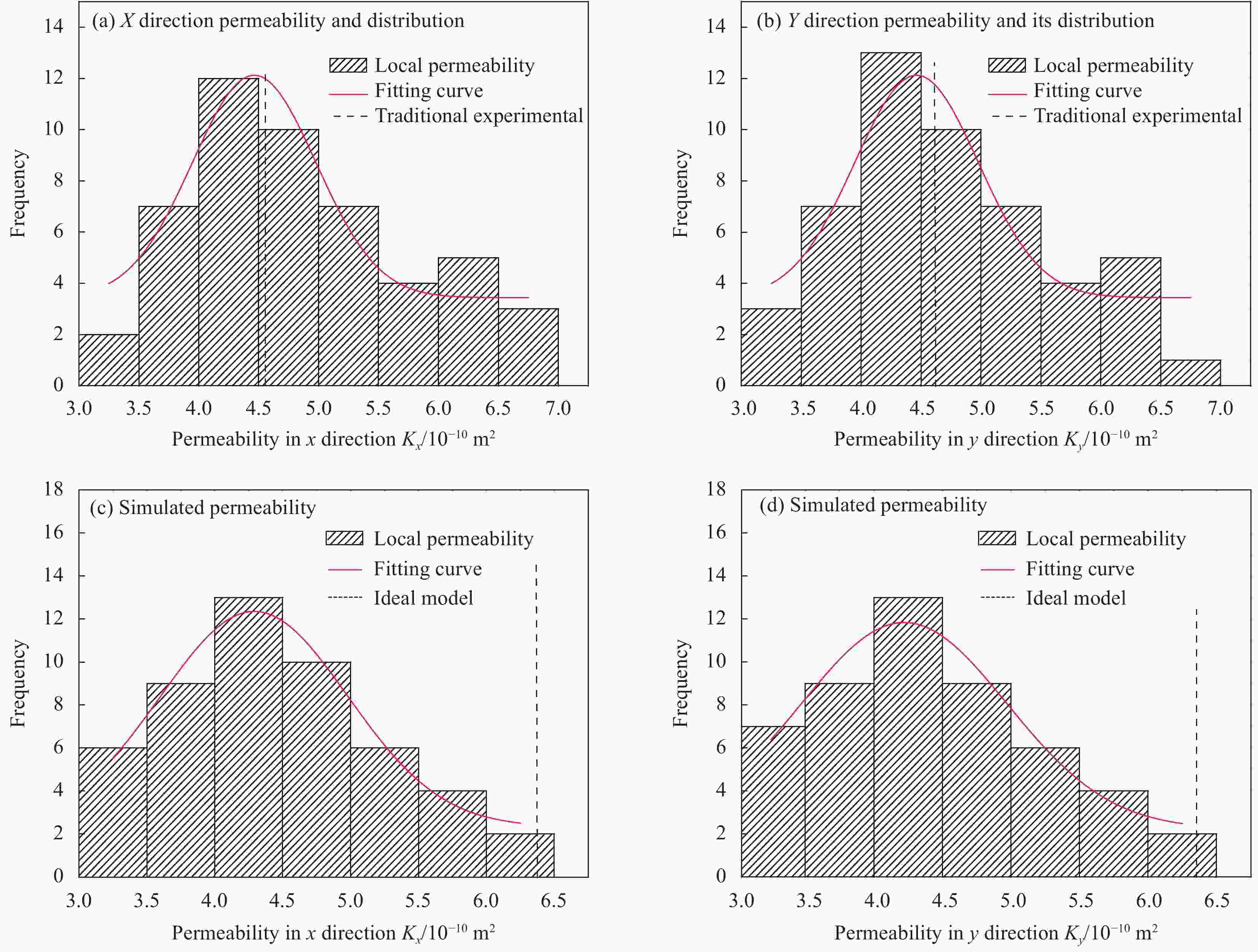

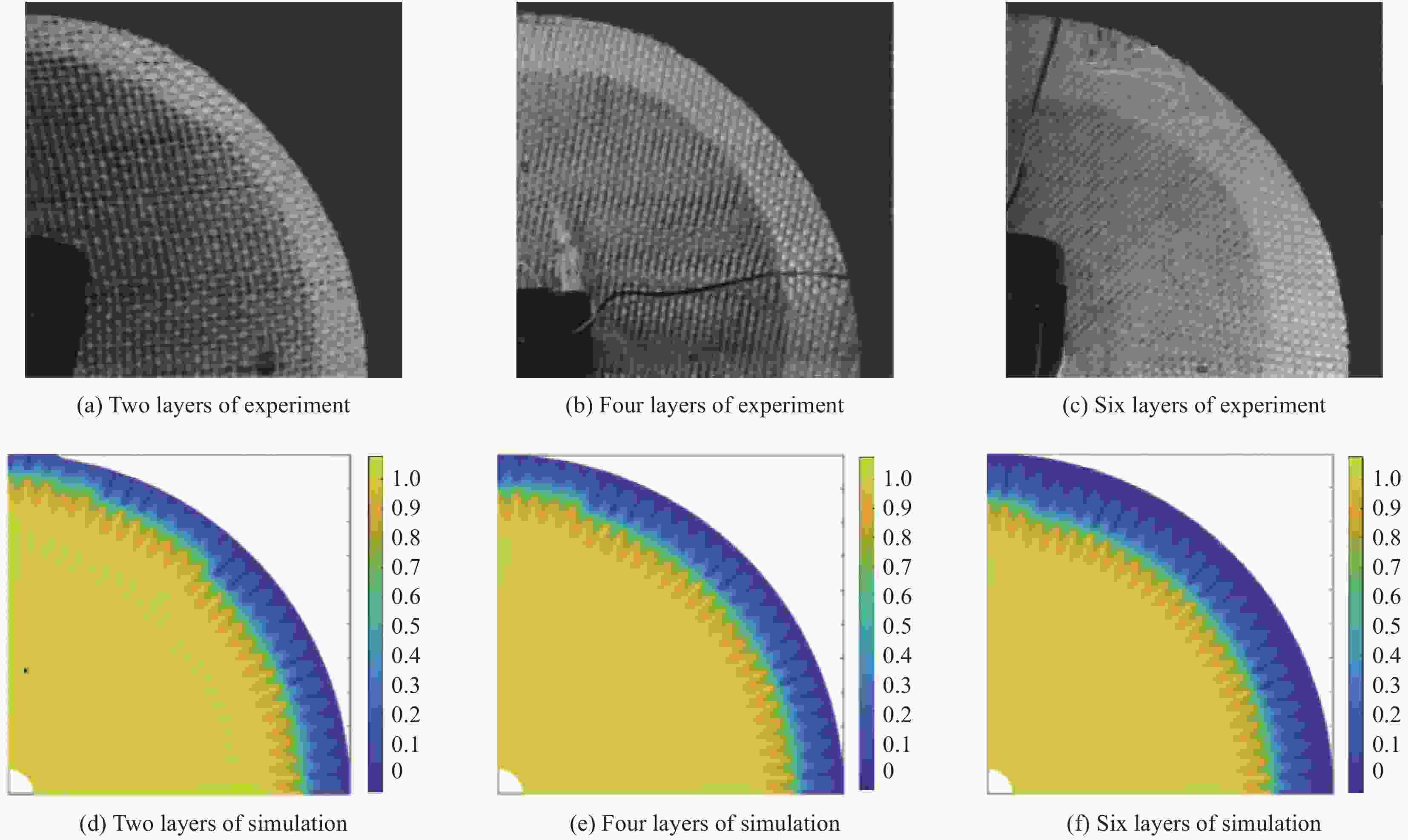

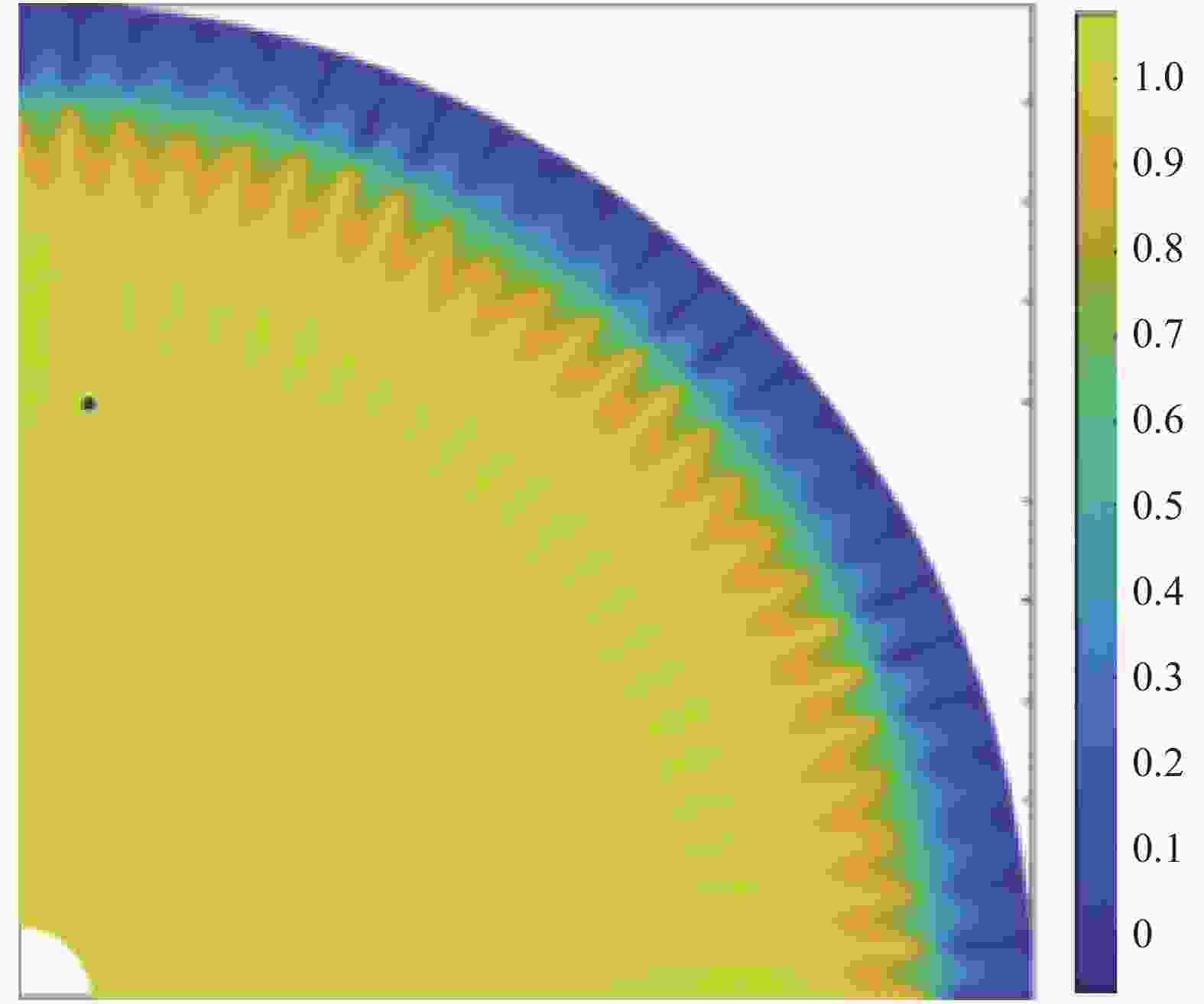

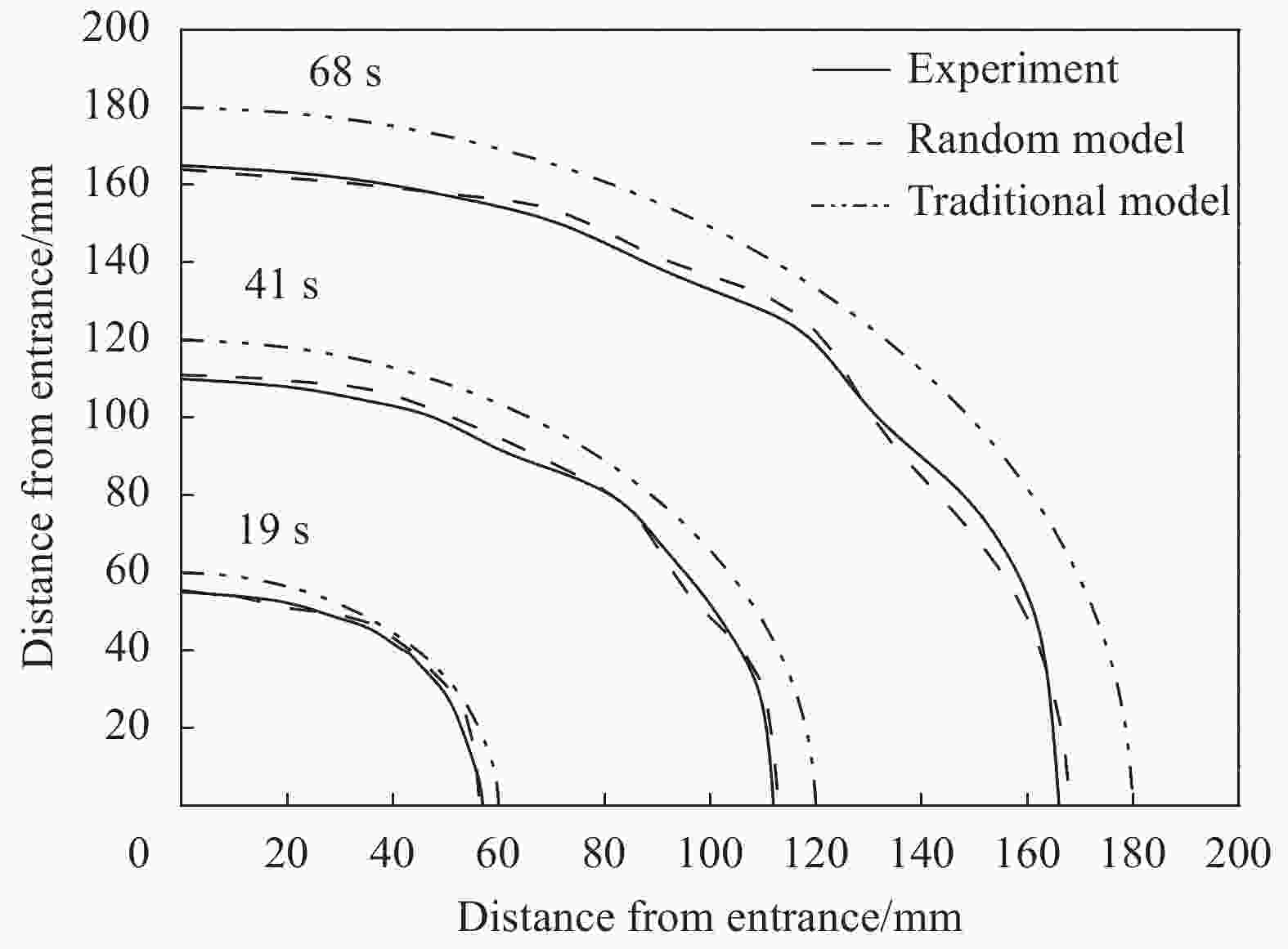

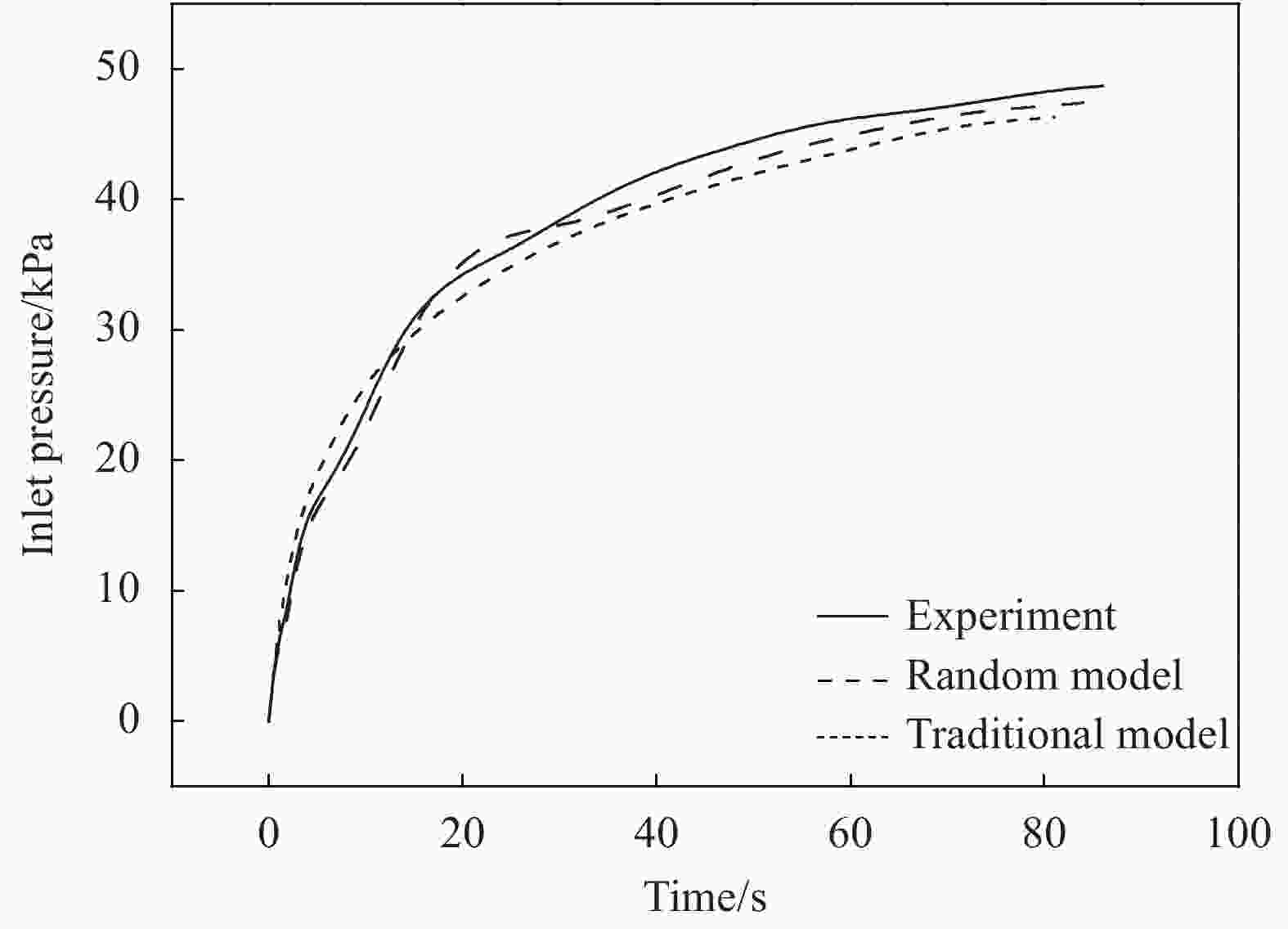

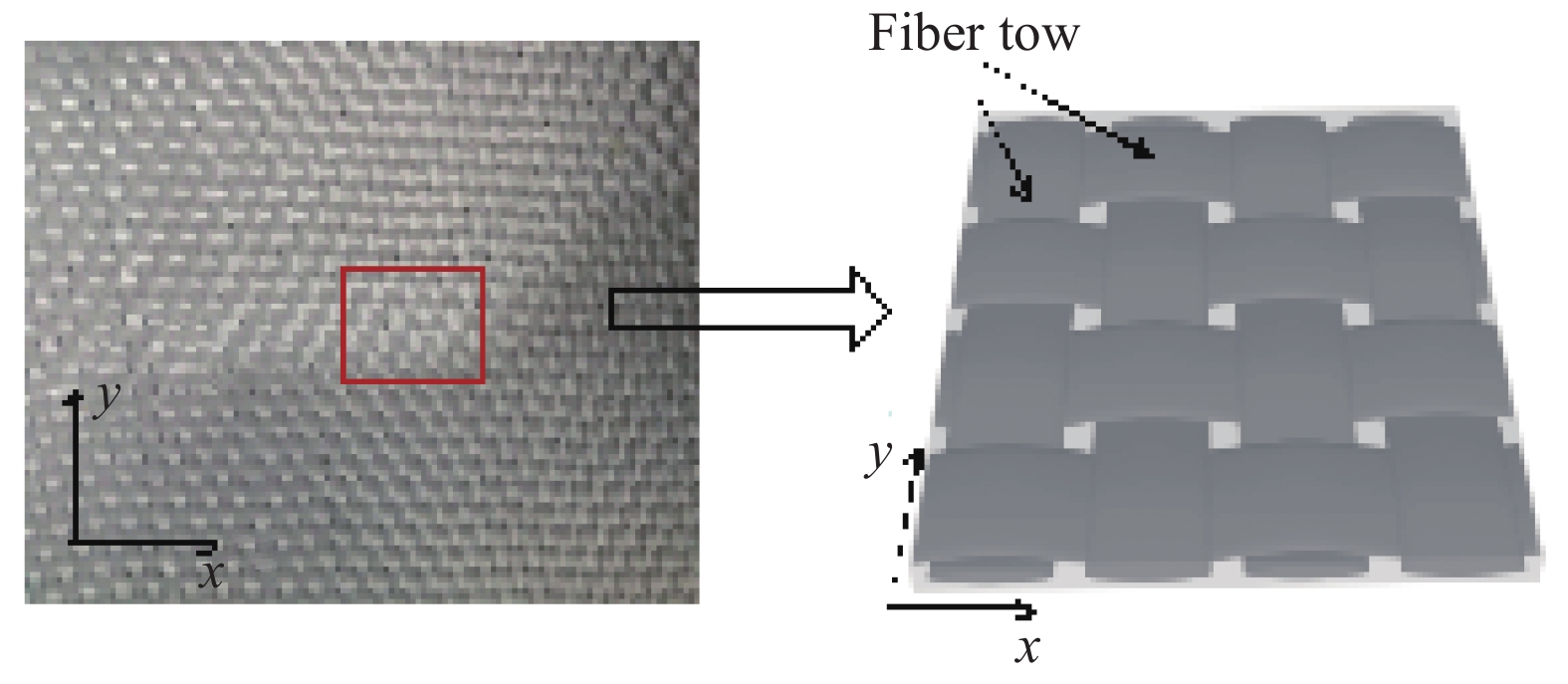

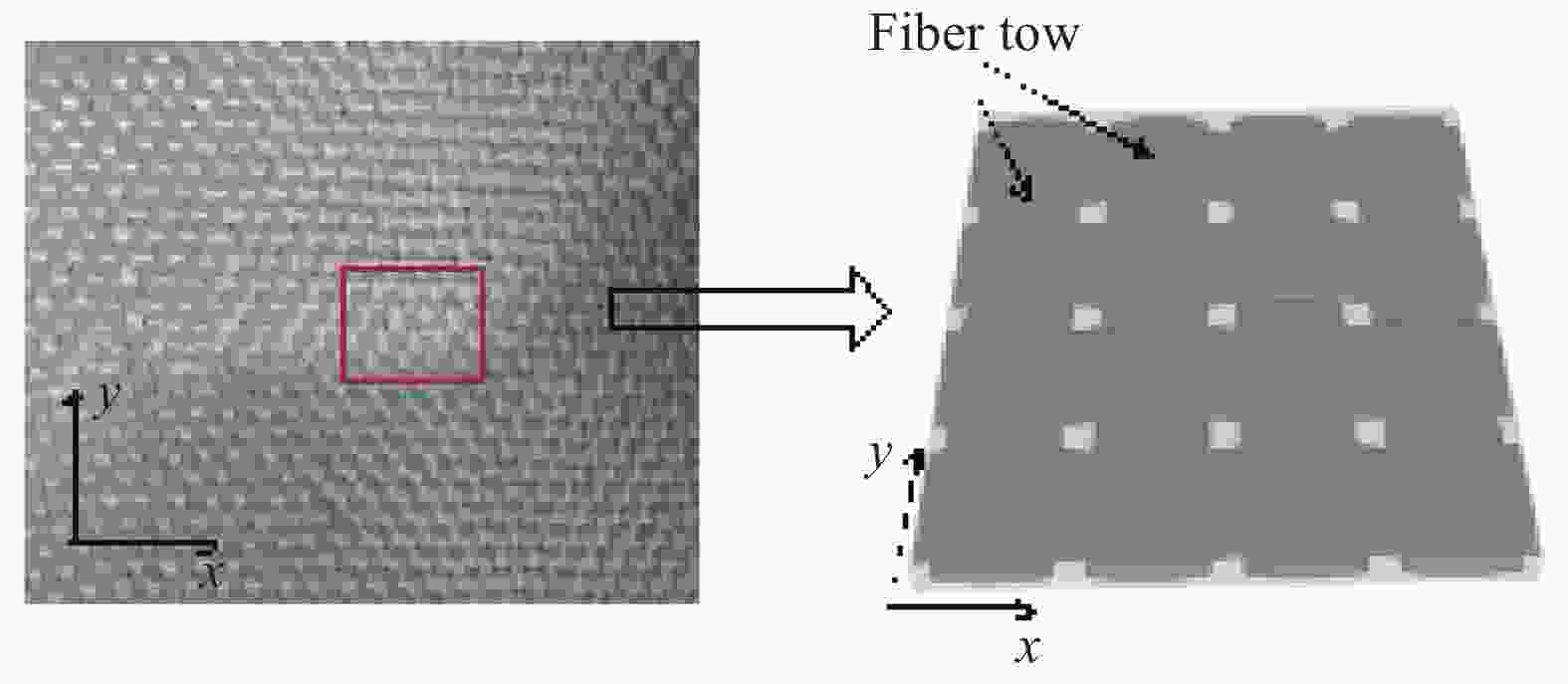

Abstract: One of the most important deformation modes in resin transfer molding (RTM) of manufacturing processes is compression along thickness direction, which reduces the thickness of the textile preform and causes the change of the fabric structure, causing the nesting effect. Nesting reduces the laminate thickness, increases the fibre volume fraction, and changes the porosity pattern. The effect of adjacent fabric layer nesting has a certain spatial dispersion. This makes the fabric permeability variable. In this work, an experimental device was designed to measure the spatial dispersion of local permeability for low viscosity resins. Then, a random nested monocyte model was established, ANSYS/CFX finite element software was used to realize the numerical simulation of single cell, and the local permeability was obtained by flow analysis. The statistical distribution of permeability was then studied. The experimental results were compared with the numerical simulation results. The reliability of the numerical simulation results was verified. Finally, the random permeability field was established based on the statistical distribution of permeability, and the numerical simulation of resin filling was carried out. The results show that this method is more advanced than traditional method based on constant permeability. The results can provide a basis for the robustness optimization of RTM process in the future.-

Key words:

- liquid composite molding (RTM) /

- nested /

- permeability variability /

- compression /

- numerical simulation

-

表 1 平纹玻璃纤维织物的初始参数

Table 1. Initial parameters of plain glass fabric

Parameter Value Areal density/(kg·m−2) 0.731 Porosity of fabric 0.67 表 2 两层织物实验与仿真渗透率分布基本参数

Table 2. Experiment and simulation of permeability distribution of two-layer fabric

Parameter Average value/

10−10 m2Standard deviation/

10−10 m2Way Kx 4.43 1.12 Experiment Ky 4.31 1.06 Experiment Kx 4.24 0.97 Simulation Ky 4.17 0.91 Simulation Notes: Kx—Permeability in x direction; Ky—Permeability in y direction. 表 3 多层织物实验渗透率分布基本参数

Table 3. Basic parameters of permeability distribution of multilayer fabrics

Parameter Average value/

10−10 m2Standard deviation/

10−10 m2Layer

numberKx 4.43 1.12 2 Ky 4.31 1.06 2 Kx 4.05 0.94 4 Ky 4.14 0.92 4 Kx 3.92 0.85 6 Ky 3.97 0.83 6 -

[1] 仲伟虹, 梁志勇, 张佐光, 等. RTM工艺及其在我国航空工业的应用前景[J]. 材料工程, 1995(1):9-11.ZHONG W H, LIANG Z Y, ZHANG Z G, et al. RTM and the application prospect of RTM in aviation industry[J]. Journal of Materials Engineering,1995(1):9-11(in Chinese). [2] 景新荣, 刘向丽, 苏霞. RTM成型工艺技术应用及加工工艺性研究浅析[J]. 橡塑技术与装备, 2015(24):132-135.JING X R, LIU X L, SU X. Application and processing technology research of RTM molding progress[J]. Plastics Technology and Equipment,2015(24):132-135(in Chinese). [3] LEBEL F, FANAEI AE, EDU R, et al. Prediction of optimal flow front velocity to minimize void formation in dual scale fibrous reinforcements[J]. International Journal of Material Forming,2014,7(1):93-116. doi: 10.1007/s12289-012-1111-x [4] ARBTER R, BERAUD JM, BINETRUY C, et al. Experimental determination of the permeability of textiles: A benchmark exercise[J]. Composites Part A : Applied Science and Manufacturing,2011,42(9):1157-68. doi: 10.1016/j.compositesa.2011.04.021 [5] VERNET N, RUIZ E, ADVANI S, et al. Experimental determination of the permeability of engineering textiles: Benchmark II[J]. Composites Part A : Applied Science and Manufacturing,2014,61:172-84. doi: 10.1016/j.compositesa.2014.02.010 [6] BODAGHI M, LOMOV S V, SIMACEK P, et al. On the variability of permeability induced by reinforcement distortions and dual scale flow in Liquid Composite Moulding: A review[J]. Composites Part A: Applied Science and Manufacturing,2019,120:188-210. doi: 10.1016/j.compositesa.2019.03.004 [7] HOES K, DINESCU D, SOL H, et al. Study of nesting induced scatter of permeability values in layered reinforcement fabrics[J]. Composites Part A: Applied Science and Manufacturing,2004,35(12):1407-1418. doi: 10.1016/j.compositesa.2004.05.004 [8] BODAGHI M, VANAERSCHOT A, LOMOV S V, et al. On the variability of mesoscale permeability of a 2/2 twill carbon fabric induced by variability of the internal geometry[J]. Composites Part A: Applied Science and Manufacturing,2017,101:394-407. doi: 10.1016/j.compositesa.2017.05.030 [9] DUNGAN F D, SENOGUZ M T, SASTRY A M, et al. Simulations and experiments on low-pressure permeation of fabrics: Part I—3D M odeling of unbalanced fabric[J]. Composite Materials,2001,35(12):1250-84. [10] SENOGUZ M T, DUNGAN F D, SASTRY A M, et al. Simulations and experiments on low-pressure permeation of fabrics: Part II-the variable gap model and prediction of permeability[J]. Composite Materials,2001,35(14):1285-1322. [11] GRUJICIC M, CHITTAJALLU K M, Walsh S. Effect of shear, compaction and nesting onpermeability of the orthogonal plain-weave fabric preforms[J]. Materials Chemistry and Physics,2004,86:358-69. doi: 10.1016/j.matchemphys.2004.03.015 [12] BELOV E B, LOMOV S V, VERPOEST I, et al. Modelling of permeability of textile reinforcements: Lattice Boltzmann method[J]. Composites Science and Technology,2004,64(7-8):1069-80. [13] DELERUE F, LOMOV SV, PARNAS RS, et al. Pore network modeling of permeability for textile reinforcements[J]. Polymers & Polymer Composites,2003,24(3):344-57. doi: 10.1002/pc.10034 [14] HE L F, YAN S L, LI Y J, et al. Simulation of stochastic flow considering mesoscale permeability variability during the resin transfer molding process[J]. Polymer Composites,2020,41:1701-1710. doi: 10.1002/pc.25490 [15] 谢翔宇, 李永静, 晏石林. 液体模塑成型工艺二维径向非饱和流动数值模拟[J]. 复合材料学报, 2018, 35(12):3386-3392.XIE X Y, LI Y J, YAN S L. Numerical simulation of 2-dimensional radial unsaturated flow in liquid composite molding processes[J]. Acta Materiae Compositae Sinica,2018,35(12):3386-3392(in Chinese). [16] 何龙飞, 晏石林, 李永静, 等. 双尺度纤维织物二维非饱和流动的数值模拟与实验[J]. 复合材料学报, 2020, 37(4):135-142.HE L F, YAN S L, LI Y J, et al. Numerical simulation and experiment of 2-dimensional unsaturated flow of dual-scale fiber mat[J]. Acta Materiae Compositae Sinica,2020,37(4):135-142(in Chinese). [17] WEI B J, ZHANG Y C, YUAN Y, et al. Online estimation and monitoring of local permeability in resin transfer molding[J]. Polymer Composites,2016,37(4):1249-1258. doi: 10.1002/pc.23290 [18] ENDRUWEIT A, LONG A C. Influence of stochastic variations in the fibre spacing on the permeability of bi-directional textile fabrics[J]. Composites Part A Applied Science and Manufacturing,2006,37(5):679-694. doi: 10.1016/j.compositesa.2005.08.003 [19] HUANG S, MAHADEVAN S, REBBA R. Collocation-based stochastic finite element analysis for random field problems[J]. Probabilistic Engineering Mechanics,2007,22(2):194-205. doi: 10.1016/j.probengmech.2006.11.004 [20] ZHANG F, COSSON B, BINETRUY C, et al. Efficient stochastic simulation approach for RTM process with random fibrous permeability[J]. Composites Science and Technology,2011,71(12):1478-1485. doi: 10.1016/j.compscitech.2011.06.006 -

下载:

下载: