Seismic behavior of high-strength concrete columns reinforced with CFRP tendons and high-strength steels

-

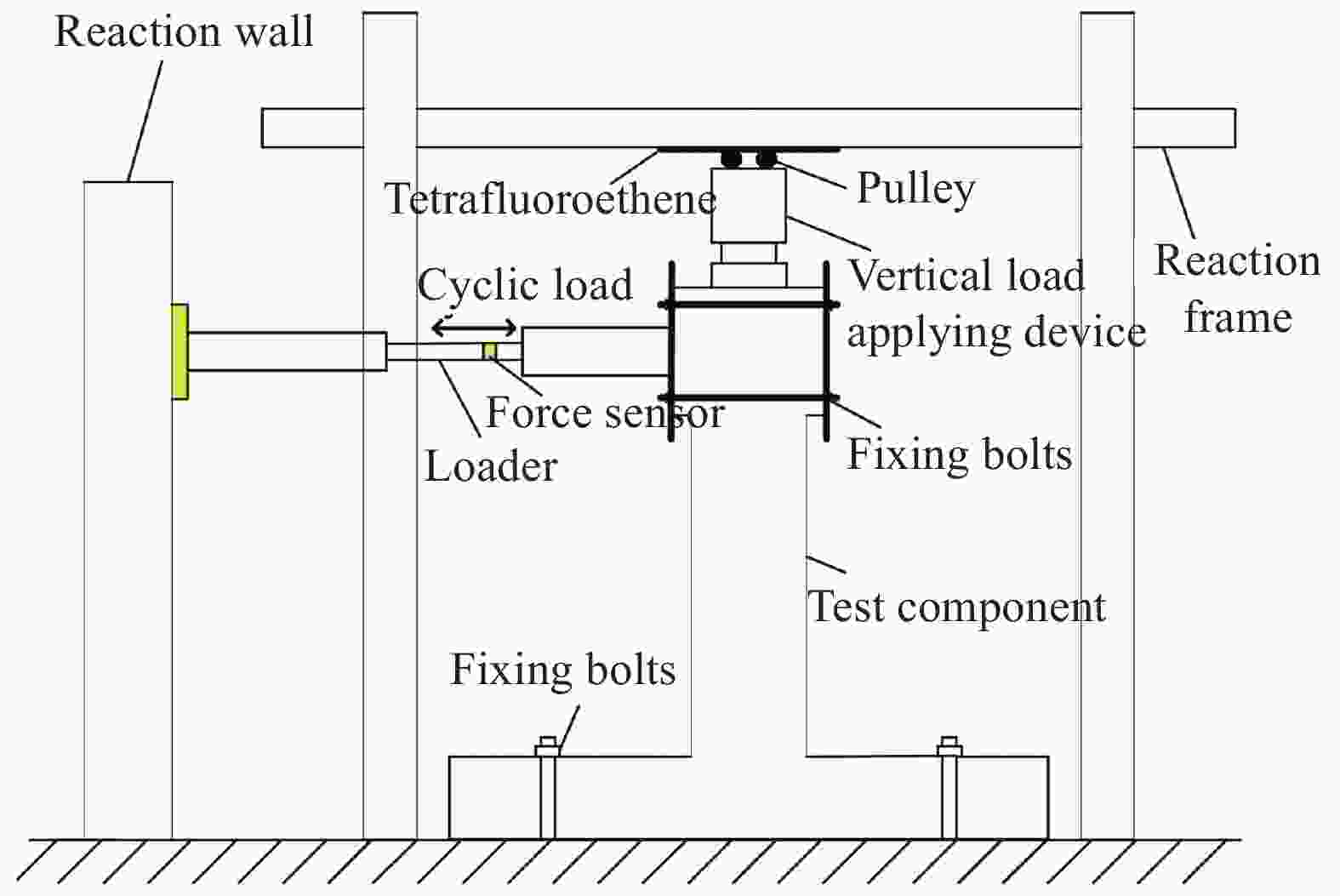

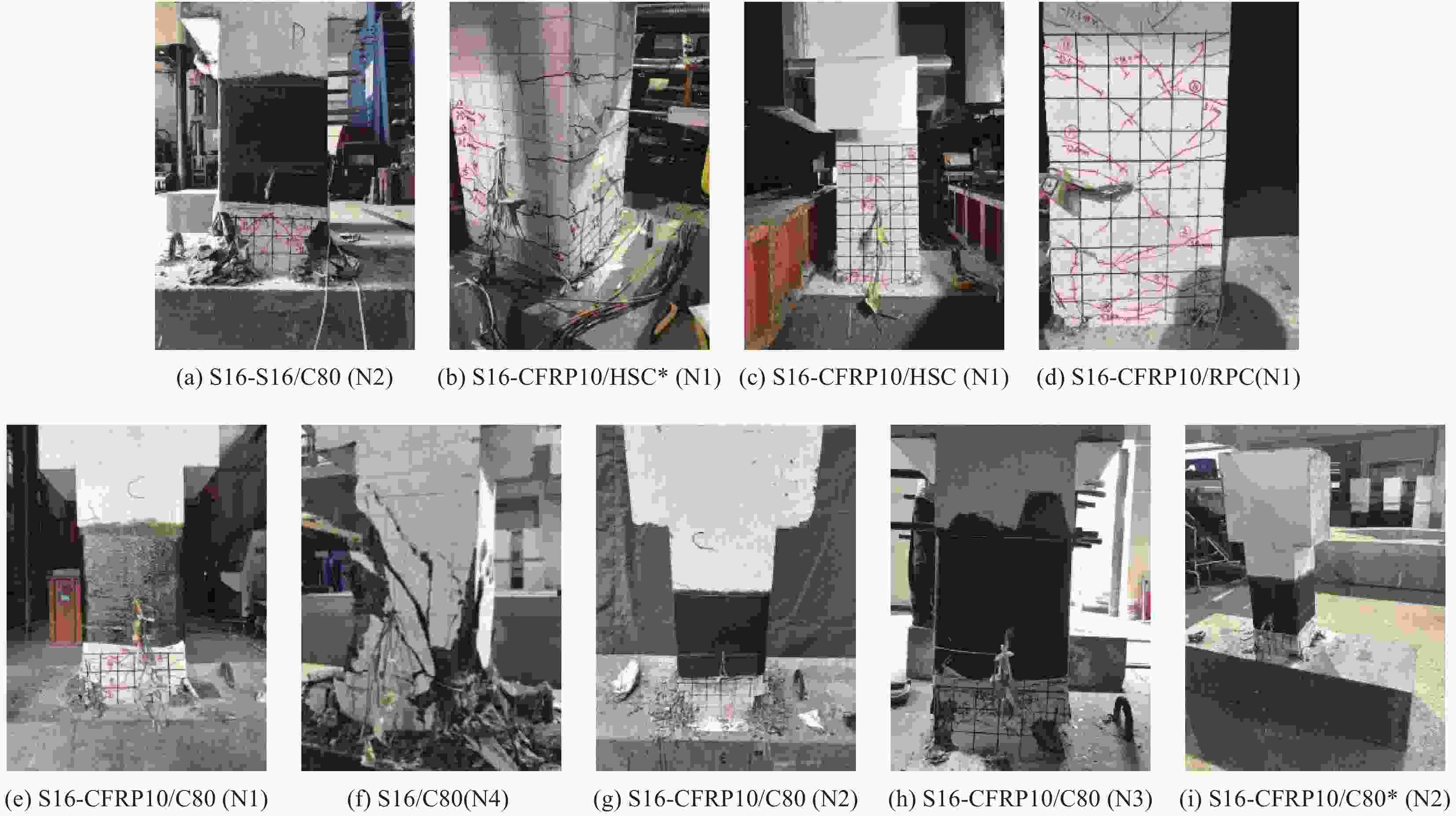

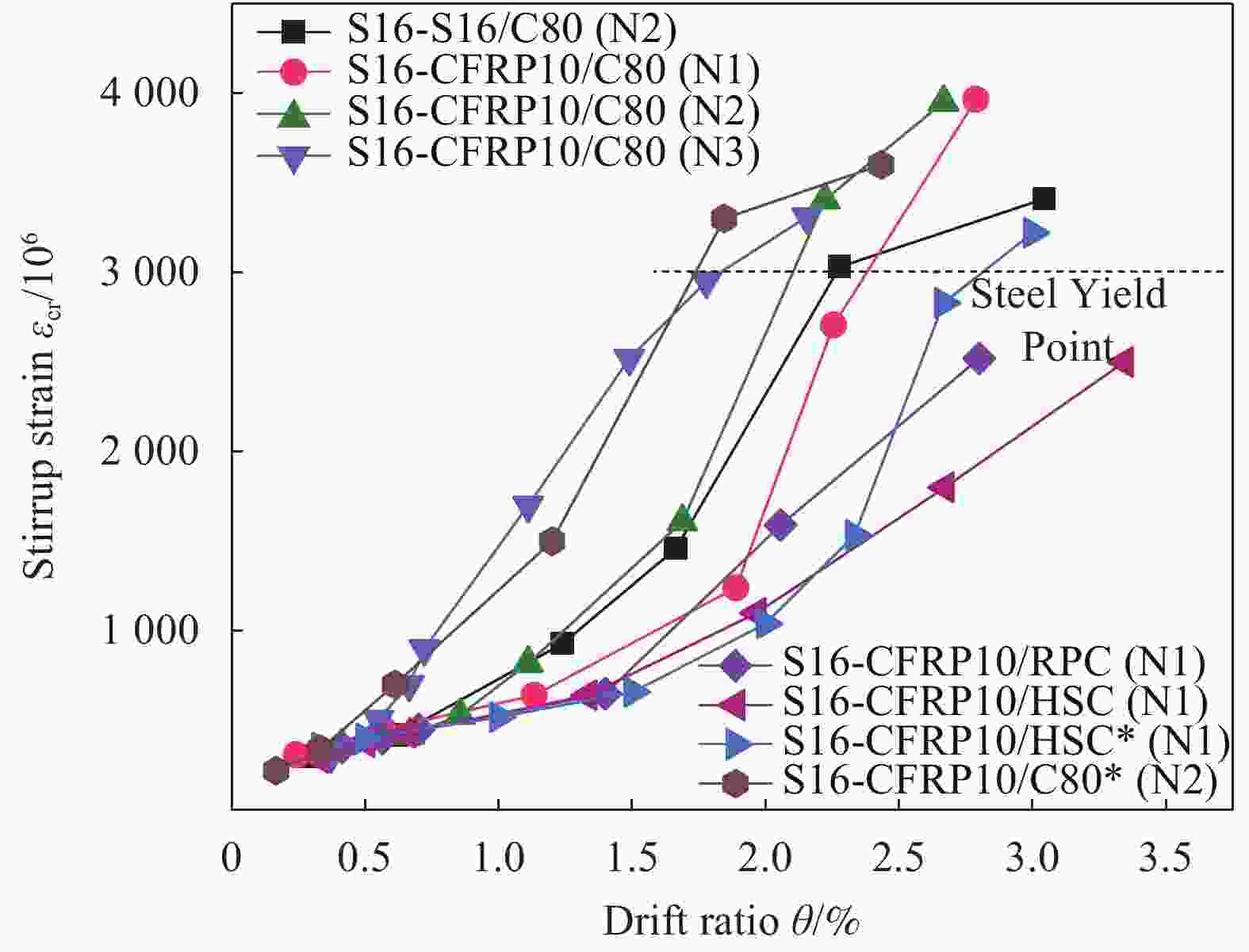

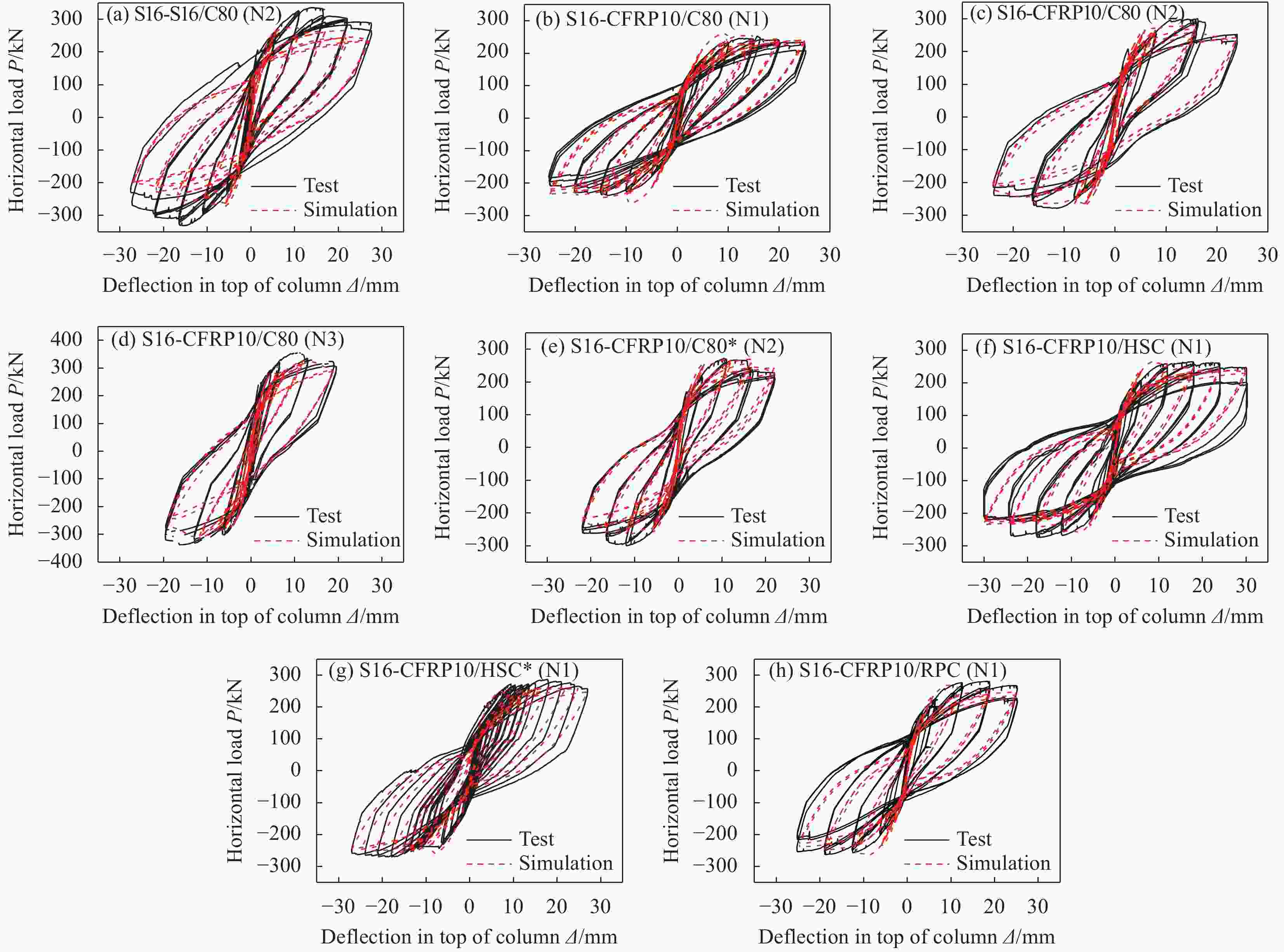

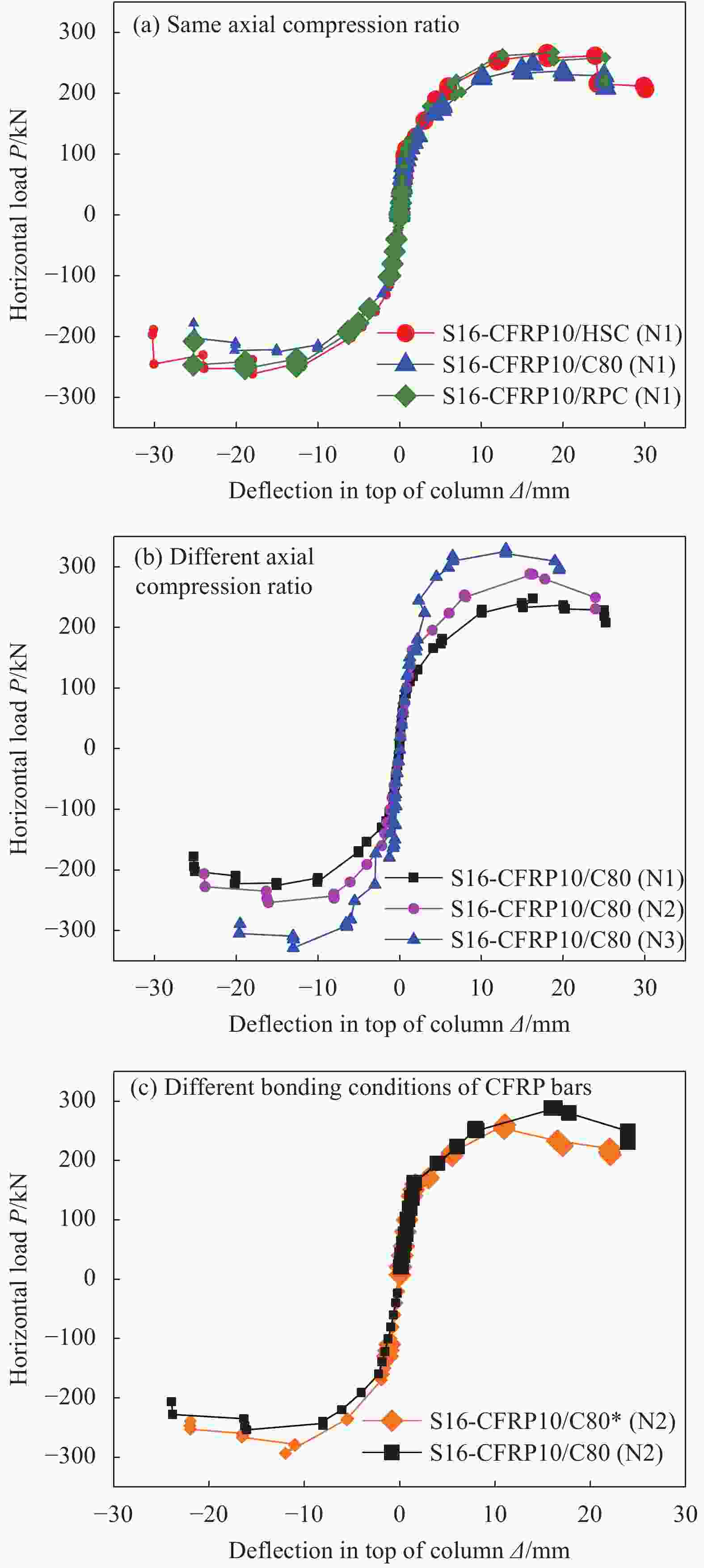

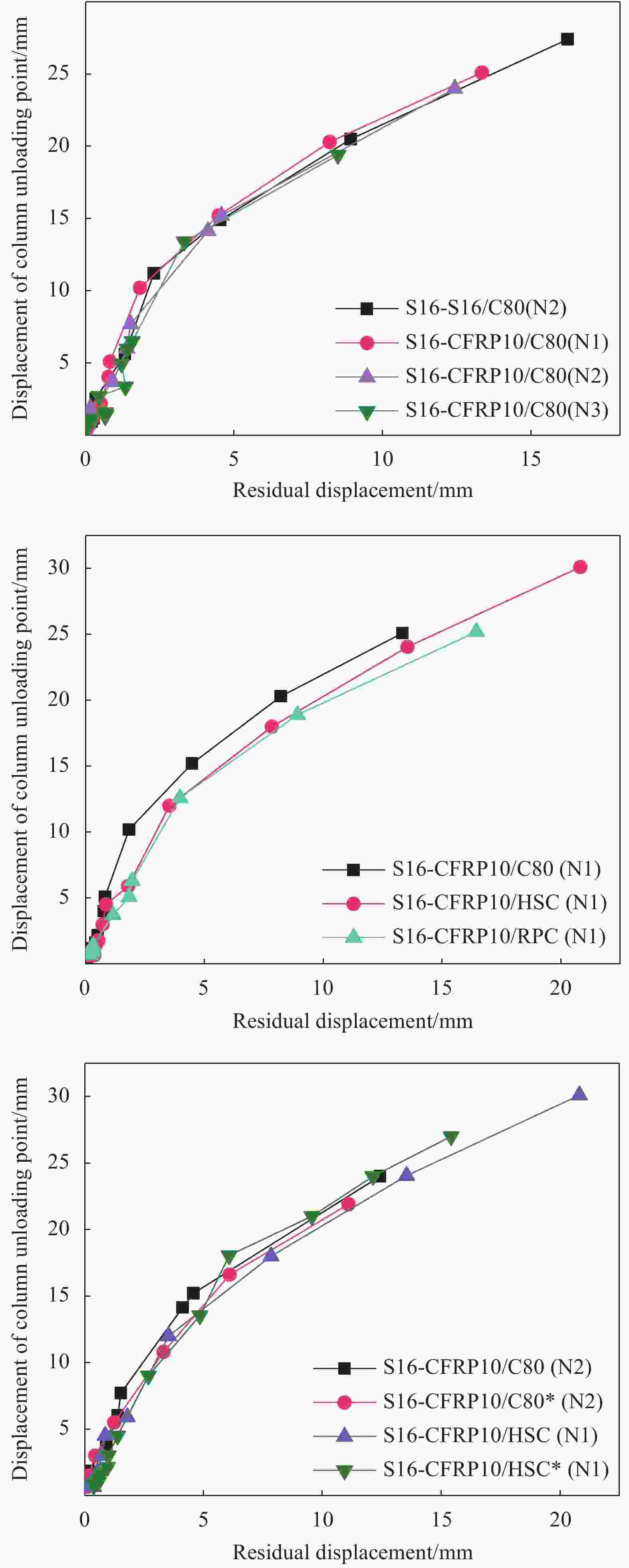

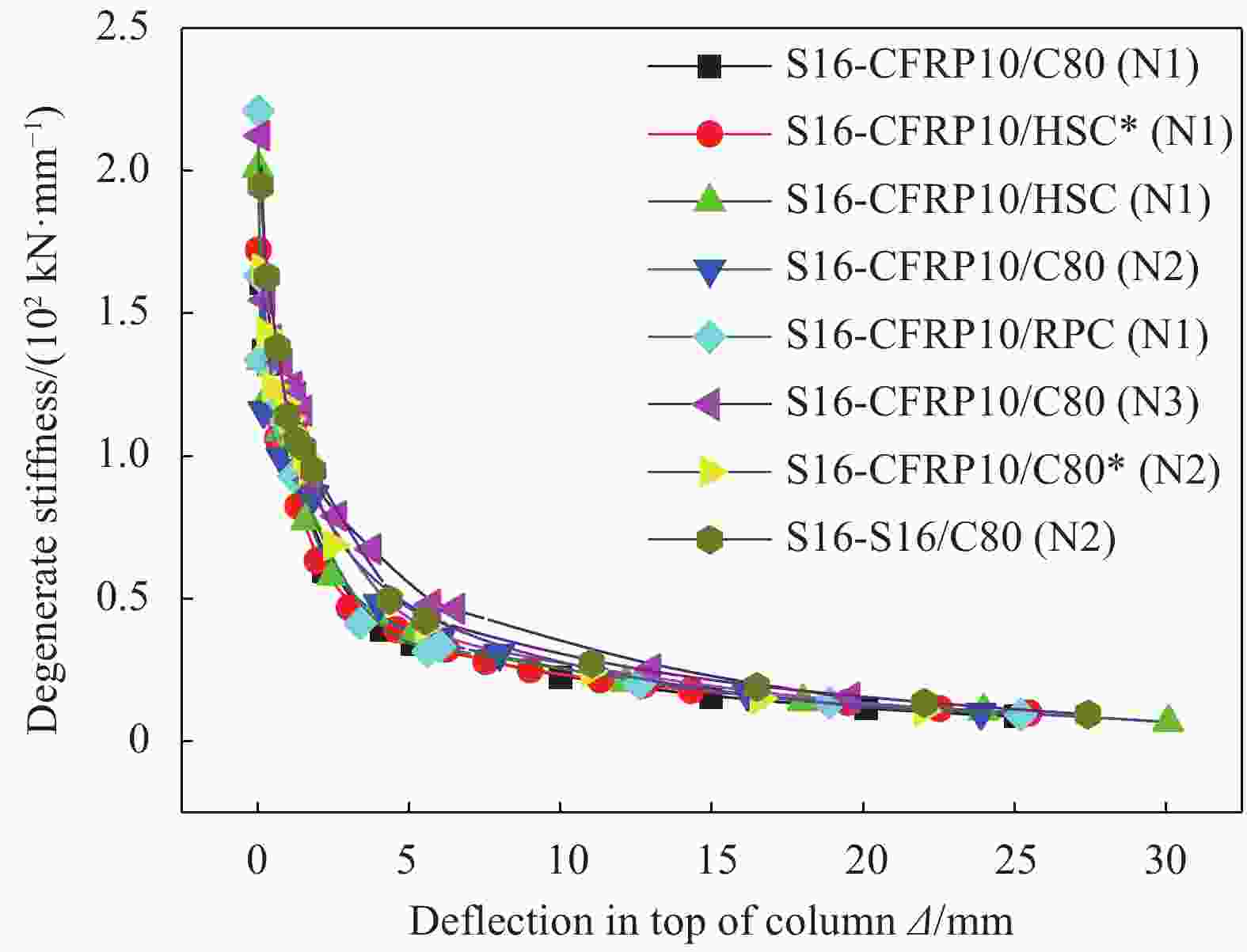

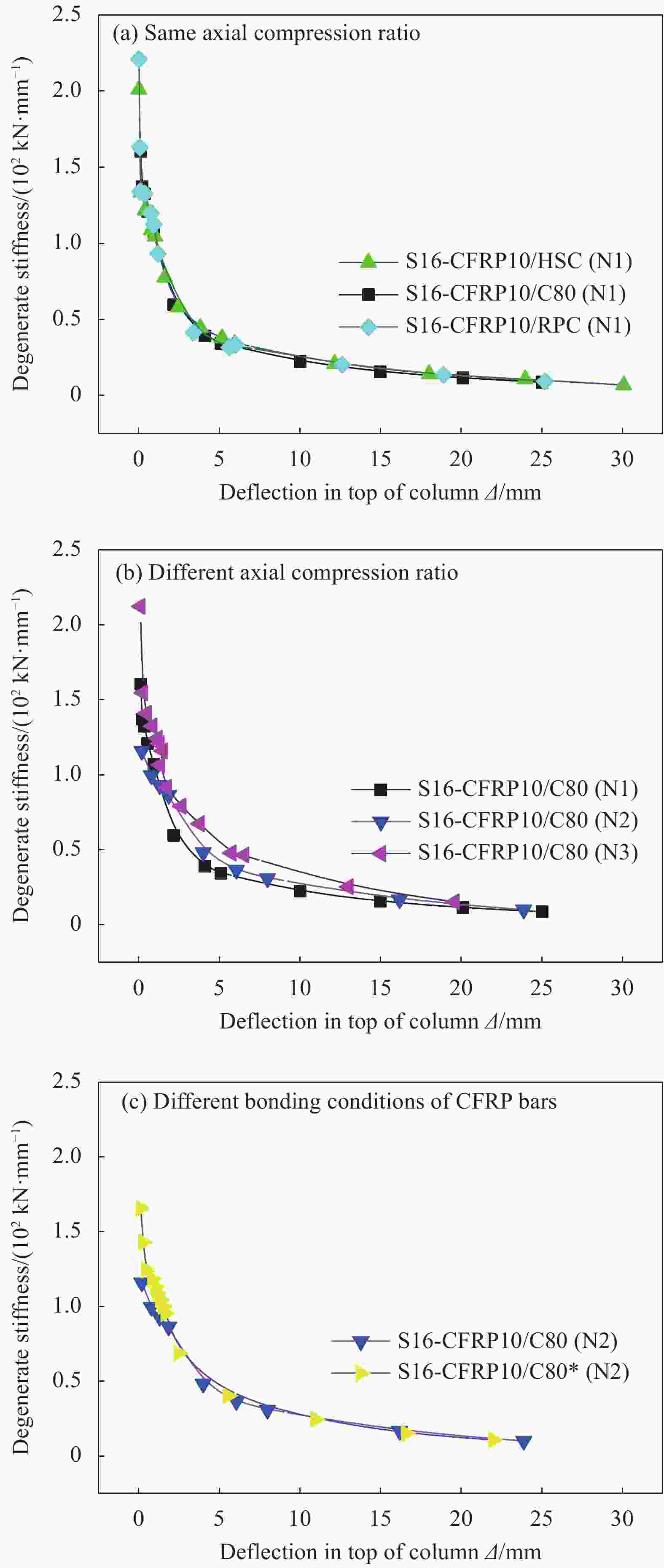

摘要: 为了研究高强钢筋和碳纤维增强树脂复合材料(CFRP)混合配筋/高强混凝土柱的抗震性能,对CFRP筋-高强钢筋混合配筋的高强混凝土柱进行了低周反复荷载试验和有限元分析,研究了CFRP筋的粘结条件、不同轴压比以及高强混凝土种类等参数对其抗震性能的影响。结果表明:所有的高强混合配筋高强混凝土柱均发生延性破坏;在相同条件下,高强混合配筋混凝土中分别添加了钢纤维活性粉末和钢纤维后,表现出更好的耗能能力和延性;有粘结CFRP筋混合配筋高强混凝土柱比无粘结CFRP筋混合配筋柱的变形能力和承载力分别提高了9.6%和17.1%,但是延性系数降低了22.5%;在延性破坏的条件下,随着轴压比的增加,CFRP筋-高强钢筋混合配筋柱的屈服强度和极限强度明显增大,极限位移和耗能能力也逐渐减小;高强钢筋和CFRP筋配筋率越高,高强混合配筋柱的极限承载力和变形能力越大。Abstract: In order to investigate the seismic performance of high-strength concrete columns reinforced with carbon fiber reinforced polymer (CFPR) and high-strength steel, hybrid reinforced concrete columns with CFRP tendons and high-strength steels and two high-strength reinforced concrete columns were prepared and tested. The experimental and numerical results were used to explore the factors influencing the seismic performance of high strength concrete columns, including the bonding condition of CFRP tendons, axial compression ratio and concrete type. The results show that all high-strength concrete columns with CFRP tendons and high-strength steel have ductile failure. The concrete columns with steel fiber or reactive powder concrete (RPC) exhibit good ductility and energy dissipation under the same condition. The deformation and bearing capacity of the high-strength concrete column with bonded CFRP tendons are 9.6% and 17.1% higher than that of unbonded hybrid reinforced concrete columns, but the ductility coefficient is lower than 22.5%. Under ductile failure conditions, as the axial pressure ratio increases, the bearing capacity of high-strength concrete columns is improved significantly, but the energy dissipation capacity and plastic deformation capacity decrease obviously. The higher ratio of high-strength steels and CFRP tendons, the ultimate bearing capacities and deformation capacities of high-strength hybrid reinforcement columns are higher.

-

Key words:

- CFRP tendons /

- high-strength steels /

- high-strength concrete column /

- seismic performance /

- ductility

-

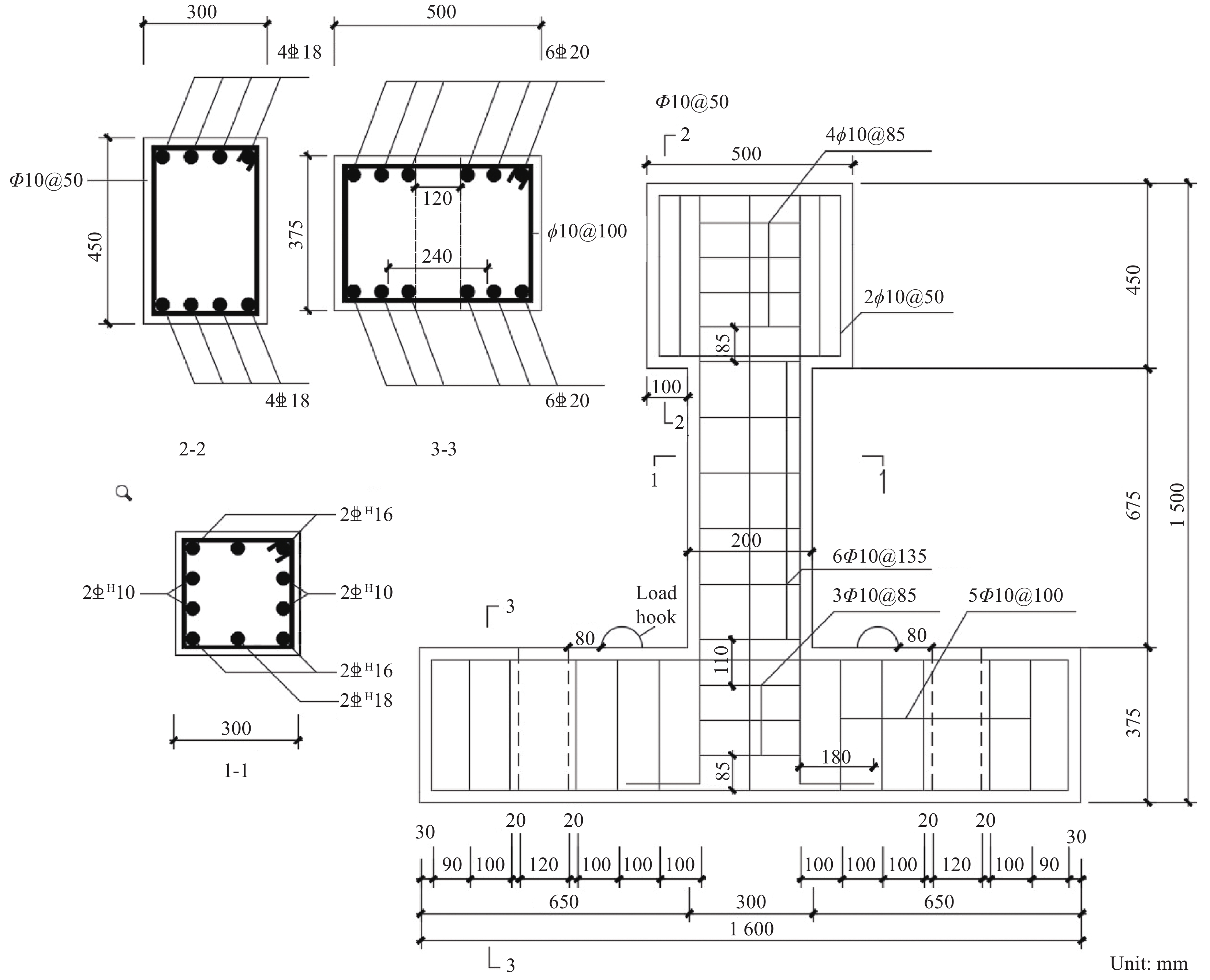

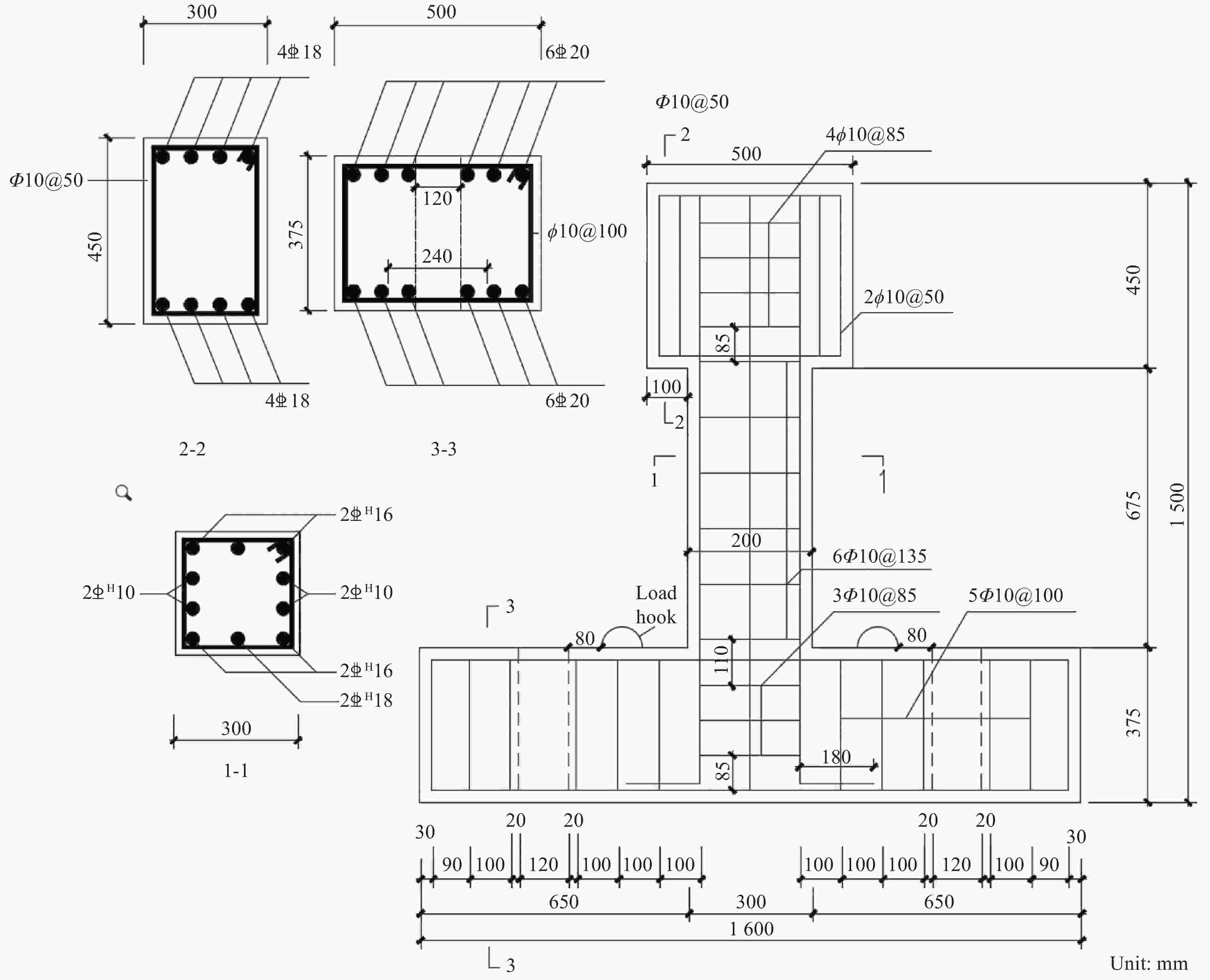

表 1 CFRP筋-高强钢筋/高强混凝土柱的主要试验参数

Table 1. Detailed experimental parameters of high-strength concrete columns with CFRP tendons and high-strength steels

Specimen Longitudinal

steelBonding condition

of CFRP tendonsAxial compression

ratioConcrete

typeWhether to mix

steel fiberS16/C80(N4) 4

Bonded 0.269 C80 No S16-CFRP10/C80(N1) 4

Bonded 0.120 C80 No S16-CFRP10/RPC(N1) 4

Bonded 0.120 RPC Yes S16-CFRP10/HSC(N1) 4

Bonded 0.120 C80H Yes S16-CFRP10/HSC*(N1) 4

Unbonded 0.120 C80H Yes S16-S16/C80(N2) 4

Bonded 0.202 C80 No S16-CFRP10/C80(N2) 4

Bonded 0.202 C80 No S16-CFRP10/C80*(N2) 4

Unbonded 0.202 C80 No S16-CFRP10/C80(N3) 4

Bonded 0.314 C80 No Notes: S16—High-strength steel bars; CFRP10—CFRP tendons; N1, N2, N3 and N4—Test axial compression ratios, which are 0.12, 0.202, 0.314 and 0.269; HSC—High-strength concrete with steel fiber volume of 45 kg/m3; RPC—Reactive powder concrete with steel fiber volume of 118 kg/m3; "*"—Use of unbonded CFRP bars;

表 2 粉煤灰混凝土(RPC)配合比

Table 2. Mix proportion of reactive powder concrete (RPC)

Superfine cement/kg Quartz sand/kg Cement/kg Slag/kg Water/kg Water-reducing admixture/kg Steel fiber/kg 235 1070 471 471 200 27 118 表 5 CFRP筋性能

Table 5. Properties of CFPR tendons

Type Diameter/

mmUltimate strength/

MPaModulus of

elasticity/GPaCR124-10 10 2297 124 表 3 混凝土立方体实测强度

Table 3. Measured strength of concrete cube

Concrete

typeCompressive

strength/MPaModulus of

elasticity/GPaC80H 93.0 388 C80 76.0 380 RPC 85.7 510 表 4 钢筋性能

Table 4. Properties of steels

Diameter/

mmSteel

gradeYield strength/

MPaUltimate strength/

MPa16 HTRB600E 670.2 856.5 10 HPB300 383.0 447.2 18 HRB400 453.2 610.0 表 6 CFRP筋-高强钢筋/高强混凝土柱抗震试验结果

Table 6. Experimental results of high-strength concrete columns with CFRP tendons and high-strength steels

Specimen Horizontal load Py/kN ∆y/mm Pm/kN ∆m/mm Pu/kN ∆u/mm θu μ S16-CFRP10/C80(N1) Push (+) 179.0 5.2 253.4 15.7 208.4 25.2 2.8% 4.8 Pull (−) 174.0 5.0 235.2 14.7 206.1 25.0 2.8% 5.0 Average 176.5 5.1 244.3 15.2 207.3 25.1 2.8% 4.9 S16-CFRP10/RPC(N1) Push (+) 221.0 6.3 280.4 18.4 227.7 25.2 2.8% 4.0 Pull (−) 196.0 6.3 262.7 18.6 211.5 25.2 2.8% 4.0 Average 208.5 6.3 271.6 18.5 219.6 25.2 2.8% 4.0 S16-CFRP10/HSC(N1) Push (+) 201.5 5.9 264.4 17.6 201.3 30.2 3.4% 5.1 Pull (−) 213.8 6.0 274.7 17.7 217.8 30.0 3.3% 5.0 Average 207.7 5.9 269.6 17.7 209.6 30.1 3.3% 5.1 S16-CFRP10/HSC*(N1) Push (+) 156.0 4.5 286.7 17.9 257.8 26.9 3.0% 6.0 Pull (−) 198.5 4.5 269.2 20.9 258.4 27.0 3.0% 6.0 Average 177.3 4.5 278.0 19.4 258.1 27.0 3.0% 6.0 S16-S16/C80(N2) Push (+) 256.0 5.6 335.6 14.3 289.3 27.5 3.1% 4.9 Pull (−) 226.0 5.6 330.3 15.5 269.4 27.2 3.0% 4.9 Average 241.0 5.6 333.0 14.9 279.4 27.4 3.0% 4.9 S16-CFRP10/C80(N2) Push (+) 250.0 7.5 335.7 14.0 232.6 24.0 2.7% 3.2 Pull (−) 245.0 7.9 330.3 16.3 213.3 23.9 2.7% 3.0 Average 247.5 7.7 333.0 15.2 222.9 24.0 2.7% 3.1 S16-CFRP10/C80*(N2) Push (+) 213.0 5.5 269.2 9.8 217.9 21.8 2.4% 4.0 Pull (−) 236.0 5.5 299.4 11.8 244.2 21.9 2.4% 4.0 Average 224.5 5.5 284.3 10.8 231.1 21.9 2.4% 4.0 S16-CFRP10/C80(N3) Push (+) 312.0 6.5 354.6 10.6 306.0 19.5 2.2% 3.0 Pull (−) 296.0 6.5 337.2 16.1 282.1 19.3 2.1% 3.0 Average 304.0 6.5 345.9 13.4 294.1 19.4 2.2% 3.0 Notes: Py—Yield load; ∆y—Yield displacement; Pm—Ultimate load; ∆m—Peak displacement; Pu—Failure load; ∆u—Ultimate displacement; μ—Displacement ductility coefficient; θu—Ultimate displacement angle. 表 7 CFRP筋-高强钢筋/高强混凝土柱的累计总耗能

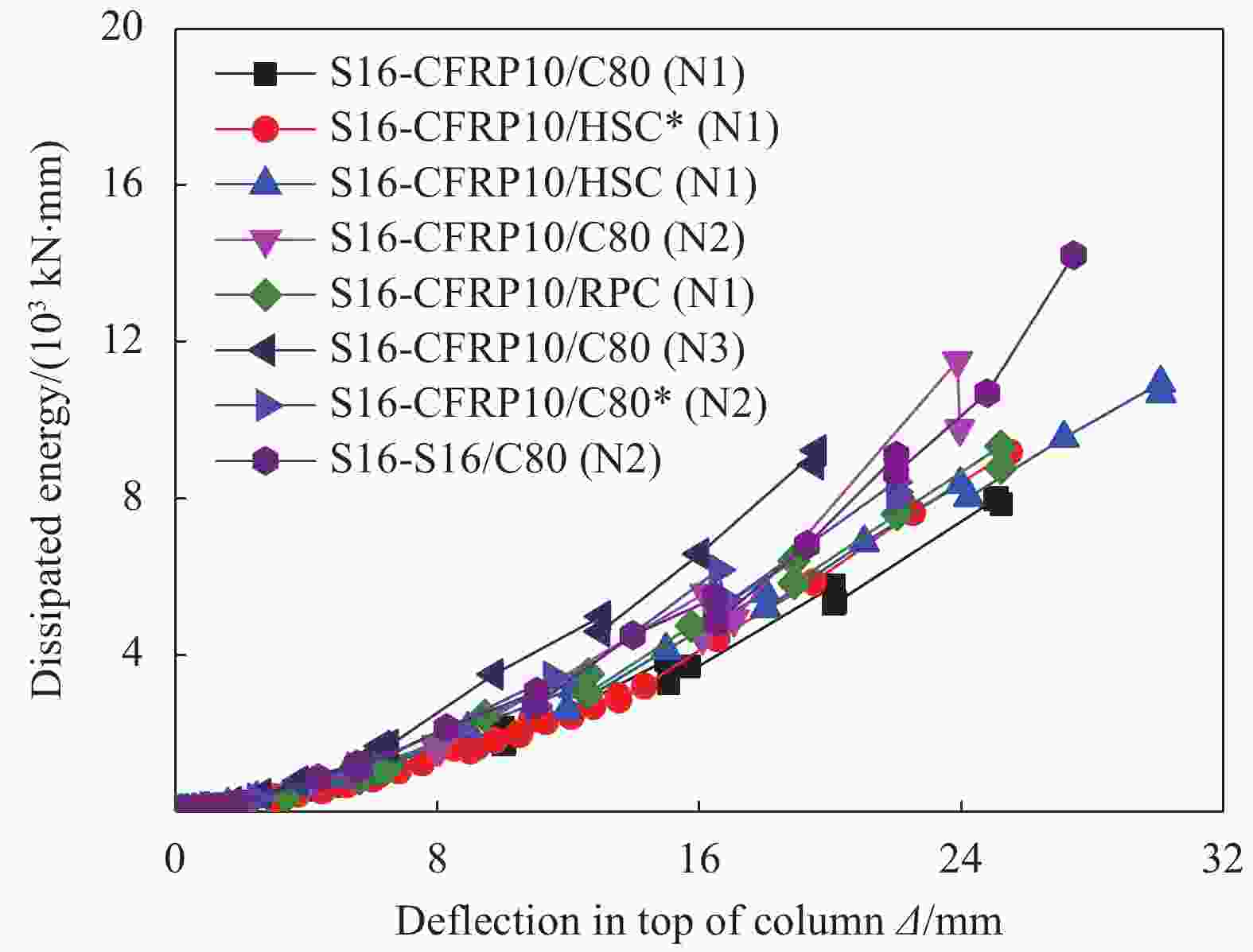

Table 7. Cumulative dissipated energy of high-strength concrete columns with CFRP tendons and high-strength steels

Specimen Energy consumption Eu/(kN·mm) S16-CFRP10/C80 (N1) 59818.3 S16-CFRP10/RPC (N1) 60610.1 S16-CFRP10/HSC (N1) 86706.2 S16-CFRP10/HSC* (N1) 70782.1 S16-CFRP10/HSC* (N1) 83191.8 S16-CFRP10/C80 (N2) 43239.3 S16-CFRP10/C80* (N2) 56671.0 S16-CFRP10/C80 (N3) 50335.2 表 8 CFRP筋-高强钢筋/高强混凝土柱有限元模型参数

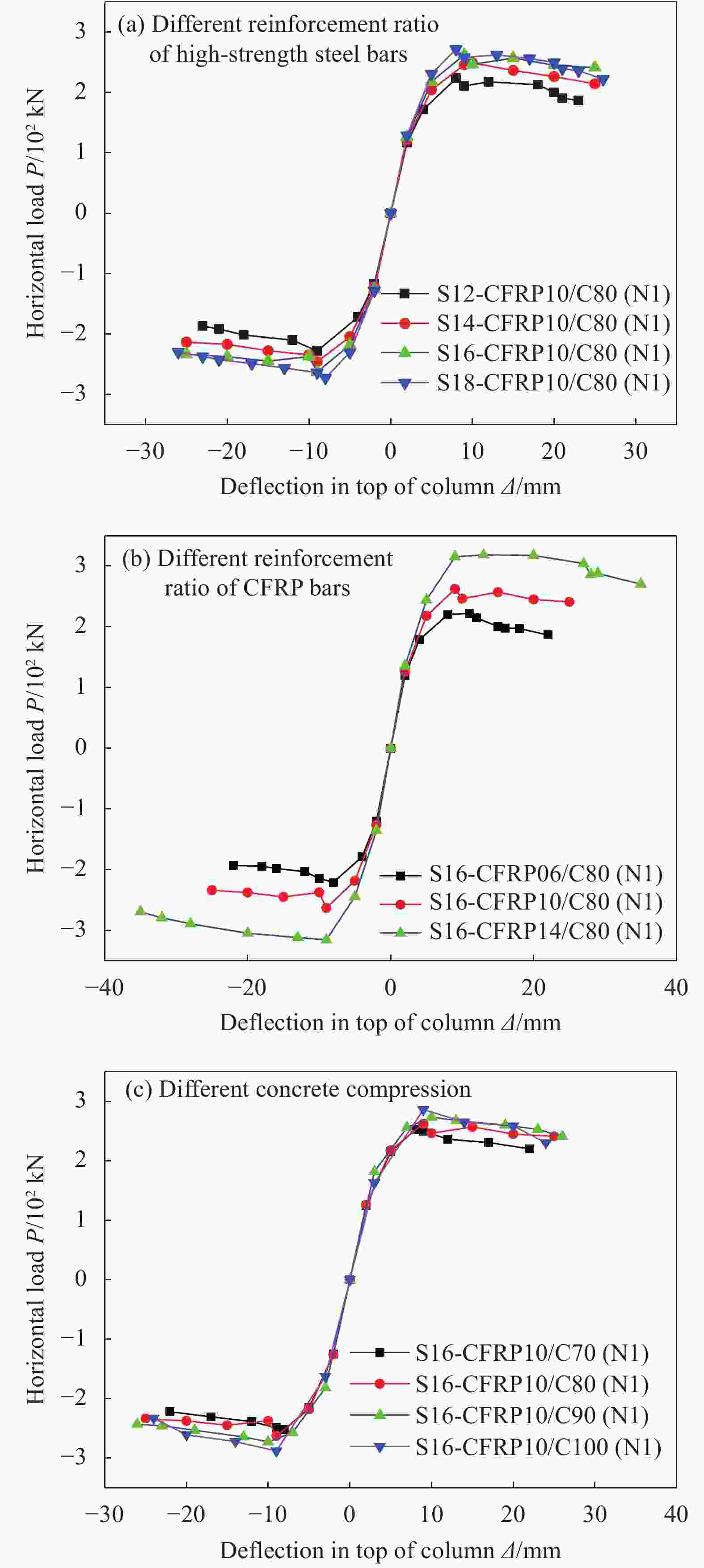

Table 8. FE model parametric analysis of high-strength concrete columns with CFRP tendons and high-strength steels

Specimen Longitudinal steel Concrete strength Nominal reinforcement ratio(%) S16-CFRP10/C80 (N1) 4

C80 1.79 S18-CFRP10/C80 (N1) 4

C80 2.02 S14-CFRP10/C80 (N1) 4

C80 1.58 S12-CFRP10/C80 (N1) 4

C80 1.39 S16-CFRP06/C80 (N1) 4

C80 1.29 S16-CFRP14/C80 (N1) 4

C80 2.48 S16-CFRP10/C70 (N1) 4

C70 1.79 S16-CFRP10/C90 (N1) 4

C90 1.79 S16-CFRP10/C100 (N1) 4

C100 1.79 -

[1] 吕西林, 陈云, 毛苑君. 结构抗震设计的新概念-可恢复功能结构[J]. 同济大学学报(自然科学版), 2011, 39(7):941-948. doi: 10.3969/j.issn.0253-374x.2011.07.001LV X L, CHEN Y, MAO Y J. New concept of structural seismic design: Earthquake resilient structures[J]. Journal of Tongji University (Nature Science),2011,39(7):941-948(in Chinese). doi: 10.3969/j.issn.0253-374x.2011.07.001 [2] SUN Z, WU G, ZHANG J, et al. Experimental study on concrete columns reinforced by hybrid steel-fiber reinforced polymer (FRP) bars under horizontal cyclic loading[J]. Construction and Building Materials,2016:S0950061816316051. [3] 关萍, 王清湘, 赵国藩. C80高强混凝土柱延性的试验研究[J]. 大连理工大学学报, 1998, 38(3):93-99.GUAN P, WANG Q X, ZHAO G F. Experimental study of C80 high strength concrete columns[J]. Journal of Dalian University of Technology,1998,38(3):93-99(in Chinese). [4] 刘文锋, 王来其, 高彦强, 等. 高强钢筋混凝土框抗震性能试验研究[J]. 土木工程学报, 2014, 47(11):64-74.LIU W F, WANG L Q, GAO Y Q, et al. Experimental study on seismic behavior of high-strength reinforced concrete frame[J]. China Civil Engineering Journal,2014,47(11):64-74(in Chinese). [5] 苏俊省, 王君杰, 王文彪, 等. 配置高强钢筋的混凝土矩形截面柱抗震性能试验研究[J]. 建筑结构学报, 2014, 35(11):20-27.SU J S, WANG J J, WANG W B, et al. Comparative experimental research on seismic performance of rectangular concrete columns reinforced with high strength steel[J]. Journal of Building Structures,2014,35(11):20-27(in Chinese). [6] 徐伟栋. 配置高强钢筋的混凝土柱抗震性能研究[D]. 上海: 同济大学, 2007.XU W D. Seismic behavior of concrete columns with high strength steel bars[D]. Shanghai: Tongji University, 2007(in Chinese). [7] 杜修力, 王作虎, 詹界东. 预应力FRP筋混凝土梁的抗震性能试验研究[J]. 土木工程学报, 2012, 45(2):43-50.DU X L, WANG Z H, ZHAN J D. Experimental studies on the Seismic performance of concrete beams prestressed with FRP tendons[J]. China Civil Engineering Journal,2012,45(2):43-50(in Chinese). [8] 叶列平, ASAD U Q, 马千里, 等. 高强钢筋对框架结构抗震破坏机制和性能控制的研究[J]. 工程抗震与加固改造, 2006, 28(1):18-24. doi: 10.3969/j.issn.1002-8412.2006.01.005YE L P, ASAD U Q, MA Q L, et al. Study on failure mechanism and seismic performance of passive control RC frame against earthquake[J]. Earthquake Resistant Engineering and Retrofitting,2006,28(1):18-24(in Chinese). doi: 10.3969/j.issn.1002-8412.2006.01.005 [9] 王作虎, 杜修力, 刘晶波. 预应力FRP筋混凝土梁在低周反复荷载下的恢复力模型[J]. 北京工业大学学报, 2012, 38(10):1509-1514.WANG Z H, DU X L, LIU J B. Hysteresis model of concrete beams prestressed with FRP tendons under low reversed cyclic loading[J]. Journal of Beijing University of Technology,2012,38(10):1509-1514(in Chinese). [10] ABDALLA H A. Evaluation of deflection in concrete members reinforced with fiber reinforced polymer (FRP) bars[J]. Composite Structures,2002,56(1):63-71. doi: 10.1016/S0263-8223(01)00188-X [11] JOHN N, AMIN G, GAMIL T. Concrete flexural members reinforced with fiber reinforced polymer: Design for cracking and deformability[J]. Canadian Journal of Civil Engineering,2002,29(1):125-134. doi: 10.1139/l01-085 [12] WEE T H, CHIN M S, MANSUR M A. Stress-strain relationship of high-strength concrete in compression[J]. Journal of Materials in Civil Engineering,1996,8(2):70-76. doi: 10.1061/(ASCE)0899-1561(1996)8:2(70) [13] 严少华, 钱七虎, 孙伟, 等. 钢纤维高强混凝土单轴压缩下应力应变关系[J]. 东南大学学报(自然科学版), 2001, 31(2):77-80. doi: 10.3321/j.issn:1001-0505.2001.02.019YAN S H, QIAN Q H, SUN W, et al. Stress-strain relationship of high-strength steel fiber reinforced concrete in compression[J]. Journal of Southeast University (Natural Science Edition),2001,31(2):77-80(in Chinese). doi: 10.3321/j.issn:1001-0505.2001.02.019 [14] 王勇威, 蒲心诚, 王志军. 单轴压力下56.3-164.9 MPa混凝土的应力-应变关系[J]. 建筑结构学报, 2005, 26(1):97-102. doi: 10.3321/j.issn:1000-6869.2005.01.015WANG Y W, PU X C, WANG Z J. Stress-strain response of concrete with different cubic compressive strength (56.3-164.9 MPa) under uniaxial compression[J]. Journal of Building Structures,2005,26(1):97-102(in Chinese). doi: 10.3321/j.issn:1000-6869.2005.01.015 [15] 王志军, 蒲心诚. 超高强混凝土单轴受压性能及应力应变曲线的试验研究[J]. 重庆建筑大学学报, 2000, 22(S1):27-33.WANG Z J, PU X C. Experimental study on uniaxial compression properties and the stress-strain curves of UHS & HPC[J]. Journal of Chongqing Jianzhu University,2000,22(S1):27-33(in Chinese). [16] 吕西林, 张颖, 年学成. 钢纤维高强混凝土在单调和重复荷载作用下轴压应力-应变曲线试验研究[J]. 建筑结构学报, 2017, 38(1):135-143.LV X L, ZHANG Y, NIAN X C. Experimental study on stress-strain curves for high-strength steel fiber reinforced concrete under monotonic and repeated compressive loadings[J]. Journal of Building Structures,2017,38(1):135-143(in Chinese). [17] 徐可, 陆春华, 宣广宇, 等. 混合配筋钢纤维增强混凝土梁受弯承载力试验及理论计算[J]. 复合材料学报, 2020, 37(9):2348-2357.XU K, LU C H, XUAN G Y, et al. Experimental and theoretical calculation on the flexural capacity of steel fiber reinforced concrete beams with hybrid reinforcing bars[J]. Acta Materiae Compositae Sinica,2020,37(9):2348-2357(in Chinese). [18] 谷倩, 董格, GETAHUNE B K, 等. 喷射FRP加固震损钢筋混凝土柱抗震性能试验[J]. 复合材料学报, 2016, 33(9):1009-1019.GU Q, DONG G, GETAHUNE B K, et al. Test of seismic performance of earthquake damaged reinforced concrete columns strengthened with sprayed FRP[J]. Acta Materiae Compositae Sinica,2016,33(9):1009-1019(in Chinese). [19] 中华人民共和国住房和城乡建设部. 混凝土结构结构设计规范: GB50367—2013[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for design of strengthening concrete structure: GB50367—2013[S]. Beijing: China Construction Industry Press, 2010(in Chinese). [20] MANDER J B, PRIESTLEY M J N, PARK R. Theoretical stress-strain model for confined concrete[J]. Journal of Structural Engineering,1988,114(8):1804-1826. doi: 10.1061/(ASCE)0733-9445(1988)114:8(1804) -

下载:

下载: