Impregnation characteristics of carbon fiber composite during ultrasonic vibration assisted RTM process

-

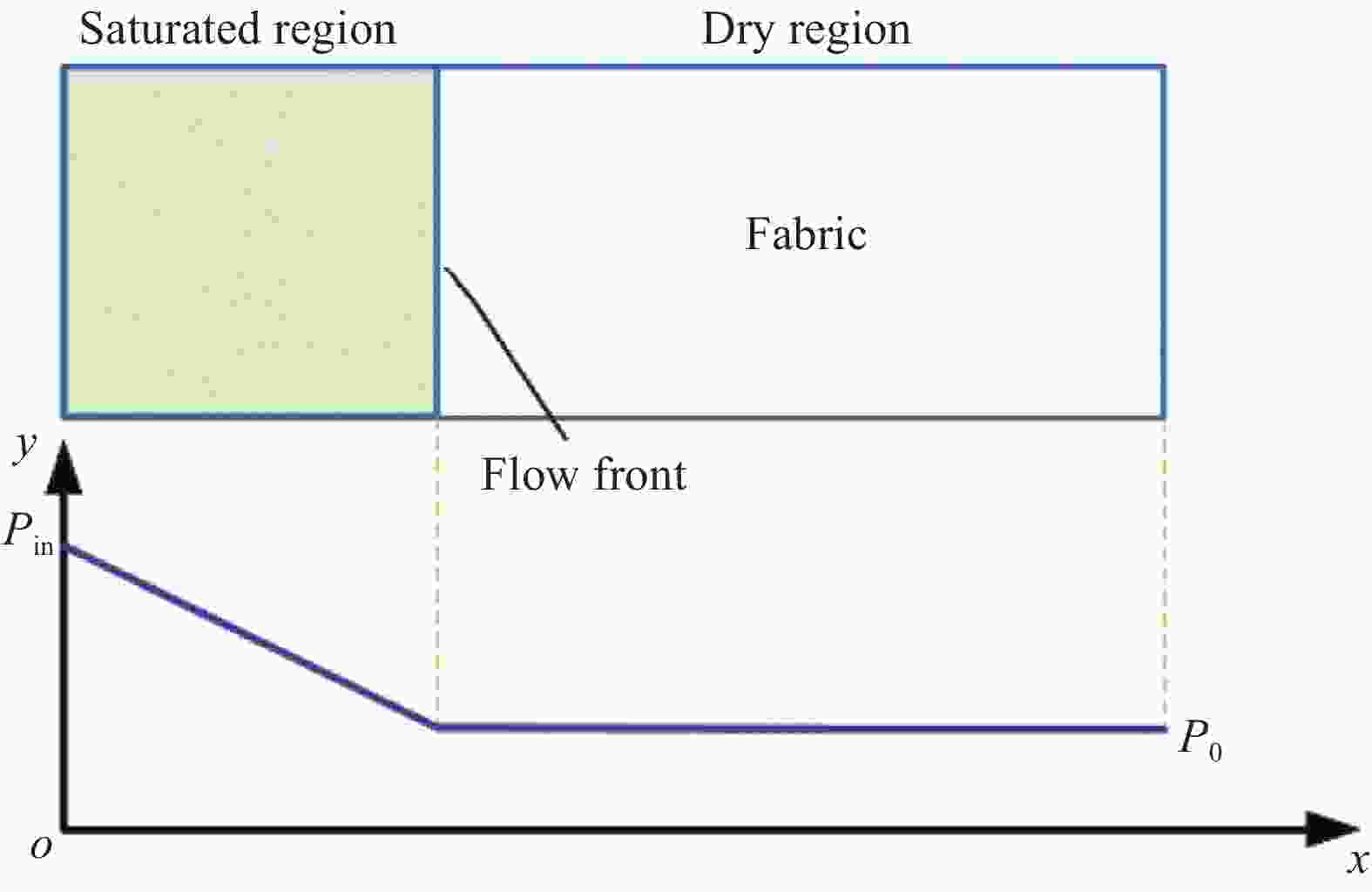

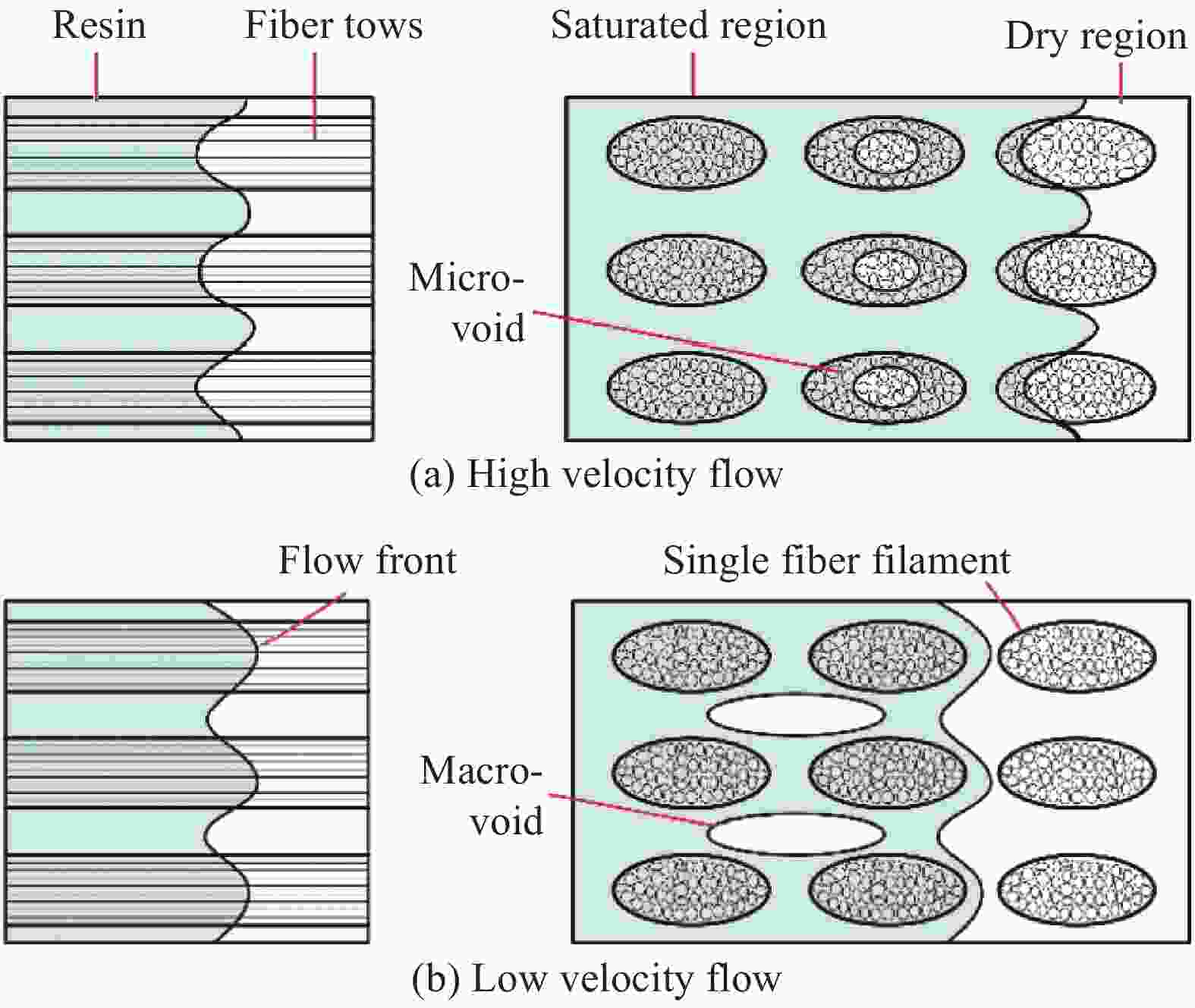

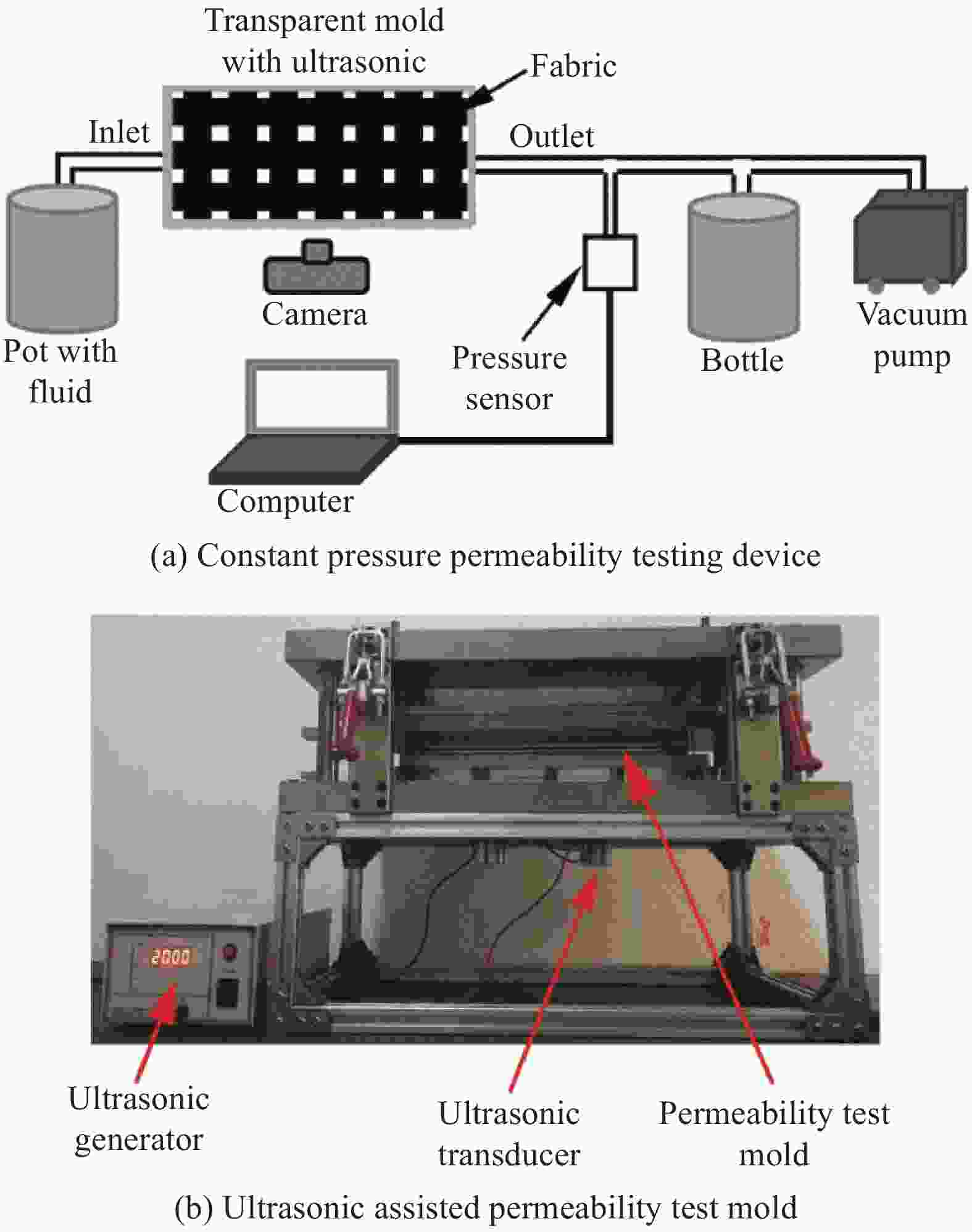

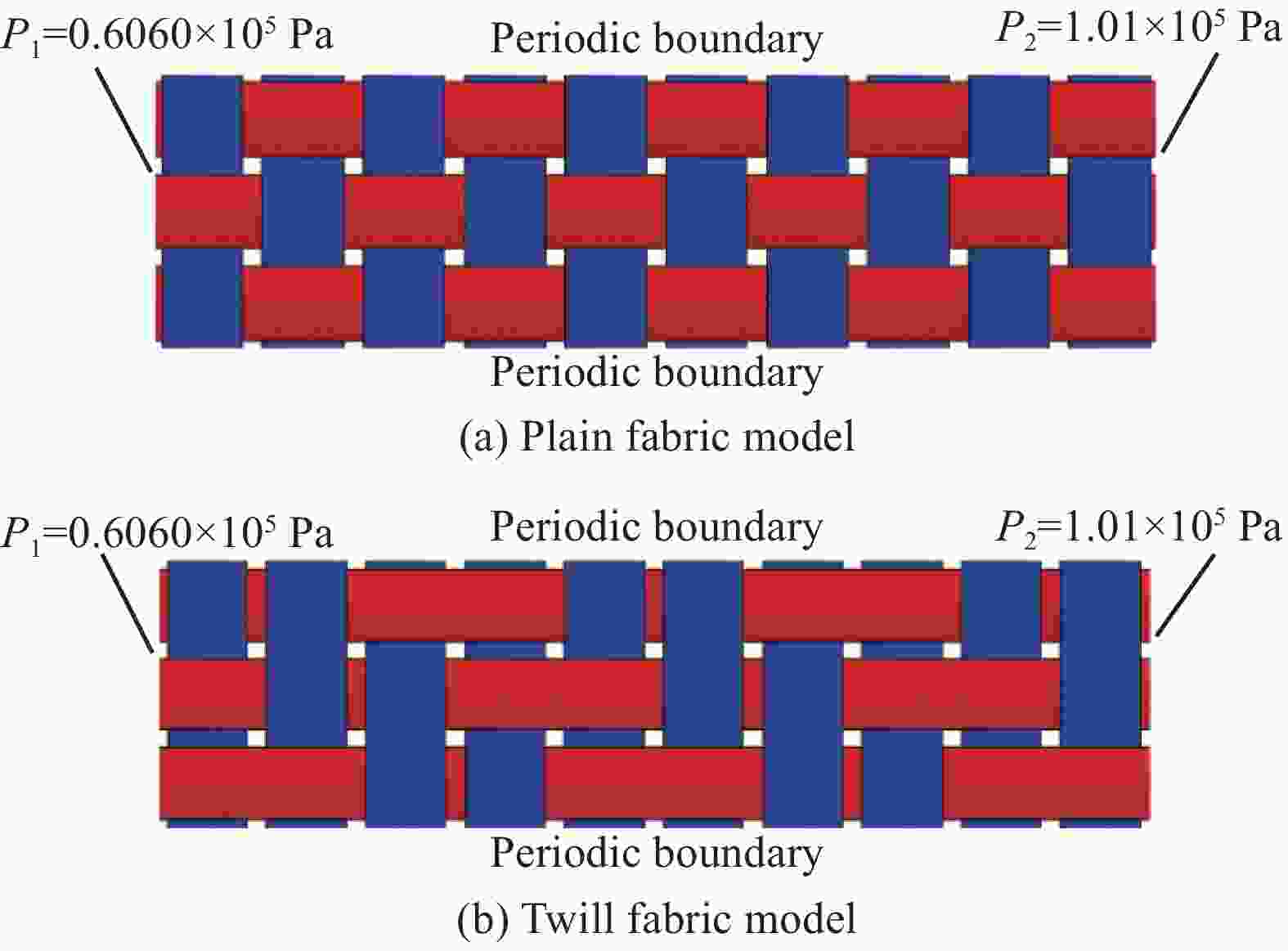

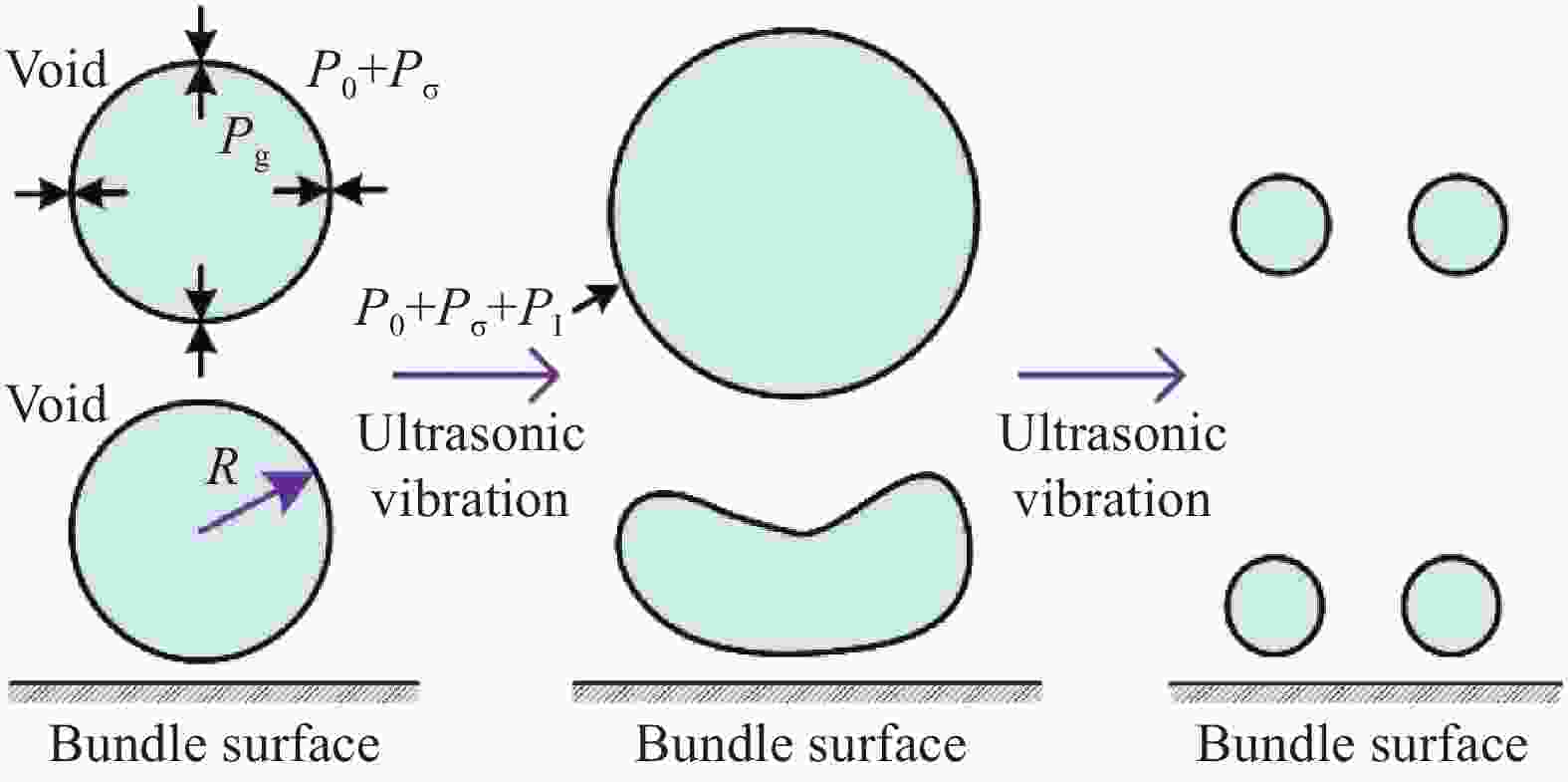

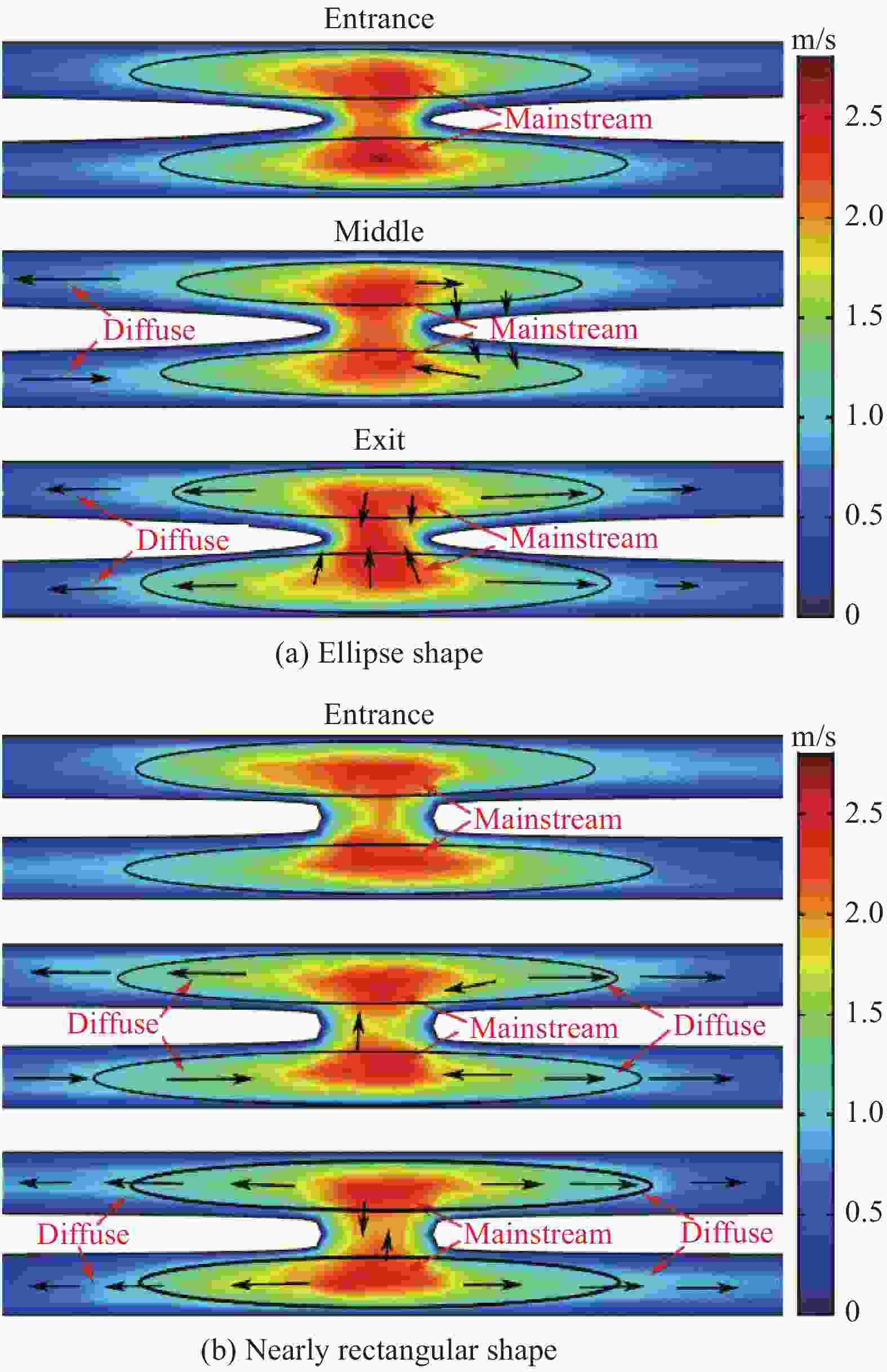

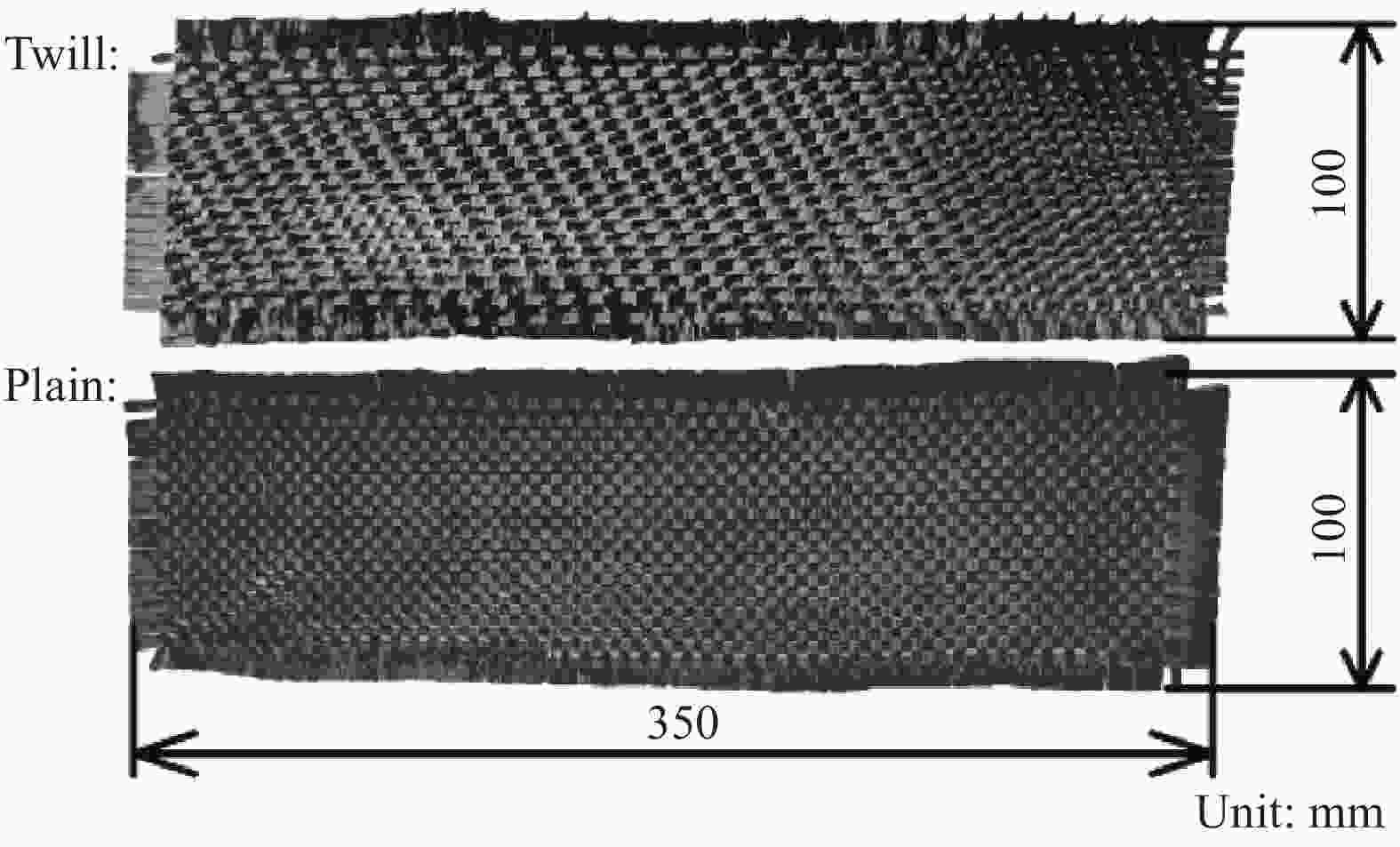

摘要: 研究了织物类型、纤维体积分数和超声振动对树脂在碳纤维织物中流动特性的影响规律,设计了超声振动辅助RTM工艺过程中单向渗透率测量装置,开展了16组渗透率测试实验,并结合COMSOL软件仿真分析了织物中的树脂流动特性。研究表明,在相同纤维体积分数水平下,斜纹编织物的纤维束间隙通道比平纹织物的更宽,2/2斜纹编织织物渗透率比平纹织物提高了约21.5%。纤维体积分数与织物渗透率呈负相关,其函数关系与半经验公式Kozeny-Carman(KC)方程吻合较好。树脂流动过程中加入超声振动,其超声空化效应、加速度效应和微射流效应作用于纤维丝束表面,提高了织物渗透率约58.2%。有限元仿真模拟了椭圆形和近矩形纤维束截面设计的织物模型的流动过程,结果发现近矩形纤维束截面高流速区域范围更广,流体向纤维布夹层浸渍的速度分量更大。超声作用于织物纤维可能带动纤维丝束蠕动,使纤维束截面趋于近矩形状,从而提高了树脂对纤维织物的浸润性。上述研究结果对优化碳纤维复合材料成型工艺和成型性能具有一定的指导意义。Abstract: The flow characteristics of carbon fiber fabric was studied under different forming conditions, including fabric type, fiber volume fraction and ultrasonic vibration. The unidirectional permeability measurement device of ultrasonic vibration assisted RTM was newly designed. Permeability testing experiment including 16 trials was carried out, and the resin flow characteristics in the fabric were analyzed using COMSOL simulation. Results show that with the same fiber volume fraction, the fiber bundle gap channel of 2/2 twill weave fabric is wider than that of plain weave fabric, and the permeability of twill weave fabric is averagely 21.5% higher than result from plain weave fabric. The fiber volume fraction is negatively correlated with fabric permeability, and the functional relationship is in good agreement with the semi-empirical Kozeny-Carman (K-C) equation. The ultrasonic vibration is introduced into the resin flow process, and the ultrasonic cavitation effect, acceleration effect and micro-jet effect acted on the surface of fiber bundle, which significantly improves the permeability of fiber fabric about 58.2%. The flow process of fabric model, which is designed with elliptic and nearly rectangular fiber bundle section, was simulated by finite element model, and results show that the high velocity area of near rectangular fiber bundle section is relatively wider, and the velocity component of fluid impregnation to the interlayer of fiber cloth is larger. Ultrasonic acting on the fabric fibers probably drives the fiber bundle peristalsis, making the fiber bundle cross section tend to be nearly rectangular, subsequently improving the resin infiltration of the fiber fabric. Experimental results from this work have certain guiding significance to optimize the forming process of composites.

-

Key words:

- flow characteristic /

- fabric type /

- resin impregnation /

- ultrasonic vibration /

- permeability

-

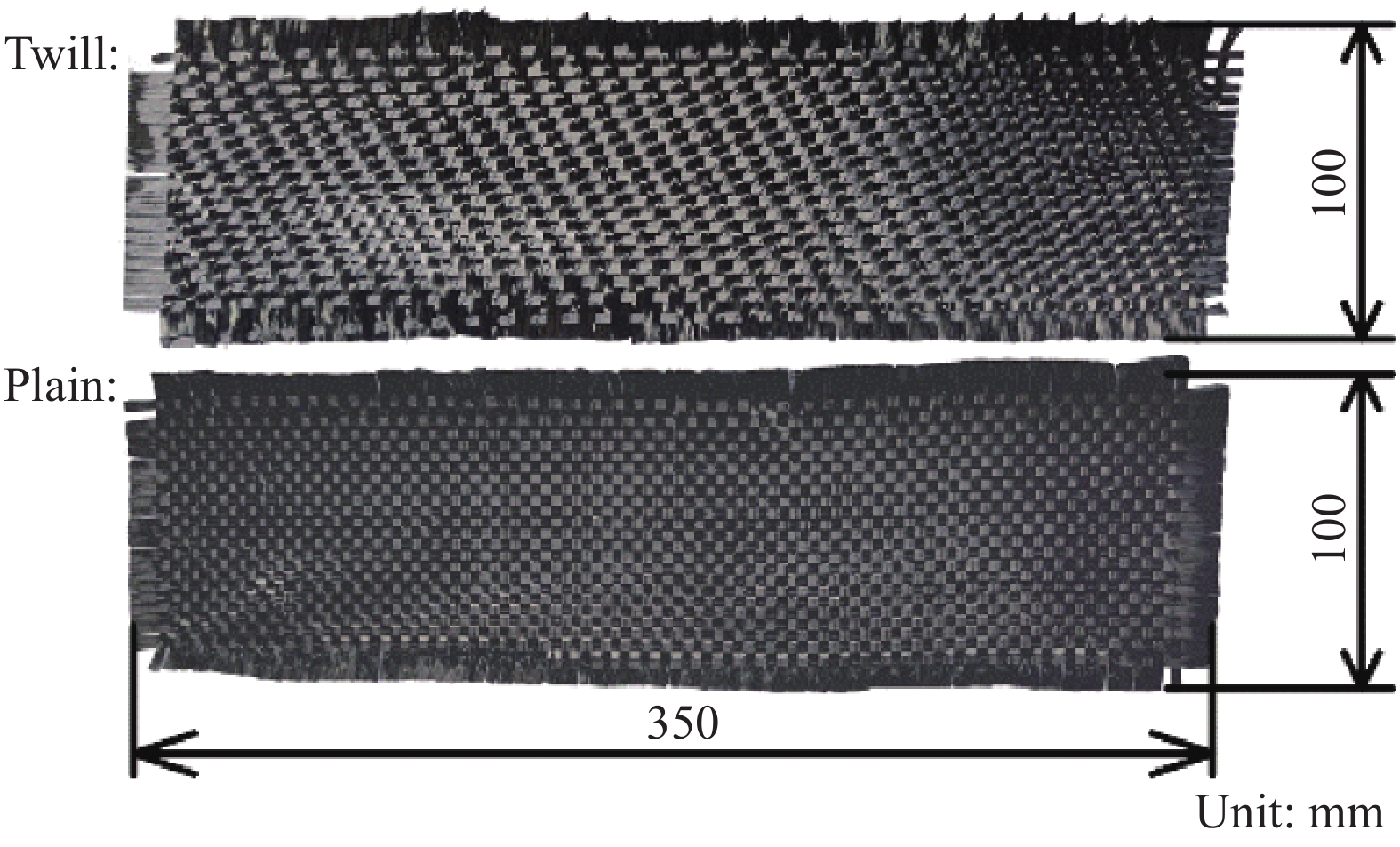

表 1 碳纤维布的主要参数

Table 1. Main parameters of carbon fiber fabric

ρs/(g·m−2) ft/K rf/μm h/mm 480 12 3.4 0.52 Notes: ρs—Area density; ft—Fiber tow type; rf —Radius of a single fiber filament; h—Thickness of fabric. 表 2 实验设计组及详细参数

Table 2. Experimental design group and detailed parameters

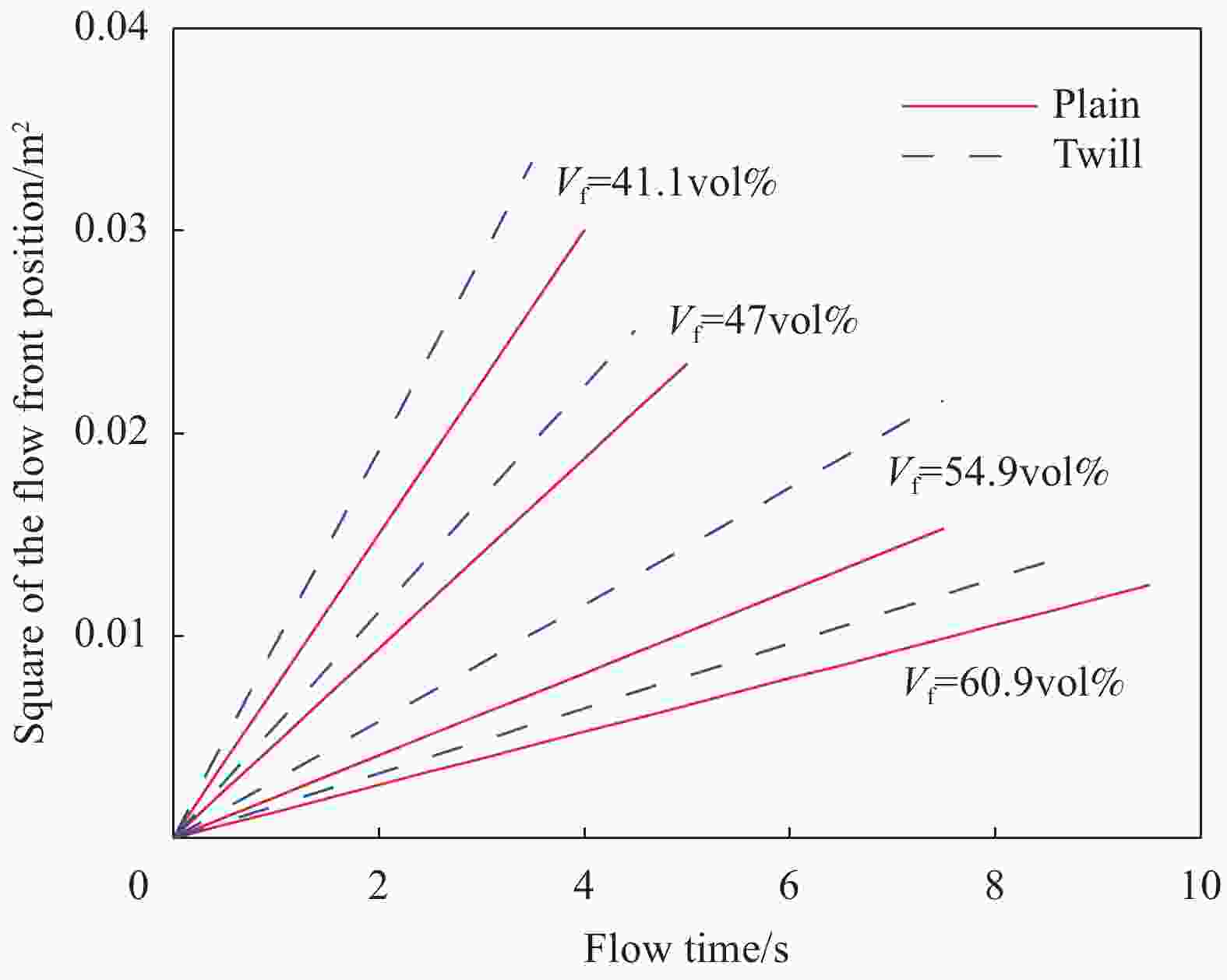

Parameter Level Fabric type Plain Twill Ultrasonic vibration Yes No Fiber volume fraction/vol% 41.1, 47.0, 54.9, 60.9 表 3 编织物不同纤维体积分数下的平方流动前沿(SFF)曲率

Table 3. Squared flow front (SFF) curvature of fabrics with different fiber volume fractions

Vf/vol% splain stwill rg/% 41.1 0.00751 0.00957 21.53 47.0 0.00469 0.00558 15.95 54.9 0.00204 0.00294 30.61 60.9 0.00132 0.00161 18.01 Notes: Vf—Fiber volume fraction; splain—Slope of plain fabric; stwill—Slope of twill fabric; rg—Relative growth rate of twill fabrics relative to plain weave fabrics. 表 4 拟合参数a的数值计算结果

Table 4. Numerical results of the fitting parameter a

Plain Ultrasound-plain Twill Ultrasound-twill a 0.8356 1.3305 1.0535 1.6749 R2 0.9956 0.9956 0.9972 0.9963 -

[1] MATSUZAKI R, KOBAYASHI S, TODOROKI A, et al. Full-field monitoring of resin flow using an area-sensor array in a VARTM process[J]. Composites Part A: Applied Science and Manufacturing,2011,42(5):550-559. doi: 10.1016/j.compositesa.2011.01.014 [2] BODAGHI M, LOMOV S V, SIMACEK P, et al. On the variability of permeability induced by reinforcement distortions and dual scale flow in liquid composite moulding: A review[J]. Composites Part A: Applied Science and Manufacturing,2019,120:188-210. doi: 10.1016/j.compositesa.2019.03.004 [3] BODAGHI M, CRISTÓVÃO C, GOMES R, et al. Experimental characterization of voids in high fibre volume fraction composites processed by high injection pressure RTM[J]. Composites Part A: Applied Science and Manufacturing,2016,82:88-99. doi: 10.1016/j.compositesa.2015.11.042 [4] PUCCI M F, LIOTIER P J, DRAPIER S. Capillary wicking in a fibrous reinforcement-Orthotropic issues to determine the capillary pressure components[J]. Composites Part A: Applied Science and Manufacturing,2015,77:133-141. doi: 10.1016/j.compositesa.2015.05.031 [5] NABOVATI A, LLEWELLIN E W, SOUSA A C M. A general model for the permeability of fibrous porous media based on fluid flow simulations using the lattice Boltzmann method[J]. Composites Part A: Applied Science and Manufacturing,2009,40(6):860-869. [6] GERVAIS P C, BARDIN-MONNIER N, THOMAS D. Permeability modeling of fibrous media with bimodal fiber size distribution[J]. Chemical Engineering Science,2012,73:239-248. doi: 10.1016/j.ces.2012.01.040 [7] WOUDBERG S. Permeability prediction of an analytical pore-scale model for layered and isotropic fibrous porous media[J]. Chemical Engineering Science,2017,164:232-245. doi: 10.1016/j.ces.2017.01.061 [8] POTLURI P, SAGAR T V. Compaction modelling of textile preforms for composite structures[J]. Composite Structures,2008,86(1):177-185. [9] HAN S H, CHO E J, LEE H C, et al. Study on high-speed RTM to reduce the impregnation time of carbon/epoxy composites[J]. Composite Structures,2015,119:50-58. doi: 10.1016/j.compstruct.2014.08.023 [10] AMERI E, LEBRUN G, LAPERRIÈRE L. In-plane permeability characterization of a unidirectional flax/paper reinforcement for liquid composite molding processes[J]. Composites Part A: Applied Science and Manufacturing,2016,85:52-64. doi: 10.1016/j.compositesa.2016.03.002 [11] PEARCE N R L, SUMMERSCALES J, GUILD F J. Improving the resin transfer moulding process for fabric-reinforced composites by modification of the fabric architecture[J]. Composites Part A: Applied Science and Manufacturing,2000,31(12):1433-1441. doi: 10.1016/S1359-835X(00)00140-8 [12] RIEBER G, JIANG J, DETER C, et al. Influence of textile parameters on the in-plane permeability[J]. Composites Part A: Applied Science and Manufacturing,2013,52:89-98. doi: 10.1016/j.compositesa.2013.05.009 [13] MARTIN B, COMAS-CARDONA S, BINETRUY C, et al. Influence of fabrics’ design parameters on the morphology and 3D permeability tensor of quasi-unidirectional non-crimp fabrics[J]. Composites Part A: Applied Science and Manufacturing,2016,90:470-479. doi: 10.1016/j.compositesa.2016.08.013 [14] SYERKO E, BINETRUY C, COMAS-CARDONA S, et al. A numerical approach to design dual-scale porosity composite reinforcements with enhanced permeability[J]. Materials & Design,2017,131:307-322. [15] GODBOLE M G, PURANDARE R, HARSHE R, et al. Influence of filament distribution on transverse tow permeability: Model predictions and experimental validation[J]. Composites Part A: Applied Science and Manufacturing,2019,118:150-161. doi: 10.1016/j.compositesa.2018.12.024 [16] BODAGHI M, VANAERSCHOT A, LOMOV S V, et al. On the variability of mesoscale permeability of a 2/2 twill carbon fabric induced by variability of the internal geometry[J]. Composites Part A: Applied Science and Manufacturing,2017,101:394-407. doi: 10.1016/j.compositesa.2017.05.030 [17] BODAGHI M, VANAERSCHOT A V, LOMOV S, et al. On the stochastic variations of intra-tow permeability induced by internal geometry variability in a 2/2 twill carbon fabric[J]. Composites Part A: Applied Science and Manufacturing,2017,101:444-458. doi: 10.1016/j.compositesa.2017.07.008 [18] ENDRUWEIT A, ZENG X, MATVEEV M, et al. Effect of yarn cross-sectional shape on resin flow through inter-yarn gaps in textile reinforcements[J]. Composites Part A: Applied Science and Manufacturing,2018,104:139-150. doi: 10.1016/j.compositesa.2017.10.020 [19] 刘丽, 张志谦, 黄玉东, 等. 超声作用对芳纶/环氧浸润行为的影响[J]. 材料科学与工艺, 2002, 10(1):69-72.LIU Li, ZHANG Zhiqian, HUANG Yudong, et al. Effect of ultrasound on wetting behavior between aramid fiber and epoxy resin[J]. Materials Science & Technology,2002,10(1):69-72(in Chinese). [20] 刘丽, 张翔, 黄玉东, 等. 超声作用对芳纶纤维表面性质的影响[J]. 复合材料学报, 2003, 20(2):35-40.LIU Li, ZHANG Xiang, HUANG Yudong, et al. Effect of ultrasonic treatment on surface characteristics of aramid[J]. Acta Materiae Compositae Sinica,2003,20(2):35-40(in Chinese). [21] 姜开宇, 李豪, 左军超, 等. 超声振动对玻纤增强聚丙烯复合材料注射成型特性的影响[J]. 复合材料学报, 2015, 32(5):1330-1340.JIANG Kaiyu, LI Hao, ZUO Junchao, et al. Effects of ultrasonic vibration on injection molding characteristics of glass fiber reinforced polypropylene composites[J]. Acta Materiae Compositae Sinica,2015,32(5):1330-1340(in Chinese). [22] SALVATORI D, CAGLAR B, TEIXIDÓ H, et al. Permeability and capillary effects in a channel-wise non-crimp fabric[J]. Composites Part A: Applied Science and Manufacturing,2018,108:41-52. doi: 10.1016/j.compositesa.2018.02.015 [23] ZHANG D, JIANG E, ZHOU J, et al. Investigation on enhanced mechanism of heat transfer assisted by ultrasonic vibration[J]. International Communications in Heat and Mass Transfer,2020,115:104523. [24] 吉智. 超声辅助注射成型充模流动特性的可视化研究[D]. 大连: 大连理工大学, 2014.JI Zhi. Visualization research on polymer filling flow characteristics of ultrasonic assisted injection molding[D]. Dalian: Dalian University of Technology, 2014(in Chinese). -

下载:

下载: