Preparation and properties of the electrospun dodecanol dodecanoate@polyvinyl alcohol thermo-regulated fibers

-

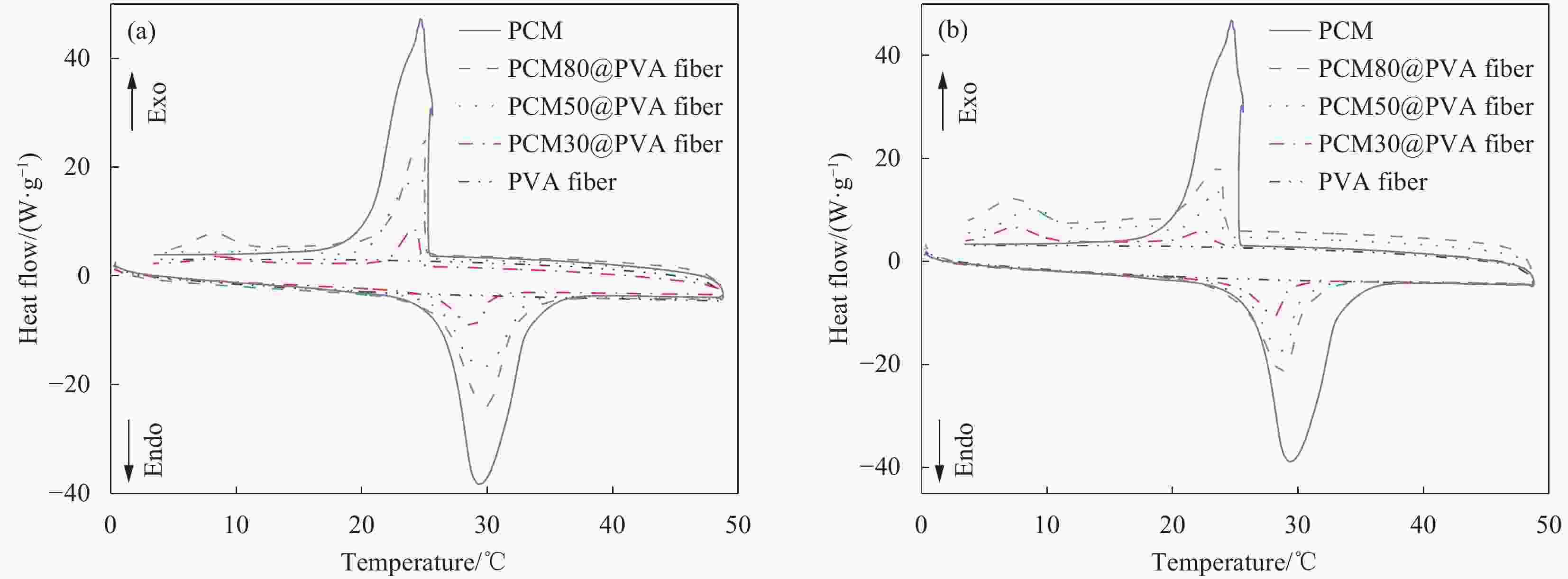

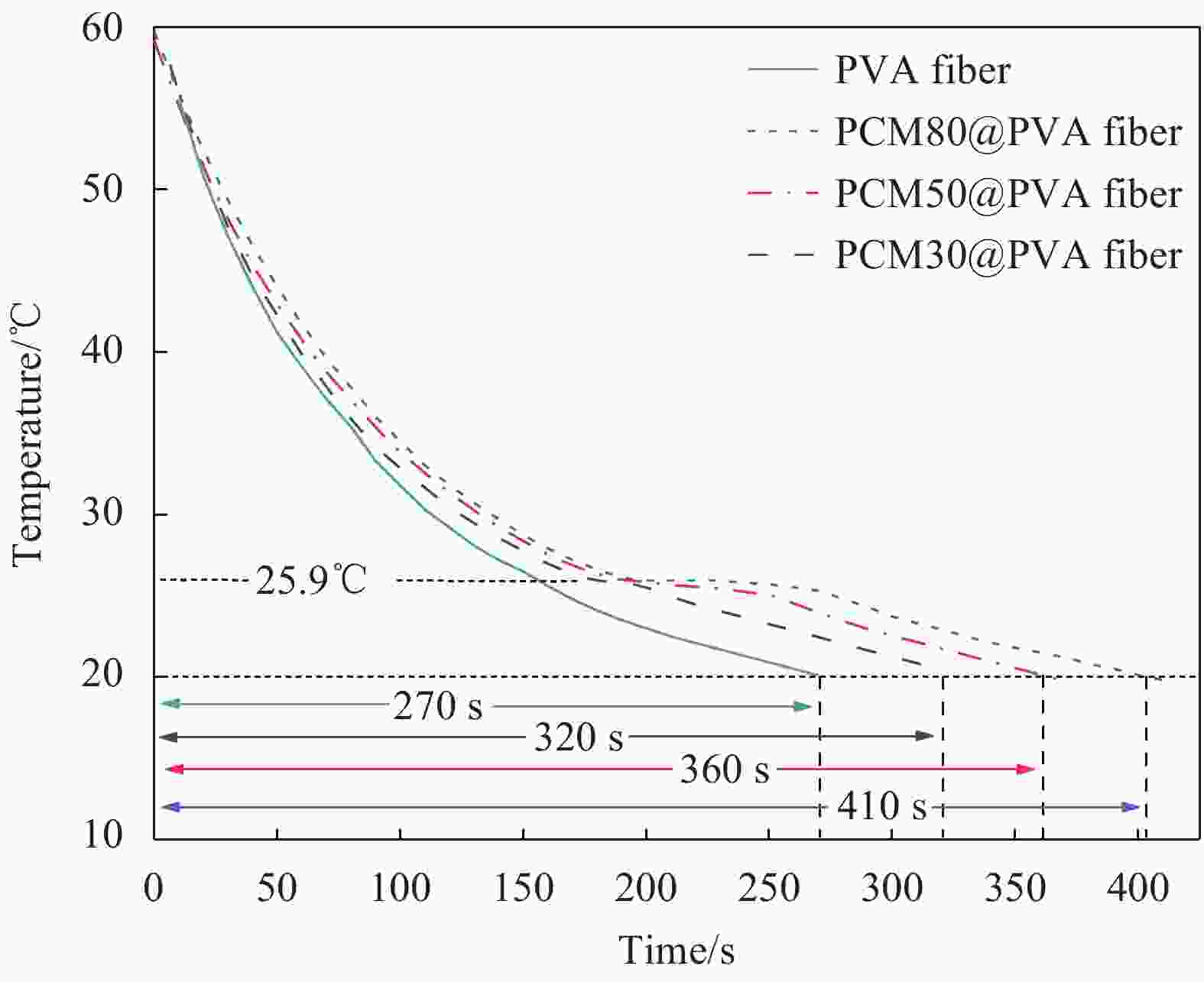

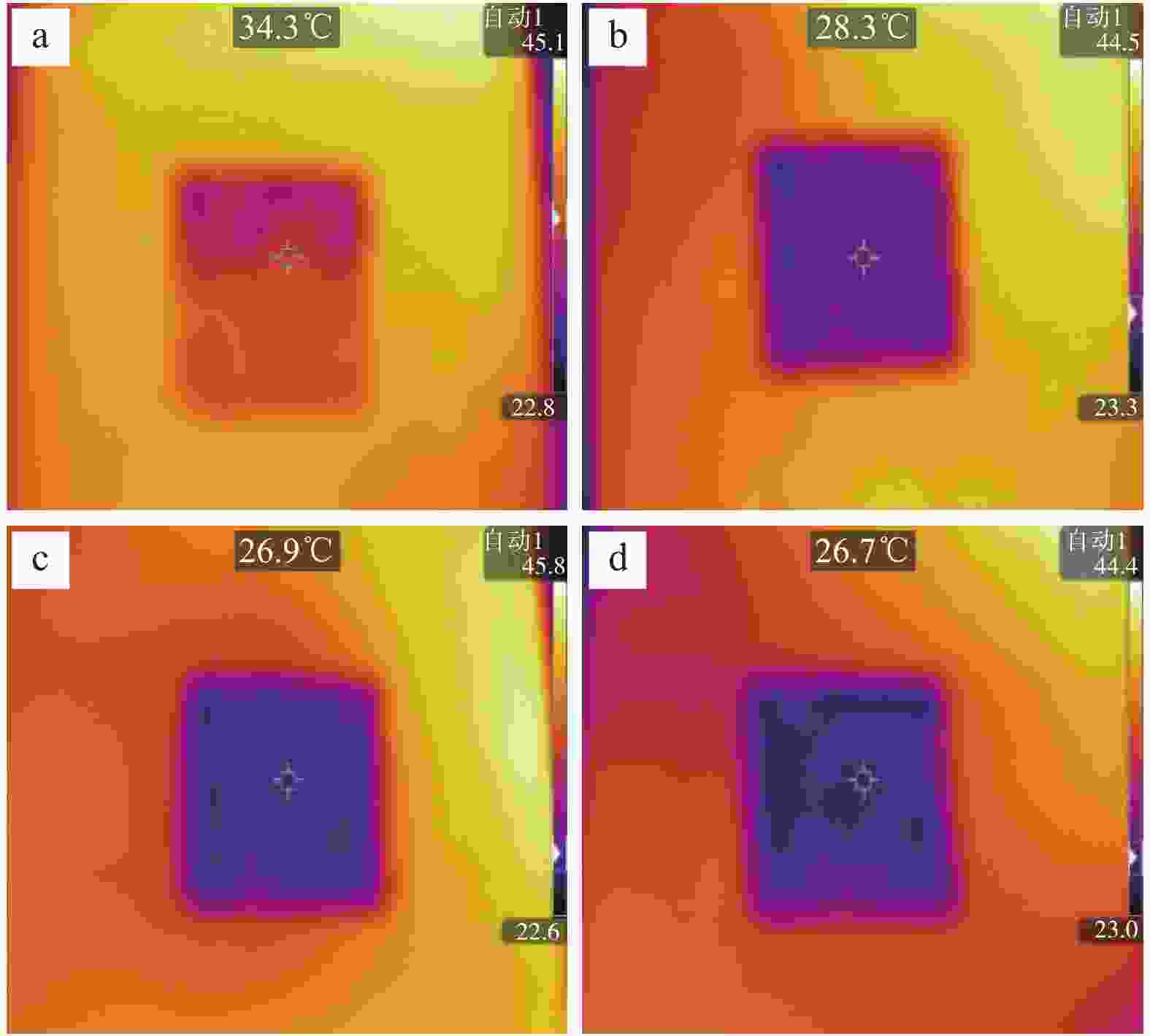

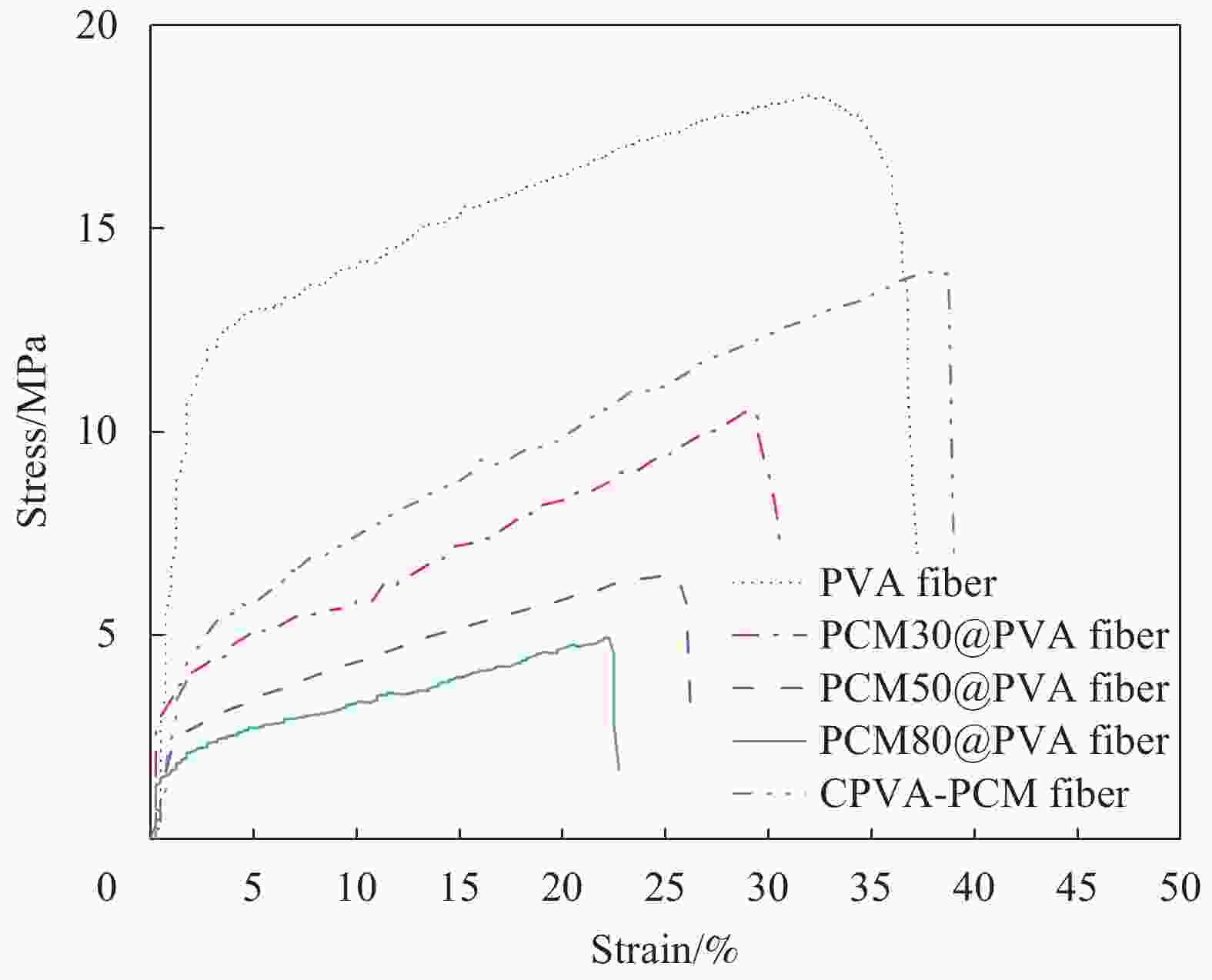

摘要: 以十二酸十二酯作为相变材料(PCM),以聚乙烯醇(PVA)作为支撑材料,通过乳液静电纺丝技术制备十二酸十二酯@PVA蓄热调温纤维。应用SEM、TEM、DSC、TGA、迷你温度记录仪和红外热成像仪等研究了纺丝液组成及静电纺纤维的表面形貌、潜热值、热稳定性、调温性能、力学性能和水溶性。结果表明,当PVA浓度为10.0wt%、十二酸十二酯∶PVA质量比为50%时,纺丝液具有较好的稳定性和可纺性。十二酸十二酯@PVA静电纺纤维具有明显的芯-鞘结构,纤维中PCM的热分解温度比纯PCM提高了20℃,具有良好的热稳定性。十二酸十二酯@PVA静电纺纤维的潜热值在63 J/g左右,在降温冷却和热红外成像测试中,显示出良好的蓄热调温性能。经戊二醛交联后,静电纺纤维中支撑材料的热稳定性显著增强,而且,纤维的力学性能和水溶解性得到明显改善。Abstract: With dodecanol dodecanoate as the phase change material (PCM) and polyvinyl alcohol (PVA) as the supporting material, the dodecanol dodecanoate@PVA thermo-regulated fibers were prepared by emulsion electrospinning technology. The SEM, TEM, DSC, TGA, mini temperature recorder and infrared thermal imager were applied to study the composition of the spinning solution and the surface morphology, latent heat value, thermal stability, temperature regulating properties, mechanical property and water solubility of the electrospun fibers. The results show that with 10.0wt% of PVA and dodecanol dodecanoate∶PVA mass ratio of 50%, the spinning solution has better stability and spinnability. The dodecanol dodecanoate@PVA electrospun fibers have apparent core-sheath structure, and the thermal decomposition temperature of PCM in the fibers is 20℃ higher than the pure PCM, displaying good thermal stability. The latent heat value of dodecanol dodecanoate@PVA electrospun fibers is about 63 J/g, showing good heat storage and temperature regulation performance in cooling process and thermal infrared imaging test. After the crosslinking with glutaraldehyde, the thermal stability of the support material in the electrospun fibers is significantly enhanced, and the mechanical properties and water solubility of the fibers have notable improvement.

-

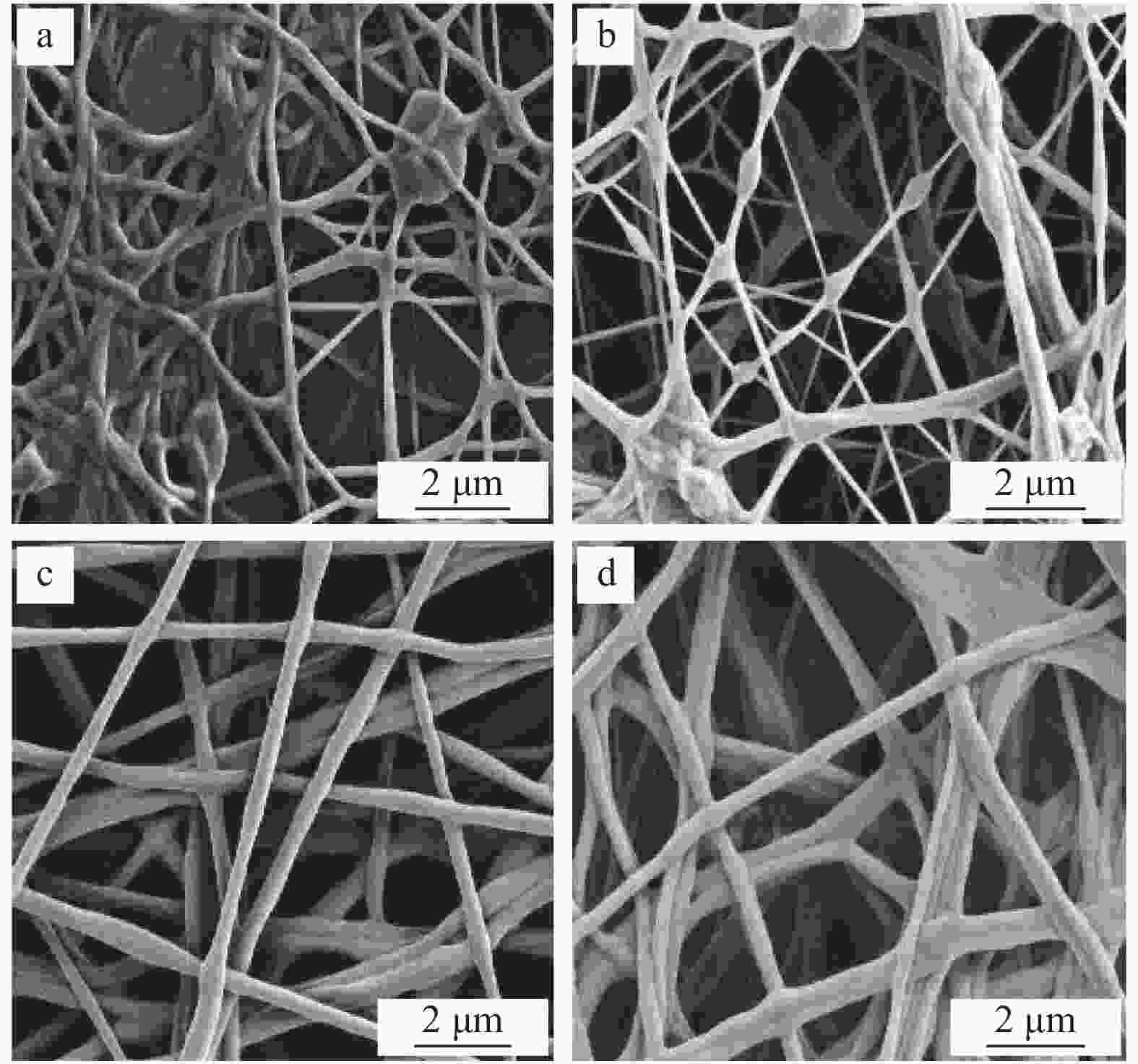

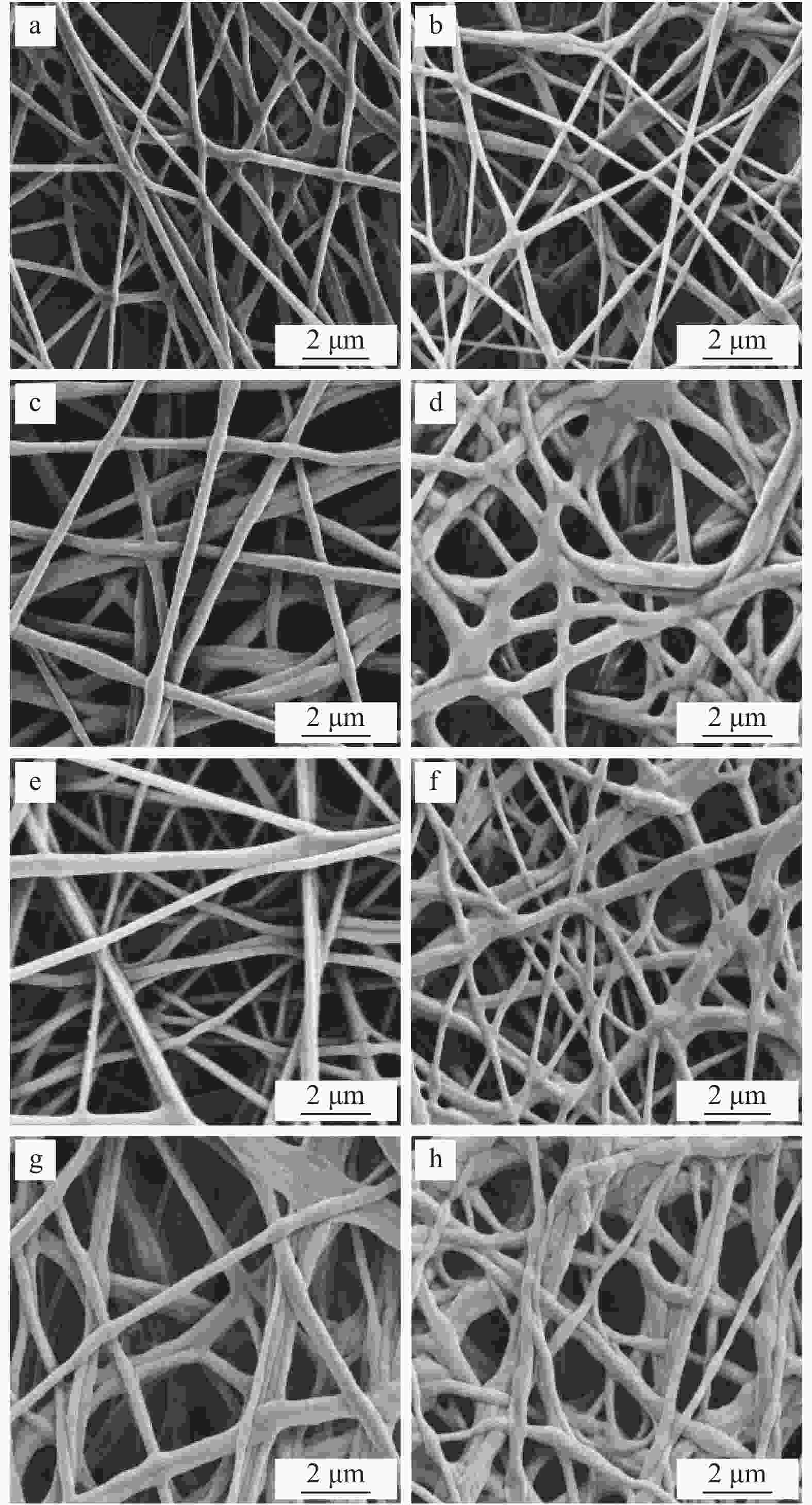

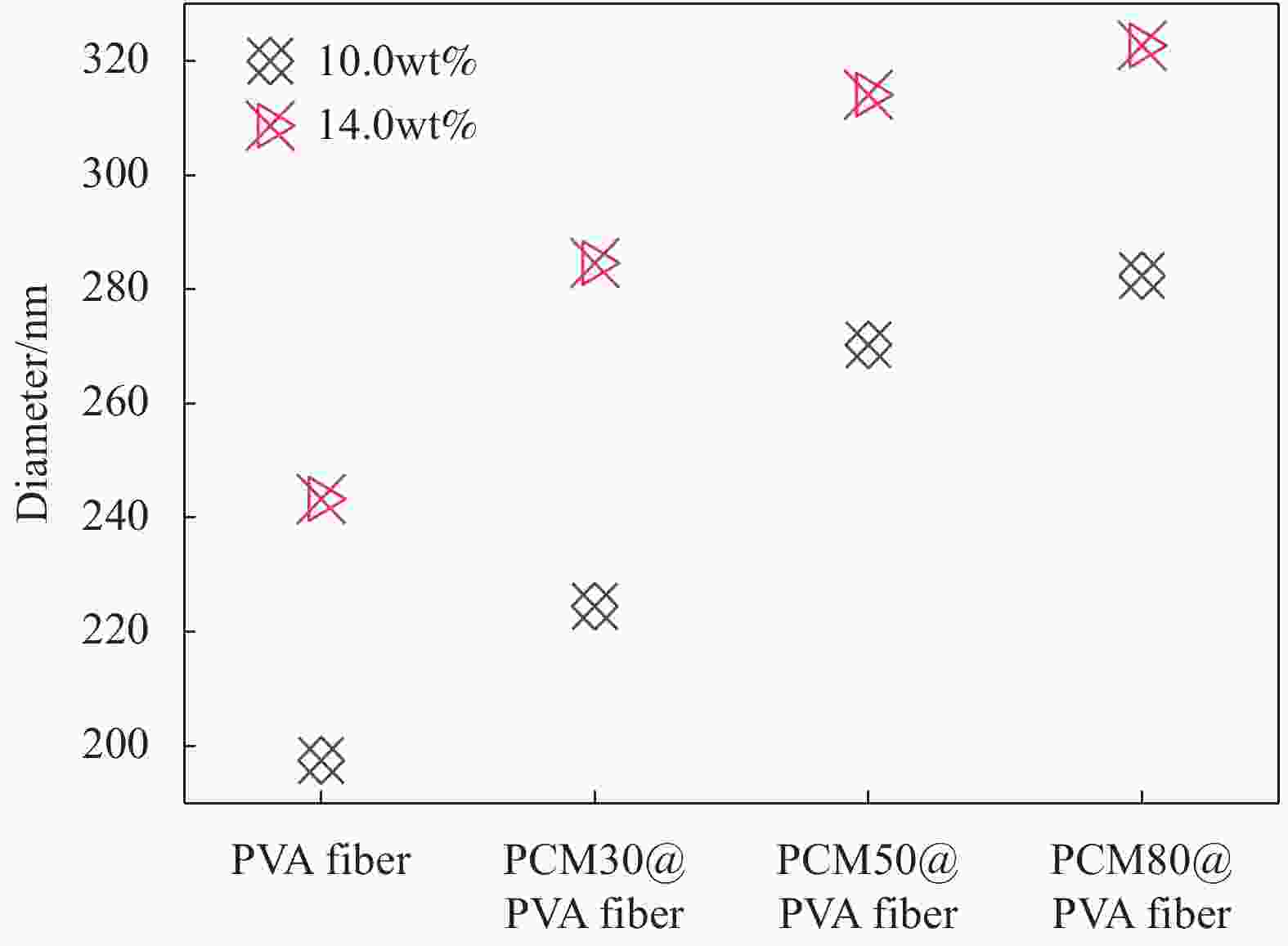

图 3 10.0wt%和14.0wt%PVA浓度制备的静电纺纤维的SEM图像

Figure 3. SEM images of electrospun fibers with 10.0wt% and 14.0wt% PVA concentrations ((a) PVA fiber (10.0wt%); (b) PCM30@PVA fiber (10.0wt%); (c) PCM50@PVA fiber (10.0wt%); (d) PCM80@PVA fiber (10.0wt%); (e) PVA fiber (14.0wt%); (f) PCM30@PVA fiber (14.0wt%); (g) PCM50@PVA fiber (14.0wt%); (h) PCM80@PVA fiber (14.0wt%))

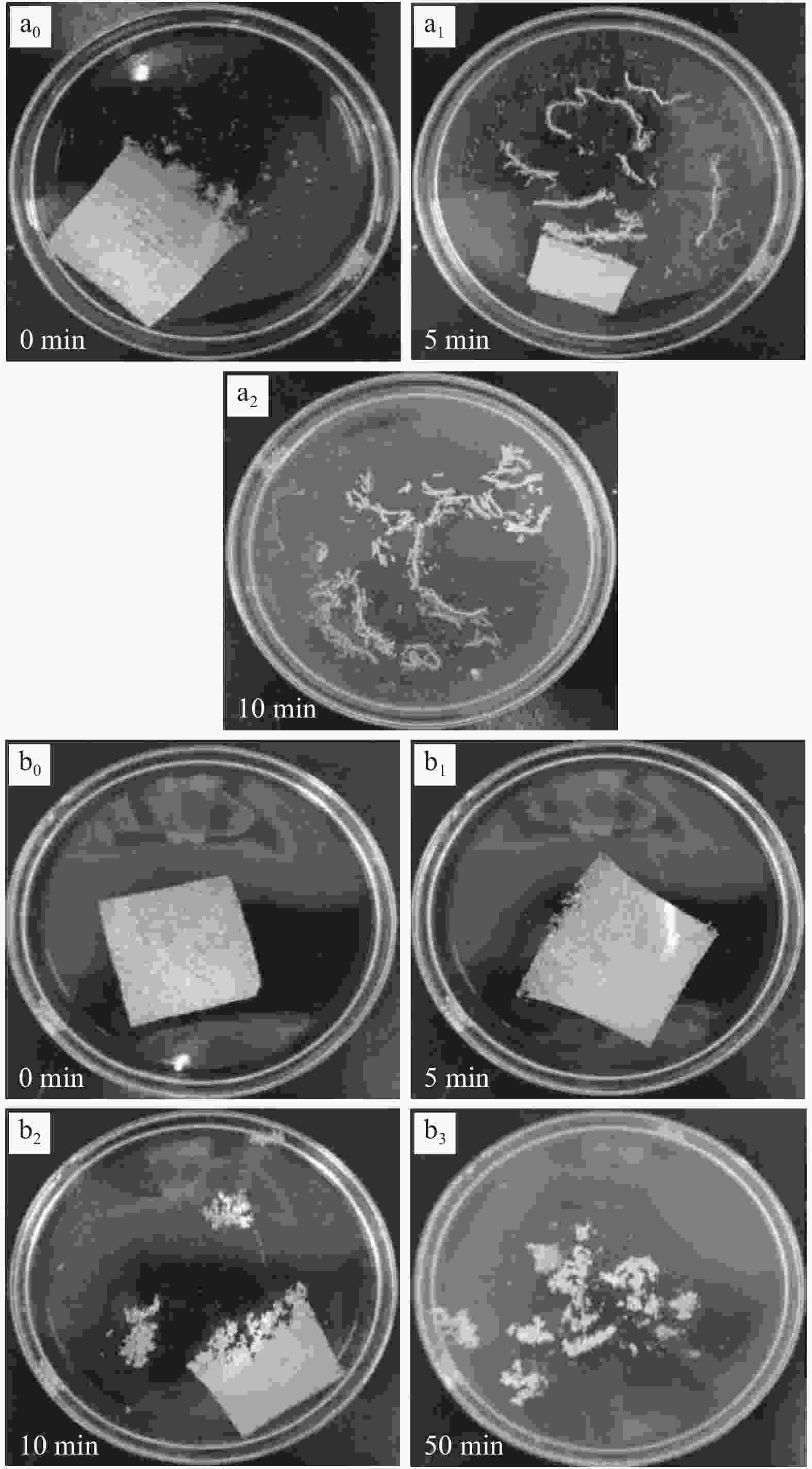

图 6 10.0wt%和14.0wt%PVA制备的PCM@PVA纤维热处理后在吸油纸上的照片

Figure 6. Photos of PCM@PVA fibers prepared by 10.0wt% and 14.0wt% PVA on oil-absorbing sheet after heat treatment ((a) PCM30@PVA fiber (10.0wt%); (b) PCM50@PVA fiber (10.0wt%); (c) PCM80@PVA fiber (10.0wt%); (d) PCM30@PVA fiber (14.0wt%); (e) PCM50@PVA fiber (14.0wt%); (f) PCM80@PVA fiber (14.0wt%))

表 1 材料名称与缩写对应

Table 1. Corresponding of material name and abbreviation

Sample Abbreviation Fibers with different dodecanol dodecanoate∶PVA mass ratios 30% PCM30@PVA fiber 50% PCM50@PVA fiber 80% PCM80@PVA fiber Dodecanol dodecanoate@polyvinyl alcohol thermal storage solution PCM@PVA solution Dodecanol dodecanoate-polyvinyl alcohol thermal storage fiber PCM@PVA fiber Crosslinked polyvinyl alcohol/dodecanol dodecanoate thermal storage fiber CPVA-PCM fiber Notes: PCM—Phase change material; PVA—Polyvinyl alcohol; CPVA—Crosslinking PVA. 表 2 不同PCM@PVA纤维样品的热性能数据

Table 2. Thermal performance data of different PCM@PVA fiber samples

Sample Tmo/℃ Tm/℃ ΔHm/(J·g−1) Tco/℃ Tc1/℃ Tc2/℃ ΔHc/(J·g−1) PCM 25.10 28.10 193.70 24.34 23.64 — 193.25 PVA fiber(10.0wt%) — — — — — — — PCM30@PVA fiber(10.0wt%) 25.96 28.72 26.91 24.81 23.99 8.51 26.99 PCM50@PVA fiber(10.0wt%) 26.30 29.71 63.18 25.11 24.88 14.63 62.52 PCM80@PVA fiber(10.0wt%) 26.69 29.07 72.48 25.07 25.01 14.29 72.32 PVA fiber(14.0wt%) — — — — — — — PCM30@PVA fiber(14.0wt%) 25.38 28.07 28.53 25.42 22.41 7.29 27.42 PCM50@PVA fiber(14.0wt%) 25.59 28.60 63.50 24.04 23.47 8.67 61.23 PCM80@PVA fiber(14.0wt%) 25.30 28.72 73.37 24.16 23.72 7.43 73.44 Notes: Tmo—Onset melting temperature; Tm—Melting temperature; ΔHm—Melting enthalpy; Tco—Onest crystallizing temperature; Tc1—First crystallizing temperature; Tc2—Second crystallizing temperature; ΔHc—Crystallization enthalpy. 表 3 不同样品的热分解数据

Table 3. Thermal decomposition data of different samples

Sample T1/℃ W1/wt% T2/℃ W2/wt% T3/℃ W3/wt% T4/℃ W4/wt% W/wt% PCM 190 100 — — — — — — 100 PVA fiber 20 7.5 270 64.5 445 22 — — 94 PCM30@PVA fiber 20 7.5 210 13.5 270 57 434 15 93 PCM50@PVA fiber 20 7.5 210 21 270 44.5 420 21 94 PCM80@PVA fiber 20 7.5 210 29 270 42 434 14.5 93 CPVA-PCM fiber 20 7.5 210 42.5 355 25 450 19 94 Notes: T1, T2, T3, T4—Initial degradation temperatures of the 1st, 2nd, 3rd and 4th stages; W1, W2, W3, W4—Mass loss fractions of the 1st, 2nd, 3rd and 4th stages; W—Final mass loss fraction. -

[1] 张渤, 牟思阳, 李圣林, 等. 二元脂肪酸/生物基SiO2复合相变材料的制备与性能[J]. 复合材料学报, 2016, 33(11):2674-2681.ZHANG B, MOU S Y, LI S L, et al. Preparation and properties of binary fatty acids/bio-based SiO2 phase change composites[J]. Acta Materiae Compositae Sinica,2016,33(11):2674-2681(in Chinese). [2] 李树芹, 陈赛, 王学晨, 等. 梳状相变聚合物为芯材的复合调温纤维的制备及热性能[J]. 复合材料学报, 2018, 35(1):8-15.LI S Q, CHEN S, WANG X C, et al. Fabrication and thermal properties of wet-spun thermo-regulating fibers with a novel comb-like phase change polymer core[J]. Acta Materiae Compositae Sinica,2018,35(1):8-15(in Chinese). [3] ZHOU D, ZHAO C Y, TIAN Y. Review on thermal energy storage with phase change materials (PCMs) in building applications[J]. Applied Energy,2012,92(4):593-605. [4] CHOI K, CHO G. Physical and mechanical properties of thermostatic fabrics treated with nanoencapsulated phase change materials[J]. Journal of Applied Polymer Science,2011,121(6):3238-3245. doi: 10.1002/app.33870 [5] BENMOUSSA D, MOLNAR K, HANNACHE H, et al. Novel thermo-regulating comfort textile based on poly(allyl ethylene diamine)/n-hexadecane microcapsules grafted onto cotton fabric[J]. Advances in Polymer Technology,2016,37(24):419-428. [6] WUTTIG M, YAMADA N. Phase-change materials for rewriteable data storage[J]. Nature materials,2007,6(11):824-832. doi: 10.1038/nmat2009 [7] BHARDWAJ N, KUNDU S C. Electrospinning: A fascinating fiberfabrication technique[J]. Biotechnology Advances,2010,28(3):325-347. doi: 10.1016/j.biotechadv.2010.01.004 [8] NASOURI K, SHOUSHTARI A M, MOJTAHEDI M R M. Effects of polymer/solvent systems on electrospun polyvinylpyrrolidone nanofiber morphology and diameter[J]. Polymer Science Series A,2015,57(6):747-755. doi: 10.1134/S0965545X15060164 [9] YUAN Y, ZHANG N, TAO W, et al. Fatty acids as phase change materials: A review[J]. Renewable and Sustainable Energy Reviews,2014,29:482-498. doi: 10.1016/j.rser.2013.08.107 [10] LIU C Z, RAO Z H, ZHAO J T, et al. Review on nanoencapsulated phase change materials: Preparation, characterization and heat transfer enhancement[J]. Nano Energy,2015,13:814-826. [11] DO C V, NGUYEN T T T, PARK J S. Fabrication of polyethylene glycol/polyvinylidene fluoride core/shell nanofibers via melt electrospinning and their characteristics[J]. Solar Energy Materials and Solar Cells,2012,104:131-139. doi: 10.1016/j.solmat.2012.04.029 [12] WU Y, CHEN C Z, JIA Y F, et al. Review on electrospun ultrafine phase change fibers (PCFs) for thermal energy storage[J]. Applied Energy,2018,210:167-181. doi: 10.1016/j.apenergy.2017.11.001 [13] 蔡以兵, 孙桂岩, 刘盟盟, 等. 定形相变复合材料的研究进展—静电纺丝法[J]. 高分子通报, 2015(2):18-25.CAI Y B, SUN G Y, LIU M M, et al. The research progress of form-stable phase change composite marerials—electrospinning[J]. Polymer Bulletin,2015(2):18-25(in Chinese). [14] ZHANG C, FENG F Q, ZHANG H. Emulsion electrospinning: Fundamentals, food applications and prospects[J]. Trends in Food Science & Technology,2018,80:175-186. [15] ZHAO L, LUO J, LI Y, et al. Emulsion-electrospinning n-octadecane/silk composite fiber as environmental-friendly form-stable phase change materials[J]. Journal of Applied Polymer Science,2017,134(47):1-10. [16] ZDRAVEVA E, FANG J, MIJOVIC B, et al. Electrospun poly(vinyl alcohol)/phase change material fibers: Morphology, heat properties, and stability[J]. Industrial & Engineering Chemistry Research,2015,54(35):8706-8712. [17] ZHANG G Q, CAI C W, ZHU G C, et al. Preparation, properties and encapsulation of high thermostability phase-change material[J]. Journal of Fiber Bioengineering and Informatics,2019,12(1):43-54. doi: 10.3993/jfbim00307 [18] CAI C W, OUYANG X, ZHOU L, et al. Cosolvent free interfacial polycondensation and properties of polyurea PCM microcapsules with dodecanol dodecanoate as core material[J]. Solar Energy,2020,199:721-730. doi: 10.1016/j.solener.2020.02.071 [19] PAIPITAK K, PORNPRA T, MONGKONTALANG P, et al. Characterization of PVA-chitosan nanofibers prepared by electrospinning[J]. Procedia Engineering,2011,13(8):101-105. [20] ZHAO J H, SUN Z Y, SHAO Z B, et al. Effect of surface-active agent on morphology and properties of electrospun PVA nanofibres[J]. Fibers and Polymers,2016,17(6):896-901. doi: 10.1007/s12221-016-6163-y [21] 李珍, 王军. 静电纺丝可纺性影响因素的研究成果[J]. 合成纤维, 2008, 9:6-11. doi: 10.3969/j.issn.1001-7054.2008.09.002LI Z, WANG J. Studies on influential factors on nanofiber spinnability of electrospinning[J]. Synthetic Fiber in China,2008,9:6-11(in Chinese). doi: 10.3969/j.issn.1001-7054.2008.09.002 [22] WANG J, YAO H B, HE D, et al. Facile fabrication of gold nanoparticles-poly(vinyl alcohol) electrospun water-stable nanofibrous mats: Efficient substrate materials for biosensors[J]. ACS Applied Materials & Interfaces,2012,4(4):1963-1971. [23] PERESIN M S, HABIBI Y, ZOPPE J O, et al. Nanofiber composites of polyvinyl alcohol and cellulose nanocrystals: Manufacture and characterization[J]. Macromolecules,2010,11:674-681. -

下载:

下载: