Axial tensile mechanical properties and constitutive relation model of ultra-high performance concrete under cyclic loading

-

摘要: 对具有不同拉伸应变特性(应变强化和应变软化)的超高性能混凝土(Ultra high performance concrete, UHPC)进行了单调和循环荷载作用下的直接拉伸试验。试验结果表明:应变强化UHPC基体开裂后进入多点微裂纹分布的应变强化段,达到极限抗拉强度后进入单缝开裂的应变软化段;应变软化UHPC基体开裂后直接进入单缝开裂的应变软化段;循环荷载下两种类型UHPC的轴拉应力-应变曲线包络线与单调荷载下的应力-应变曲线基本一致;基于刚度退化过程建立了两种类型UHPC的轴拉损伤演化方程,根据实测应力-应变曲线和试件的裂缝分布形态建立了两种类型UHPC的轴拉本构关系模型,与试验结果基本吻合;采用能量法研究了应变强化UHPC两阶段轴拉本构关系在数值计算时的等效方法。最后,通过无筋应变强化UHPC抗弯试验梁的数值模拟对本文建立的应变强化UHPC轴拉本构关系模型和损伤演化方程及相关假定进行了验证,结果表明本文建立的应变强化UHPC轴拉本构模型能较好地预测UHPC弯拉构件的极限承载力,轴拉损伤变量能在宏观层面上较好地反应试件的裂缝分布状态。

-

关键词:

- 超高性能混凝土(UHPC) /

- 直接拉伸试验 /

- 循环荷载 /

- 轴拉本构模型 /

- 数值模拟

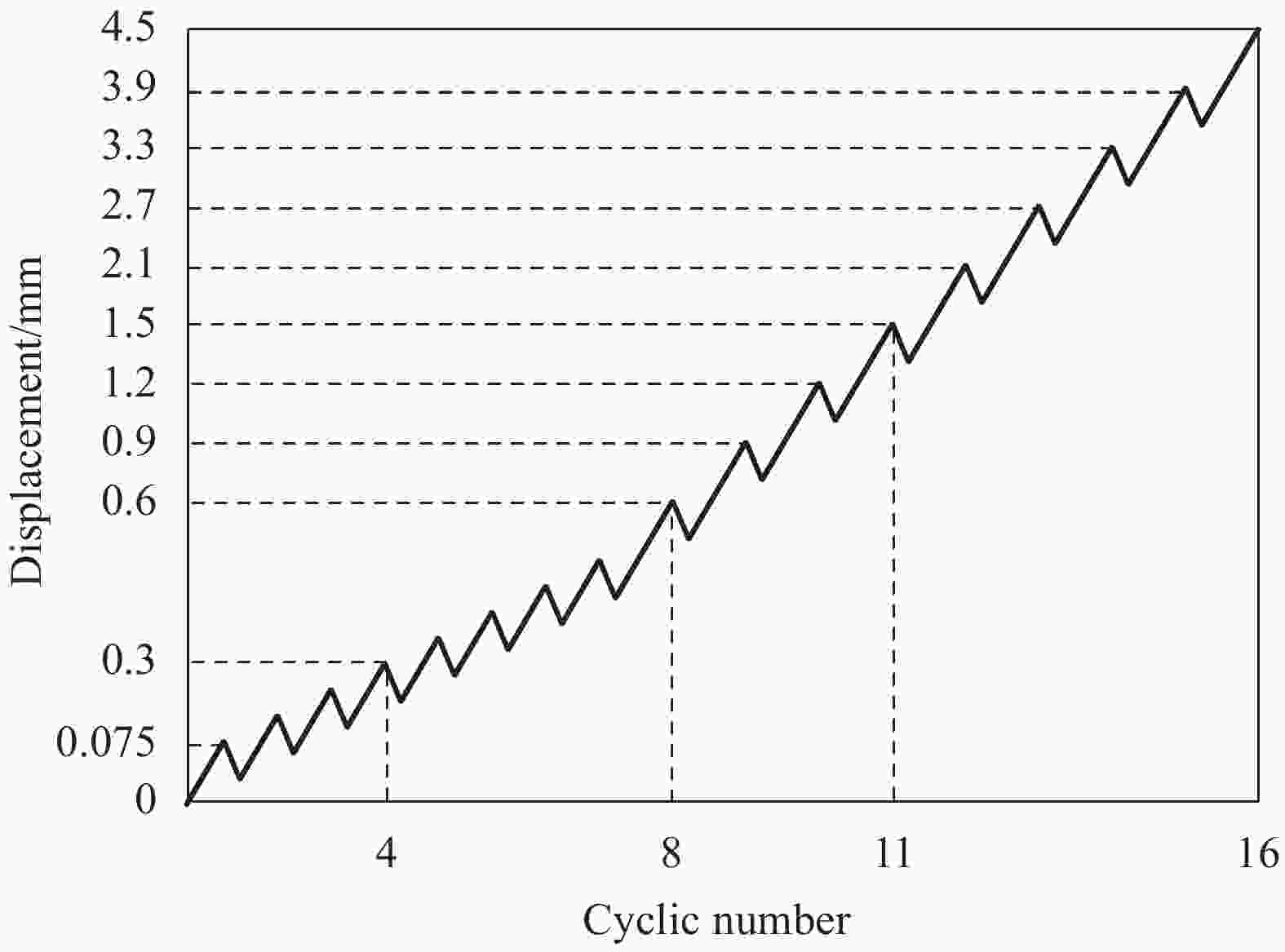

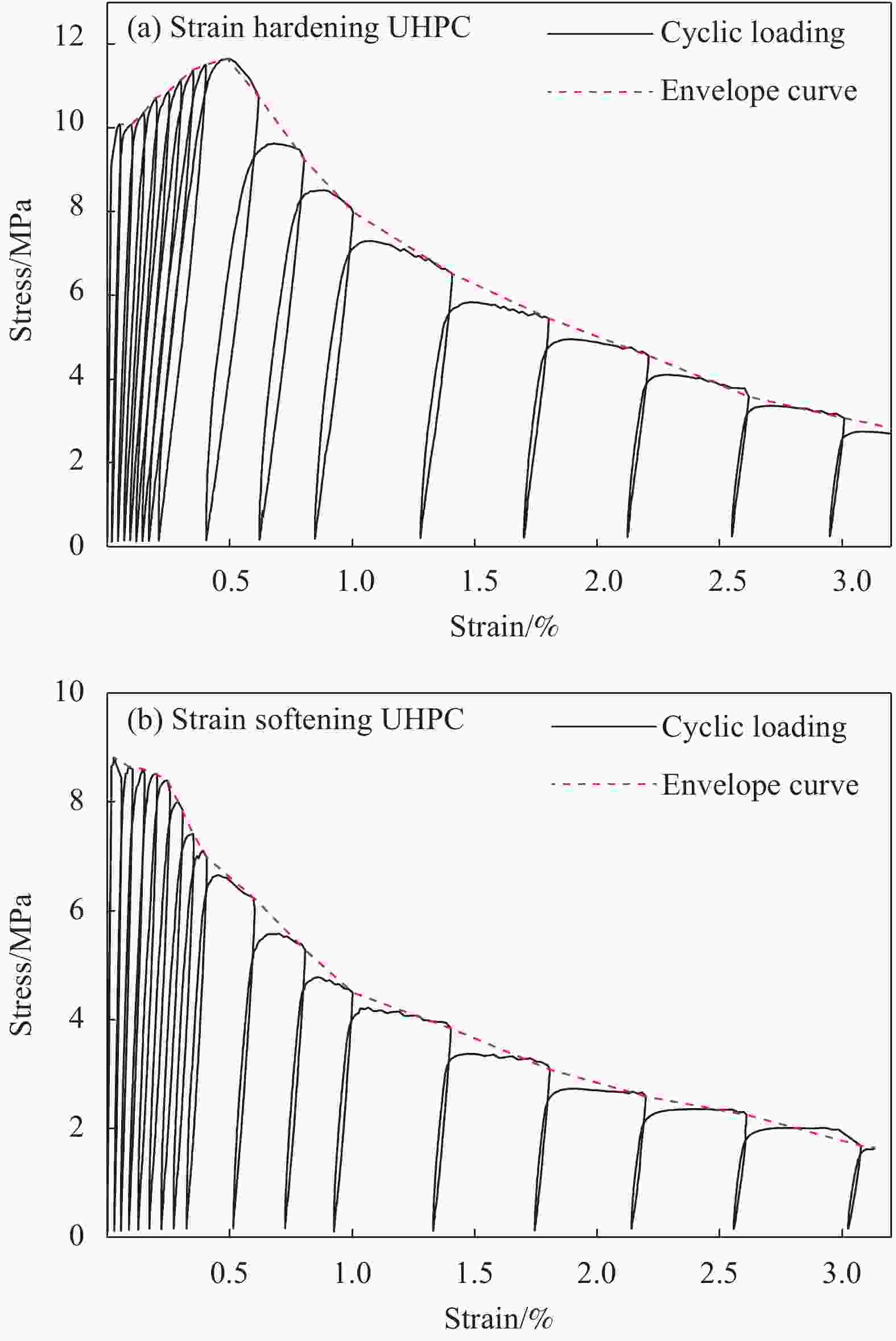

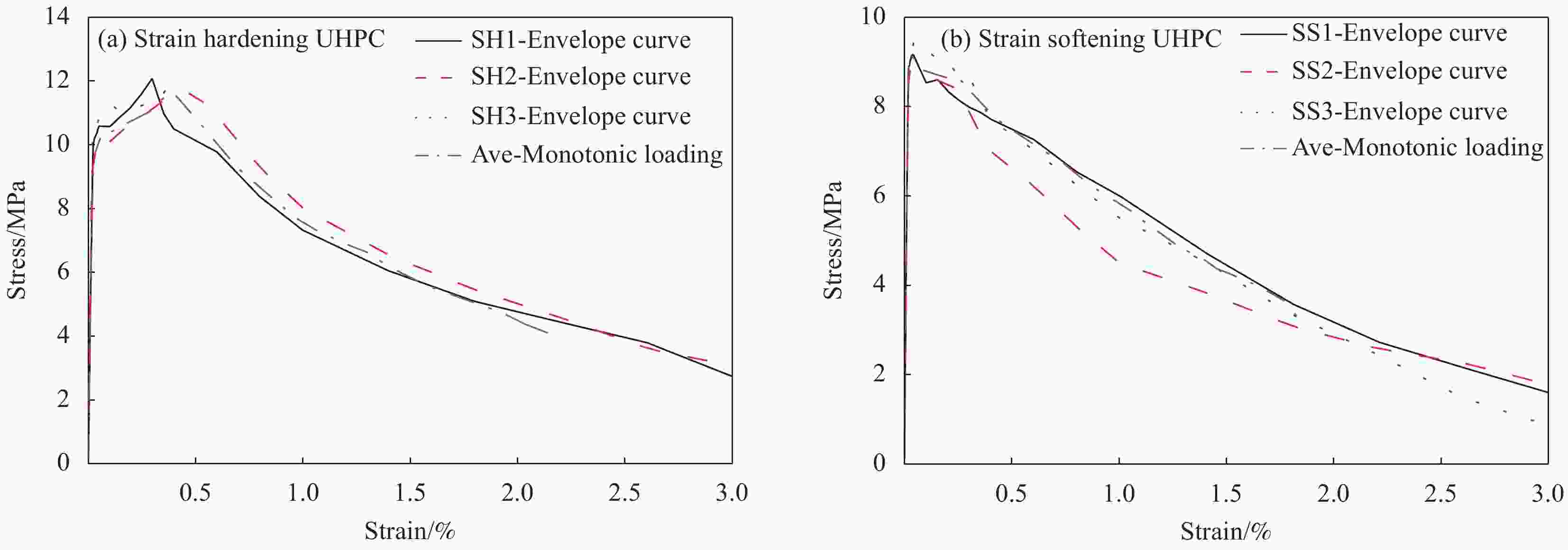

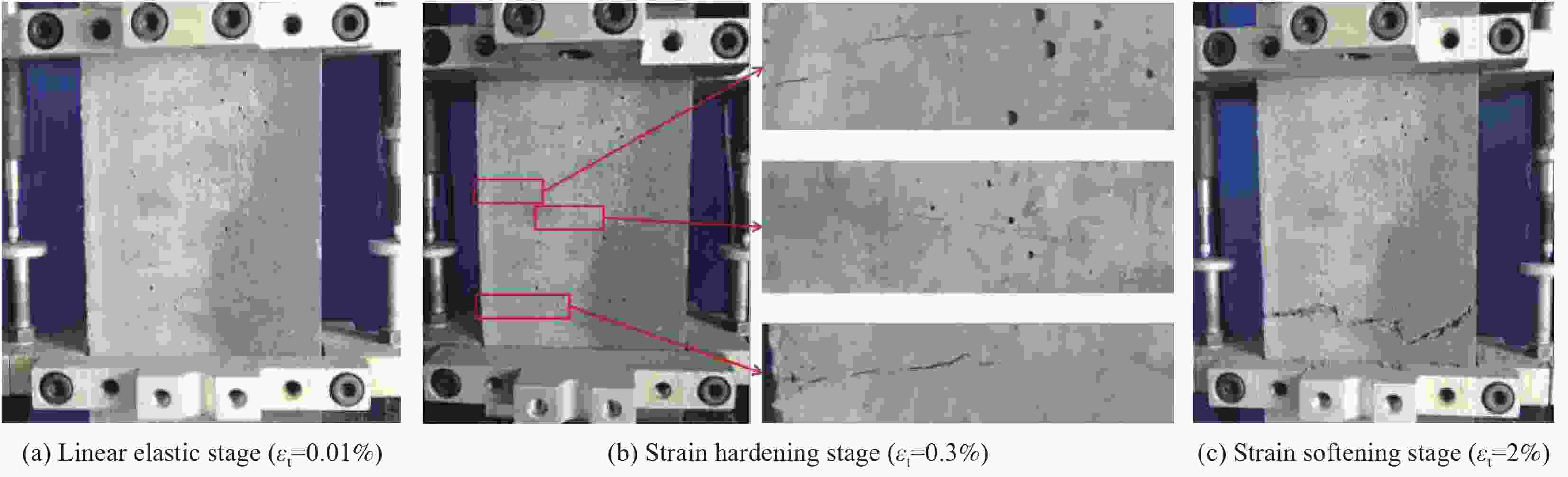

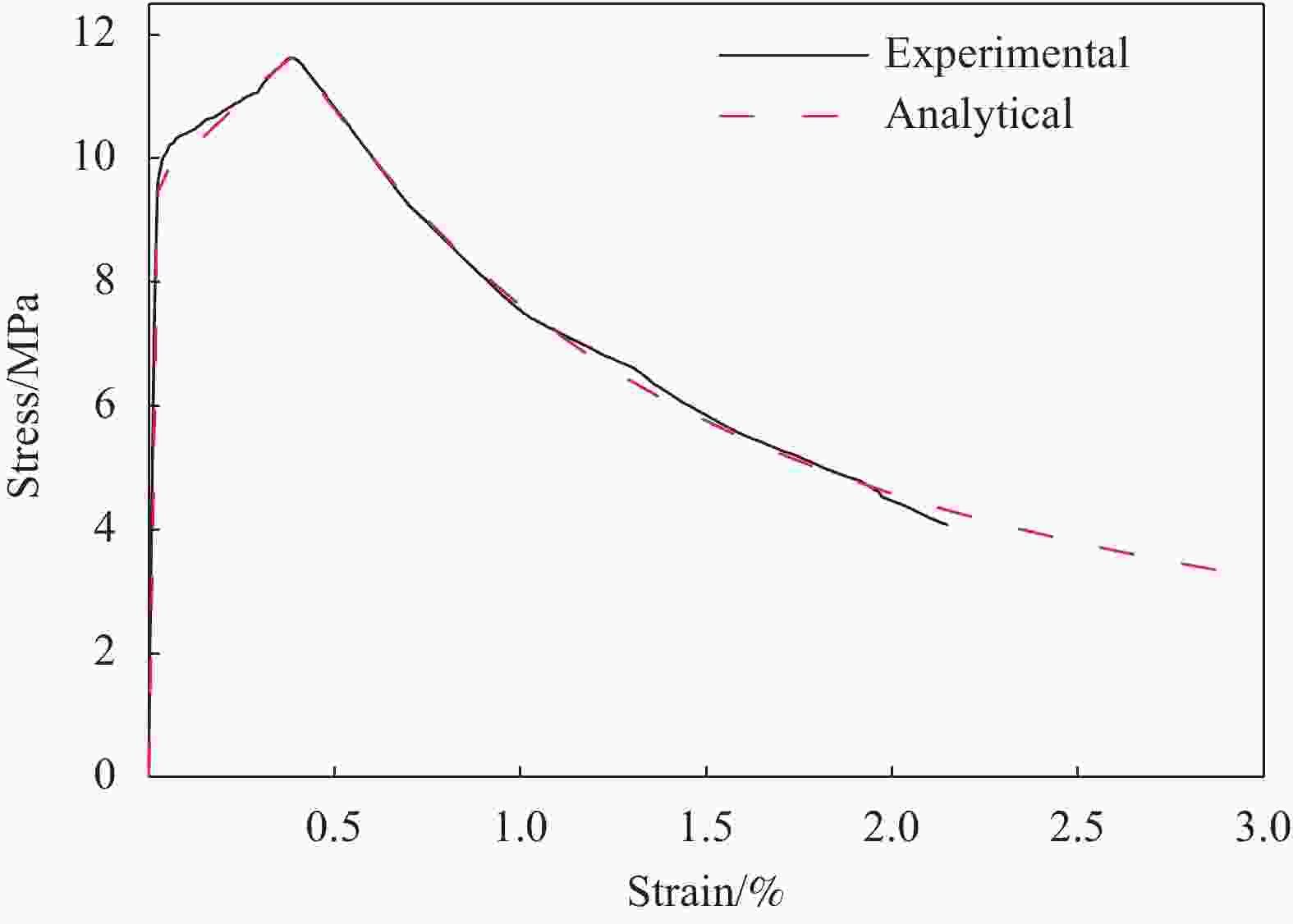

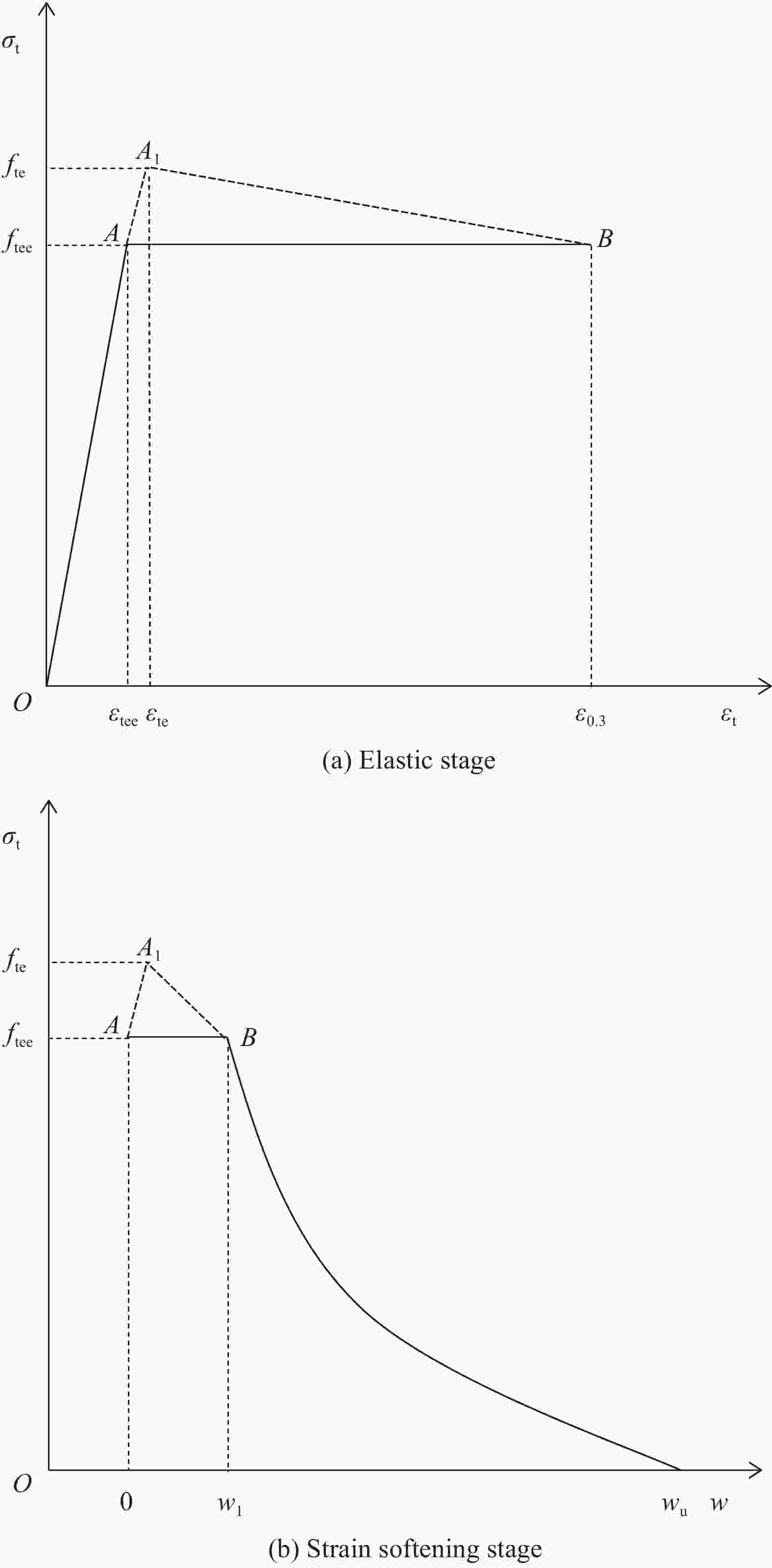

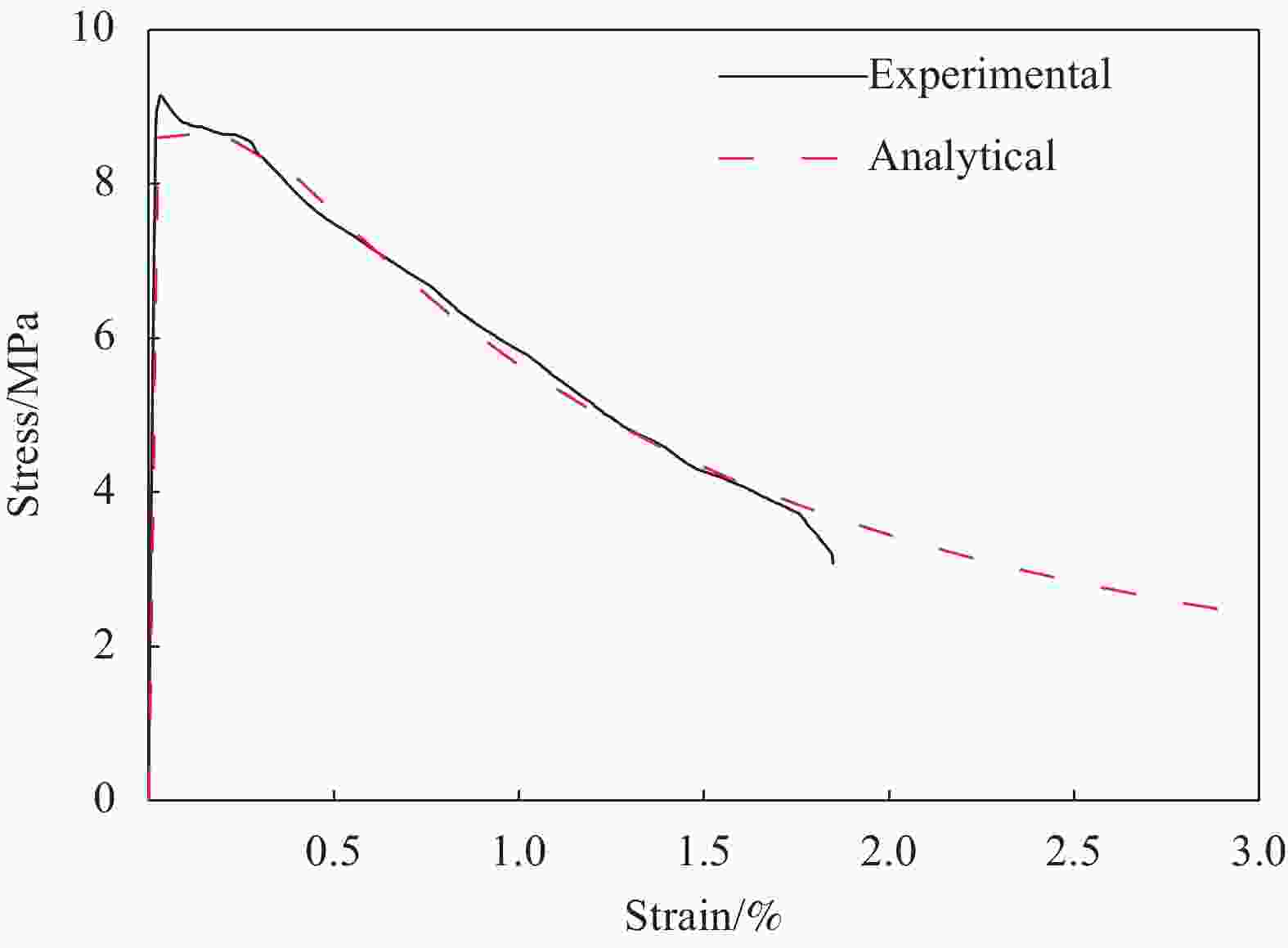

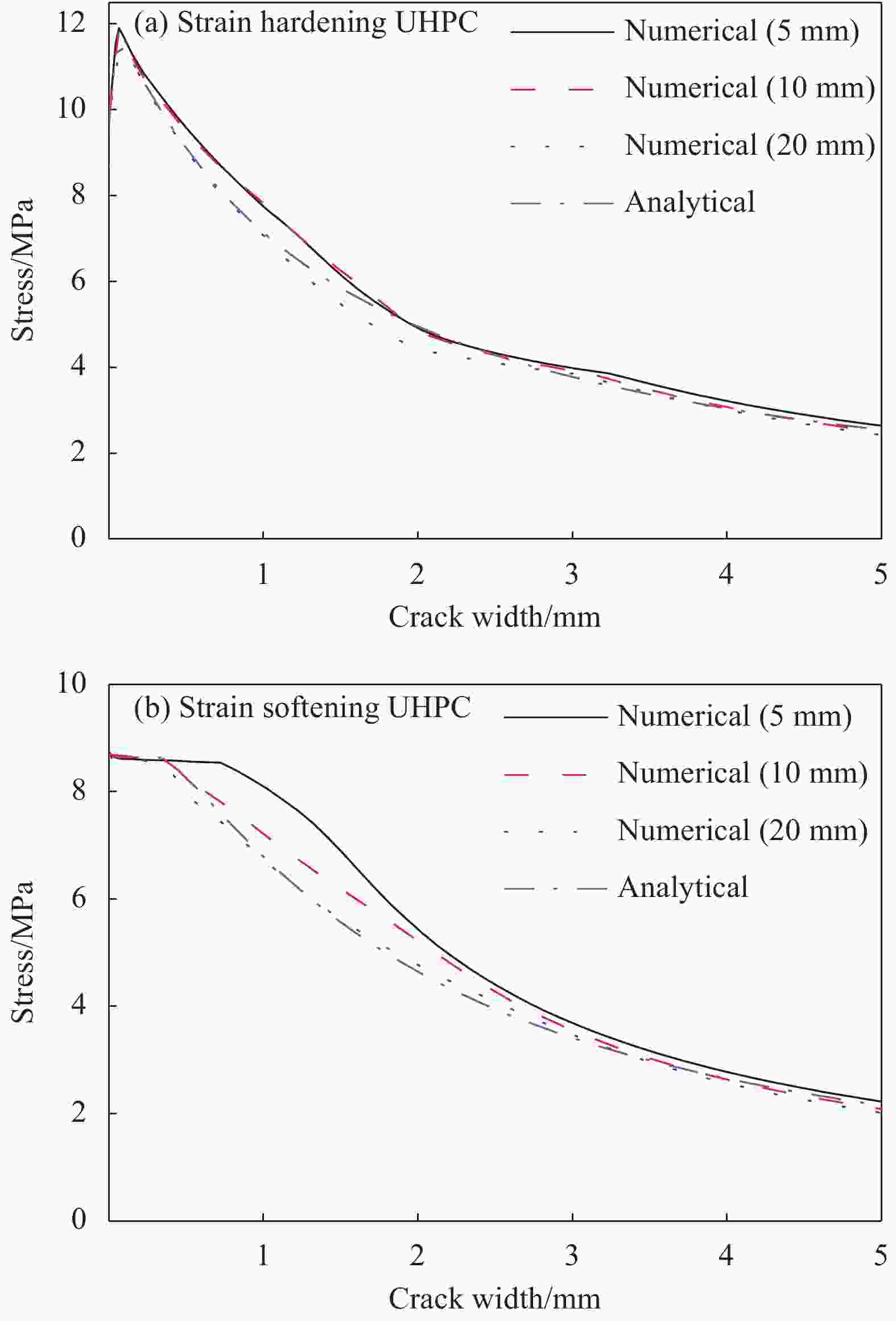

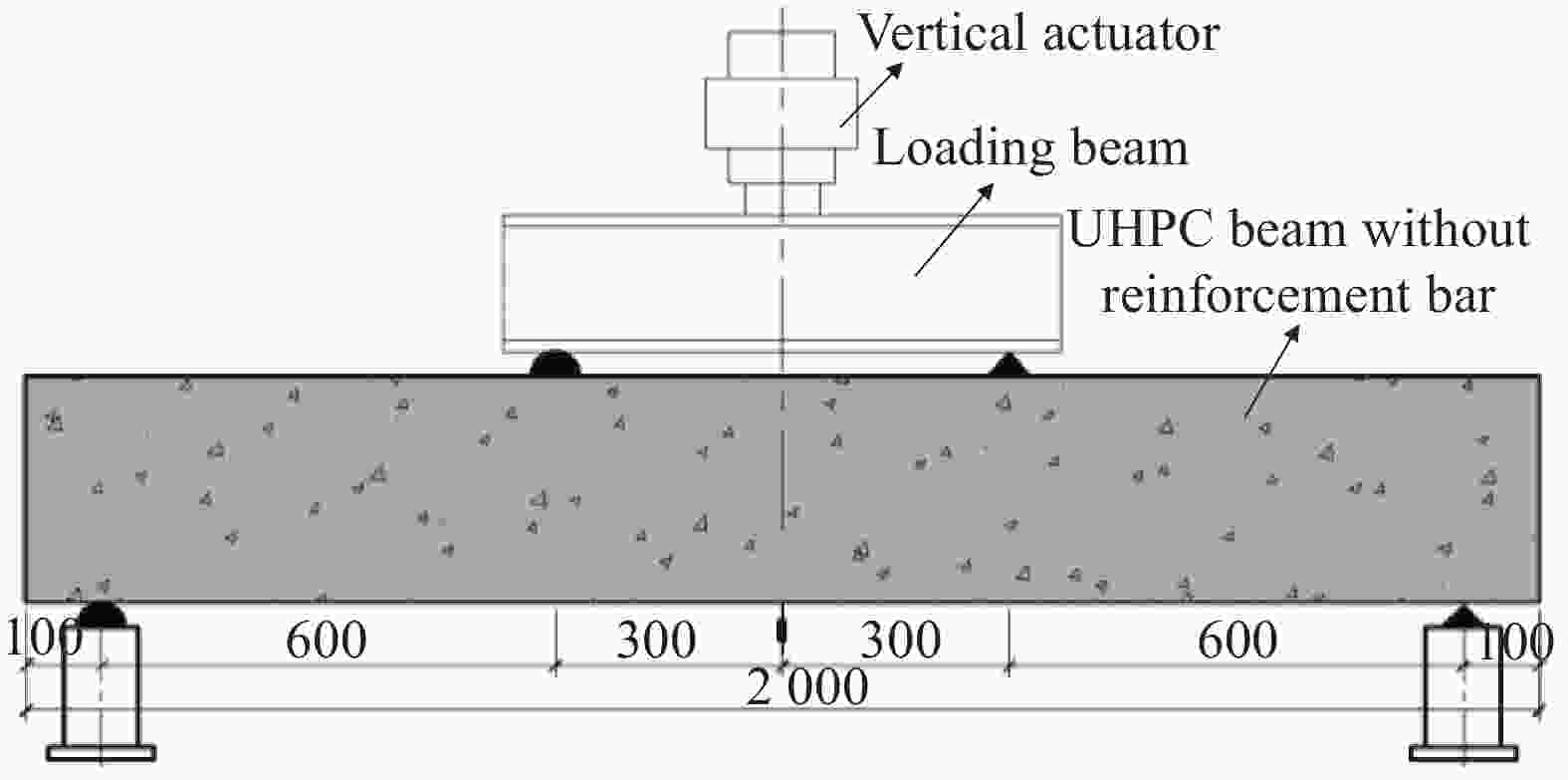

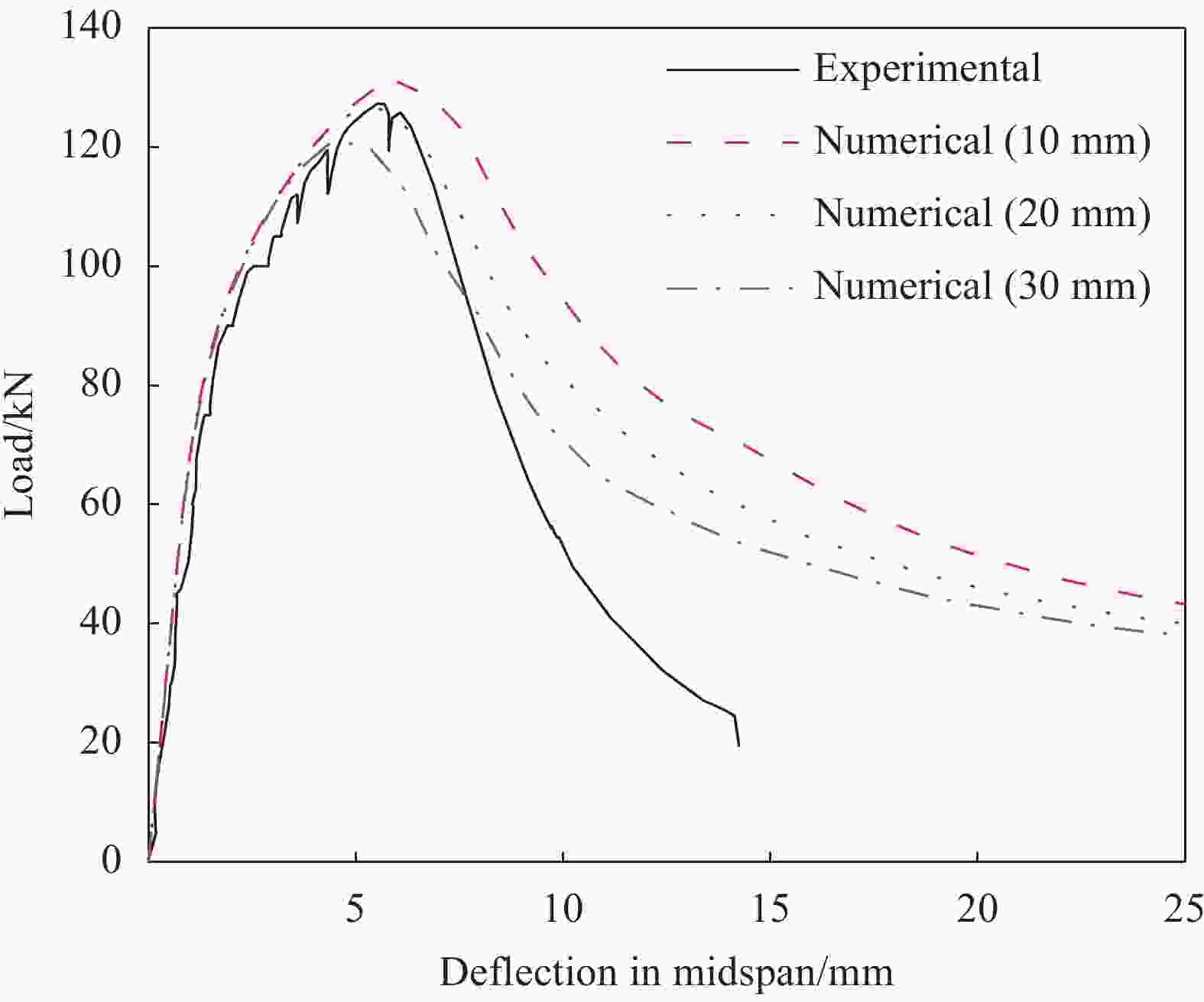

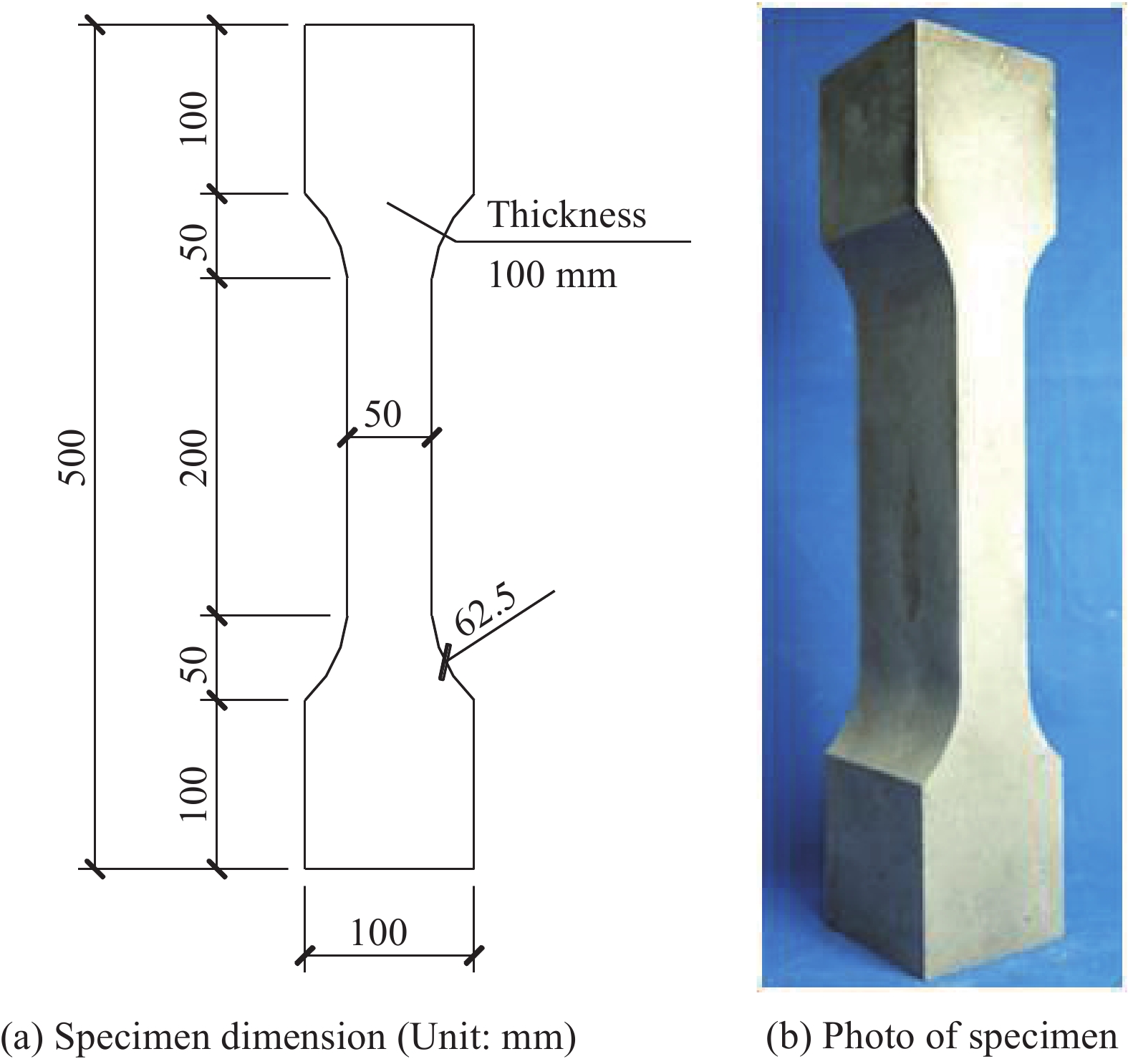

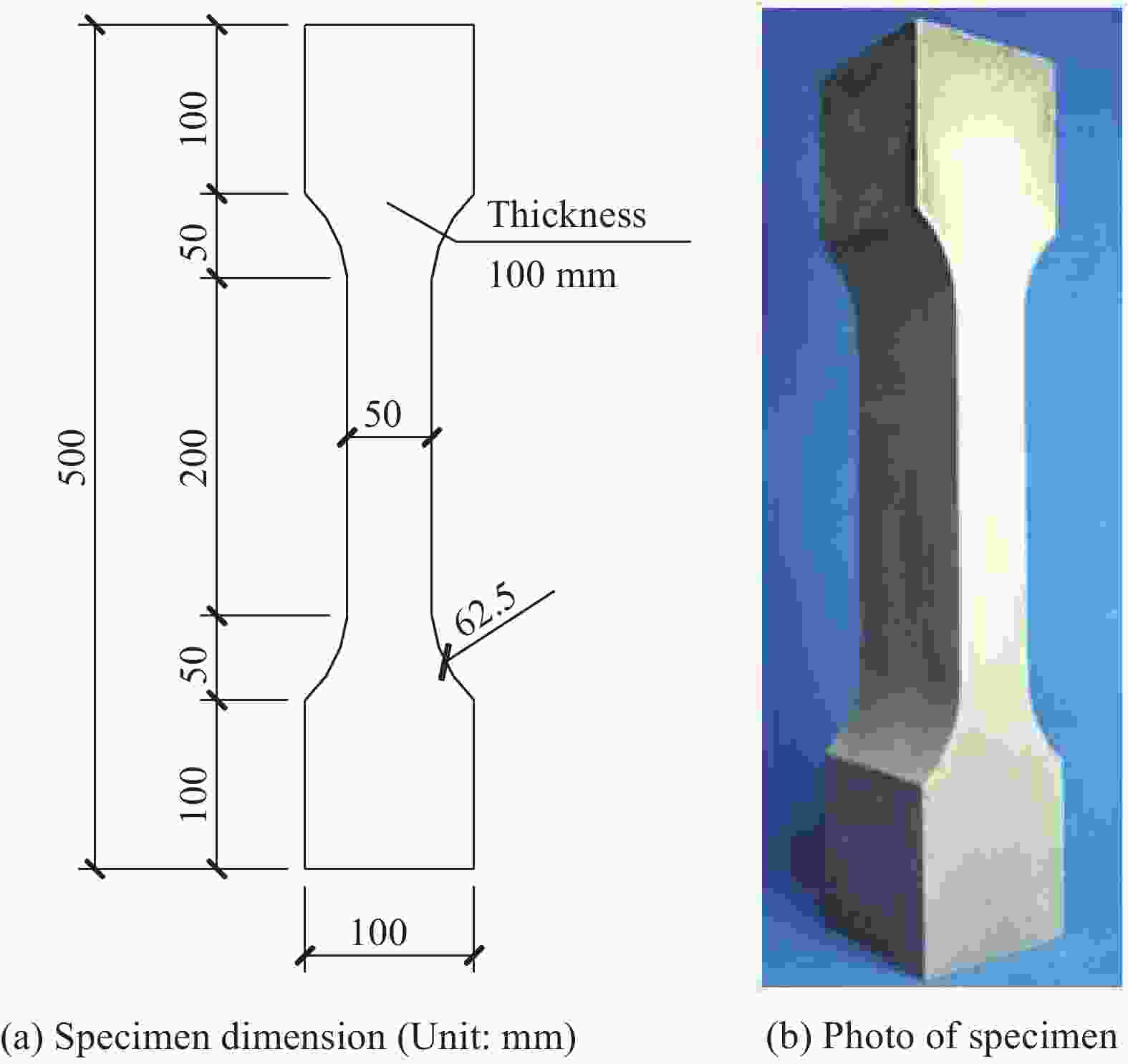

Abstract: The direct tensile tests under monotonic and cyclic loading were conducted on the ultra high performance concrete (UHPC) with different tensile strain characteristics (strain hardening and strain softening). The test results reflect that the strain hardening UHPC enters the stage of strain hardening with multi-point microcrack distribution after the cracking of UHPC matrix, and it enters the strain softening section with single seam cracking after reaching the ultimate tensile strength. The strain softening UHPC enters the strain softening stage with single seam crack after the cracking of UHPC matrix. The envelope of axial tensile stress-strain curves of the two types UHPC under cyclic load are generally consistent with that curves under monotonic load. Based on the stiffness degradation process, the axial tensile damage evolution equations of two types of UHPC were established. Based on the measured stress-strain curves and the crack distribution of the specimens, the axial tensile constitutive relation models of the two UHPCs were established. The test data are satisfactorily approximate to the proposed models. The equivalent method for the strain hardening UHPC with two-stage axial tensile constitutive relation in numerical calculation was studied by using energy method. Finally, the proposed axial tensile constitutive relation model and damage evolution equation of strain hardening UHPC were verified according to the numerical simulation of unreinforced strain strengthened UHPC flexural test beam. The results reveal that the proposed axial tensile constitutive model could precisely predict the ultimate bearing capacity of UHPC flexural-tensile members, and the axial tensile damage variables could generally reflect the crack distribution of the specimens. -

表 1 超高性能混凝土(UHPC)基体配合比(kg/m3)

Table 1. Mix proportions of ultra high performance concrete (UHPC) matrix(kg/m3)

Cement Silica fume Ground quartz Quartz sand Water Superplasticizer 745 223.5 223.5 998.3 179.0 13.1 表 2 钢纤维特征参数

Table 2. Properties of the steel fibres

Fiber shape Tensile strength/MPa Elastic modulus/GPa Length/mm Diameter/μm Density/(kg·m−3) Straight smooth 2500 200 16 200 7850 表 3 两种类型UHPC的基本力学性能

Table 3. Basic mechanical properties of two types of UHPC

Specimen type fc/MPa (Cov) Ec/GPa (Cov) Strain softening UHPC 127.8 (0.032) 47.4 (0.031) Strain hardening UHPC 135.2 (0.044) 48.9 (0.026) Notes: fc─Compressive strength; Ec─Elastic modulus. 表 4 应变强化(SH)UHPC轴拉应力-应变曲线特征参数

Table 4. Characteristic parameters of axial tensile stress-strain curve of strain hardening (SH) UHPC

Specimen Monotonic loading Cyclic loading fte/MPa εte/10−4 ftu/MPa εtu/10−3 fte/MPa εte/10−4 ftu/MPa εtu/10−3 SH1 9.62 2.2 11.71 4.11 9.75 2.1 12.08 3.49 SH2 9.76 2.1 11.28 3.72 9.42 2.3 11.65 4.55 SH3 8.71 2.3 12.01 3.82 10.19 2.1 12.18 4.45 Mean 9.36 2.2 11.67 3.89 9.79 2.2 11.97 4.16 Cov 0.06 0.6 0.03 0.05 0.04 0.7 0.02 0.14 Notes: fte─Elastic ultimate tensile strength; εte─Elastic ultimate tensile strain; ftu─Ultimate tensile strength; εtu─Ultimate tensile strain. 表 5 应变软化(SS)UHPC轴拉应力-应变曲线特征参数

Table 5. Characteristic parameters of axial tensile stress-strain curve of strain softening (SS) UHPC

Specimen Monotonic loading Cyclic loading fte/MPa εte/10−4 ftee/MPa ftee/fte fte/MPa εte/10−4 ftee/MPa ftee/fte SS1 9.09 2.2 8.45 0.93 9.01 2.4 8.32 0.92 SS2 9.28 2.8 8.83 0.95 8.69 2.2 8.52 0.98 SS3 9.47 2.2 − − 9.47 3.1 8.51 0.89 Mean 9.28 2.4 8.64 0.94 9.06 2.6 8.45 0.93 Cov 0.02 1.6 0.03 0.02 0.04 1.9 0.01 0.04 Notes: ftee─Equivalent tensile strength. 表 6 UHPC轴拉损伤演化方程中的参数

Table 6. Parameters for the evolution equation of axial tensile damage of UHPC

a0 t0 a1 t1 b Strain hardening UHPC 0.1048 3.1381 0.8541 0.0739 −0.0118 Strain softening UHPC 0.2037 3.3832 0.8076 0.0763 −0.0162 表 7 UHPC梁极限承载力的有限元计算和试验结果对比

Table 7. Comparison of ultimate bearing capacity between finite element calculation results and test results of UHPC beam

Beam Pu,test/kN Pu,FEA/kN Pu,test/Pu,FEA Numerical (10 mm) 127.23 131.27 0.97 Numerical (20 mm) 127.23 126.73 1.01 Numerical (30 mm) 127.23 120.81 1.05 Notes: Pu,test─Ultimate bearing capacity obtained from experiment results;Pu,FEA─Ultimate bearing capacity obtained from numerical simulation results. -

[1] GRAYBEAL B A. Material property characterization of ultra-high performance concrete: FHWA-HRT-06-103[R]. US: US Department of Transportation, Federal Highway Administration, 2006. [2] 阎培渝. 超高性能混凝土(UHPC)的发展与现状[J]. 混凝土世界, 2010(9):36-41. doi: 10.3969/j.issn.1674-7011.2010.09.009YAN Peiyu. The development and current situation of ultra-high performance concrete (UHPC)[J]. World of Concrete,2010(9):36-41(in Chinese). doi: 10.3969/j.issn.1674-7011.2010.09.009 [3] 赵筠, 廉慧珍, 金建昌. 钢-混凝土复合的新模式—超高性能混凝土(UHPC/UHPFR)之一: 钢-混凝土复合模式的现状、问题及对策与UHPC发展历程[J]. 混凝土世界, 2013, 52(1):67-80.ZHAO Jun, LIAN Huizhen, JIN Jianchang. A new model of steel concrete composite structure-ultra high performance concrete (UHPC/UHPFRC): The status quo, problems and countermeasures and the development process of UHPC[J]. China Concrete,2013,52(1):67-80(in Chinese). [4] 王德辉, 史才军, 吴林妹. 超高性能混凝土在中国的研究和应用[J]. 硅酸盐学报, 2016, 35(1):141-149.WANG Dehui, SHI Caijun, WU Linmei. Research and applications of ultra-high performance concrete (UHPC) in China[J]. Bulletin of the Chinese Ceramic Society,2016,35(1):141-149(in Chinese). [5] 杨娟, 朋改非, 税国双. 再生钢纤维增韧超高性能混凝土的力学性能[J]. 复合材料学报, 2019, 36(8):1949-1956.YANG Juan, PENG Gaifei, SHUI Guoshuang. Mechanical properties of recycled steel fiber reinforced ultra high performance concrete[J]. Acta Materiae Compositae Sinica,2019,36(8):1949-1956(in Chinese). [6] SAKR M A, EL-KHORIBY S R, KHALIFA T M, et al. Modeling of RC shear walls strengthened with ultra-high performance fiber reinforced concrete (UHPFRC) jackets[J]. Engineering Structures,2019,200(9):1-13. [7] 梁兴文, 王莹, 于婧, 等. 预制UHPC模板及采用预制模板的RC板受力性能及承载力分析[J]. 工程力学, 2019, 36(7):146-155.LIANG Xingwen, WANG Ying, YU Jing, et al. Mechanical properties and strength of prefabricated UHPC formwork and RC slab with prefabricated UHPC formwork[J]. Engineering Mechanics,2019,36(7):146-155(in Chinese). [8] 王俊颜, 郭君渊, 肖汝诚, 等. 高应变强化超高性能混凝土的裂缝控制机理和研究[J]. 土木工程学报, 2017, 50(11):10-17.WANG Junyan, GUO Junyuan, XIAO Rucheng, et al. Study on crack control mechanical of strain-harding ultra-high performance concrete[J]. China Civil Engineering Journal,2017,50(11):10-17(in Chinese). [9] WILLE K, JOO K D, NAAMAN A E. Strain hardening UHP FRC with low fiber contents[J]. Materials & Structures,2011,44(3):583-598. [10] WILLE K, TAWIL S E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP FRC) under direct tensile loading[J]. Cement & Concrete Composites,2014,48:53-66. [11] KANG S T, CHOI J I, KOH K T, et al. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete[J]. Composite Structures,2016,145(6):37-42. [12] 张哲, 邵旭东, 李文光, 等. 超高性能混凝土轴拉性能试验[J]. 中国公路学报, 2015, 28(8):50-58. doi: 10.3969/j.issn.1001-7372.2015.08.007ZHANG Zhe, SHAO Xudong, LI Wenguang, et al. Axial tensile behavior test of ultra high performance concrete[J]. China Journal of Highway and Transport,2015,28(8):50-58(in Chinese). doi: 10.3969/j.issn.1001-7372.2015.08.007 [13] SETRA-AFGC. Ultra high performance fiber-reinforced concretes recommendations[S]. France: AFGC, 2013. [14] MCS-EPFL. Ultra-high performance fibre reinforced cement-based composites (UHPFRC): Construction material, dimensioning and application[S]. Switzerland: Swiss Federal Institute of Technology, 2016. [15] 管品武, 涂雅筝, 张普, 等. 超高性能混凝土单轴拉压本构关系研究[J]. 复合材料学报, 2019, 36(5):1295-1305.GUAN Pinwu, TU Yazheng, ZHANG Pu, et al. A review on constitutive relationship of ultra-high-performance concrete under uniaxial compression and tensile[J]. Acta Materiae Compositae Sinica,2019,36(5):1295-1305(in Chinese). [16] KRAHL P A, CARRAZEDO R, ELDEBS M K, et al. Mechanical damage evolution in UHPFRC: Experimental and numerical investigation[J]. Engineering Structures,2018,170(1):63-77. [17] PASCHALIS S A, LAMPROPOULOS A P. Ultra-high-performance fiber-reinforced concrete under cyclic loading[J]. ACI Materials Journal,2016,113(4):419-427. [18] 中华人民共和国住房和城乡建设部. 活性粉末混凝土: GB/T 31387—2015[S]. 北京: 中国标准出版社, 2015.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Reactive powder concrete: GB/T 31387—2015[S]. Beijing: China Standard Press, 2015(in Chinese). [19] TJIPTOBROTO P, HANSEN W. Tensile strain hardening and multiple cracking in high-performance cement-based composites containing discontinuous fibers[J]. ACI Materials Journal,1993,90(1):16-25. [20] 任晓丹. 混凝土随机损伤本构关系试验研究[D]. 上海: 同济大学, 2006.REN Xiaodan. Experimental research on stochastic damage constitutive law for concrete[D]. Shanghai: Tongji University, 2006(in Chinese). [21] WANG, J Y, GUO, J Y. Damage investigation of ultra high performance concrete under direct tensile test using acoustic emission techniques[J]. Cement & Concrete Composites,2018,88(1):17-28. [22] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2015.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB 50010—2010[S]. Beijing: China Architecture & Building Press, 2015(in Chinese). [23] 聂建国, 王宇航. ABAQUS中混凝土本构模型用于模拟结构静力行为的比较研究[J]. 工程力学, 2013, 30(4):59-67.NIE Jianguo, WANG Yuhang. Comparison study of constitutive model of concrete in abaqus for static analysis of structures[J]. Engineering Mechanics,2013,30(4):59-67(in Chinese). -

下载:

下载: