Effect of polypropylene fiber on the damage and permeability of concrete

-

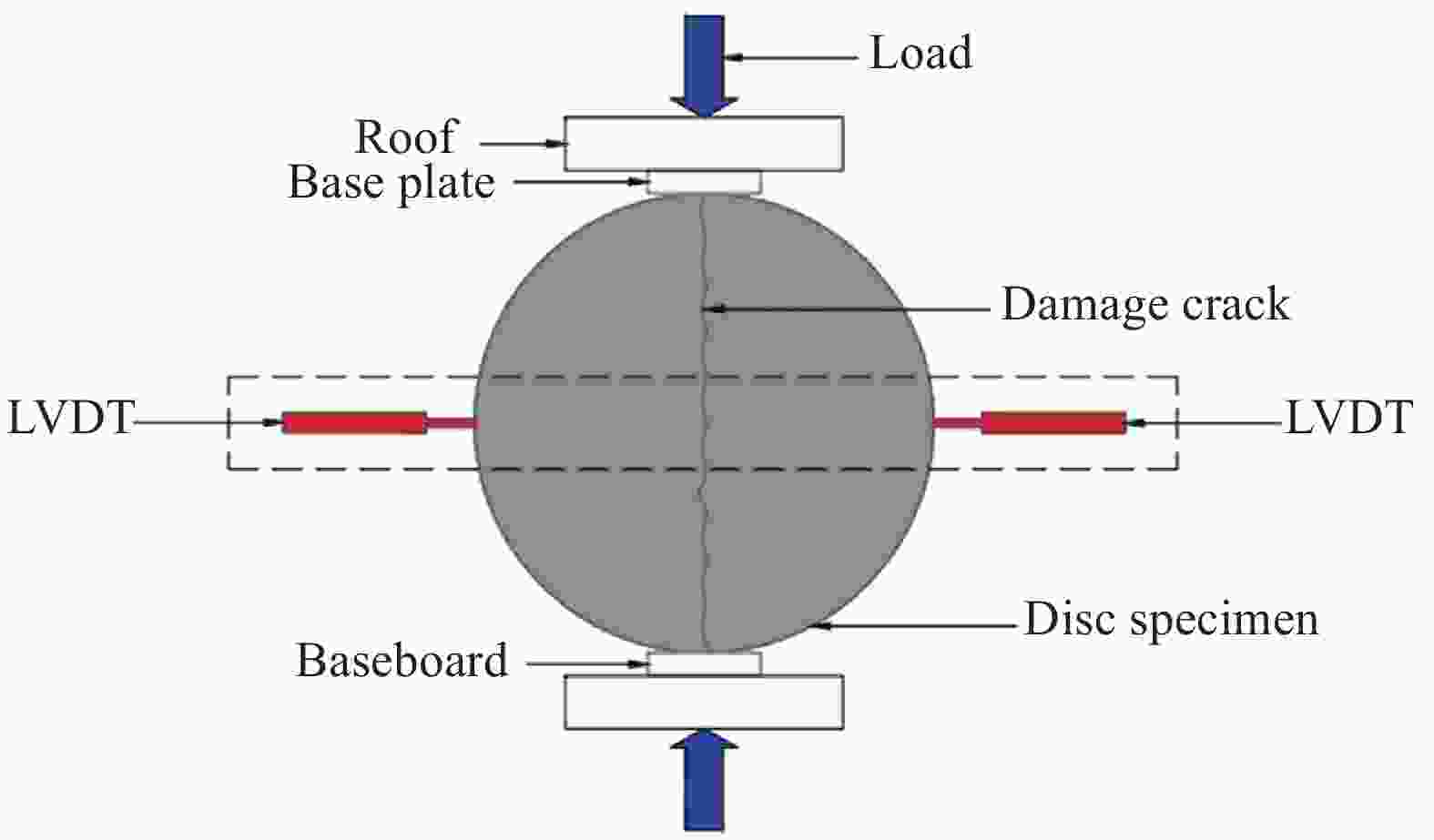

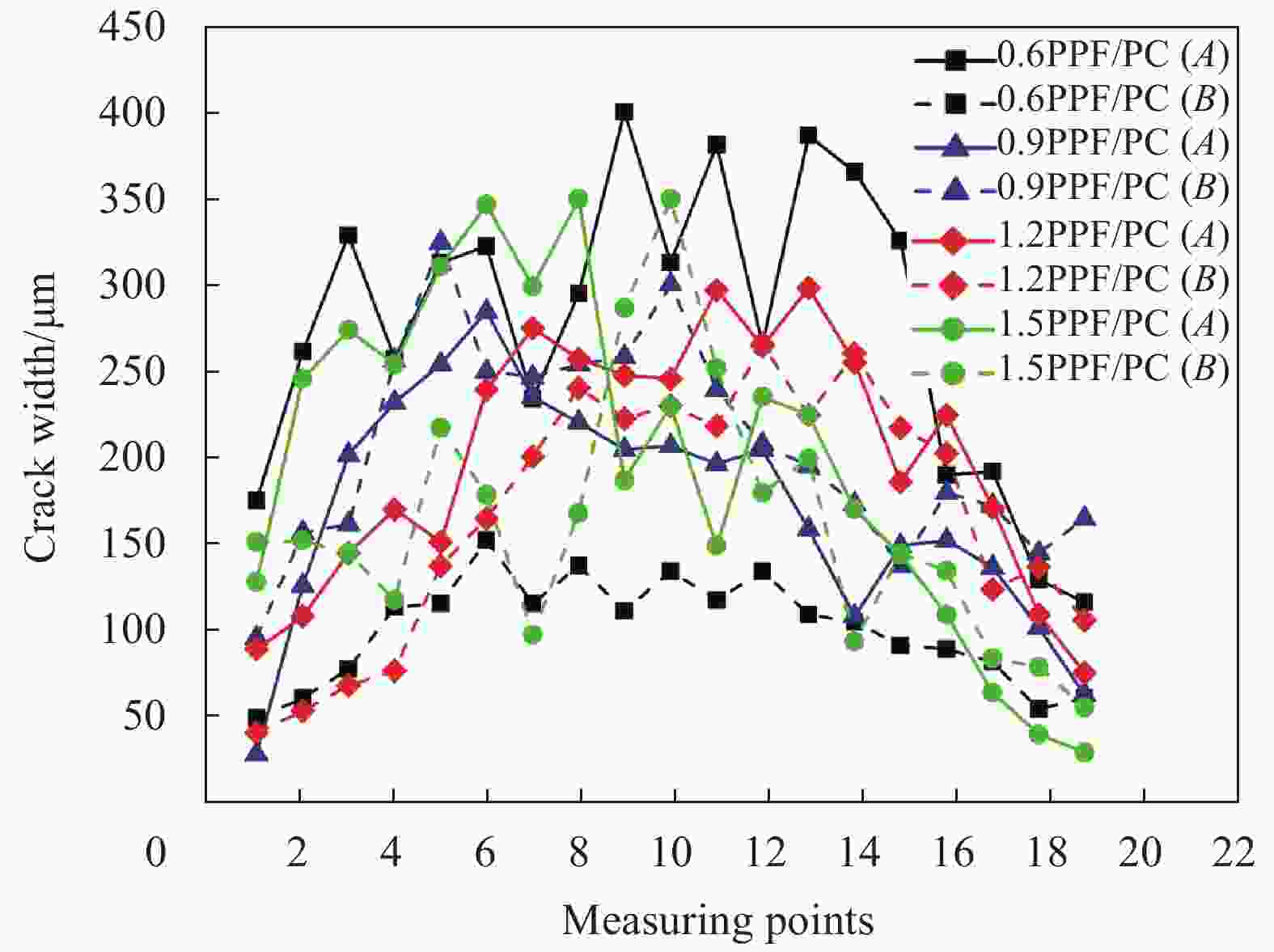

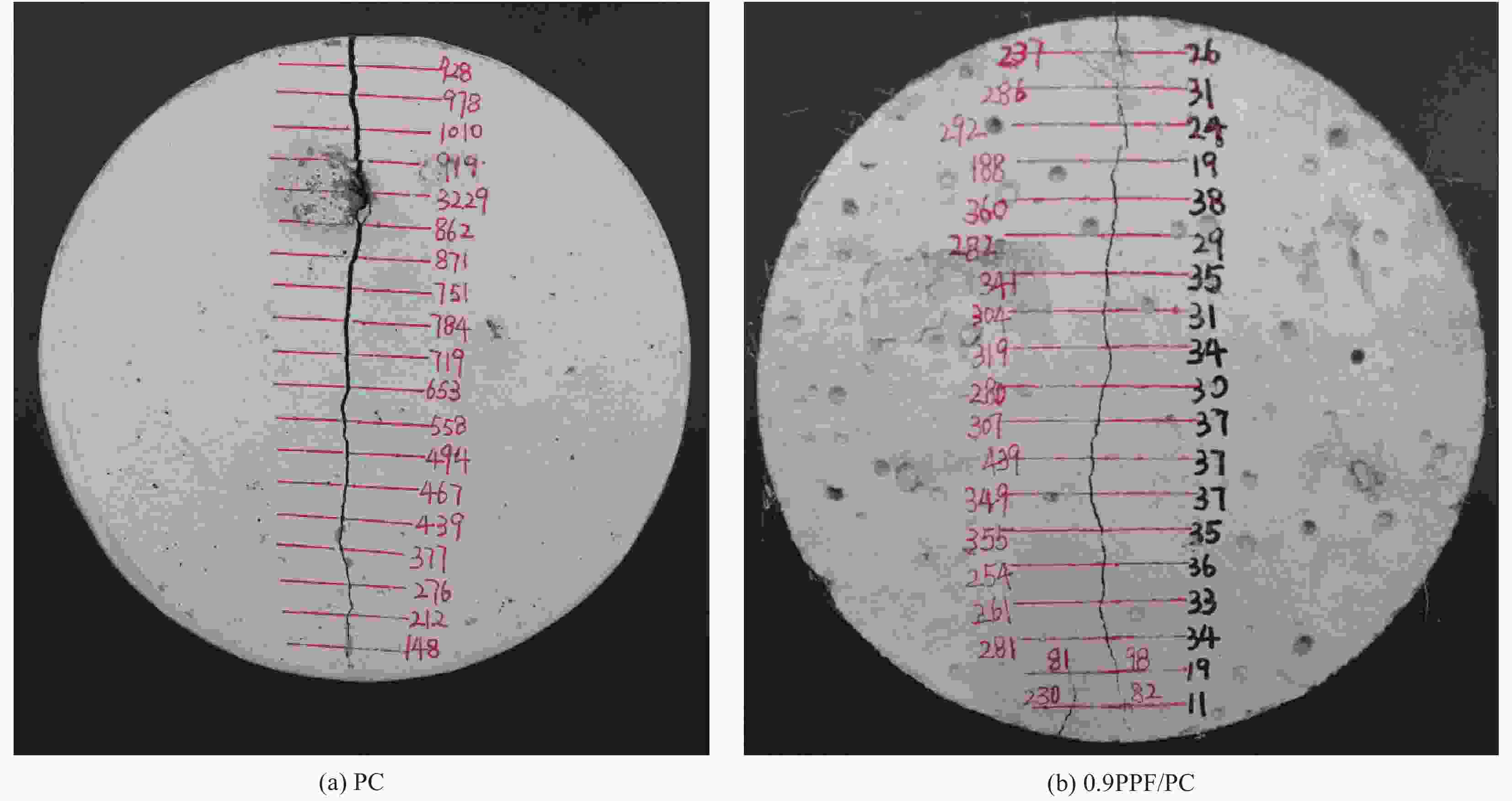

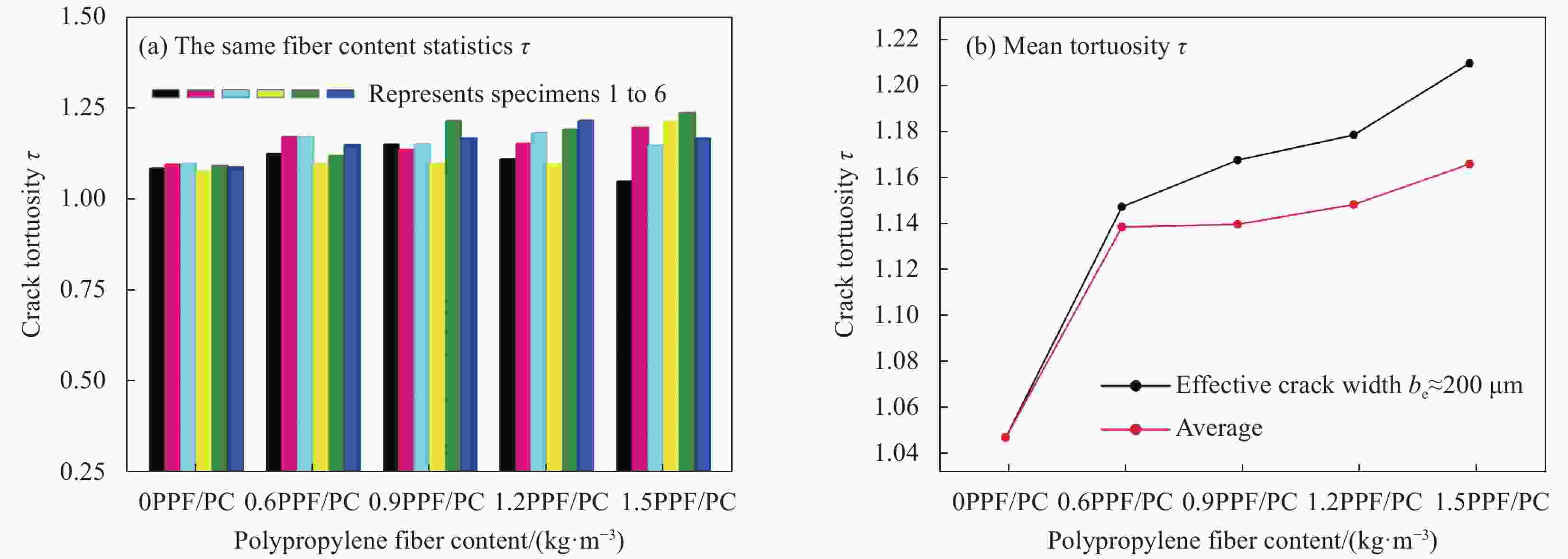

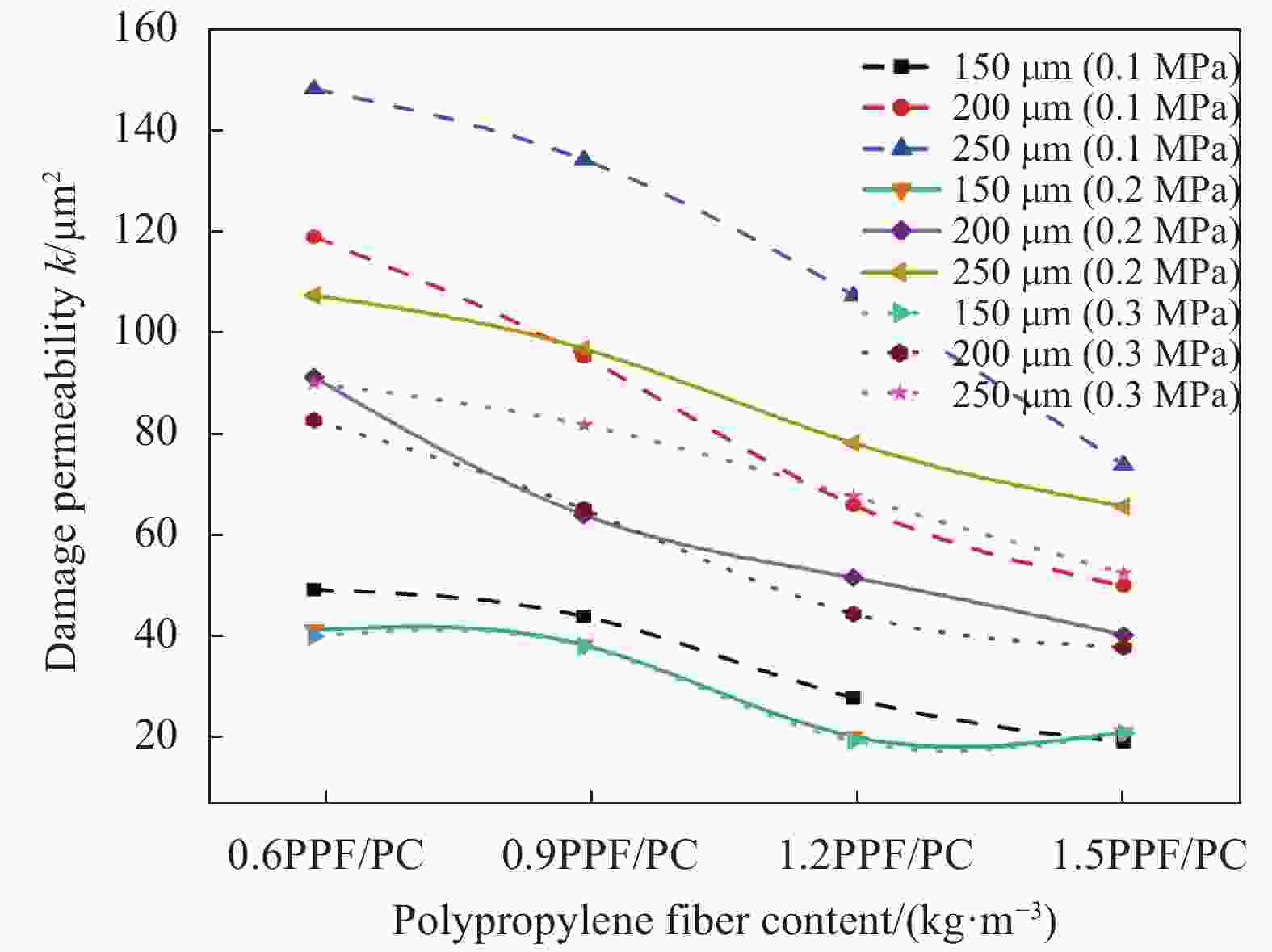

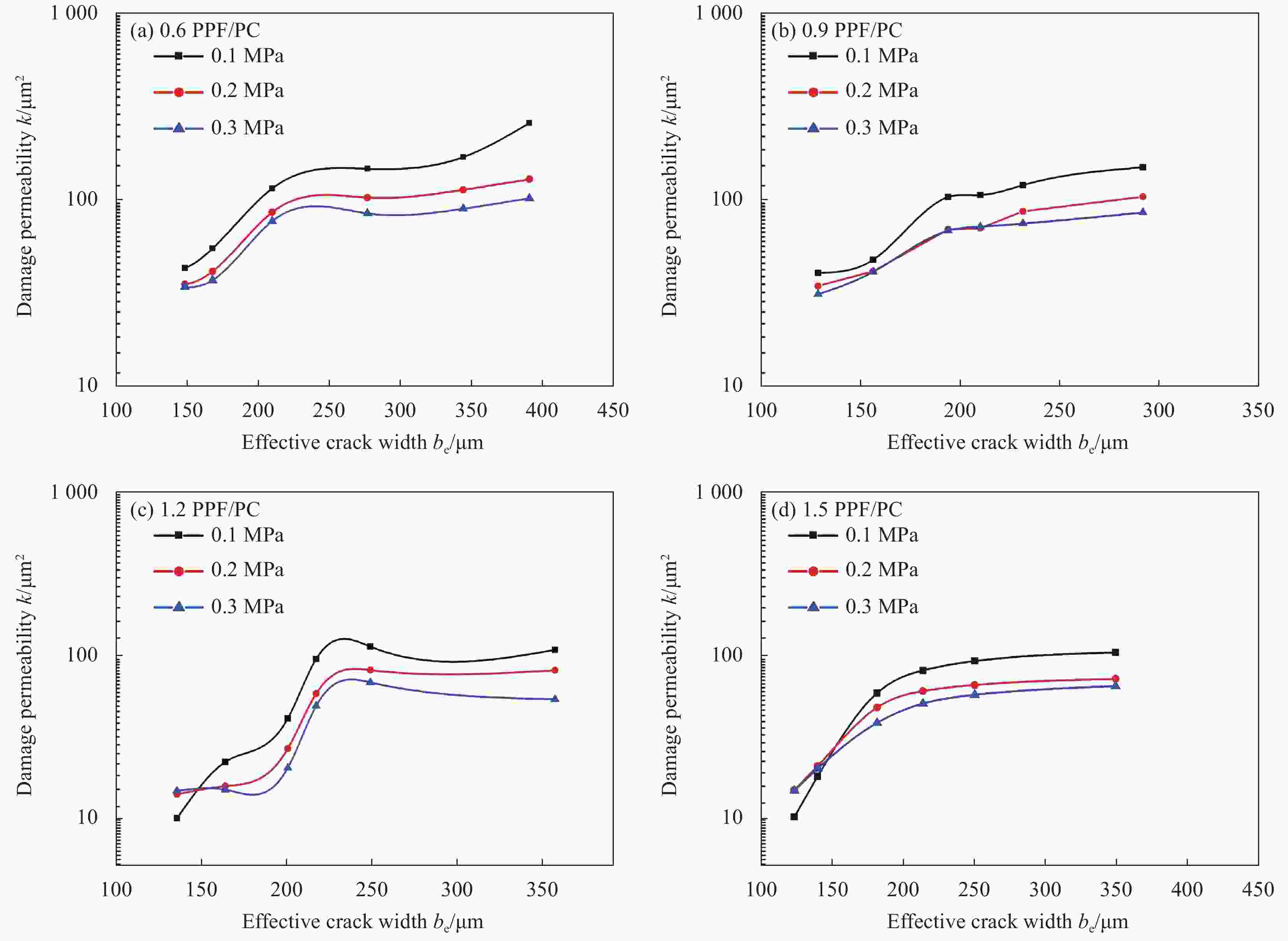

摘要: 为研究损伤开裂后聚丙烯纤维/混凝土(PPF/PC)的渗透特性,通过圆盘劈裂试验预制了不同宽度的裂缝(100~400 μm),比较了PPF掺量对裂缝曲折度的影响。利用自行设计的渗透试验装置对混凝土损伤后的渗透率进行了研究,分析了不同PPF掺量、不同水压力下混凝土的损伤渗透率的变化规律。通过研究发现,加入PPF后,混凝土脆性较低,内部裂缝更易控制,裂缝曲折度相对于PC更高,且与PPF掺量成正比;相同水压力,相同有效裂缝宽度条件下,随着PPF掺量的增加,混凝土损伤渗透率降低,PPF的存在能够有效提高混凝土损伤后的抗渗性能;相同水压力下,相同PPF掺量的混凝土试件损伤渗透率整体上与有效裂缝宽度成正比;不同水压力下,相同PPF掺量的PPF/PC损伤渗透率在同一有效裂缝宽度情况下,随水压力增加而减小;修正后的泊肃叶渗流模型可以更好地评价PPF/PC损伤渗透特性。Abstract: In order to study the permeability characteristics of polypropylene fiber reinforced concrete (PPF/PC) after damage and cracking, cracks with different width (100-400 μm) were prefabricated by disc splitting test, and the influence of PPF content on the crack tortuosity was compared. The permeability of concrete after damage was studied by using a self-designed permeability test device, and the change law of damage permeability of the concrete under different fiber contents and water pressures was analyzed. It is found that after adding PPF, the brittleness of concrete is lower, the internal cracks are easier to control, the crack tortuosity is higher than the ordinary concrete (PC), and is proportional to the fiber content; under the same water pressure and the same effective crack width, with the increase of PPF content, the damage permeability of concrete decreases, and the existence of fiber can effectively improve the impermeability of concrete after damage. Under the same water pressure, the damage permeability of concrete specimens with the same amount of PPF is directly proportional to the effective crack width; under different water pressures, the damage permeability of PPF/PC with the same PPF content decreases with the increase of water pressure under the same effective crack width; the modified Poiseuille model can better evaluate the damage and permeability characteristics of PPF/PC.

-

Key words:

- polypropylene fiber/plain concrete /

- damage /

- fiber content /

- tortuosity /

- water pressure /

- permeability

-

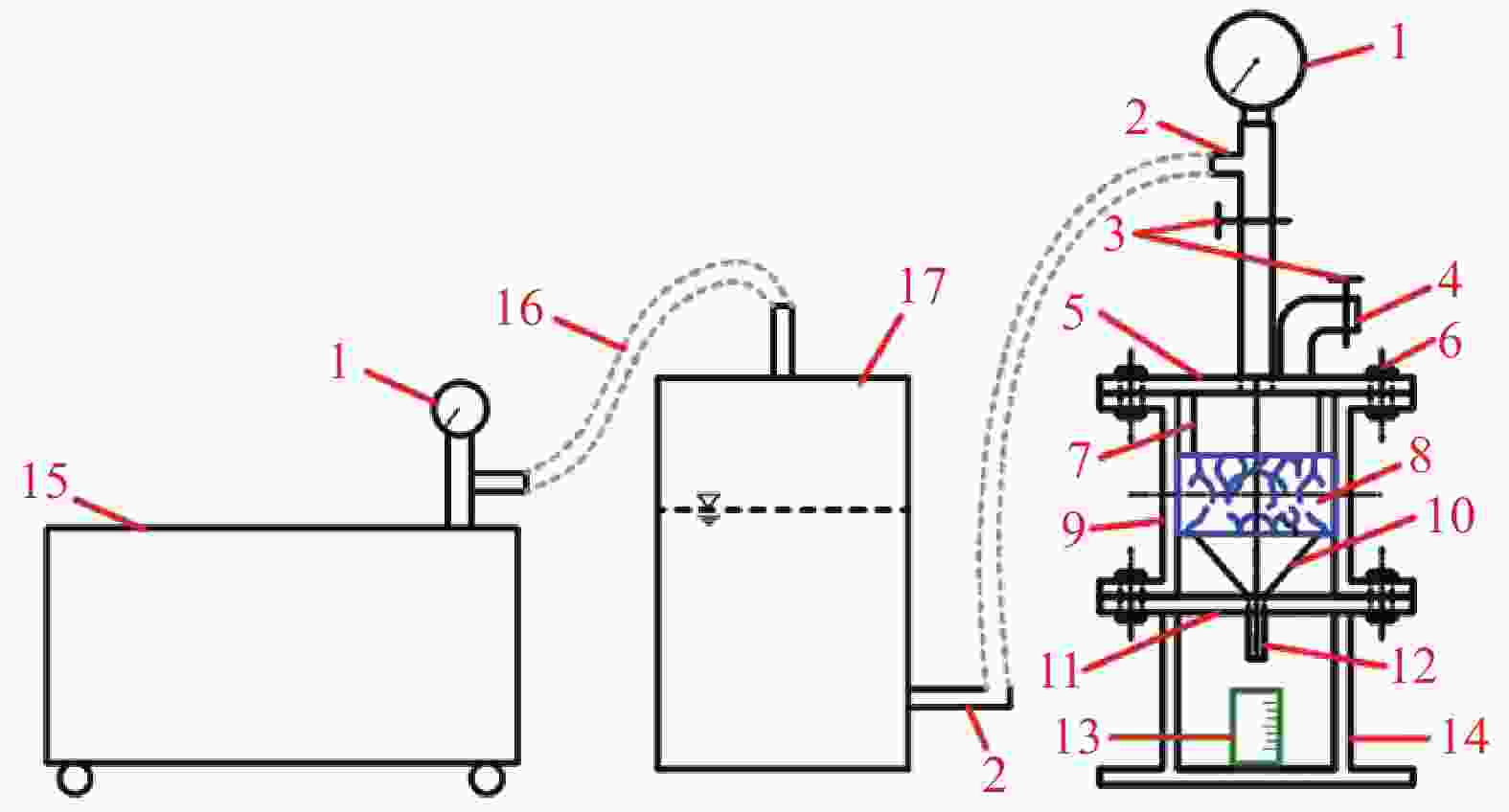

图 5 损伤渗透试验装置简图[18]

Figure 5. Schematic diagram of damage penetration test facility[18]

1—Pressure gauge; 2—Water pipe; 3—Valve; 4—Vent hole; 5—Top cover; 6—Six bolts; 7—Thin-walled annular sleeve; 8—Concrete specimen; 9—Support sleeves wall; 10—Water flows collector; 11—Bottom covers; 12—Water outlet; 13—Measuring cup; 14—Steel support bases

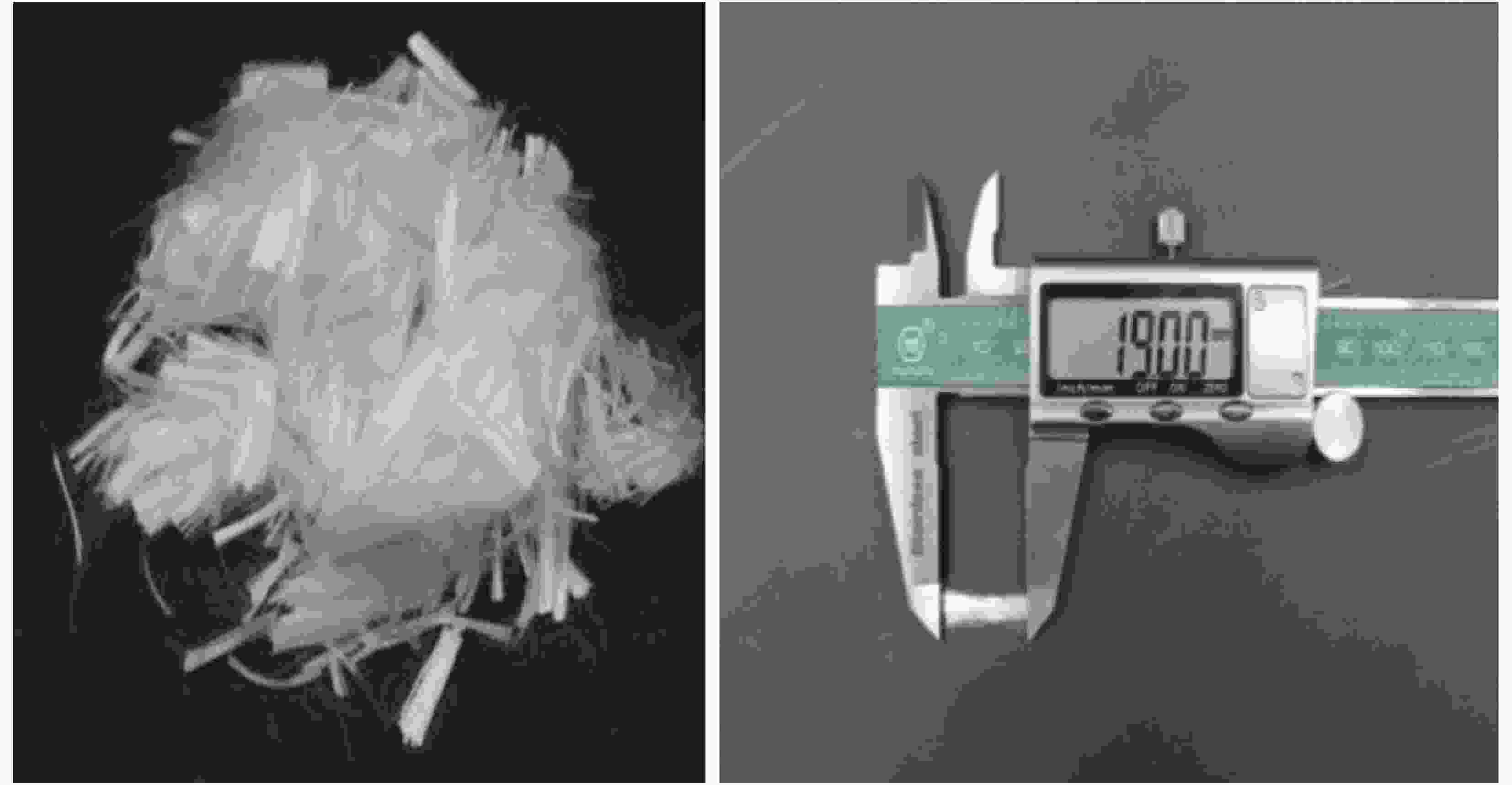

表 1 PPF性能参数

Table 1. Physical properties of PPF

Shape Density/(g·cm−3) Length/mm Diameter/μm Tensile strength/MPa Elastic modulus/MPa Elongation at break/% Bundle shape 0.91 19 31.2 565 5900 27 表 2 混凝土基准配合比及抗压强度

Table 2. Basic mix design and compressive strength of concrete

Specimen Water/

(kg·m−3)Cement/

(kg·m−3)Fly ash/

(kg·m−3)Fine aggregate/

(kg·m−3)Coarse aggregate/

(kg·m−3)Admixture/

(kg·m−3)Fiber content/

(kg·m−3)Strength/

MPaPC 135 275 90 815 1 080 10 0 33.29 PPF/PC 135 275 90 815 1 080 10 0.6 35.79 0.9 39.20 1.2 36.83 1.5 35.03 Note: PC—Plain concrete. 表 3 PPF/PC泊肃叶渗流模型修正系数

$\xi $ 取值Table 3. Poiseuille flow model correction coefficient

$\xi $ values of PPF/PCWater pressure/MPa Correction coefficient $\xi $/Relativity R2 0.6PPF/ PC 0.9PPF/PC 1.2PPF/PC 1.5PPF/PC 0.1 $\xi $ 0.0192 0.0214 0.0157 0.0107 R2 0.9000 0.8882 0.6338 0.7196 0.2 $\xi $ 0.0182 0.0158 0.0113 0.0082 R2 0.8608 0.8123 0.7101 0.5653 0.3 $\xi $ 0.0105 0.0139 0.0085 0.0073 R2 0.6157 0.6984 0.4856 0.6125 -

[1] DING Y N, LI D, ZHANG Y L, et al. Quantitative analysis of macro steel fiber influence on crack geometry and water permeability of concrete[J]. Composite Structures,2018,187:325-335. doi: 10.1016/j.compstruct.2017.12.074 [2] 丁一宁, 王卿, 林宇栋, 等. 纤维对开裂后混凝土渗透性及裂缝恢复的影响[J]. 复合材料学报, 2017, 34(8):1853-1861.DING Yining, WANG Qing, LIN Yudong, et al. Effect of fiber on permeability and crack recovery of cracked concrete[J]. Acta Materiae Compositae Sinica,2017,34(8):1853-1861(in Chinese). [3] 孙家瑛. 应力作用下纤维混凝土抗渗特征研究[J]. 建筑材料学报, 2012, 15(4):474-477. doi: 10.3969/j.issn.1007-9629.2012.04.007SUN Jiaying. Study on impermeability of fiber reinforced concrete under stress[J]. Journal of Building Materials,2012,15(4):474-477(in Chinese). doi: 10.3969/j.issn.1007-9629.2012.04.007 [4] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T50082—2009[S]. 北京. 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of lon-term performance and durability of ordinary concrete: GB/T50082—2009[S]. Beijing: China Architercture & Building Press, 2009(in Chinese). [5] WANG K, JANSEN D C, SHAH S P, et al. Permeability study of cracked concrete[J]. Cement and Concrete Research,1997,27(3):381-393. [6] 李庆华, 高栋, 徐世烺, 等. 超高韧性水泥基复合材料(UHTCC)的水渗透性能试验研究[J]. 水利学报, 2012, 43(S1):76-84.LI Qinghua, GAO Dong, XU Shilang, et al. Experimental study on water permeability of ultra-high toughness cement-based composite (UHTCC)[J]. Journal of Water Conservancy,2012,43(S1):76-84(in Chinese). [7] 李乐, 庞晓贇, 李克非. 含裂纹网络水泥基材料的渗透性[J]. 硅酸盐学报, 2015, 43(8):1047-1054.LI Le, PANG Xiaoyun, LI Kefei, et al. Permeability of cement-based materials with cracks[J]. Journal of Silicate,2015,43(8):1047-1054(in Chinese). [8] 吴刚, 李希龙, 史丽华, 等. 聚丙烯纤维混凝土抗渗性能的研究[J]. 混凝土, 2010(7):95-97, 101. doi: 10.3969/j.issn.1002-3550.2010.07.031WU Gang, LI Xilong, SHI Lihua, et al. Study on impermeability of polypropylene fiber reinforced concrete[J]. Concrete,2010(7):95-97, 101(in Chinese). doi: 10.3969/j.issn.1002-3550.2010.07.031 [9] 向阳开, 蓝祥雨. 隧道聚丙烯纤维混凝土抗渗性能分析及试验比较[J]. 土木建筑与环境工程, 2010, 32(5):114-118.XIANG Yangkai, LAN Xiangyu. Analysis and experimental comparison of impermeability polypropylene fiber reinforced concrete in tunnel[J]. Civil, Architectural and Environmental Engineering,2010,32(5):114-118(in Chinese). [10] 李冬, 丁一宁. 结构型纤维对开裂混凝土渗透性能的影响[J]. 土木工程学报, 2017, 50(10):62-68.LI Dong, DING Yining. Effect of structural fiber on permeability of cracked concrete[J]. Journal of Civil Engineering,2017,50(10):62-68(in Chinese). [11] JULIE R, CORINA M A, SURENDRA P, et al. Permeability of cracked steel fiber-reinforced concrete[J]. Journal of Materials in Civil Engineering,2002,14(4):355-358. [12] ALDEA C M, SHAH S P, KARR A. Permeability of crackedconcrete[J]. Materials and Structures,1999,32(5):370-376. [13] INCENT P, ABDELHAFID K, HERVE B, et al. Crack effects on gas and water permeability of concretes[J]. Cement and Concrete Research,2009,39(6):537-547. [14] SURENDRA P, SHAH J, LAWLER S, et al. Permeability of cracked hybrid fiber-reinforced mortar under load[J]. ACI Materials Journal,2002,99(4):379-385. [15] ALIREZA A, SEYED M H S, FARSHAD R. Quantifying the effects of crack width, tortuosity, and roughness on water permeability of cracked mortars[J]. Cement and Concrete Research,2012,42(2):313-320. doi: 10.1016/j.cemconres.2011.10.002 [16] ISMAIL M, TOUMI A, FRANCOIS R, et al. Effect of crack opening on the local diffusion of chloride in inert materials[J]. Cement and Concrete Research,2004,34(4):711-716. doi: 10.1016/j.cemconres.2003.10.025 [17] DESMETTRE C, CHARRON J P. Water permeability of reinforced concrete with and without fiber subjected to static and constant tensile loading[J]. Cement and Concrete Research,2012,42(7):945-952. doi: 10.1016/j.cemconres.2012.03.014 [18] 马伟丽. 纤维混凝土损伤后渗透特性试验研究[D]. 西安: 西安理工大学, 2020.MA Weili. Experimental study on permeability characteristics of fiber reinforced concrete after damage[D]. Xi’an: Xi’an University of Technology, 2020(in Chinese). [19] HUBERT, MAXIME, DESMETTRE, et al. Influence of fiber content and reinforcement ratio on the water permeability of reinforced concrete[J]. Materials and Structures,2015,48(9):2795-2807. doi: 10.1617/s11527-014-0354-z [20] 翁其能, 袁勇, 王学军. 渗透作用下开裂混凝土的材料损伤模型[J]. 材料导报, 2008(5):104-106, 110. doi: 10.3321/j.issn:1005-023X.2008.05.026WENG Qineng, YUAN Yong, WANG Xuejun. Material damage model of cracked concrete under infiltration[J]. Material Guide,2008(5):104-106, 110(in Chinese). doi: 10.3321/j.issn:1005-023X.2008.05.026 [21] 曾伟, 丁一宁. 荷载作用下结构型纤维对混凝土裂缝渗透率演化的影响[J]. 复合材料学报, 2020, 37(9): 2314-2323.ZENG Wei, DING Yining. Effect of structura fiber on crack permeability evolution of concrete under loading[J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2314-2323(in Chinese). [22] 郝晓卫. 纤维对混凝土裂缝断面曲折度及渗透性的影响[D]. 大连: 大连理工大学, 2018.HAO Xiaowei. Effect of fiber on curvature and permeability of concrete crack section[D]. Dalian: Dalian University of Technology, 2018(in Chinese). -

下载:

下载: