| [1] |

益小苏, 杜善义, 张立同. 复合材料手册[M]. 北京: 化学工业出版社, 2009: 365-368.YI X S, DU S Y, ZHANG L T. Composite materials brochure[M]. Beijing: Chemical Industry Press, 2009: 365-368(in Chinese).

|

| [2] |

OLIVEIRA T L L, ZITOUNE R, ANCELOTTI A C, et al. Smart machining: monitoring of CFRP milling using AE and IR[J]. Composite Structures,2020,249:112611. doi: 10.1016/j.compstruct.2020.112611

|

| [3] |

MA X S, BIAN K, LIU H G, et al. Numerical and experimental investigation of the interface properties and failure strength of CFRP T-stiffeners subjected to pull-off load[J]. Materials and Design,2020,185:108231. doi: 10.1016/j.matdes.2019.108231

|

| [4] |

石经纬, 赵娟, 刘传军, 等. 复合材料翼面壁板轴压稳定性[J]. 复合材料学报, 2020, 37(6):1321-1333.SHI J W, ZHAO J, LIU C J, et al. Stability of composite stiff ened panels under compression[J]. Acta Materiae Compositae Sinica,2020,37(6):1321-1333(in Chinese).

|

| [5] |

HOPKINS D, NEAU G, LE B L. Advanced phased-array technologies for ultrasonic inspection of complex composite parts[J]. Cinde Journal,2012,33(2):273-282.

|

| [6] |

何方成, 王铮, 史丽军. 复合材料制件拐角部位超声检测技术[J]. 材料工程, 2011(7):80-84. doi: 10.3969/j.issn.1001-4381.2011.07.017HE F C, WANG Z, SHI L J. Ultrasonic testing technique for the inspection of defects in the corner of composites[J]. Journal of Materials Engineering,2011(7):80-84(in Chinese). doi: 10.3969/j.issn.1001-4381.2011.07.017

|

| [7] |

BULLINGER O, SCHNARS U, SCHULTING D, et al. Laminographic inspection of large carbon fibre composite aircraft-structures at airbus[C] // PURSCHKE M. 19th World Conference on Non-Destructive Testing. Munich Germany: Curran Associates, Inc. 2016: 204-213.

|

| [8] |

GEORGESON G. A century of Boeing innovation in NDE[J]. Boeing Technology Journal,2016:1-11.

|

| [9] |

HABERMEHL J, LAMARRE A. Ultrasonic phased array tools for composite inspection during maintenance and manufacturing[C] // GENG R S. 17th World Conference on Nondestructive Testing. Shanghai China: Curran Associates, Inc. 2008: 3070-3075.

|

| [10] |

HU H J, ZHU X, WANG C H, et al. Stretchable ultrasonic transducer arrays for three-dimensional imaging on complex surfaces[J]. Science Advances,2018,4(3):3979. doi: 10.1126/sciadv.aar3979

|

| [11] |

ROBERT S, CASULA O, ROY O, et al. Real-time nondestructive testing of composite aeronautical structures with a self-adaptive ultrasonic technique[J]. Measurement Science and Technology,2013,24:074011. doi: 10.1088/0957-0233/24/7/074011

|

| [12] |

LIN L, CAO H Q, LUO Z B. Total focusing method imaging of multidirectional CFRP laminate with model-based time delay correction[J]. NDT and E International,2018,97:51-58. doi: 10.1016/j.ndteint.2018.03.011

|

| [13] |

LIN L, CAO H Q, LUO Z B. Dijkstra’s algorithm-based ray tracing method for total focusing method imaging of CFRP laminates[J]. Composite Structures,2019,215:298-304. doi: 10.1016/j.compstruct.2019.02.086

|

| [14] |

DEYDIER S, GENGEMBRE N, CALMON P, et al. Ultrasonic field computation into multilayered composite materials using a homogenization method based on ray theory[C] // THOMPSON D O. Review of Progress in Quantitative Nondestructive Evaluation. New York: American Institute of Physics, 2005: 1057-1064.

|

| [15] |

JOURNIAC S, LEYMARIE N, DOMINGUEZ N, et al. Simulation of ultrasonic inspection of composite using bulk waves: application to curved components[J]. Journal of Physics: Conference Series,2011,269:012022. doi: 10.1088/1742-6596/269/1/012022

|

| [16] |

DOMINGUEZ N, REVERDY F. Simulation of ultrasonic testing of composite structures[C] // MAZAL P. 11th European Conference on Non-Destructive Testing. New York: Curran Associates, Inc., 2014: 2998-3007.

|

| [17] |

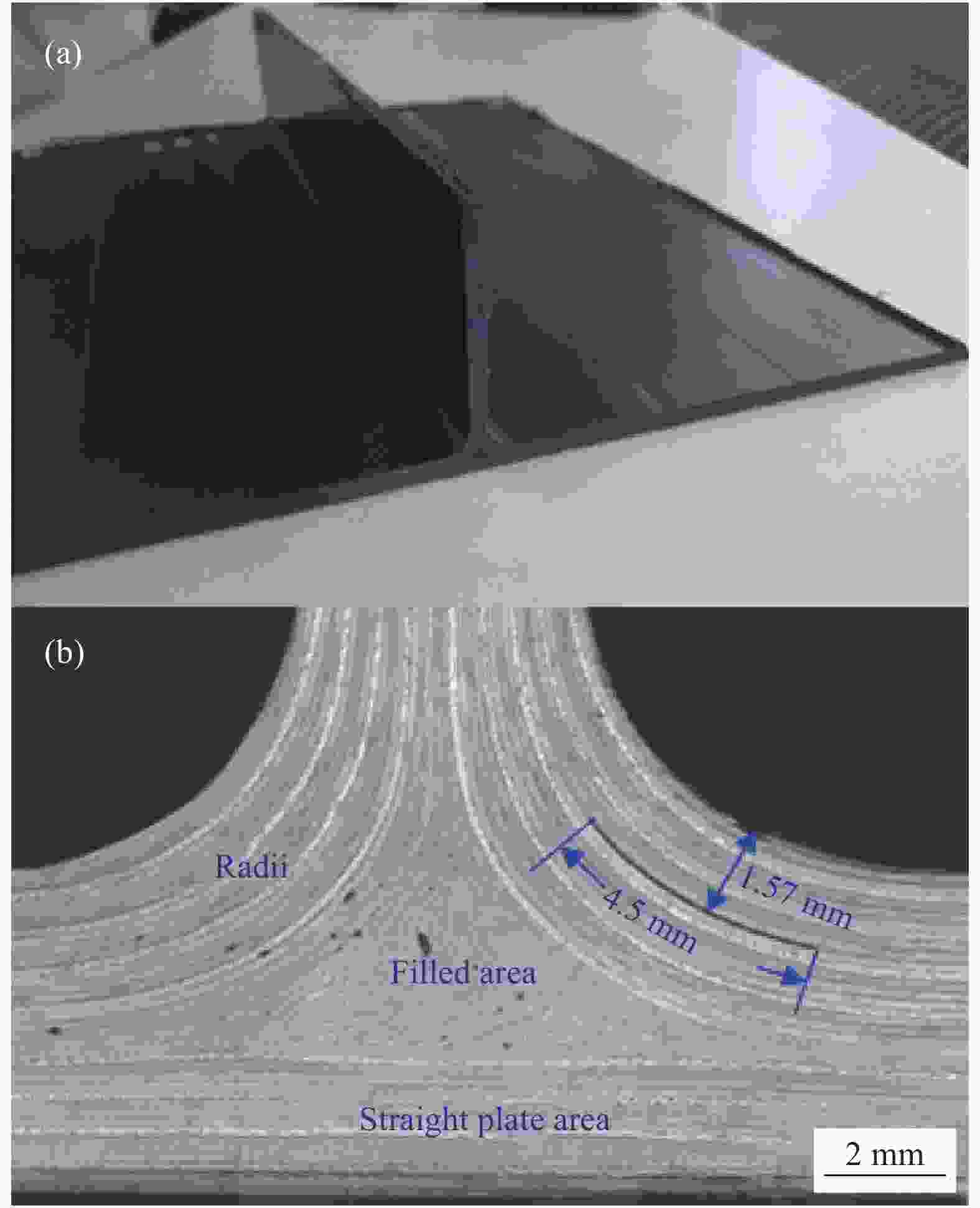

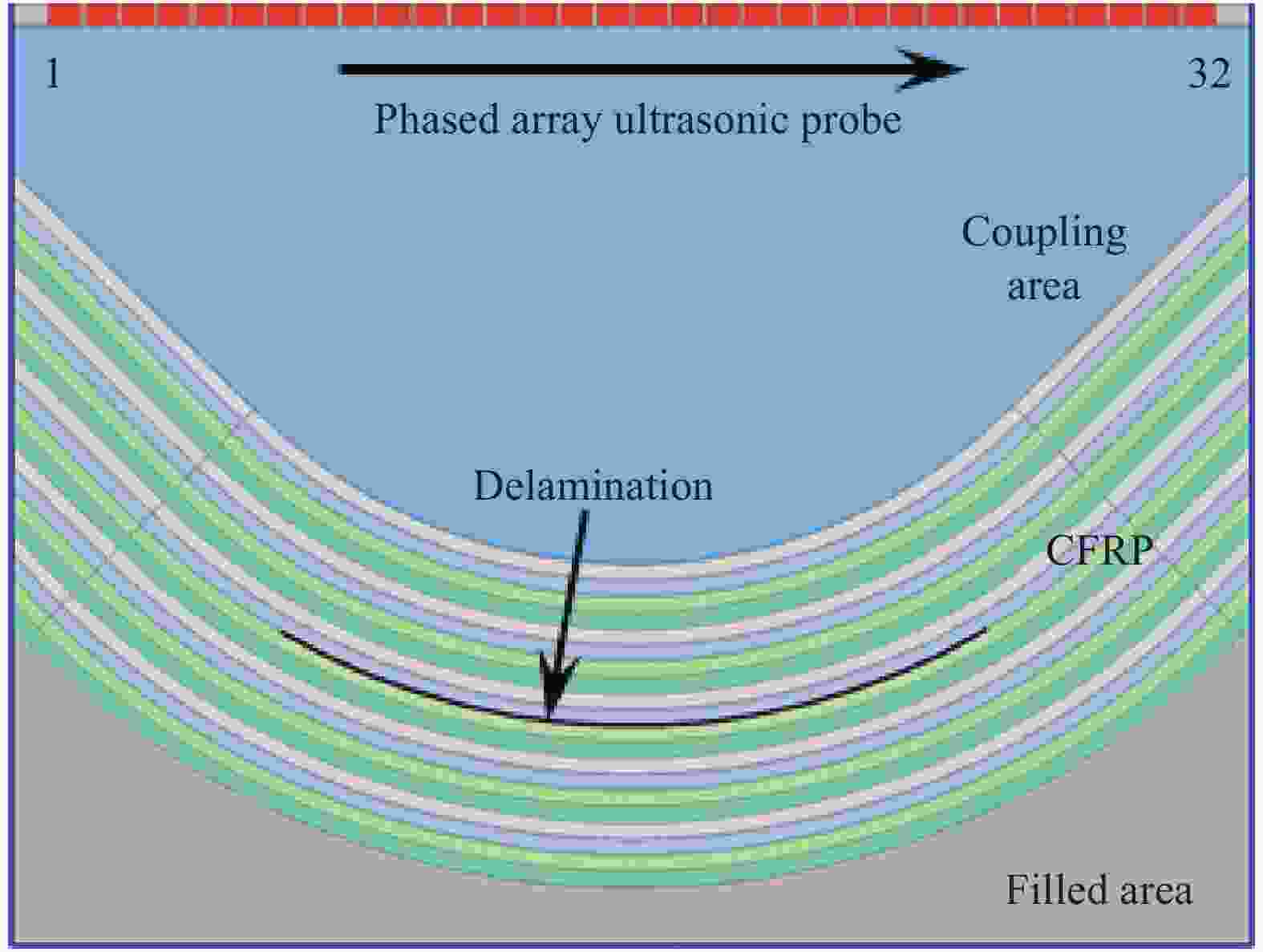

XU N, ZHOU Z G. Numerical simulation and experiment for inspection of corner-shaped components using ultrasonic phased array[J]. NDT and E International,2014,63:28-34. doi: 10.1016/j.ndteint.2014.01.005

|

| [18] |

ITO J, BIWA S, HAYASHI T, et al. Ultrasonic wave propagation in the corner section of composite laminate structure: Numerical simulations and experiments[J]. Composite Structures,2015,123:78-87. doi: 10.1016/j.compstruct.2014.12.026

|

| [19] |

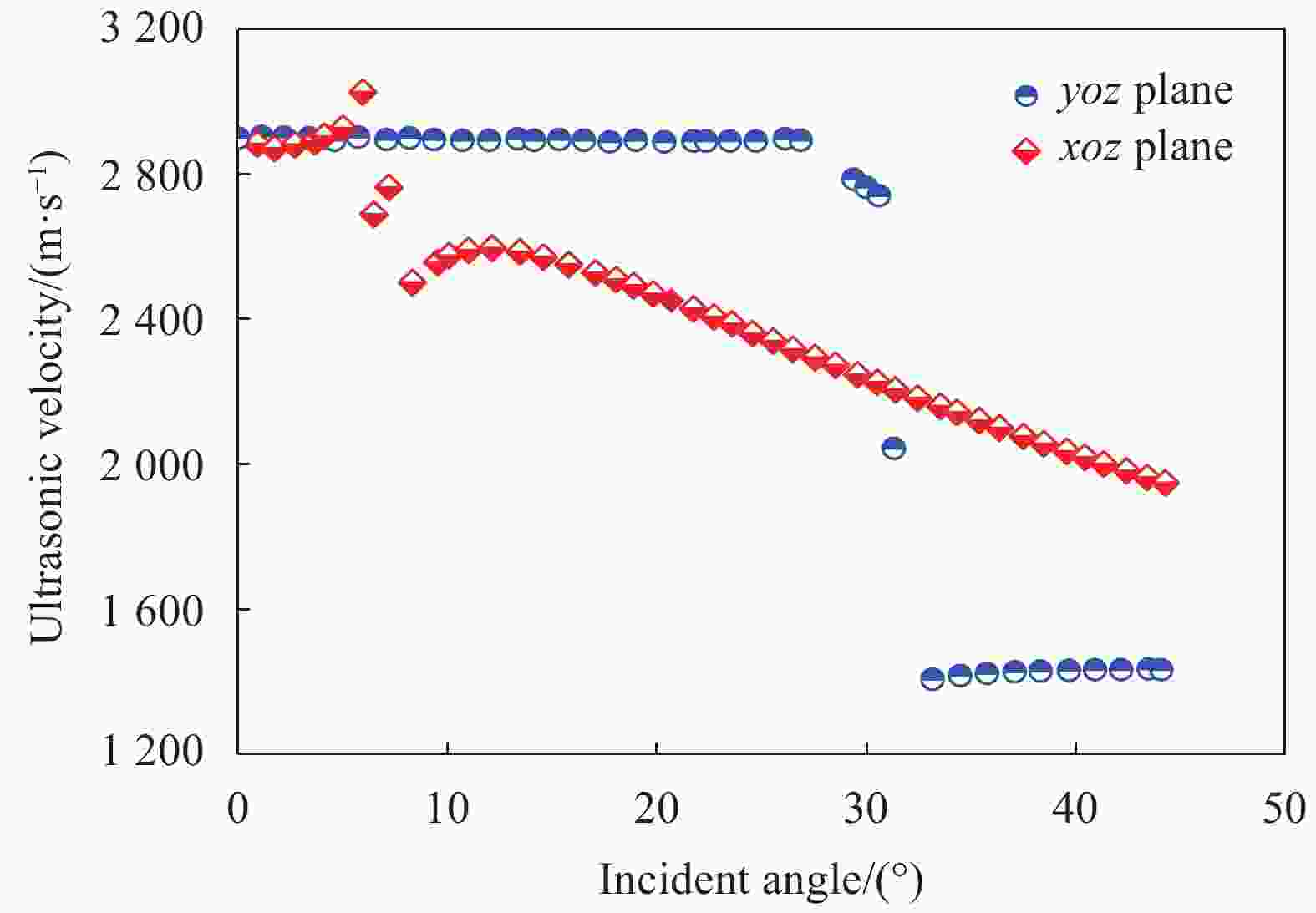

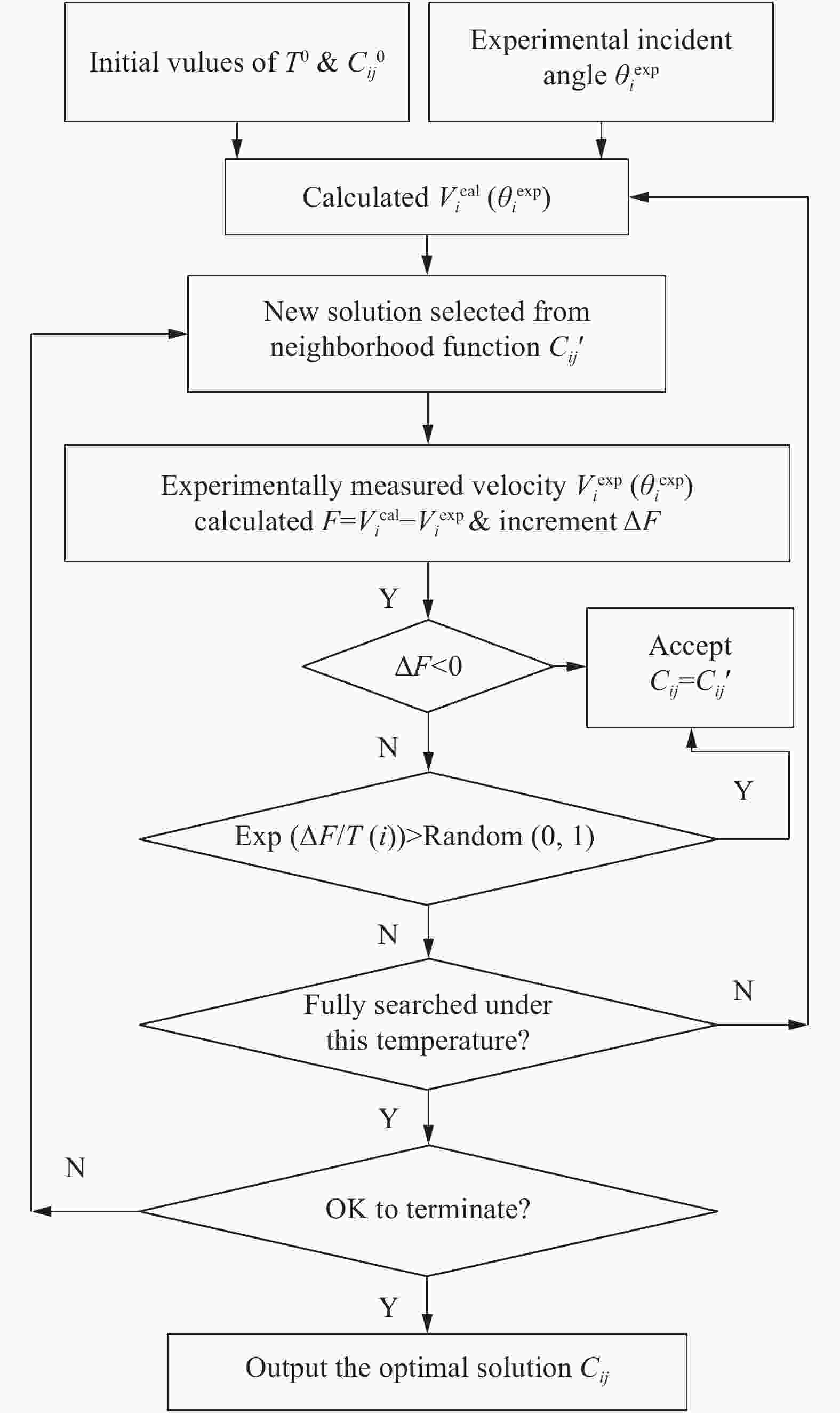

苏慧敏, 罗忠兵, 曹欢庆, 等. 提高碳纤维增强树脂基复合材料弹性常数超声表征精度的方法[J]. 复合材料学报, 2016, 33:2510-2516.SU H M, LUO Z B, CAO H Q, et al. Improve methods for elastic constants ultrasonic characterization accuracy of carbon fiber reinforced plastics[J]. Acta Materiae Compositae Sinica,2016,33:2510-2516(in Chinese).

|

| [20] |

CASTELLANO A, FOTI P, FRADDOSIO A, et al. Mechanical characterization of CFRP composites by ultrasonic immersion tests: Experimental and numerical approaches[J]. Composite Part B: Engineering,2014,66:299-310. doi: 10.1016/j.compositesb.2014.04.024

|

| [21] |

ROSE J L. Ultrasonic waves in solid media[M]. New York: Cambridge University Press, 1999: 274-277.

|

| [22] |

SU H M, LUO Z B, CAO H Q, et al. Focal law design for phased array ultrasonic testing of CFRP based on finite element modeling[C]. 2016 IEEE Far East NDT New Technology & Application Forum. IEEE, 2016: 1690-1696.

|

下载:

下载: