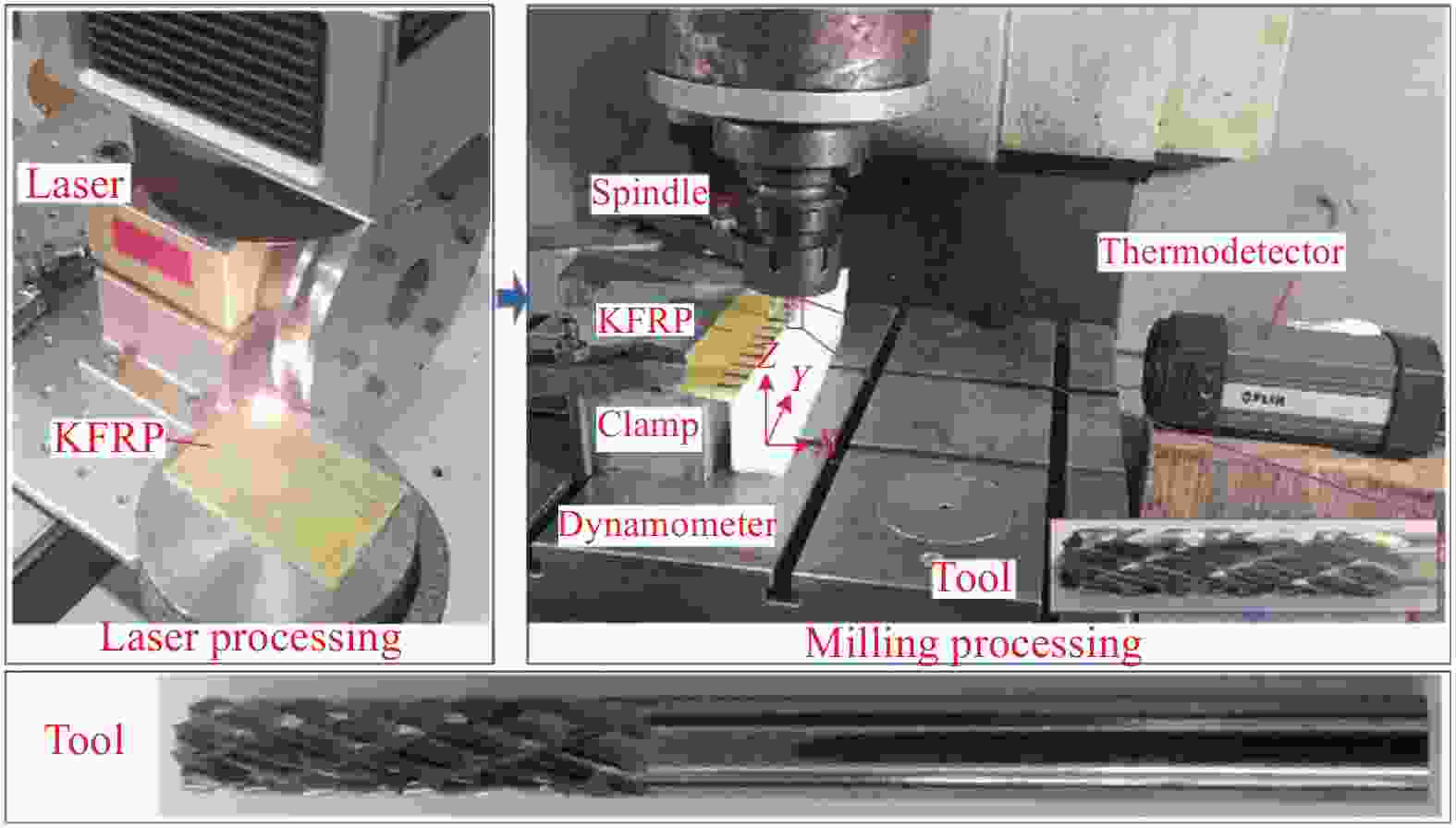

Research on the feasibility and machining experiment of the laser-milling combination machining for Kevlar fiber reinforced composite

-

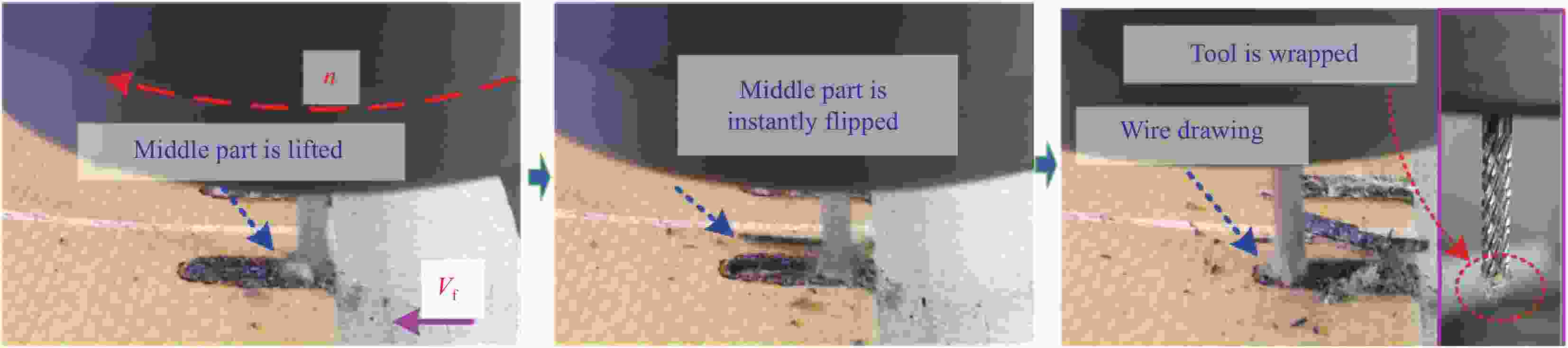

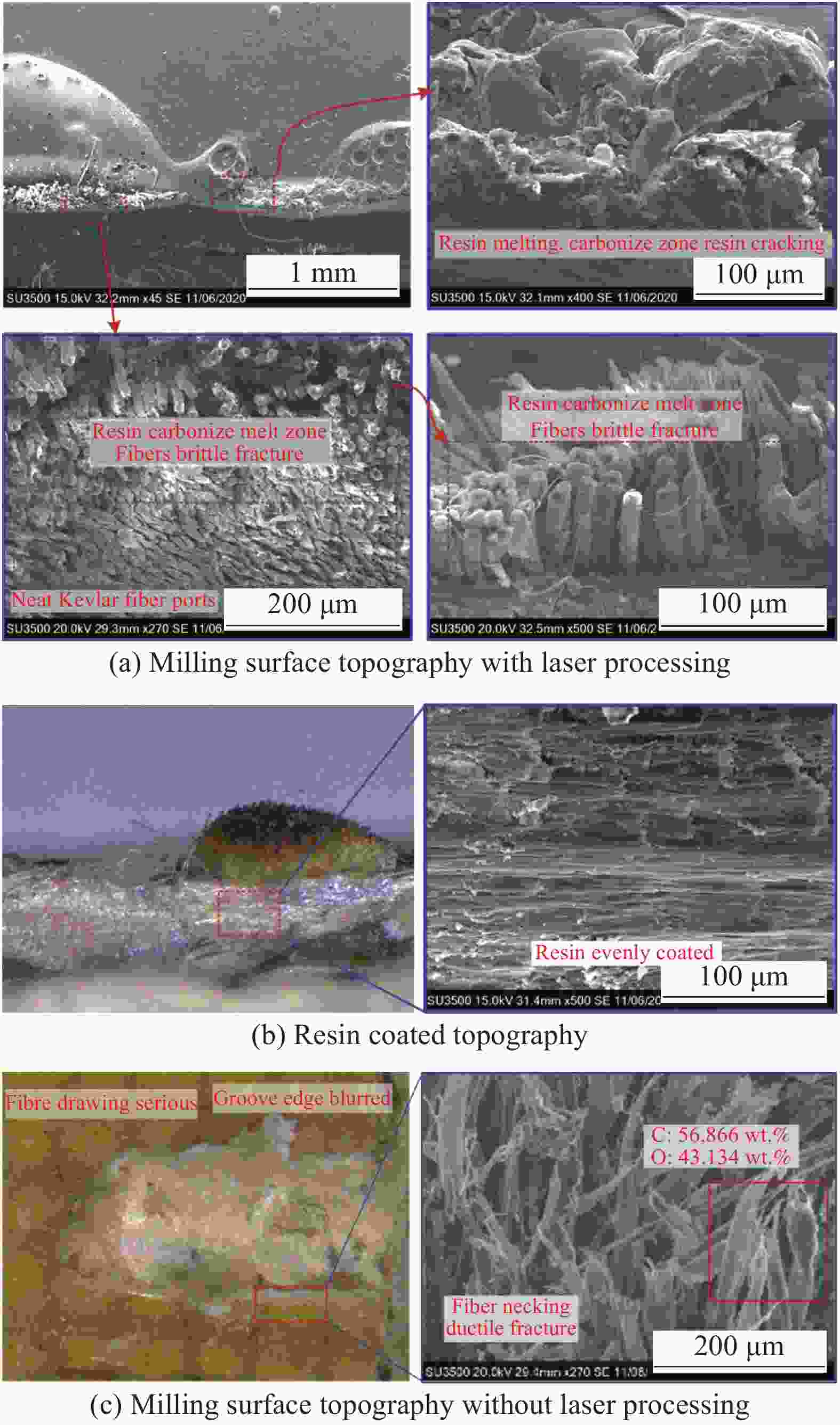

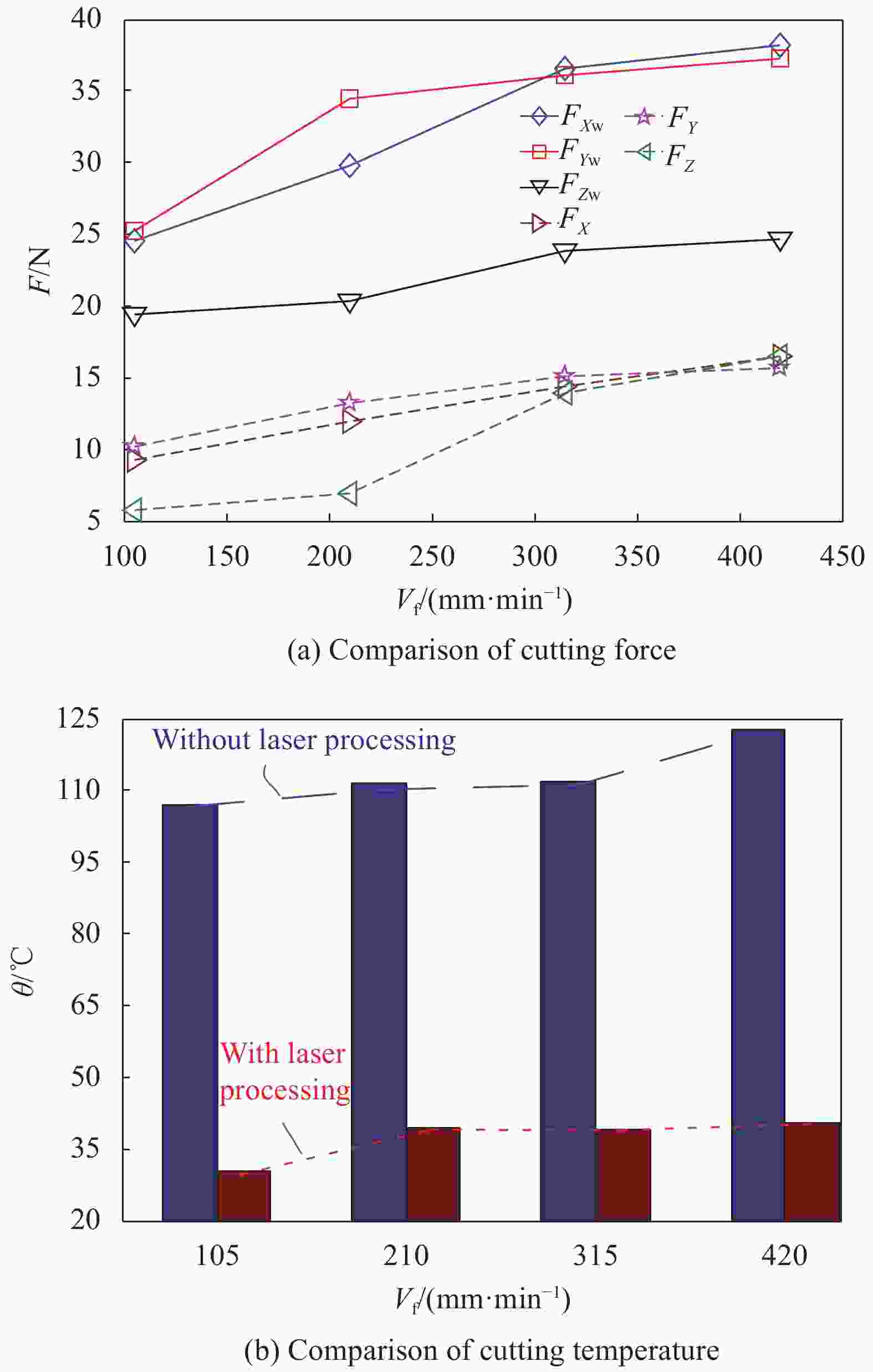

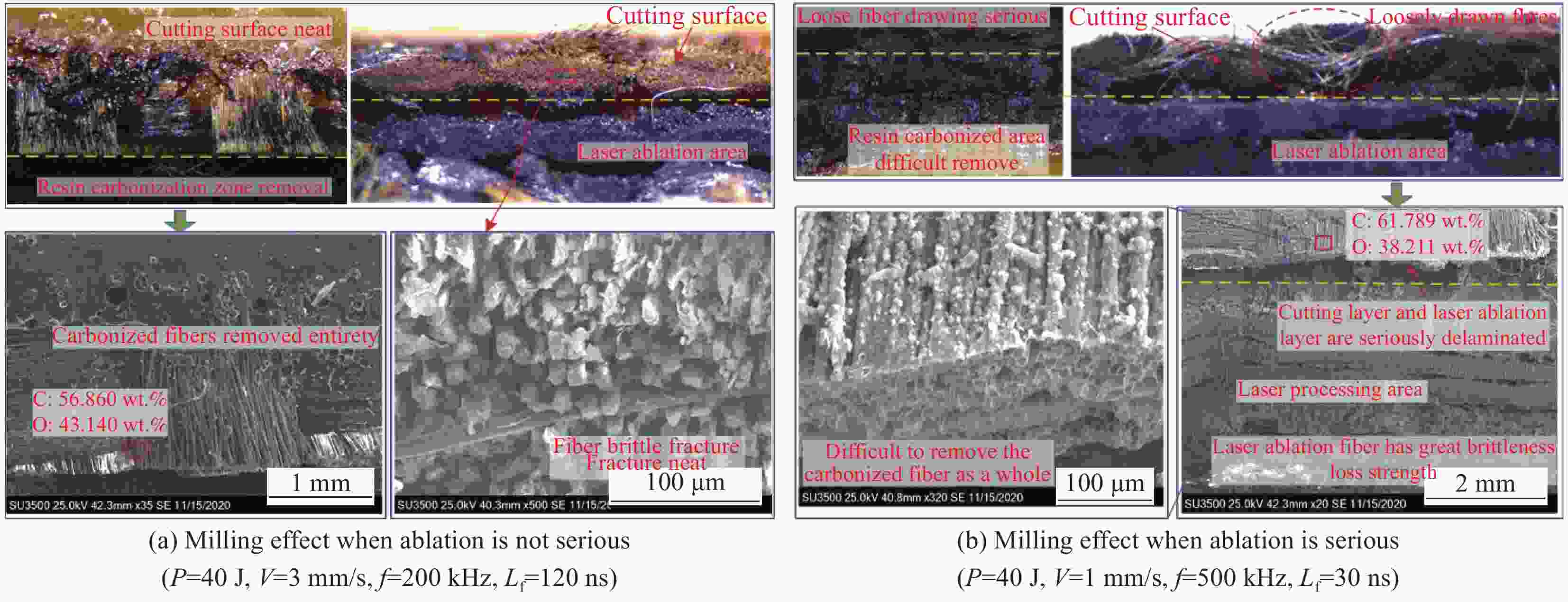

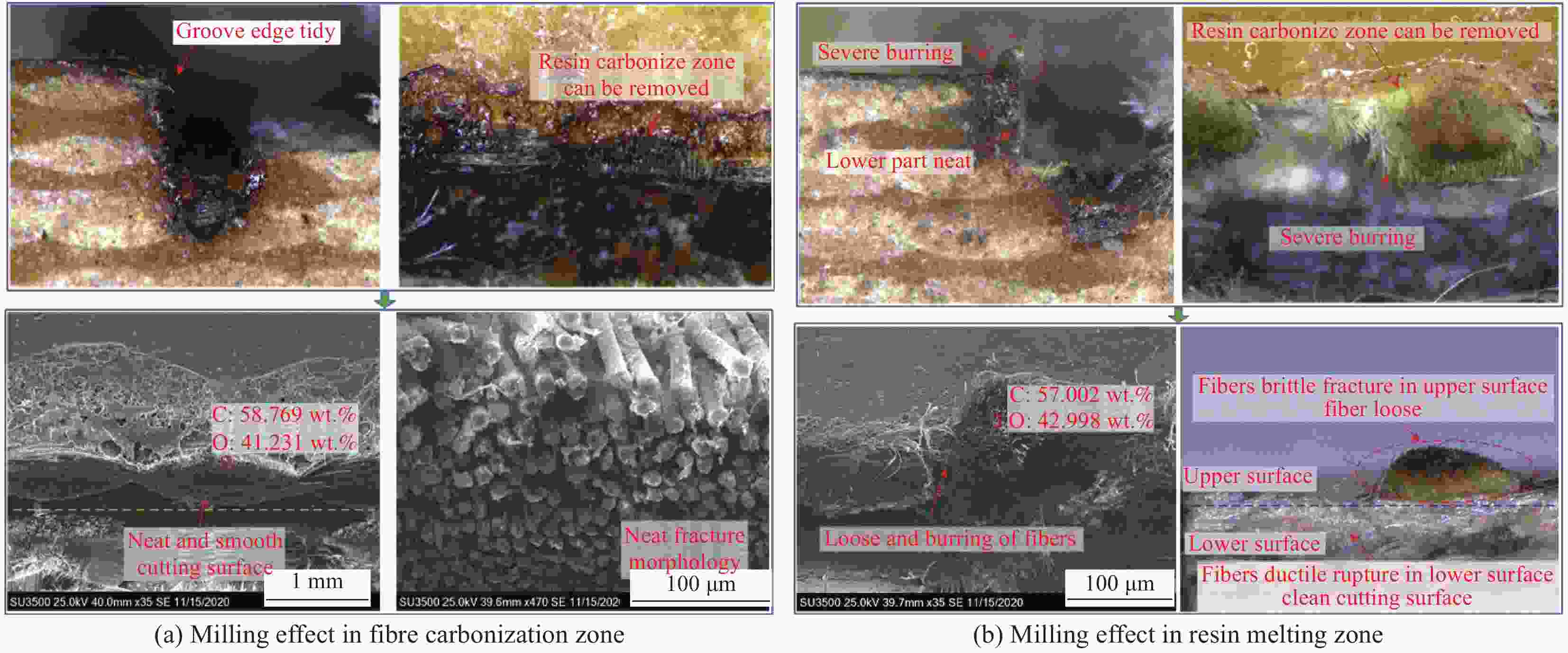

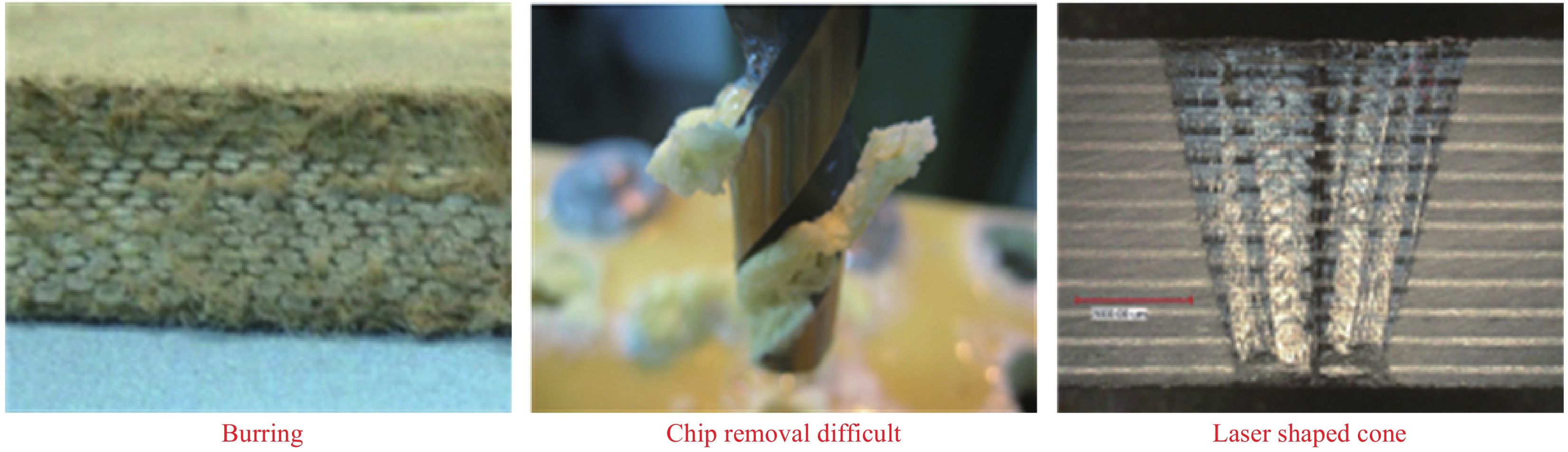

摘要: Kevlar增强复合材料(Kevlar fiber-reinforced plastic,KFRP)在武器装甲防护领域受到了强烈的关注和广泛的应用。在机械加工中极易产生拉毛、难以排屑、刀具磨损严重等问题,在激光加工中依然存在诸多难点。为同时规避KFRP机械加工缺陷和激光加工的短板问题,本文提出KFRP激光-铣削组合加工,分析KFRP激光-铣削组合加工工艺的可行性。试验表明,KFRP激光加工中存在明显的纤维炭化区、树脂熔融区,其中,在树脂熔融区,纤维基本未受损。激光加工的最大切缝宽度在0.5 mm以下,深度不超过2 mm,激光加工工艺参数对切缝宽度a的影响相对较小,但对切缝深度h、纤维炭化区宽度A、树脂熔融区宽度Am影响显著。激光-铣削组合加工中,切屑呈大块状和絮状,当纤维烧蚀不完全时,容易出现抽丝现象。KFRP激光-铣削组合加工,不仅能有效的避免纤维拉毛现象,还能大幅度降低切削力和切削温度,从而提高加工质量,降低加工难度。

-

关键词:

- Kevlar纤维增强复合材料(KFRP) /

- 激光-铣削 /

- 加工机制 /

- 组合加工 /

- 激光加工

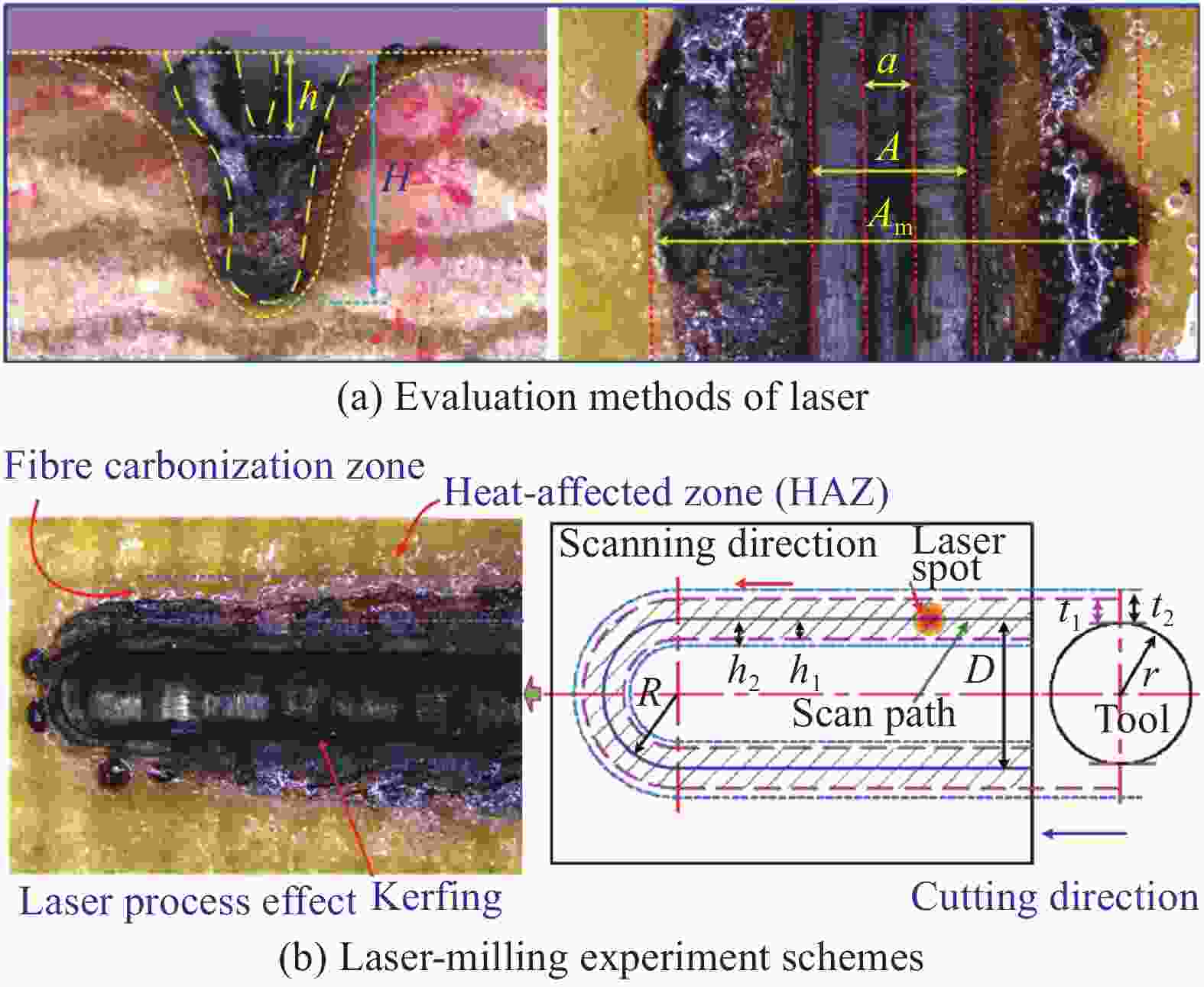

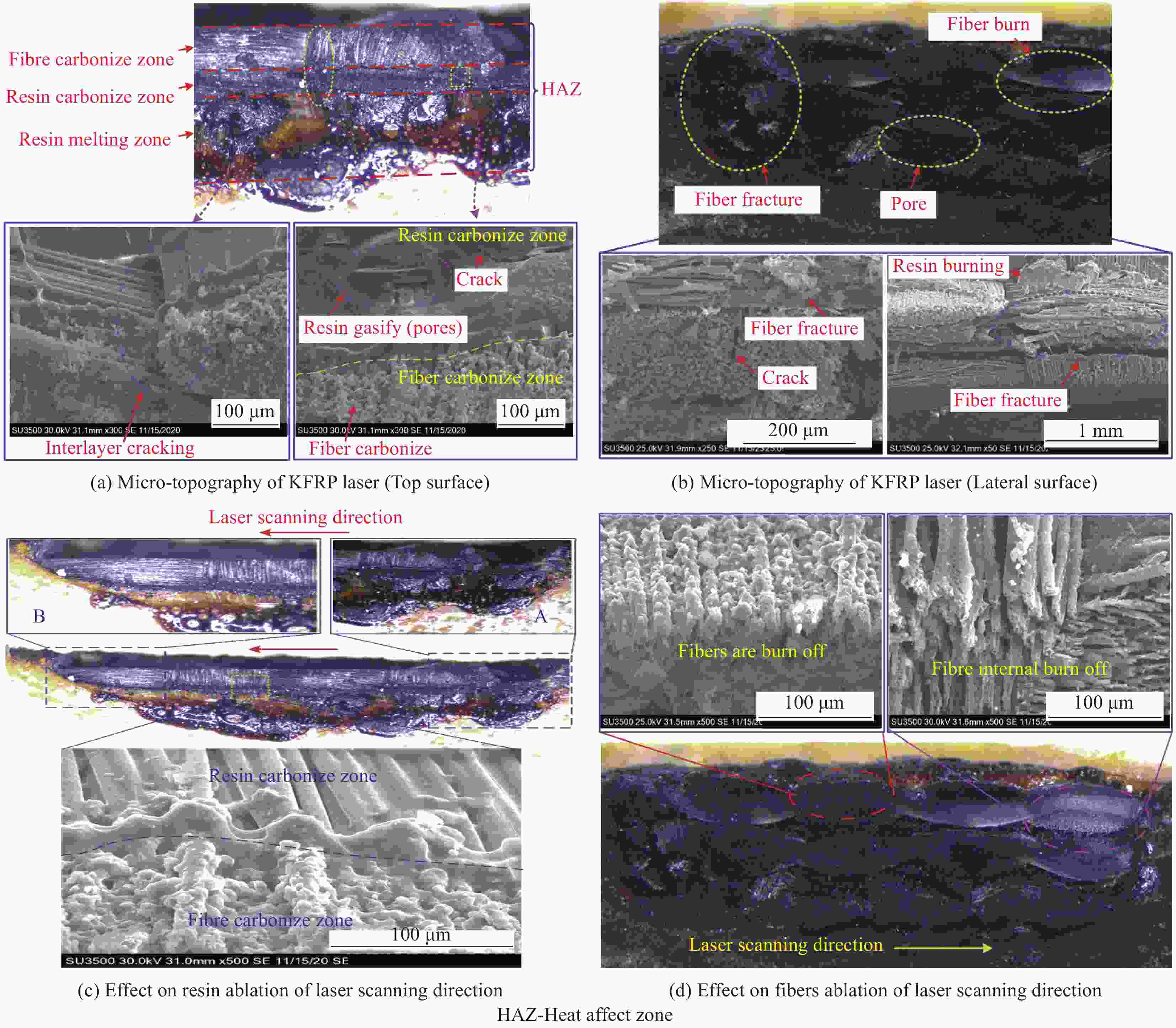

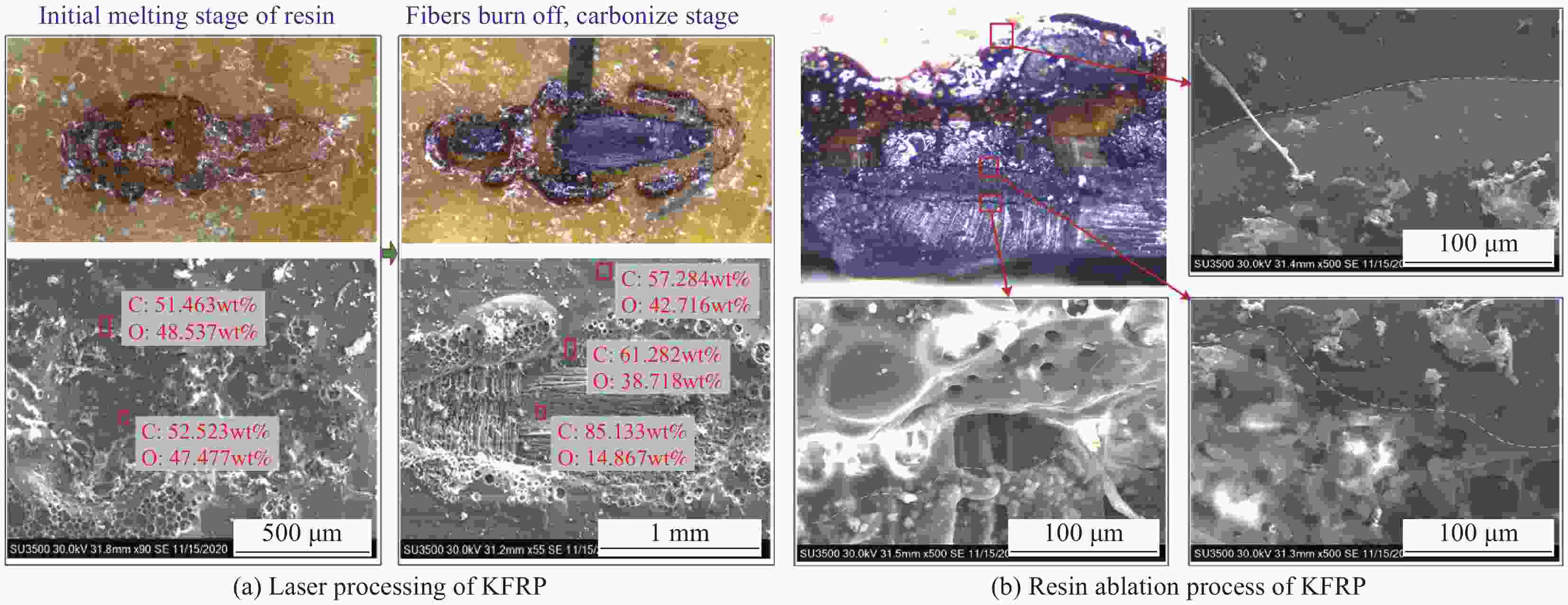

Abstract: The Kevlar fiber-reinforced plastic (KFRP) had been received much attention and wide application in the field of weapon armor protection. There were many problems in mechanical processing, such as furry, difficult to chip removal, severe tool wear and so on. Many processing difficulties still remained. In order to avoid these defects of mechanical processing and these drawbacks, the laser-milling combination machining for KFRP was presented in this paper. The feasibility of the machining laser-milling combination machining was analyzed. The results show that the fiber carbonization zone and resin melting zone are observed after KFRP laser processing. In resin melting zone, the fibers are basically intact. The maximum kerf width is no more than 0.5 mm, and the kerf depth is less than 2 mm. The effects of the laser parameters on the kerf width a are relatively small, but that on the kerf depth h, fiber carbonization zone width A and resin melting zone width Am are significant. During milling of the laser-milling processing, the shape of the chip is big blocked and flocculent. If the fibers are incomplete ablation, the burrs are easy to occur. The burrs not only can be effectively avoided, but also the cutting forces and cutting temperature can be greatly reduced. Therefore, the processing quality can be improved and the degree of the processing difficulty can be reduced by using the laser-milling combination machining for KFRP. -

图 3 激光加工评价方法及激光-铣削试验方案

Figure 3. Evaluation methods of laser and experiment schemes of laser-milling

a—Kerf width; A—Carbonized width; Am—Heat affected zone width; H—Carbonized depth; h1—U-shaped carbonization zone width; h2—U-shaped heat affected zone width; D—U-shaped track diameter; R—U-shaped track radius; r—Tool radius; t1—Carbonized zone boundary; t2—Heat affected zone boundary

表 1 激光加工工艺参数

Table 1. Values of laser parameters

No. P/W V/(mm·s−1) f/kHz Lf/ns 1 10 3 200 20 2 20 3 200 20 3 30 3 200 20 4 40 3 200 20 5 50 3 200 20 6 30 1 200 20 7 30 2 200 20 8 30 3 200 20 9 30 4 200 20 10 30 5 200 20 11 30 3 50 20 12 30 3 350 20 13 30 3 500 20 14 30 3 650 20 15 30 3 200 30 16 30 3 200 60 17 30 3 200 120 Notes: P—Power; V—Scanning speed; f—Frequency; Lf—Pulse width. -

[1] 郑雷. 高性能轻质材料及其复合构件的加工技术研究[D]. 南京: 南京理工大学, 2008.ZHENG Lei. Machining technologies of high performance lightweight materials and composite components[D]. Nanjing: Nanjing University of Science and Technology, 2008(in Chinese). [2] 王晋宇, 刘海波, 刘阔, 等. 芳纶纤维增强树脂复合材料液氮冷却钻孔试验[J]. 复合材料学报, 2020, 37(1):89-95.WANG Jinyu, LIU Haibo, LIU Kuo, et a1. Experiment of liquid nitrogen cooling drilling test of aramid fiber-reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2020,37(1):89-95(in Chinese). [3] 霍豪闯. 芳纶纤维复合材料高质量制孔工艺研究[D]. 大连: 大连理工大学, 2019.HUO Haochuang. Study on high quality hole making of aramid fiber composites[J]. Dalian: Dalian University of Technology, 2019(in Chinese). [4] 张开虎, 于洋, 张夏明, 等. 纤维增强树脂基复合材料激光切割热影响探析[J]. 导航与控制, 2019, 18(5):60-83.ZHANG Kaihu, YU Yang, ZHANG Xiaming, et al. Laser cutting induced heat affected zone in fiber reinforced polymer: A comparative analysis[J]. Navigation and Control,2019,18(5):60-83(in Chinese). [5] 石文天, 刘玉德, 张永安, 等. 芳纶纤维复合材料切削加工研究进展[J]. 表面技术, 2016, 45(1):28-35.SHI Wentian, LIU Yude, ZHANG Yongan, et al. Research progress on the cutting process of aramid fiber compo-sites[J]. Surface Technology,2016,45(1):28-35(in Chinese). [6] 庄原. 芳纶纤维复合材料切磨复合加工技术研究[D]. 大连: 大连理工大学, 2013.ZHUANG Yuan. Study on the combined machining technology of sawing and grinding for aramid composites[D]. Dalian: Dalian University of Technology, 2013(in Chinese). [7] 黄均亮. 芳纶纤维复合材料加工用金刚石磨粒工具的研制[D]. 大连: 大连理工大学, 2013.HUANG Junliang. Development of diamond abrasive tools used for machining aramid fiber composites[D]. Dalian: Dalian University of Technology, 2013(in Chinese). [8] 石文天, 韩冬, 刘玉德, 等. 超低温微铣削芳纶纤维复合材料表面质量[J]. 中国机械工程, 2019, 30(9):1056-1064. doi: 10.3969/j.issn.1004-132X.2019.09.007SHI Wentian, HAN Dong, LIU Yude, et al. Surface quality of aramid fiber composites with ultra-low temperature and micro-milling[J]. China Mechanical Engineering,2019,30(9):1056-1064(in Chinese). doi: 10.3969/j.issn.1004-132X.2019.09.007 [9] PAN C T, HOCHENG H. The anisotropic heat-affected zone in the laser grooving of fiber reinforced composite material[J]. Journal of Materials Processing Technology,1996,62:54-60. doi: 10.1016/0924-0136(95)02192-2 [10] CHIPPENDALE R D, GOLOSNOY I O, LEWIN P L. Numerical modelling of thermal decomposition processes and associated damage in carbon fibre composites[J]. Journal of Physics D: Applied Physics,2014,47:1-15. [11] CAPRINO G, TAGLIAFERRI V, COVELLI L. The importance of material structure in the laser cutting of glass fiber reinforced plastic composites[J]. Journal of Engineering Materials and Technology,1995,117:133-138. doi: 10.1115/1.2804364 [12] CENNA A A, MATHEW P. Analysis and prediction of laser cutting parameters of fibre reinforced plastics (FRP) composite materials[J]. International Journal of Machine Tools & Manufacture,2002,42:105-113. [13] YILBAS B S, AKHTAR S S, KARATAS C. Laser circular cutting of Kevlar sheets: Analysis of thermal stress filed and assessment of cutting geometry[J]. Optics and Laser Technology,2017,96:180-189. doi: 10.1016/j.optlastec.2017.05.029 [14] GAUTAMA G D, PANDEY A K. Teaching learning algorithm based optimization of kerf deviations in pulsed Nd: YAG laser cutting of Kevlar-29 composite laminates[J]. Infrared Physics & Technology,2018,89:203-217. [15] 朱德志. 碳纤维复合材料紫外短脉冲激光加工工艺研究[D]. 上海: 上海交通大学, 2018.ZHU Dezhi. Technology investigation of carbon fiber reinforced plastics UV short plused laser machining[D]. Shanghai: Shanghai Jiao Tong University, 2018(in Chinese). [16] DIRK Herzog, MATTIAS Schmidt-Lehr, MAX Oberlander, et al. Laser cutting of carbon fibre reinforced plastics of high thickness[J]. Materials and Design,2016,92:742-749. doi: 10.1016/j.matdes.2015.12.056 [17] SALAMA A, LI L, MATIVENGA P, et al. High-power picosecond laser drilling/machining of carbon fibre- reinforced polymer (CFRP) composites[J]. Applied Physics A,2016,122(73):1-11. [18] WOLFGANG Hintze, MARCEL Cordes, TOBIAS Geis, et al. Laser scored machining of fiber reinforced plastics to prevent delamination[J]. Procedia Manufacturing, 2016, 6: 1-8. [19] 张文武, 张天润, 焦健. 陶瓷基复合材料加工工艺简评[J]. 航空制造技术, 2014, 6:45-49. doi: 10.3969/j.issn.1671-833X.2014.01.004ZHANG Wenwu, ZHANG Tianrun, JIAO Jian. Comment on ceramic matrix composites machining processes[J]. Aeronautical Manufacturing Technology,2014,6:45-49(in Chinese). doi: 10.3969/j.issn.1671-833X.2014.01.004 [20] DIRK Herzog, PETER Jaeschke, OLIVER Meier, et al. Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP[J]. International Journal of Machine Tools & Manufacture,2008,48:1464-1473. [21] SALAMA A, LI L, MATIVENGA P, et al. High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites[J]. Applied Physics A,2016,122(2):1-11. [22] 王贵兵, 罗飞, 刘仓理, 等. 芳纶纤维复合材料激光烧蚀损伤形貌研究[J]. 激光技术, 2006, 30(2):168-180. doi: 10.3969/j.issn.1001-3806.2006.02.002WANG Guibing, LUO Fei, LIU Cangli, et al. The research of the ablation morphology of the composite reinforced by polyaryl amide fibers irradiated by laser[J]. Laser Technology,2006,30(2):168-180(in Chinese). doi: 10.3969/j.issn.1001-3806.2006.02.002 -

下载:

下载: