A method to analyze the axially symmetric problem of composite thick tubes with arbitrary angles

-

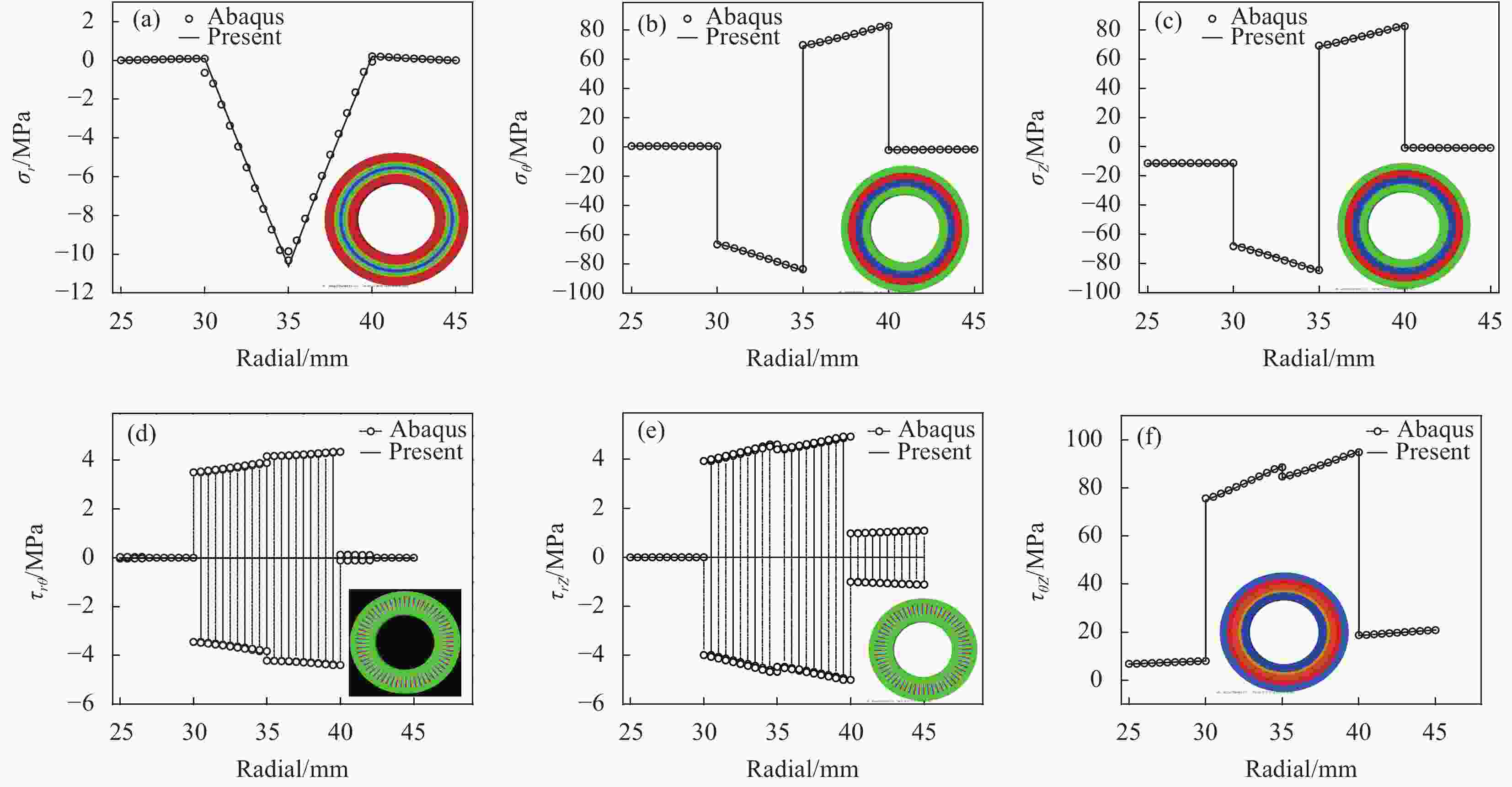

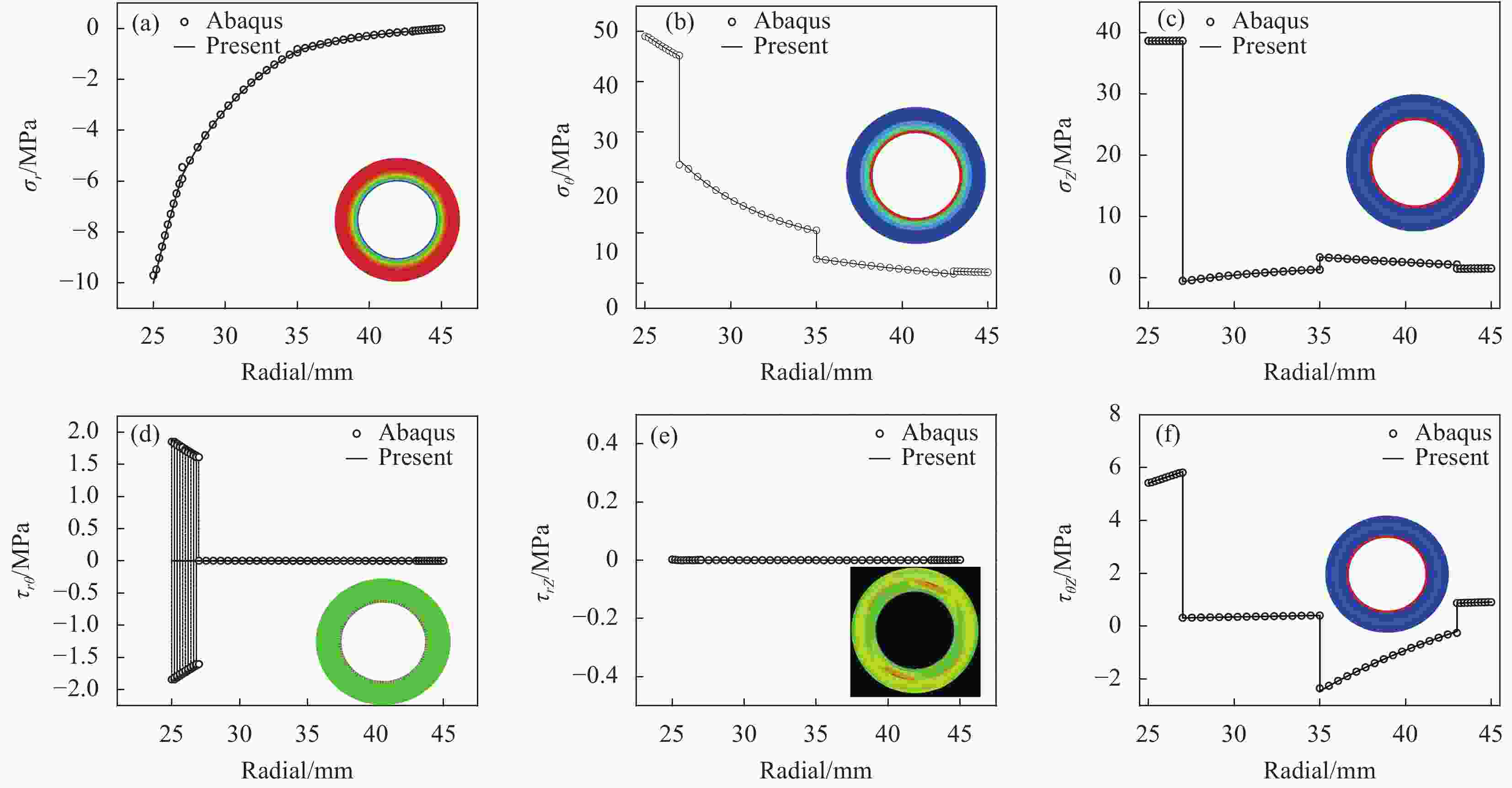

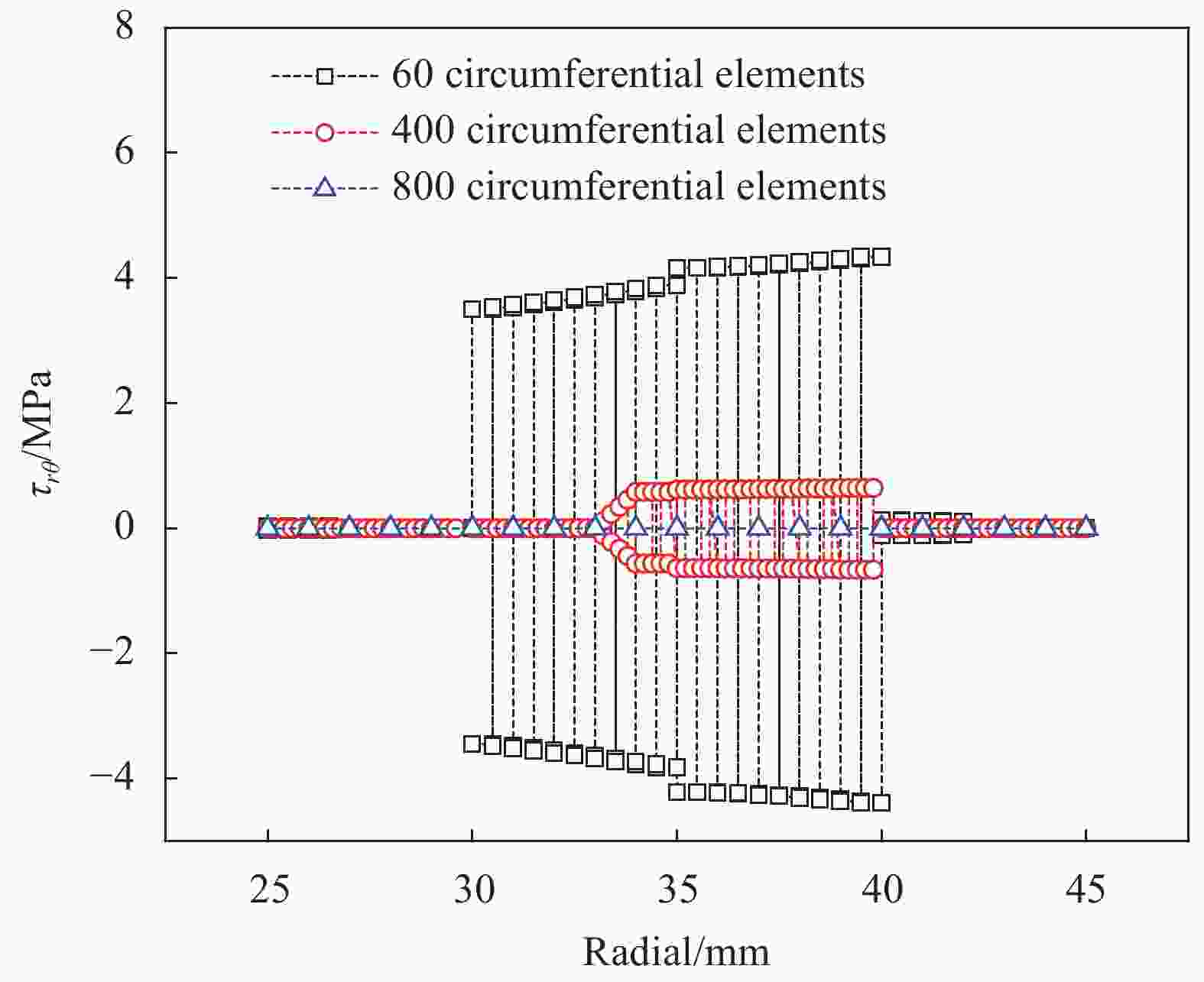

摘要: 提出了一种任意角度复合材料厚壁管的轴对称问题的分析方法。传统的Lekhnitskii理论能够获得普通缠绕层复合材料厚壁管的精确弹性解,但是,当厚壁管内存在0°缠绕层或者各项同性材料层时,该两种特殊层都会出现奇异参数,从而导致特殊层与普通层界面的连续性条件不能被满足。因此,讨论了特殊层存在奇异参数的原因,并对这类参数进行连续性分析和极限计算,从而解决了参数奇异的问题,使Lekhnitskii理论的应用范围扩展到任意缠绕角的复合材料厚壁管。最后,通过有限元计算软件ABAQUS分析了不同复合材料组合管的力学响应,有限元计算结果与改进理论结果基本一致。Abstract: A method was proposed to analysis the axisymmetric problem of composite tubes made up of winding layers with arbitrary angles. The traditional Lekhnitskii theory can obtain the exact elastic solution of the thick composite tubes with common winding layers. However, when there are 0° winding layers or isotropic layers in the thick walled tubes, singular parameters will appear in the both special layers. And the discontinuity condition between the special layer and the common layer could not be satisfied. Therefore, the reasons for the existence of singular parameters in special layers were discussed. Then, the continuity analysis and limit calculation of these parameters were carried out, so that the problem of parameter singularity was solved and the application of Lekhnitskii theory was extended to composite thick tubes with arbitrary angles. Finally, the mechanical responses of different compo-site tubes were analyzed by ABAQUS, and the results of finite element calculation were basically consistent with the developed theoretical results.

-

Key words:

- composite material /

- axisymmetric problem /

- winding angles /

- thick tubes /

- theoretical analysis

-

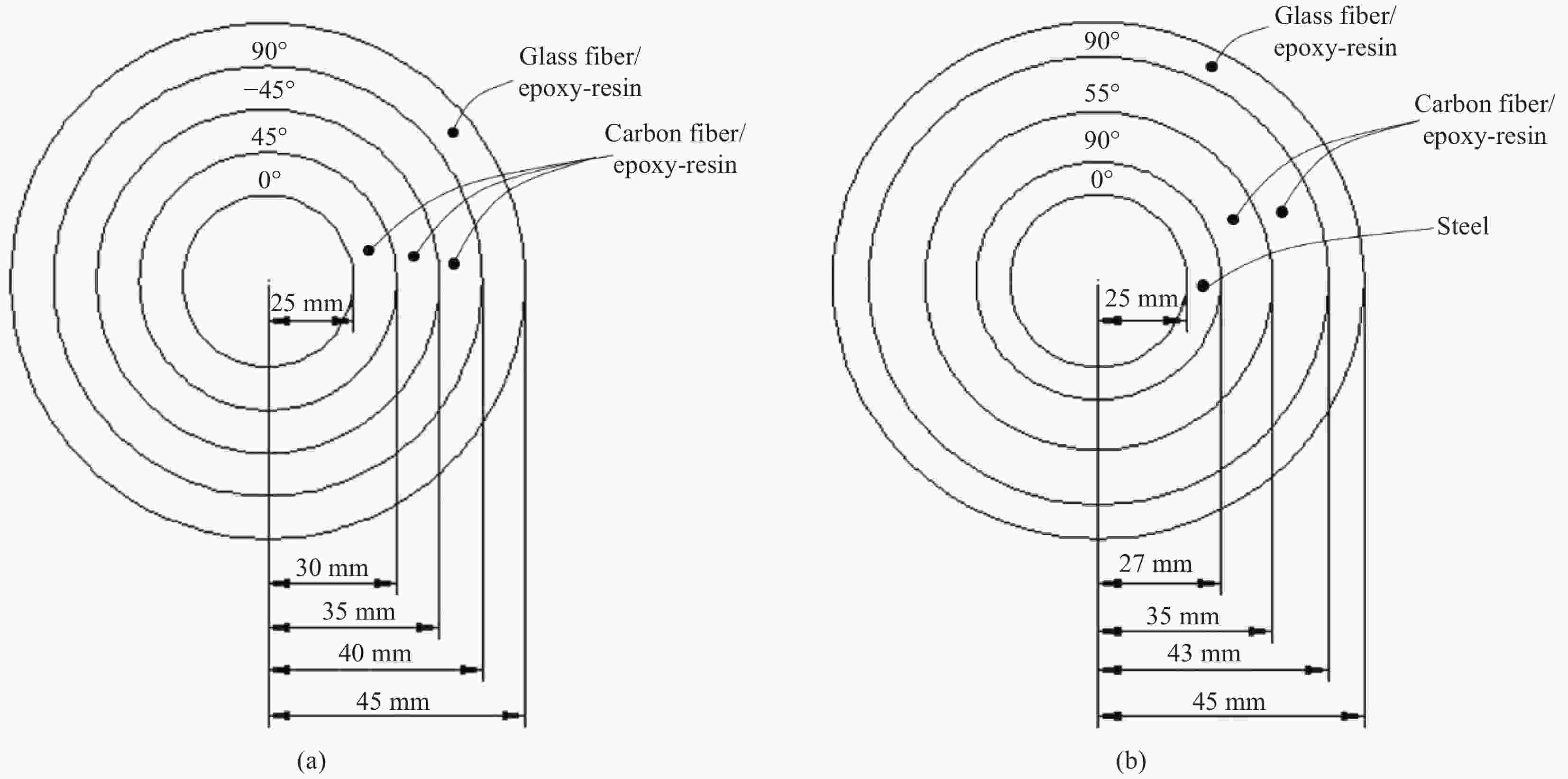

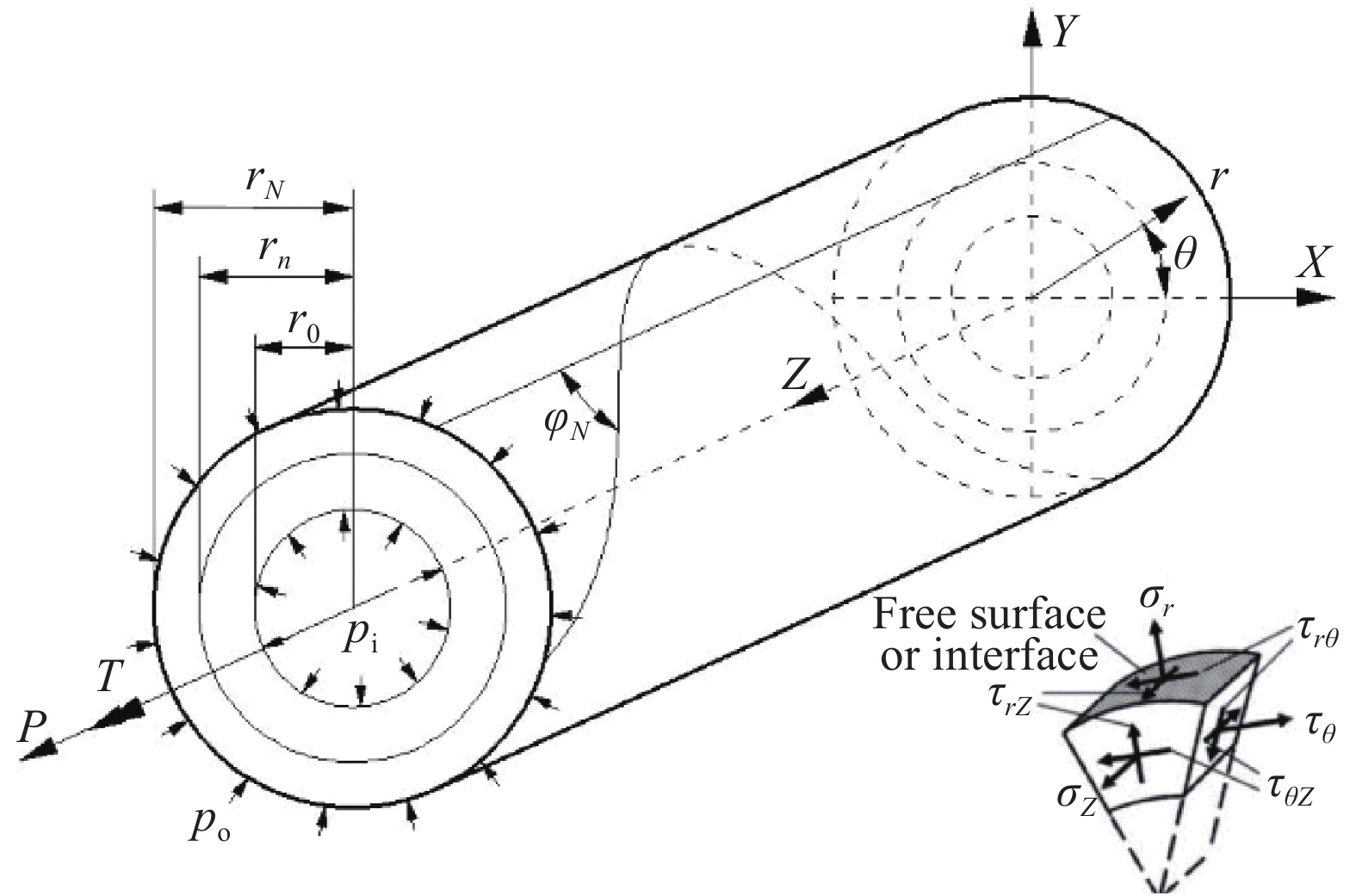

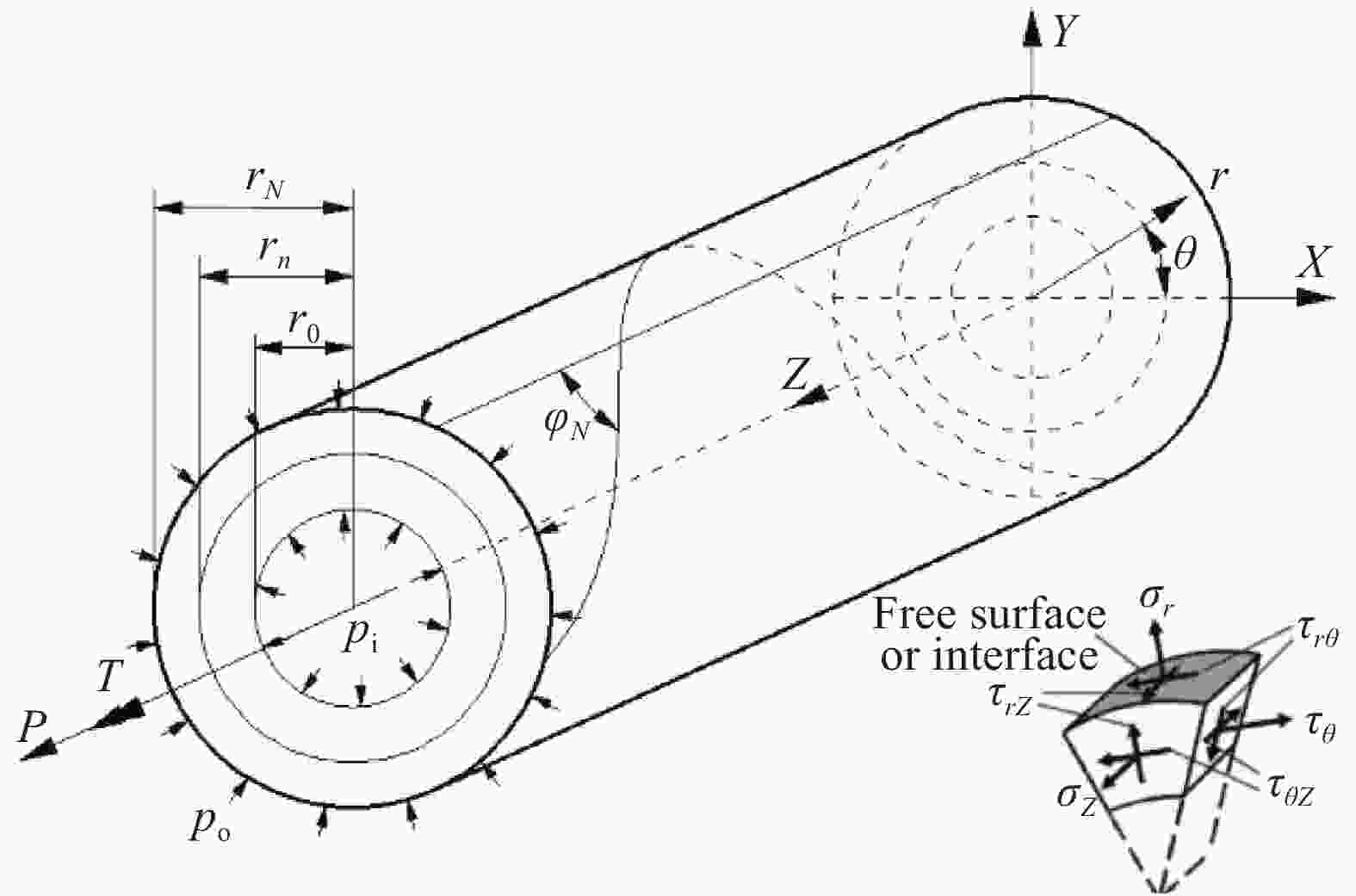

图 1 轴对称载荷作用下的复合材料厚壁管

Figure 1. Composite tube subjected to axisymmetric loads

P, T, pi and po—Axial load, torque, internal pressure and outer pressure, respectively; r0 and rN—Internal radius and outer radius of the composite thick tube; rn and φn—Outer radius and winding angle of the nth layer; σZ—Axial stress component; σr, σθ and τrθ—Stress components parallel to the cross section; τθZ and τrZ—Stress components perpendicular to the cross section

表 1 各层材料的力学性能参数

Table 1. Material property for each layer

Carbon fiber/epoxy-resin E1=155 GPa, E2=E3=12.1 GPa; v12=v13=0.248; v23=0.458; G12=G13=4.4 GPa; G23=3.2 GPa Glass fiber/epoxy-resin E1=60 GPa, E2=E3=11 GPa;

v12 = v13=0.26; v23=0.4; G12=G13=7.6 GPa; G23=3.7 GPaSteel E=210 GPa;v=0.3 Notes: E1, E2, E3—Modulus in fiber direction, in-plane transverse modulus and out-of-plane transverse modulus respectively; ν12, G12—Poisson's ratio and shear modulus of fiber direction and in-plane transverse direction; ν13 and G13—Poisson's ratio and shear modulus of fiber direction and out-of-plane transverse direction; ν23 and G23—Poisson's ratio, shear modulus of in-plane transverse direction and out-of-plane transverse direction; E and v—Modulus and poisson’s ratio of the steel. -

[1] VASILIEV V, BARYNIN V A, RASIN A F. Anisogrid lattice structures-survey of development and application[J]. Composite Structures,2001,54(2):361-370. [2] VASILIEV V, BARYNIN V A, RASIN A F. Anisogrid composite lattice structures development and aerospace applications[J]. Composite Structures,2012,94(3):1117-1127. doi: 10.1016/j.compstruct.2011.10.023 [3] FAN Hualin, FANG Daining, CHEN Liming, et al. Manufacturing and testing of a CFRC sandwich cylinder with Kagome cores[J]. Composites Science and Technology,2009,69(15-16):2695-2700. doi: 10.1016/j.compscitech.2009.08.012 [4] FAN H L, JING F N, FANG D N, et al. Mechanical properties of hierarchical cellular materials, Part I: Analysis[J]. Composites Science & Technology,2008,68:3380-3387. doi: 10.1016/j.compscitech.2008.09.022 [5] 郑津洋, 李静媛, 黄强华. 车用高压燃料气瓶技术发展趋势和我国面临的挑战[J]. 压力容器, 2014(2):43-51. doi: 10.3969/j.issn.1001-4837.2014.02.007ZHENG Jinyang, LI Jingyuan, HUANG Qianghua. Technology trends of high pressure vehicle fuel tanks and challenges for China[J]. Pressure Vessel Technology,2014(2):43-51(in Chinese). doi: 10.3969/j.issn.1001-4837.2014.02.007 [6] 中华人民共和国国家质量监督检验检疫总局、中国国家标准化管理委员会. 车用压缩氢气铝内胆碳纤维全缠绕气瓶: GB/T 35544—2017[S]. 北京: 中国标准出版社, 2017.Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, China National Standardization Management Committee. FuIly-wrapped carbon fiber reinforced cylinders with an aluminum liner for the on-board storage of compressed hydrogen as a fuel for land vehicles: GB/T 35544—2017[S]. Beijing: China Standards Press, 2017(in Chinese). [7] 顾付伟, 顾周越, 朱晓磊, 等. 一种无焊缝连接金属内衬复合材料压力容器的制备工艺及其液压实验[J]. 复合材料学报, 2021, 38(1):198-208.GU Fuwei, GU Zhouyue, ZHU Xiaolei, et al. The design and hydraulic tests of a metal liner composite overwrapped pressure vessels with seamless connection technology[J]. Acta Materiae Compositae Sinica,2021,38(1):198-208(in Chinese). [8] 蔡光胜, 张锦光, 毛戈. 碳纤维复合材料直升机传动轴设计研究[J]. 玻璃钢/复合材料, 2019(10):71-75.CAI Guangsheng, ZHANG Jinguang, MAO Ge. Design and research of carbon fiber composite helicopter drive shaft[J]. Fiber Reinforced Plastics/Composites,2019(10):71-75(in Chinese). [9] 胡晶, 李晓星, 张天敏, 等. 碳纤维复合材料传动轴承扭性能优化设计[J]. 复合材料学报, 2009, 26(6):177-181. doi: 10.3321/j.issn:1000-3851.2009.06.030HU Jing, LI Xiaoxing, ZHANG Tianmin, et al. Design optimization on torsion property of carbon-fiber composite drive shaft[J]. Acta Materiae Compositae Sinica,2009,26(6):177-181(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.06.030 [10] 沈观林. 复合材料力学[M]. 北京: 清华大学出版社, 2013.SHEN Guanlin. Mechanics of composite materials[M]. Beijing: Tsinghua University Press, 2013(in Chinese). [11] JIANG S Y, SUN F, FAN H L. Multi-failure theory of composite orthogrid sandwich cylinder[J]. Aerospace Science and Technology,2017,70(11):520-525. [12] JIANG S Y, SUN F, FAN H L, et al. Fabrication and testing of composite orthogrid sandwich cylinder[J]. Composites Science & Technology,2017,142(4):171-179. [13] XIA M, TAKAYANAGI H, KEMMOCHI K. Analysis of multi-layered filament-wound composite pipes under internal pressure[J]. Composite Structures,2001,53(4):483-491. doi: 10.1016/S0263-8223(01)00061-7 [14] ROY A K, TSAI S W. Design of thick composite cylinders[J]. Journal of Pressure Vessel Technology,1988,110:255-262. doi: 10.1115/1.3265597 [15] HYER M W. Hydrostatic response of thick laminated composite cylinders[J]. Journal of Reinforced Plastics and Composites,1988,7(4):321-340. doi: 10.1177/073168448800700402 [16] LEKHNITSKII S G. Theory of elasticity of an anisotropic elastic body[M]. Moscow: Mir Publishers, 1981: 215-262. [17] STROH A N. Dislocations and cracks in anisotropic elasticity[J]. Philosophical Magazine,1958,3:625-646. doi: 10.1080/14786435808565804 [18] ZU L, WANG J, LI S. Analysis of multi-layered thick-walled filament-wound hydrogen storage vessels[J]. International Journal of Hydrogen Energy,2014,39(36):21083-21096. doi: 10.1016/j.ijhydene.2014.10.075 [19] TING T C T. Anisotropic elasticity theory and applications[M]. Oxford: Oxford University Press, 1996: 118-163. [20] JOLICOEUR C, CARDOU A. Analytical solution for bending of coaxial orthotropic cylinders[J]. Journal of Engineering Mechanics,1994,120(12):2556-2574. doi: 10.1061/(ASCE)0733-9399(1994)120:12(2556) [21] 张灿辉, 张建霖, 柯淼宏, 等. 采用独立双应力函数分析纯弯曲复合材料厚壁管[J]. 厦门大学学报(自然科学版), 2017, 56(6):900-906.ZHANG Canhui, ZHANG Jianlin, KE Miaohong, et al. Analysis of composite material thick walled tubes subjected to pure bending loading using two stress functions independent to each other[J]. Journal of Xiamen University (Natural Science),2017,56(6):900-906(in Chinese). [22] 柯淼宏. 纯弯曲复合材料组合管统一联系参数法的进一步研究[D]. 厦门: 厦门大学, 2017.KE Miaohong. More investigation of unified-connected-parameter method for composite material combined tubes under pure bending loading[D]. Xiamen: Xiamen University, 2017(in Chinese). [23] 刘沛. 复合材料厚壁管弯曲性能分析的统一参数法及杂交应力有限元最佳假设应力场构造的定量方法[D]. 厦门: 厦门大学, 2014.LIU Pei. The unified-parameter method for bending perfor-mance analysis of composite thick tube as well as the quanti-tave method to determine the optimal assumed stress fields for hybrid stress finite elements[D]. Xiamen: Xiamen University, 2014(in Chinese). [24] ZHANG C H, HOA S V. Limit based approach to the stress analysis of cylindrically orthotropic composite cylinders (0/90) subjected to pure bending[J]. Composite Structure,2012,94:2610-2619. doi: 10.1016/j.compstruct.2012.02.030 [25] ZHANG C H, HOA S V, LIU P. A method to analyze the pure bending of tubes of cylindrically anisotropic layers with arbitrary angles including 0 and 90[J]. Composite Structure,2014,109:57-67. doi: 10.1016/j.compstruct.2013.10.038 -

下载:

下载: