Preparation and properties of TiCp/Cr15 high chromium cast iron composites

-

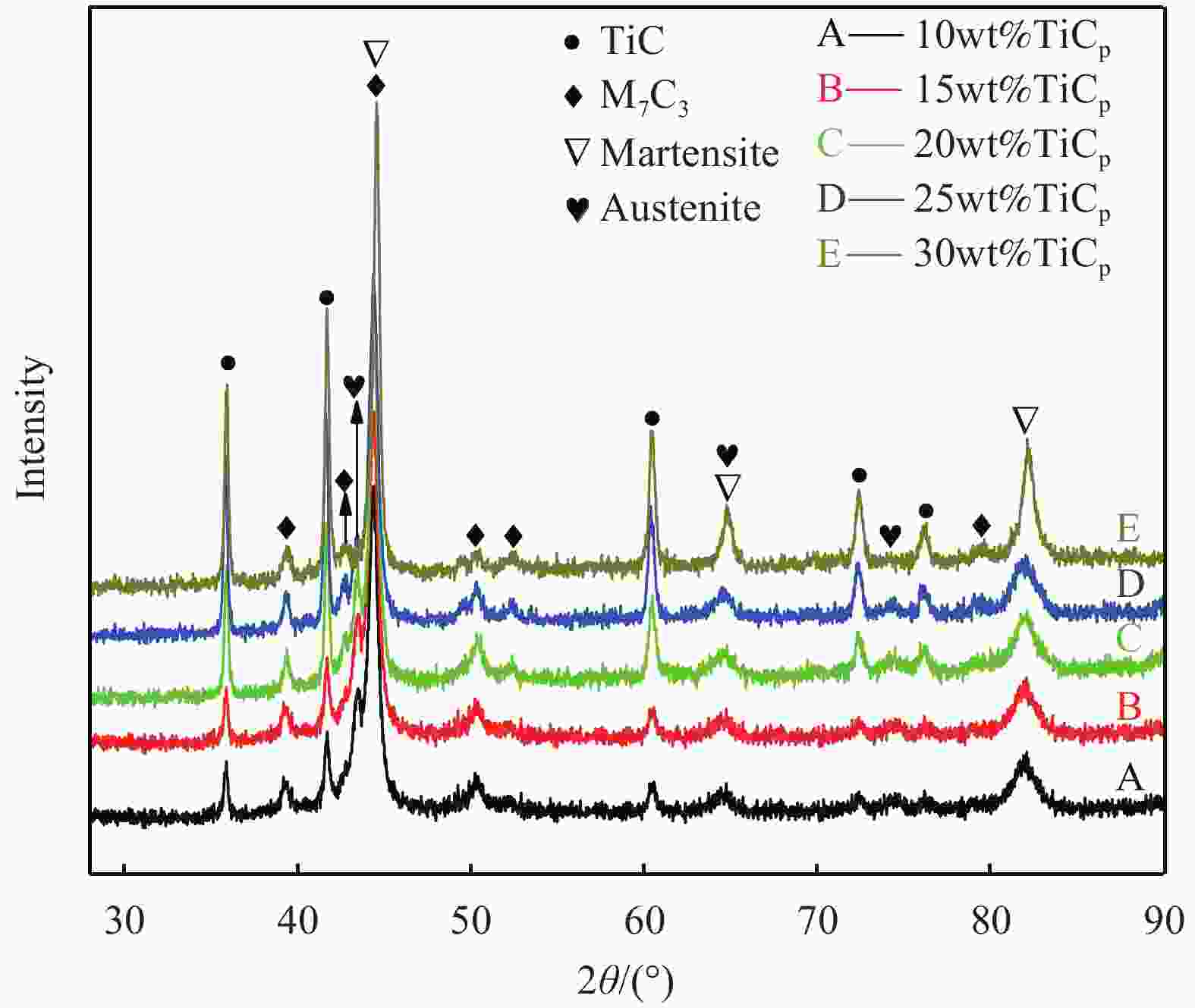

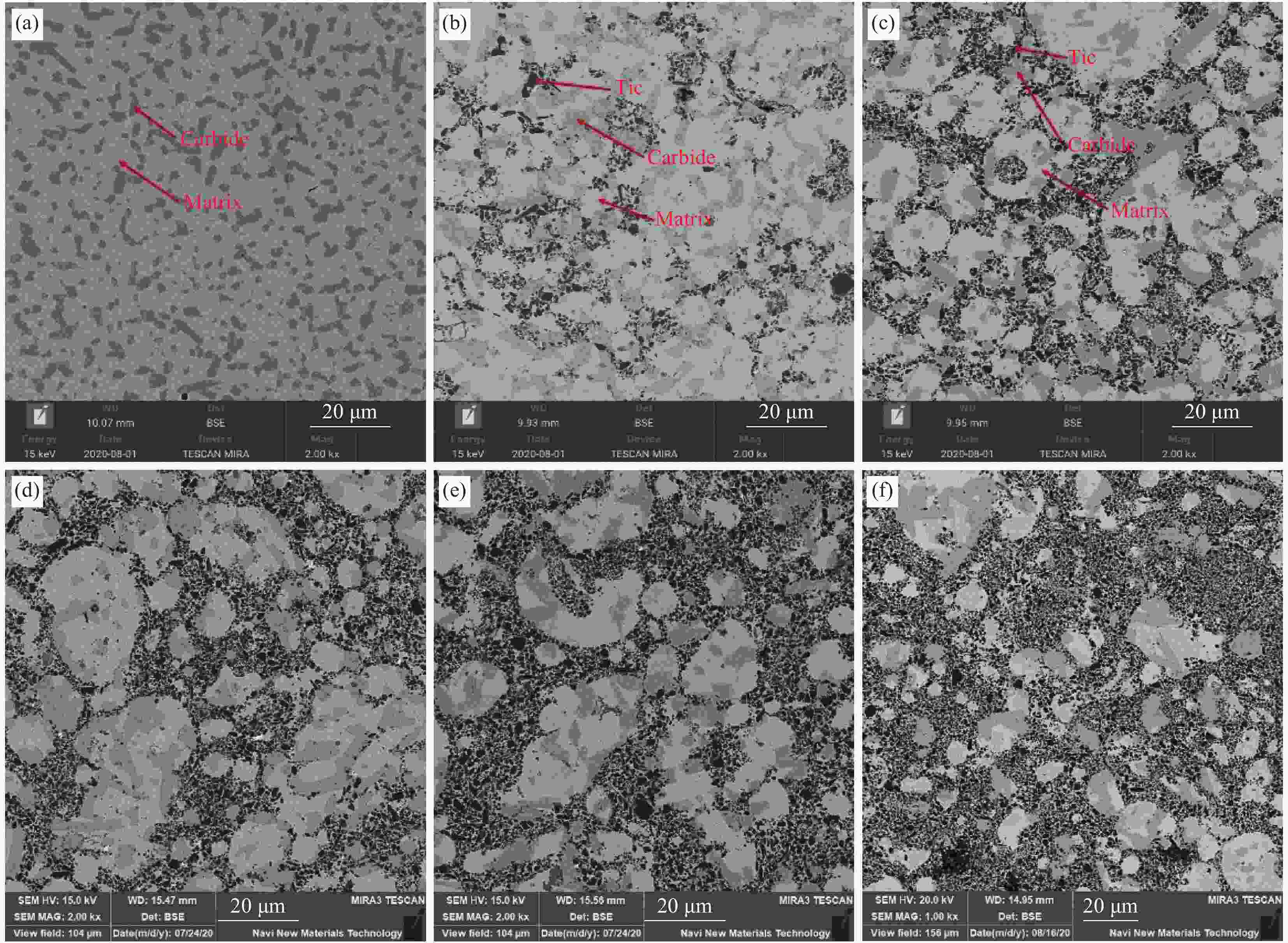

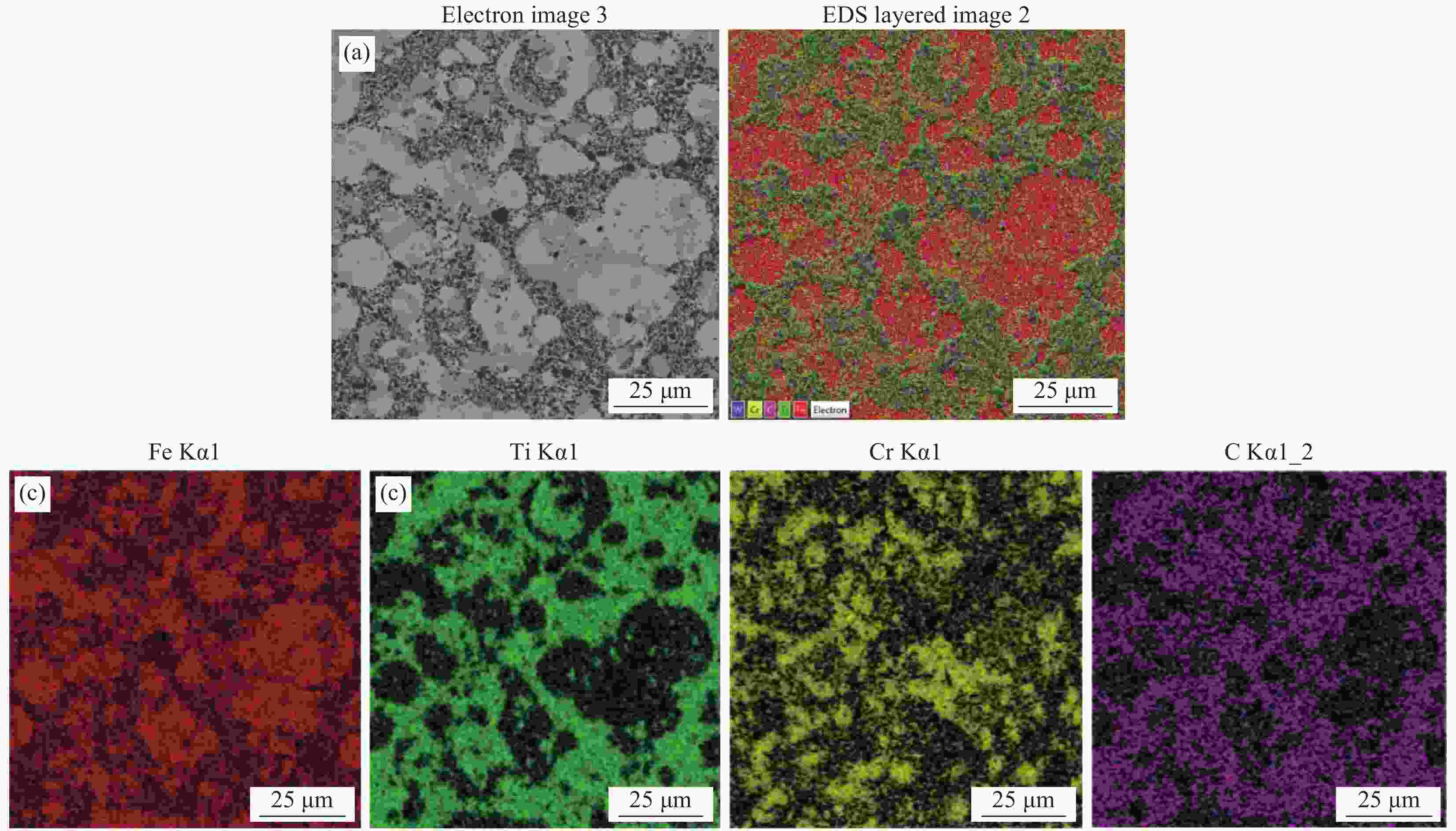

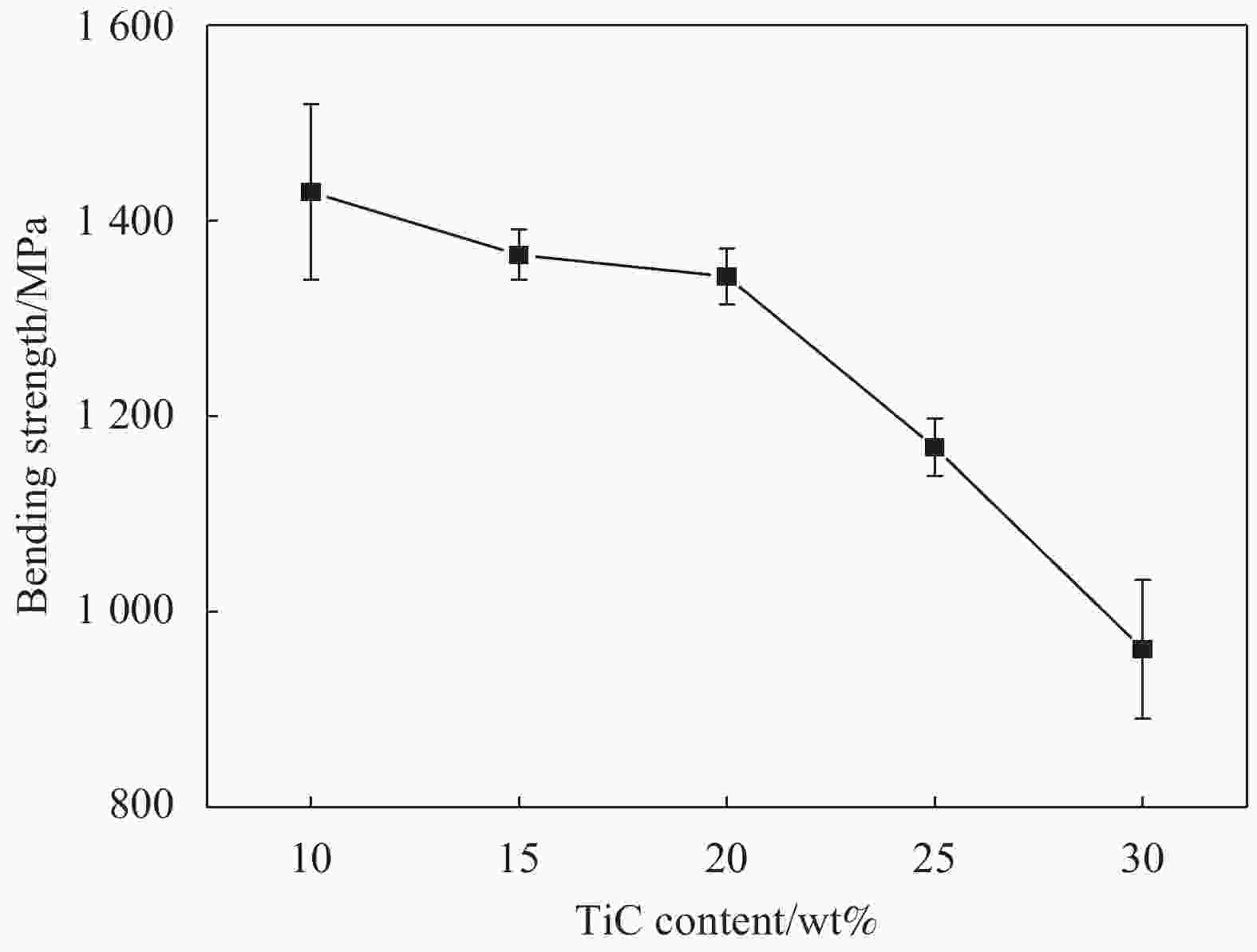

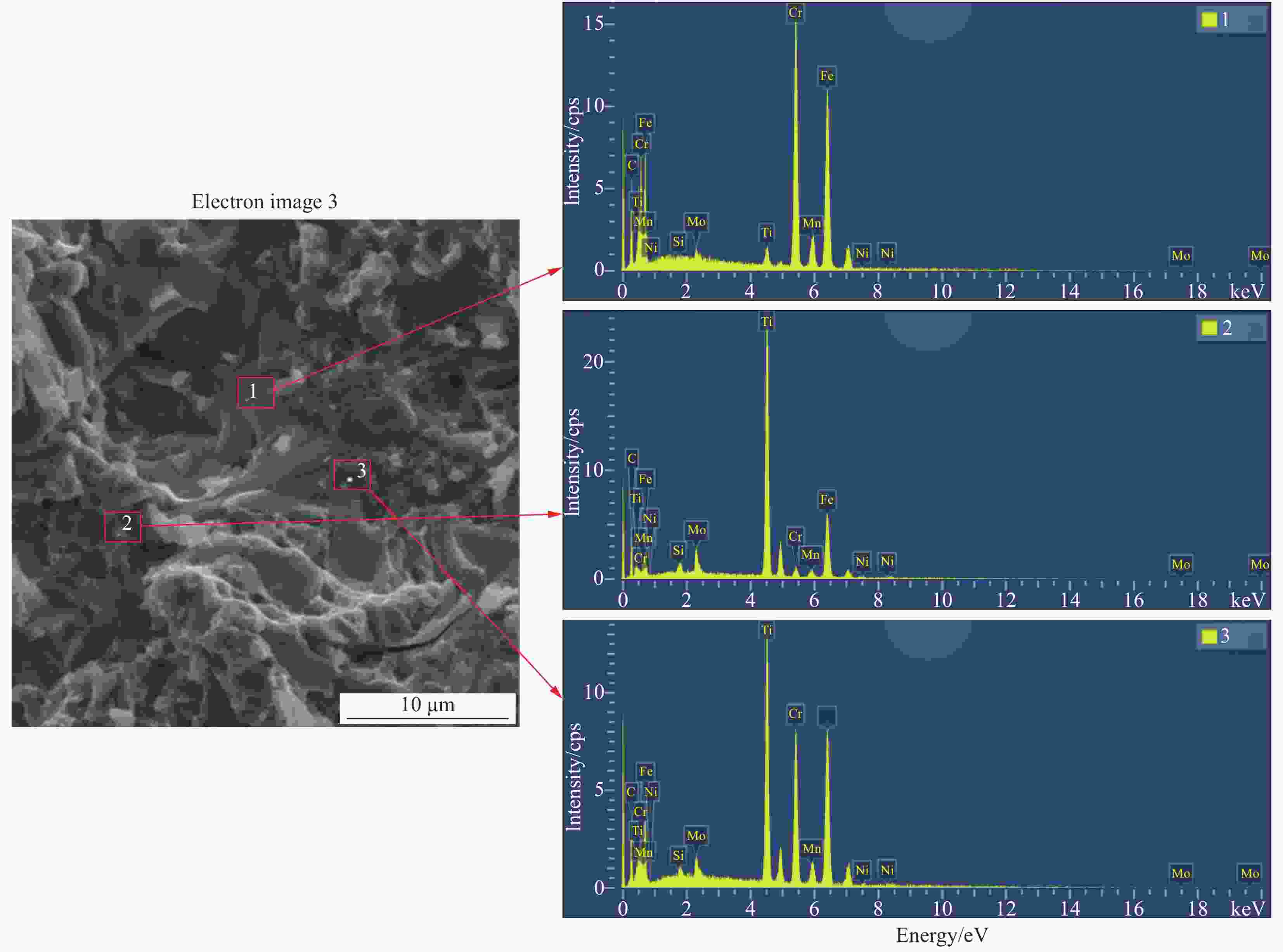

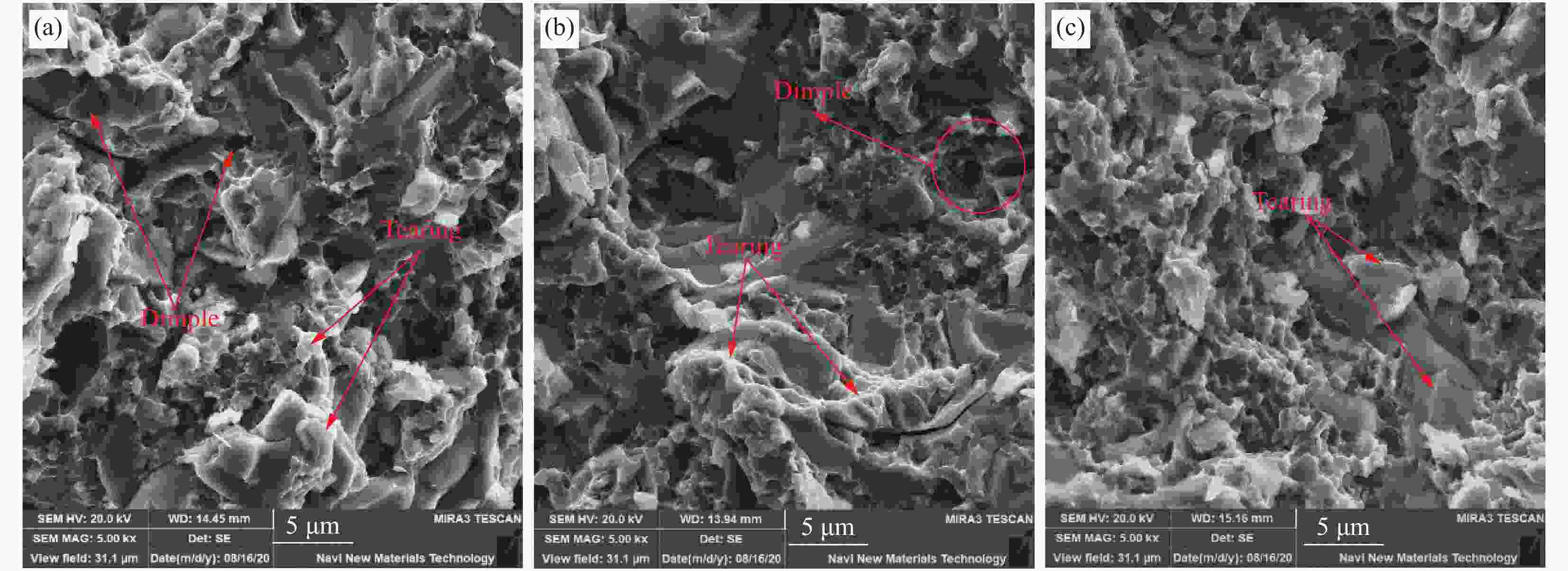

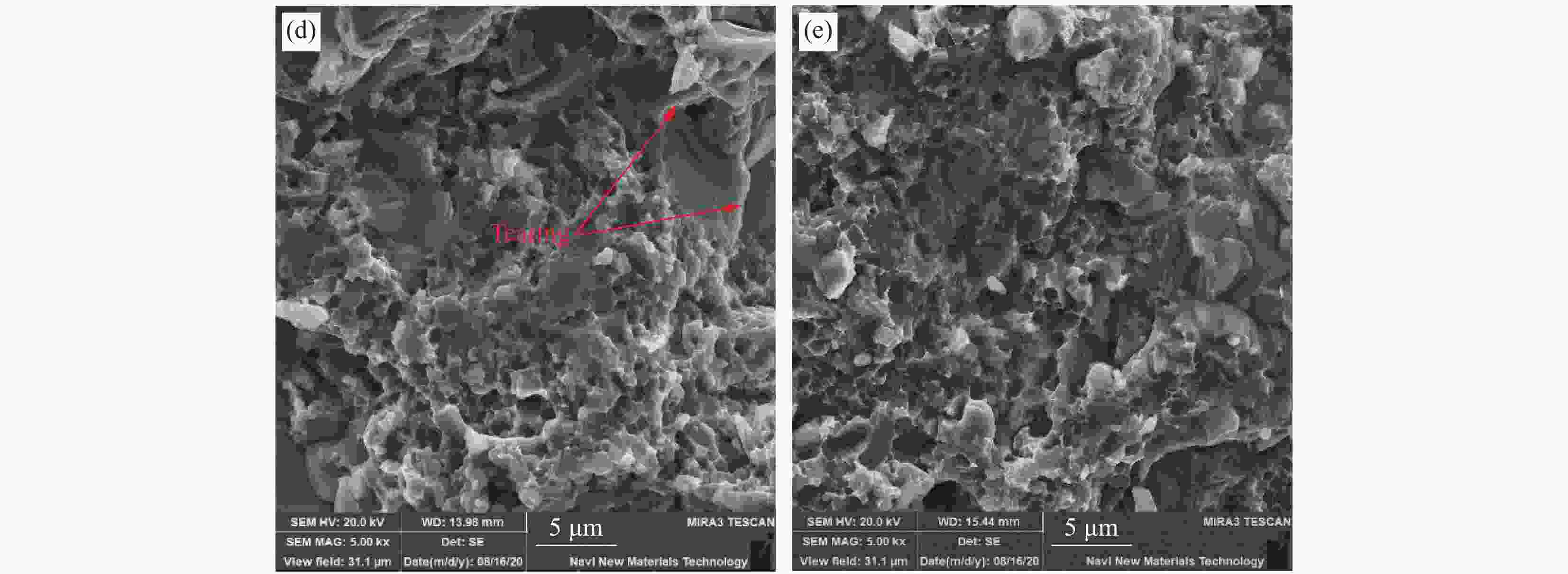

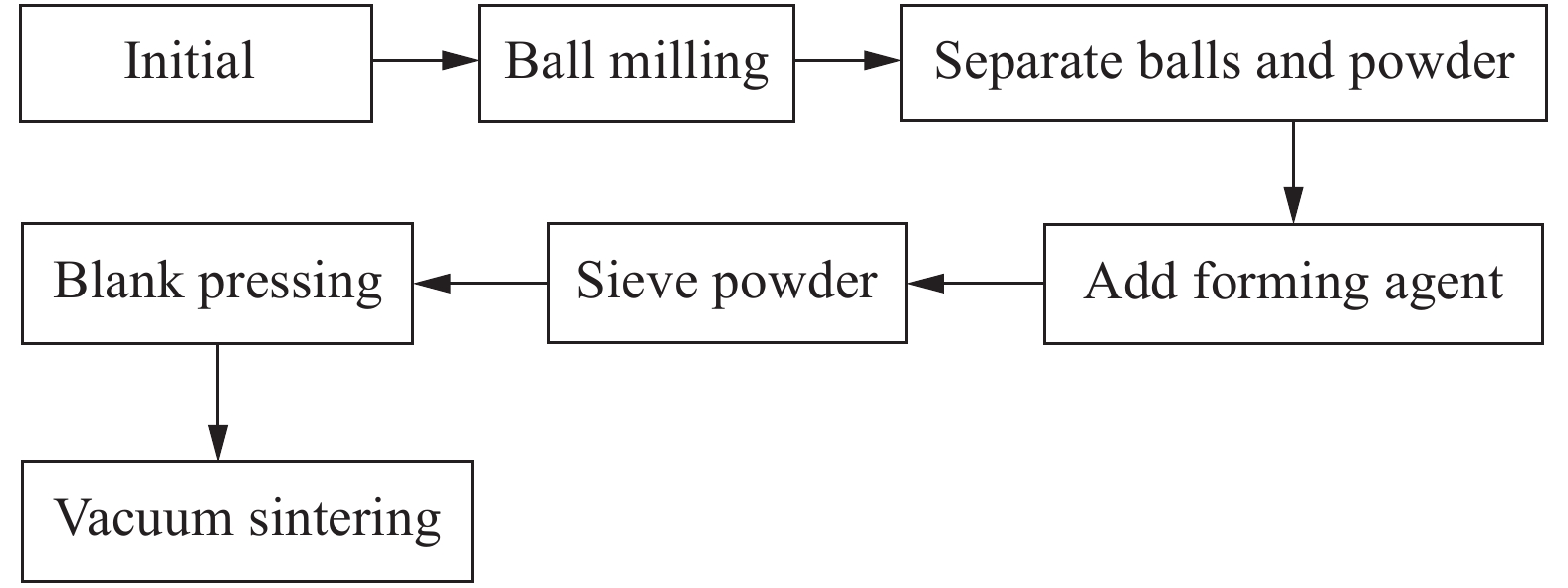

摘要: 以TiCp粉末和水雾化Cr15高铬铸铁粉末为原料,采用粉末冶金液相烧结技术制备TiCp增强高铬铸铁复合材料。研究了TiCp含量对高铬铸铁的物相组成、显微组织和力学性能的影响。研究结果表明,全致密的TiCp增强高铬铸铁基体复合材料的构成相为TiC、M7C3型碳化物、马氏体和少量奥氏体;随着TiCp添加量增大,金属基体逐步呈孤岛状,并在其中析出越来越多的M7C3型碳化物,同时TiCp逐步呈连续网状分布;同时,其硬度稳步提升,而抗弯强度和冲击韧性降低。当TiCp添加量为20wt%时烧结态复合材料具有最佳综合力学性能。此时硬度为HRC 66.8 ,冲击韧性为6.86 J/cm2,抗弯强度为1 343.10 MPa。当TiCp添加量为25wt%时硬度达到最大值HRC 67.20 。Abstract: TiCp reinforced high chromium cast iron composites with full density have been fabricated by liquid phase sintering technology with water atomized Cr15 high chromium cast iron powders and TiC particles as raw materials. The effect of TiC content on the microstructure evolution, phase composition and mechanical properties was investigated systematically. The research results show that the composites consist of TiC, M7C3 type carbides, martensite and a small amount of austenite; With the increase of TiCp addition, the metal matrix is gradually partitioned into island-like fragments, and M7C3 type carbides are principally precipitated in them. Hence continuous TiC particle network is formed step by step either. The composites’ hardness steadily increases at the same time, while both its bending strength and impact toughness decline. The sintered composite obtains its optimized mechanical quality as the TiCp addition amount is 20wt%, that is hardness of HRC 66.8, the impact toughness of 6.86 J/cm2 and bending strength of 1343.10 MPa. Its hardness reaches the maximum value of HRC 67.20 while 25wt% TiCp is added.

-

Key words:

- high chromium cast iron /

- TiCp /

- composite /

- microstructure /

- mechanical property

-

表 1 高铬铸铁(HCCI)粉末基本化学成分

Table 1. Basic chemical composition of high chromium cast iron (HCCI) powder

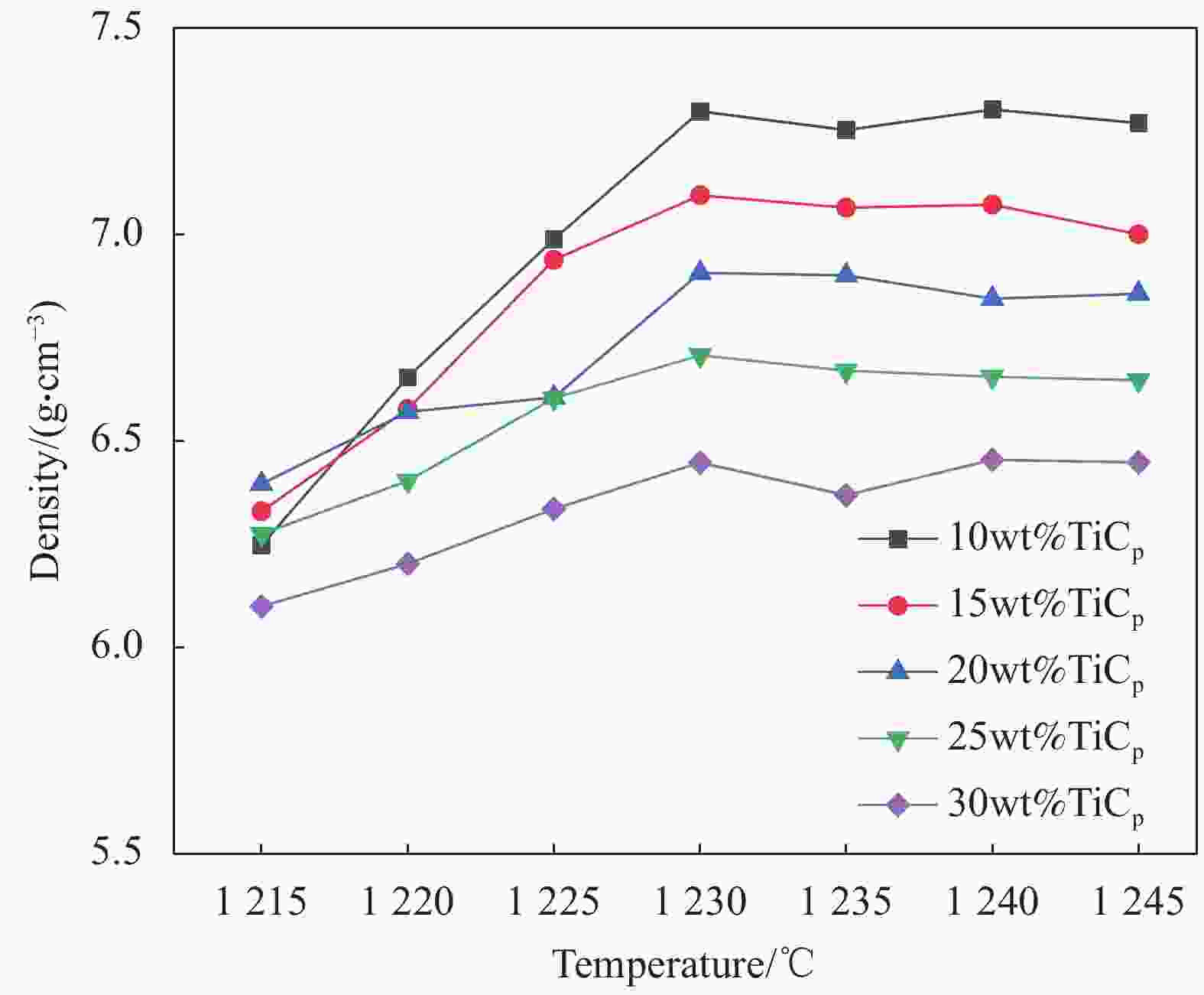

Element C Cr Mn Si Fe Content/wt% 2.67 15.40 0.63 0.77 Balance 表 2 烧结TiCp/HCCI复合材料的相对密度

Table 2. Relative densities of sintered TiCp/HCCI composites

TiCp content/wt% 10 15 20 25 30 ρ1/(g·cm−3) 7.30 7.10 6.91 6.71 6.45 ρ2/(g·cm−3) 7.48 7.27 7.08 6.89 6.71 ρ/% 97.59 97.66 97.59 97.38 96.13 Notes:ρ1—True density; ρ2—Theoretical density; ρ—Relative density. -

[1] 贾成厂, 孙兰. 工业的牙齿—硬质合金(1)[J]. 金属世界, 2011(4):7-9. doi: 10.3969/j.issn.1000-6826.2011.04.004JIA Chengchang, SUN Lan. Industrial teeth—Cemented carbide(1)[J]. Metal World,2011(4):7-9(in Chinese). doi: 10.3969/j.issn.1000-6826.2011.04.004 [2] 范安平, 肖平安, 李晨坤, 等. TiC基钢结硬质合金的研究现状[J]. 粉末冶金技术, 2013, 31(4):298-303. doi: 10.3969/j.issn.1001-3784.2013.04.011FAN Anping, XIAO Ping’an, LI Chenkun, et al. Research status of TiC-based steel-bonded cemented carbide[J]. Powder Metallurgy Technology,2013,31(4):298-303(in Chinese). doi: 10.3969/j.issn.1001-3784.2013.04.011 [3] 顾金宝, 高建, 时凯华, 等. 矿用WC-Co梯度硬质合金的制备及应用研究现状[J]. 稀有金属与硬质合金, 2019, 47(4):83-88.GU Jinbao, GAO Jian, SHI Kaihua, et al. Preparation and application research status of WC-Co gradient cemented carbide for mining[J]. Rare Metals and Cemented Carbides,2019,47(4):83-88(in Chinese). [4] 魏世忠, 徐流杰. 钢铁耐磨材料研究进展[J]. 金属学报, 2020, 56(4):523-53.WEI Shizhong, XU Liujie. Research progress of steel wear-resistant materials[J]. Acta Metallurgica Sinica,2020,56(4):523-53(in Chinese). [5] TABRETT C P, SARE I R, GHOMASHCHI M R. Microstructure-property relationships in high chromium white iron alloys[J]. International Materials Reviews,1996,41(2):59-82. doi: 10.1179/imr.1996.41.2.59 [6] DOGAN O N, HAWK J A, LAIRD G. Solidification structure and abrasion resistance of high chromium white irons[J]. Metallurgical and Materials Transactions A,1997,28(6):1315-1327. doi: 10.1007/s11661-997-0267-3 [7] HANLON D N, RAINFORTH W M, SELLARS C M. The effect of spray forming on the microstructure and properties of a high chromium white cast iron[J]. Journal of Materials Science,1999,34(10):2291-2301. doi: 10.1023/A:1004573524282 [8] FILIPOVIC M, KAMBEROVIC Z, KORAC M, et al. Microstructure and me-chanical properties of Fe-Cr-C-Nb white cast irons[J]. Materials & Design,2013,47:41-48. [9] HUANG, Tian-xing, et al. Microstructure and wear properties of SiC woodceramics reinforced high-chromium cast iron[J]. Ceramics International,2020,46(3):2592-2601. [10] 刘相熠, 郑开宏, 罗铁钢, 等. 自生TiC铁基复合材料的三体磨料磨损性能的工艺探究[J]. 铸造技术, 2018, 39(5):976-979.LIU Xiangyi, ZHENG Kaihong, LUO Tiegang, et al. Process research on the three-body abrasive wear performance of in-situ TiC iron-based composites[J]. Foundry Technology,2018,39(5):976-979(in Chinese). [11] 董晓蓉, 郑开宏, 王娟, 等. 铸造烧结法制备(Ti, W)C表面增强铁基复合材料[A]. 中国复合材料学会、杭州市人民政府. 第三届中国国际复合材料科技大会论文集[C]. 中国复合材料学会、杭州市人民政府: 中国复合材料学会, 2017: 7.DONG Xiaorong, ZHENG Kaihong, WANG Juan, et al. Preparation of (Ti, W)C surface-reinforced iron-based composites by casting and sintering method[A]. Chinese Society for Composite Materials, Hangzhou Municipal People’s Government. The 3rd China International Composites Technology Conference Proceedings[C]. China Society for Composite Materials, Hangzhou Municipal People's Government: China Society for Composite Materials, 2017: 7(in Chinese). [12] 王娟, 郑开宏. ZTA颗粒增强铁基复合材料的高温磨料磨损性能研究[J]. 热加工工艺, 2018, 47(10):101-105, 109.WANG Juan, ZHENG Kaihong. Research on high temperature abrasive wear performance of ZTA particle reinforced iron-based composites[J]. Hot Working Technology,2018,47(10):101-105, 109(in Chinese). [13] 姜吉鹏, 李世波, 胡树郡, 等. 添加TiC对高铬铸铁性能的影响[J]. 稀有金属材料与工程, 2020, 49(2):701-705.JIANG Jipeng, LI Shibo, HU Shujun, et al. The effect of adding TiC on the properties of high chromium cast iron[J]. Rare Metal Materials and Engineering,2020,49(2):701-705(in Chinese). [14] 周玉成, 魏世忠, 徐流杰, 等. Al2O3颗粒增强钢铁基复合材料的研究进展[J]. 热加工工艺, 2010, 39(20):87-90. doi: 10.3969/j.issn.1001-3814.2010.20.027ZHOU Yucheng, WEI Shizhong, XU Liujie, et al. Research progress of Al2O3 particle reinforced steel matrix composites[J]. Hot Working Technology,2010,39(20):87-90(in Chinese). doi: 10.3969/j.issn.1001-3814.2010.20.027 [15] BOCANEGRA-BERNAL M H. Hot isostatic pressing (HIP) technology and its applications to metals and ceramics[J]. Journal of Materials Science,2004,39(21):6399-6420. doi: 10.1023/B:JMSC.0000044878.11441.90 [16] GU J H, XIAO P G, SONG J Y, et al. Sintering of a hypoeutectic high chromium cast iron as well as its microstructure and properties[J]. Journal of Alloys and Compounds,2018,740:485-491. doi: 10.1016/j.jallcom.2017.11.189 [17] 李忠涛, 肖平安, 顾景洪, 等. 烧结Cr15高铬铸铁组织与性能的研究[J]. 材料科学与工艺, 2020, 28(01):7-16.LI Zhongtao, XIAO Ping’an, GU Jinghong, et al. Research on the structure and properties of sintered Cr15 high chromium castiron[J]. Materials Science and Technology,2020,28(01):7-16(in Chinese). [18] LEON C A, DREW R A L. Preparation of nickel-coated powders as precursors to reinforce MMCs[J]. Journal of Materials Science,2000,35(19):4763-4768. doi: 10.1023/A:1004860326071 [19] OZBEN T, KILICKAP E, CAK1R O. Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC[J]. Journal of Materials Processing Technology,2008,198(1-3):220-225. doi: 10.1016/j.jmatprotec.2007.06.082 [20] 汝娟坚, 贺涵. 陶瓷增强钢铁基复合材料中基体与陶瓷的选择[J]. 科技创新与应用, 2019(17):127-128.RU Juanjian, HE Han. The choice of matrix andceramics in ceramic reinforced steel matrix composites[J]. Science and Technology Innovation and Application,2019(17):127-128(in Chinese). [21] 卢瑞青, 肖平安, 宋建勇, 等. 新型烧结高铬铸铁的冲击磨粒磨损性能[J]. 粉末冶金材料科学与工程, 2018, 23(1):70-77. doi: 10.3969/j.issn.1673-0224.2018.01.010LU Ruiqing, XIAO Ping'an, SONG Jianyong, et al. Impact abrasive wear resistance of a new type of sintered high chromium cast iron[J]. Materials Science and Engineering of Powder Metallurgy,2018,23(1):70-77(in Chinese). doi: 10.3969/j.issn.1673-0224.2018.01.010 [22] 郭继伟, 刘钦雷, 荣守范, 等. 碳化钛系钢结硬质合金的研究现状[J]. 铸造设备与工艺, 2010(1):48-54. doi: 10.3969/j.issn.1674-6694.2010.01.015GUO Jiwei, LIU Qinlei, RONG Shoufan, et al. Research status of titanium carbide series steel-bonded cemented carbide[J]. Foundry Equipment and Technology,2010(1):48-54(in Chinese). doi: 10.3969/j.issn.1674-6694.2010.01.015 [23] 肖平安, 肖璐琼, 顾景洪, 等. 15Cr系亚共晶高铬铸铁的烧结制备与性能研究[J]. 湖南大学学报(自然科学版), 2019, 46(12):58-64.XIAO Ping’an, XIAO Luqiong, GU Jinghong, et al. Sintering preparation and properties of 15Cr hypoeutectic high chromium cast iron[J]. Journal of Hunan University (Natural Science Edition),2019,46(12):58-64(in Chinese). [24] 周瑞. 粉末冶金M3: 2高速钢烧结行为及力学性能研究[D]. 哈尔滨工业大学, 2008.ZHOU Rui. Research on sintering behavior and mechanical properties of powder metallurgy M3: 2 high speed steel[D]. Harbin Institute of Technology, 2008(in Chinese). [25] ZHANG X, SUN Y, NIU M, et al. Microstructureand mechanical behavior of in situ TiC reinforced Fe3Al(Fe-23Al-3Cr) matrix composites by mechanical alloying and vacuum hot-pressing sintering technology[J]. Vacuum,2020,180:109544. doi: 10.1016/j.vacuum.2020.109544 -

下载:

下载: