Fatigue performance of open-cell aluminium matrix composite foams reinforced by carbon nanotubes

-

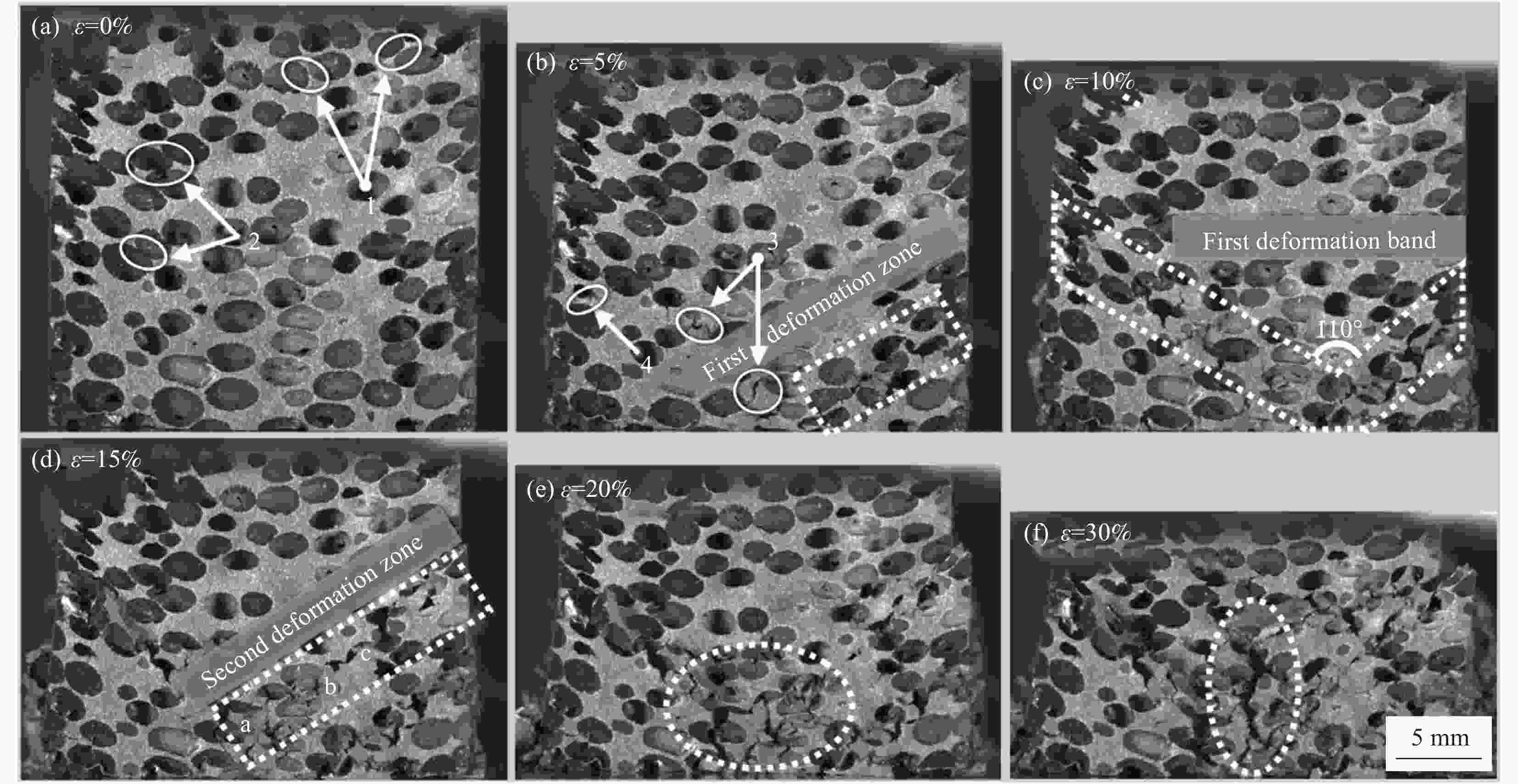

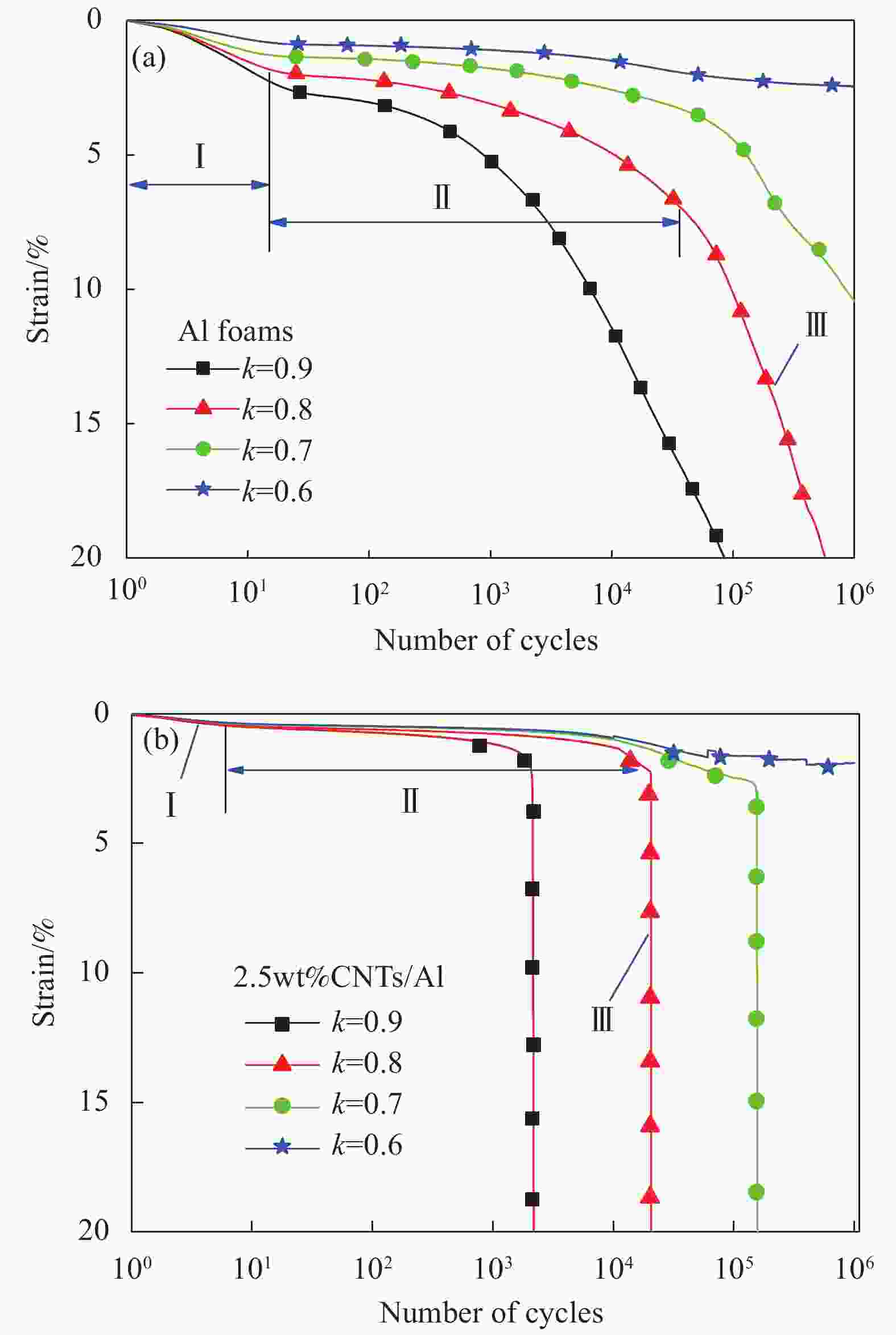

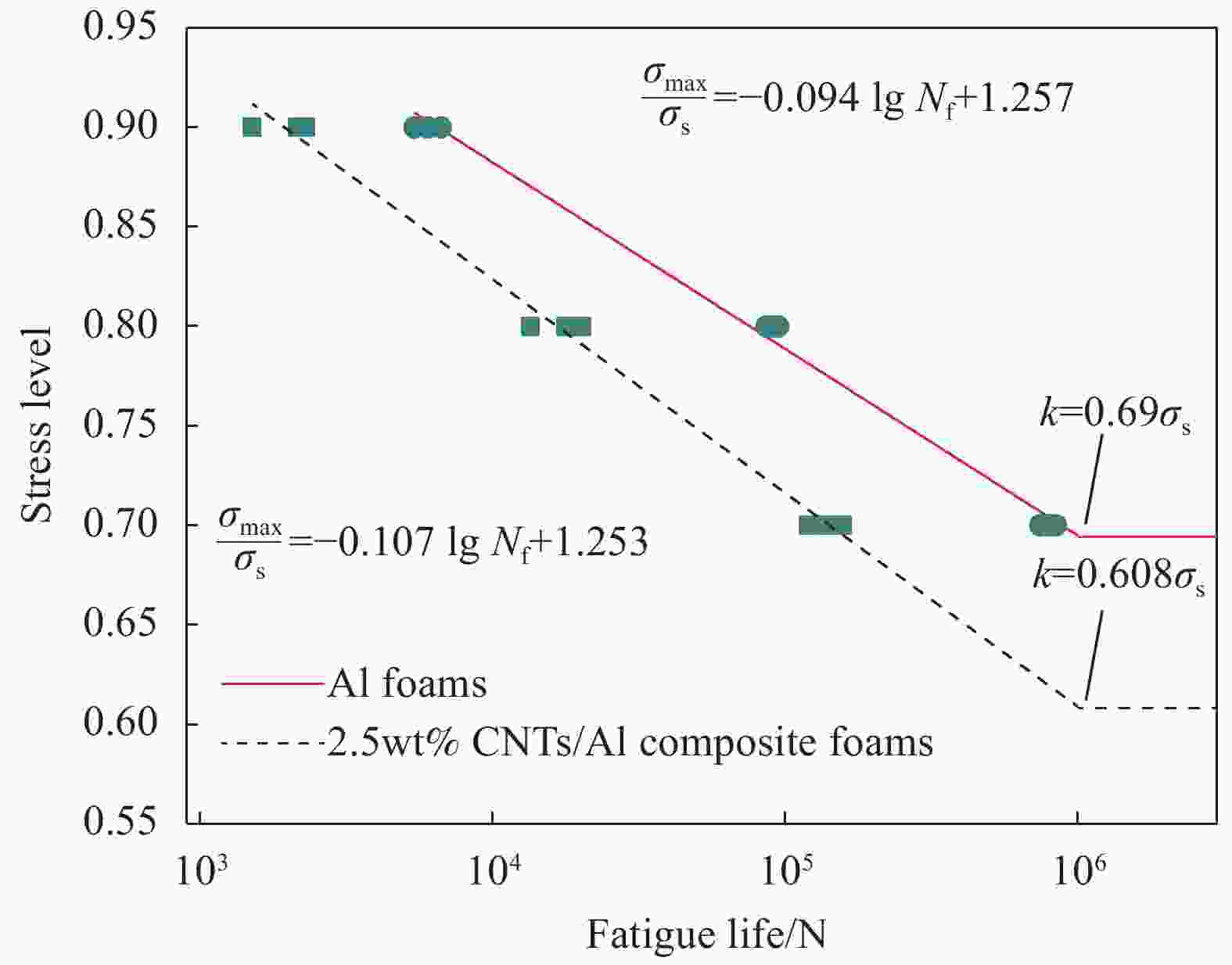

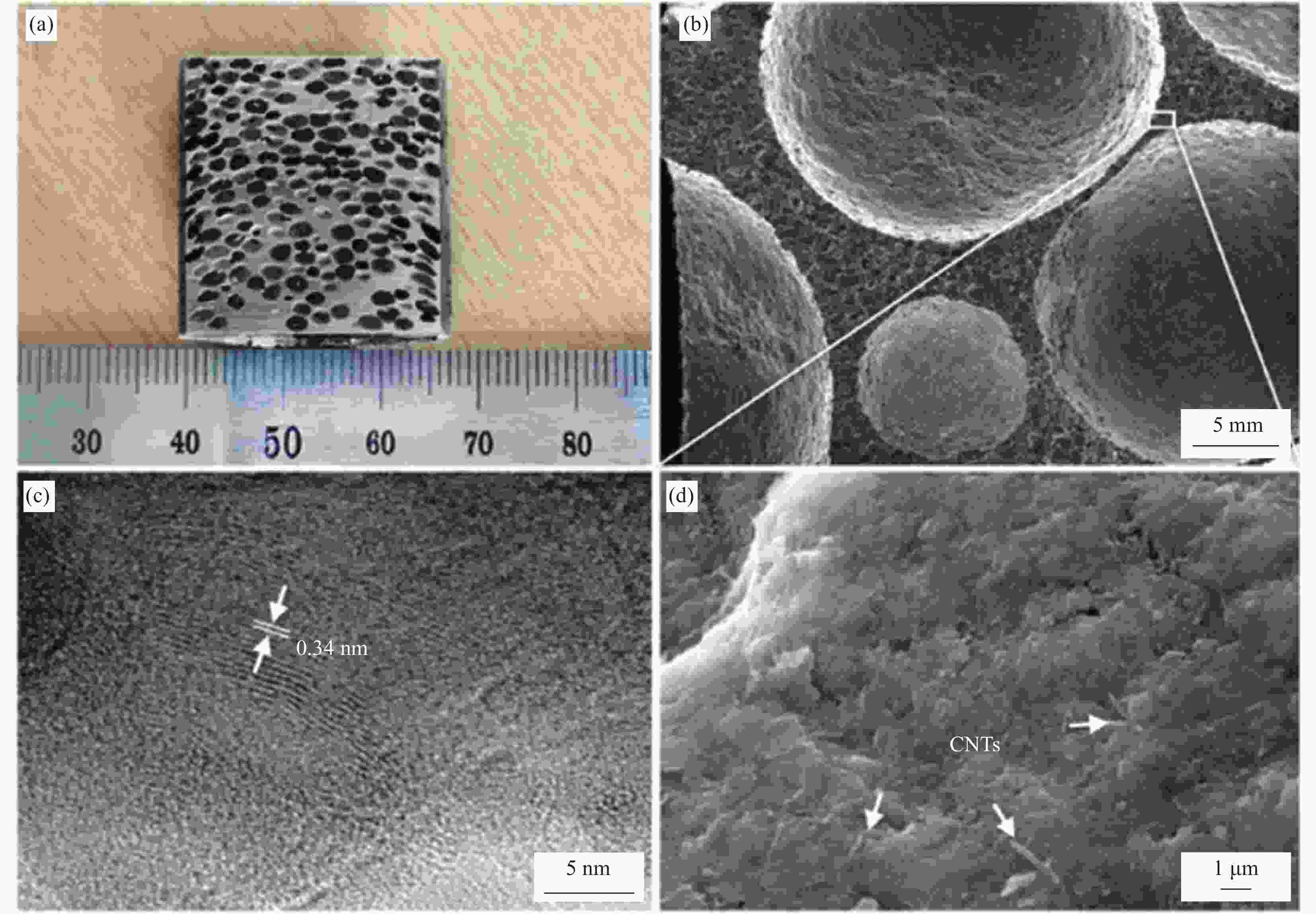

摘要: 采用原位化学气相沉积、短时球磨和填加造孔剂法相结合的工艺制备了碳纳米管(CNTs)/Al复合泡沫,研究了其在压缩-压缩循环载荷下的力学性能及失效机制。结果表明,CNTs/Al复合泡沫的应变-循环次数曲线经历线弹性、应变硬化及应变快速增长三个阶段。不同于泡沫铝的逐层坍塌变形失效模式,CNTs/Al复合泡沫疲劳失效的主要原因是大量剪切变形带的形成,试样出现快速的塑性变形。此外,CNTs含量为2.5wt%、孔隙率为60%的复合泡沫试样的疲劳强度相比于泡沫铝提高了92%。CNTs的均匀分布及增强相与基体材料之间良好的界面结合性保证了疲劳载荷能够以剪切力的形式从基体传递到CNTs上,使其充分发挥自身高强度、高韧性的特点,进而提高了疲劳性能。Abstract: Carbon nanotubes (CNTs) reinforced Al matrix composites were fabricated by spacer-holder method, including in-situ chemical vapor deposition and ball milling process. The mechanical properties and failure mechanisms of the CNTs/Al composite foams were investigated under compression-compression cyclic loading. The results show that the strain-number of cycle curves of the CNTs/Al composite foams is composed of three stages: elastic stage, strain hardening stage and rapid accumulation stage, which is similar to Al foams. Different from Al foams' deformation of layer-by-layer, the main failure modes of CNTs/Al composite foams are the collapse of pores within significant shear deformation bands under fatigue loading and rapid plastic deformation of the specimens. In addition, the fatigue strength of the CNTs/Al composite foams with CNTs content of 2.5wt% and porosity of 60% increases by 92% than Al foams. The CNTs/Al composites exhibit uniform CNTs distribution and good interfacial bonding between CNTs and Al matrix, which guarantees the effective transmission of fatigue loading in the way of shear stress from Al matrix to CNTs, so that the CNTs can give full play to the characteristics of high strength and high toughness, and then improve the fatigue performance.

-

Key words:

- aluminum foams /

- carbon nanotubes /

- compression fatigue /

- failure mechanism /

- enhancement mechanism

-

表 1 泡沫铝和2.5wt%CNTs/Al复合泡沫的压缩性能

Table 1. Compression performance of Al foams and 2.5wt% CNTs/Al composite foams

Component σs/MPa σpl/MPa εd/% Eεd/(MJ·m−3) Al foams 10.94±1.08 18.40±1.11 62.25±4.84 12.59 Composite foams 24.03±0.91 19.36±1.33 67.33±5.34 16.51 Notes: σs—First maximum stress on the stress-strain curve; σpl—Stress between 20% and 40% compressive strain; εd—Strain corresponding to the intersection of the tangent lines of the yield plateau stage and densification stage; Eεd—Energy absorption at ε=60%. -

[1] BANHART J, SEELIGER H W. Aluminum foam sandwich panels: Manufacture, metallurgy and applications[J]. Advanced Engineering Materials,2008,10(9):793-802. doi: 10.1002/adem.200800091 [2] 王应武, 夏宇, 王志平. 泡沫铝材料应用研究现状[J]. 材料导报, 2013, 27(15):132-134. doi: 10.3969/j.issn.1005-023X.2013.15.027WANG Y W, XIA Y, WANG Z P. Application and research status of foamed aluminum material[J]. Material Review,2013,27(15):132-134(in Chinese). doi: 10.3969/j.issn.1005-023X.2013.15.027 [3] KHERADMAND A B, LALEGANI Z. Electromagnetic interference shielding effectiveness of Al/Si composite foams[J]. Journal of Materials Science: Materials in Electronics,2015,26:7530-7536. doi: 10.1007/s10854-015-3389-1 [4] ZU G Y, SONG B N, ZHONG Z Y, et al. Static three-point bending behavior of aluminum foam sandwich[J]. Journal of Alloys and Compounds,2012,540:275-278. doi: 10.1016/j.jallcom.2012.06.079 [5] YANG K M, YANG X D, HE C N, et al. Damping characteristics of Al matrix composite foams reinforced by in-situ grown carbon nanotubes[J]. Materials Letters,2017,209:68-70. doi: 10.1016/j.matlet.2017.07.126 [6] GIBSON I J, ASHBY M F. Cellular solids: Structure and properties[M]. Cambridge: Cambridge University Press, 1998. [7] 刘菊芬, 刘荣佩, 史庆南, 等. 新型泡沫铝制备工艺研究[J]. 材料导报, 2002(8):65-67. doi: 10.3321/j.issn:1005-023X.2002.08.022LIU J F, LIU R P, SHI Q N, et al. Study of fabricating process for new type aluminum foam[J]. Material Review,2002(8):65-67(in Chinese). doi: 10.3321/j.issn:1005-023X.2002.08.022 [8] 杨旭东, 毕智超, 陈亚军, 等. 泡沫铝基复合材料的研究进展[J]. 热加工工艺, 2015, 44(8):12-16.YANG X D, BI Z C, CHEN Y J, et al. Recent advances in aluminum matrix composite[J]. Hot Working Technology,2015,44(8):12-16(in Chinese). [9] GUDEN M, S. YÜKSEL. SiC-particulate aluminum compo-site foams produced from powder compacts: Foaming and compression behavior[J]. Journal of Materials Science,2006,41(13):4075-4084. [10] XIA X, CHEN X W, ZHANG Z, et al. Compressive properties of closed-cell aluminum foams with different contents of ceramic microspheres[J]. Materials & Design,2014,56:353-358. [11] LI W T, YANG X D, HE C N, et al. Compressive responses and strengthening mechanisms of aluminum composite foams reinforced by graphene nanosheets[J]. Carbon,2019,153:396-406. doi: 10.1016/j.carbon.2019.07.043 [12] 赵乃勤, 刘兴海, 蒲博闻. 多维度碳纳米相增强铝基复合材料研究进展[J]. 金属学报, 2019, 55(1):1-15.ZHAO N Q, LIU X H, PU B W. Progress on multi-dimensional carbon nanomaterials reinforced aluminum matrix composites: A review[J]. Acta Metallurgica Sinica,2019,55(1):1-15(in Chinese). [13] YANG X D, HU Q, DU J, et al. Compression fatigue properties of open-cell aluminum foams fabricated by space-holder method[J]. International Journal of Fatigue,2019,121:272-280. doi: 10.1016/j.ijfatigue.2018.11.008 [14] 杨旭东, 李宗岷, 杨昆明, 等. 碳纳米管增强铝基复合泡沫的阻尼性能[J]. 复合材料学报, 2019, 36(2):418-424.YANG X D, LI Z M, YANG K M, et al. Damping properties of Al matrix composite foams reinforced by carbon nano-tubes[J]. Acta Materiae Compositae Sinica,2019,36(2):418-424(in Chinese). [15] YANG X D, LIU E Z, SHI C S, et al. Fabrication of carbon nanotube reinforced Al composites with well-balanced strength and ductility[J]. Journal of Alloys and Compounds,2013,563:216-220. doi: 10.1016/j.jallcom.2013.02.066 [16] YANG K M, YANG X D, LIU E Z, et al. Elevated temperature compressive properties and energy absorption response of in-situ grown CNT-reinforced Al composite foams[J]. Materials Science and Engineering A,2017,690:294-302. doi: 10.1016/j.msea.2017.03.004 [17] WANG N Z, MAIRE E, CHEN X, et al. Compressive perfor-mance and deformation mechanism of the dynamic gas injection aluminum foams[J]. Materials Characterization,2019,147:11-20. doi: 10.1016/j.matchar.2018.10.013 [18] BANERJEE S, HEMRAJ-BENNY T, WON S S. Covalent surface chemistry of single-walled carbon nanotubes[J]. Advanced Materials,2005,17(1):17-29. doi: 10.1002/adma.200401340 [19] ZHANG Z, DING J, XIA X C, et al. Fabrication and characterization of closed-cell aluminum foams with different contents of multi-walled carbon nanotubes[J]. Materials & Design,2015:88. [20] ALDOSHAN A, KHANNA S. Effect of relative density on the dynamic compressive behaviour of carbon nanotube reinforced aluminum foam[J]. Materials science and Engineering A,2017,689:17-24. doi: 10.1016/j.msea.2017.01.100 [21] KATONA B, SZEBENVI G, ORBULOV I N. Fatigue properties of ceramic hollow sphere filled aluminium matrix syntactic foams[J]. Materials science and Engineering A,2017,679:350-357. doi: 10.1016/j.msea.2016.10.061 [22] SZLANCSIK A, KATONA B, ORBULOV I N, et al. Fatigue properties of EP/A356 aluminium matrix syntactic foams with different densities[C]. IOP Conference Series: Materials Science and Engineering, IOP Publishing, 2018, 426(1): 012045. [23] YANG K M, YANG X D, LIU E Z, et al. High strain rate dynamic compressive properties and deformation behavior of Al matrix composite foams reinforced by in-situ grown carbon nanotubes[J]. Materials Science and Engineering A,2018,729:487-495. doi: 10.1016/j.msea.2017.09.011 [24] 杨旭东, 杨昆明, 邹田春, 等. 球磨对碳纳米管增强泡沫铝基复合材料压缩与吸能性能的影响[J]. 复合材料学报, 2018, 35(6):1518-1524.YANG X D, YANG K M, ZOU T C, et al. Effect of ball milling on the compressive property and energy absorption capacity of the carbon nanotube reinforced aluminum compo-site foams[J]. Acta Materiae Compositae Sinica,2018,35(6):1518-1524(in Chinese). [25] WANG J W, YANG X D, ZHANG M, et al. A novel approach to obtain in-situ growth carbon nanotube reinforced aluminum foams with enhanced properties[J]. Materials Letters,2015,161:763-766. doi: 10.1016/j.matlet.2015.09.093 [26] ISO. Mechanical testing of metals-ductility testing-Compression test of porous and cellular metals: ISO 13314: 2011[S]. Geneva: ISO, 2011. [27] YANG X D, ZOU T C, SHI C S, et al. Effect of carbon nano-tube (CNT) content on the properties of in-situ synthesis CNT reinforced Al composites[J]. Materials Science and Engineering A,2016,660:11-18. doi: 10.1016/j.msea.2016.02.062 [28] PAUL A, RAMAMURTY U. Strain rate sensitivity of a closed-cell aluminum foam[J]. Materials Science and Engineering A,2000,281:1-7. doi: 10.1016/S0921-5093(99)00750-9 [29] SHI X P, LIU S Y, NIE H L, et al. Study of cell irregularity effects on the compression of closed-cell foams[J]. International Journal of Mechanical Sciences,2017,135:215-225. [30] SEKI H, TANE M, OTSUKA M, et al. Effects of pore morphology on fatigue strength and fracture surface of lotus type porous copper[J]. Journal of Materials Research,2007,22(5):1331-1338. doi: 10.1557/jmr.2007.0164 [31] LINUL E, SERBAN D A, MARSAVINA L, et al. Low-cycle fatigue behaviour of ductile closed-cell aluminum alloy foams[J]. Fatigue and Fracture of Engineering Materials and Structures,2017,40(4):597-604. doi: 10.1111/ffe.12535 [32] KOLLURI M, MUKHERJEE M, GARCIA-MORENO F, et al. Fatigue of a laterally constrained closed cell aluminum foam[J]. Acta Materialia,2008,56(5):1114-1125. doi: 10.1016/j.actamat.2007.11.004 [33] HARTE A M, FLECK N A, ASHBY M F. Fatigue failure of an open cell and a closed cell aluminum aluminum alloy foam[J]. Acta Materialia,1999,47(8):2511-2524. doi: 10.1016/S1359-6454(99)00097-X [34] HAKAMADA M, KUROMURA T, CHINO Y, et al. Monotonic and cyclic compressive properties of porous aluminum fabricated by spacer methode[J]. Materials Science and Engineering A,2007,459(1):286-293. -

下载:

下载: