Experimental study on bond properties between GFRP bars and self compacting concrete

-

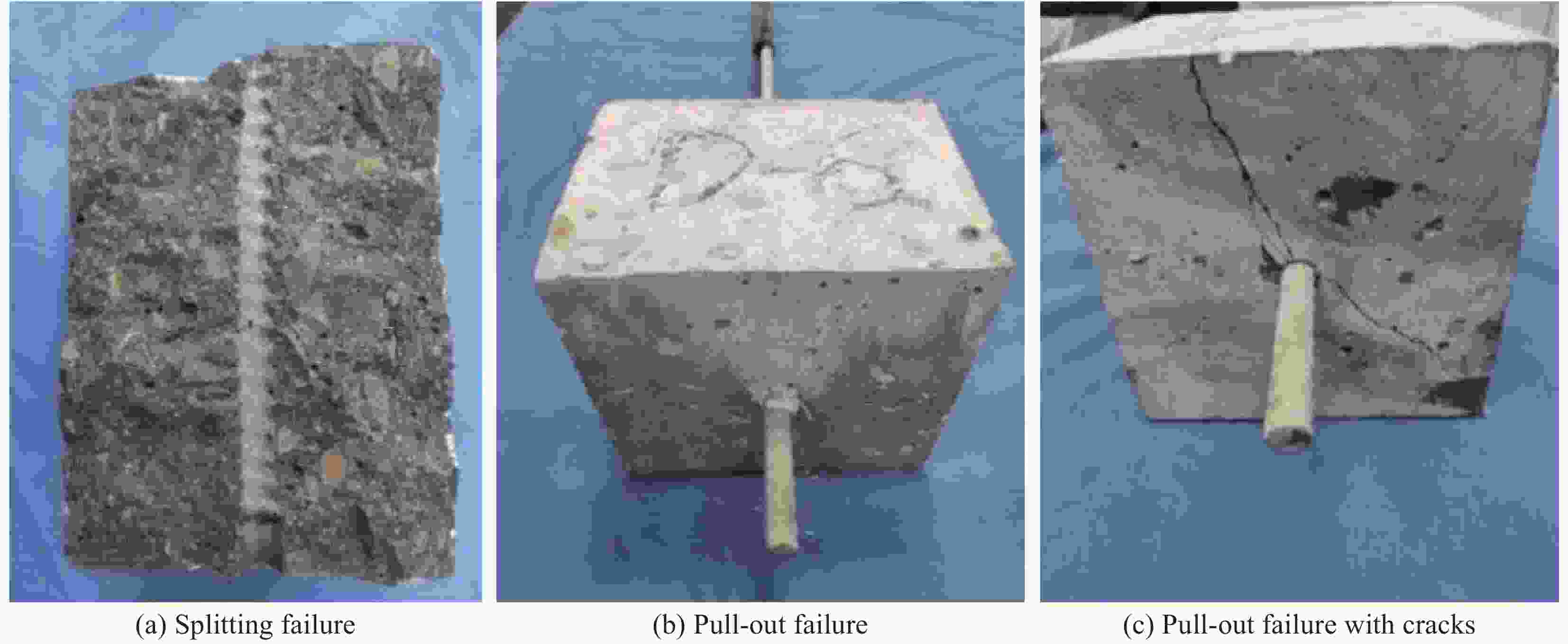

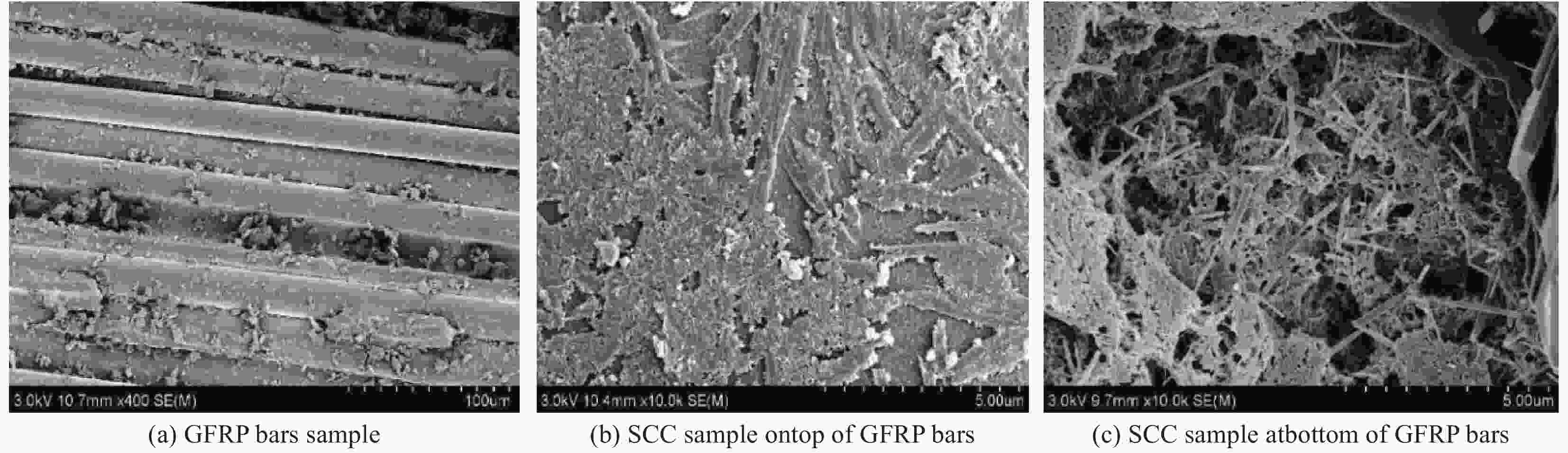

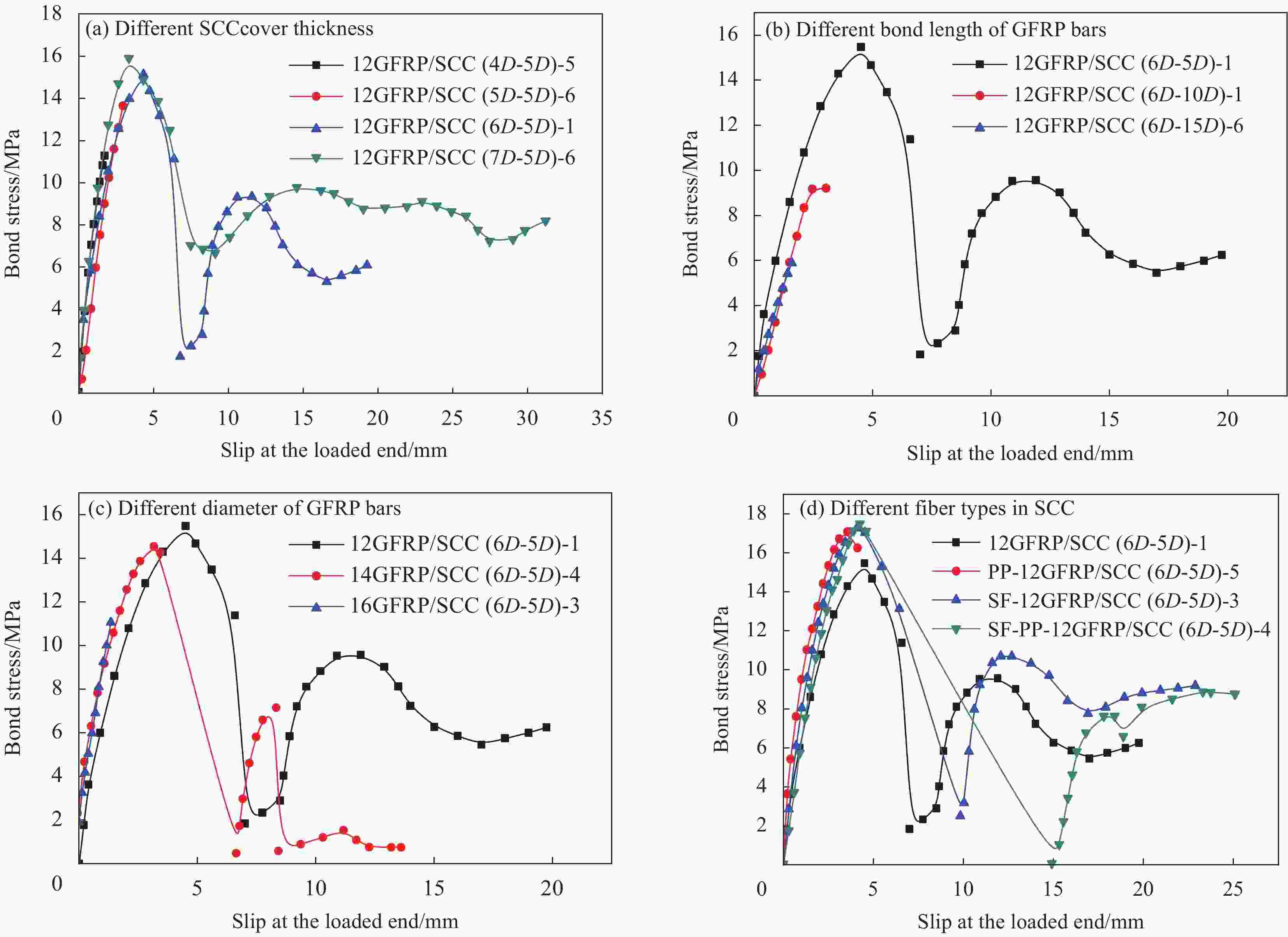

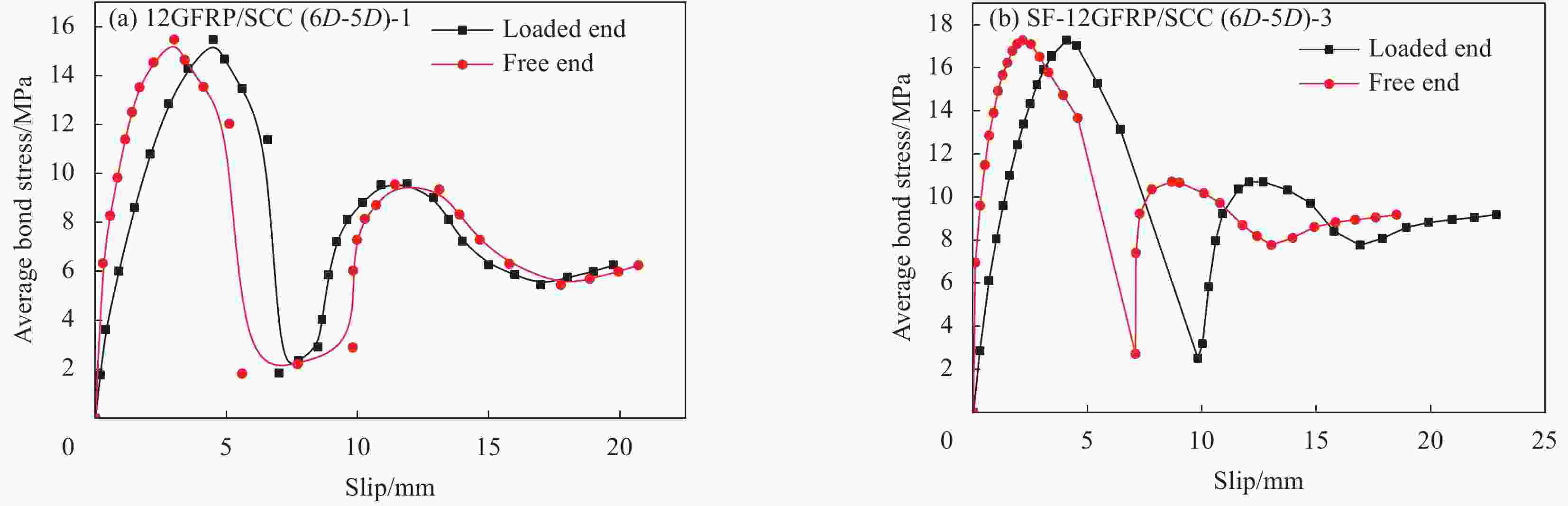

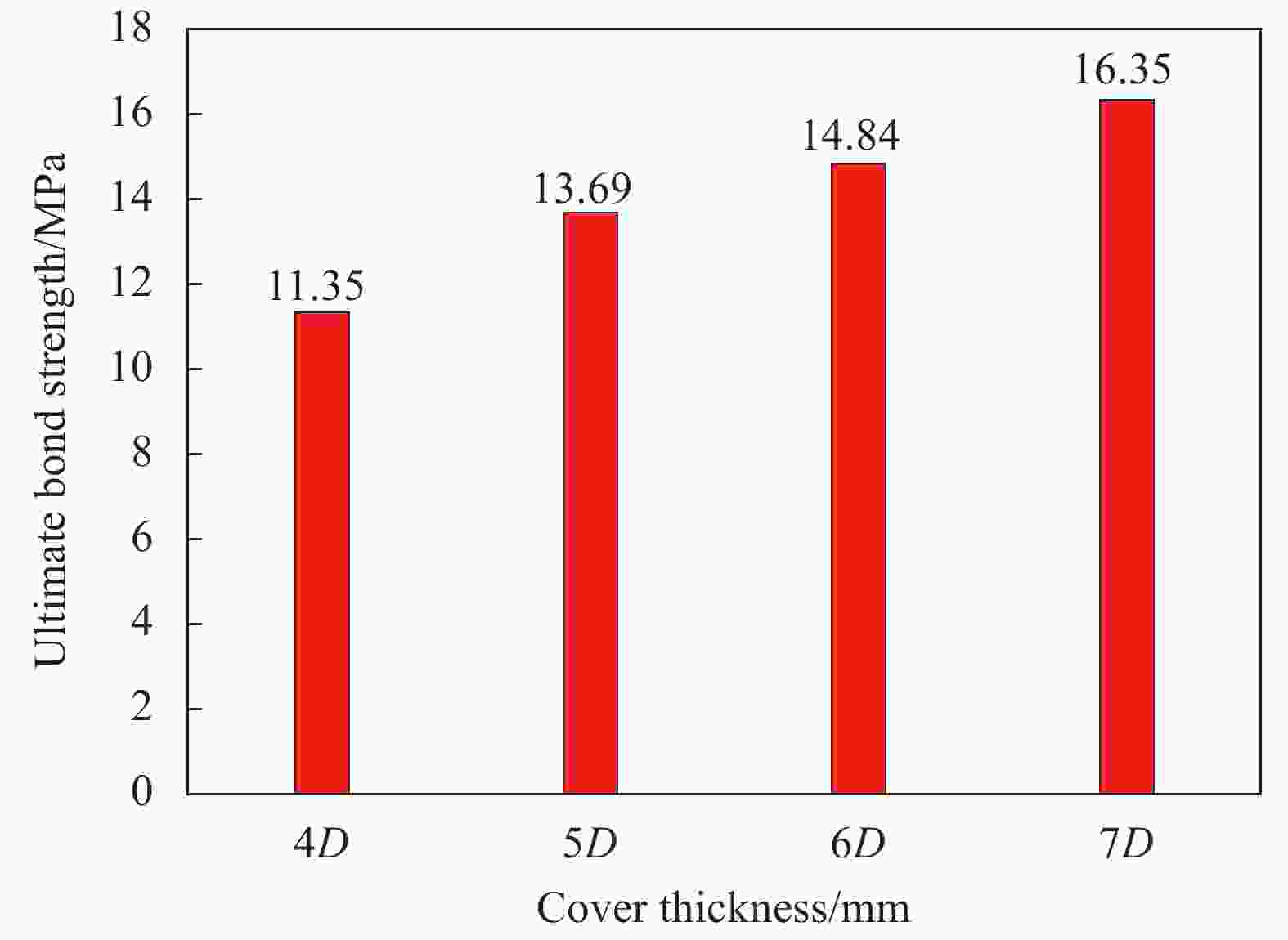

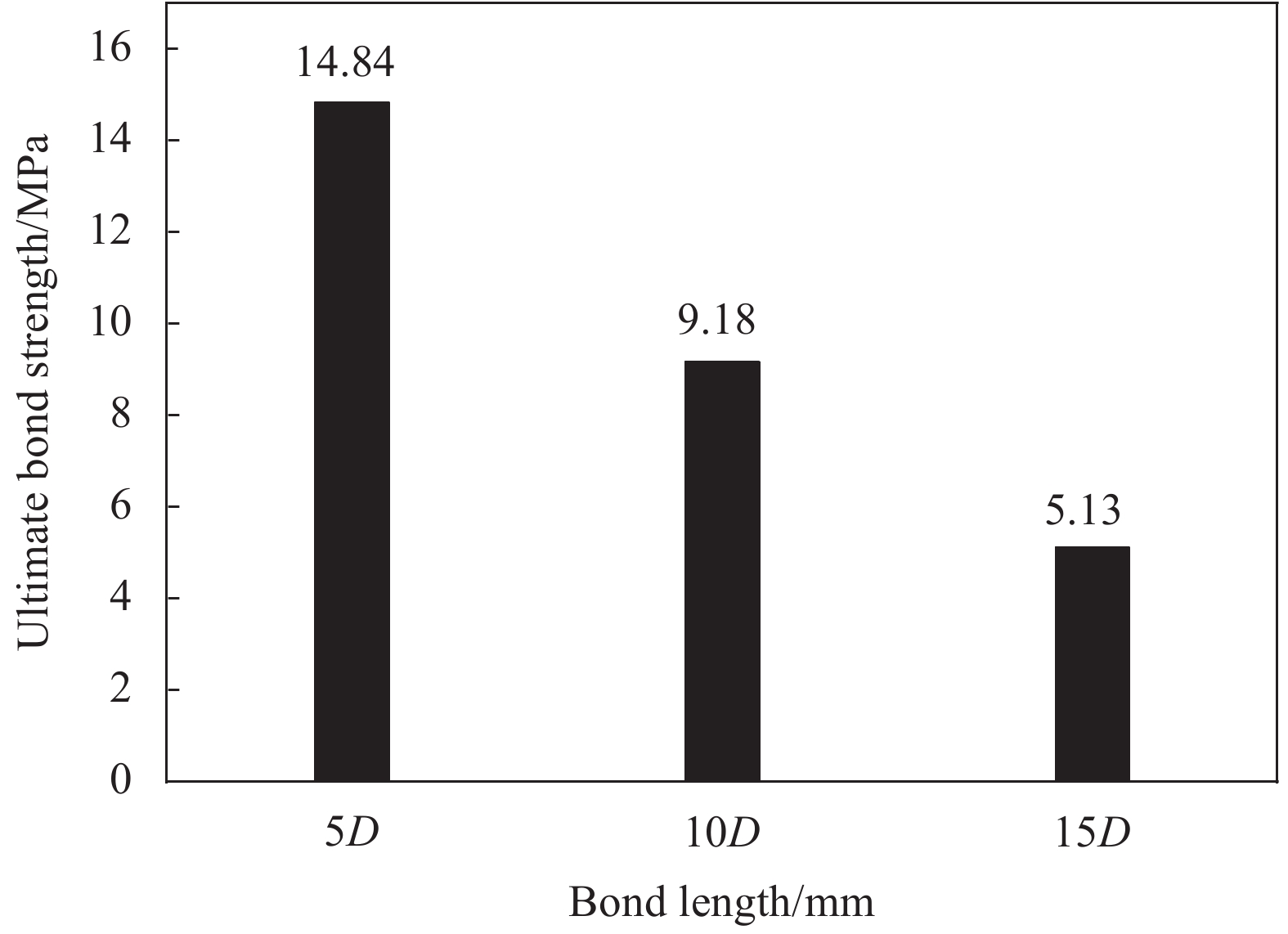

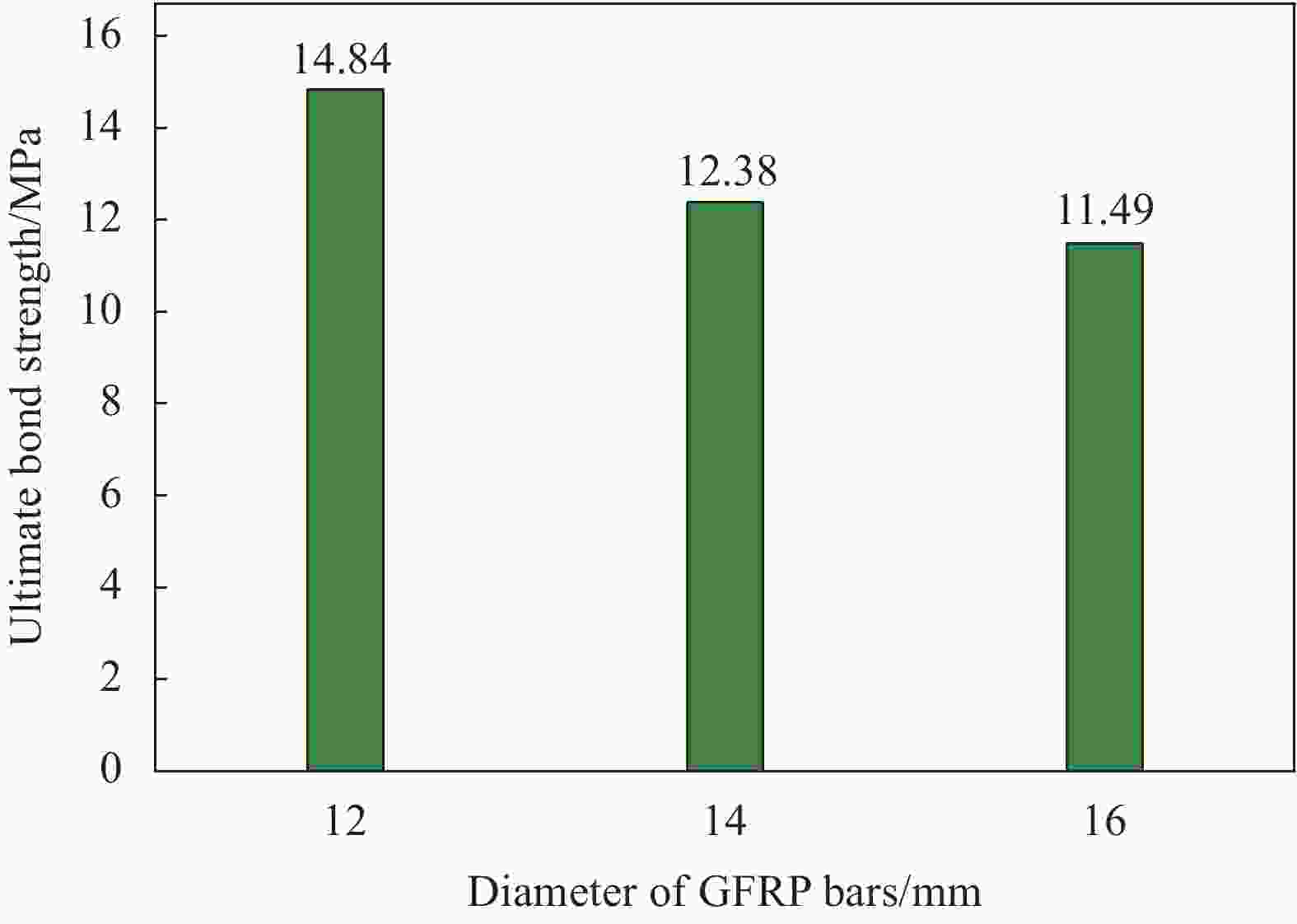

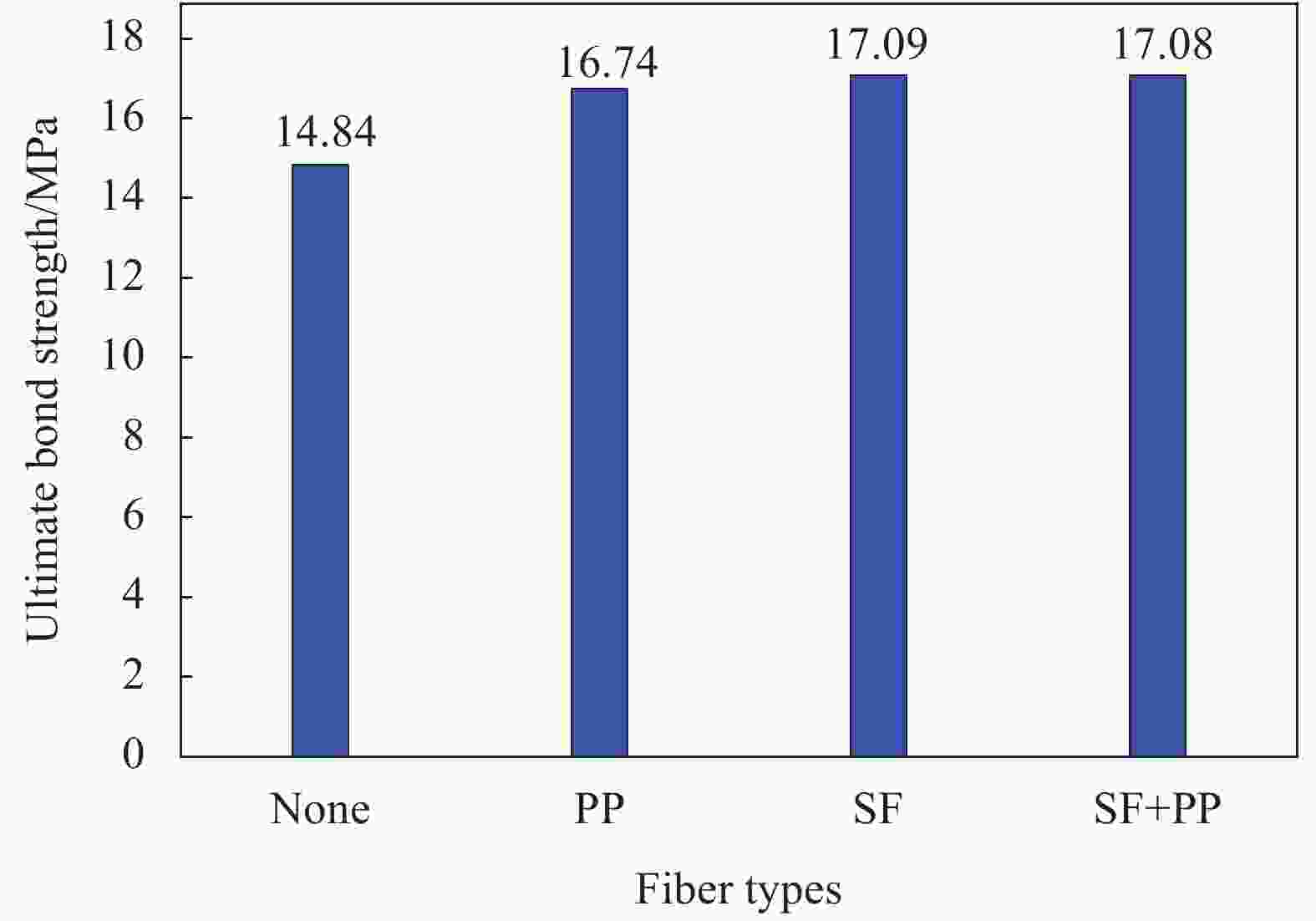

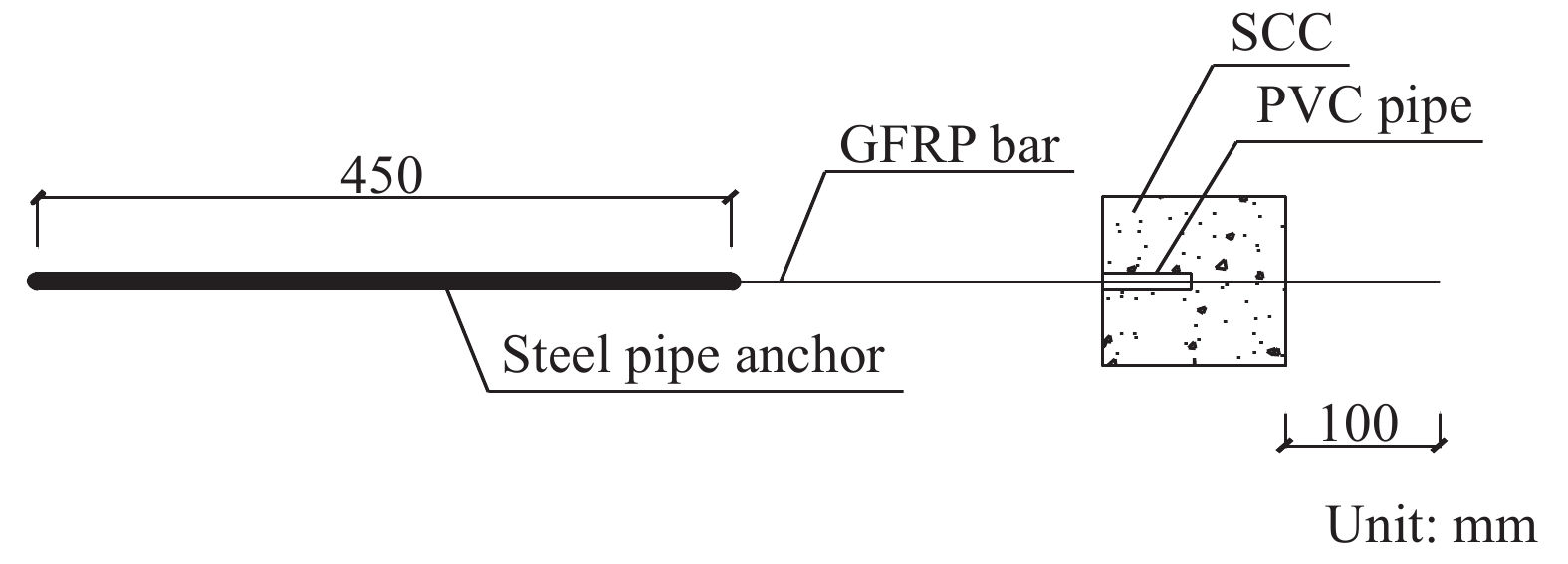

摘要: 为了研究玻璃纤维增强树脂复合材料(GFRP)筋与自密实混凝土(SCC)的黏结性能,制作了66个GFRP/SCC试件进行中心拉拔试验,研究SCC混凝土保护层厚度、GFRP筋直径和黏结长度以及SCC中添加纤维种类等因素对两者黏结性能的影响,并对试件的破坏形式进行分析。结果表明:试件主要出现了三种破坏形式,即劈裂破坏、拔出破坏、拔出带缝破坏;通过电镜扫描发现SCC浇筑方向对GFRP筋与SCC黏结界面的结构有一定影响,GFRP筋上部界面与SCC黏结更紧密。当SCC保护层厚度由4D增大至7D时,黏结强度提高了约44.05%;当GFRP筋黏结长度由5D增大至15D时,黏结强度降低了约65.43%;当GFRP筋直径由12 mm增大至16 mm时,黏结强度降低了约22.57%;SCC中添加聚丙烯纤维、钢纤维、聚丙烯纤维+钢纤维的试件黏结强度比不添加纤维的试件黏结强度分别提高12.80%、15.16%、15.09%。可以通过适当增加SCC保护层厚度、在SCC中添加纤维等措施来提高GFRP/SCC试件的黏结强度。Abstract: In order to study the bond behavior between glass fiber reinforced polymer (GFRP) bars and self compacting concrete (SCC), pull-out tests on sixty-six GFRP/SCC specimens were deployed and carried out. The effects of SCC cover thickness, bond length and diameter of GFRP bars as well as the fiber types added to SCC on bond properties were investigated. In addition, the failure modes of specimens were analyzed. The results show that there are mainly three failure modes, namely splitting failure, pull-out failure and pull-out failure with cracks. It is found by scanning electron microscopy (SEM) that the infilling direction of SCC has a certain influence on the structure of the bar-SCC interface. The upper interface of GFRP bars is bonded more closely to SCC compared with the lower one. When the SCC cover thickness increases from 4D to 7D, the bond strength is increased by about 44.05%. When the bond length of GFRP bars increases from 5D to 15D, the bond strength decreases by about 65.43%. When the diameter of GFRP bars increases from 12 mm to 16 mm, the bond strength decreases by about 22.57%. Meanwhile, the bond strengths of the specimens mixed with polypropylene fiber, steel fiber, hybrid fiber (polypropylene fiber and steel fiber) in SCC are about 12.80%, 15.16%, 15.09% higher than that of the specimens without any fibers respectively. Hence, the bond strength of GFRP/SCC specimens can be improved by increasing the SCC cover thickness, or adding fibers to SCC etc.

-

Key words:

- GFRP bar /

- self compacting concrete /

- pull-out test /

- bond strength /

- fiber

-

表 1 纤维物理性能

Table 1. Physical properties of fibers

Variety Diameter/

mmLength/

mmLength/

DiameterDensity/

(g·cm−3)Elastic

modulus/GPaTensile

strength/MPaBreaking

elongation/%Surface friction

coefficientSF 0.22 13 59.1 7.85 100 2800 10.1 0.35 PP 0.9 40 44.4 0.92 9.05 500 — 0.63 Notes: SF—Steel fiber; PP—Polypropylene fiber. 表 2 C60自密实混凝土(SCC)配合比

Table 2. C60 self compacting concrete (SCC) mix proportion

Cement Fly ash Sand Pebble Water-reducer Water Water-binder ratio Sand ratio/% 2.98 0.99 5.28 5.51 0.03 1 0.27 49 表 3 玻璃纤维增强树脂复合材料(GFRP)筋物理参数

Table 3. Physical parameters of glass fiber reinforced polymer (GFRP) bars

Diameter/mm Rib pitch dr/mm Rib height hr/mm Rib angle α/(°) Effective diameter de/mm 12 12 0.72 71.3 12 14 14 0.84 71.3 14 16 16 0.96 71.3 16 表 4 中心拉拔GFRP筋/SCC试件明细

Table 4. Schedule of central pull-out GFRP bars/SCC specimen

Serial number Bar diameter D/mm Bond length/mm Cover thickness/mm Size/mm Number 12GFRP/SCC(4D-5D) 12 60(5D) 48(4D) 108×108×150 6 12GFRP/SCC(5D-5D) 12 60(5D) 60(5D) 132×132×150 6 12GFRP/SCC(6D-5D) 12 60(5D) 72(6D) 156×156×150 6 12GFRP/SCC(7D-5D) 12 60(5D) 84(7D) 180×180×150 6 12GFRP/SCC(6D-10D) 12 120(10D) 72(6D) 156×156×150 6 12GFRP/SCC(6D-15D) 12 180(15D) 72(6D) 156×156×200 6 14GFRP/SCC(6D-5D) 14 70(5D) 84(6D) 182×182×150 6 16GFRP/SCC(6D-5D) 16 80(5D) 96(6D) 208×208×150 6 PP-12GFRP/SCC(6D-5D) 12 60(5D) 72(6D) 156×156×150 6 SF-12GFRP/SCC(6D-5D) 12 60(5D) 72(6D) 156×156×150 6 SF-PP-12GFRP/SCC(6D-5D) 12 60(5D) 72(6D) 156×156×150 6 Notes: Serial number of bond specimens apply a-bGFRP/SCC(c-d): a—Types of fiber (i.e., PP—Polypropylene fiber; SF—Steel fiber; SF-PP—Polypropylene fiber and steel fiber); b—Diameter of GFRP bar; c—Cover thickness of SCC (D—Diameter of GFRP bar); d—Bond length. 表 5 GFRP筋/SCC中心拉拔试验结果

Table 5. Results of central pull-out test for GFRP bars/SCC

Serial number S1/mm S2/mm Fmax/kN τmax/MPa Failure mode 12GFRP/SCC(4D-5D)-1 1.70 0.43 24.58 10.87 P 12GFRP/SCC(4D-5D)-2 1.81 0.47 25.32 11.20 P 12GFRP/SCC(4D-5D)-3 1.75 0.43 25.69 11.36 P 12GFRP/SCC(4D-5D)-4 1.69 0.42 26.51 11.93 P 12GFRP/SCC(4D-5D)-5 1.73 0.42 25.52 11.29 P 12GFRP/SCC(4D-5D)-6 2.12 0.36 25.93 11.47 P 12GFRP/SCC(5D-5D)-1 2.73 0.82 32.29 14.28 P 12GFRP/SCC(5D-5D)-2 3.15 0.90 30.67 13.56 P 12GFRP/SCC(5D-5D)-3 2.93 0.72 31.34 13.86 P 12GFRP/SCC(5D-5D)-4 1.89 0.43 27.34 12.09 P 12GFRP/SCC(5D-5D)-5 3.01 1.07 32.56 14.40 P 12GFRP/SCC(5D-5D)-6 3.11 0.77 31.54 13.95 P 12GFRP/SCC(6D-5D)-1 4.51 3.01 34.97 15.47 B 12GFRP/SCC(6D-5D)-2 3.57 1.99 34.99 15.48 B 12GFRP/SCC(6D-5D)-3 2.78 1.35 32.02 14.16 BF 12GFRP/SCC(6D-5D)-4 3.20 1.37 32.83 14.52 BF 12GFRP/SCC(6D-5D)-5 3.62 1.23 32.67 14.45 P 12GFRP/SCC(6D-5D)-6 3.83 1.53 33.89 14.99 P 12GFRP/SCC(7D-5D)-1 3.89 1.92 36.68 16.22 B 12GFRP/SCC(7D-5D)-2 3.34 1.57 38.46 17.01 B 12GFRP/SCC(7D-5D)-3 2.72 0.96 34.57 15.29 B 12GFRP/SCC(7D-5D)-4 3.04 1.41 39.03 17.26 B 12GFRP/SCC(7D-5D)-5 4.15 1.87 36.37 16.09 B 12GFRP/SCC(7D-5D)-6 3.51 1.83 36.74 16.25 B 12GFRP/SCC(6D-10D)-1 3.03 0.24 41.69 9.22 P 12GFRP/SCC(6D-10D)-2 — — — — M 12GFRP/SCC(6D-10D)-3 2.87 0.56 40.37 8.93 P 12GFRP/SCC(6D-10D)-4 2.56 0.62 41.13 9.10 P 12GFRP/SCC(6D-10D)-5 2.69 0.48 42.79 9.46 P 12GFRP/SCC(6D-10D)-6 2.88 0.59 41.58 9.19 P 12GFRP/SCC(6D-15D)-1 1.61 — 40.38 5.95 P 12GFRP/SCC(6D-15D)-2 1.53 — 39.87 5.88 P 12GFRP/SCC(6D-15D)-3 1.59 — 37.49 5.53 P 12GFRP/SCC(6D-15D)-4 1.64 — 36.66 5.41 P 12GFRP/SCC(6D-15D)-5 — — — — M 12GFRP/SCC(6D-15D)-6 1.58 — 40.02 5.90 P 14GFRP/SCC(6D-5D)-1 2.63 0.92 41.53 13.49 BF 14GFRP/SCC(6D-5D)-2 2.49 0.75 39.85 12.95 BF 14GFRP/SCC(6D-5D)-3 3.97 1.16 44.35 14.41 P 14GFRP/SCC(6D-5D)-4 3.52 1.89 46.87 15.23 BF 14GFRP/SCC(6D-5D)-5 — 1.89 46.67 15.17 P 14GFRP/SCC(6D-5D)-6 2.67 0.88 43.27 14.06 M 16GFRP/SCC(6D-5D)-1 1.99 0.14 45.90 11.42 P 16GFRP/SCC(6D-5D)-2 — — — — M 16GFRP/SCC(6D-5D)-3 1.59 0.30 46.34 11.53 P 16GFRP/SCC(6D-5D)-4 1.67 0.21 49.86 12.40 P 16GFRP/SCC(6D-5D)-5 — — — — M 16GFRP/SCC(6D-5D)-6 1.95 0.21 42.68 10.62 P PP-12GFRP/SCC(6D-5D)-1 4.60 1.89 38.42 16.99 BF PP-12GFRP/SCC(6D-5D)-2 3.29 1.30 38.01 16.81 BF PP-12GFRP/SCC(6D-5D)-3 3.17 1.24 38.13 16.86 BF PP-12GFRP/SCC(6D-5D)-4 2.42 1.04 37.53 16.60 BF PP-12GFRP/SCC(6D-5D)-5 3.55 2.25 38.61 17.08 P PP-12GFRP/SCC(6D-5D)-6 2.48 1.16 36.46 16.13 P SF-12GFRP/SCC(6D-5D)-1 4.07 1.80 36.33 16.07 B SF-12GFRP/SCC(6D-5D)-2 3.81 1.78 38.65 17.10 B SF-12GFRP/SCC(6D-5D)-3 4.09 2.17 39.07 17.28 B SF-12GFRP/SCC(6D-5D)-4 3.57 1.85 39.85 17.63 B SF-12GFRP/SCC(6D-5D)-5 3.68 1.75 38.67 17.10 B SF-12GFRP/SCC(6D-5D)-6 4.15 1.97 39.26 17.36 B SF-PP-12GFRP/SCC(6D-5D)-1 4.10 2.15 40.84 18.06 BF SF-PP-12GFRP/SCC(6D-5D)-2 3.28 1.53 37.24 16.47 BF SF-PP-12GFRP/SCC(6D-5D)-3 4.23 2.20 37.14 16.43 B SF-PP-12GFRP/SCC(6D-5D)-4 4.25 1.76 39.54 17.49 B SF-PP-12GFRP/SCC(6D-5D)-5 3.12 0.89 37.20 16.45 B SF-PP-12GFRP/SCC(6D-5D)-6 3.94 2.06 39.79 17.59 B Notes: S1—Slip at the loaded end; S2—Slip at the free end; Fmax—Maximum pull-out load; τmax—Maximum bond strength; In the failure mode, P—Splitting failure; B—Pull-out failure; BF—Pull-out failure with cracks; M—Destroy of bottom anchor of GFRP bars. -

[1] 吴庆, 袁迎曙. 锈蚀钢筋力学性能退化规律试验研究[J]. 土木工程学报, 2008(12):42-47. doi: 10.3321/j.issn:1000-131X.2008.12.007WU Qing, YUAN Yingshu. Experimental study on the deterioration of mechanical properties of corroded steel bars[J]. China Civil Engineering Journal,2008(12):42-47(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.12.007 [2] 施锦杰, 孙伟. 混凝土中钢筋锈蚀研究现状与热点问题分析[J]. 硅酸盐学报, 2010, 38(9):1753-1764.SHI Jinjie, SUN Wei. Recent research on steel corrosion in concrete[J]. Journal of the Chinese Ceramic Society,2010,38(9):1753-1764(in Chinese). [3] 薛伟辰, 王伟, 付凯. 碱环境下不同应力水平GFRP筋抗拉性能试验[J]. 复合材料学报, 2013, 30(6):67-75. doi: 10.3969/j.issn.1000-3851.2013.06.010XUE Weichen, WANG Wei, FU Kai. Experimental study on tensile properties of GFRP rebars under different stress levels as exposed to alkaline solution[J]. Acta Materiae Compositae Sinica,2013,30(6):67-75(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.06.010 [4] 吴丽丽, 王云飞, 谢灵慧, 等. 玻璃纤维增强聚合物复合材料筋与工程水泥基复合材料黏结性能[J]. 复合材料学报, 2020, 37(3):696-706.WU Lili, WANG Yufei, XIE Linghui, et al. Bonding behavior between glass fiber reinforced polymer composite bars and engineered cementitious composite[J]. Acta Materiae Compositae Sinica,2020,37(3):696-706(in Chinese). [5] 郝庆多, 王言磊, 侯吉林, 等. GFRP带肋筋粘结性能试验研究[J]. 工程力学, 2008(10):158-165, 179.HAO Qingduo, WANG Yanlei, HOU Jilin, et al. Experimental study on bond behavior of GFRP ribbed rebars[J]. Engineering Mechanics,2008(10):158-165, 179(in Chinese). [6] HAO Qingduo, WANG Yanlei, HE Zheng, et al. Bond strength of glass fiber reinforced polymer ribbed rebars in normal strength concrete[J]. Construction and Building Materials,2008,23(2):865-871. [7] CHAALLAL O, BENMOKRANE B. Pullout and bond of glass-fibre rods embedded in concrete and cement grout[J]. Materials and Structures,1993(26):167-175. [8] 周继凯, 杜钦庆, 陈诗学, 等. GFRP筋拉伸力学性能温度效应试验研究[J]. 岩石力学与工程学报, 2008, 27(S1):2707-2714.ZHOU Jikai, DU Qinqing, CHEN Shixue, et al. Experimental research on thermal effect of tensile mechanical properties of gfrp rebar[J]. Chinese Journal of Rock Mechanics and Engineering,2008,27(S1):2707-2714(in Chinese). [9] COSENZA E. Behavior and modeling of bond of FRP rebars to concrete[J]. Journal of Composites for Construction,1997,1(2):40-51. doi: 10.1061/(ASCE)1090-0268(1997)1:2(40) [10] WANG Huanzi. Static and fatigue bond characteristics of FRP rebars embedded in fiber-reinforced concrete[J]. Journal of Composite Materials,2010,44(13):1605-1622. doi: 10.1177/0021998309355845 [11] COSENZA E, MANFREDI G, REALFONZO R. 20 Analytical modelling of bond between FRP reinforcing bars and concrete[C]. Non-metallic (FRP) Reinforcement for Concrete Structures: Proceedings of the Second International RILEM Symposium, 1995: 164-171. [12] OKELO R., YUAN R. L. Bond strength of fiber reinforced polymer rebars in normal strength concrete[J]. Journal of Composites for Construction,2005,9(3):203-213. doi: 10.1061/(ASCE)1090-0268(2005)9:3(203) [13] 陈剑. GFRP筋与纤维混凝土粘结滑移试验研究[D]. 大连: 大连理工大学, 2008.CHEN Jian. The experimental research on bond-slip performance of GFRP bars embedded in fiber reinforced concrete[D]. Dalian: Dalian University of Technology, 2008(in Chinese). [14] ISLAM S, AFEFY H M, SENNAH K, et al. Bond characteristics of straight and headed end, ribbed surface, GFRP bars embedded in high strength concrete[J]. Construction and Building Materials,2015,83:283-298. doi: 10.1016/j.conbuildmat.2015.03.025 [15] YAN Fei, LIN Zhibin, ZHANG Dalu, et al. Experimental study on bond durability of glass fiber reinforced polymer bars in concrete exposed to harsh environmental agents: Freeze-thaw cycles and alkaline-saline solution[J]. Composites Part B: Eningeering,2016,116:406-421. [16] 郝庆多, 王言磊, 欧进萍. 拉拔条件下GFRP筋与混凝土粘结强度试验研究[J]. 建筑结构学报, 2008(1):103-111. doi: 10.3321/j.issn:1000-6869.2008.01.015HAO Qingduo, WANG Yanlei, OU Jinping. Experimental investigation on bond strength between GFRP rebars and concrete under pullout conditions[J]. Journal of Building Structures,2008(1):103-111(in Chinese). doi: 10.3321/j.issn:1000-6869.2008.01.015 [17] FARHAD A, FATEMEH H, AFSANEH V, et al. High-performance fibre-reinforced heavyweight self-compacting concrete: Analysis of fresh and mechanical properties[J]. Construction and Building Materials,2020,232:117230. doi: 10.1016/j.conbuildmat.2019.117230 [18] GIL A M, KHAYAT K H, TUTIKIAN B F. An experimental approach to design self-consolidating concrete[J]. Construction and Building Materials,2019,229:116939. doi: 10.1016/j.conbuildmat.2019.116939 [19] 吕兴军, 丁言兵, 曹明莉. 自密实混凝土配合比设计研究进展[J]. 混凝土, 2013(8):696-706.LV Xingjun, DING Yanbing, CAO Mingli. Progress of the researching on proportional rate design methods of self-compacting concrete[J]. Concrete,2013(8):696-706(in Chinese). [20] 罗素蓉, 郑建岚, 王国杰. 自密实高性能混凝土力学性能的研究与应用[J]. 工程力学, 2005(1):164-169. doi: 10.3969/j.issn.1000-4750.2005.01.029LUO Surong, ZHENG Jianlan, WANG Guojie. On mechanical property of self-compacting concrete and its engineering application[J]. Engineering Mechanics,2005(1):164-169(in Chinese). doi: 10.3969/j.issn.1000-4750.2005.01.029 [21] 刘运华, 谢友均, 龙广成. 自密实混凝土研究进展[J]. 硅酸盐学报, 2007(5):671-678. doi: 10.3321/j.issn:0454-5648.2007.05.028LIU Yunhua, XIE Youjun, LONG Guangcheng. Progress of research on self-compacting concrete[J]. Journal of the Chinese Ceramic Society,2007(5):671-678(in Chinese). doi: 10.3321/j.issn:0454-5648.2007.05.028 [22] 丁一宁, 李娟, 王宝民, 等. 纤维对GFRP筋与自密实混凝土基体粘结性能影响分析[J]. 建筑结构学报, 2011, 32(1):63-69.DING Yining, LI Juan, WANG Baomin, et al. Effect of fibers on bond behavior between GFRP bars and self-compacting concrete[J]. Journal of Building Structures,2011,32(1):63-69(in Chinese). [23] BAZLI M, ASHRAFI H, OSKOUEI A V. Experiments and probabilistic models of bond strength between GFRP bar and different types of concrete under aggressive environments[J]. Construction and Building Materials,2017,148:429-443. doi: 10.1016/j.conbuildmat.2017.05.046 [24] ZEMOUR N, ASADIAN A, AHMED E A, et al. Experimental study on the bond behavior of GFRP bars in normal and self-consolidating concrete[J]. Construction and Building Materials,2018,189:869-881. doi: 10.1016/j.conbuildmat.2018.09.045 [25] 刘洋. 纤维对筋材与自密实混凝土的粘结性能的影响[D]. 大连: 大连理工大学, 2010.LIU Yang. Fiber effect on bond behaviour between bars and self-compacting concrete matrix[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [26] ACI Committee 440. Guide for the design and construction of structural concrete reinforced with fiber-reinforced polymer bars: ACI 440.1R—15[S]. Michigan: American Concrete Institute, 2015. -

下载:

下载: