Quasi-static mechanical properties and constitutive model of fly ash cenosphere/aluminum syntactic foam

-

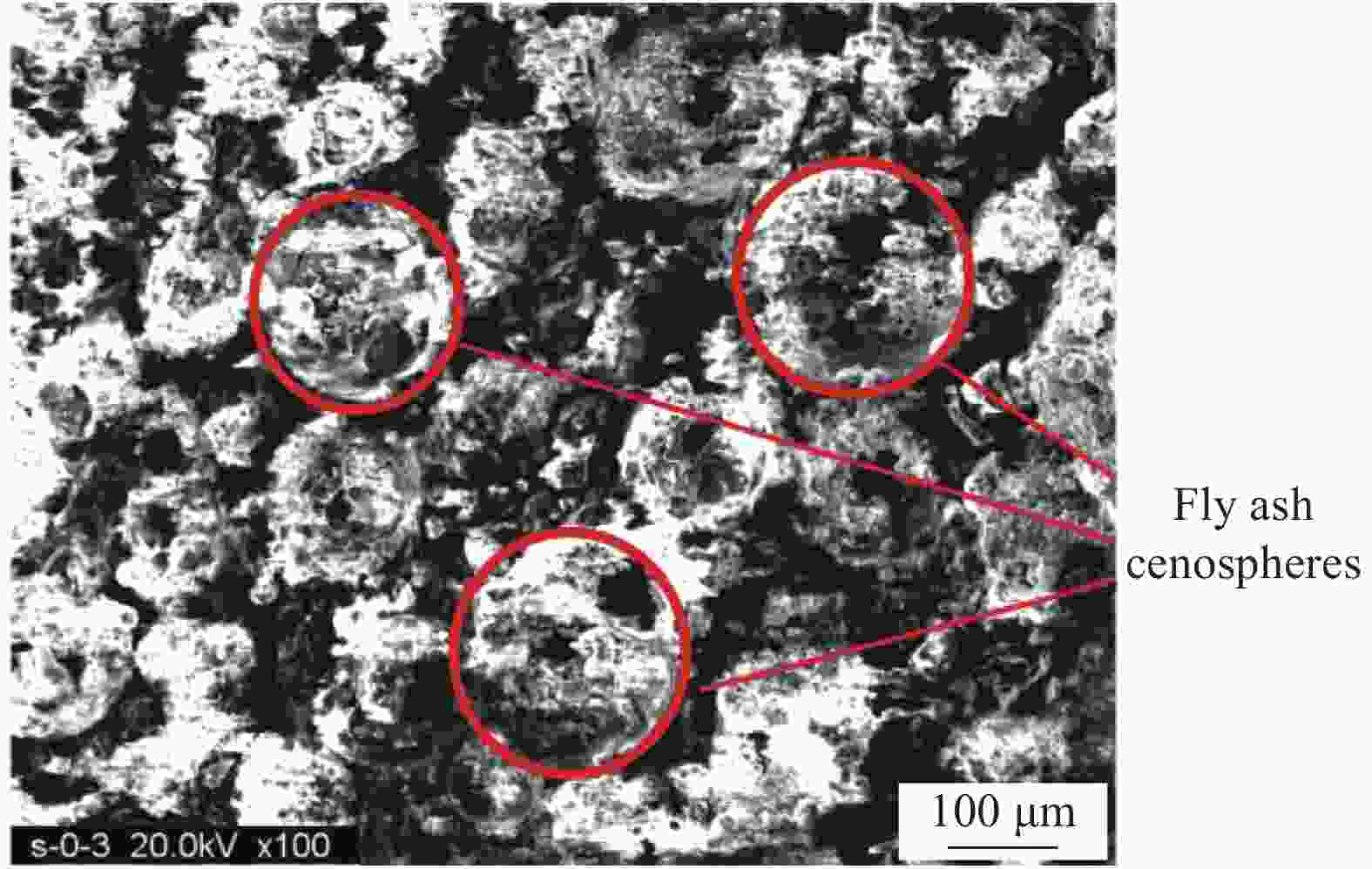

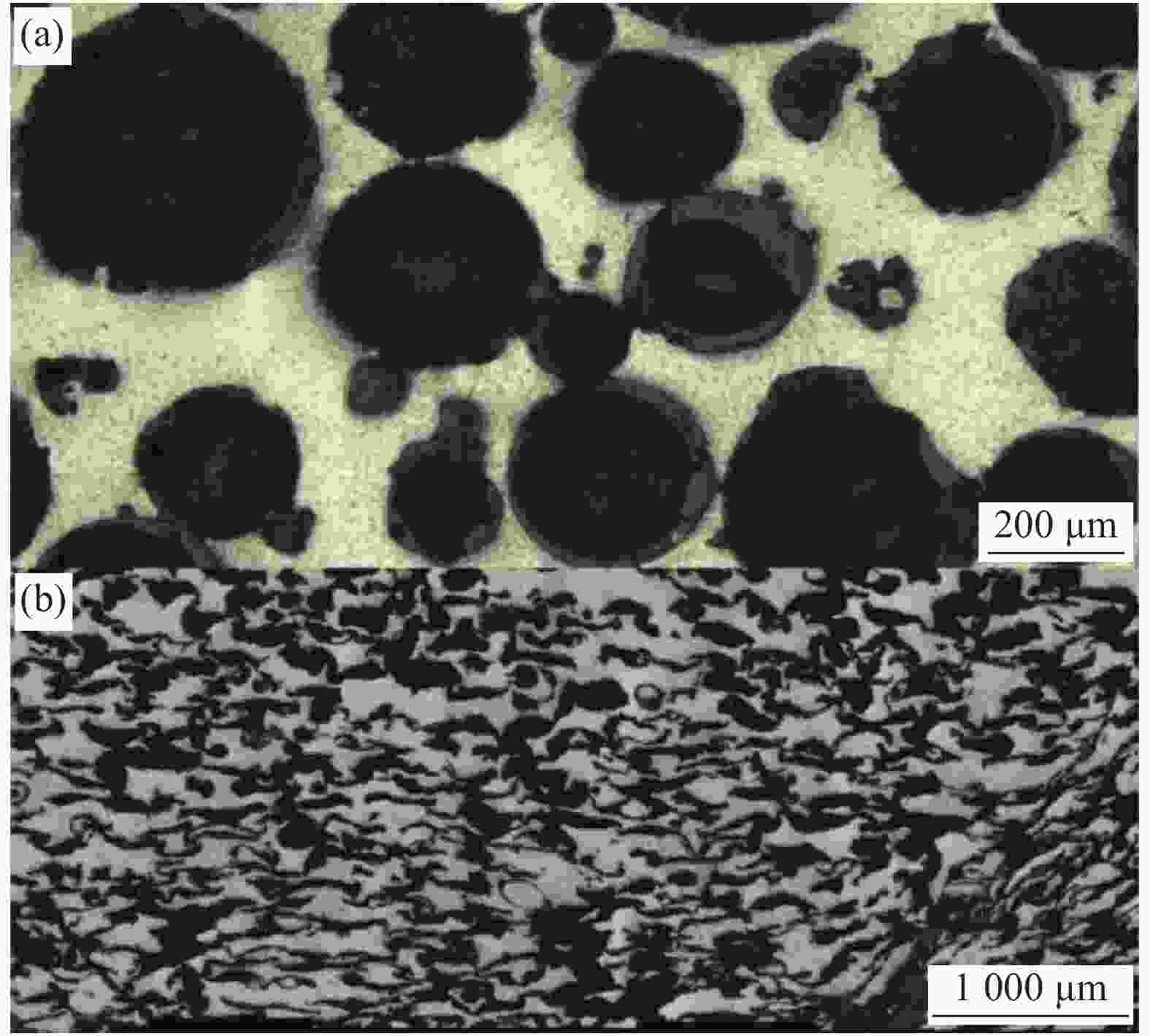

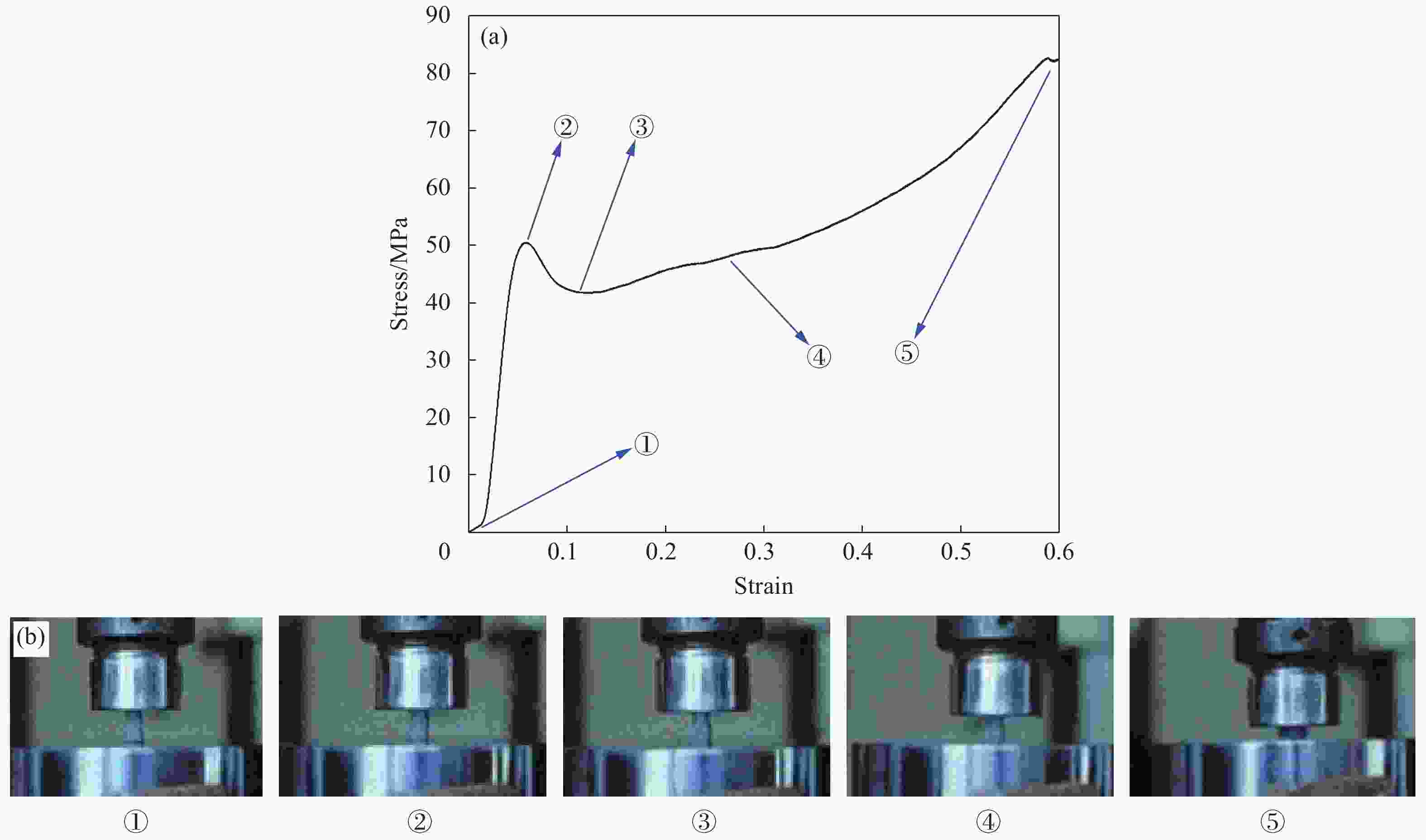

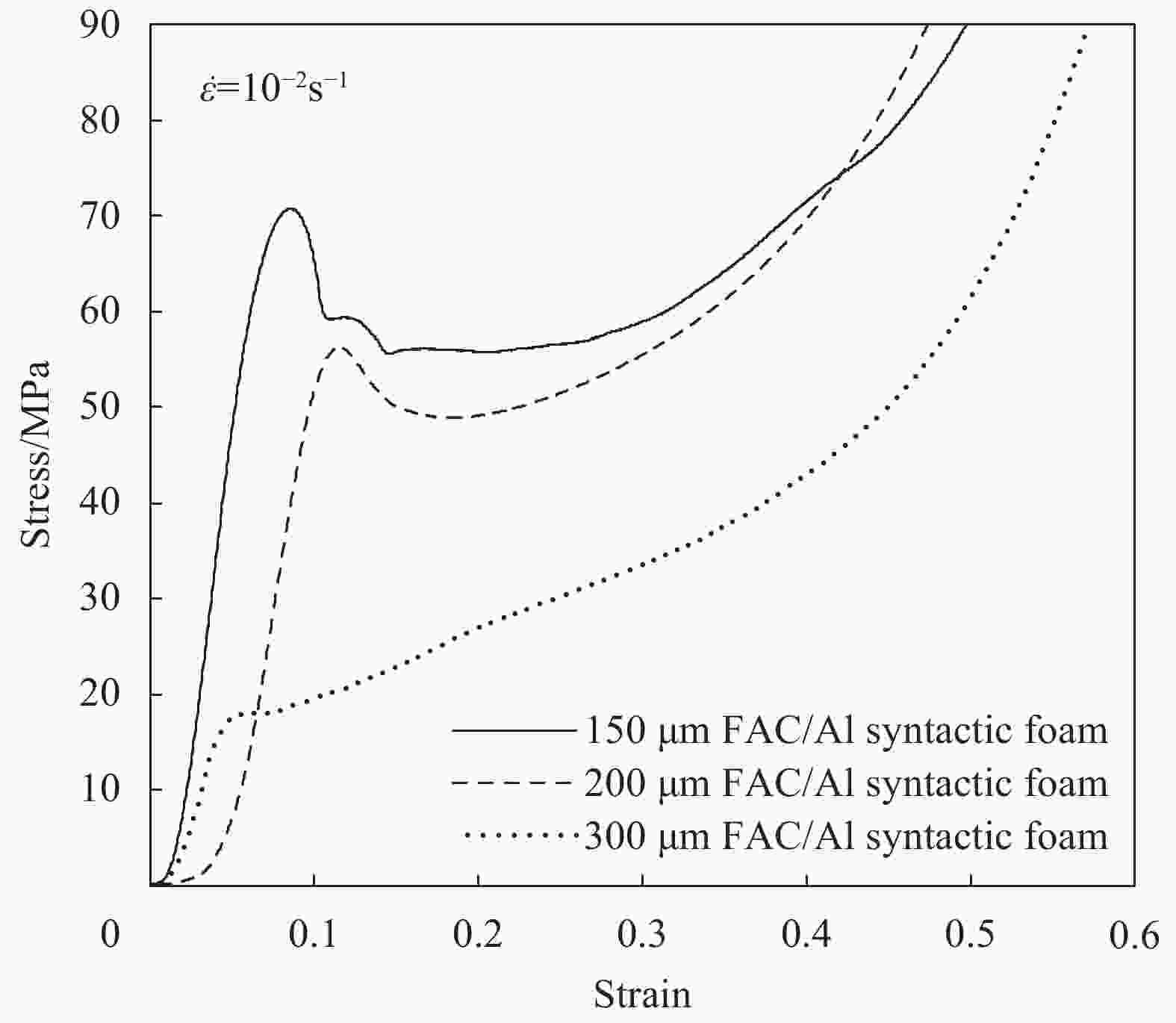

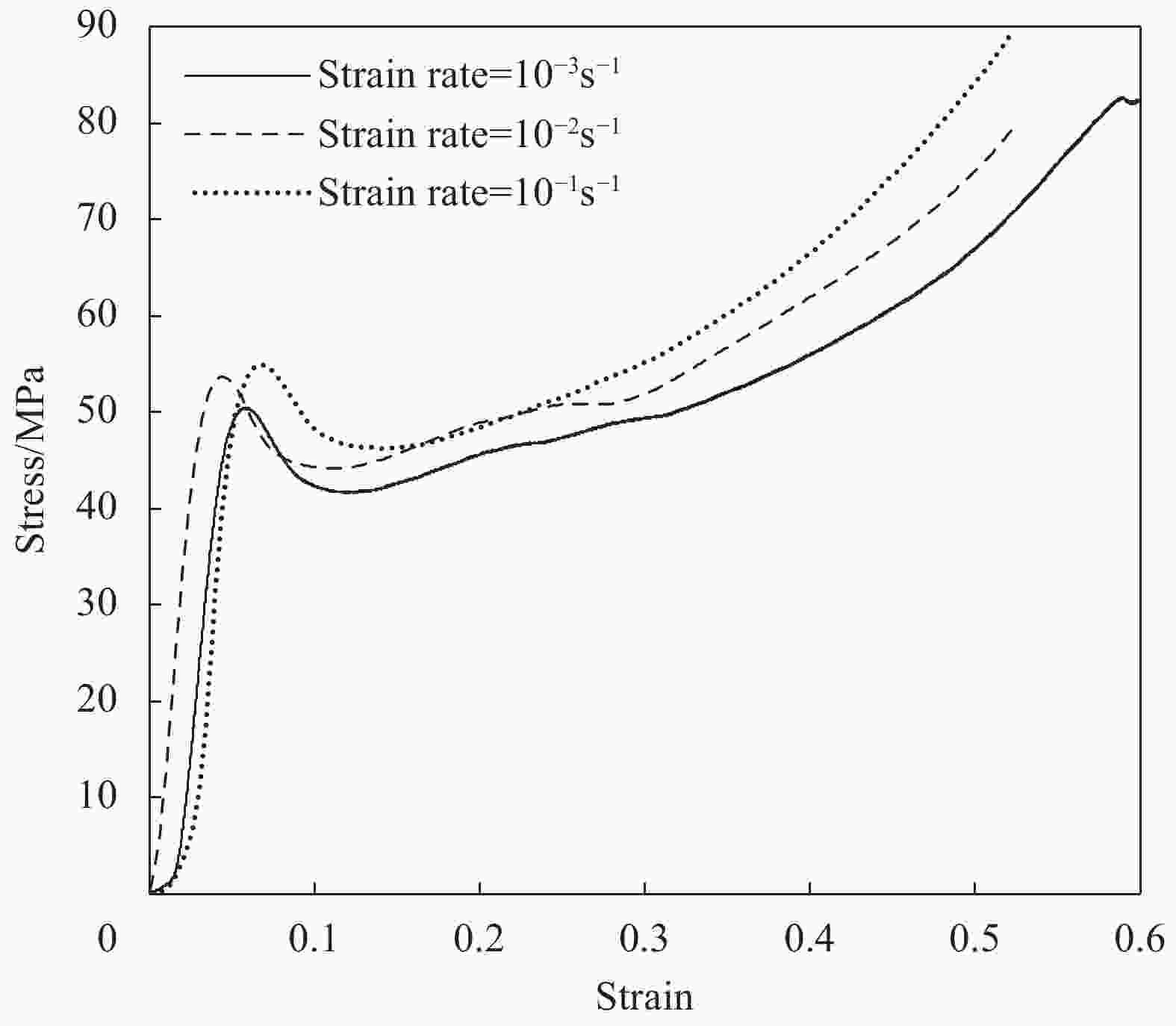

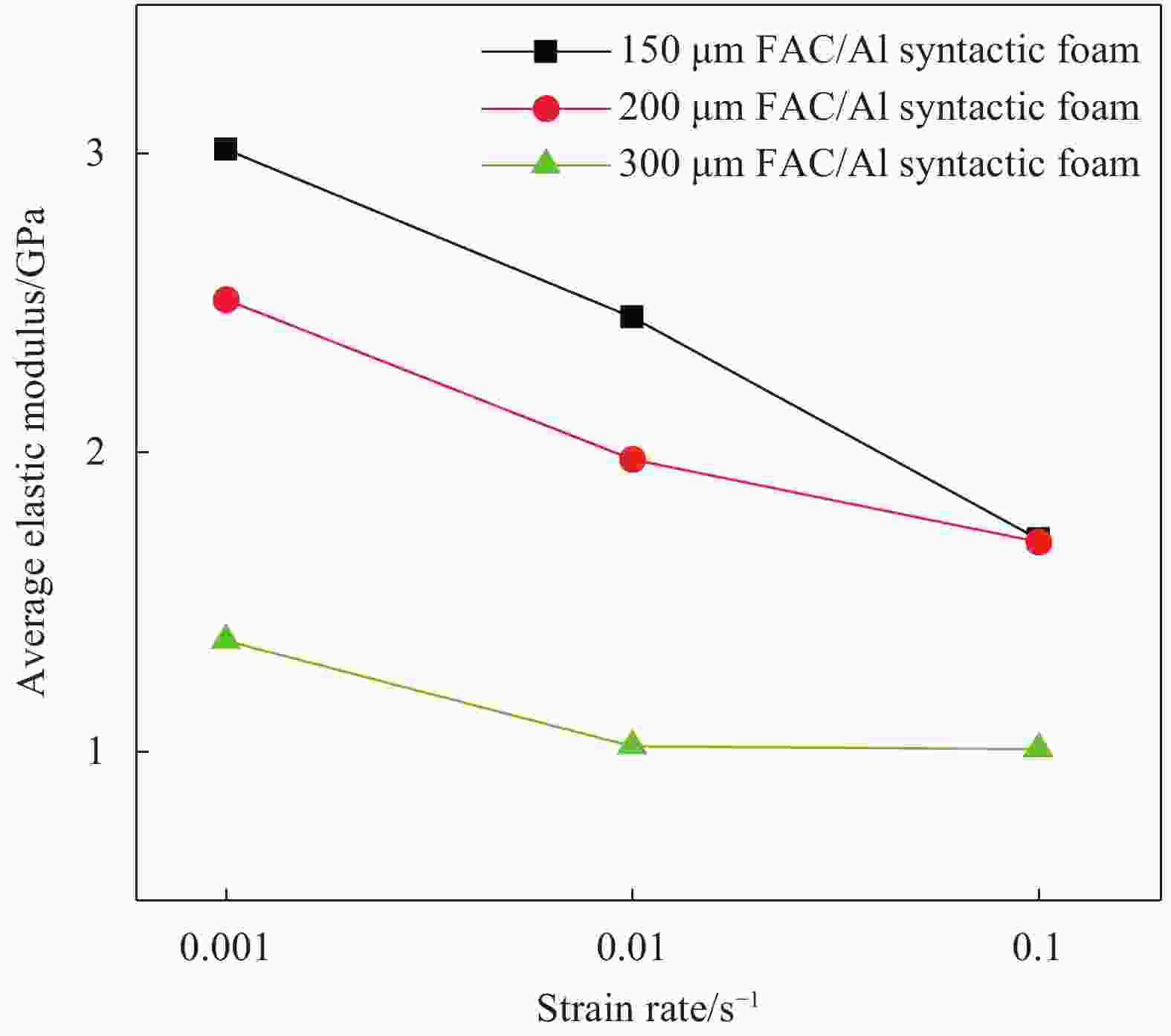

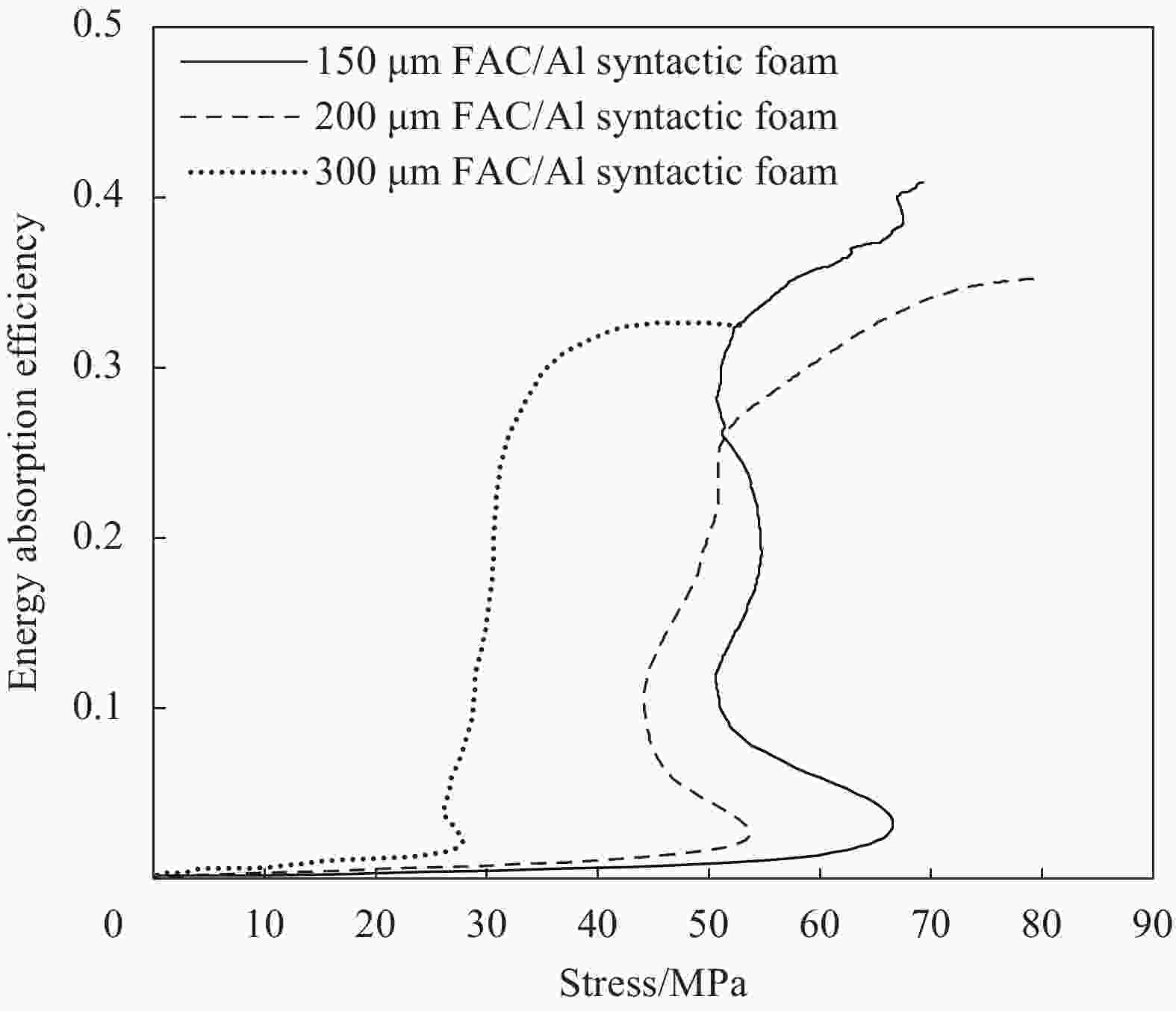

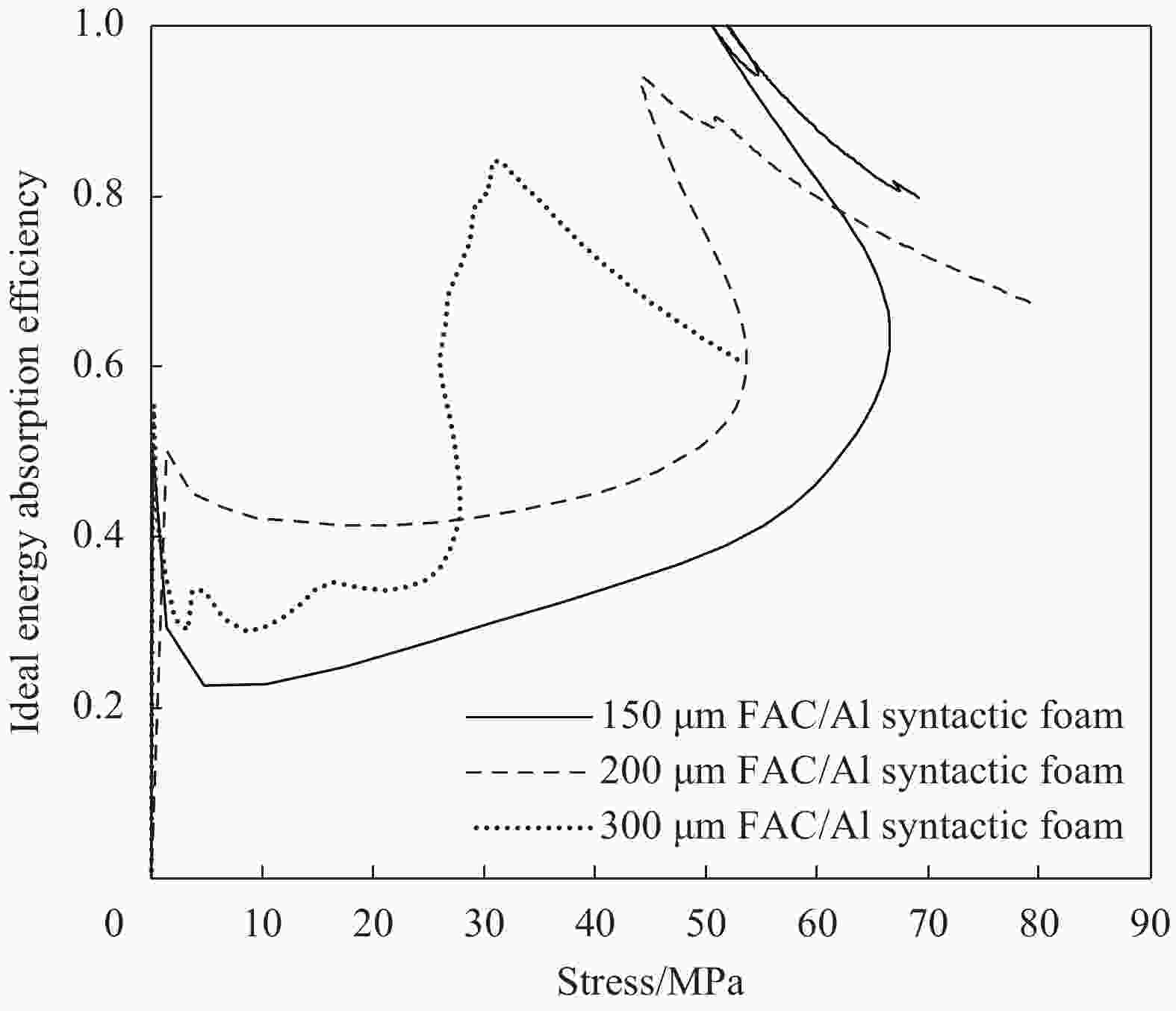

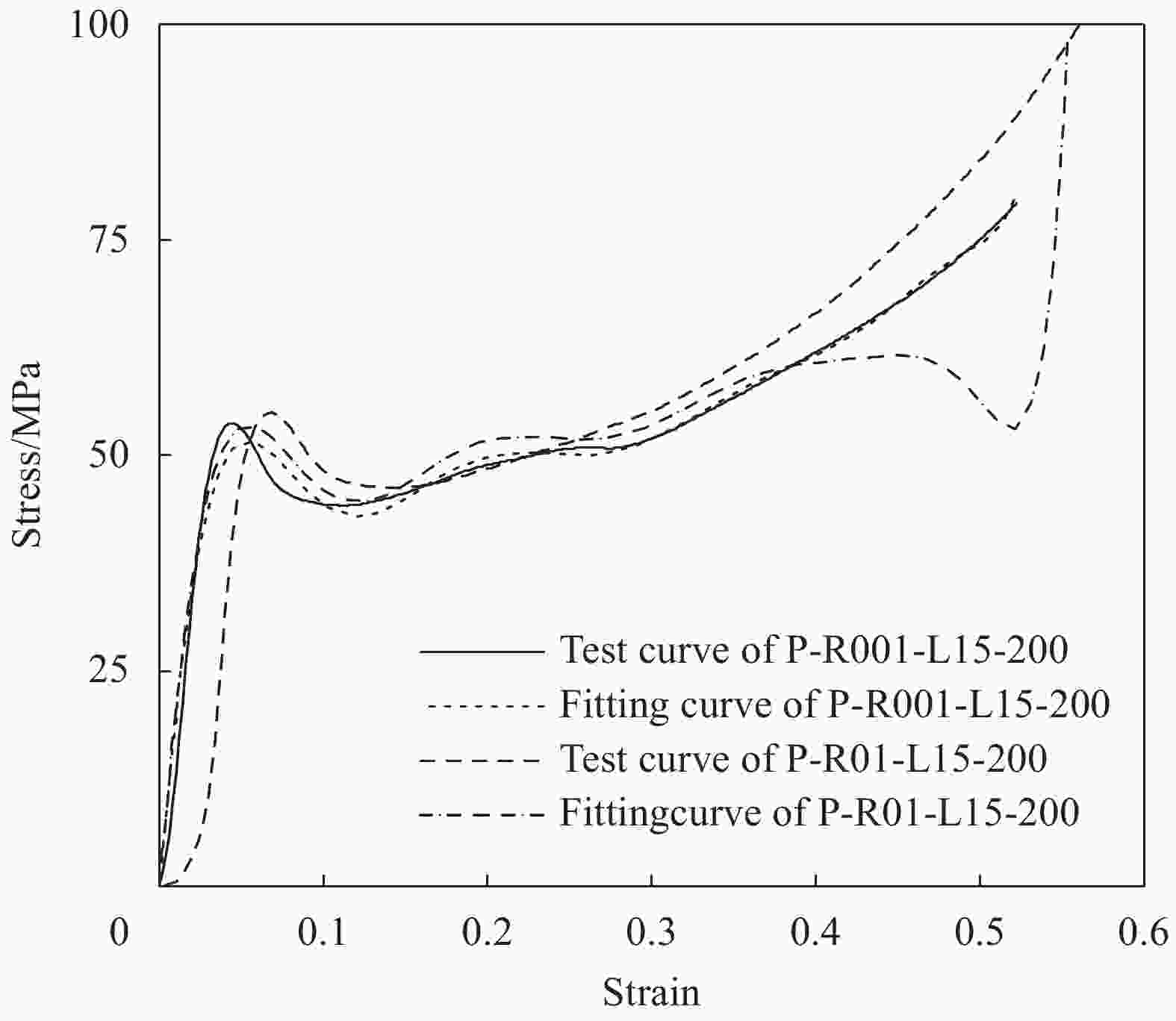

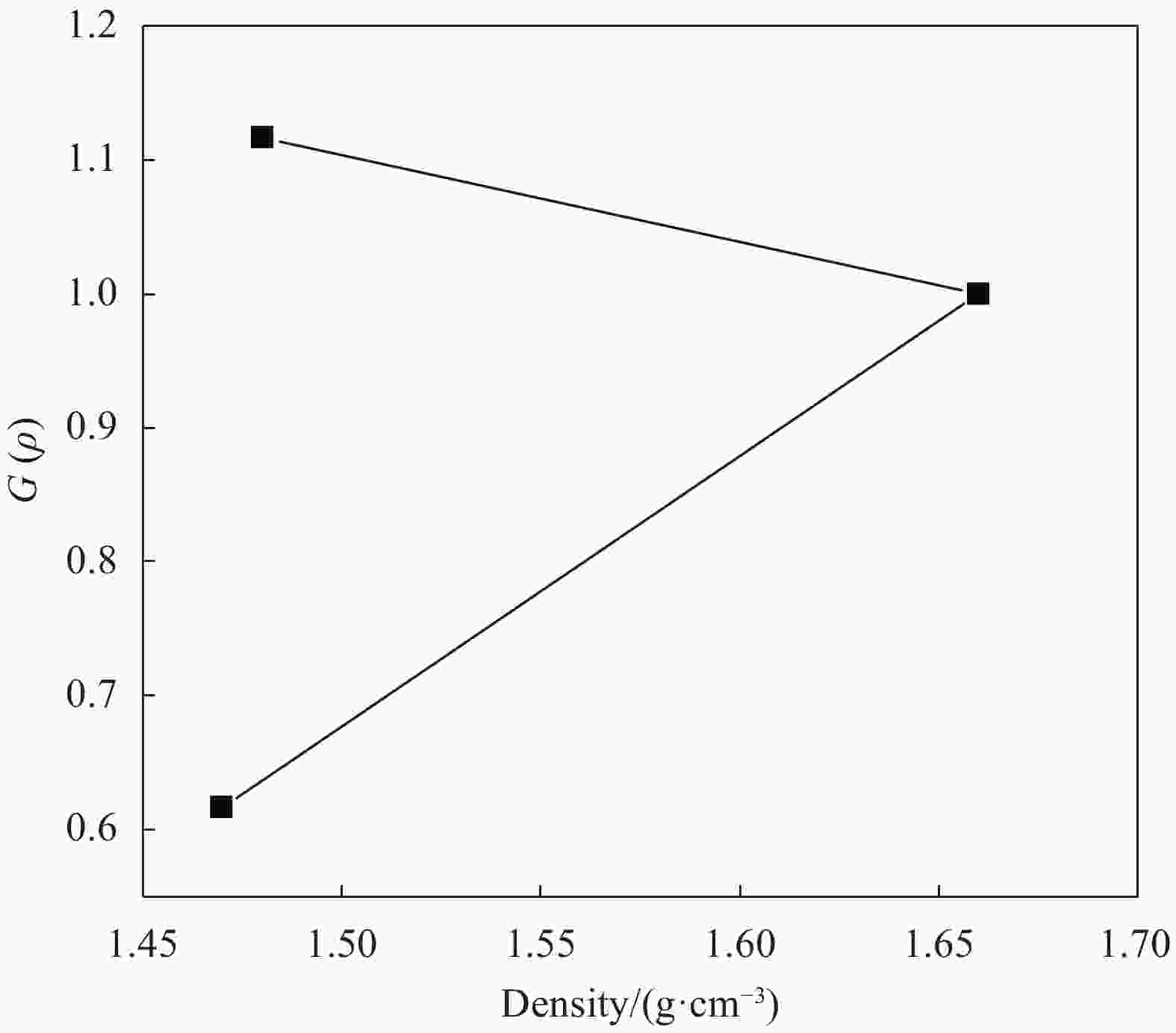

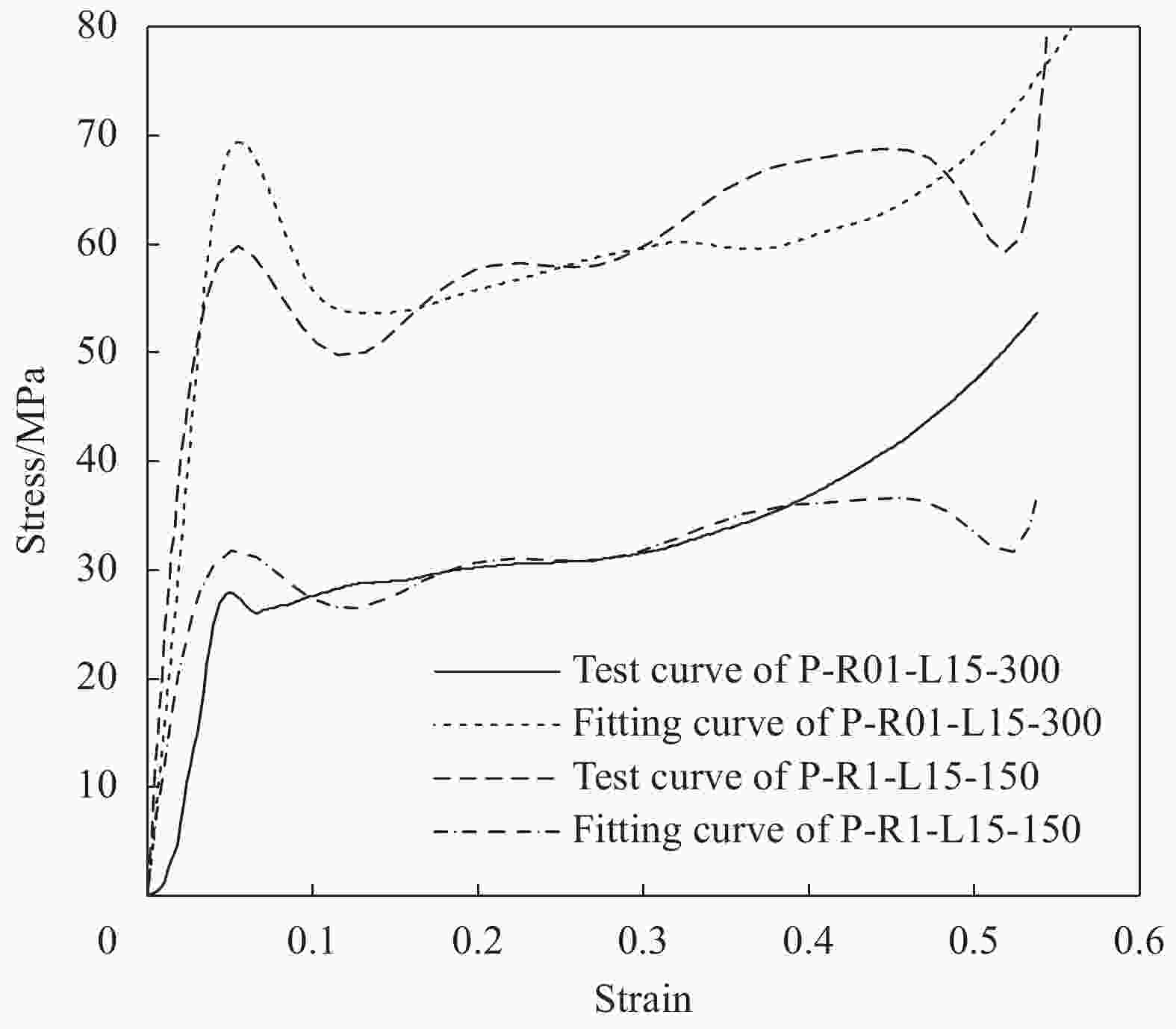

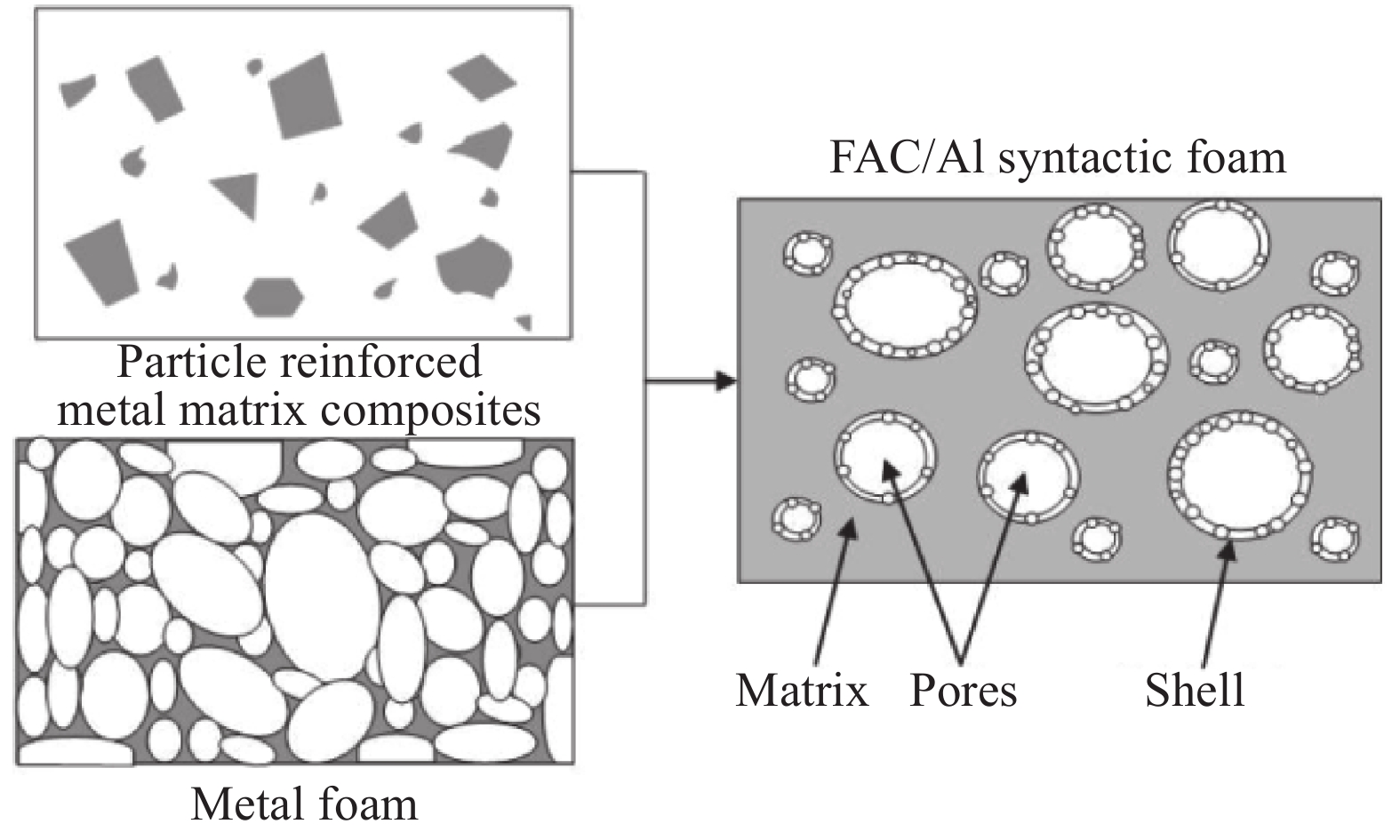

摘要: 为研究粉煤灰空心球/Al(Fly ash cenosphere/aluminum syntactic foam,FAC/Al)复合泡沫材料静力性能,采用万能试验机对铝基复合泡沫材料进行了准静态轴向压缩性能试验,考察了不同空心球平均粒径(分别为150、200和300 μm)对铝基复合泡沫材料变形失效模式及力学性能的影响,并获取了具有不同空心球粒径的复合材料在准静态下的应力-应变曲线,在此基础上分析了空心球粒径大小对复合材料能量吸收性能的影响。试验结果表明,在准静态荷载作用下,随着空心球粒径的增大,复合材料的压缩屈服强度、吸能能力及理想吸能效率有着明显的降低。此外,在获得的应力-应变曲线基础上,采用最小二乘法拟合得到了铝基复合泡沫在准静态荷载作用下的本构方程,并对其进行了验证,结果表明该方程具有较好的拟合度。Abstract: In order to study the quasi-static performance of fly ash cenosphere/aluminum (FAC/Al) syntactic foam, quasi-static compression performance tests were conducted on the FAC/Al specimens by using a universal testing machine. The effects of different average particle sizes on the deformation and failure modes and mechanical performance of the aluminum matrix composite foam material specimens were investigated, and the stress-strain curves of the material specimens with different particle sizes under quasi-static load were obtained. And based on the stress-strain curves, the effects of particle sizes on the energy absorption performance of the material were analyzed. And the test results show that the compressive yield strength and energy absorption capacity and the ideal absorption efficiency of the material decrease with the increase of the particle sizes. In addition, by using the least square method to fit based on the stress-strain curves, the constitutive equation of FAC/Al under quasi-static load was given and verified, and the results show that the equation has a good fitting.

-

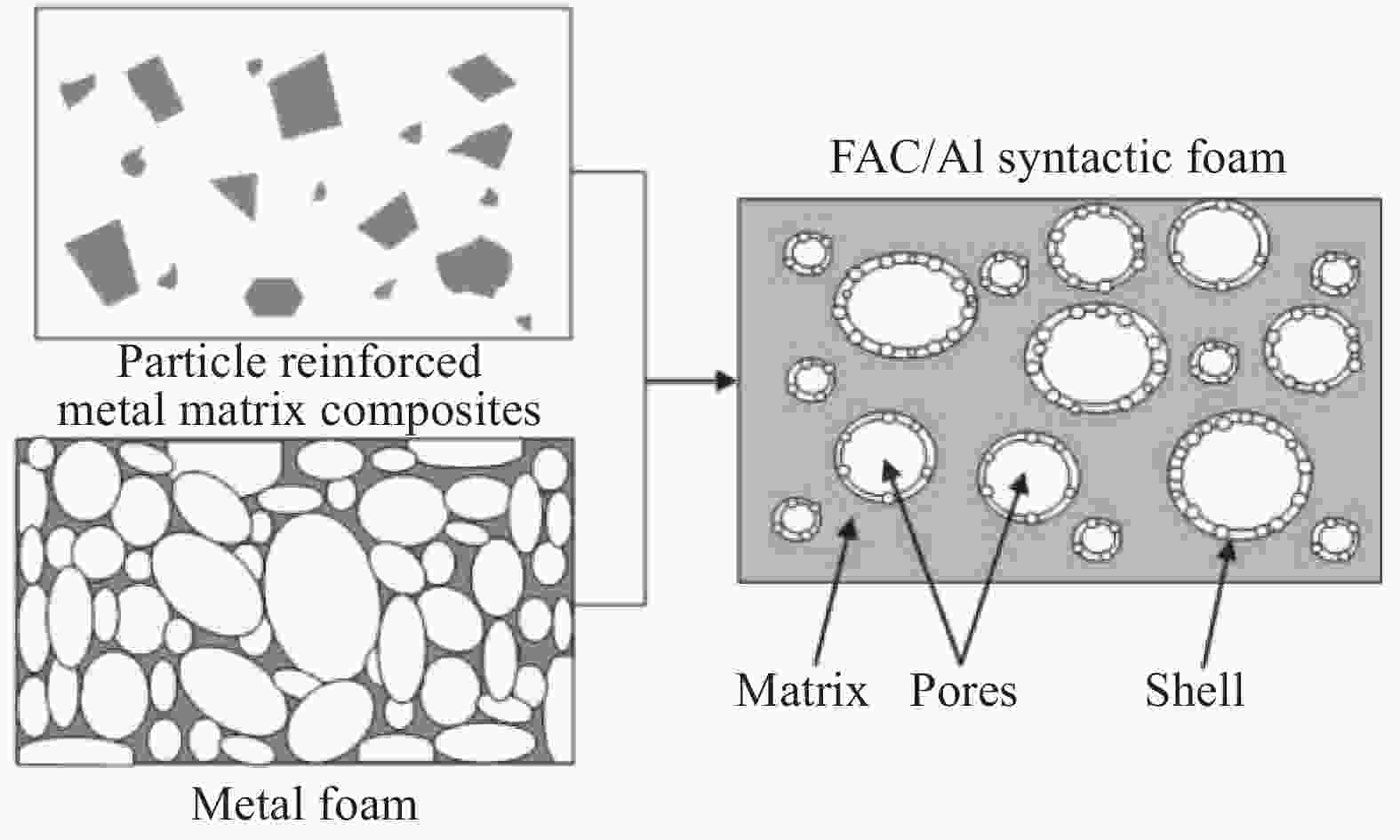

图 1 粉煤灰空心球(FAC)/Al基复合泡沫的设计思路[23]

Figure 1. Design for fly ash cenosphere (FAC)/aluminum syntactic foam

表 1 FAC/Al复合泡沫试件几何参数及加载应变率

Table 1. Geometric parameters and loading strain rates of FAC/Al syntactic foam specimens

Group Foam Length/mm Cenosphere particle size/μm Strain rate/s−1 Diameter/mm Group1 P-R001-L15-150 15 150 0.001 10 P-R001-L15-200 15 200 0.001 10 P-R001-L15-300 15 300 0.001 10 Group2 P-R01-L15-150 15 150 0.01 10 P-R01-L15-200 15 200 0.01 10 P-R01-L15-300 15 300 0.01 10 Group3 P-R1-L15-150 15 150 0.1 10 P-R1-L15-200 15 200 0.1 10 P-R1-L15-300 15 300 0.1 10 Group4 P-R01-L5-150 5 150 0.01 10 P-R01-L5-200 5 200 0.01 10 P-R01-L5-300 5 300 0.01 10 Notes: P—Compression; R001, R01 and R1—Strain rate are 0.001, 0.01 and 0.1, respectively; L15 and L5—Length are 15 and 5 mm, respectively; 150, 200 and 300—Cenosphere particle size. 表 2 FAC/Al复合泡沫应变相关形状函数的拟合参数Ai

Table 2. Fitting parameters of strain dependent shape function Ai of FAC/Al syntactic foam specimens

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 2 199.66 −21 182.08 −265 269.12 6.70×106 −5.71×107 2.62×108 −7.13×108 1.15×109 −1.02×109 3.83×108 -

[1] GIBSON L. Mechanical behavior of metallic foams[J]. Annual Review of Materials Science,2000,30:191-227. doi: 10.1146/annurev.matsci.30.1.191 [2] GARAI F, BÉRES G, WELTSCH Z. Development of tubes filled with aluminum foams for lightweight vehicle manufacturing[J]. Materials Science and Engineering: A,2020,790:139743. doi: 10.1016/j.msea.2020.139743 [3] YANG D, ZHANG Z, CHEN X, et al. Quasi-static compression deformation and energy absorption characteristics of basalt fiber-containing closed-cell aluminum foam[J]. Metals,2020,10(7):921. doi: 10.3390/met10070921 [4] KUMAR R, JAIN H, SRIRAM S, et al. Lightweight open cell aluminum foam for superior mechanical and electromagnetic interference shielding properties[J]. Materials Chemistry and Physics,2020,240:122274. doi: 10.1016/j.matchemphys.2019.122274 [5] ZHANG J, CHEN L, WU H, et al. Experimental and microscopic investigation of double-layer aluminum foam under impact loading[J]. Composite Structures,2020,241:110859. doi: 10.1016/j.compstruct.2019.04.031 [6] 姚卓, 王国斌. 泡沫铝基复合防撞技术在公路桥墩中的应用[J]. 石家庄铁道大学学报(自然科学版), 2017(S1):127-131.YAO Zhuo, WANG Guobin. Application of foam aluminum base composite anti-collision technology in highway piers[J]. Journal of Shijiazhuang Tiedao University(Natural Science Edition),2017(S1):127-131(in Chinese). [7] HUO X, LIU H, LUO Q, et al. On low-velocity impact response of foam-core sandwich panels[J]. International Journal of Mechanical Sciences,2020(181):105681. [8] 窦作勇, 姜龙涛, 武高辉. 新型低成本空心球/Al多孔材料的冲击吸能特性[C]. 中国力学学会. 第十五届全国复合材料学术会议论文集(上册). 中国力学学会, 2008: 163-166.DOU Zuoyong, JIANG Longtao, WU Gaohui. Impact energy absorption characteristics of new type low cost cenosphere/Al porous materials[C]. The Chinese Society of Theoretical and Applied Mechanics. Proceedings of The 15th National Conference on Composite Materials(Volume 1). The Chinese Society of Theoretical and Applied Mechanics, 2008: 163-166(in Chinese). [9] 李硕. 铝基复合泡沫填充圆钢管静态力学及吸能性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.LI Shuo. Study on static mechanical properties and energy absorption performance of aluminum matrix composite foam-filled circular tube[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [10] DOU Z Y, JIANG L T, WU G H, et al. High strain rate compression of cenosphere-pure aluminum syntactic foams[J]. Scripta Materialia,2007,57(10):945-948. doi: 10.1016/j.scriptamat.2007.07.024 [11] WU G H, DOU Z Y, SUN D L, et al. Compression behaviors of cenosphere-pure aluminum syntactic foams[J]. Scripta Materialia,2007,56(3):221-224. doi: 10.1016/j.scriptamat.2006.10.008 [12] 武高辉, 姜龙涛. 含微小封闭孔洞的泡沫铝: 中国, 03200299.8[P]. 2004-05-26.WU Gaohui, JIANG Longtao. Aluminum foam with tiny closed holes: China, 03200299.8[P]. 2004-05-26(in Chinese). [13] 武高辉, 姜龙涛. 一种高强轻质泡沫铝复合材料及其制备方法: 中国, 03100180.7[P]. 2003-06-18.WU Gaohui, JIANG Longtao. The cenosphere-aluminum syntactic foam with high strength and lightweight and its fabricating method: China, 03100180.7[P]. 2003-06-18(in Chinese). [14] 王瑞, 林振荣, 卢玉松, 等. 爆炸荷载作用下泡沫铝复合材料数值模拟[J]. 塑性工程学报, 2010, 17(6):127-130.WANG Rui, LIN Zhenrong, LU Yusong, et al. Numerical simulation of foam aluminum composite under explosion loading[J]. Journal of Plasticity Engineering,2010,17(6):127-130(in Chinese). [15] 丁珂. 冲击作用下铝基复合泡沫填充管动态力学及吸能性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.DING Ke. Study on dynamic mechanical properties and energy absorption performance of aluminum matrix compo-site foam-filled circular tube under impact[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [16] 张博一, 王伟, 武高辉. 空心微珠/Al复合材料的动态压缩力学性能和吸能特性[J]. 爆炸与冲击, 2014, 34(1):28-34. doi: 10.3969/j.issn.1001-1455.2014.01.006ZHANG Boyi, WANG Wei, WU Gaohui. Dynamic-compression mechanical properties and energy-absorption capability of fly-ash cenospheres-reinforced 1199Al-matrix composite foam[J]. Explosion and Shock,2014,34(1):28-34(in Chinese). doi: 10.3969/j.issn.1001-1455.2014.01.006 [17] ZHANG Q, LIN Y, CHI H, et al. Quasi-static and dynamic compression behavior of glass cenospheres/5A03 syntactic foam and its sandwich structure[J]. Composite Structures,2018,183:499-509. doi: 10.1016/j.compstruct.2017.05.024 [18] 许庆彦, 陈玉勇, 李庆春. 多孔泡沫金属的研究现状[J]. 铸造设备研究, 1997(1):18-24, 55.XU Qingyan, CHEN Yuyong, LI Qingchun. Research status of porous foam metals[J]. Research on casting equipment,1997(1):18-24, 55(in Chinese). [19] 左孝青, 孙加林. 泡沫金属制备技术研究进展[J]. 材料科学与工程学报, 2004(3):452-456. doi: 10.3969/j.issn.1673-2812.2004.03.036ZUO Xiaoqing, SUN Jialin. Review on foam metal manufacture techniques[J]. Journal of materials science and Engineering,2004(3):452-456(in Chinese). doi: 10.3969/j.issn.1673-2812.2004.03.036 [20] 胡时胜, 王悟, 潘艺, 等. 泡沫材料的应变率效应[J]. 爆炸与冲击, 2003(1):13-18. doi: 10.3321/j.issn:1001-1455.2003.01.003HU Shisheng, WANG Wu, PAN Yi, et al. Strain rate effect on the properties foam materials[J]. Explosion and Shock,2003(1):13-18(in Chinese). doi: 10.3321/j.issn:1001-1455.2003.01.003 [21] 王曦, 虞吉林. 泡沫铝的单向力学行为[J]. 实验力学, 2001(4):438-443. doi: 10.3969/j.issn.1001-4888.2001.04.014WANG Xi, YU Jilin. Uniaxial mechanical behavior of aluminum foam[J]. Experimental Mechanics,2001(4):438-443(in Chinese). doi: 10.3969/j.issn.1001-4888.2001.04.014 [22] 王二恒, 虞吉林, 王飞, 等. 泡沫铝材料准静态本构关系的理论和实验研究[J]. 力学学报, 2004(6):673-679. doi: 10.3321/j.issn:0459-1879.2004.06.005WANG Erheng, YU Jilin, WANG Fei, et al. Theoretical and experimental study on quasi-static constitutive relationship of aluminum foam[J]. Journal of Mechanics,2004(6):673-679(in Chinese). doi: 10.3321/j.issn:0459-1879.2004.06.005 [23] 邹林池. 空心球/Al微孔材料的压缩变形行为和吸能性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.ZOU Linchi. Compressive deformation behavior and energy absorption property of cenospere/Al syntactic foam[D]. Harbin: Harbin Institute of Technology, 2014(in Chinese). [24] JAMES A S, COLIN C F. Constitutive modeling and simulation of energy absorbing polyurethane foam under impact loading[J]. Polymer Engineering and Science,1992,32(16):1138-1146. doi: 10.1002/pen.760321611 [25] 胡永乐, 王峰超, 胡时胜. 泡沫铝经验型动态本构模型及其在LS-DYNA中的实现[J]. 兵工学报, 2014, 35(2):46-50.HU Yongle, WANG Fengchao, HU Shisheng. An empirical dynamic constitutive model for aluminum foams and its implementation in LS-DYNA[J]. Journal of China Ordnance,2014,35(2):46-50(in Chinese). [26] 王婧. 强冲击载荷作用下多孔钛动态力学行为研究[D]. 北京: 北京理工大学, 2017.WANG Jing. Investigation on dynamic behavior of cellular titanium subjected to impact loading[D]. Beijing: Beijing Institute of Technology, 2017(in Chinese). -

下载:

下载: