| [1] |

CHENG Laifei, SUN Mengyong, YE Fang, et al. Structure design, fabrication, properties of laminated ceramics: A review[J]. International Journal of Lightweight Materials & Manufacture,2018,3(1):126-141.

|

| [2] |

ZHOU Peng, HU Ping, ZHANG Xinghong, et al. Laminated ZrB-SiC ceramic with improved strength and toughness[J]. Scripta Materialia,2011,64(3):276-279. doi: 10.1016/j.scriptamat.2010.10.005

|

| [3] |

李冬云, 乔冠军, 金志浩. SiC/BN层状陶瓷耐损伤性能的研究[J]. 复合材料学报, 2003, 20(6):21-25. doi: 10.3321/j.issn:1000-3851.2003.06.005LI Dongyun, QIAO Guanjun, JIN Zhihao. Damage resistance of SiC/BN laminated ceramics[J]. Acta Materiae Compositae Sinica,2003,20(6):21-25(in Chinese). doi: 10.3321/j.issn:1000-3851.2003.06.005

|

| [4] |

李冬云, 乔冠军, 金志浩. 层状复合陶瓷材料的研究进展[J]. 无机材料学报, 2002, 17(1):10-16. doi: 10.3321/j.issn:1000-324X.2002.01.002LI Dongyun, QIAO Guanjun, JIN Zhihao. Progress in research on laminated ceramic composites[J]. Journal of Inorganic Materials,2002,17(1):10-16(in Chinese). doi: 10.3321/j.issn:1000-324X.2002.01.002

|

| [5] |

陈蓓, 丁培道. 强界面结合层状陶瓷研究现状及增韧机制[J]. 材料导报, 2001, 15(6):28-29.CHEN Bei, DING Peidao. Current status of strong-binding interface laminate ceramics study and toughening mechanism[J]. Materials Review,2001,15(6):28-29(in Chinese).

|

| [6] |

陈勇强, 李红霞, 刘国齐. 层状陶瓷及层状耐火材料研究进展[J]. 材料导报, 2019, 33(17):2847-2853. doi: 10.11896/cldb.18100092CHEN Yongqiang, LI Hongxia, LIU Guoqi. Research progress of layered ceramics and layered refractories[J]. Materials Reports,2019,33(17):2847-2853(in Chinese). doi: 10.11896/cldb.18100092

|

| [7] |

李冬云, 乔冠军, 金志浩. SiC/BN层状陶瓷的阻力曲线行为[J]. 中国有色金属学报, 2003, 13(4):944-948. doi: 10.3321/j.issn:1004-0609.2003.04.025LI Dongyun, QIAO Guanjun, JIN Zhihao. R-curve behavior of SiC/BN laminated ceramic[J]. The Chinese Journal of Nonferrous Metals,2003,13(4):944-948(in Chinese). doi: 10.3321/j.issn:1004-0609.2003.04.025

|

| [8] |

蔡胜有, 李金林, 谢志鹏, 等. 氮化硅层状陶瓷界面性能对力学性能的影响[J]. 复合材料学报, 1999, 16(2):110-115. doi: 10.3321/j.issn:1000-3851.1999.02.021CAI Shengyou, LI Jinlin, XIE Zhipeng, et al. Influence of interfacial bonding of Si3N4 laminated composites on the mechanical properties[J]. Acta Materiae Compositae Sinica,1999,16(2):110-115(in Chinese). doi: 10.3321/j.issn:1000-3851.1999.02.021

|

| [9] |

昝青峰, 蔡胜有. Si3N4/BN层状陶瓷软层成分对材料韧性的影响[J]. 山东陶瓷, 1999, 22(2):4-8.ZAN Qingfeng, CAI Shengyou. The influence of the toughness on the component of soft-layer in the Si3N4/BN multilayered materials[J]. Shandong Ceramics,1999,22(2):4-8(in Chinese).

|

| [10] |

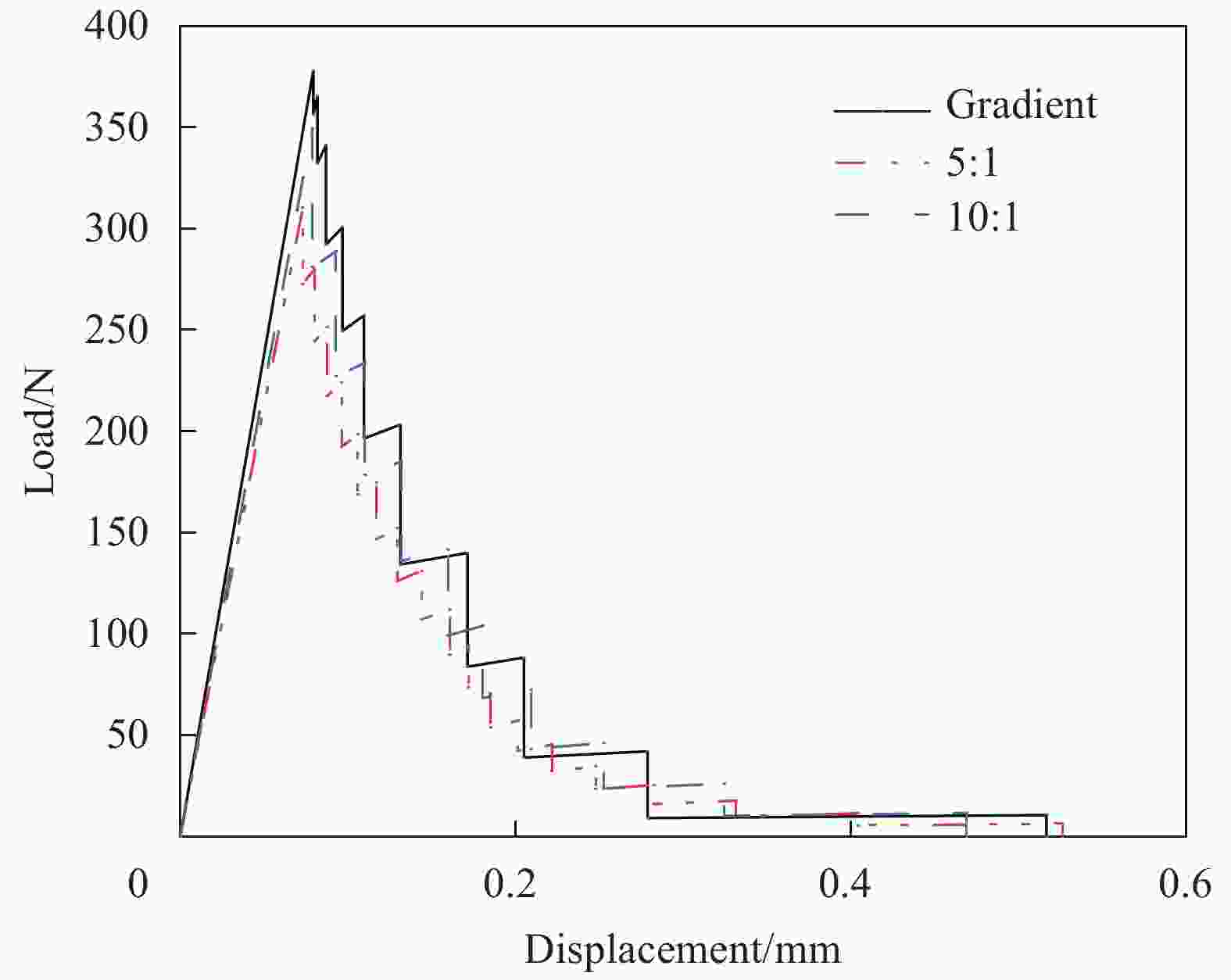

SUN Mengyong, BAI Yuhang, LI Mingxing, et al. Structural design and energy absorption mechanism of laminated SiC/BN ceramics[J]. Journal of the European Ceramic Society,2018,38(11):3742-3751. doi: 10.1016/j.jeurceramsoc.2018.04.052

|

| [11] |

袁旭暄, 贾德昌. BN-SiC层状复合陶瓷的断裂行为研究[J]. 材料科学与工艺, 2005, 13(4):378-380. doi: 10.3969/j.issn.1005-0299.2005.04.012YUAN Xuxuan, JIA Dechang. Study on fracture behavior of BN-SiC laminated composite ceramics[J]. Materials Science & Technology,2005,13(4):378-380(in Chinese). doi: 10.3969/j.issn.1005-0299.2005.04.012

|

| [12] |

李冬云, 杨辉, 乔冠军, 等. 弱层成分对SiC/BN层状陶瓷阻力行为的影响[J]. 复合材料学报, 2006, 23(2):110-114. doi: 10.3321/j.issn:1000-3851.2006.02.020LI Dongyun, YANG Hui, QIAO Guanjun, et al. Influence of the component of weaklayer in the SiC/BN multilayered ceramics on its resistance behavior[J]. Acta Materiae Compositae Sinica,2006,23(2):110-114(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.02.020

|

| [13] |

李冬云, 杨辉, 乔冠军, 等. SiC/BN层状陶瓷的抗热震性能研究[J]. 材料科学与工程学报, 2006, 24(1):17-19. doi: 10.3969/j.issn.1673-2812.2006.01.005LI Dongyun, YANG Hui, QIAO Guanjun, et al. Study on thermal shock behavior of SiC/BN laminated ceramic composites[J]. Journal of Materials Science & Engineering,2006,24(1):17-19(in Chinese). doi: 10.3969/j.issn.1673-2812.2006.01.005

|

| [14] |

钱晓倩, 葛曼珍, 吴义兵, 等. 层状复合陶瓷强韧化机制及其优化设计因素[J]. 无机材料学报, 1999, 14(4):9-15.QIAN Xiaoqian, GE Manzhen, WU Yibing, et al. Reinforcement mechanisms and optimum design of laminated ceramic composites[J]. Journal of Inorganic Materials,1999,14(4):9-15(in Chinese).

|

| [15] |

陈艳林, 梅炳初, 朱教群. 用热压法制备Ti3SiC2层状陶瓷的研究[J]. 陶瓷学报, 2004, 25(1):55-59.CHEN Yanlin, MEI Bingchu, ZHU Jiaoqun. Study on the fabrication of Ti3SiC2 by hot pressing[J]. Journal of Ceramics,2004,25(1):55-59(in Chinese).

|

| [16] |

苏盛彪, 包亦望, 杨建军. 强界面陶瓷层状复合材料优化设计的最佳层厚比探讨[J]. 硅酸盐学报, 2003, 31(8):743-747. doi: 10.3321/j.issn:0454-5648.2003.08.005SU Shengbiao, BAO Yiwang, YANG Jianjun. Optimal layer thickness ratio for optimization of ceramic laminates[J]. Journal of the Chinese Ceramic Society,2003,31(8):743-747(in Chinese). doi: 10.3321/j.issn:0454-5648.2003.08.005

|

| [17] |

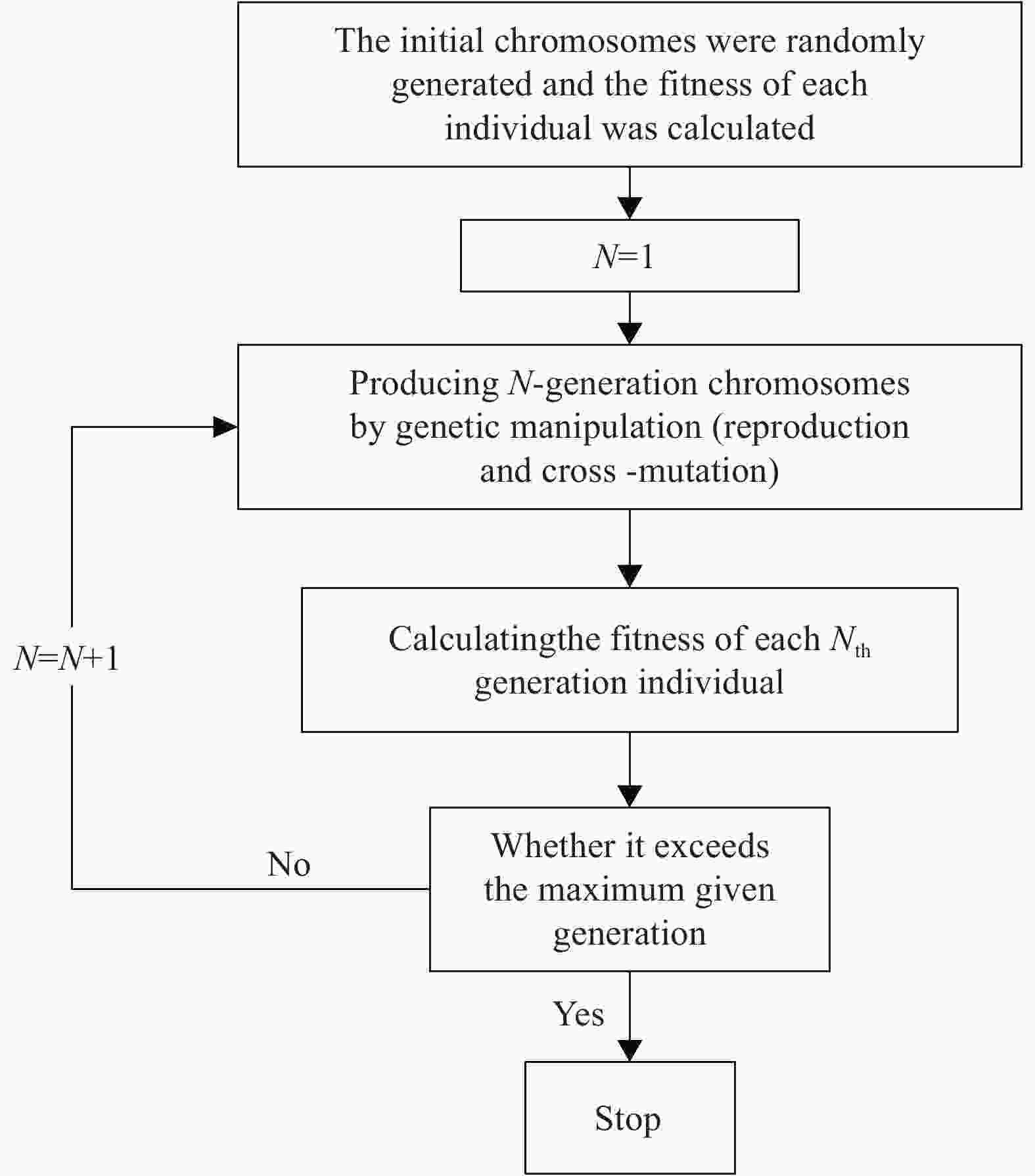

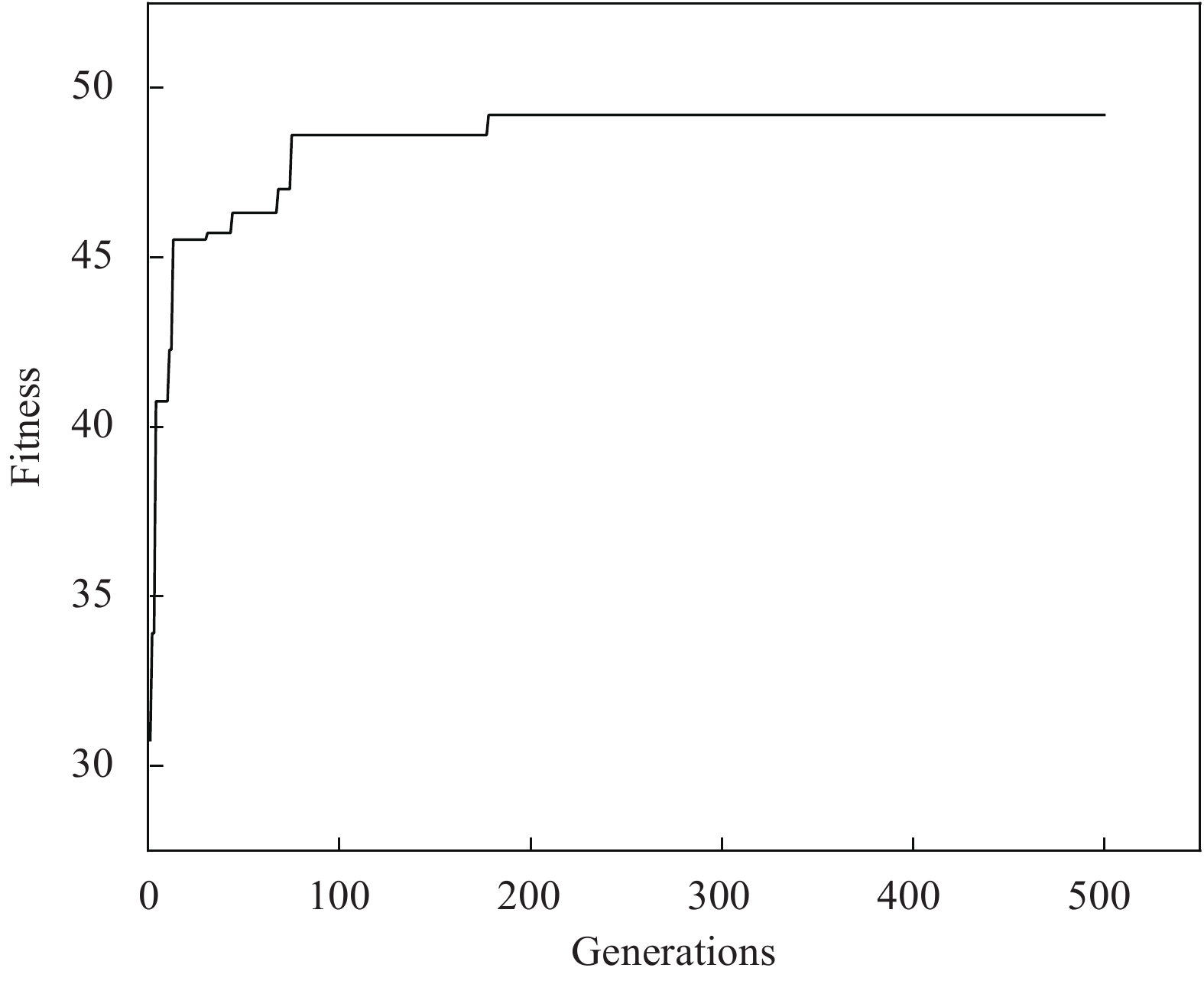

郭晓芳, 李向东. 一类带区间系数的分式双层规划问题的遗传算法[J]. 应用数学进展, 2015, 4(1):63-69. doi: 10.12677/AAM.2015.41008GUO Xiaofang, LI Xiangdong. A genetic algorithm for a class of fractional bilevel programming problems with interval coefficients[J]. Advances in Applied Mathematics,2015,4(1):63-69(in Chinese). doi: 10.12677/AAM.2015.41008

|

| [18] |

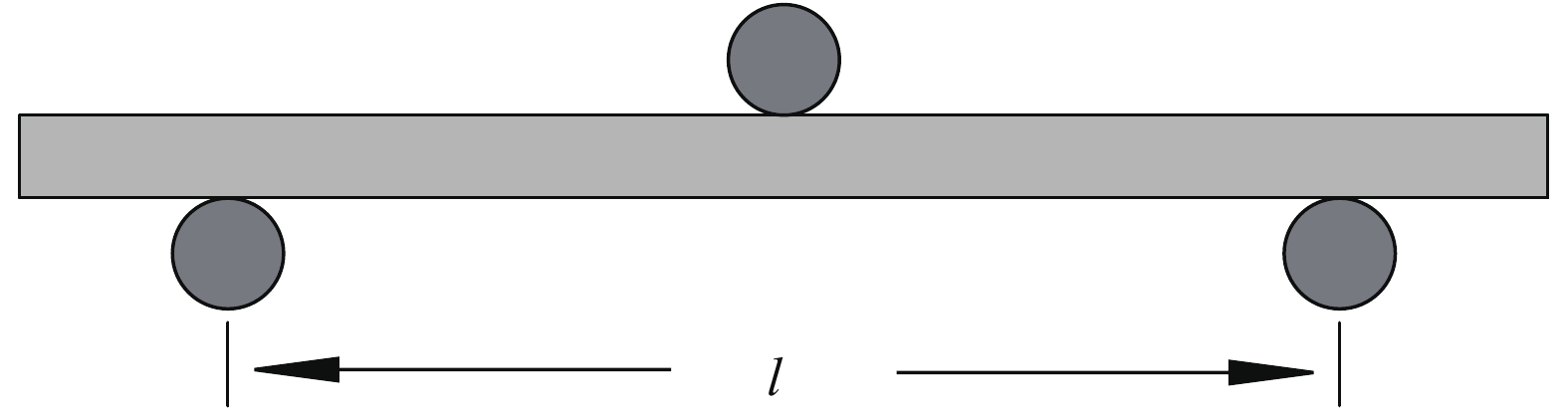

曾东, 方岱宁. 用界面元分析层状陶瓷的三点弯曲断裂性能[J]. 应用基础与工程科学学报, 2000, 8(4):398-404. doi: 10.3969/j.issn.1005-0930.2000.04.009ZENG Dong, FANG Daining. Numerical analysis of fracture behavior of laminated ceramic in three-point bending[J]. Journal of Basic Science and Engineering,2000,8(4):398-404(in Chinese). doi: 10.3969/j.issn.1005-0930.2000.04.009

|

| [19] |

PRIKHODKO M, MIAO M S, LAMBRECHT W R L. Pressure dependence of sound velocities in 3C-SiC and their relation to the high-pressure phase transition[J]. Physical Review B,2002,66(12):1-5.

|

| [20] |

LUTZ E H, SWAIN M V. Fracture toughness and thermal shock behavior of silicon nitride-boron nitride ceramics[J]. Journal of the American Ceramic Society,1992,75(1):67-70. doi: 10.1111/j.1151-2916.1992.tb05443.x

|

| [21] |

FRANÇOIS G, ALEXANDRE A, JEAN-DANIEL L, et al. Densification of SiC by SPS-effects of time, temperature and pressure[J]. Journal of the European Ceramic Society,2007,27(7):2725-2728. doi: 10.1016/j.jeurceramsoc.2006.10.005

|

| [22] |

OMORI M, TAKEI H. Pressureless sintering of SiC[J]. Journal of the American Ceramic Society,1982,65(6):c92. doi: 10.1111/j.1151-2916.1982.tb10460.x

|

| [23] |

American Society of Testing Materials. Standard test method for flexural properties of continuous fiber-reinforced advanced ceramic composites: ASTM C1341—2013[S]. Los Angeles: ASTM, 2018.

|

| [24] |

CLEGG W J, KENDALL K, ALFORD N M, et al. A simple way to make tough ceramics[J]. Nature,1990,347(6292):455-457. doi: 10.1038/347455a0

|

| [25] |

郭海, 黄勇, 李建保. 层状氮化硅陶瓷的性能与结构[J]. 硅酸盐学报, 1997, 25(5): 532-536.GUO Hai, HUANG Yong, LI Jianbao. Properties and structure of Si3N4 laminated ceramics[J]. Journal of the Chinese Ceramic Society, 1997, 25(5): 532-536(in Chinese).

|

下载:

下载: