Research progress of cellulose conductive substrates and its flexible electronic devices

-

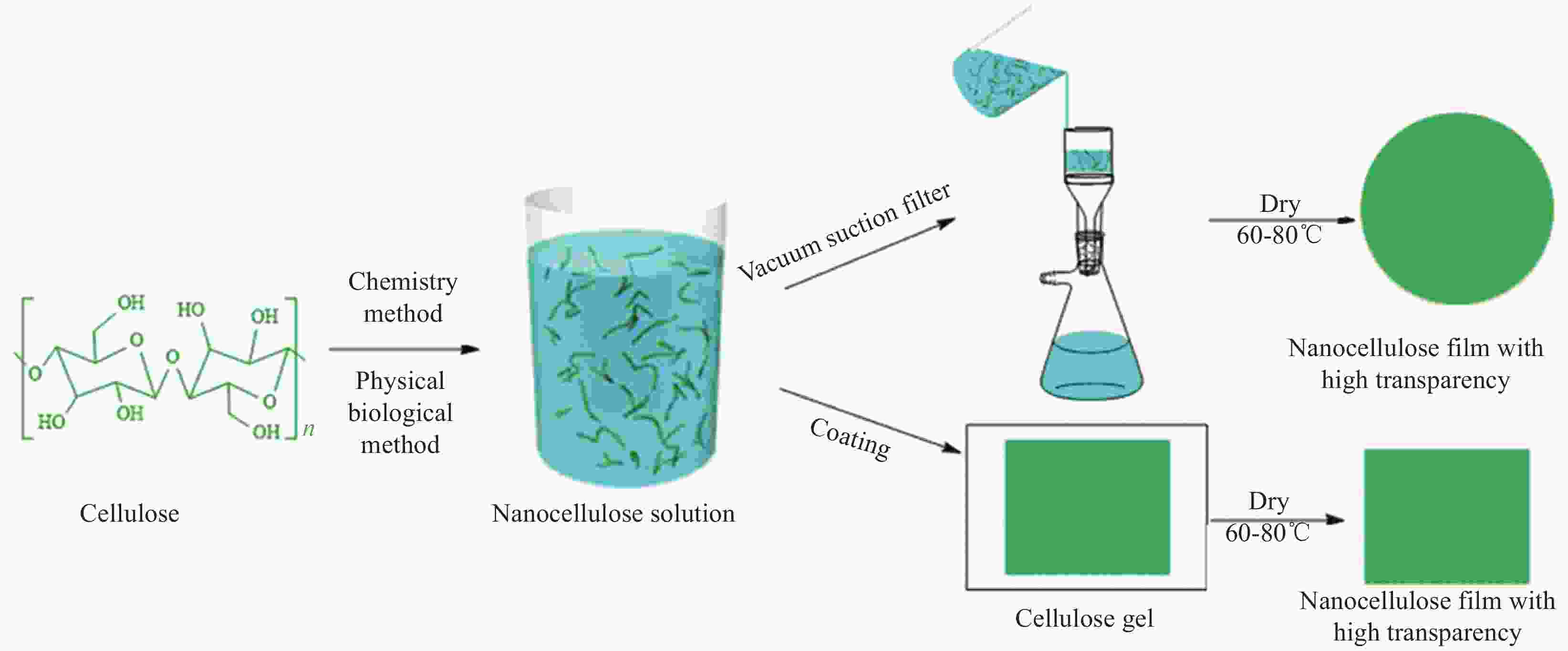

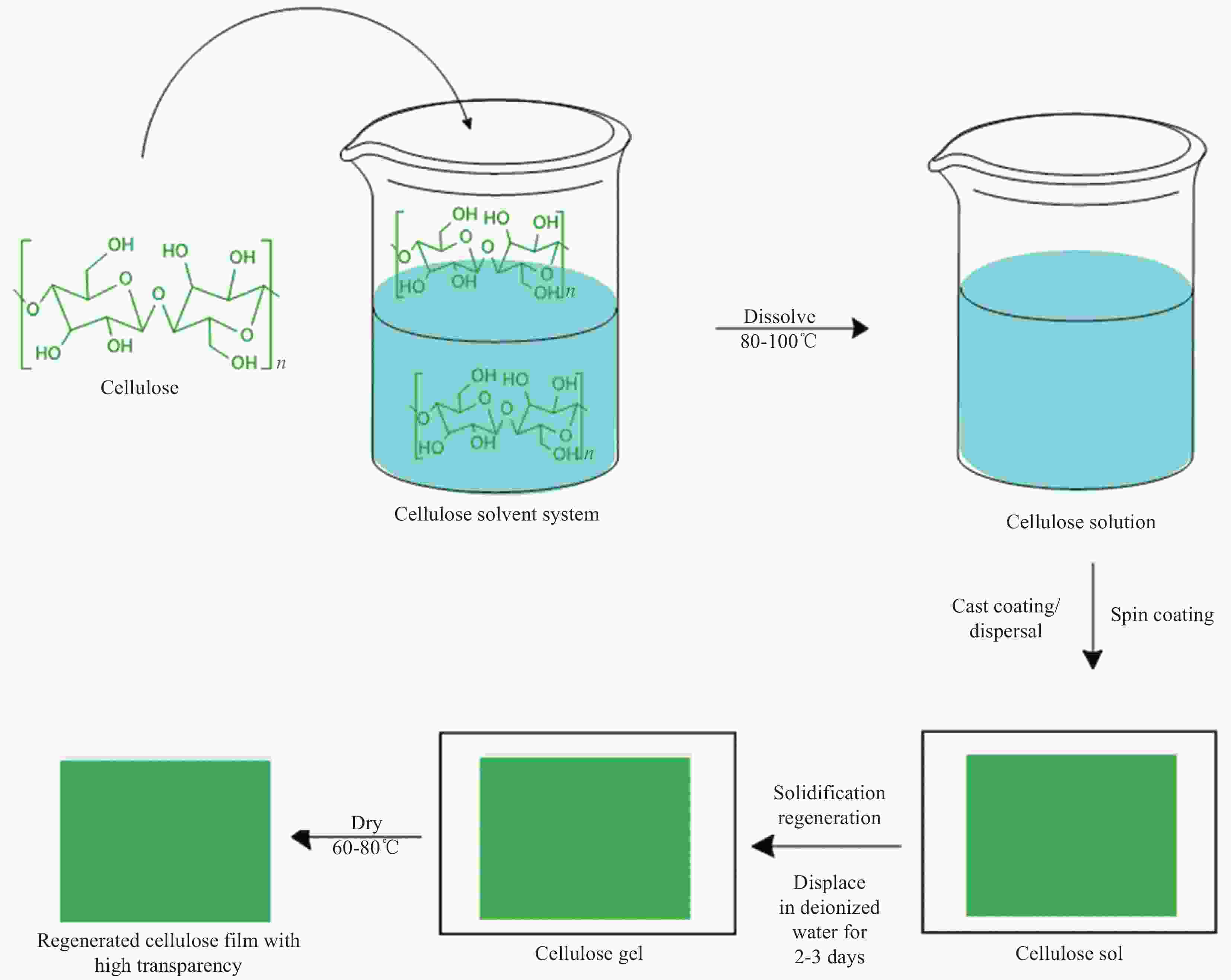

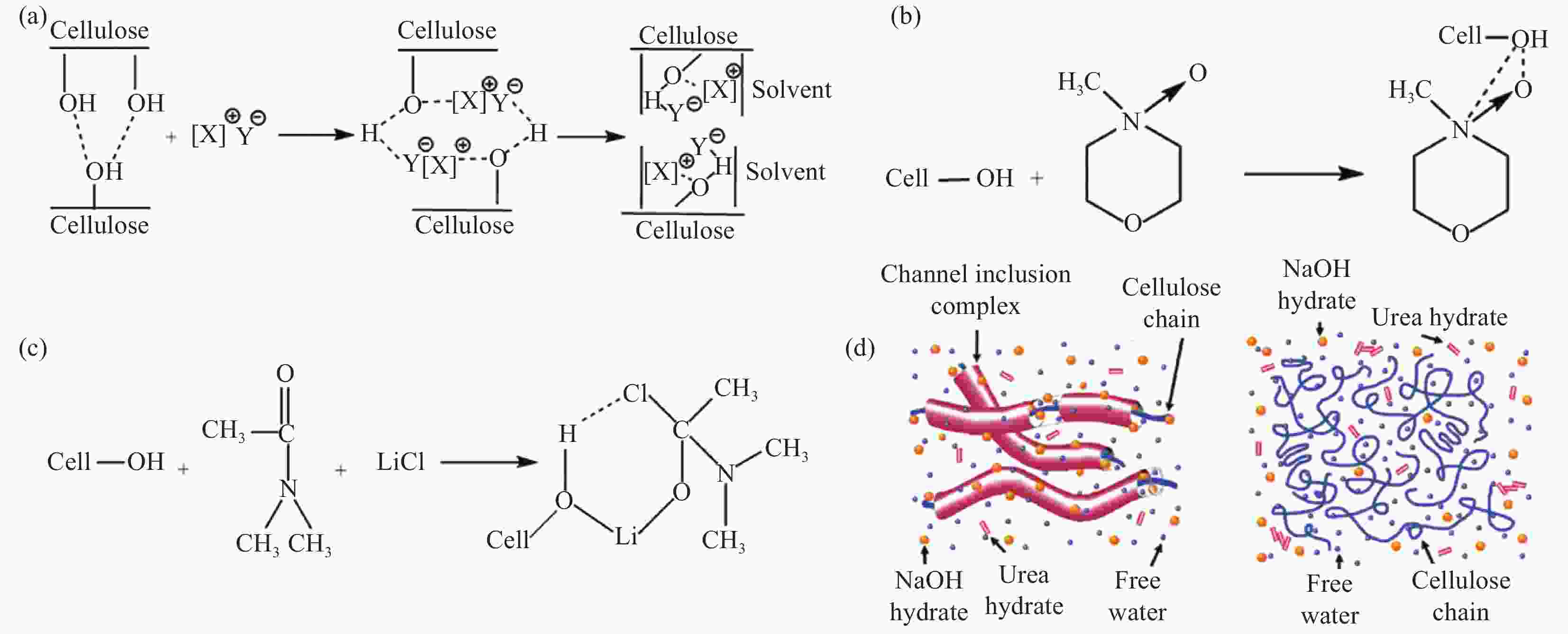

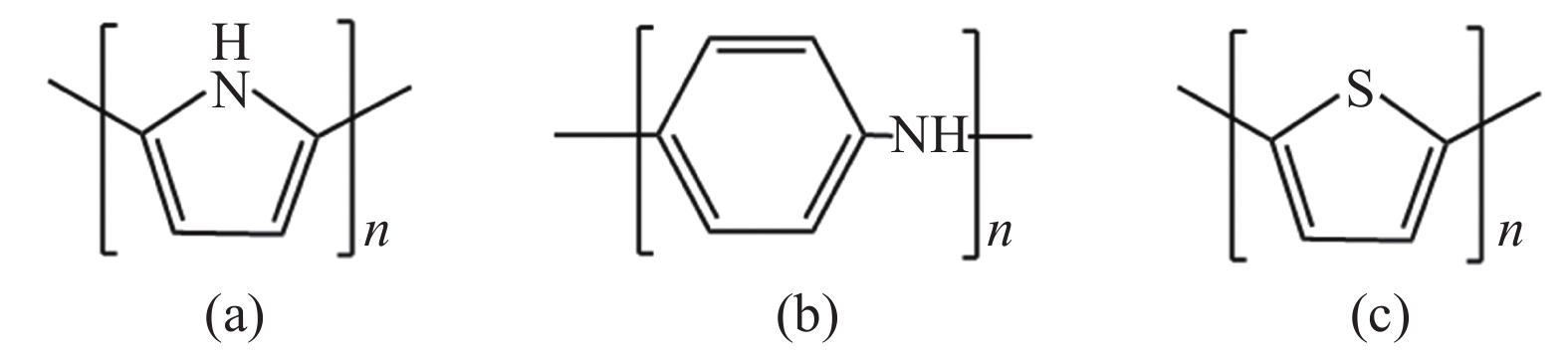

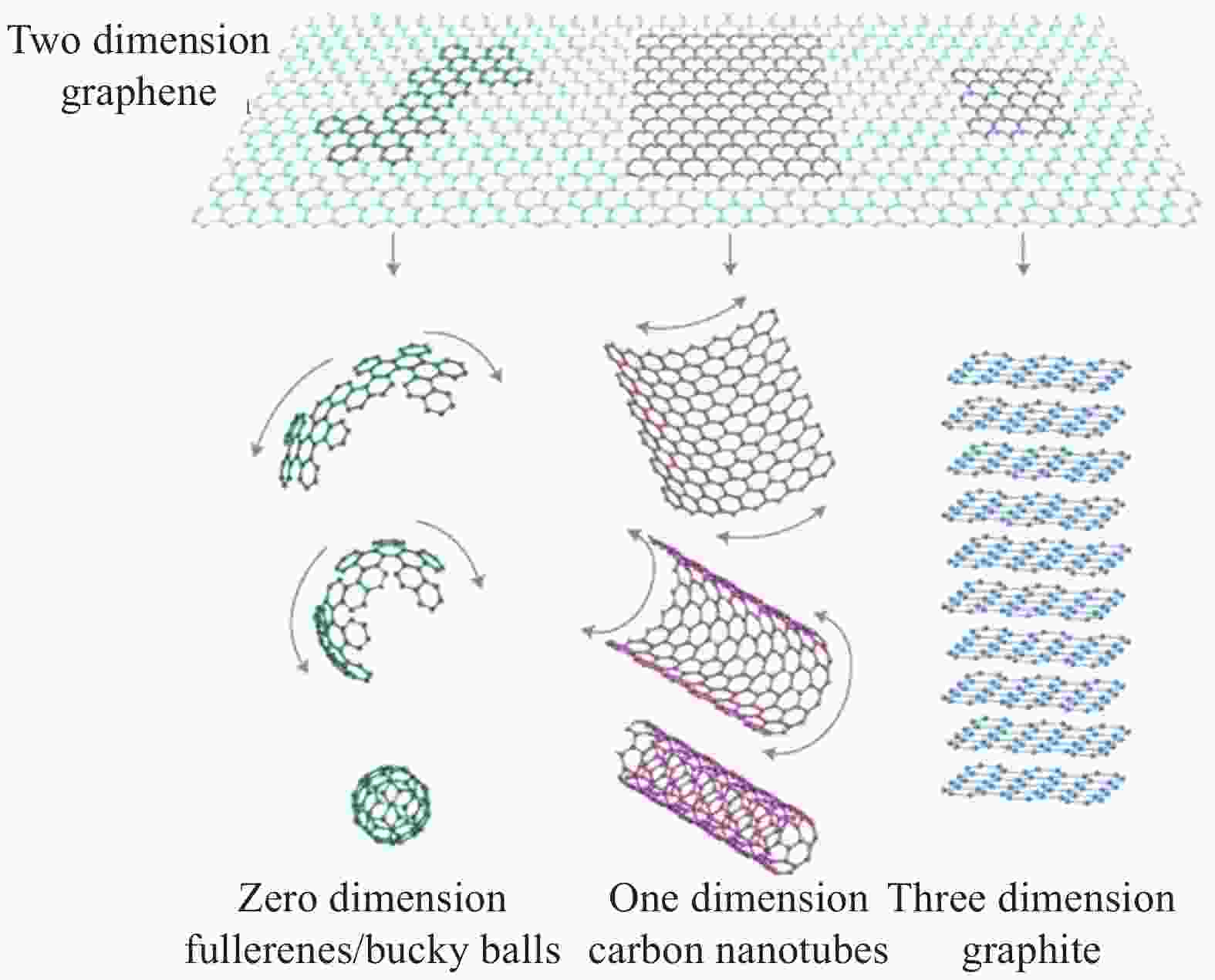

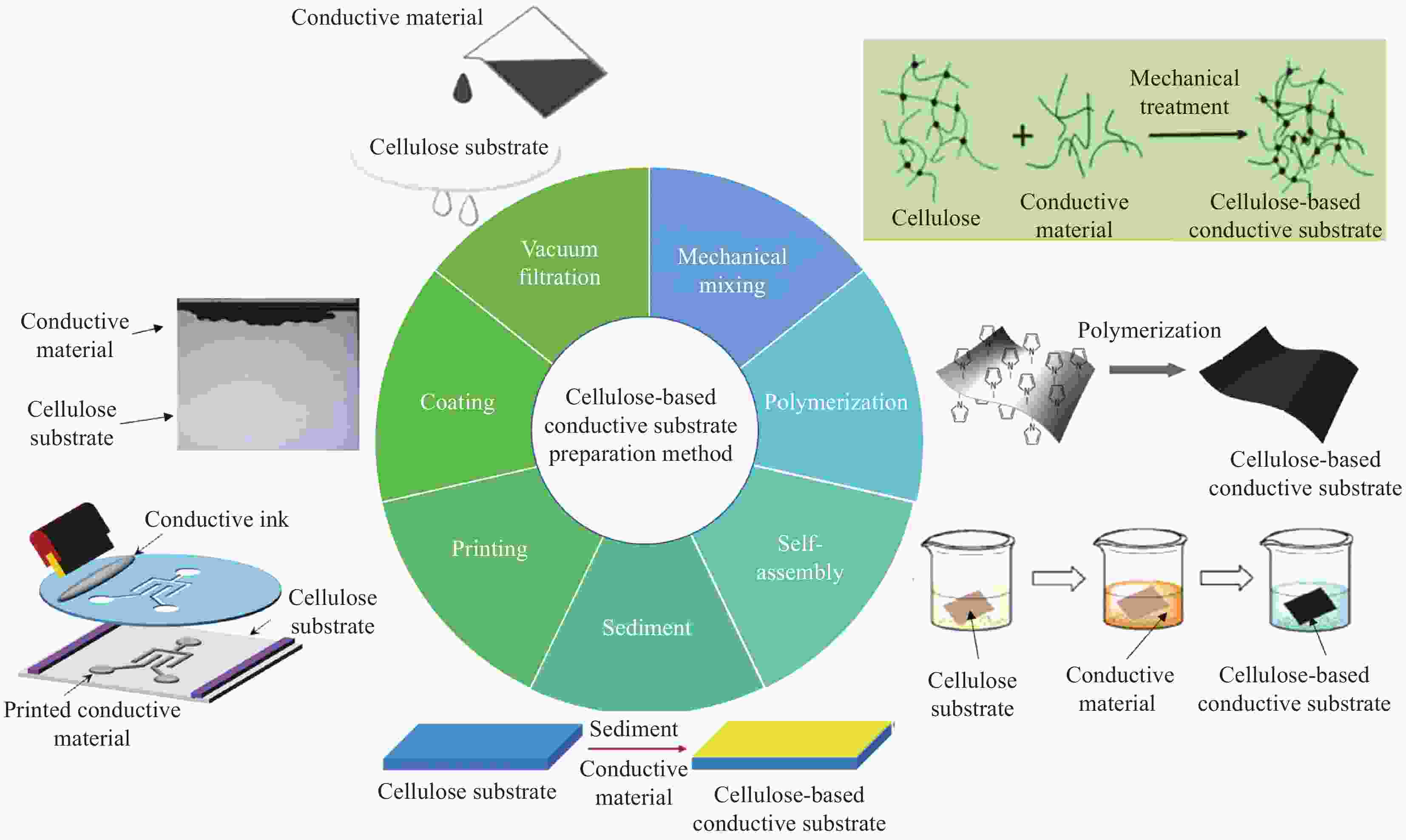

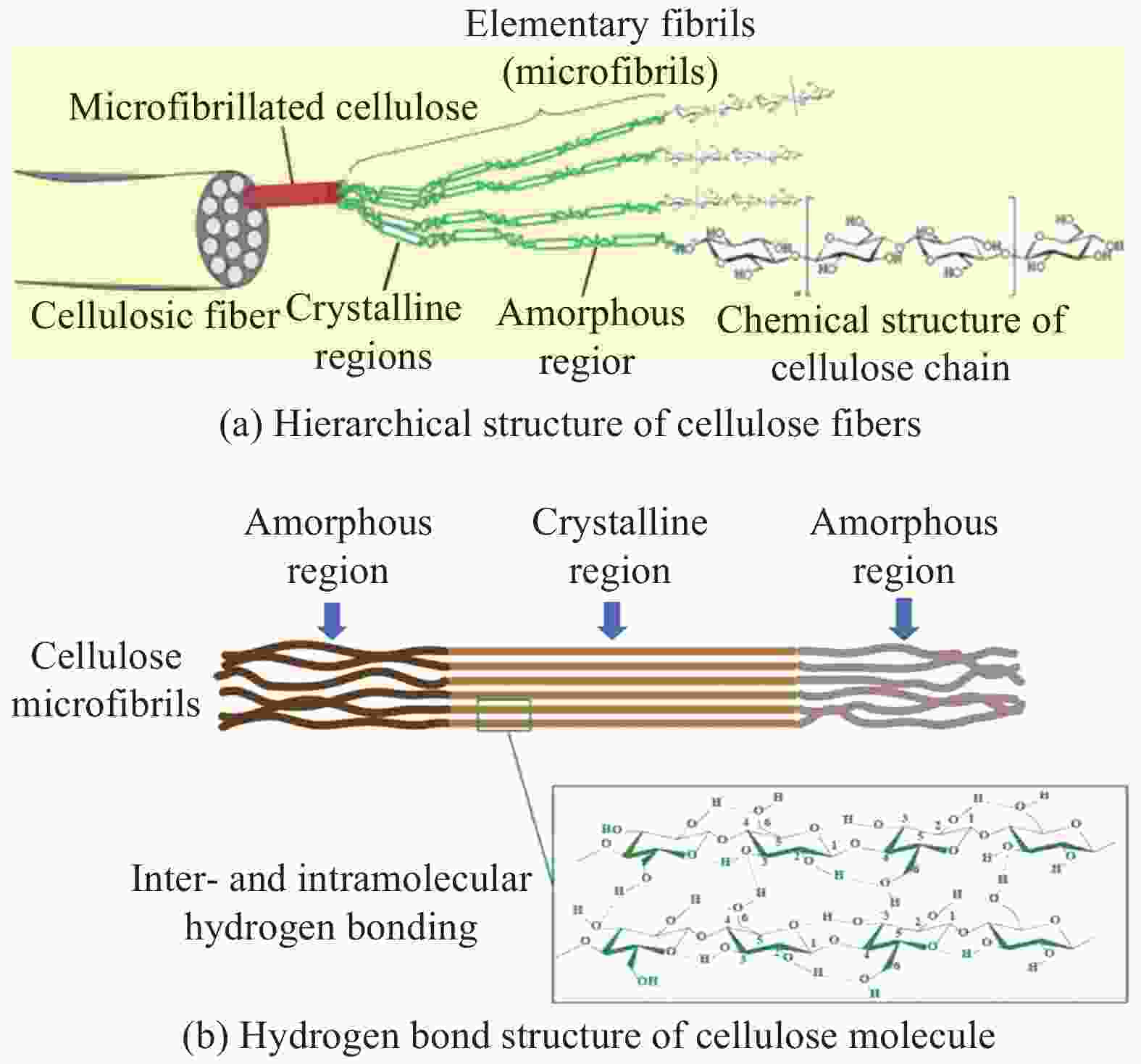

摘要: 纤维素是自然界中含量丰富且可再生、可降解的天然材料。本文综述了物理、化学、生物或相结合的技术对纤维素的影响作用及可制备的纤维素基元材料,例如纤维素纤维、纳米纤维素和纤维素分子。基于纤维素纤维,利用湿法造纸技术可以生产具有高孔隙率的纤维素纸张基底;基于纳米纤维素,利用真空抽滤或涂布等方式可制备具有低表面粗糙度及高透明度的纳米纤维素膜基底;基于纤维素分子,利用涂布或铸涂等方式可生产具有均一的表面形态及高透明度的再生纤维素膜基底。本文进一步分析了常用的导电材料(金属导电材料、聚合物导电材料及碳基导电材料等)及其与纤维素基底结合的方法(涂布、沉积、原位聚合、自组装等),进而可以制备柔韧轻质的纤维素导电基底。基于高性能的纤维素导电基底可以组装柔性电子器件,在光电转化、能量储存及电磁屏蔽等领域展现了广阔的应用前景。总之,利用天然纤维素制备柔性电子器件对于扩大纤维素的应用范围、提升纤维素的利用价值及推动柔性电子器件的进一步发展具有重要意义。Abstract: Cellulose is a kind of natural material with the abundant, renewable, and degradable distinction. This article reviews the effects of physical, chemical, biological or combined technologies on cellulose, which can lead to the cellulosic materials, such as cellulose fibers, nanocellulose, and cellulose molecules. Based on cellulose fiber, the cellulose paper substrate with high porosity can be produced by wet papermaking technology. Based on nanocellulose, the nanocellulose membrane substrate with low surface roughness and high transparency can be prepared via vacuum filtration or coating. Based on cellulose molecules, the regenerated cellulose membrane substrate with uniform surface morphology and high transparency can be produced by coating or casting. The commonly used conductive materials (metal conductive materials, polymer conductive materials and carbon based conductive materials, etc.) are further investigated for manufacturing the flexible, light and conductive cellulose substrates by various preparing methods, such as coating, deposition, in-situ polymerization, or self-assembly. The high performance cellulose conductive substrates can effectively construct the flexible electronic devices, which can be applied in the fields of photoelectric conversion, energy storage and electromagnetic shielding. In conclusion, the preparation of flexible electronic devices from natural cellulose is of great significance to expand the applications of cellulose, enhances the utilization value of cellulose, and promotes the further development of flexible electronic devices.

-

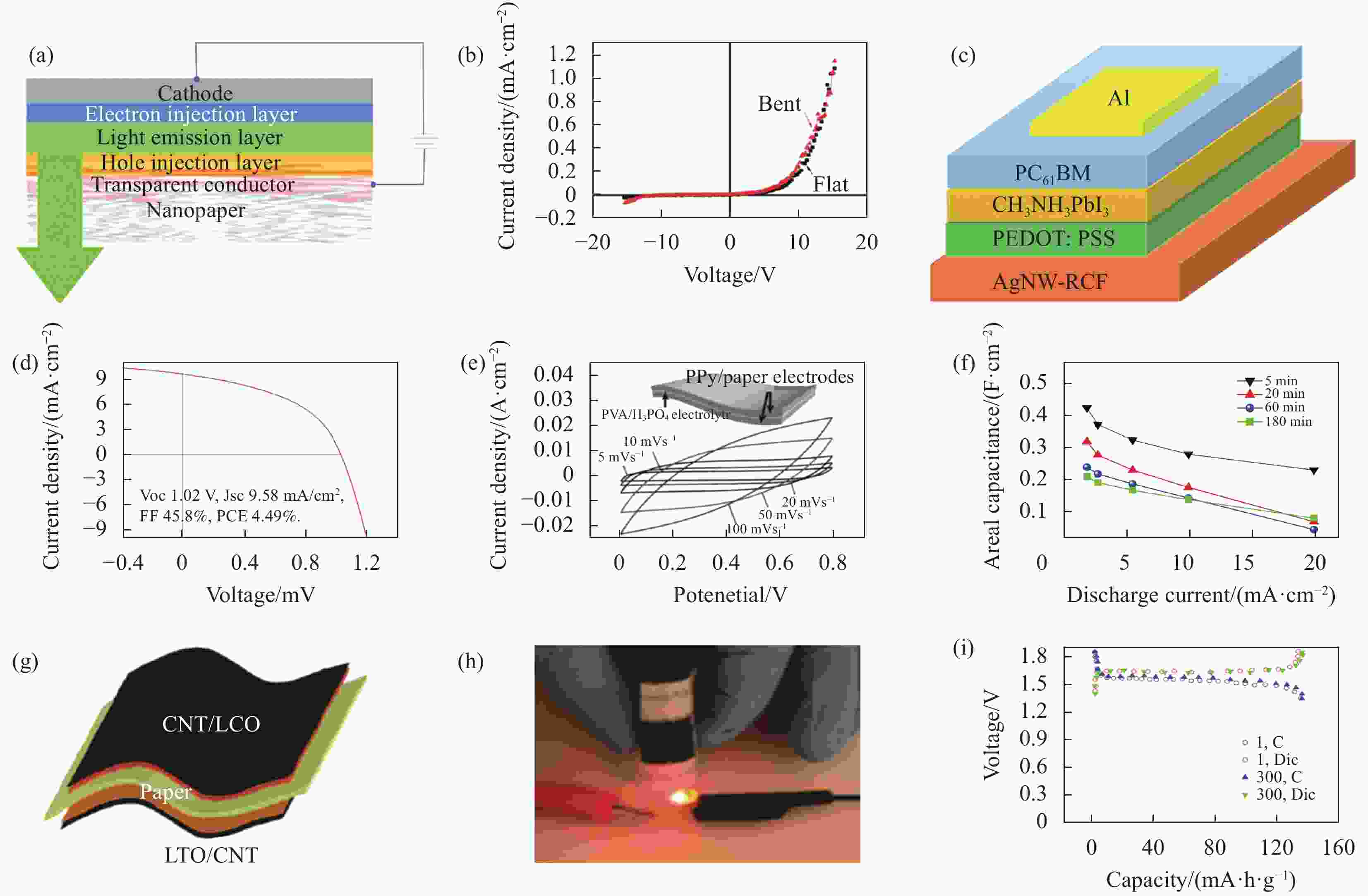

图 8 纤维素导电基底的电子器件[110, 129-131]((a)~(b) 纤维素基底有机发光二极管(OLED)装置图,在平坦和弯曲状态下的J-V曲线,弯曲半径为1.5 mm;(c)~(d) 纤维素基底钙钛矿薄膜太阳能电池结构图伏安特性曲线;(e)~(f) 纤维素基底固态超级电容器的示意图及循环伏安曲线和电容曲线图;(g)~(i) 纤维素基底锂离子电池装置结构示意图、运行图、LTO(Li4Ti5O12)阳极半电池恒流充放电曲线)

Figure 8. Electronic devices with cellulose conductive substrate[110, 129-131] ((a)-(b) Cellulose-based oganic light emitting diodes (OLED) device diagram, J-V curve in flat and curved state, with a bending radius of 1.5 mm; (c)-(d) cellulose-based perovskite thin film solar cell structure diagram and its volt-ampere characteristic curve; (e)-(f) Schematic diagram and cyclic voltammetry curve, capacitance curve diagramr; (g)-(i) Schematic diagram of cellulose-based lithiumion battery device structure, operation diagram, LTO (Li4Ti5O12) anode half battery constant current charge and discharge curve)

LCO—LiCoO2; CNT—Carbon nanotube

表 1 纳米纤维素的分类

Table 1. Classification of nanocellulose

Type of nanocellulose Average size Preparation method Typical sources Nanofibrillar cellulose Diameter: 5-70 nm

Length: 1-30 µmChemical-physical method Wood, cotton, sugar beet, flax, algae Nanocrystalline cellulose Diameter: 5-70 nm

Length: 100-250 nmChemical method Wood, cotton, flax, wheat straw, mulberry bark, algae Bacterial nanocellulose Diameter: 20-100 nm Bacterial synthesis Low molecular weight sugars, alcohols -

[1] LIU X, LI D, CHEN X, et al. Highly transparent and flexible all-solid-state supercapacitors based on ultra-long silver nanowire conductive networks[J]. ACS Applied Materials & Interfaces,2018,10(38):32536-32542. doi: 10.1021/acsami.8b10138 [2] ZHENG Q H, LI H X, ZHNEG Y L, et al. Cellulose-based flexible organic light-emitting diodes with enhanced stability and external quantum efficiency[J]. Journal of Materials Chemistry C,2021,9(13):4496-4504. [3] KENJIRO F, KILHO Y, TAKAO S. The future of flexible organic solar cells[J]. Advanced Energy Materials,2020,10(25):2000765. [4] MARTTI C, CHAN C K, MA J, et al. Printable thin film supercapacitors using single-walled carbon nanotubes[J]. Nano Letters,2009,9(5):1872-1876. doi: 10.1021/nl8038579 [5] YAO B, ZHANG J, KOU T Y, et al. Paper-based electrodes for flexible energy storage devices[J]. Advanced Science,2017,4(7):1700107. [6] ZHANG Y, ZHANG L N, CUI K, et al. Flexible electronics based on micro/nanostructured paper[J]. Advanced Science,2018,30(51):1801588. [7] HYUN W J, SECOR E B, KIM C H, et al. Scalable, self-aligned printing of flexible graphene micro-supercapacitors[J]. Advanced Energy Materials,2017,7(17):1-10. [8] NOGI M, YANO H. Optically transparent nanofiber sheets by deposition of transparent materials: A concept for a roll-to-roll processing[J]. Applied Physics Letters,2009,94(23):374. [9] RATHMELL A R, WILEY B J. The synthesis and coating of long, thin copper nanowires to make flexible, transparent conducting films on plastic substrates[J]. Advanced Materials,2011,23(41):4798-4803. doi: 10.1002/adma.201102284 [10] YU W J, LEE S Y, CHAE S H, et al. Small hysteresis nanocarbon-based integrated circuits on flexible and transparent plastic substrate[J]. Nano Letters,2011,11(3):1344-1350. doi: 10.1021/nl104488z [11] LABUNSKA, IRYNA, ABDALLAH M A E, et al. Human dietary intake of organohalogen contaminants at e-waste recycling sites in Eastern China[J]. Environment International,2015,74:209-220. doi: 10.1016/j.envint.2014.10.020 [12] LAVOINE N, DESLOGES I, DUFRESNE A, et al. Microfibrillated cellulose-its barrier properties and applications in cellulosic materials: A review[J]. Carbohydrate Polymers,2012,90(2):735-764. doi: 10.1016/j.carbpol.2012.05.026 [13] MISHRA R K, ARJUN S, TIWARI S K. Materials chemistry and the futurist eco-friendly applications of nanocellulose: Status and prospect[J]. Journal of Saudi Chemical Society,2018,22(8):949-978. doi: 10.1016/j.jscs.2018.02.005 [14] DEFRENNE Y, ZHDANKIN V, RAMANNA S, et al. Three-dimensional pore structure visualization and characterization of paper using X-ray computed tomography[J]. Tappi Journal,2017,16(9):519-530. doi: 10.32964/TJ16.9.519 [15] TOBJORK D, OSTERBACKA R. Paper electronics[J]. Advanced Materials,2011,23(17):1935-1961. doi: 10.1002/adma.201004692 [16] JIANG B, CHEN C J, LIANG Z Q, et al. Lignin as a wood-inspired binder enabled strong, water stable, and biodegradable paper for plastic replacement[J]. Advanced Functional Materials,2020,30(4):1906307. [17] HAYAKA F, TSUGUYUKIS S, AKIRA I. Influence of TEMPO-oxidized cellulose nanofibril length on film properties[J]. Carbohydrate Polymers,2013,93(1):172-177. doi: 10.1016/j.carbpol.2012.04.069 [18] HIROTAKA K, MASAYA N, NATSUKI K, et al. Uniformly connected conductive networks on cellulose nanofiber paper for transparent paper electronics[J]. NPG Asia Materials,2014,6(3):e93. [19] ISRAEL G, HELENA O, QUIM T, et al. Immobilization of antimicrobial peptides onto cellulose nanopaper[J]. International Journal of Biological Macromolecules,2017,105:741-748. doi: 10.1016/j.ijbiomac.2017.07.094 [20] KANG X Y, SUN P P, SHIGENORI K, et al. Thin cellulose nanofiber from corncob cellulose and its performance in transparent nanopaper[J]. ACS Sustainable Chemistry & Engineering,2017,5(3):2529-2534. [21] NIE S X, ZHANG K, LIN X J, et al. Enzymatic pretreatment for the improvement of dispersion and film properties of cellulose nanofibrils[J]. Carbohydrate Polymers,2018,181:1136-1142. doi: 10.1016/j.carbpol.2017.11.020 [22] YANG Q L, HAYAKA F, TSUGUYUKI S, et al. Transparent cellulose films with high gas barrier properties fabricated from aqueous alkali/urea solutions[J]. Biomacromolecules,2011,12(7):2766-2771. doi: 10.1021/bm200766v [23] WANG Q Y, CAI J, ZHANG L N, et al. A bioplastic with high strength constructed from a cellulose hydrogel by changing the aggregated structure[J]. Journal of Materials Chemistry A,2013,1(22):6678-6686. doi: 10.1039/c3ta11130j [24] QI H, CHANG C Y, ZHANG L N. Properties and applications of biodegradable transparent and photoluminescent cellulose films prepared via a green process[J]. Green Chem,2009,11(2):177-184. doi: 10.1039/B814721C [25] 宋怡佳, 陈胜, 张学铭, 等. 纤维素基透明功能材料的制备与应用进展[J]. 造纸科学与技术, 2018, 37(6):31-38.SONG Yijia, CHEN Sheng, ZHANG Xueming, et al. Progress in the preparation and application of cellulose-based transparent functional materials[J]. Paper Science and Technology,2018,37(6):31-38(in Chinese). [26] DIETER K, FRIEDERIKE K, SEBASTIAN M, et al. Nanocelluloses: A new family of nature-based materials[J]. Angewandte Chemie-International Edition,2011,50:5438-5466. doi: 10.1002/anie.201001273 [27] CELIA R P, LAURA S M, MIGUEL V. Nanocellulose as analyte and analytical tool: Opportunities and challenges[J]. Trac Trends in Analytical Chemistry,2017,87:1-18. doi: 10.1016/j.trac.2016.11.007 [28] SKOCAJ M. Bacterial nanocellulose in papermaking[J]. Cellulose,2019,26(11):6477-6488. doi: 10.1007/s10570-019-02566-y [29] 李兵云, 耿青杰, 王冉冉, 等. 草酸水解制备纤维素纳米纤丝工艺条件的优化[J]. 中国造纸, 2019, 38(1):20-25.LI Bingyun, GENG Qingjie, WANG Ranran, et al. Optimization of technological conditions for preparing cellulose nanofibrils by oxalic acid hydrolysis[J]. China Paper,2019,38(1):20-25(in Chinese). [30] LIU Y F, WANG H S, YU G, et al. A novel approach for the preparation of nanocrystalline cellulose by using phosphotungstic acid[J]. Carbohydrate Polymers,2014,110:415-422. doi: 10.1016/j.carbpol.2014.04.040 [31] ZHOU Y X, SAITO T, BERGSTROM L, et al. Acid-free preparation of cellulose nanocrystals by TEMPO oxidation and subsequent cavitation[J]. Biomacromolecules,2018,19(2):633-639. [32] SAITO T, HIROTA M, TAMURA N, et al. Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions[J]. Biomacromolecules,2009,10(7):1992-1996. doi: 10.1021/bm900414t [33] 杨建校, 章丽萍, 左宋林, 等. TEMPO氧化法制备氧化纤维素纳米纤维[J]. 东北林业大学学报, 2011, 39(3):96-98. doi: 10.3969/j.issn.1000-5382.2011.03.028YANG Jianxiao, ZHANG Liping, ZUO Songlin, et al. Preparation of oxidized cellulose nanofibers by TEMPO oxidation method[J]. Journal of Northeast Forestry University,2011,39(3):96-98(in Chinese). doi: 10.3969/j.issn.1000-5382.2011.03.028 [34] TSUGUYUKI SATOSHI, YOSHIHARU, et al. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose[J]. Biomacromolecules,2007,8:2485-2491. doi: 10.1021/bm0703970 [35] 王钰, 刘志明. 纳米纤丝化纤维素制备及硅烷化改性[J]. 生物质化学工程, 2015, 49(2):17-20. doi: 10.3969/j.issn.1673-5854.2015.02.004WANG Yu, LIU Zhiming. Preparation and silanization modification of nanofibrillated cellulose[J]. Biomass Chemical Engineering,2015,49(2):17-20(in Chinese). doi: 10.3969/j.issn.1673-5854.2015.02.004 [36] 欧文. ZnCl2解离法制备纳米晶体纤维素及其作为纸张增强剂的研究[D]. 福州: 福建农林大学, 2012.OU Wen. Preparation of nanocrystalline cellulose by ZnCl2 dissociation method and its use as a paper strengthening agent[D]. Fuzhou: Fujian Agriculture and Forestry University, 2012(in Chinese). [37] VIJAY B, JIRI M. Ball milling of jute fibre wastes to prepare nanocellulose[J]. World Journal of Engineering,2012,9(1):45-50. doi: 10.1260/1708-5284.9.1.45 [38] 卓治非, 房桂干, 王戈, 等. 酶解竹子溶解浆制备纳米微晶纤维素的研究[J]. 造纸科学与技术, 2014, 33(3):6-8, 71.ZHUO Zhifei, FANG Guigan, WANG Ge, et al. Preparation of nanocrystalline cellulose by enzymatic hydrolysis of dissolved bamboo pulp[J]. Paper Science and Technology,2014,33(3):6-8, 71(in Chinese). [39] 蒋玲玲, 陈小泉. 纤维素酶解天然棉纤维制备纳米纤维素晶体及其表征[J]. 化学工程与装备, 2008(10):1-4, 9.JIANG Lingling, CHEN Xiaoquan. Preparation and characterization of nanocellulose crystals from natural cotton fibers by enzymatic hydrolysis of cellulose[J]. Chemical Engineering and Equipment,2008(10):1-4, 9(in Chinese). [40] ASHRAF Z, LUCIA L, KRAUSE W. Bioengineering tunable porosity in bacterial nanocellulose matrices[J]. Soft Matter,2019,15(45):9359-9367. doi: 10.1039/C9SM01895F [41] XU T, JIANG Q, GHIM D, et al. Catalytically active bacterial nanocellulose based ultrafiltration membrane[J]. Small,2018,14:1704006. doi: 10.1002/smll.201704006 [42] TANIGUCHI T, OKAMIRA K. New films produced from microfibrillated natural fibres[J]. Polymer International,1998,47(3):291-294. doi: 10.1002/(SICI)1097-0126(199811)47:3<291::AID-PI11>3.0.CO;2-1 [43] 胡月, 李大纲, 徐丽, 等. 高强度透明纳米纤维素膜的制备及性能研究[J]. 纤维素科学与技术, 2012, 20(3):51-56. doi: 10.3969/j.issn.1004-8405.2012.03.009HU Yue, LI Dagang, XU Li, et al. Preparation and properties of high strength transparent nanocellulose membranes[J]. Cellulose Science and Technology,2012,20(3):51-56(in Chinese). doi: 10.3969/j.issn.1004-8405.2012.03.009 [44] 李美灿, 刘金刚, 陈京环, 等. 多孔性纳米纤维素膜的制备及应用综述[J]. 中国造纸, 2019, 38(9):59-68.LI Meican, LIU Jingang, CHEN Jinghuan, et al. Preparation and application of porous nanocellulose membranes[J]. China Paper & Paper,2019,38(9):59-68(in Chinese). [45] 林嫦妹. 高雾度透明纤维素膜的制备及其性能研究[D]. 福州: 福建农林大学, 2019.LIN Changmei. Preparation and properties of high haze transparent cellulose membrane[D]. Fuzhou: Fujian Agriculture and Forestry University, 2019(in Chinese). [46] 许凤, 陈阳雷, 游婷婷, 等. 纤维素溶解机理研究述评[J]. 林业工程学报, 2019, 4(1):1-7.XU Feng, CHEN Yanglei, YOU Tingting, et al. Review of research on dissolution mechanism of cellulose[J]. Journal of Forestry Engineering,2019,4(1):1-7(in Chinese). [47] ZHANG J, ZHANG H, WU J, et al. NMR specroscopic studies of cellobiose solvation in EmimAc aimed to understand the dissolution mechanism of cellulose in ionic liquids[J]. Physical Chemistry Chemical Physics,2010,12(8):1941-1947. doi: 10.1039/b920446f [48] 吴翠玲, 李新平, 秦胜利, 等. 新型有机纤维素溶剂-NMMO的研究[J]. 兰州理工大学学报, 2005(2):73-76. doi: 10.3969/j.issn.1673-5196.2005.02.021WU Cuiling, LI Xinping, QIN Shengli, et al. Study on a novel organic cellulose solvent-NMMO[J]. Journal of Lanzhou University of Technology,2005(2):73-76(in Chinese). doi: 10.3969/j.issn.1673-5196.2005.02.021 [49] MCCORMICK C L, CALLAIS P A, HUTCHINSON B H. Solution studies of cellulose in lithium chloride and N, N-dimethylacetamide[J]. Macromolecules,1985,18:2394-2401. doi: 10.1021/ma00154a010 [50] 高珊珊, 王建清. 利用LiCl/DMAc溶解体系制造绿色纤维素包装薄膜[J]. 印刷技术, 2009(8):24-25. doi: 10.3969/j.issn.1003-1960.2009.08.009GAO Shanshan, WANG Jianqing. Manufacturing of green cellulose packaging film by LiCl/DMAC solution system[J]. Printing Technology,2009(8):24-25(in Chinese). doi: 10.3969/j.issn.1003-1960.2009.08.009 [51] 陈雄. 低温NaOH/尿素体系中纤维素溶解及其新型水凝胶制备[D]. 北京: 北京林业大学, 2016.CHEN Xiong. Cellulose dissolution in low temperature NaOH/ urea system and preparation of novel hydrogels[D]. Beijing: Beijing Forestry University, 2016(in Chinese). [52] 王向利. 离子液体溶剂法制备再生纤维素纤维[J]. 人造纤维, 2011, 41(1):21-23.WANG Xiangli. Preparation of regenerated cellulose fiber by ionic liquid solvent method[J]. Man-made Fiber,2011,41(1):21-23(in Chinese). [53] RAN L, ZHANG L N, MIN X. Novel regenerated cellulose films prepared by coagulating with water: Structure and properties[J]. Carbohydrate Polymers,2012,87(1):95-100. doi: 10.1016/j.carbpol.2011.07.023 [54] 付时雨. 纤维素的研究进展[J]. 中国造纸, 2019, 38(6):54-64.FU Shiyu. Research progress of cellulose[J]. China Paper & Paper,2019,38(6):54-64(in Chinese). [55] 张同平. 纤维素/石墨烯纳米复合材料的制备及性能研究[D]. 青岛: 青岛科技大学, 2016.ZHANG T P. Preparation and properties of cellulose/graphene nanocomposites[D]. Qingdao: Qingdao University of Science and Technology, 2016 (in Chinese). [56] 关振铎, 张中太, 焦金生. 无机材料物理性能[M]. 第2版. 北京: 清华大学出版社, 2011: 176-195.GUAN Zhenduo, ZHANG Zhongtai, JIAO Jinsheng. Physical properties of inorganic materials[M]. 2nd Ed. Beijing: Tsinghua University Press, 2011: 176-195(in Chinese). [57] 刘强, 黄新友. 材料物理性能[M]. 北京: 化学工业出版社, 2009: 106-117.LIU Qiang, HUANG Xinyou. Physical properties of materials[M]. Beijing: Chemical Industry Press, 2009: 106-117(in Chinese). [58] GAO W J, JIA C C, JIA X, et al. Effect of processing parameters on the microstructure and thermal conductivity of diamond/Ag composites fabricated by spark plasma sintering[J]. Rare Metals,2010,29(6):625-629. doi: 10.1007/s12598-010-0182-4 [59] HUANG X Y, JIANG P K, XIE L Y. Ferroelectric polymer/silver nanocomposites with high dielectric constant and high thermal conductivity[J]. Applied Physics Letters,2009,95(24):014105. [60] TAO T, LIU X, ISLAM A, et al. Flexible and conductive cellulose substrate by layered growth of silver nanowires and indium-doped tin oxide[J]. BioResources,2020,15(3):4699-4710. [61] CHEN W, WANG Z F, ZHI C Y, et al. High thermal conductivity and temperature probing of copper nanowire/upconversion nanoparticles/epoxy composite[J]. Composites Science & Technology,2016,130:63-69. doi: 10.1016/j.compscitech.2016.05.004 [62] AMIT R, MOORE A L. Enhanced thermal conduction and influence of interfacial resistance within flexible high aspect ratio copper nanowire/polymer composites[J]. Composites Science & Technology,2017,144:70-78. doi: 10.1016/j.compscitech.2017.03.020 [63] BALACHANDER N, SESHADRI I, MEHTA R J, et al. Nanowire-filled polymer composites with ultrahigh thermal conductivity[J]. Applied Physics Letters,2013,102(9):093117. [64] LI X B, ZHANG X, LI L C, et al. Preparation of nano-ZnO/regenerated cellulose composite particles via co-gelation and low-temperature hydrothermal synthesis[J]. Materials Letters,2016,175:122-125. doi: 10.1016/j.matlet.2016.04.012 [65] 王赫, 杨弋涛, 曾志翔, 等. 纤维素/ZnO复合膜的制备及其光催化性能[J]. 中国表面工程, 2015, 28(5):30-36.WANG H, YANG Yitao, ZENG Zhixiang, et al. Preparation and photocatalytic performance of cellulose/ZnO composite films[J]. China Surface Engineering,2015,28(5):30-36(in Chinese). [66] LIU K, JOSEPH N, CHEN L H, et al. Preparation of CNC-dispersed Fe3O4 nanoparticles and their application in conductive paper[J]. Carbohydrate Polymers,2015,126:175-178. doi: 10.1016/j.carbpol.2015.03.009 [67] SUN R H, YAO H, ZHANG H B, et al. Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy composites[J]. Composites Science and Technology,2016,137:16-23. doi: 10.1016/j.compscitech.2016.10.017 [68] MA Z Z, LI Z R, LIU K, et al. Indium-tin-oxide for high-performance electro-optic modulation[J]. Nanophotonics,2015,4(2):198-213. [69] KHONDOKER M A, YANG S Y, MUN S C, et al. Flexible and conductive ITO electrode made on cellulose film by spin-coating[J]. Synthetic Metals,2012,162(21-22):1972-1976. doi: 10.1016/j.synthmet.2012.09.005 [70] LIU X, HUANG K X, LIN X X, et al. Transparent and conductive cellulose film by controllably growing aluminum doped zinc oxide on regenerated cellulose film[J]. Cellulose,2020,27(9):4847-4855. doi: 10.1007/s10570-020-03147-0 [71] KAZUTOMO D, TOSHIHARU E, AKIRA I. Method for controlling surface energies of paper substrates to create paper-based printed electronics[J]. Chemical Engineering and Processing: Process Intensification,2013,68:21-25. doi: 10.1016/j.cep.2013.01.003 [72] LI J G, YANG H Y, HUANG K X, et al. Conductive regenerated cellulose film as counter electrode for efficient dye-sensitized solar cells[J]. Cellulose,2018,25(2):5113-5122. [73] 南松楠. 基于石墨烯导电纸的制备及其性能研究[D]. 广州: 华南理工大学, 2015.NAN Songnan. Preparation and properties of graphene-based conductive paper[D]. Guangzhou: South China University of Technology, 2015(in Chinese). [74] 赵文元, 王亦军. 功能高分子材料[M]. 第2版. 北京: 化学工业出版社, 2020: 60-99.ZHAO Wenyuan, WANG Yijun. Functional polymer materials[M]. 2nd Ed. Beijing: Chemical Industry Press, 202: 60-99(in Chinese). [75] 丁林. 噻吩基导电聚合物复合材料的合成及其超电容性能[D]. 南京: 南京航空航天大学, 2014.DING Lin. Synthesis of thiophene-based conductive polymer composites and their supercapacitive properties[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2014(in Chinese). [76] 张诗浩. 基于聚噻吩/导电炭黑原位聚合导电油墨的制备及在包装防伪中的应用[D]. 长沙: 湖南工业大学, 2019.ZHANG Shihao. Preparation of Conductive ink based on polythiophene/conductive carbon black in-situ polymerization and its application in anti-counterfeiting packaging[D]. Changsha: Hunan University of Technology, 2019(in Chinese). [77] THEODOROS M, VASSILIOS D, THOMAS S, et al. A quasi solid-state dye-sensitized solar cell made of polypyrrole counter electrodes[J]. Electrochim Acta,2011,56(5):2004-2008. doi: 10.1016/j.electacta.2010.11.076 [78] RAGHUNATHAN S P, POIKAVILA S, POULOSE A C, et al. Flexible regenerated cellulose/polypyrrole composite films with enhanced dielectric properties[J]. Carbohydrate Polymers,2017,157:1024-1032. doi: 10.1016/j.carbpol.2016.10.065 [79] SADIA A, AKHTAR M S, KIM Y S, et al. Sulfamic acid-doped polyaniline nanofibers thin film-based counter electrode: Application in dye-sensitized solar cells[J]. Journal of Physics Chemistry A,2010,114(10):4760-4764. [80] XIAO Y M, HAN G Y, LI Y P, et al. High performance of Pt-free dye-sensitized solar cells based on two-step electropolymerized polyaniline counter electrodes[J]. Journal of Materials Chemistry A,2014,2(10):3452-3460. doi: 10.1039/C3TA14879C [81] PRINGLE J M, FORAYTH M, MACFARLANE D R, et al. The influence of the monomer and the ionic liquid on the electrochemical preparation of polythiophene[J]. Polymer,2005,46(7):2047-2058. doi: 10.1016/j.polymer.2005.01.034 [82] 汪丽. 阳离子聚丙烯酸酯掺杂作用下聚吡咯/木质纤维导电纸的制备及性能研究[D]. 西安: 陕西科技大学, 2015.WANG Li. Preparation and properties of polypyrrole/wood fiber conductive paper doped with cationic polyacrylate[D]. Xi’an: Shaanxi University of Science and Technology, 2015(in Chinese). [83] MANGIL A, XING Q, SHIM B S, et al. Conductive paper from lignocellulose wood microfibers coated with a nanocomposite of carbon nanotubes and conductive polymers[J]. Nanotechnology,2009,20(21):215602. [84] HAN J Q, WANGg H X, YUE Y Y, et al. A self-healable and highly flexible supercapacitor integrated by dynamically cross-linked electro-conductive hydrogels based on nanocellulose-templated carbon nanotubes embedded in a viscoelastic polymer network[J]. Carbon,2019,149:1-18. doi: 10.1016/j.carbon.2019.04.029 [85] 吕少一, 傅峰, 王思群, 等. 纳米纤维素基导电复合材料研究进展[J]. 林业科学, 2015, 51(10):117-125.LV Shaoyi, FU Feng, WANG Siqun, et al. Research progress of nanocellulose based conductive composites[J]. Scientia Silvae Sinica,2015,51(10):117-125(in Chinese). [86] 孙红娟, 侯波, 彭同江. 石墨的矿物学属性、功能化与石墨新材料的应用[J]. 矿产保护与利用, 2019, 39(6):8-13.SUN Hongjuan, HOU Bo, PENG Tongjiang. Mineralogical properties and functionalization of graphite and application of new graphite materials[J]. Conservation and Utilization of Mineral Resources,2019,39(6):8-13(in Chinese). [87] 赵嘉蕊, 杨柯, 刘琳琳, 等. 印刷电子中碳基导电材料发展现状[J]. 今日印刷, 2019(12):64-67. doi: 10.3969/j.issn.1002-6533.2019.12.026ZHAO Jiarui, YANG Ke, LIU Linlin, et al. Development Status of carbon-based conductive materials in printed electronics[J]. Print Today,2019(12):64-67(in Chinese). doi: 10.3969/j.issn.1002-6533.2019.12.026 [88] CAMPBEL B, MANNING J. The rise of victimhood culture: Microaggressions, safe spaces, and the new culture wars. Rise vict cult microaggressions, safe spaces, new cult wars[M]. New York: Palgrave Macmillan, 2018: 1-265. [89] 韩景泉, 王思伟, 岳一莹, 等. 静电纺定向纳米纤维素-碳纳米管/聚乙烯醇复合纤维导电膜及性能[J]. 复合材料学报, 2018, 35(9):2351-2361.HAN Jingquan, WANG Siwei, YUE Yiying, et al. Electrospinning oriented nanocellulose/carbon nanotubes/polyvinyl alcohol composite conductive film and its properties[J]. Acte Materiae Compositae Sinica,2018,35(9):2351-2361(in Chinese). [90] LEE C K, LEE S B, HWANG S W, et al. Cellulosic binder-assisted formation of graphene-paper electrode with flat surface and porous internal structure[J]. Journal of Nanoscience and Nanotechnology,2013,13(11):7391-7395. doi: 10.1166/jnn.2013.7860 [91] 余登伟, 刘哲, 唐海珊. 石墨/再生纤维素复合膜的制备及导电性表征[J]. 纤维素科学与技术, 2020, 28(2):57-63.YU Dengwei, LIU Zhe, TANG Haishan. Preparation and conductivity characterization of graphite/regenerated cellulose composite membrane[J]. Cellulose Science and Technology,2020,28(2):57-63(in Chinese). [92] 曾敏, 伍江涛, 冯猛, 等. 碳系填料在聚合物基导电复合材料中的应用[J]. 橡胶工业, 2010, 57(6):378-382. doi: 10.3969/j.issn.1000-890X.2010.06.014ZENG Min, WU Jiangtao, FENG Meng, et al. Application of carbon filler in conductive polymer matrix composites[J]. Rubber Industry,2010,57(6):378-382(in Chinese). doi: 10.3969/j.issn.1000-890X.2010.06.014 [93] WEN Z, SU Y, WANG D W, et al. Graphene-cellulose paper flexible supercapacitors[J]. Advanced Energy Materials,2011,1(5):917-922. doi: 10.1002/aenm.201100312 [94] SHEN B, ZHAI W T, LU D D, et al. Ultrasonication-assisted direct functionalization of graphene with macromolecules[J]. RSC Advances,2012,2(11):4713-4719. doi: 10.1039/c2ra01098d [95] 胡圣飞, 张帆, 张荣, 等. 石墨烯表面改性及其在聚合物导电复合材料中的应用研究[J]. 高分子材料科学与工程, 2017, 33(8):184-190.HU Shengfei, ZHANG Fan, ZHANG Rong, et al. Surface modification of graphene and its application in conductive polymer composites[J]. Polymer Materials Science and Engineering,2017,33(8):184-190(in Chinese). [96] 祁帅, 黄国强. 超声波辅助二元溶剂剥离制备石墨烯[J]. 材料导报, 2017, 31(5):72-76. doi: 10.11896/j.issn.1005-023X.2017.05.012QI Shuai, HUANG Guoqiang. Preparation of graphene by ultrasonic-assisted dual solvent peeling[J]. Materials Review,2017,31(5):72-76(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.05.012 [97] 郑克勤, 吕旺燕, 王贻波, 等. 表面活性剂复配对石墨烯分散性的影响及其在复合镀银中的应用[J]. 电镀与涂饰, 2019, 38(4):147-152.ZHENG Keqin, LV Wangyan, WANG Yibo, et al. Effect of surfactant compound on dispersion of graphene and its application in composite silver plating[J]. Electroplating and Finishing,2019,38(4):147-152(in Chinese). [98] 张浩, 朱明. 基于纳米纤维素的柔性导电材料研究进展[J]. 中国造纸, 2019, 38(1):65-70.ZHANG Hao, ZHU Ming. Research progress of flexible conductive materials based on nanocellulose[J]. China Paper & Paper,2019,38(1):65-70(in Chinese). [99] HU L B, CUI Y. Energy and environmental nanotechnology in conductive paper and textiles[J]. Energy & Environmental Science,2012,5(4):6423-6435. [100] YUAN L Y, YAO B, HU B, et al. Polypyrrole-coated paper for flexible solid-state energy storage[J]. Energy & Environmental Science,2013,6(2):470-476. [101] HYUN W J, SECOR E B, ROJAS G A, et al. All-printed, foldable organic thin-film transistors on glassine paper[J]. Advanced Materials,2015,27(44):7058-+. doi: 10.1002/adma.201503478 [102] 黄文靖, 丁子先, 邱学青, 等. 自组装聚合法制备木质素磺酸/聚吡咯柔性导电纸[J]. 高等学校化学学报, 2018, 39(11):2601-2610. doi: 10.7503/cjcu20180122HUANG Wenjing, DING Zixian, QIU Xueqing, et al. Preparation of lignosulfonate/polypyrrole flexible conductive paper by self-assembly polymerization[J]. Chemical Journal of Chinese Universities,2018,39(11):2601-2610(in Chinese). doi: 10.7503/cjcu20180122 [103] YUAN L Y, XIAO X, DING T P, et al. Paper-based supercapacitors for self-powered nanosystems[J]. Angew Andte Chemie-International Edition,2012,124(20):4934-4938. [104] 张浩, 洪亮, 吕金燕, 等. 纳米微晶纤维素导电薄膜的制备及性能表征[J]. 中国造纸, 2018, 37(11):1-6. doi: 10.11980/j.issn.0254-508X.2018.11.001ZHANG Hao, HONG Liang, LV Jinyan, et al. Preparation and properties characterization of nanocrystalline cellulose conductive films[J]. China Paper & Paper,2018,37(11):1-6(in Chinese). doi: 10.11980/j.issn.0254-508X.2018.11.001 [105] ZHANG H Y, SHI L L, FENG X. Use of chitosan to reinforce transparent conductive cellulose nanopaper[J]. Journal of Materials Chemistry C,2018,6(2):242-248. doi: 10.1039/C7TC03980H [106] LARSEN L S. The development of wood polymer penetrant and in situ polymerization with electron beam and X-radiaton[D]. New York: State University of New York, 2006. [107] RICHARD B, IBACH R E, CONSTANTINE L, et al. Evaluating physical property changes for small-diamcter, plantation-grown southern pine after in situ polymerization of an acrylic monomer[J]. Forest Product Joumal,2009,59(10):64-71. doi: 10.13073/0015-7473-59.10.64 [108] LI J, QIAN X R, WANG L J, et al. XPS characterization and percolation behavior of polyaniline-coated conductive paper[J]. BioResources,2010,5(2):712-726. [109] HAN J Q, WANG S W, ZHU S L, et al. Electrospun core-shell nanofibrous membranes with nanocellulose-stabilized carbon nanotubes for use as high-performance flexible supercapacitor electrodes with enhanced water resistance, thermal stability, and mechanical toughness[J]. ACS Applied Materials & Interfaces,2019,11(47):44624-44635. [110] HU L B, ZHENG G Y, YAO J, et al. Transparent and conductive paper from nanocellulose fibers[J]. Energy & Environmental Science,2013,6(2):513-518. [111] YANG W F, LIU Z G, PENG D L. Room-temperature deposition of transparent conducting Al-doped ZnO films by RF magnetron sputtering method[J]. Applied Surface Science,2009,255(11):5669-5673. doi: 10.1016/j.apsusc.2008.12.021 [112] HU L B, WU H, CUI Y. Printed energy storage devices by integration of electrodes and separators into single sheets of paper[J]. Applied Physics Letters,2010,96(18):1754. [113] KREBS F C, MIKKEL J, KION N, et al. A complete process for production of flexible large area polymer solar cells entirely using screen printing-First public demonstration[J]. Solar Energy Materials & Solar Cells,2009,93(4):422-441. [114] GATES B D, XU Q B, STEWART M, et al. New approaches to nanofabrication: Molding, printing, and other techniques[J]. Chemical Reviews,2005,36(27):1171-1196. [115] 曹宏辉, 孙晓刚, 王健, 等. 十八胺改性碳纳米管导电纸的性能研究[J]. 材料导报, 2013, 27(2):21-23. doi: 10.3969/j.issn.1005-023X.2013.02.006CAO Honghui, SUN Xiaogang, WANG Jian, et al. Properties of carbon nanotube conductive paper modified with octadecylamine[J]. Materials Review,2013,27(2):21-23(in Chinese). doi: 10.3969/j.issn.1005-023X.2013.02.006 [116] SHINGO O, DAIKI M, ITSUO H. Inkjet drawing dynamics of conductive polymer droplets on cellulose nanopapers[J]. AIP Advances,2020,10(4):045122. [117] ZHU H L, NARAKATHU B B, FANG Z Q, et al. A gravure printed antenna on shape-stable transparent nanopaper[J]. Nanoscale,2014,6(15):9110-9115. doi: 10.1039/C4NR02036G [118] 张馨琪, 黄彪彪, 赵若男, 等. 纳米微晶纤维素/石墨烯柔性导电薄膜的制备与表征[J]. 纸和造纸, 2018, 37(2):10.ZHANG Xinqi, HUANG Biaobiao, ZHAO Ruonan, et al. Preparation and characterization of nanocrystalline cellulose/graphene flexible conductive films[J]. Paper and Paper,2018,37(2):10(in Chinese). [119] COLIN P, FANG Z Q, JOSEPH M, et al. Silver nanowire transparent conducting paper-based electrode with high optical haze[J]. Journal of Materials Chemistry C,2013,2:1248-1254. [120] TANG Y J, HE Z, MOSSELER J A, et al. Production of highly electro-conductive cellulosic paper via surface coating of carbon nanotube/graphene oxide nanocomposites using nanocrystalline cellulose as a binder[J]. Cellulose,2014,21:4569-4581. doi: 10.1007/s10570-014-0418-9 [121] 庞志鹏, 孙晓刚, 程晓圆, 等. 碳纤维-碳纳米管复合导电纸的制备及电磁屏蔽性能研究[J]. 人工晶体学报, 2015, 44(5):1314-1319, 1324. doi: 10.3969/j.issn.1000-985X.2015.05.029PANG Zhipeng, SUN Xiaogang, CHENG Xiaoyuan, et al. Preparation and electromagnetic shielding performance of carbon fiber/carbon nanotube composite conductive paper[J]. Journal of Artificial Crystals,2015,44(5):1314-1319, 1324(in Chinese). doi: 10.3969/j.issn.1000-985X.2015.05.029 [122] 庞志鹏, 孙晓刚, 程晓圆, 等. 碳纳米管导电纸的制备及改性研究[J]. 功能材料, 2015, 46(7):7109-7112, 7117. doi: 10.3969/j.issn.1001-9731.2015.07.024PANG Zhipeng, SUN Xiaogang, CHENG Xiaoyuan, et al. Preparation and modification of carbon nanotube conductive paper[J]. Functional Materials,2015,46(7):7109-7112, 7117(in Chinese). doi: 10.3969/j.issn.1001-9731.2015.07.024 [123] 朱正意. 基于层层自组装技术石墨烯复合材料的制备及性能研究[D]. 无锡: 江南大学, 2014.ZHU Zhengyi. Preparation and properties of graphene composites based on layer self-assembly technology[D]. Wuxi: Jiangnan University, 2014(in Chinese). [124] 陈宇泽. 层层自组装制备石墨烯/聚苯胺复合薄膜及其应用研究[D]. 无锡: 江南大学, 2014.CHEN Yuze. Preparation of graphene/polyaniline composite films by layer self-assembly and its application[D]. Wuxi: Jiangnan University, 2014(in Chinese). [125] ZHANG M N, YAN Y M, GONG K P, et al. Electrostatic layer-by-layer assembled carbon nanotube multilayer film and its electrocatalytic activity for O2 reduction[J]. Langmuir,2004,20(20):8781-8785. doi: 10.1021/la048923l [126] KIM B S, PARK S W, HAMMOND P T. Hydrogen-bonding layer-by-layer-assembled biodegradable polymeric micelles as drug delivery vehicles from surfaces[J]. ACS Nano,2008,2(2):386-392. doi: 10.1021/nn700408z [127] KRASS H, PAPASTAVROU, G, KURTH D G. Layer-by-layer self-assembly of a polyelectrolyte bearing metal ion coordination and electrostatic functionality[J]. Chemistry of Materials,2003,15(1):196-203. doi: 10.1021/cm020808d [128] GAO K Z, SHAO Z Q, WU X, et al. Cellulose nanofibers/reduced graphene oxide flexible transparent conductive paper[J]. Carbohydr Polym,2013,97(1):243-251. doi: 10.1016/j.carbpol.2013.03.067 [129] ZHU H L, XIAO Z G, LIU D T, et al. Biodegradable transparent substrates for flexible organic-light-emitting diodes[J]. Energy & Environmental Science,2013,6(7):2105-2111. [130] MA X J, DENG Q D, WANG L, et al. Cellulose transparent conductive film and its feasible use in perovskite solar cells[J]. RSC Advances,2019,9(17):9348-9353. doi: 10.1039/C9RA01301F [131] HU L B, WU H, LA M F, et al. Thin, flexible secondary Li-ion paper batteries[J]. ACS Nano,2010,4(10):5843-5848. doi: 10.1021/nn1018158 [132] 庞志鹏, 孙晓刚, 程晓圆, 等. 碳纳米管导电纸制备及其电磁屏蔽性能研究[J]. 人工晶体学报, 2014, 43(10):2635-2640+2645. doi: 10.3969/j.issn.1000-985X.2014.10.028PANG Zhipeng, SUN Xiaogang, CHENG Xiaoyuan, et al. Preparation of carbon nanotube conductive paper and its electromagnetic shielding performance[J]. Journal of Artificial Crystals,2014,43(10):2635-2640+2645(in Chinese). doi: 10.3969/j.issn.1000-985X.2014.10.028 [133] SURESHA K M, YANG S Y, LEE M., et al. Actuator, sensor and MEMS devices based on regenerated cellulose[J]. Composite Interfaces,2008,15(7-9):679-685. doi: 10.1163/156855408786778393 [134] KIM J H, YUN S, K o, H U, et al. A flexible paper transistor made with aligned single-walled carbon nanotube bonded cellulose composite[J]. Current Applied Physics,2013,13(5):897-901. doi: 10.1016/j.cap.2013.01.036 [135] YAGYU H, SAITO T, ISOGAI A, et al. Chemical modification of cellulose nanofibers for the production of highly thermal resistant and optically transparent nanopaper for paper devices[J]. ACS Applied Materials & Interfaces,2015,7(39):22012-22017. [136] 吴越齐, 柯嘉洪, 陈大柱, 等. 基于LCA的晶体硅太阳能电池环境影响评价[J]. 广东化工, 2019, 6(16):12-14. doi: 10.3969/j.issn.1007-1865.2019.16.007WU Yueqi, KE Jiahong, CHEN Dazhu, et al. Environmental impact assessment of crystalline silicon solar cells based on LCA[J]. Guangdong Chemical Industry,2019,6(16):12-14(in Chinese). doi: 10.3969/j.issn.1007-1865.2019.16.007 [137] 李雨芹. 钙钛矿太阳能电池及其研究进展[J]. 现代盐化工, 2012, 3:62-63.LI Yuqin. Perovskite solar cells and their research development[J]. Modern Salt Chemical Industry,2012,3:62-63(in Chinese). [138] 李平, 陆亚利, 梁倩倩. 石墨烯及其衍生物在有机太阳能电池中的应用进展[J]. 化工新型材料, 2020, 48(S1):1-6, 10.LI Ping, LU Yali, LIANG Qianqian. Application progress of graphene and its derivatives in organic solar cells[J]. New Chemical Materials,2020,48(S1):1-6, 10(in Chinese). [139] FANG Z Q, ZHU H L, YUAN Y B, et al. Novel Nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells[J]. Nano Letters,2014,14(2):765-773. doi: 10.1021/nl404101p [140] ZHENG W Z, LV R H, NA B, et al. Nanocellulose-mediated hybrid polyaniline electrodes for high performance flexible supercapacitors[J]. Journal of Materials Chemistry A,2017,5(25):12969-12976. doi: 10.1039/C7TA01990D [141] LEIJONMARCK S, CORNELL A, LINDBERGH G, et al. Single-paper flexible Li-ion battery cells through a paper-making process based on nano-fibrillated cellulose[J]. Journal of Materials Chemistry A,2013,1(15):4671-4677. doi: 10.1039/c3ta01532g [142] 刘家辉, 柳和生. 冷冻干燥法制备木浆纤维素隔膜在锂离子电池中的应用[J]. 广东化工, 2020, 47(7):11-12, 23. doi: 10.3969/j.issn.1007-1865.2020.07.006LIU Jiahui, LIU Hesheng. Application of wood pulp cellulose membrane prepared by freeze-drying method in lithium ion battery[J]. Guangdong Chemical Industry,2020,47(7):11-12, 23(in Chinese). doi: 10.3969/j.issn.1007-1865.2020.07.006 -

下载:

下载: