Synergistic properties of microencapsulated intumescent flame retardant-organically modified montmorillonite/ethylene-vinyl acetate copolymer composites

-

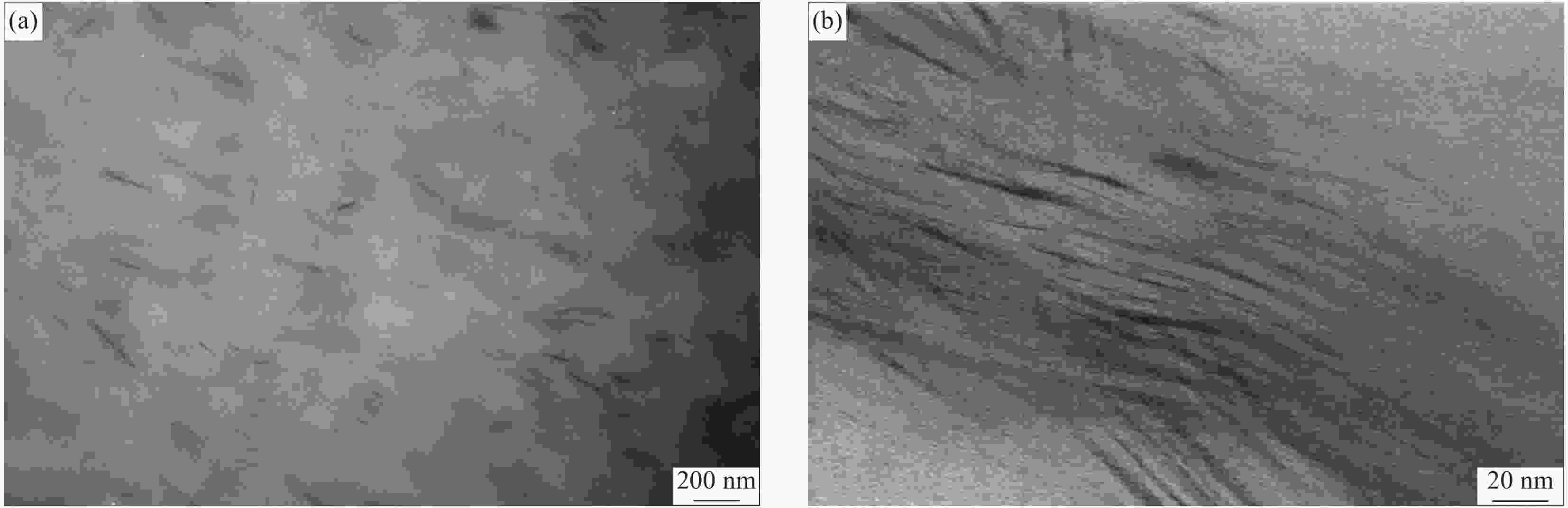

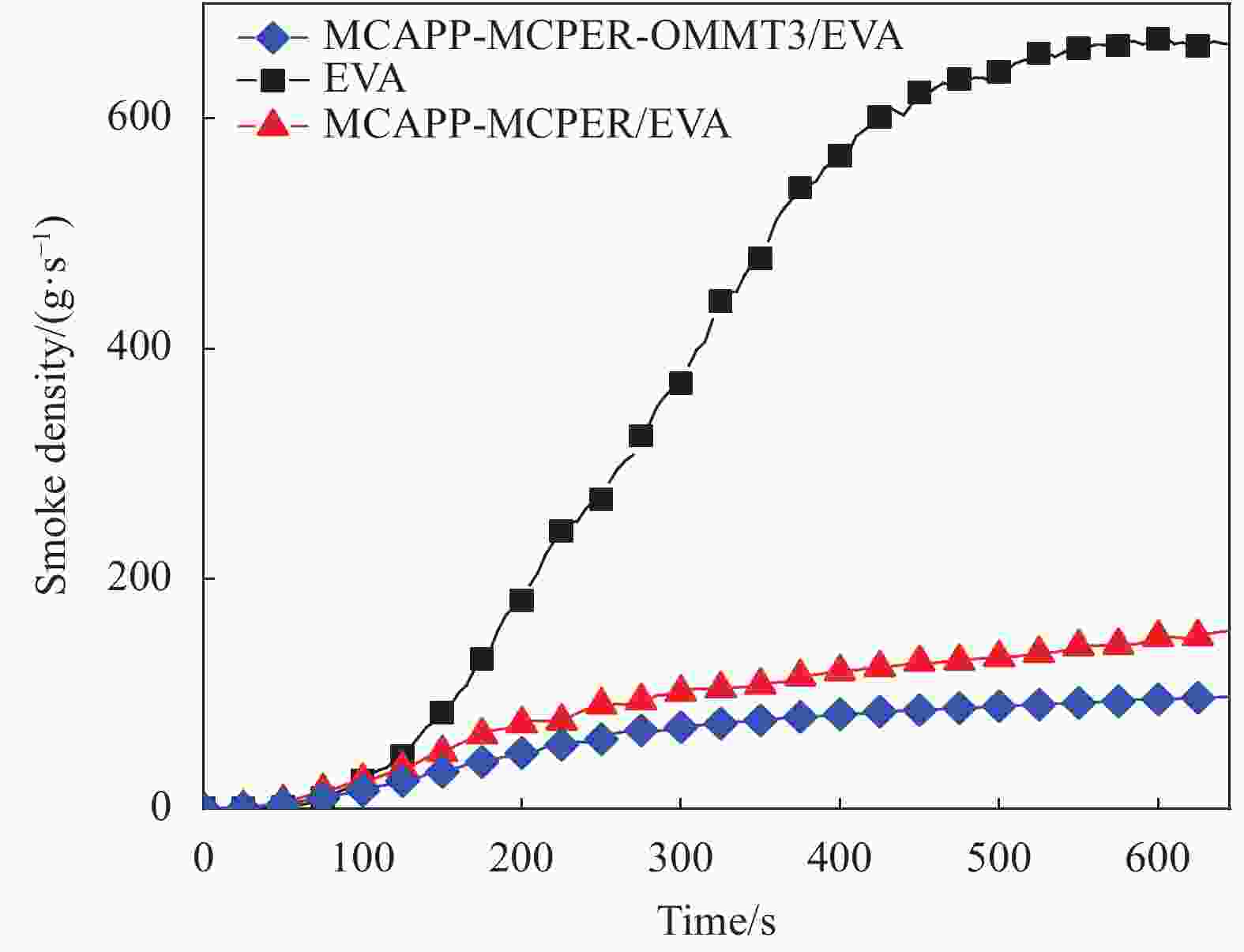

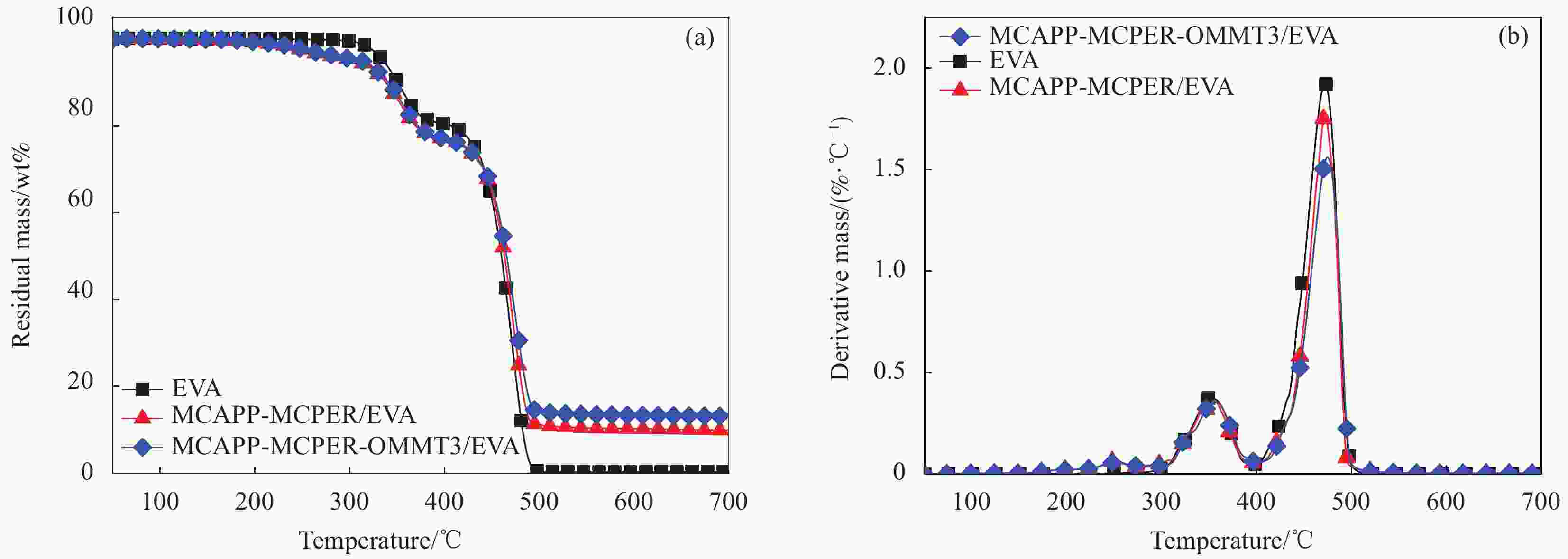

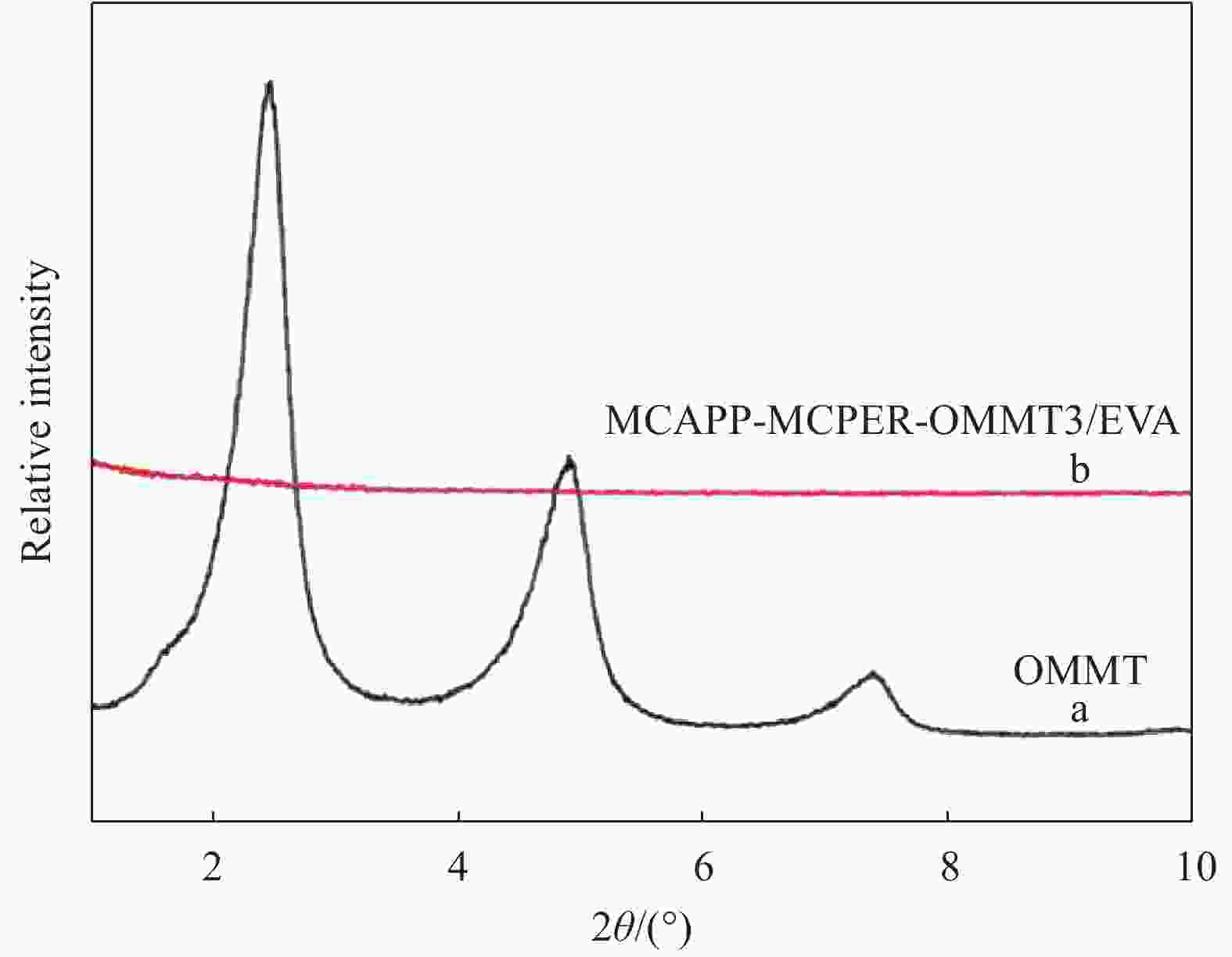

摘要: 通过纳米复合的方式,将微胶囊化的膨胀型阻燃体系—聚磷酸铵(APP)-季戊四醇(PER)与有机改性的片层蒙脱土(OMMT)用于协效阻燃乙烯-醋酸乙烯共聚物(EVA)。采用XRD、TEM、TGA、极限氧指数(LOI)、垂直燃烧(UL-94)、锥形量热仪、烟密度和动态机械热分析对微胶囊化APP(MCAPP)-微胶囊化PER(MCPER)-OMMT/EVA复合材料的结构与性能进行研究。研究结果表明,OMMT被完全剥离开,并以层离或插层的状态分散在EVA中;MCAPP-MCPER与OMMT之间存在明显的协效阻燃作用,用3wt%OMMT代替MCAPP-MCPER后,MCAPP-MCPER-OMMT/EVA复合材料的LOI值从25.5vol%提高到29.5vol%,垂直燃烧结果由V-2上升到V-0级别,残炭量也由14.5wt%增大到15.9wt%,烟密度由154.7 g/s降低到97.5 g/s,材料的阻燃性能得到有效提高。此外,万能拉伸测试及动态机械热分析测试表明,通过纳米复合制备的阻燃MCAPP-MCPER-OMMT/EVA复合材料具有更好的力学和动态热机械性能。Abstract: Flame retardant ethylene-vinyl acetate (EVA) composites were prepared by combination of microencapsulated intumescent flame retardants-ammonium polyphosphate (APP)-pentaerythritol (PER) and organically modified montmorillonite (OMMT). The microencapsulated APP (MCAPP)-microencapsulated PER (MCPER)-OMMT/EVA composites were further characterized through XRD and TEM, confirming OMMT sheets are well dispersed in the matrix as exfoliated or intercalated nanocomposite state. Limiting oxygen index (LOI), TGA, underwriters laboratories 94 vertical burning (UL-94), cone and smoke density test results indicate the synergistic flame retardancy effect between MCAPP-MCPER and OMMT in MCAPP-MCPER-OMMT/EVA composites. Replacing the same amount of MCAPP-MCPER with 3wt% OMMT could improve the LOI value of the MCAPP-MCPER-OMMT/EVA composites from 25.5vol% to 29.5vol%. The UL-94 rating increases from V-2 to V-0. The char residue of MCAPP-MCPER-OMMT/EVA composites is improved from 14.5wt% to 15.9wt% and the smoke density significantly decreases from 154.7 g/s to 97.5 g/s. Besides, the mechanical property of MCAPP-MCPER-OMMT/EVA composites was tested by universal testing machine and dynamic thermomechanical analysis (DMA), the result shows that the flame-retardant MCAPP-MCPER-OMMT/EVA composites has better mechanical properties.

-

表 1 微胶囊化聚磷酸铵(MCAPP)-微胶囊化季戊四醇(MCPER)-有机蒙脱土(OMMT)/乙烯-醋酸乙烯共聚物(EVA)阻燃复合材料的配方及其相应的阻燃测试结果

Table 1. Formulations and flame retardant test results of microencapsulated ammonium polyphosphate (MCAPP)-microencapsulated pentaerythritol (MCPER)-organically modified montmorillonite (OMMT)/ethylene-vinyl acetate (EVA) composites

Sample EVA/wt% MCAPP/wt% MCPER/wt% OMMT/wt% LOI/% UL-94 EVA 100 0 0 0 17.0 NR MCAPP-MCPER/EVA 75 16.67 8.33 0 25.5 V-2 MCAPP-MCPER-OMMT0.5/EVA 75 16.33 8.17 0.5 26.0 V-2 MCAPP-MCPER-OMMT1/EVA 75 16.00 8.01 1.0 26.5 V-2 MCAPP-MCPER-OMMT1.5/EVA 75 15.67 7.83 1.5 27.5 V-2 MCAPP-MCPER-OMMT2/EVA 75 15.33 7.67 2.0 28.0 V-0 MCAPP-MCPER-OMMT3/EVA 75 14.67 7.33 3.0 29.5 V-0 MCAPP-MCPER-OMMT5/EVA 75 13.33 6.67 5.0 26.5 NR Notes: LOI—Limiting oxygen index; UL-94—Underwriters laboratories 94 vertical burning; NR—No rating. 表 2 MCAPP-MCPER-OMMT/EVA复合材料的锥形量热仪测试数据

Table 2. Cone data of MCAPP-MCPER-OMMT/EVA composites

Sample TTI/s Tp/s PHRR/(kW·m−2) THR/(MJ·m−2) Average HRR/(kW·m−2) Residues/wt% EVA 48 145 1 503.31 89.90 495.4 0.2 MCAPP-MCPER/EVA 24 280 298.95 81.33 188.6 14.5 MCAPP-MCPER-OMMT3/EVA 15 100 192.16 73.52 138.4 15.9 Notes: TTI—Time to ignition; PHRR—Peak of heat release rate; Tp—Time to PHRR; THR—Total heat release; Average HRR—Average heat release rate. 表 3 MCAPP-MCPER-OMMT/EVA复合材料的TGA数据

Table 3. TGA data of MCAPP-MCPER-OMMT/EVA composites

Sample T−5wt%/℃ T1max/℃ T2max/℃ Residues at 700℃/wt% EVA 335.6 350.0 471.9 0.4 MCAPP-MCPER/EVA 304.8 355.7 472.6 9.9 MCAPP-MCPER-OMMT3/EVA 311.9 356.7 474.5 13.1 Notes: T−5wt%—Onset degradation temperature; T1max and T2max—Maximum decomposition temperature in the first and second stage. 表 4 MCAPP-MCPER-OMMT/EVA复合材料的力学性能

Table 4. Mechanical properties of MCAPP-MCPER-OMMT/EVA composites

Sample Tensile strength/MPa Elongation at break/% EVA 18.6±1.5 889.3±39 MCAPP-MCPER/EVA 8.1±0.7 731.0±30 MCAPP-MCPER-OMMT3/EVA 11.0±0.9 780.8±35 -

[1] XIAO N Y, ZHANG X Q, MA X Y, et al. Construction of EVA/chitosan based PEG-PCL micelles nanocomposite films with controlled release of iprodione and its application in pre-harvest treatment of grapes[J]. Food Chemistry,2020,331:127-277. [2] CHAI F, WANG G, LIU F, et al. Preparation and properties of flame-retardant neutron shielding material based on EVA polymer reinforced by radiation modification[J]. Radiation Physics and Chemistry,2020,174:108984. [3] 陈志杰, 郑玉婴, 张延兵, 等. 无卤阻燃乙烯-醋酸乙烯酯共聚物泡沫复合材料的制备及性能表征[J]. 复合材料学报, 2015, 32(3):649-656.CHEN Zhijie, ZHENG Yuying, ZHANG Yanbing, et al. Preparation and property characterization of halogen-free fire retardant ethylene-vinyl acetate copolymer foam compo-sites[J]. Acta Materiae Compositae Sinica,2015,32(3):649-656(in Chinese). [4] 刘继纯, 李行, 贺云鹏, 等. 纳米Mg(OH)2微胶囊红磷/乙烯-乙酸乙烯酯共聚物阻燃复合材料的性能[J]. 复合材料学报, 2019, 36(11):2530-2540.LIU Jichun, LI Xing, HE Yunpeng, et al. Properties of nano Mg(OH)2-microencapsulated red phosphorus/ethylene-vinyl acetate copolymer flame-retardant composites[J]. Acta Materiae Compositae Sinica,2019,36(11):2530-2540(in Chinese). [5] WANG X, BI B, LIU J, et al. Halogen-free intumescent flame-retardant ethylene-vinyl acetate copolymer system based on organic montmorillonite and graphene nanosheets[J]. Journal of Applied Polymer Science,2018,135(23):46361. [6] XIE F, WANG Y Z. A novel intumescent flame-retardant polyete system[J]. Macromolecular Materials and Enginneering,2006,291(3):247-253. doi: 10.1002/mame.200500356 [7] XU Z, CHU Z, YAN L, et al. Effect of chicken eggshell on the flame-retardant and smoke suppression properties of an epoxy-based traditional APP-PER-MEL system[J]. Polymer Composites,2019,40(7):2712-2723. doi: 10.1002/pc.25077 [8] WANG B, SHENG H, SHI Y, et al. Recent advances for microencapsulation of flame retardant[J]. Polymer Degradation and Stability,2015,113:96-109. doi: 10.1016/j.polymdegradstab.2015.01.008 [9] WANG Q, LI W, ZHANG L, et al. Enhanced flame retardancy and mechanical properties of intumescent flame-retardant polypropylene with triazine derivative-modified nano-SiO2[J]. Polymer Science Series B,2020,62(3):306-318. [10] CHEN B, GAO W, SHEN J, et al. The multilayered distribution of intumescent flame retardants and its influence on the fire and mechanical properties of polypropylene[J]. Composites Science and Technology,2014,93:54-60. doi: 10.1016/j.compscitech.2013.12.022 [11] LI X L, ZHANG F H, JIAN R K, et al. Influence of eco-friendly calcium gluconate on the intumescent flame-retardant epoxy resin: Flame retardancy, smoke suppression and mechanical properties[J]. Composites Part B: Engineering,2019,176:107200. doi: 10.1016/j.compositesb.2019.107200 [12] CHEN J, WANG J, CHEN H, et al. Synergistic effect of intumescent flame retardant and attapulgite on mechanical properties and flame retardancy of glass fibre reinforced polyethylene composites[J]. Composite Structures,2020:246. [13] ZHENG Z, LIU Y, DAI B, et al. Synergistic effect of organically modified zinc aluminum layered double hydroxide in intumescent flame-retarding polypropylene composites containing melamine phytate and dipentaerythritol[J]. Polymer Engineering and Science,2019,59:2301-2312. doi: 10.1002/pen.25233 [14] QIAN W, LIA X Z, ZHOU J, et al. High synergistic effects of natural-based tea saponin in intumescent flameretardant coatings for enhancement of flame retardancy and pyrolysis performance[J]. Progress in Organic Coatings,2019,127:408-418. doi: 10.1016/j.porgcoat.2018.10.031 [15] LAI X J, ZENG X G, LI H Q, et al. Synergistic effect of phosphorus-containing nanosponges on intumescent flame-retardant polypropylene[J]. Journal of Applied Polymer Science,2012,125:1758-1765. doi: 10.1002/app.35646 [16] 程博, 李定华, 吴凡, 等. 不同蒙脱土Al(OH)3/乙烯-醋酸乙烯酯复合材料力学性能和阻燃性能的影响[J]. 复合材料学报, 2017, 34(12):2715-2721.CHENG Bo, LI Dinghua, WU Fan, et al. Effect of montmorillonite type on mechanical and flame retarded properties of Al(OH)3/ethylene vinyl acetate copolymer composites[J]. Acta Materiae Compositae Sinica,2017,34(12):2715-2721(in Chinese). [17] TANG Q B, WANG B B, TANG G, et al. Preparation of microcapsulated ammonium polyphosphate, pentaerythritol with glycidyl methacrylate, butyl methacrylate and their synergistic flame- retardancy for ethylene vinyl acetate copolymer[J]. Polymers for Advanced Technologies,2014,25:73-82. doi: 10.1002/pat.3207 [18] 中国国家标准化管理委员会. 塑料燃烧性能的测定水平法和垂直法: GB/T 2408—2008[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic ofChina. Plastics: Determination of burning characteristics: Horizontal and vertical test: GB/T 2408—2008[S]. Beijing: China Standards Press, 2009(in Chinese). [19] American Society for Testing Material International. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index): ASTM D2863−19[S]. West Conshohocken: ASTM International, 2019. [20] International Organization for Standardization. Reaction-to-fire tests-Heat release, smoke production and mass loss rate-Part 5: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement) under reduced oxygen atmospheres: ISO/TS 5660-5:2020[S]. West Conshohocken: ASTM International, 2020. [21] International Organization for Standardization. Controlled equivalence ratio method for the determination of hazardous components of fire effluents-Steady-state tube furnace: ISO/TS 19700:2016[S]. West Conshohocken: ASTM International, 2016. [22] 吴发盛. 金属氧化物/蒙脱土对膨胀型阻燃聚丙烯复合物性能的研究[D]. 上海: 上海交通大学, 2009.WU Fasheng. Study on synergistic effects of metal oxides/organic-modified montmorillonite in an intumescent flame retardant polypropylene system[d]. Shanghai: Shanghai Jiao Tong University, 2009(in Chinese). [23] JENNY A, MERIMA P, ALBERTO F. Novel flame retardants containing cylodextrin nanosponges and phosphorus compounds to enhance EVA combustion properties[J]. Polymer Degradation Stability,2010,95:2093-2100. doi: 10.1016/j.polymdegradstab.2010.06.030 [24] PALACIOS J, PERERA R, ROSALES C, et al. Thermal degradation kinetics of PP/OMMT nanocomposites with mPE and EVA[J]. Polymer Degradation and Stability,2012,97(5):729-737. doi: 10.1016/j.polymdegradstab.2012.02.009 [25] CHEN X, LIU L, ZHUO J, et al. Influence of organic-modified iron-montmorillonite on smoke-suppression properties and combustion behavior of intumescent flame-retardant epoxy composites[J]. High Performance Polymers,2015,27(2):233-246. doi: 10.1177/0954008314544341 [26] FU M Z, QU B J. Synergistic flame retardant mechanism of fumed silica in ethylene-vinylacetate/magnesium hydroxide blends[J]. Polymer Degradation Stability,2004,85(1):633-639. doi: 10.1016/j.polymdegradstab.2004.03.002 [27] DUTTA S K, BHOWMICK A K, MUKUNDA P G. Thermal degradation studies of electron beam cured ethylene-vinyl acetate copolymer[J]. Polymer Degradation Stability,1995,50(1):75-82. doi: 10.1016/0141-3910(95)00125-6 [28] RAFIEE F, OTADI M, GOODARZI V, et al. Thermal and dynamic mechanical properties of PP/EVA nanocomposites containing organo-modified layered double hydroxides[J]. Composites Part B: Engineering,2016,103:122-130. doi: 10.1016/j.compositesb.2016.08.013 [29] STARK W, JAUNICH M. Investigation of ethylene/vinyl acetate copolymer (EVA) by thermal analysis DSC and DMA[J]. Polymer Testing,2011,30(2):236-242. doi: 10.1016/j.polymertesting.2010.12.003 [30] WANG B B, ZHOU K Q, WANG L, et al. Enhancement on physical properties of flame retarded ethylene-vinyl acetate copolymer/ferric pyrophosphate composites through electron beam irradiation[J]. Composites Part B: Engineering,2012,43:641-646. doi: 10.1016/j.compositesb.2011.08.027 -

下载:

下载: