Effects of interfacial layer properties on elastic properties of graphene/epoxy composites based on isoparametric graded element

-

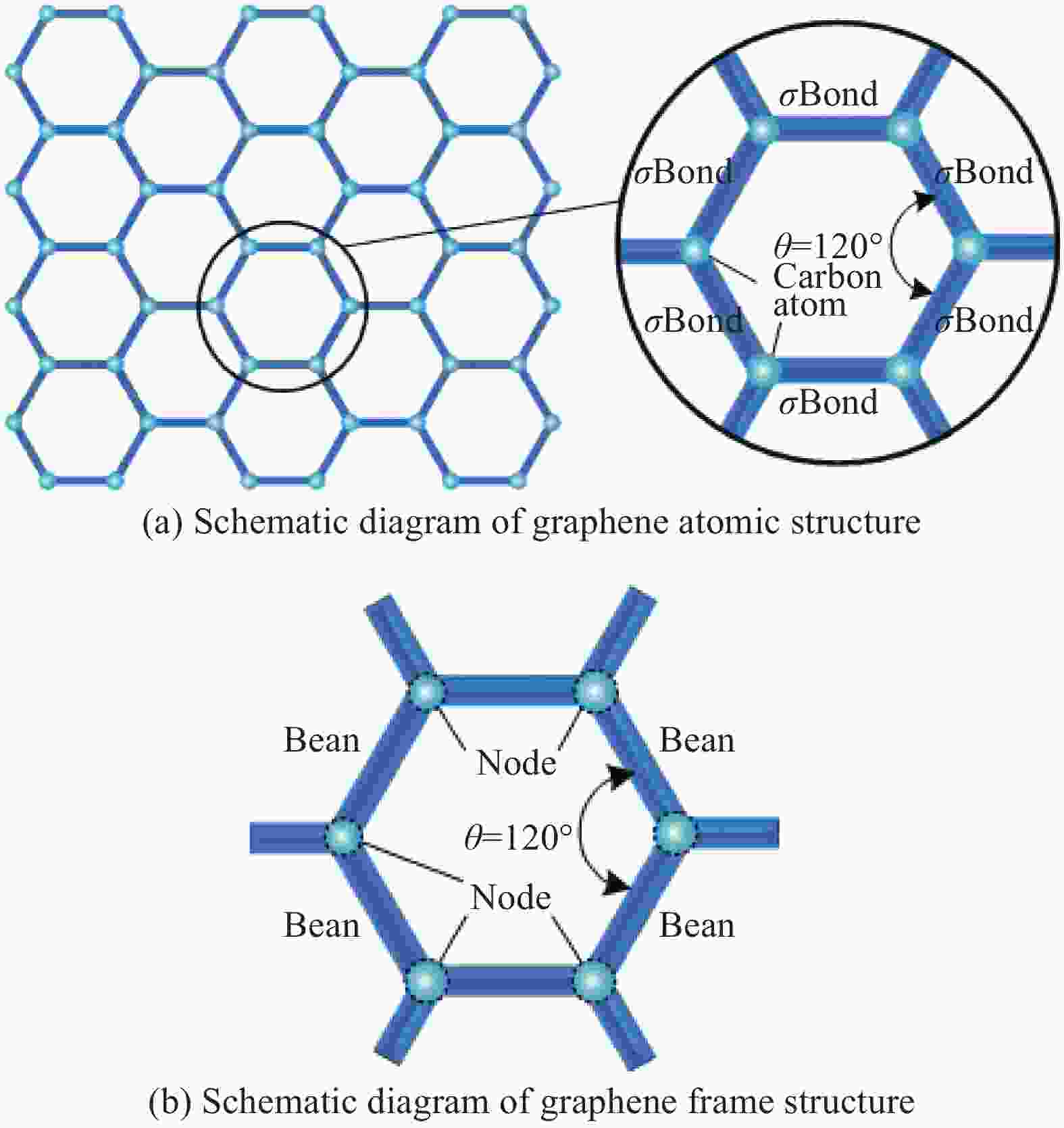

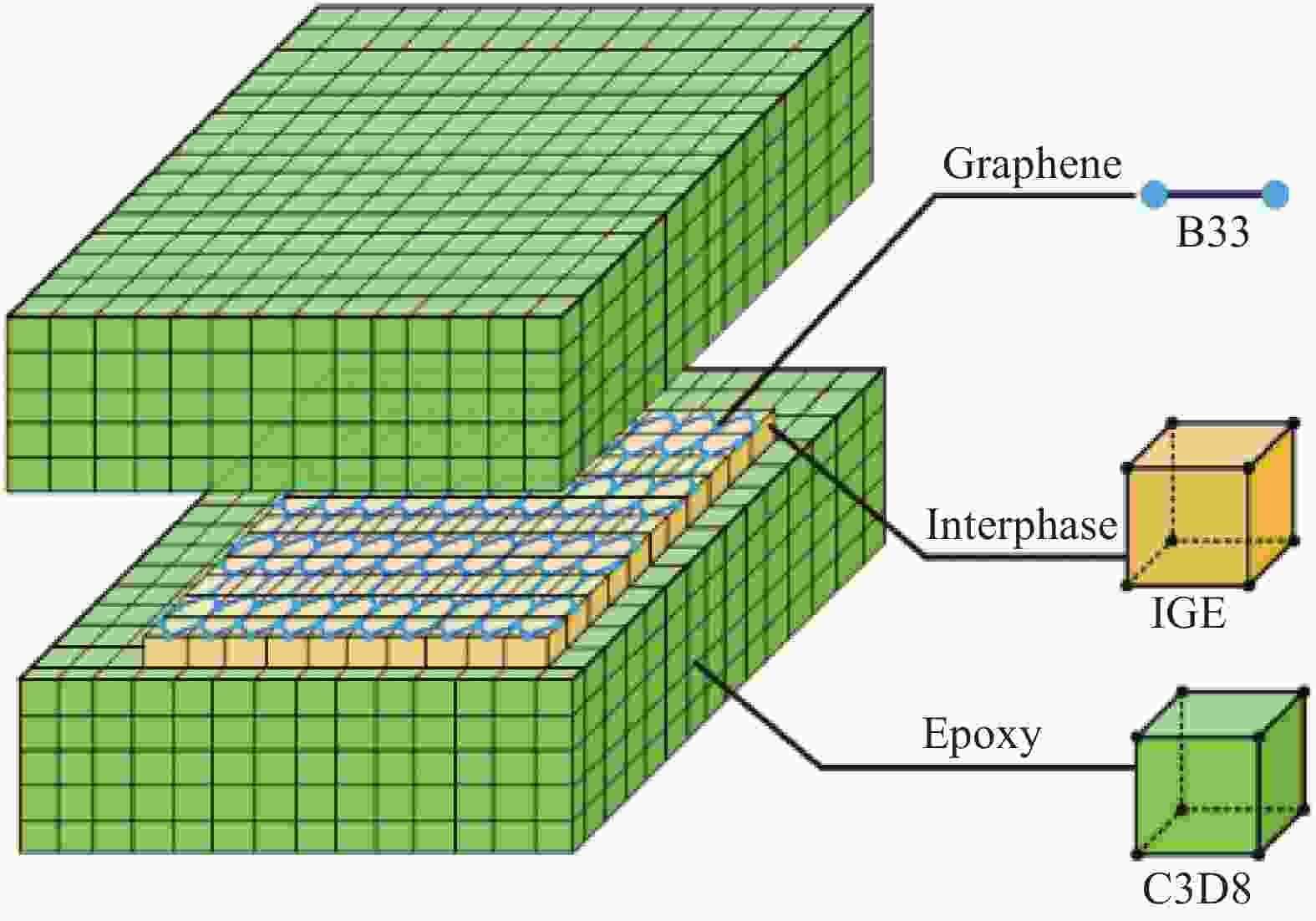

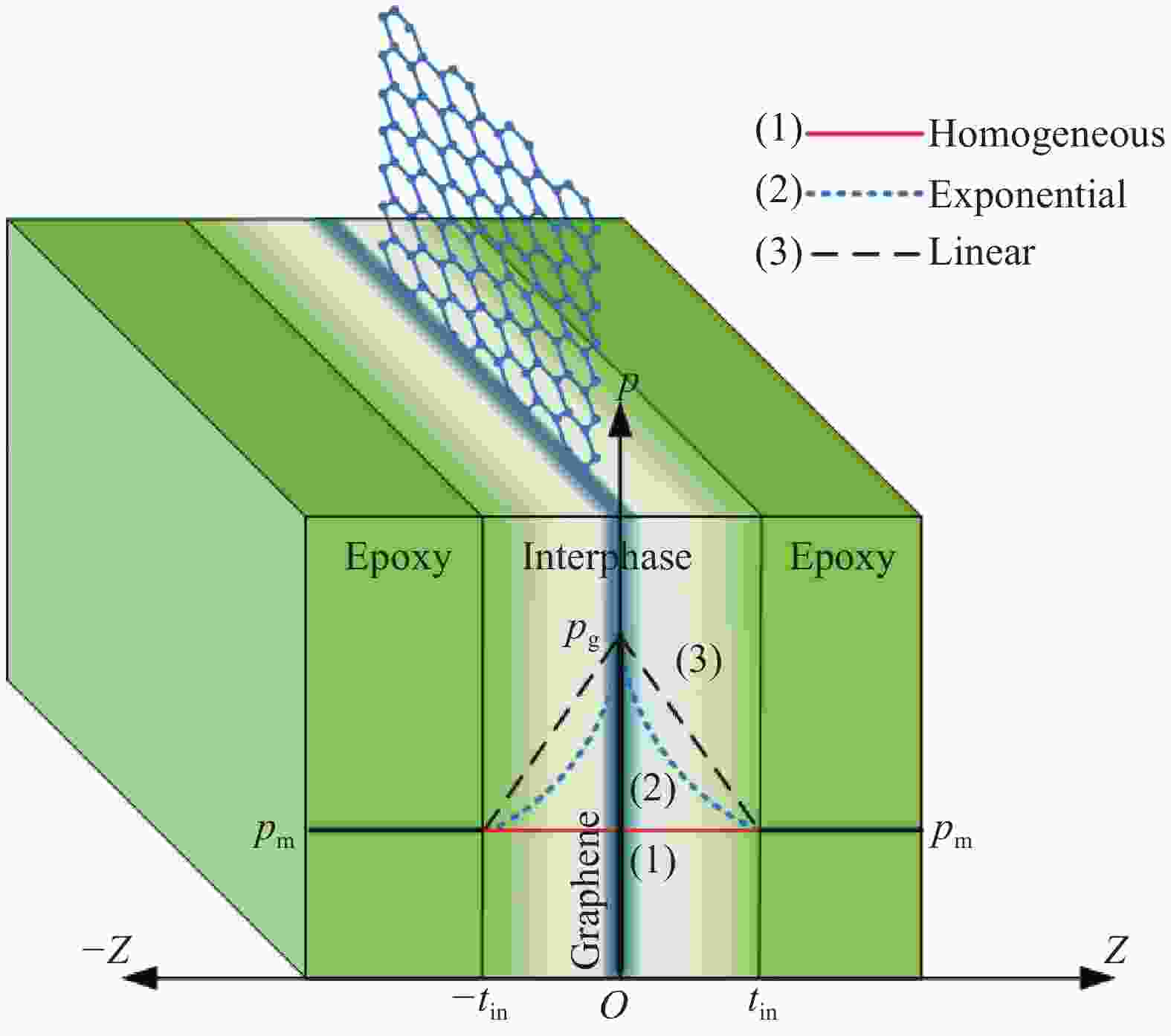

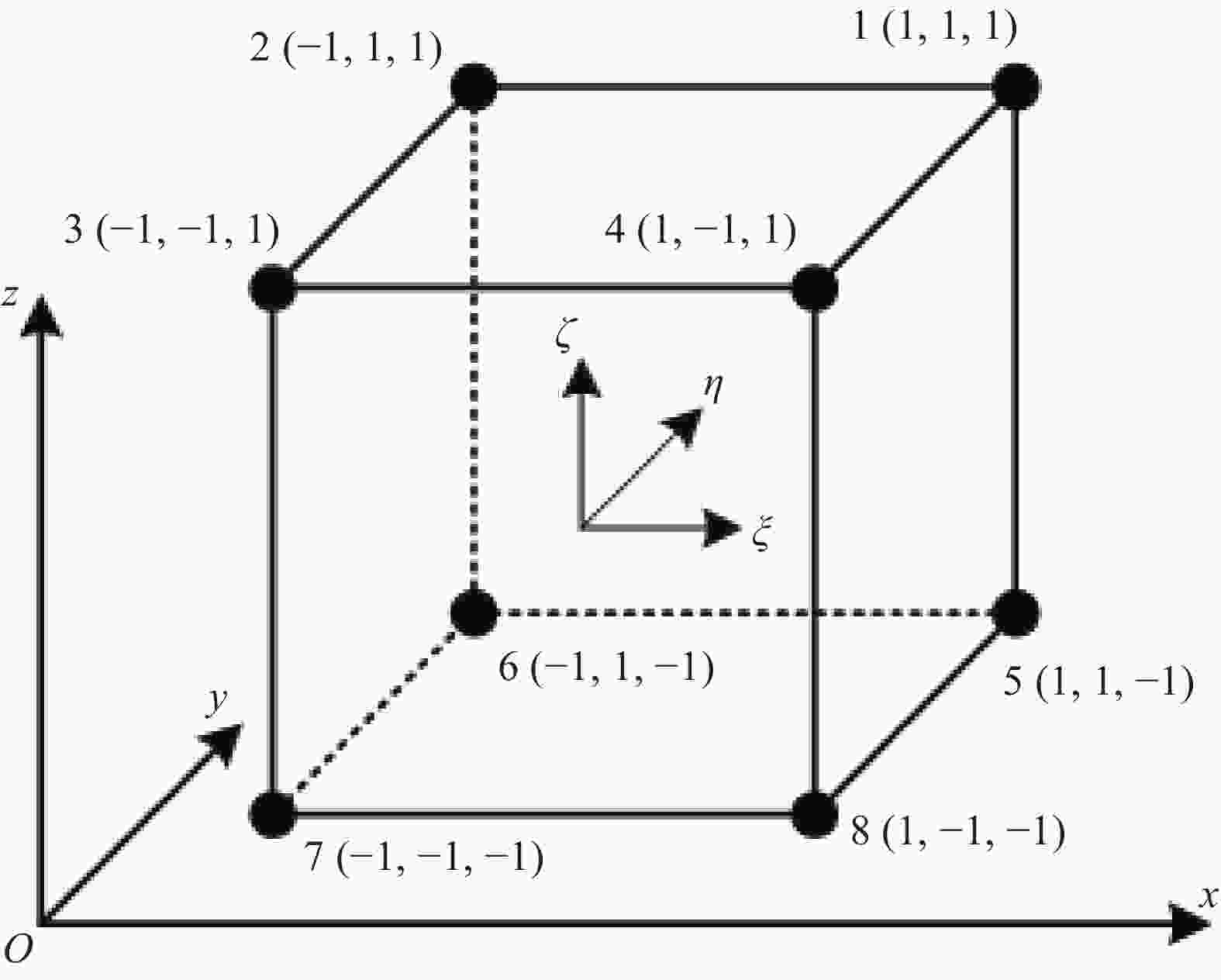

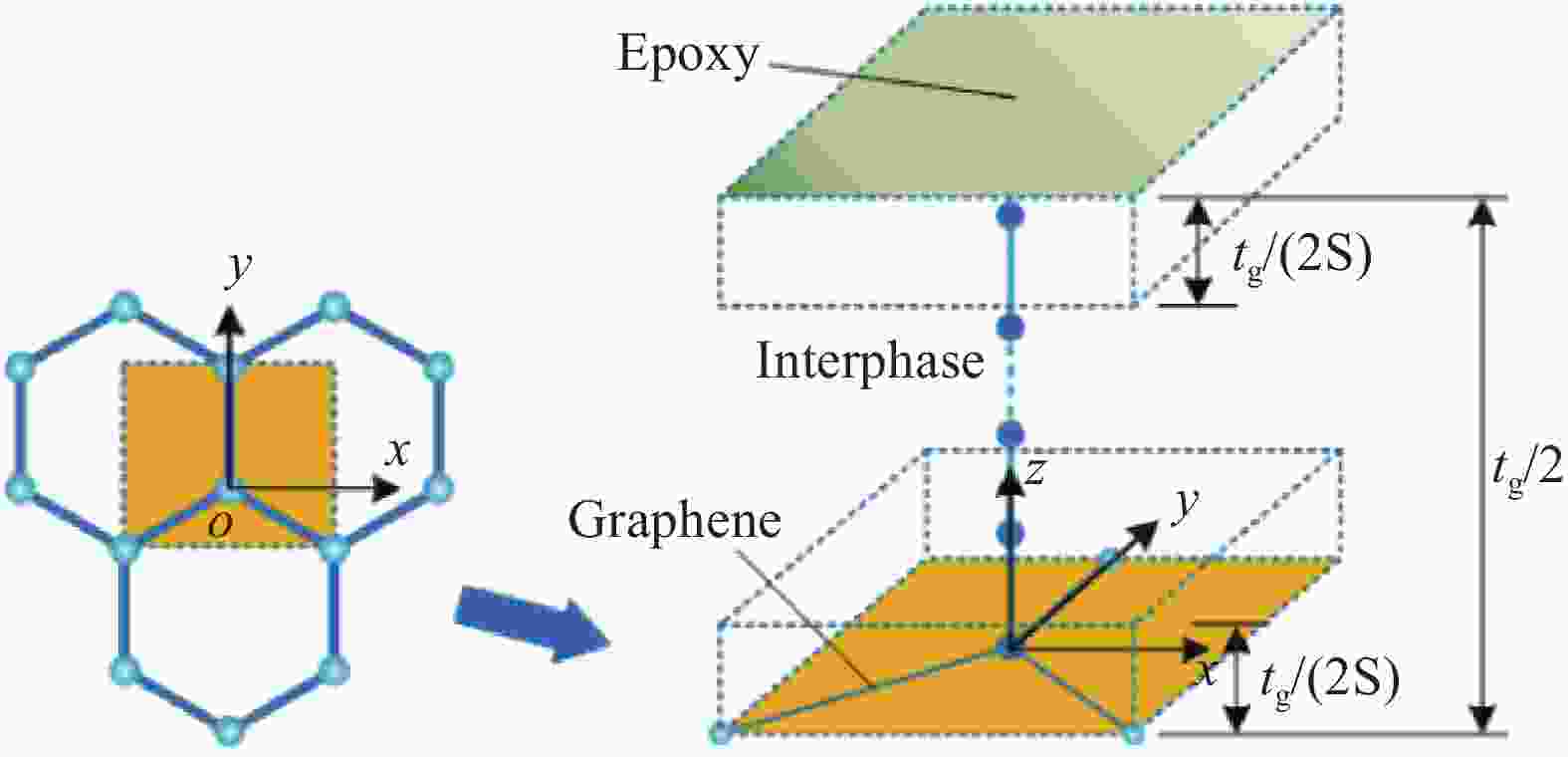

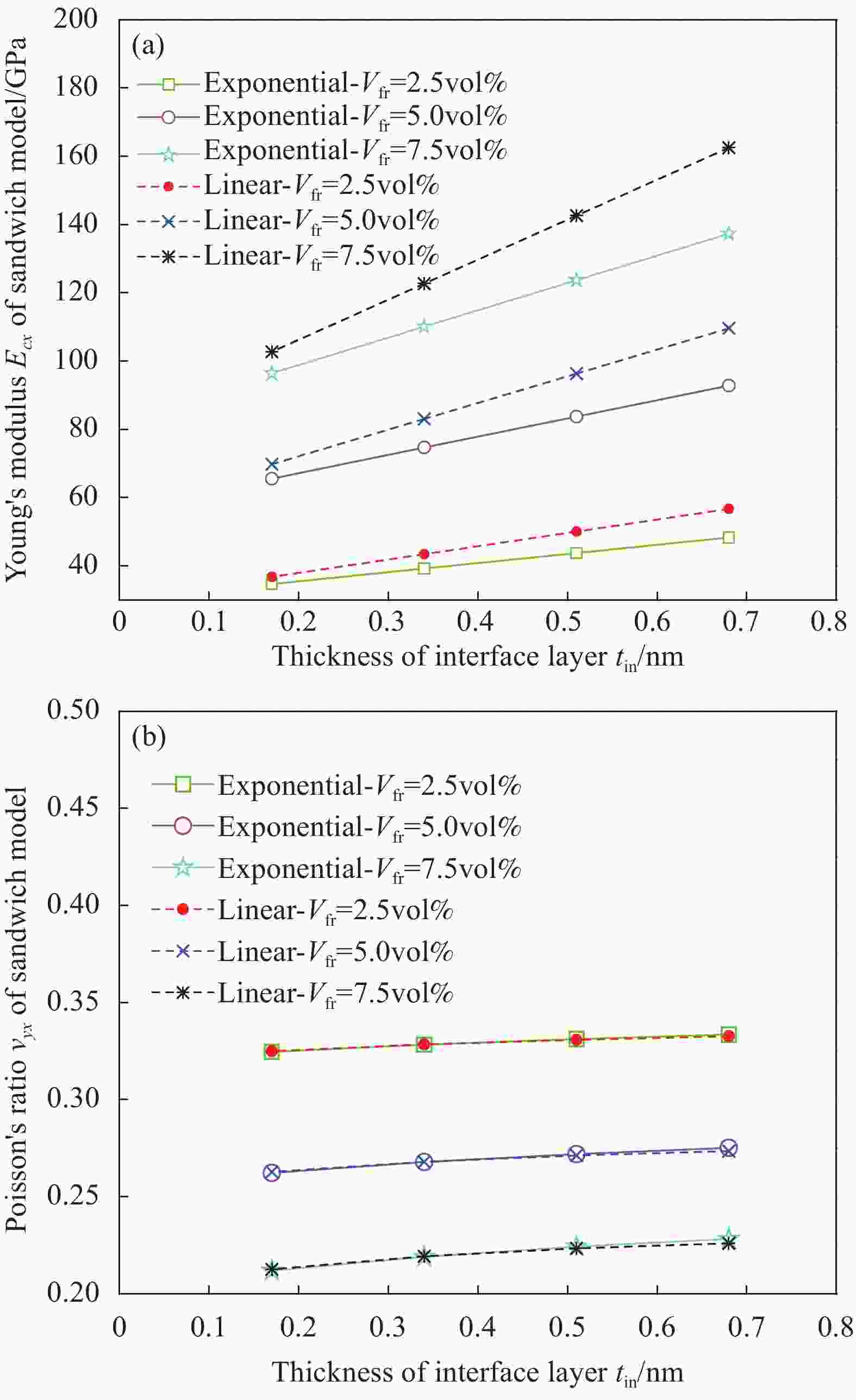

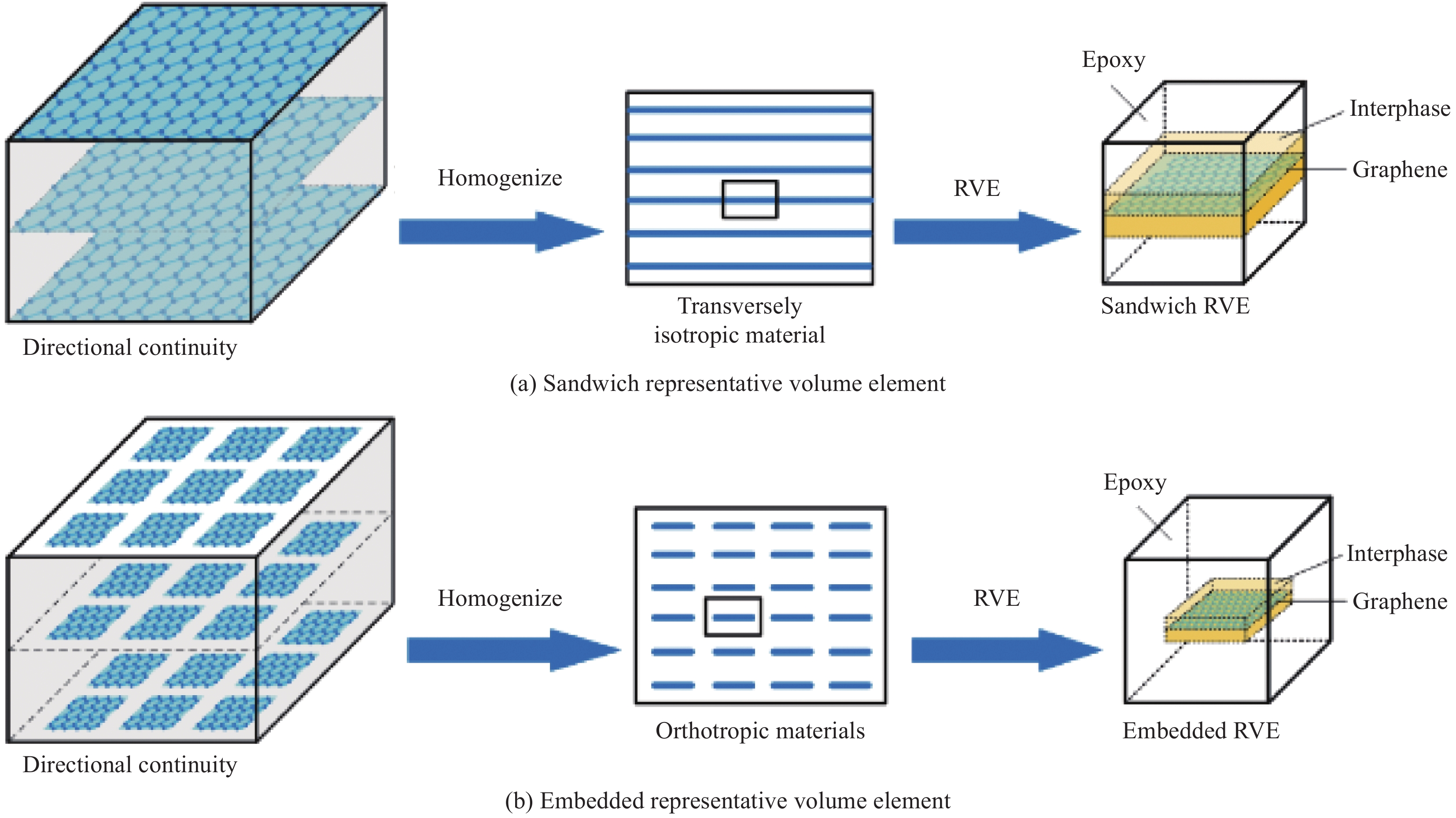

摘要: 针对石墨烯片在环氧树脂基体内定向连续和定向非连续分布的复合材料,通过分别构建三明治代表体单元和嵌入式代表体单元,进行了弹性性能预测的研究。代表体单元是三相复合结构,其中石墨烯和环氧树脂基体之间的界面层视为连续介质,其材料属性分别考虑均匀、线性和指数变化等3种情况。在代表体单元的有限元建模过程中,石墨烯和环氧树脂基体分别采用梁单元和实体单元进行离散,而界面层则采用等参梯度单元逼近。采用有限元软件ABAQUS 分析了小应变下的代表体单元的力学变形行为并提取其弹性性能,然后分析了界面层属性对石墨烯/环氧树脂复合材料弹性性能的影响。通过与混合率模型、修正的Halpin-Tsai模型及实验数据对比,验证了本文提出的基于等参梯度单元计算方法的有效性。数值算例表明,在处理界面层材料属性不均匀分布的问题方面,等参梯度单元具有计算量少、收敛快和精度高的优点。石墨烯/环氧树脂复合材料杨氏模量预测结果显示,界面层材料属性采用梯度变化的模型时,杨氏模量计算结果比均匀分布的模型、混合率模型和修正的Halpin-Tsai模型的结果偏大,但是更接近实验值。本文的研究结果说明界面层属性是影响复合材料力学性能的重要因素,并为寻求复合材料力学性能更精确地分析提供有效的途径。Abstract: The elastic properties of the composites with graphene sheets distributed continuously and discontinuously in the epoxy matrix were investigated via sandwich representative volume element (RVE) and embedded RVE, respectively. The RVEs were considered as a three phase composite structure, in which the interphase between graphene and epoxy resin matrix was treated as continuum medium while its material properties were considered to vary uniformly, linearly and exponentially. In the finite element modeling process of the RVE, the graphene was discretized using beam element and the epoxy matrix was discretized via the use of solid element while the interfacial layer was approached using isoparametric graded element (IGE). The finite element software ABAQUS was used to analyze the mechanical deformation behavior of the RVE subjected to small strains and extract its elastic properties. The extracted results of elastic properties were then used to study the effects of interfacial layer properties on the elastic properties of graphene/epoxy composites. The validity of the proposed computational method based on the IGE was verified by comparing with rule of mixture (ROM), the modified Halpin-Tsai model and the experimental data. Numerical examples illustrate that the IGE has the advantages of less computation, fast convergence and high accuracy in dealing with the uneven distribution of material properties in the interfacial layer. The prediction results of Young's modulus of composites reveal that when the material properties of interfacial layer adopt the gradient model, the calculated results of Young's modulus are larger than those of uniform distribution model, ROM and the modified Halpin-Tsai model, but closer to the experimental value. The results of this research show that the property of interfacial layer is an important factor affecting the mechanical properties of composites, and provide an effective way to seek more accurate analysis of the mechanical properties of composites.

-

Key words:

- isoparametric graded element /

- interfacial properties /

- graphene /

- composites /

- elastic properties /

- epoxy

-

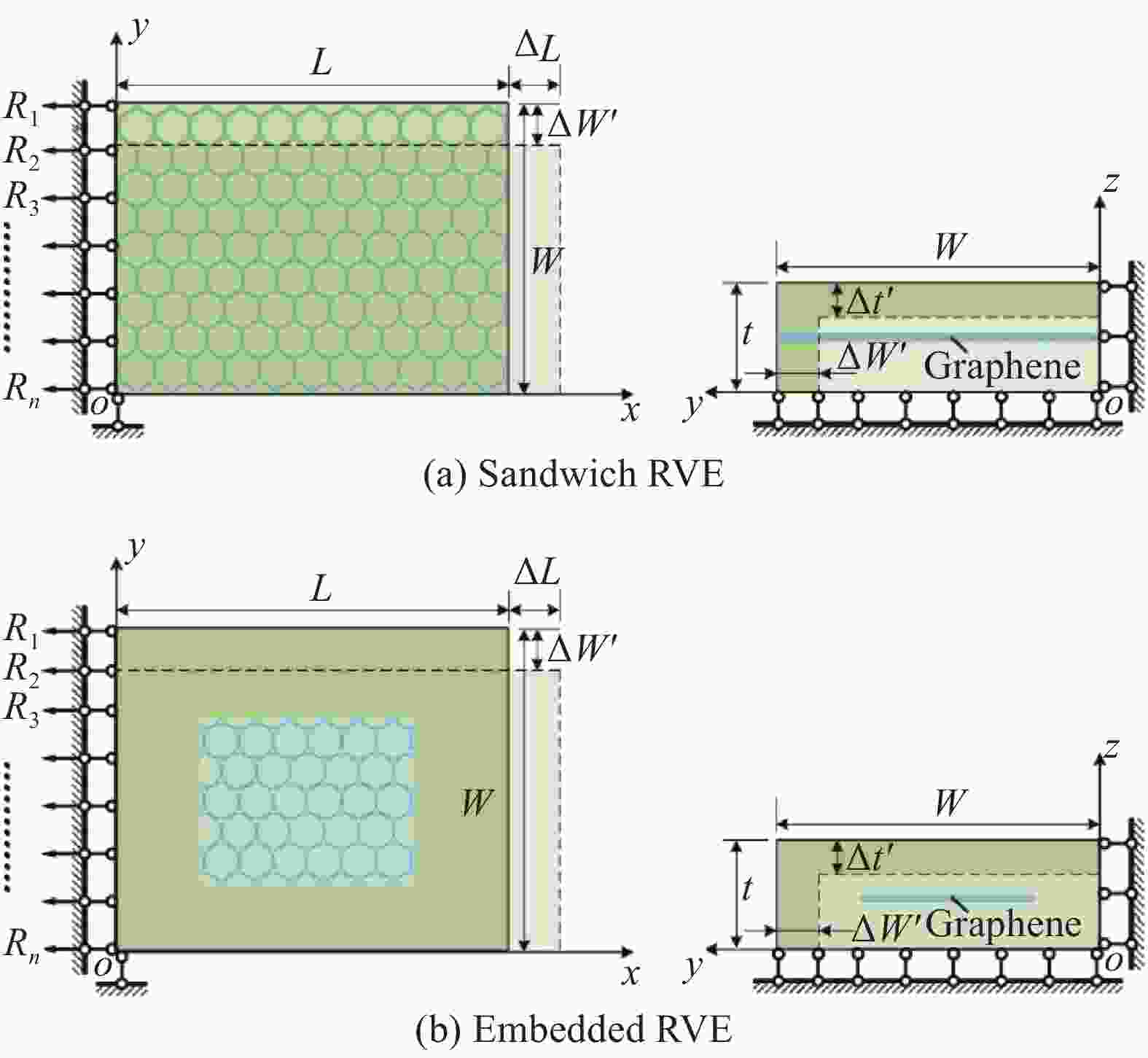

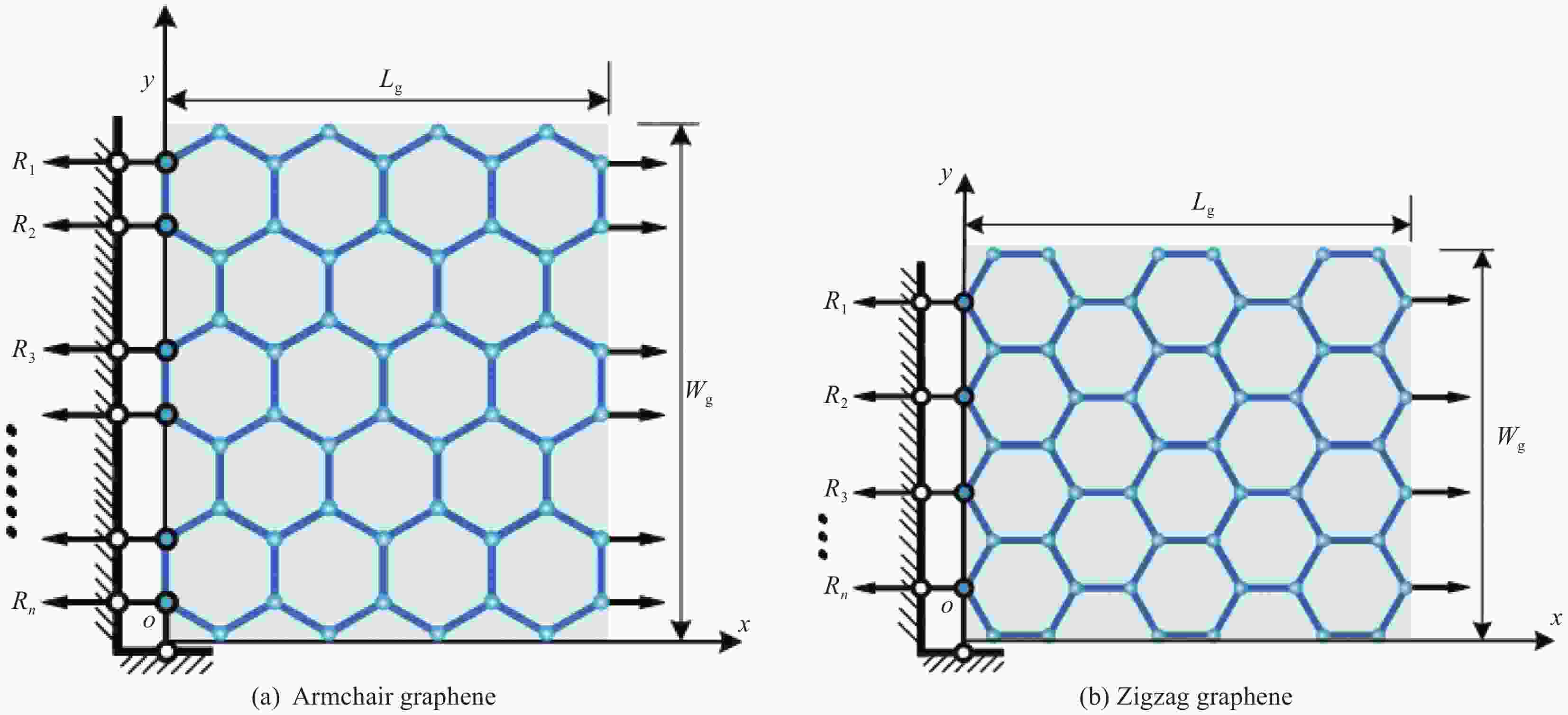

图 2 两种石墨烯/环氧树脂复合材料RVE的尺寸示意图

Figure 2. Dimension diagram of two RVE of graphene/epoxy composites

L—Length of the RVE; W—Width of the RVE; t—Thickness of RVE; Lg—Length of graphene sheet; Wg—Width of the graphene sheet; tm—Single layer thickness of substrate; tin—Unilateral thickness of the interfacial layer; t'—Distance between the outer boundary of graphene sheet in each direction and the outer surface of RVE in embedded RVE

图 3 石墨烯/环氧树脂复合材料模型单向拉伸受力图

Figure 3. Force diagram of model of graphene/epoxy composites under uniaxial tension

Rn—Support reaction in x direction of each node; ΔL—Displacement in x direction of surface, x=L; ΔW'—Displacement in y direction of surface, y=W; Δt'—Displacement in z direction of surface, z=t

表 1 分子力学常数

Table 1. Molecular mechanics constants

Stretching

constant

kr/(N·nm−1)Bond angle

bending constant

kθ/(N·nm·rad−2)Torsion

constant

kτ/(N·nm·rad−2)6.52×10−7 8.76×10−10 2.78×10−10 表 2 材料参数和几何参数

Table 2. Material and geometric parameters

Length of

beam

l/nmDiameter

d/nmSectional

area

A/nm2Young’s modulus

of beam

E/GPaShear

modulus

G/GPaMoment of

inertia

I/nm4Polar moment

of inertia

J/nm4Young’s modulus

of epoxy

Em/GPaPoisson’s ratio

of epoxy

νm0.1421 0.1466 0.01688 5487.5 7627.6 2.267×10−5 4.534×10−5 3.8 0.4 表 3 石墨烯片杨氏模量和泊松比计算结果

Table 3. Calculation results of Young's modulus and Poisson's ratio of graphene sheet

Size of graphene/(nm×nm) Armchair Zigzag Young’s modulus Eg/GPa Poisson’s ratio νg Young’s modulus Eg/GPa Poisson’s ratio νg 1×1 1106.811 0.133 999.142 0.119 2×2 1084.729 0.096 1020.232 0.089 3×3 1073.213 0.083 1027.222 0.079 4×4 1062.424 0.077 1030.972 0.074 5×5 1059.296 0.073 1032.965 0.071 6×6 1056.941 0.071 1034.302 0.069 7×7 1053.812 0.069 1035.346 0.068 8×8 1052.836 0.068 1036.168 0.067 9×9 1051.802 0.067 1036.693 0.066 10×10 1050.294 0.066 1037.156 0.065 20×20 1045.813 0.063 1039.111 0.062 50×50 1042.975 0.061 1040.307 0.061 100×100 1042.042 0.060 1040.702 0.060 表 4 界面层属性呈线性分布情况时不同体积含量的石墨烯/环氧树脂三明治模型的杨氏模量

Table 4. Young's modulus of graphene/epoxy sandwich model with different volume fractions under linear distribution of interfacial properties

Volume

fraction

Vfr/vol%Number of layers in single side interface 1 2 3 4 Young’s modulus Ecx/GPa — Young’s modulus Ecx/GPa ${\varDelta _1}$/% Young’s modulus Ecx/GPa ${\varDelta _2}$/% Young’s modulus Ecx/GPa ${\varDelta _3}$/% 2.5 43.596 — 43.441 0.357 43.408 0.076 43.395 0.030 5.0 83.389 — 83.079 0.373 83.012 0.081 82.987 0.030 7.5 123.172 — 122.707 0.379 122.606 0.082 122.569 0.030 10.0 162.936 — 162.315 0.383 162.180 0.083 162.130 0.031 Note: Δi(i=1,2.3)—Deviation of Young's modulus when the interface is divided into i and i+1 layer. 表 5 界面层属性呈指数分布情况时不同体积含量的石墨烯/环氧树脂三明治模型的杨氏模量

Table 5. Young's modulus of graphene/epoxy sandwich model with different volume fractions under exponential distribution of interfacial properties

Volume

fraction

Vfr/vol%Number of layers in single side interface 1 2 3 4 Ecx/GPa — Ecx/GPa ${\varDelta _1}$/% Ecx/GPa ${\varDelta _2}$/% Ecx/GPa ${\varDelta _3}$/% 2.5 43.595 — 39.238 11.104 38.373 2.254 38.064 0.811 5.0 83.387 — 74.673 11.670 72.942 2.373 72.324 0.854 7.5 123.170 — 110.098 11.873 107.501 2.416 106.575 0.869 10.0 162.935 — 145.502 11.981 142.040 2.437 140.804 0.878 表 6 等参梯度单元与分层法的计算量对比

Table 6. Comparison of computational cost between isoparametric graded element and layering method

表 7 不同体积含量和尺寸情况下石墨烯/环氧树脂嵌入式模型的杨氏模量

Table 7. Young’s modulus of graphene/epoxy embedded model with different volume contents and sizes

Volume

fraction/

vol%Size of graphene/(nm×nm) 1×1 5×5 10×10 Ecx/GPa Deviation Ecx/GPa Deviation Ecx/GPa Deviation H-T equation Present study H-T equation Present study H-T equation Present study 2.5 4.085 4.053 −0.80% 4.812 4.733 −1.65% 5.665 5.593 −1.27% 5.0 4.386 4.290 −2.19% 5.876 5.777 −1.68% 7.621 7.503 −1.54% 7.5 4.702 4.546 −3.32% 6.994 6.878 −1.66% 9.674 9.531 −1.48% 10.0 5.036 4.882 −3.06% 8.173 8.030 −1.75% 11.833 11.628 −1.73% 表 8 体积含量为1.12vol%的石墨烯/环氧树脂嵌入式模型归一化杨氏模量值与实验值对比(Ecx/Em)

Table 8. Comparison of the normalized Young's modulus of 1.12vol% graphene/epoxy embedded model with the experimental result (Ecx/Em)

-

[1] JIANG J W, LENG J T, LI J X, et al. Twin graphene: A novel two-dimensional semiconducting carbon allotrope[J]. Carbon,2017,118:370-375. doi: 10.1016/j.carbon.2017.03.067 [2] 高锋, 白刚, 肖伟, 等. 石墨烯微片/氰酸酯多功能树脂基体研究[J]. 玻璃钢/复合材料, 2019(5):83-88.GAO Feng, BAI Gang, XIAO Wei, et al. Study on multifunctional GNPs/cyanate ester resin matrix[J]. Fiber Reinforced Plastics/Composties,2019(5):83-88(in Chinese). [3] LIAO K, LI S. Interfacial characteristics of a carbon nanotube-polystyrene composite system[J]. Applied Physics Letters,2001,79(25):4225-4227. doi: 10.1063/1.1428116 [4] GOU J H, LIANG Z Y, ZHANG C, et al. Computational analysis of effect of singlewalled carbon nanotube rope on molecular interaction and load transfer of nanocomposites[J]. Composites Part B: Engineering,2005,36(6-7):524-533. doi: 10.1016/j.compositesb.2005.02.004 [5] SHOKRIEH M M, RAFIEE R. On the tensile behavior of an embedded carbon nanotube in polymer matrix with non-bonded interphase region[J]. Composite Structures,2010,92(3):647-652. doi: 10.1016/j.compstruct.2009.09.033 [6] GIANNOPOULOS G I, GEORGANTZINOS S K, KATSAREAS D E, et al. Numerical prediction of Young’s and shear moduli of carbon nanotube composites incorporating nanoscale and interfacial effects[J]. Computer Modeling in Engineering and Sciences,2010,56(3):231-248. [7] ZHAO Z, TENG K, LI N, et al. Mechanical, thermal and interfacial performances of carbon fiber reinforced compo-sites flavored by carbon nanotube in matrix/interface[J]. Composite Structures,2017,159:761-772. doi: 10.1016/j.compstruct.2016.10.022 [8] SUI X, SHI J, YAO H, et al. Interfacial and fatigue-resistant synergetic enhancement of carbon fiber/epoxy hierarchical composites via an electrophoresis deposited carbon nanotube-toughened transition layer[J]. Composites Part A: Applied Science and Manufacturing,2017,92:134-144. doi: 10.1016/j.compositesa.2016.11.004 [9] 张策, 徐志伟, 郭兴峰. 基于微波等离子体方法生长的纳米碳对碳纤维/环氧树脂复合材料界面性能的影响[J]. 复合材料学报, 2018, 35(11):2994-3000.ZHANG Ce, XU Zhiwei, GUO Xingfeng. Effect of nanocarbon on interfacial properties of carbon fiber/exoxy composites based on microwave plasma enhanced chemical vapor deposition[J]. Acta Materiae Compositae Sinica,2018,35(11):2994-3000(in Chinese). [10] NI Y, CHEN L, TENG K Y, et al. Superior mechanical properties of epoxy composites reinforced by 3D interconnected graphene skeleton[J]. American Chemical Society Applied Materials and Interfaces,2015,7(21):11583-11591. doi: 10.1021/acsami.5b02552 [11] 黄立新, 姚祺, 张晓磊, 等. 基于分层法的功能梯度材料有限元分析[J]. 玻璃钢/复合材料, 2013(2):43-48.HUANG Lixin, YAO Qi, ZHANG Xiaolei, et al. Finite element analysis of functionally graded materials based on layering method[J]. Fiber Reinforced Plastics/Composties,2013(2):43-48(in Chinese). [12] GIANNOPOULOS G I, GEORGANTZINOS S K, KATSAREAS D E, et al. Numerical prediction of Young’s and shear moduli of carbon nanotube composites incorporating nanoscale and interfacial effects[J]. Computer Modeling in Engineering and Sciences,2009,1465(1):1-17. [13] GIANNOPOULOS G I, GEORGANTZINOS S K, ANIFANTIS N K. A semi-continuum finite element approach to evaluate the Young’s modulus of single-walled carbon nano-tube reinforced composites[J]. Composites Part B: Engineering,2010,41(8):594-601. doi: 10.1016/j.compositesb.2010.09.023 [14] GIANNOPOULOS G I, KALLIVOKAS I G. Mechanical properties of graphene based nanocomposites incorporating a hybrid interphase[J]. Finite Elements in Analysis and Design,2014,90:31-40. doi: 10.1016/j.finel.2014.06.008 [15] SPANOS K N, GEORGANTZINOS S K, ANIFANTIS N K. Mechanical properties of graphene nanocomposites: A multiscale finite element prediction[J]. Composite Structures,2015,132:536-544. doi: 10.1016/j.compstruct.2015.05.078 [16] SPANOS K N, ANIFANTIS N K. Finite element prediction of stress transfer in graphene nanocomposites: The interface effect[J]. Composite Structures,2016,154:269-276. doi: 10.1016/j.compstruct.2016.07.058 [17] GUO Z X, SONG L B, BOAY C G, et al. A new multiscale numerical characterization of mechanical properties of graphene-reinforced polymer-matrix composites[J]. Composite Structures,2018,199:1-9. [18] KIM J H, PAULINO G H. Finite element evaluation of mixed mode stress intensity factors in functionally graded materials[J]. International Journal for Numerical Methods in Engineering,2002,53(8):1903-1935. doi: 10.1002/nme.364 [19] 陈康, 许希武. 梯度复合材料热传导分析的梯度单元法[J]. 复合材料学报, 2012, 29(4):178-185.CHEN Kang, XU Xiwu. Graded element method for the heat conduction analysis of gradient composites[J]. Acta Materiae Compositae Sinica,2012,29(4):178-185(in Chinese). [20] ARROYO M, BELYTSCHKO T. Finite crystal elasticity of carbon nanotubes based on the exponential Cauchy-Born rule[J]. Physical Review B,2004,69(11):115415.1-115415.11. [21] SAKHAEE-POUR A. Elastic properties of single-layered graphene sheet[J]. Solid State Communications,2009,149(1-2):91-95. doi: 10.1016/j.ssc.2008.09.050 [22] HUANG J, WU Y, HUANG L X. Evaluation of the mechanical properties of graphene-based nanocomposites incorporating a graded interphase based on isoparametric graded finite element model[J]. Composite Interfaces, 2020(28): 1-33. [23] 沈观林, 胡更开, 刘彬. 复合材料力学(第2版)[M]. 北京: 清华大学出版社, 2013: 47-52.SHEN Guanlin, HU Gengkai, LIU Bin. Mechanics of composite materials (Second edition)[M]. Beijing: Tsinghua University Press, 2013: 47-52(in Chinese). [24] ZHAO X, ZHANG Q H, CHEN D J, et al. Enhanced mechanical properties of graphene-based poly(vinyl alcohol) composites[J]. Macromolecules,2010,43(5):2357-2363. doi: 10.1021/ma902862u [25] RAFIEE M A, RAFIEE J, WANG Z, et al. Enhanced mechanical properties of nanocomposites at low graphene content[J]. American Chemical Society Nano,2009,3(12):3884-3890. -

下载:

下载: