Mechanical properties of CFRP bar and bond-type anchorage system after elevated temperature exposure

-

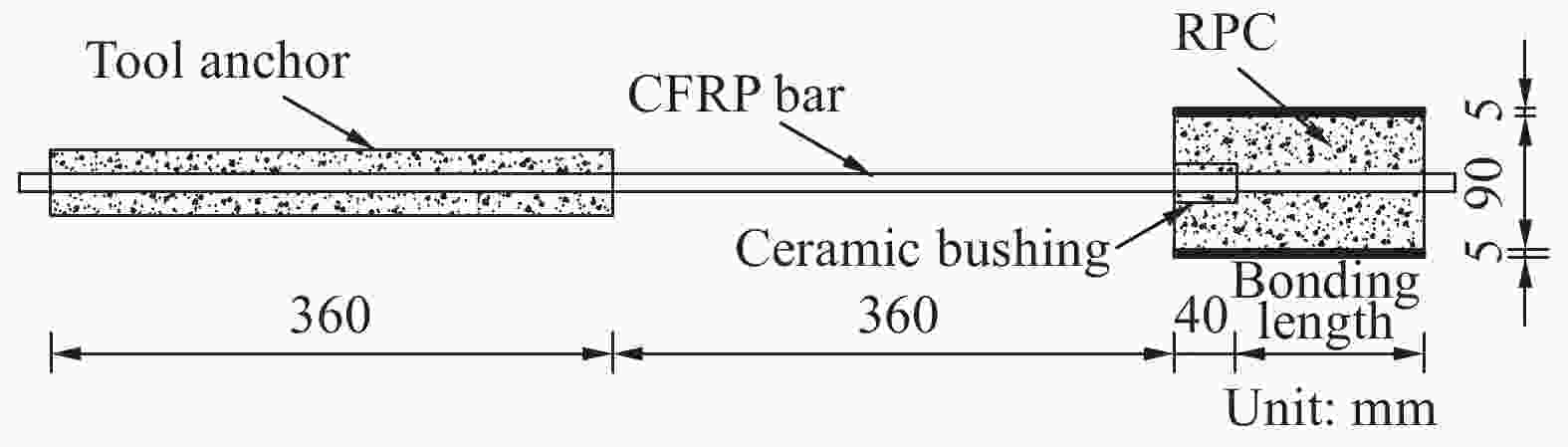

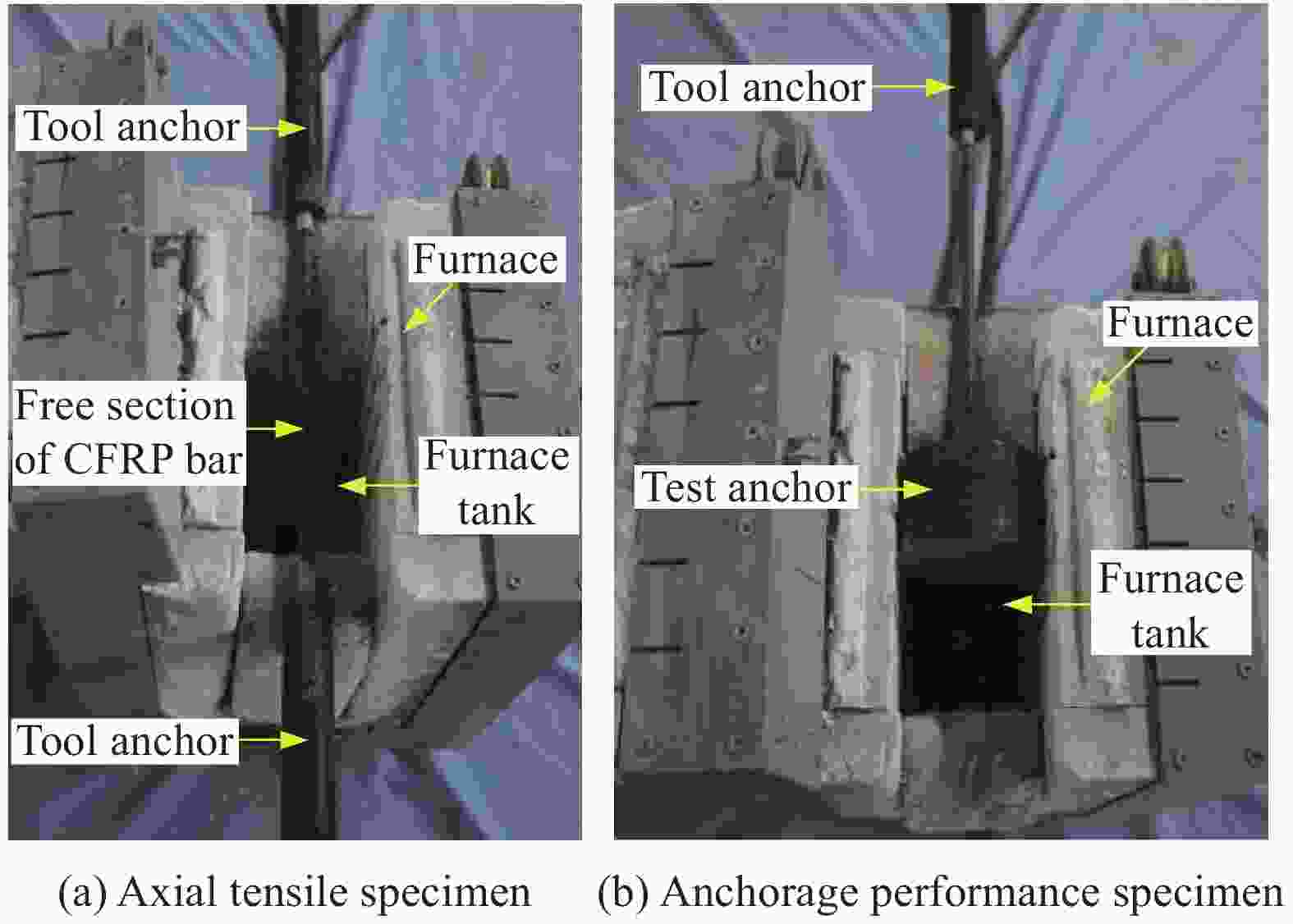

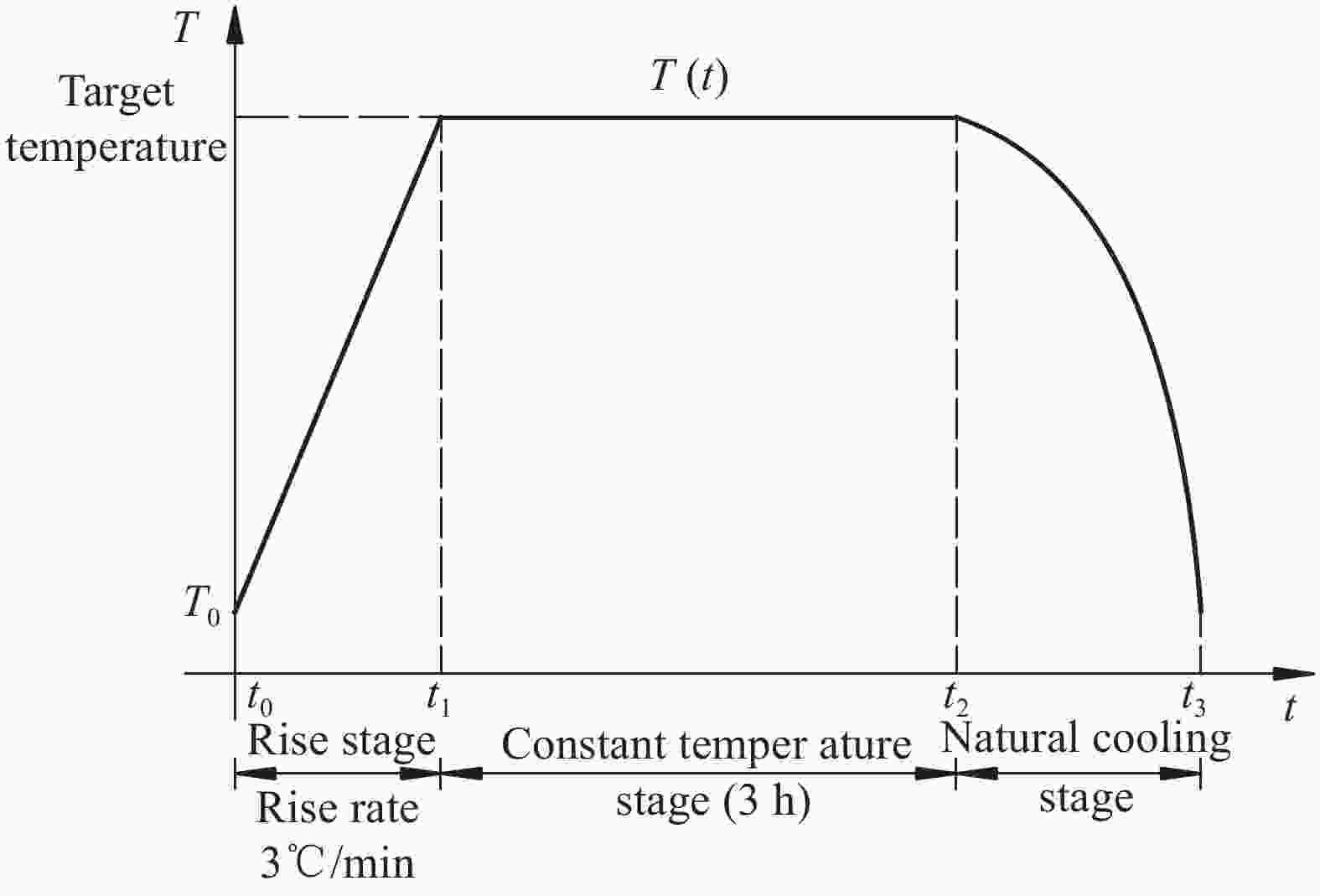

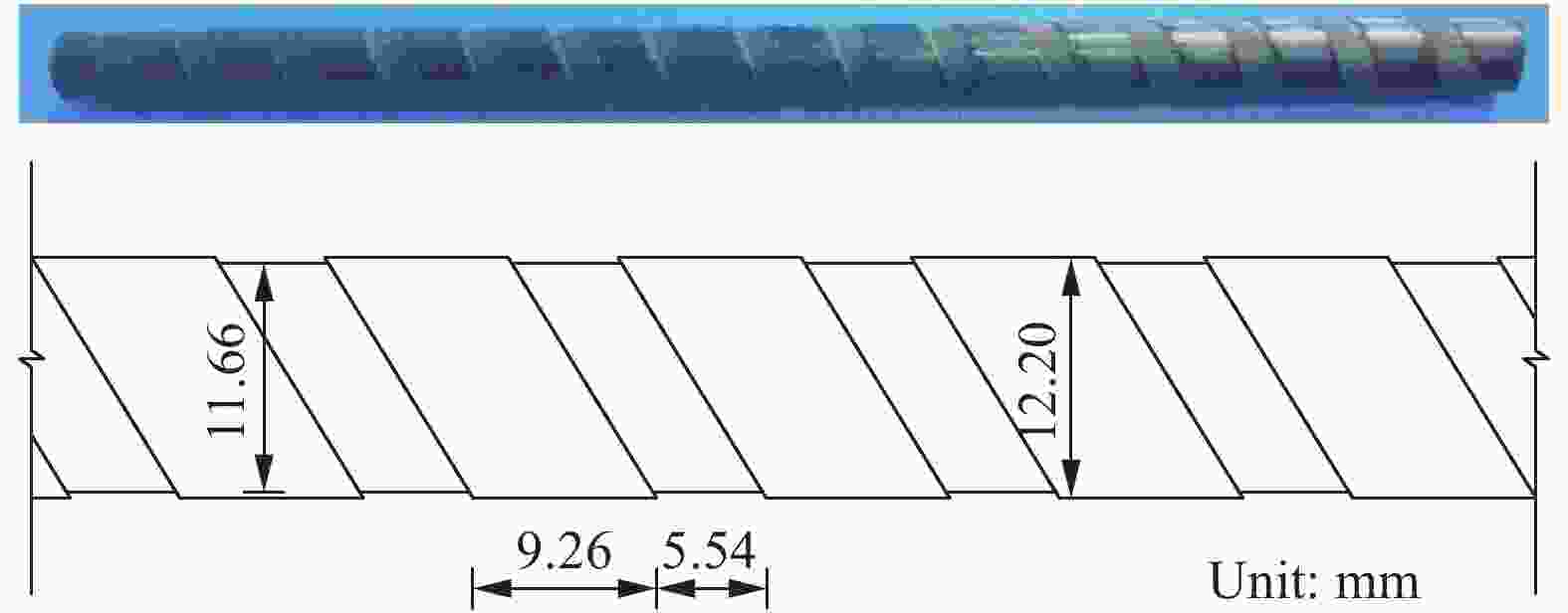

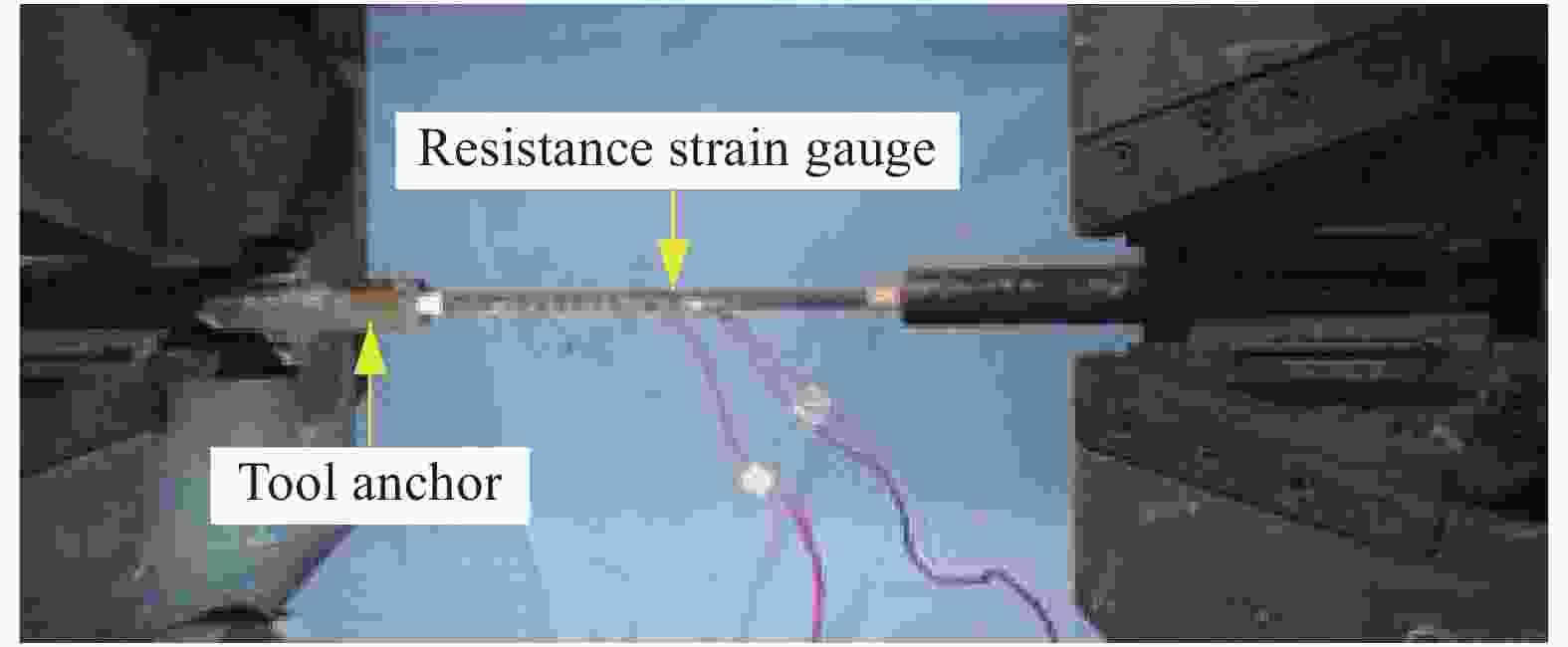

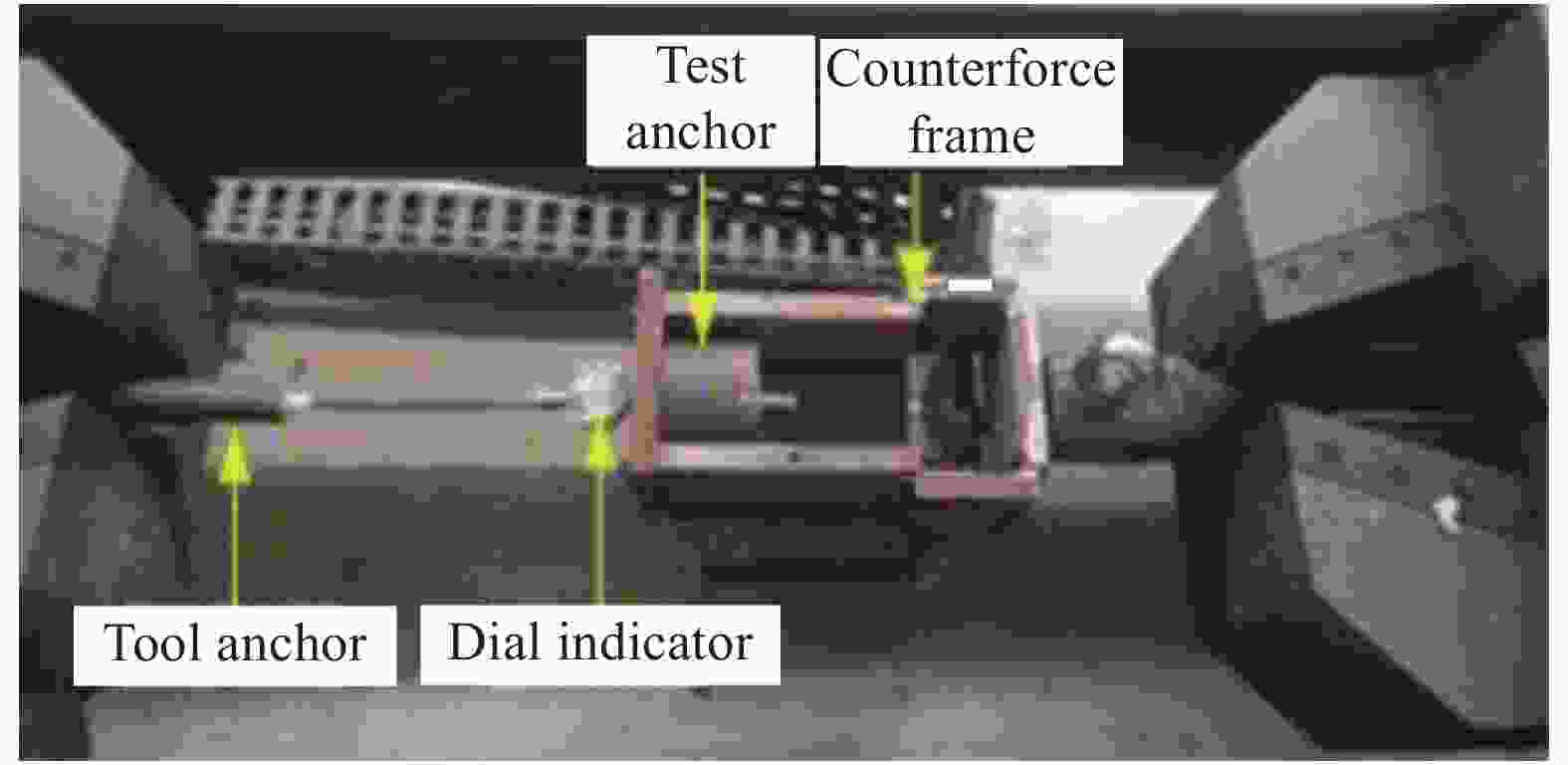

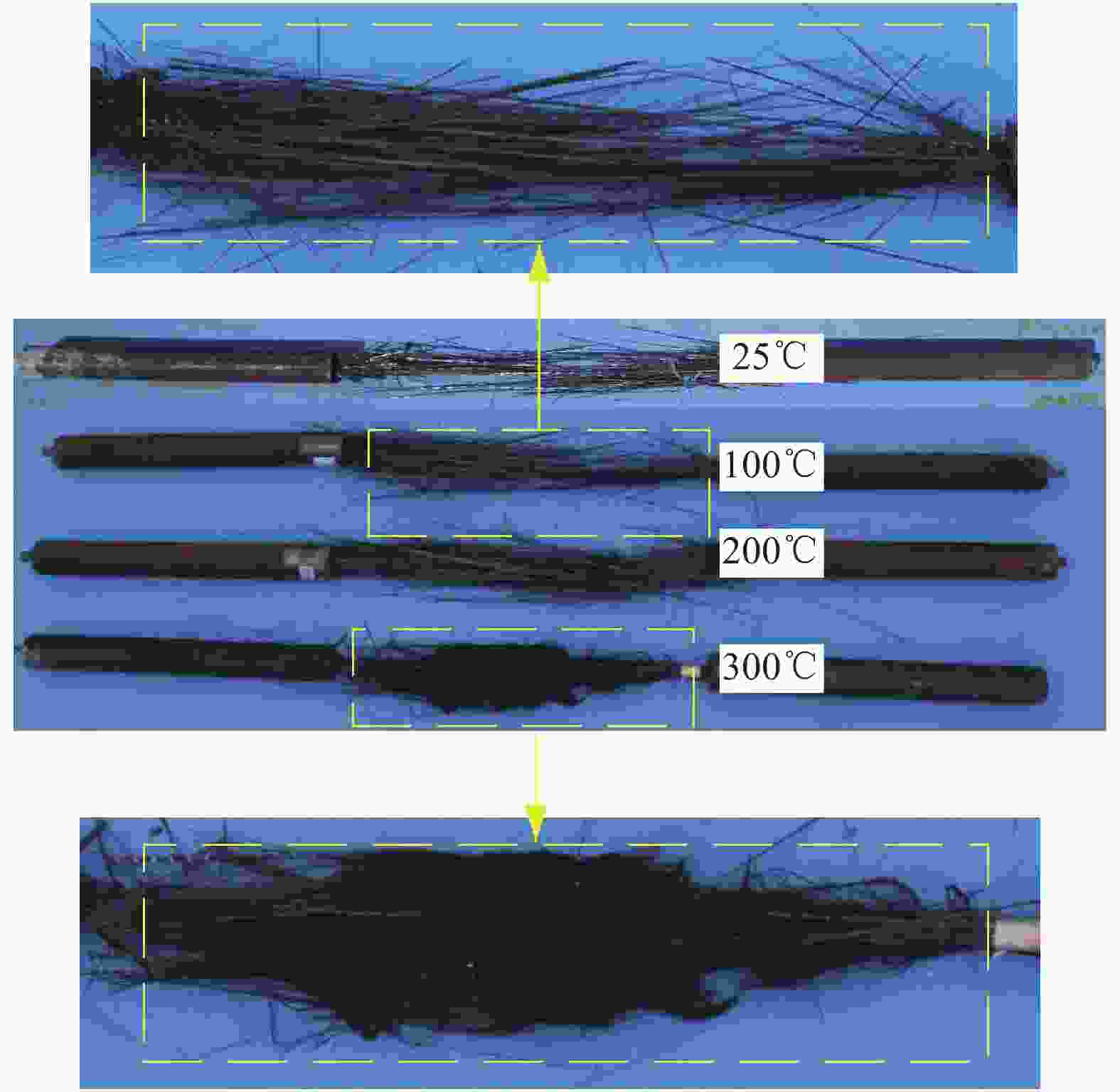

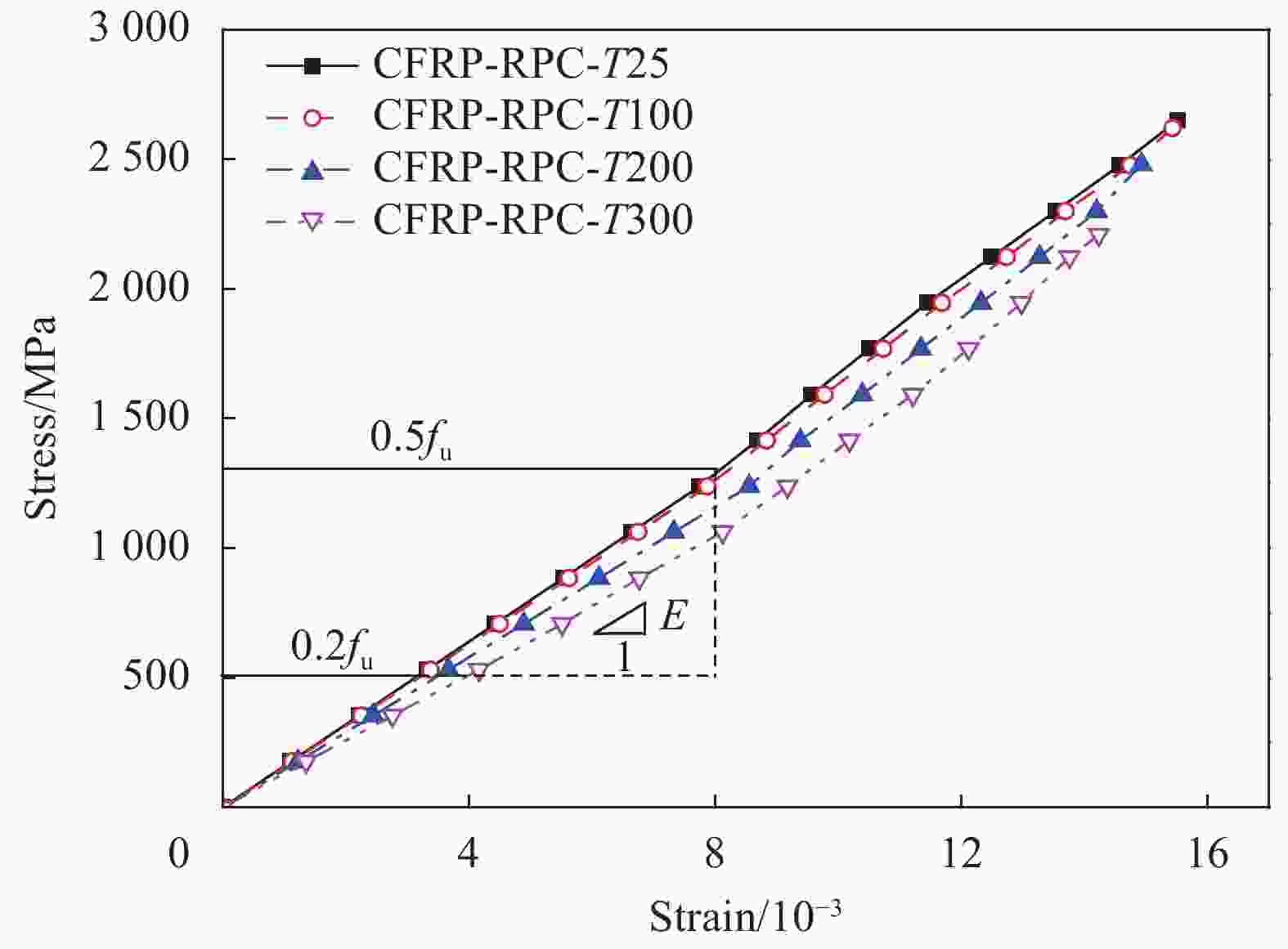

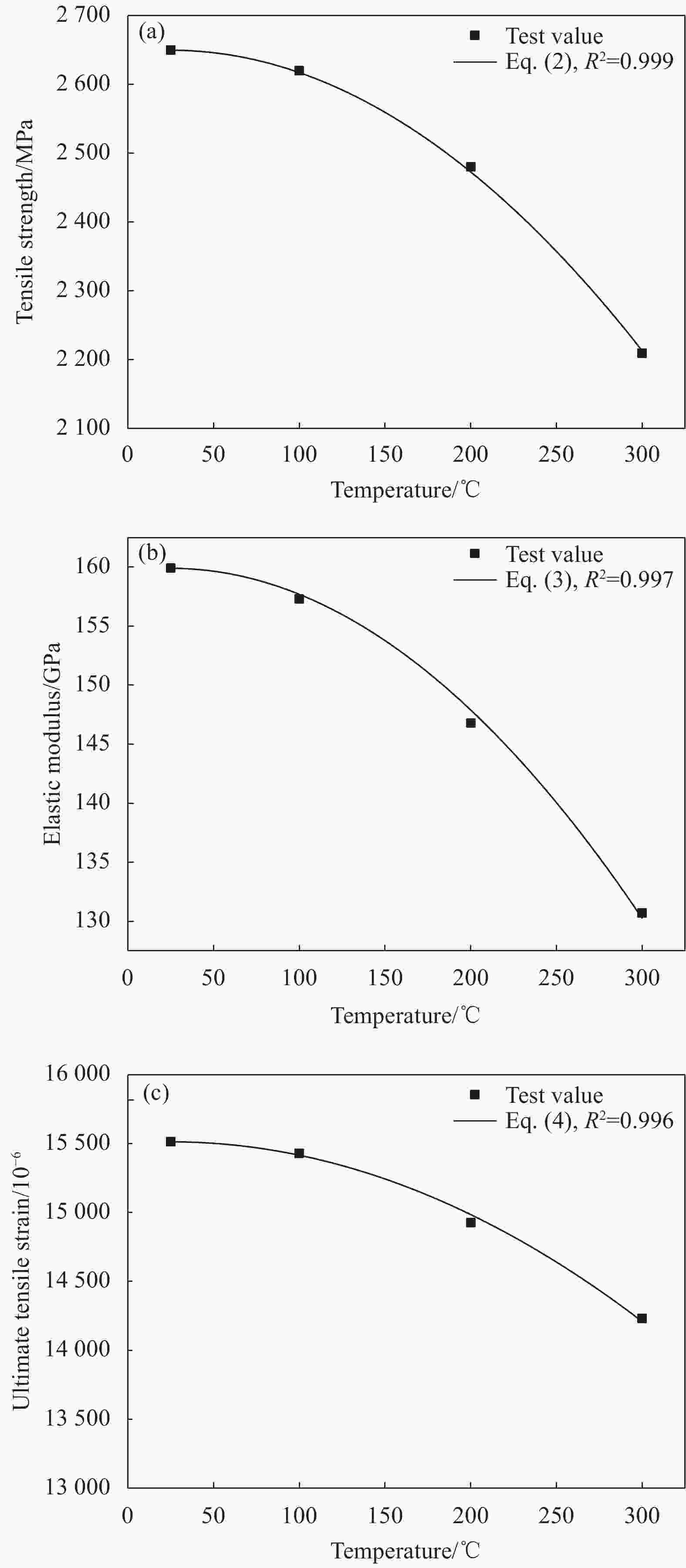

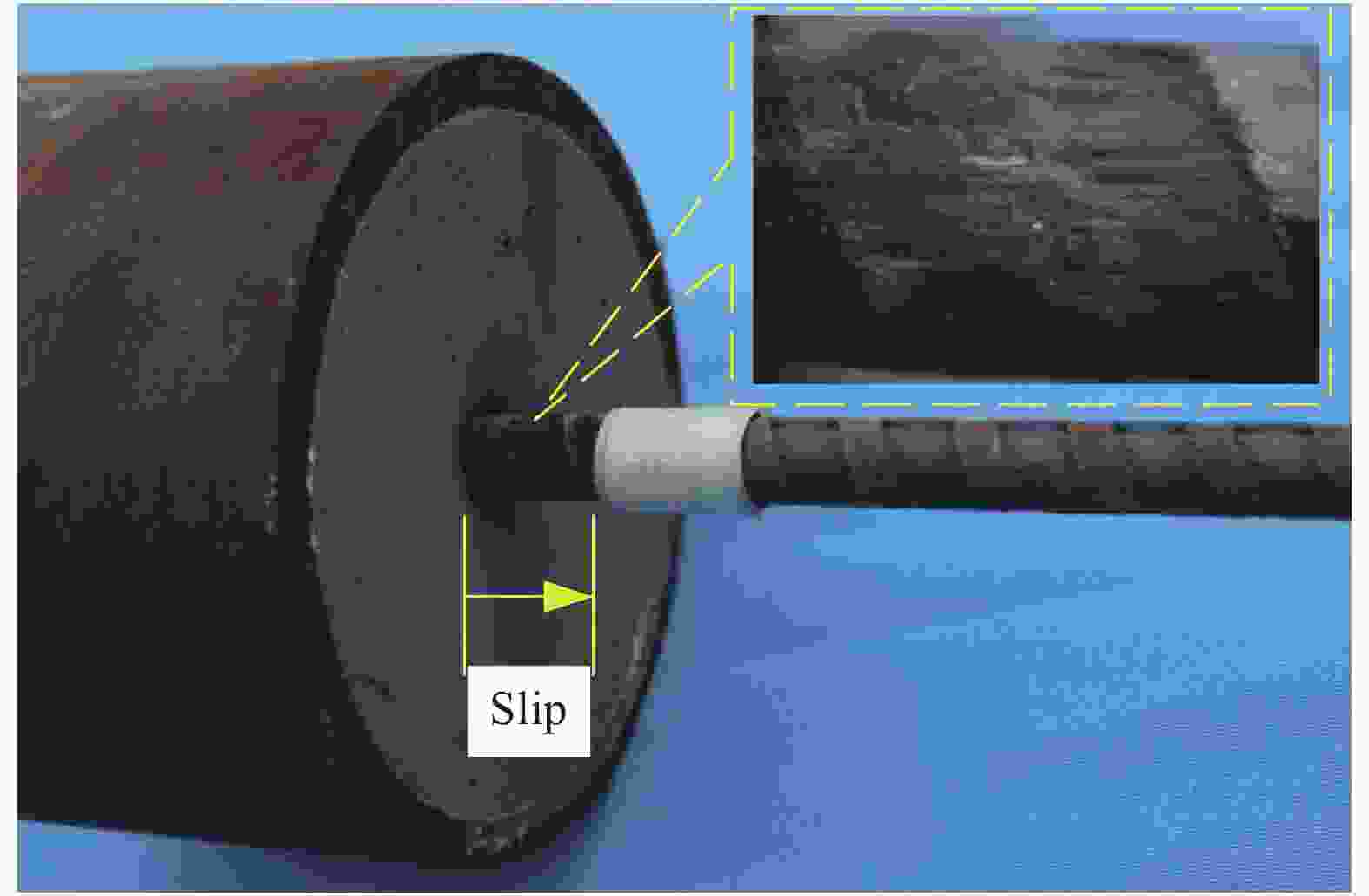

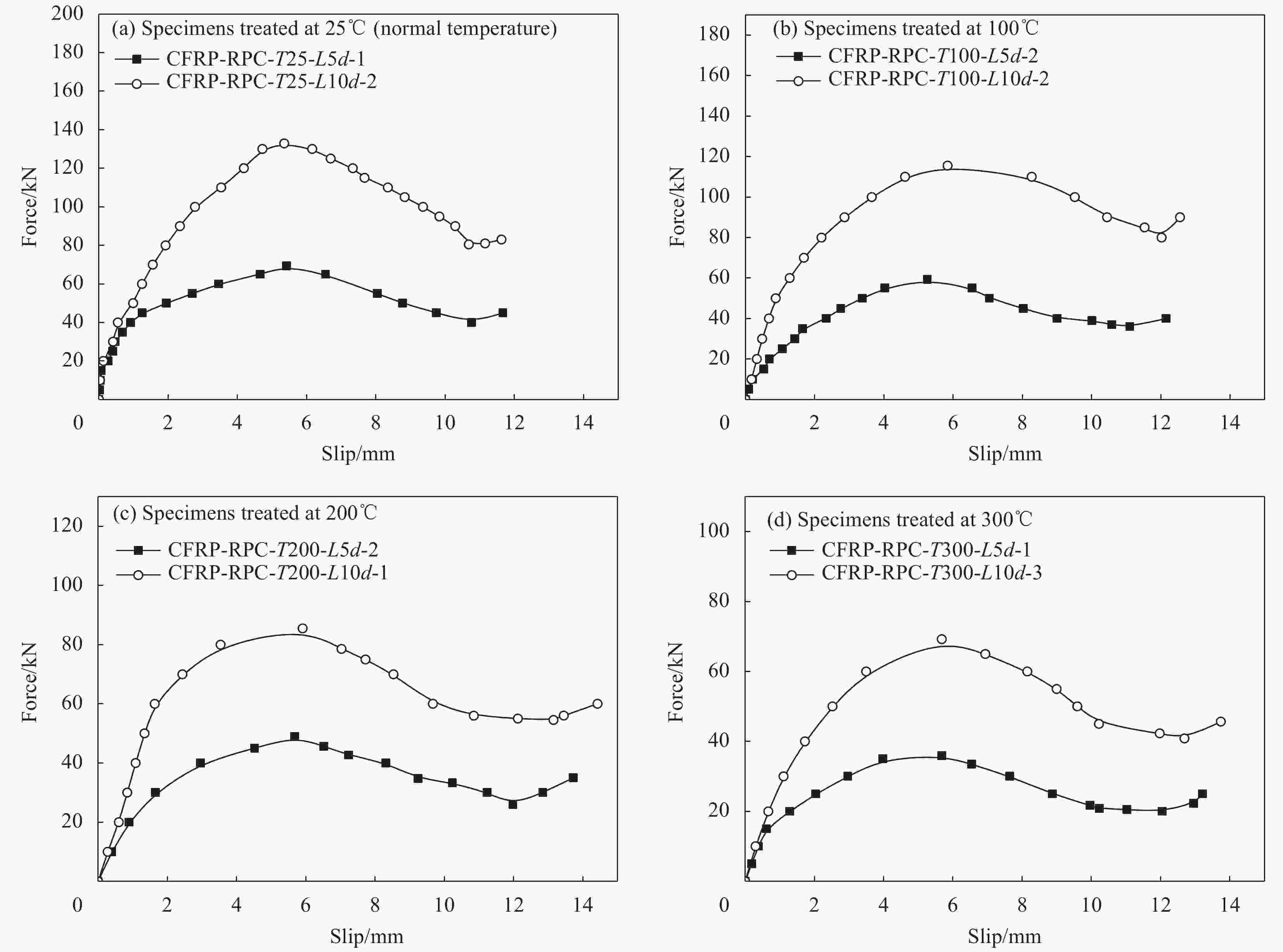

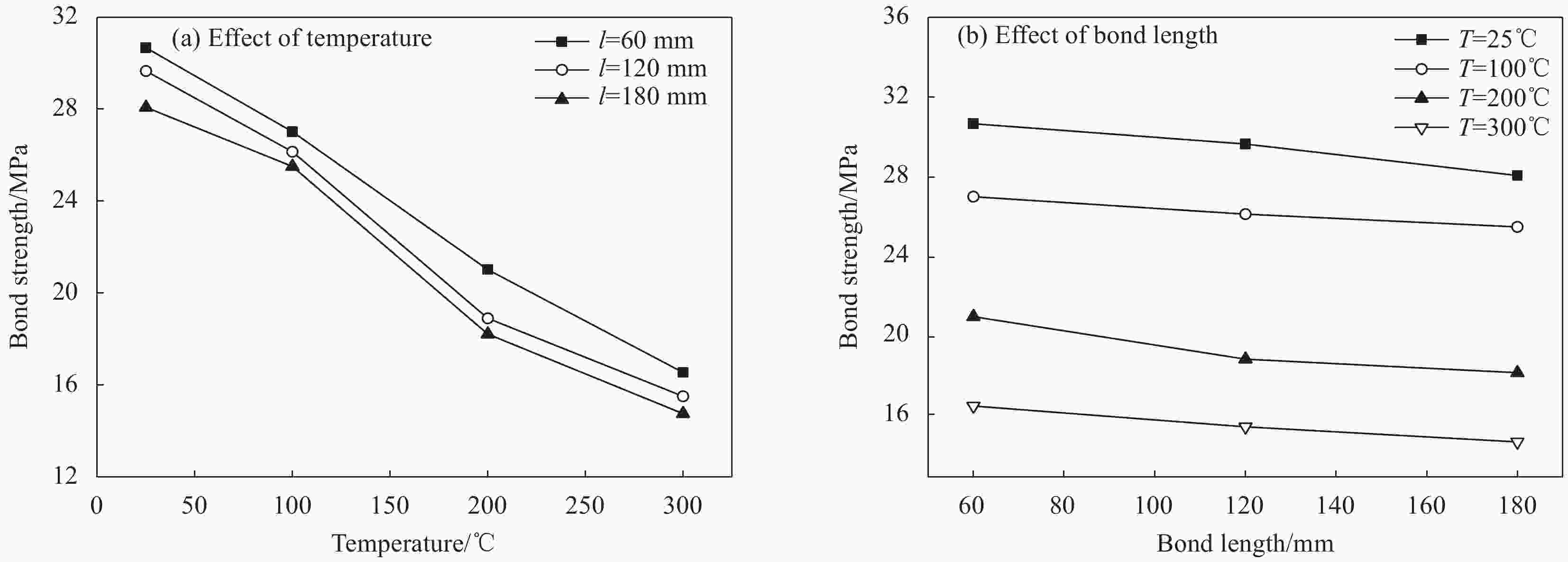

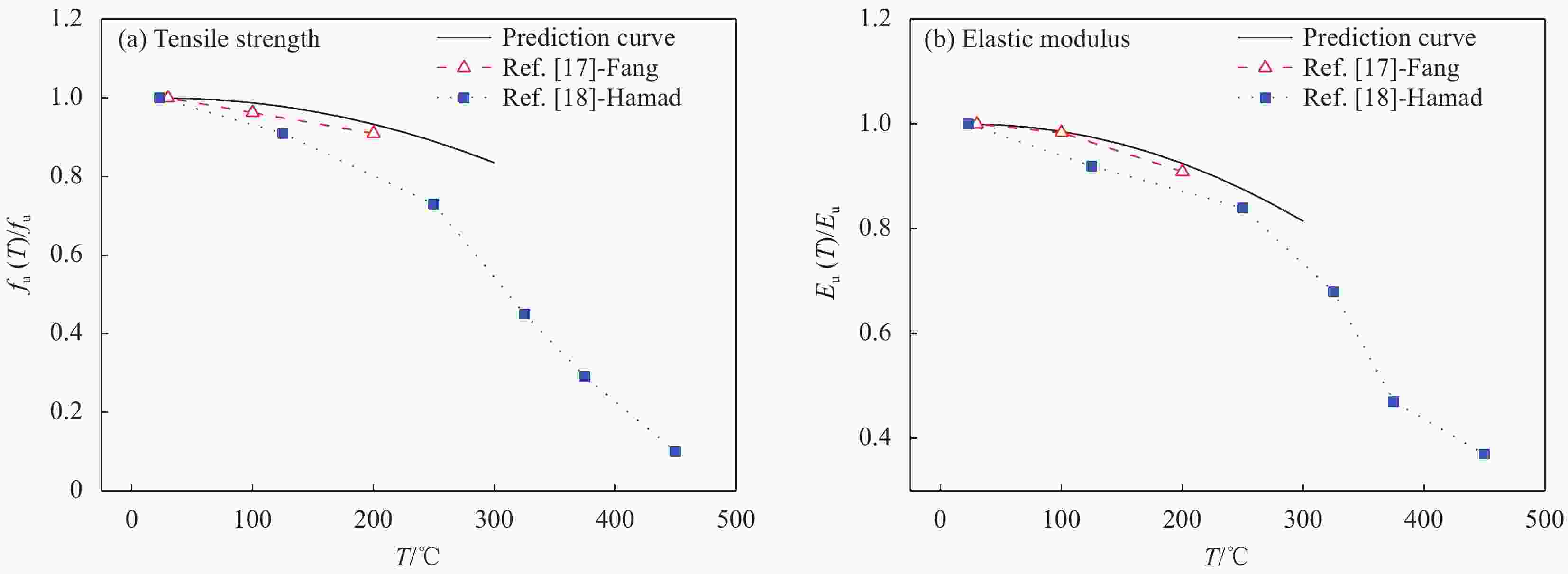

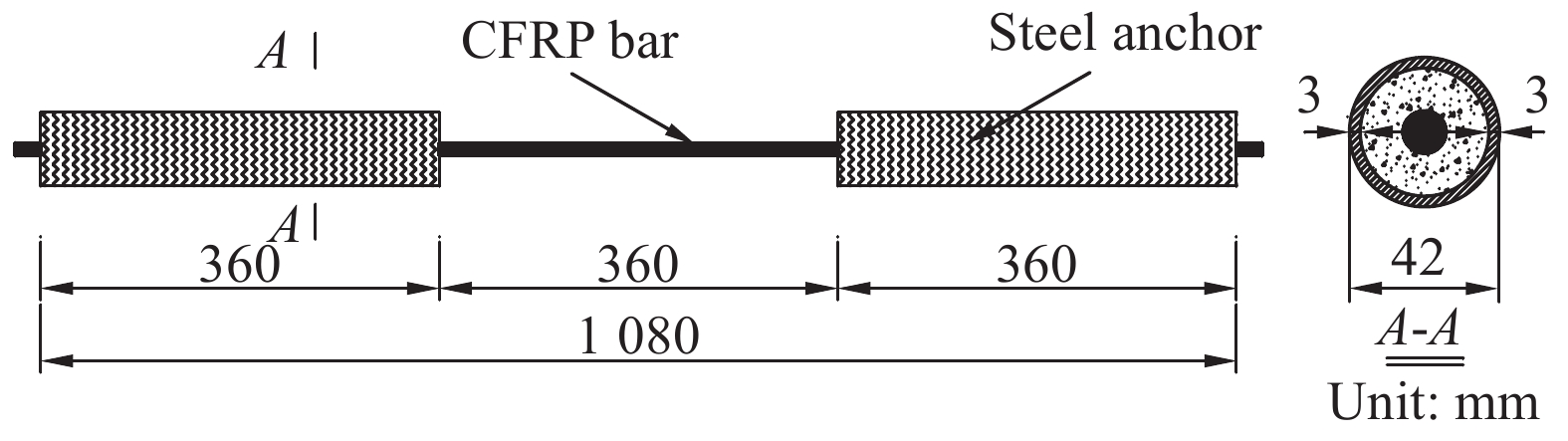

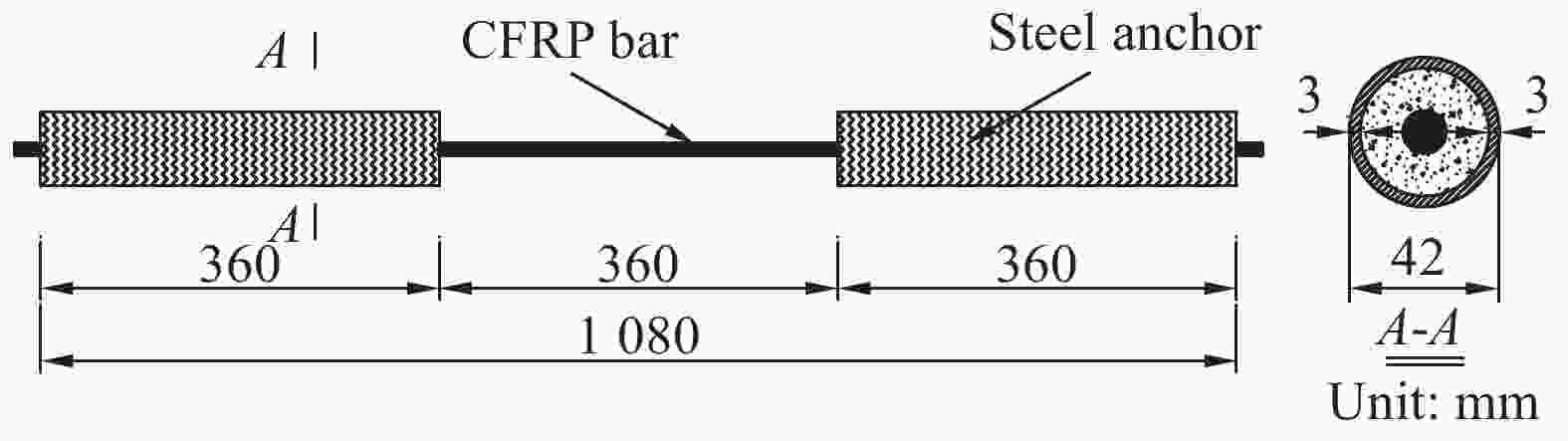

摘要: 为明确高温后碳纤维增强树脂复合材料(Carbon fiber reinforced polymer,CFRP)筋材及其粘结型锚固系统的力学性能,以筋材的处理温度为试验参数,完成了12个筋材试件的轴向拉伸试验;以粘结式锚具的处理温度和粘结长度为试验参数,完成了36个试件的锚固性能试验。结果表明:对于筋材轴向拉伸试件,处理温度为100℃时,筋材静力性能与常温试件相比未发生明显变化,筋材经历200℃和300℃温升作用后,其抗拉强度、弹性模量和极限拉应变较常温试件分别下降了6.4%、8.2%、3.8%和16.6%、18.3%、8.3%;对于锚固性能试验,试件的粘结强度随处理温度和粘结长度的增加而降低,粘结长度一定时,处理温度为200℃与300℃试件的粘结强度较常温试件分别下降了31.5%~36.3%和44.2%~47.4%。建立了适于分析高温后CFRP筋轴向拉伸性能、粘结型锚固系统粘结强度及临界锚固长度的实用计算公式,且具较高精度。Abstract: To investigate the mechanical properties of carbon fiber reinforced polymer (CFRP) bar and bond-type anchorage system after different elevated temperature exposures, the axial tensile tests and anchorage perfor-mance tests were conducted on 12 specimens and 36 specimens with different elevated temperatures and bond lengths, respectively. The results demonstrate that the static performance of CFRP bar exposed to elevated temperature of 100℃ degenerates slightly compared with the specimen at room temperature in the axial tensile tests. The tensile strength, elastic modulus and ultimate strain of specimens exposed to the elevated temperature of 200℃ and 300℃ decrease by 6.4%, 8.2%, 3.8% and 16.6%, 18.3%, 8.3%, respectively, compared with the specimen at room temperature. In the anchorage performance tests, the bond strength of the specimens decreases with the increase of elevated temperature and bond length. Compared with the specimen at room temperature, the bond strengths of the specimens exposed to the elevated temperature of 200℃ and 300℃ decrease by 31.5%-36.3% and 44.2%-47.4%, respectively, while the bonding length is fixed. The practical formulas with high accuracy for determining the axial tensile performance of CFRP bars, bond strength and critical anchorage length of the bond-type anchorage system after elevated temperature exposure were developed.

-

表 1 CFRP筋外观尺寸及玻璃化转变温度Tg

Table 1. Dimensions and glass transition temperature Tg of CFRP bar

Nominal diameter/mm Rib width/mm Rib height/mm Embossing spacing/mm Tg/℃ 12 9.26 0.27 14.8 211.6 表 2 RPC配合比及抗压强度

Table 2. Mix proportion and compressive strengths of RPC

Strength grade Cement Silica fume Quartz flour Quartz sand Water reducer Water binder ratio Measured strength/MPa RPC150 1 0.25 0.25 1.1 0.02 0.16 158 表 3 CFRP筋-RPC轴向拉伸试验结果

Table 3. Results of axial tensile test for CFRP bar-RPC

Specimen code $\overline{ P_{\rm{u}}}$/kN Pu/kN fu/MPa $ \overline{ f_{\rm{u}}} $/MPa E/GPa $ \overline E $/GPa εu/10−6 $ \overline{\varepsilon _{\rm{u}}} $/10−6 CFRP-RPC-T25-1 280.8 282.8 2631.1 162.2 15627 CFRP-RPC-T25-2 283.1 2652.6 2649.8 161.8 159.9 15464 15513 CFRP-RPC-T25-3 284.5 2665.7 155.6 15448 CFRP-RPC-T100-1 279.9 279.6 2622.6 162.3 15482 CFRP-RPC-T100-2 278.8 2612.3 2619.8 153.6 157.3 15385 15428 CFRP-RPC-T100-3 280.1 2624.5 156.0 15417 CFRP-RPC-T200-1 260.6 264.7 2441.8 151.7 15084 CFRP-RPC-T200-2 269.2 2522.4 2480.2 146.2 146.8 15012 14925 CFRP-RPC-T200-3 264.3 2476.5 142.5 14679 CFRP-RPC-T300-1 242.7 235.8 2274.1 128.4 14285 CFRP-RPC-T300-2 231.4 2168.2 2209.4 133.3 130.7 14364 14232 CFRP-RPC-T300-3 233.3 2186.0 130.4 14047 Notes: Specimen code indicates the test type and treatment temperature; for example, CFRP-RPC-T25-1 means the first specimen of CFRP-RPC anchorage specimen treated at 25℃ in axial tensile test; Pu—Tensile breaking force; $\overline {{P_{\rm{u}}}} $—Average value; $\overline {{f_{\rm{u}}}} $—Average value; E—Elastic modulus; $\overline E $—Average value; εu—Ultimate tensile strain; $\overline {{\varepsilon _{\rm{u}}}} $—Average value. 表 4 CFRP筋-RPC锚固性能试验结果

Table 4. Results of anchorage performance test for CFRP bar-RPC

Specimen code T/

℃l/

mmPu/

kN${\overline {P_{\rm{u}}} }$/

kNτu/

MPas/

mmSpecimen code T/

℃l/

mmPu/

kN${\overline {P_{\rm{u}}}} $/

kNτu/

MPas/

mmCFRP-RPC-T25-L5d-1 25 60 69.3 69.35 30.67 5.42 CFRP-RPC-T200-L5d-1 200 60 41.23 47.53 21.02 5.74 CFRP-RPC-T25-L5d-2 69.45 5.36 CFRP-RPC-T200-L5d-2 48.9 5.68 CFRP-RPC-T25-L5d-3 69.3 5.26 CFRP-RPC-T200-L5d-3 52.45 5.80 CFRP-RPC-T25-L10d-1 25 120 135.3 134.1 29.66 5.52 CFRP-RPC-T200-L10d-1 200 120 85.5 85.46 18.9 5.91 CFRP-RPC-T25-L10d-2 132.9 5.35 CFRP-RPC-T200-L10d-2 81.68 5.98 CFRP-RPC-T25-L10d-3 — — CFRP-RPC-T200-L10d-3 89.2 5.93 CFRP-RPC-T25-L15d-1 25 180 192.4 190.47 28.08 — CFRP-RPC-T200-L15d-1 200 180 118.9 123.57 18.22 — CFRP-RPC-T25-L15d-2 192.7 — CFRP-RPC-T200-L15d-2 131.8 — CFRP-RPC-T25-L15d-3 186.3 — CFRP-RPC-T200-L15d-3 120 — CFRP-RPC-T100-L5d-1 100 60 62.37 61.09 27.02 5.14 CFRP-RPC-T300-L5d-1 300 60 35.92 37.42 16.55 5.68 CFRP-RPC-T100-L5d-2 59.35 5.26 CFRP-RPC-T300-L5d-2 41.98 5.36 CFRP-RPC-T100-L5d-3 61.55 5.37 CFRP-RPC-T300-L5d-3 34.35 5.41 CFRP-RPC-T100-L10d-1 100 120 119.5 118.23 26.15 5.85 CFRP-RPC-T300-L10d-1 300 120 66.23 70.12 15.51 5.73 CFRP-RPC-T100-L10d-2 115.5 5.84 CFRP-RPC-T300-L10d-2 74.9 5.75 CFRP-RPC-T100-L10d-3 119.7 6.73 CFRP-RPC-T300-L10d-3 69.23 5.68 CFRP-RPC-T100-L15d-1 100 180 173.6 173 25.51 — CFRP-RPC-T300-L15d-1 300 180 105.3 100.11 14.76 — CFRP-RPC-T100-L15d-2 174.3 — CFRP-RPC-T300-L15d-2 96.93 — CFRP-RPC-T100-L15d-3 171.1 — CFRP-RPC-T300-L15d-3 98.11 — Notes: Specimen code indicates the test type and treatment temperature; for example, CFRP-RPC-T25-L5d-1 means the first specimen of CFRP-RPC anchorage specimen treated at 25℃ with bond length of 5d; T—Treatment temperature; l—Bond length; τu—Average bond strength; s—Slip of loading end corresponding to Pu. 表 5 CFRP筋-RPC试件粘结强度试验值与计算值对比

Table 5. Comparison between measured and predicted bond strength of CFRP bar-RPC specimen

Specimen code fcu/MPa τu,t/MPa τu,c/MPa τu,t/τu,c CFRP-RPC-T25-L5d 158 30.67 30.97 1.01 CFRP-RPC-T25-L10d 158 29.66 29.06 0.98 CFRP-RPC-T25-L15d 158 28.08 28.42 1.01 CFRP-RPC-T100-L5d 158 27.02 26.91 1.00 CFRP-RPC-T100-L10d 158 26.15 25.25 0.97 CFRP-RPC-T100-L15d 158 25.51 24.70 0.97 CFRP-RPC-T200-L5d 158 21.02 21.49 1.02 CFRP-RPC-T200-L10d 158 18.9 20.17 1.07 CFRP-RPC-T200-L15d 158 18.22 19.72 1.08 CFRP-RPC-T300-L5d 158 16.55 16.08 0.97 CFRP-RPC-T300-L10d 158 15.51 15.08 0.97 CFRP-RPC-T300-L15d 158 14.76 14.75 1.00 Average 1.00 Variation coefficient 0.04 Notes: fcu—Cube compressive strength of RPC; τu,t, τu,c—Experimental and calculated values of interfacial bond strength between CFRP bars and RPC, respectively. 表 6 CFRP筋-RPC试件临界锚固长度计算值及预测的破坏形态

Table 6. Critical anchorage length determined by formula and predicted failure mode of CFRP bar-RPC specimen

Source of

test resultsSpecimen code T/℃ Anchorage

length/mmActua failure

modeCritical anchorage

length/mmPredicted

failure modePresent study CFRP-RPC-T25 25 360 Fracture 284.4 Fracture CFRP-RPC-T100 CFRP-RPC-T200 CFRP-RPC-T300 Present study CFRP-RPC-T25-L15d 25 180 Slip 284.4 Slip CFRP-RPC-T100-L15d 100 324.8 CFRP-RPC-T200-L15d 200 386.5 CFRP-RPC-T300-L15d 300 462.0 Ref.[17] AT30 30 160 Fracture 126.3 Fracture AT100 100 Fracture 151.1 Fracture AT200 200 Slip 221.0 Slip Notes: Failure modes of tensile failure in CFRP bar and slip failure in CFRP-RPC interface were abbreviated as fracture and slip, respectively. -

[1] 滕锦光. 新材料组合结构[J]. 土木工程学报, 2018, 51(12):1-11.TENG Jinguang. New-material hybrid structures[J]. China Civil Engineering Journal,2018,51(12):1-11(in Chinese). [2] 叶列平, 冯鹏. FRP 在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-36.YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-36(in Chinese). [3] 朱虹, 钱洋. 工程结构用FRP筋的力学性能[J]. 建筑科学与工程学报, 2006, 23(3):26-31. doi: 10.3321/j.issn:1673-2049.2006.03.005ZHU Hong, QIAN Yang. Mechanics performance of FRP tendons used in engineering structure[J]. Journal of Architecture and Civil Engineering,2006,23(3):26-31(in Chinese). doi: 10.3321/j.issn:1673-2049.2006.03.005 [4] 郝庆多, 王勃, 欧进萍. 纤维增强塑料筋在土木工程中的应用[J]. 混凝土, 2006(9):38-40, 44. doi: 10.3969/j.issn.1002-3550.2006.09.012HAO Qingduo, WANG Bo, OU Jinping. Fiber reinforced polymer rebar's application to civil engineering[J]. Concrete,2006(9):38-40, 44(in Chinese). doi: 10.3969/j.issn.1002-3550.2006.09.012 [5] 方志, 梁栋, 蒋田勇. 不同粘结介质中CFRP筋锚固性能的试验研究[J]. 土木工程学报, 2006, 39(3):47-51.FANG Zhi, LIANG Dong, JIANG Tianyong. Experimental investigation on the anchorage performance of CFRP tendon in different bond mediums[J]. China Civil Engineering Journal,2006,39(3):47-51(in Chinese). [6] REDA T M M, SHRIVE N G. New concrete anchors for carbon fiber reinforced polymer post-tensioning tendons Part 1: State-of-the-art review/design[J]. ACI Structural Journal,2003,100(1):86-95. [7] WANG L C, ZHANG J Y, XU J, et al. Anchorage systems of CFRP cables in cable structures-A review[J]. Construction and Building Materials,2018,160:82-99. doi: 10.1016/j.conbuildmat.2017.10.134 [8] LIU Y, ZWINGMANN B, SCHLAICH M. Carbon fiber reinforced polymer for cable structures-A review[J]. Polymers,2015,7(10):2078-2099. doi: 10.3390/polym7101501 [9] FANG Z, ZHANG K Y, TU B. Experimental investigation of a Bond-type anchorage system for multiple FRP tendons[J]. Engineering Structures,2013,57(12):364-373. [10] ZHANG K Y, FANG Z, ANTONIO N, et al. Experimental study of a large-scale ground anchor system with FRP tendon and RPC grout medium[J]. Journal of Composite for Construction,2015,9(4):04014073. [11] 李国强, 吴波, 蒋首超. 工程结构抗火研究进展与建议[J]. 建筑钢结构进展, 2010, 12(5):13-18.LI Guoqiang, WU Bo, JIANG Shouchao. State of the art and suggestions of research on fire resistance of structures[J]. Progress in Steel Building Structures,2010,12(5):13-18(in Chinese). [12] ZHANG Y, FANG Z, JIANG R N, et al. Static performance of a long-span concrete cable-stayed bridge subjected to multiple-cable loss during construction[J]. Journal of Bridge Engineering,2010,25(3):04020002. [13] 张帅, 张隐, 潘明珠. 阻燃预警智能涂层的研究进展[J]. 复合材料学报, 2021, 38(1):1-12. doi: 10.13801/j.cnki.fhclxb.20200813.001ZHANG Shuai, ZHANG Yin, PAN Mingzhu. Research progress of intelligent flame retardant coating with fire-warning capabilities[J]. Acta Materiae Compositae Sinica,2021,38(1):1-12(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200813.001 [14] 姚秀鹏, 韩阳, 沈雷, 等. 高温后聚丙烯纤维增强水泥基复合材料导热的多尺度方法[J]. 复合材料学报, 2020, 38(10):3541-3552.YAO Xiupeng, HAN Yang, SHEN Lei, et al. Multi-scale method for thermal conductivity of polypropylene fiber reinforced cementitious composites after high temperature[J]. Acta Materiae Compositae Sinica,2020,38(10):3541-3552(in Chinese). [15] HAMED A, MILAD B, ESMAEIL P N, et al. The effect of mechanical and thermal properties of FRP bars on their tensile performance under elevated temperatures[J]. Construction and Building Materials,2017,157:1001-1010. doi: 10.1016/j.conbuildmat.2017.09.160 [16] 周飞. 火场温度作用下CFRP筋混凝土受弯构件的结构性能研究[D]. 南京: 东南大学, 2019.ZHOU Fei. Study on structural behavior of concrete flexural members with CFRP tendons under fire action[D]. Nanjing: Southeast University, 2019(in Chinese). [17] 方志, 黄道斌, 方亚威, 等. 经历不同温升作用后CFRP筋受力性能的试验研究[J]. 土木工程学报, 2020, 53(1):52-63.FANG Zhi, HUANG Daobin, FANG Yawei, et al. Experimental study on mechanical properties of CFRP bar after elevated temperature exposure[J]. China Civil Engineering Journal,2020,53(1):52-63(in Chinese). [18] HAMAD R J A, MEGAT J M A, HADDAD R H. Mechanical properties and bond characteristics of different fiber reinforced polymer rebars at elevated temperatures[J]. Construction and Building Materials,2017,142:521-535. doi: 10.1016/j.conbuildmat.2017.03.113 [19] ELLIS D S, TABATABAI H, NABIZADEH A. Residual tensile strength and bond properties of GFRP bars after exposure to elevated temperatures[J]. Materials,2018,11(3):346. doi: 10.3390/ma11030346 [20] YU B, KODUR V K R. Effect of high temperature on bond strength of near-surface mounted FRP reinforcement[J]. Composite Structures,2014,110:88-97. doi: 10.1016/j.compstruct.2013.11.021 [21] 王英来. 高温后FRP筋拉伸性能及其与混凝土粘结性能试验研究[D]. 郑州: 郑州大学, 2013.WANG Yinglai. Experimental study on tensile property of frp bars and bond behavior between frp bars and concrete after high temperature[D]. Zhengzhou: Zhengzhou University, 2013(in Chinese). [22] 中国建筑材料联合会. 纤维增强复合材料筋基本力学性能试验方法: GB/T 30022—2013[S]. 北京: 中国标准出版社, 2013.China Building Material Council. Fundamental mechanical properties test method of fiber reinforced polymer bar: GB/T 30022—2013[S]. Beijing: China Standars Press, 2013(in Chinese). [23] 方志, 王常林, 张洪侨, 等. 碳纤维绞线在活性粉末混凝土中锚固性能的试验研究[J]. 中国公路学报, 2016, 29(6):198-206. doi: 10.3969/j.issn.1001-7372.2016.06.006FANG Zhi, WANG Changlin, ZHANG Hongqiao, et al. Experimental study on anchoring performance of CFRP strand in reactive powder concrete[J]. China Journal of Highway and Transport,2016,29(6):198-206(in Chinese). doi: 10.3969/j.issn.1001-7372.2016.06.006 [24] ACI. Guide for the design and construction of structural concrete reinforced with fiber-reinforced polymer (FRP) bars: ACI 440.1R—15[S]. Farmington Hills: American Concrete Institute, 2015. -

下载:

下载: