Processing aramid nanofiber/poly(vinyl alcohol) hydrogel into high-strength composite films

-

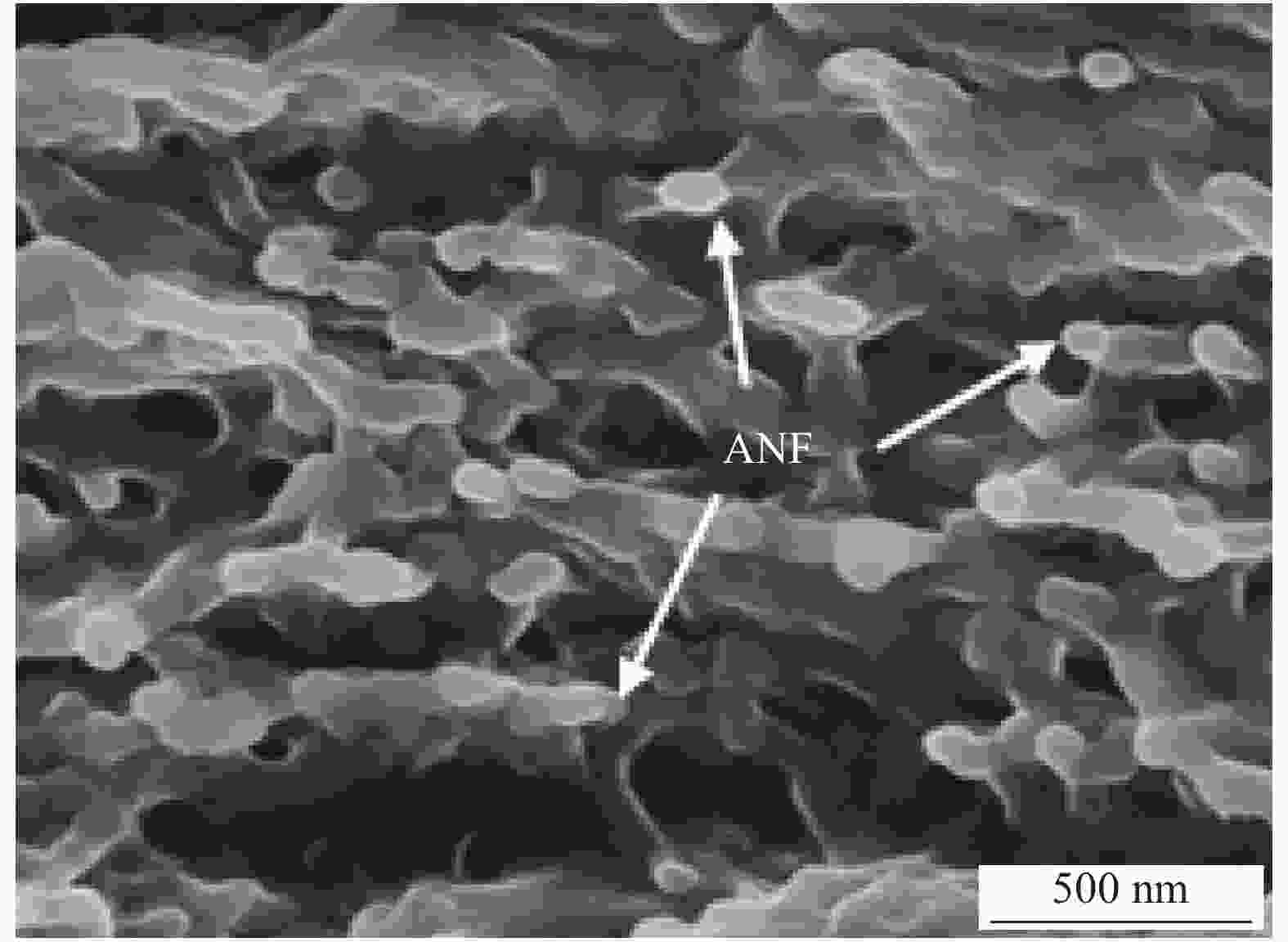

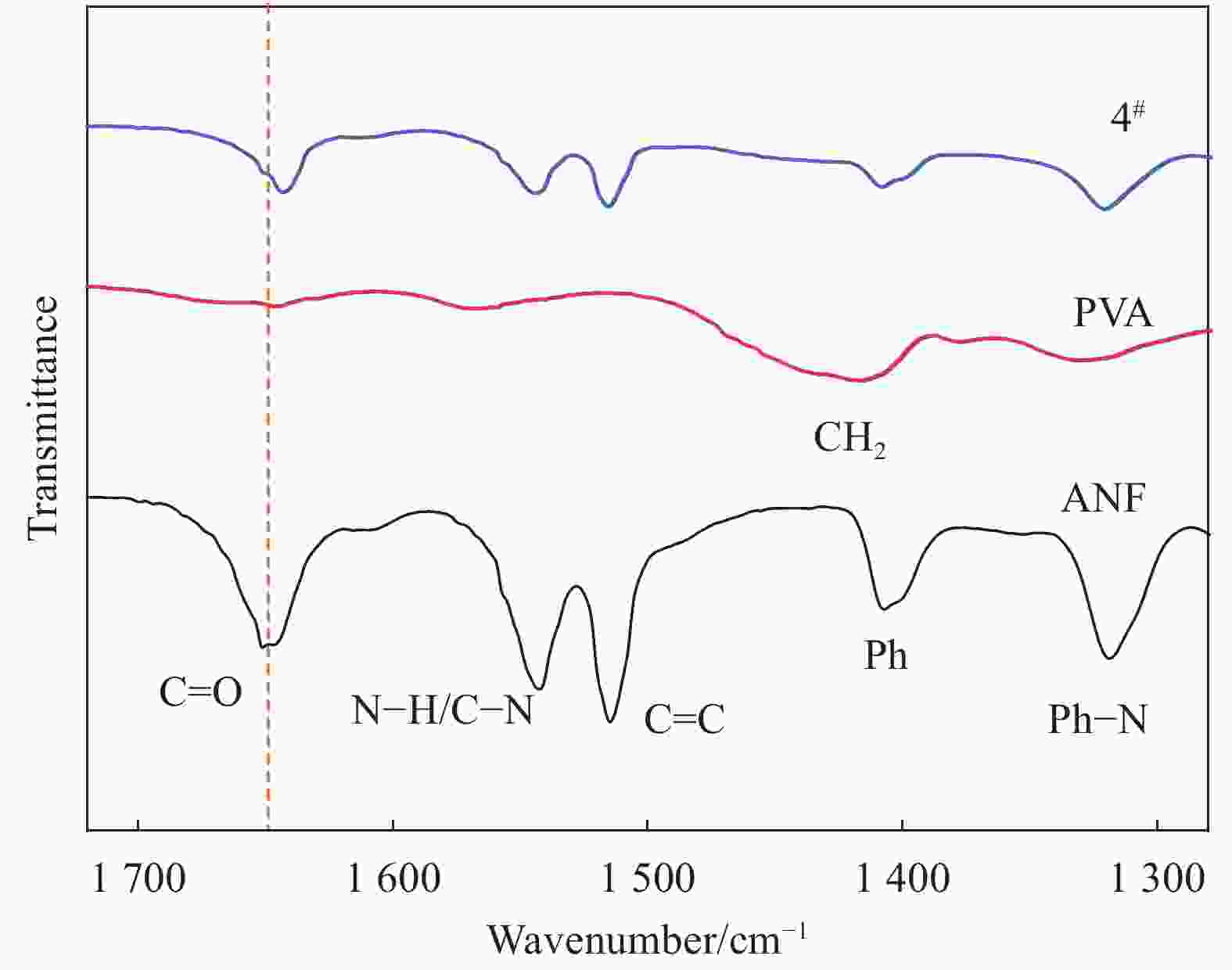

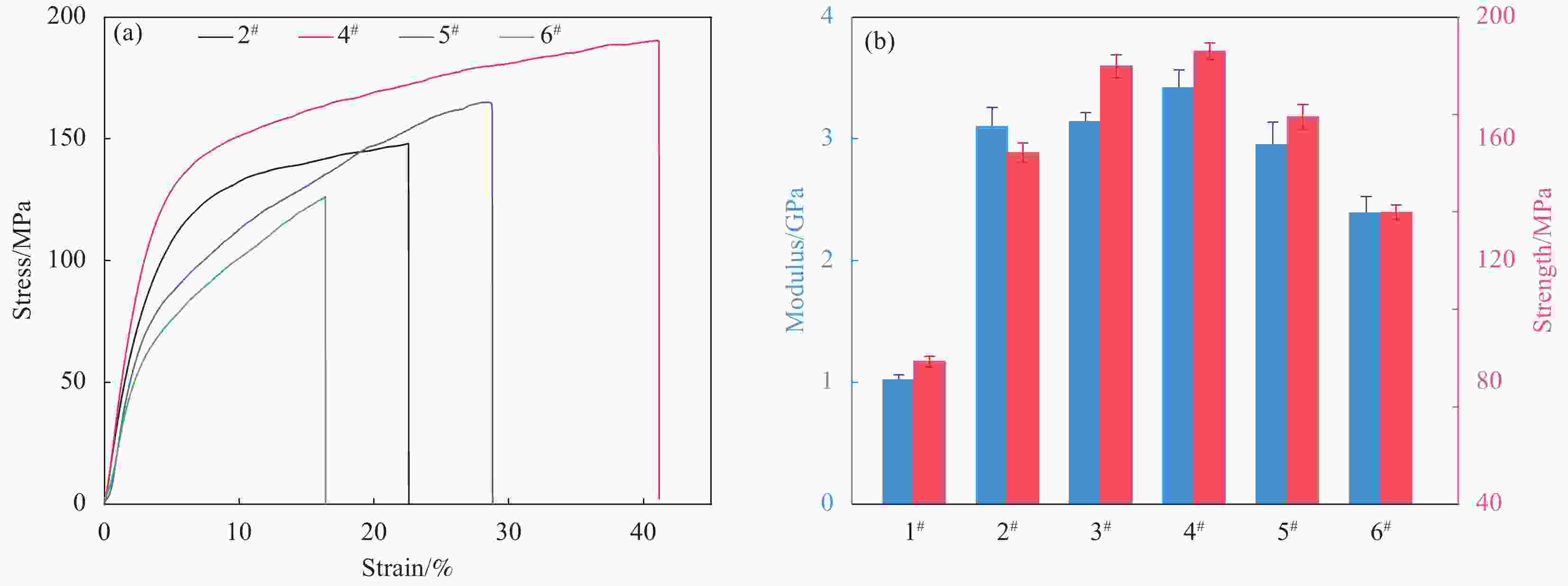

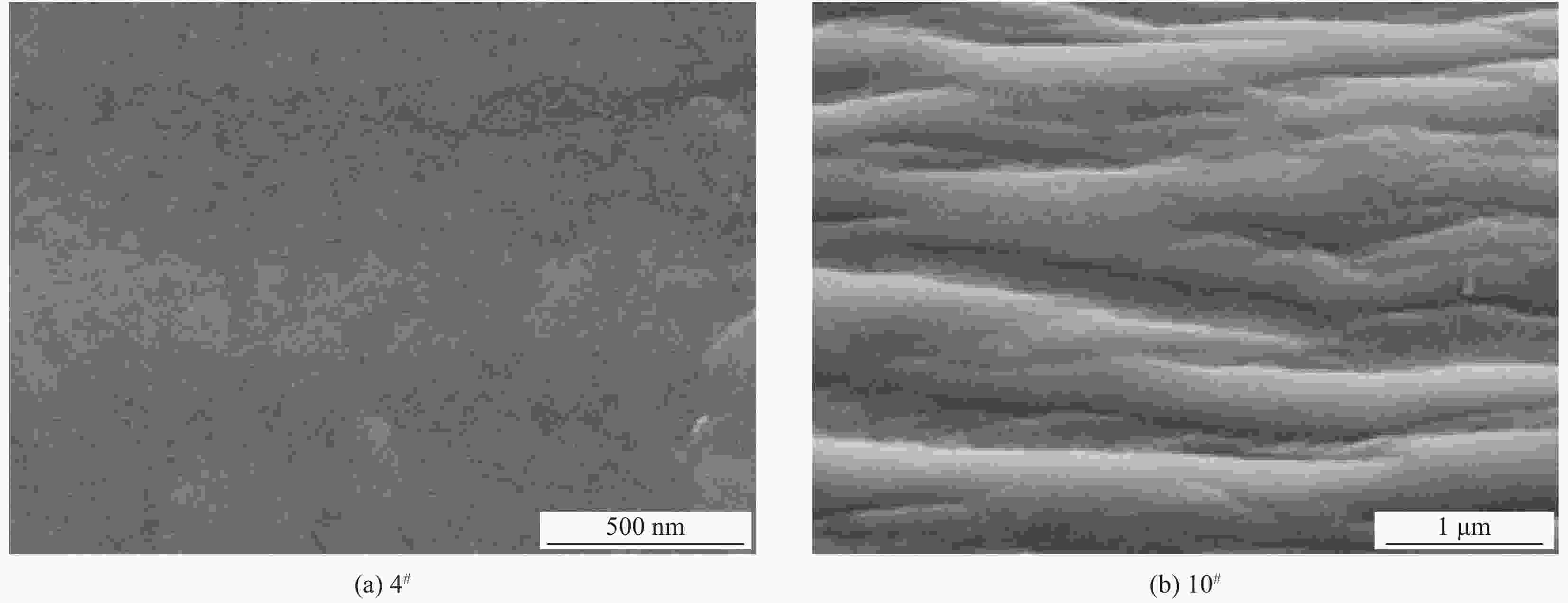

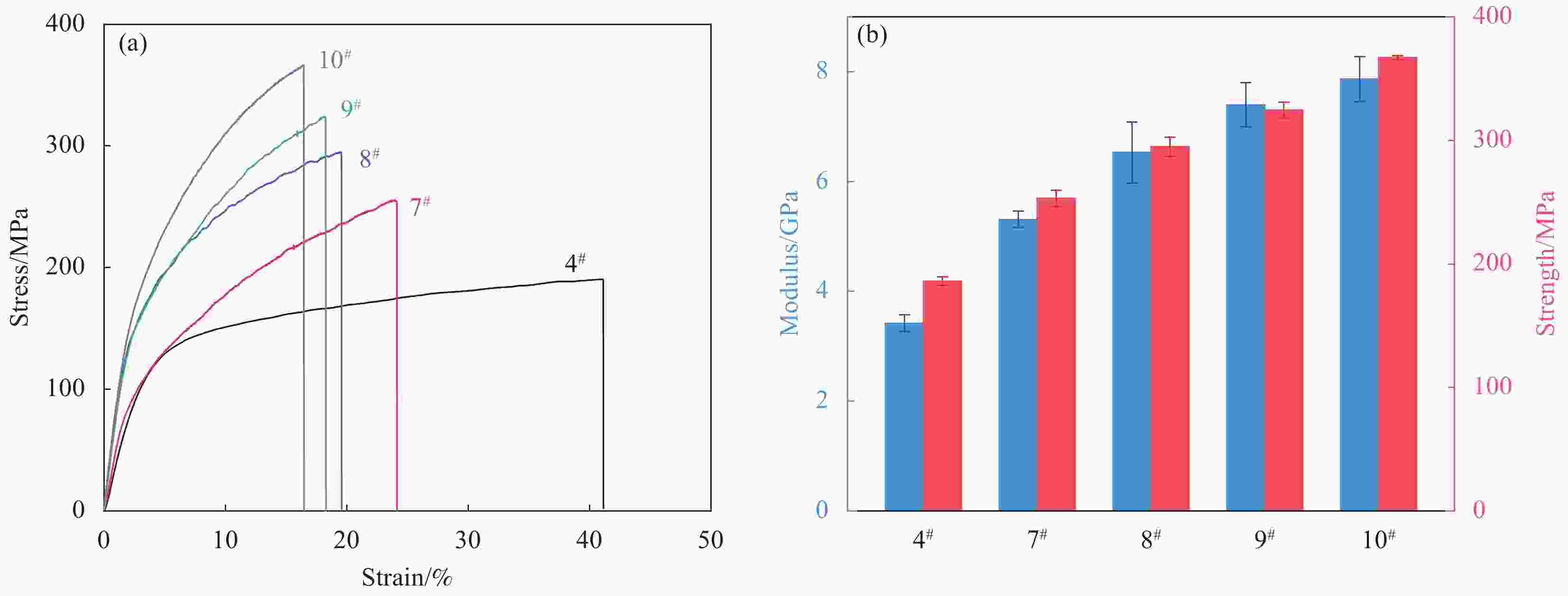

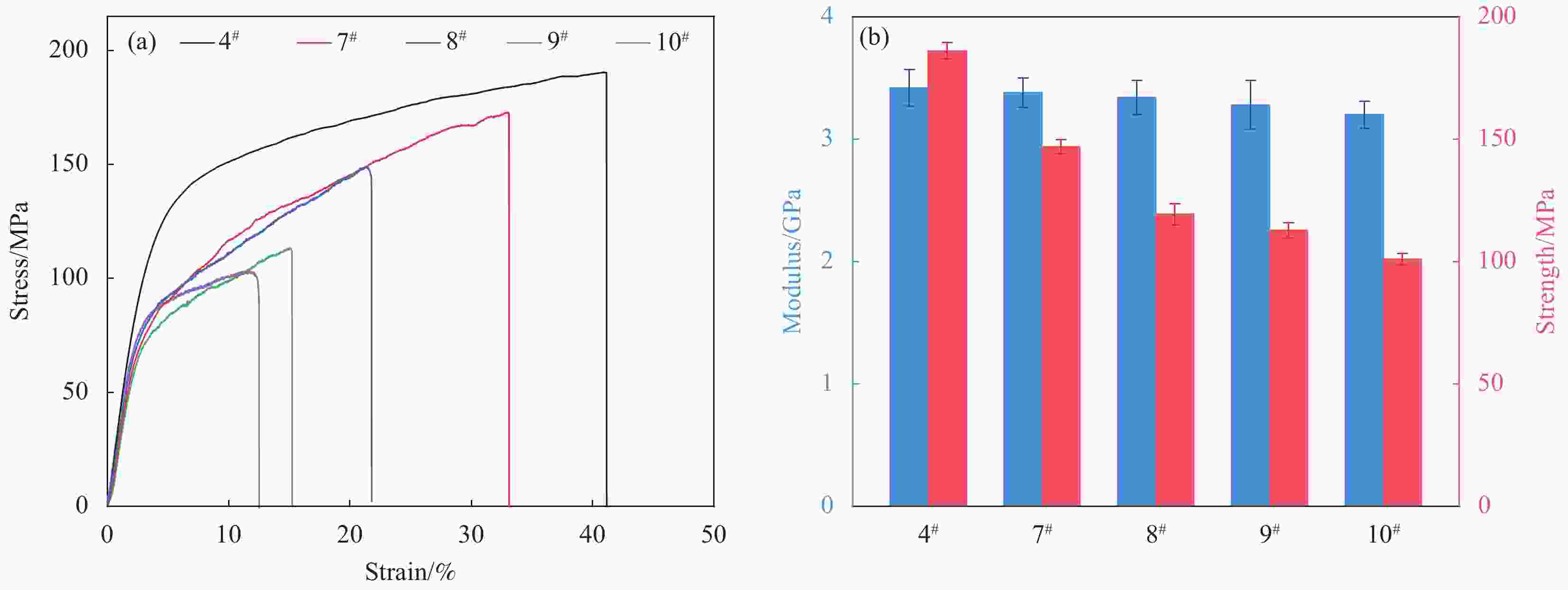

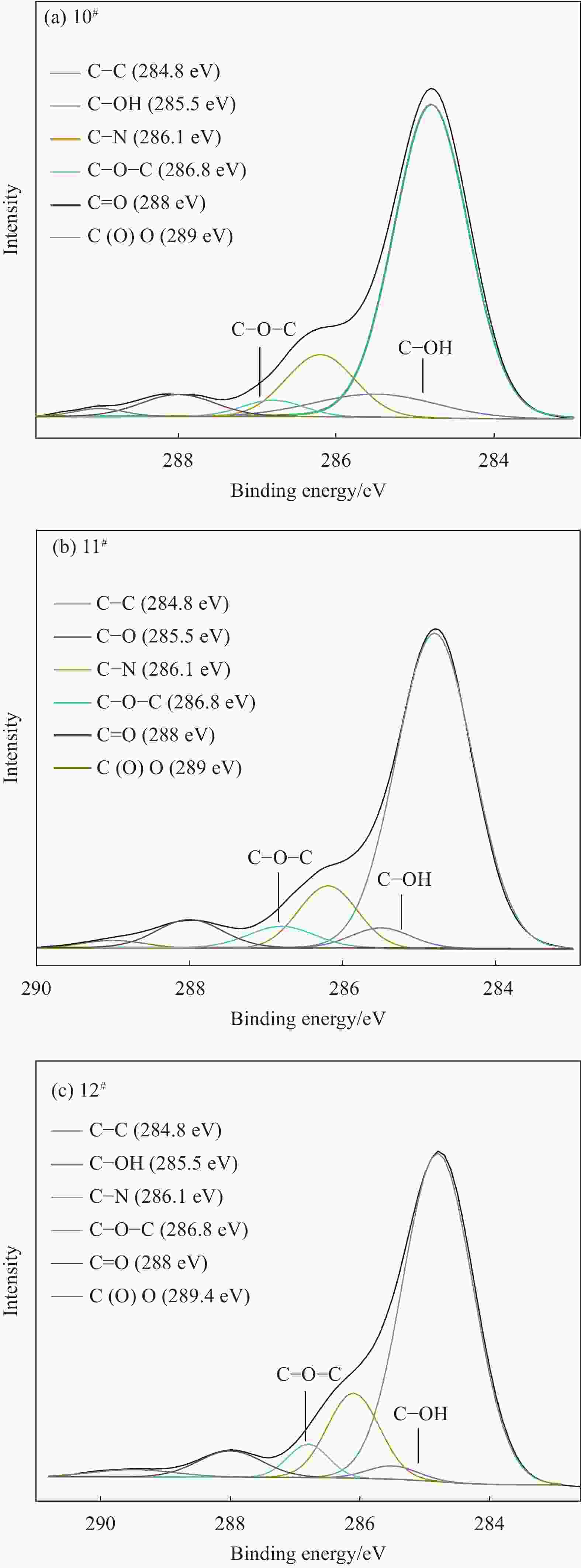

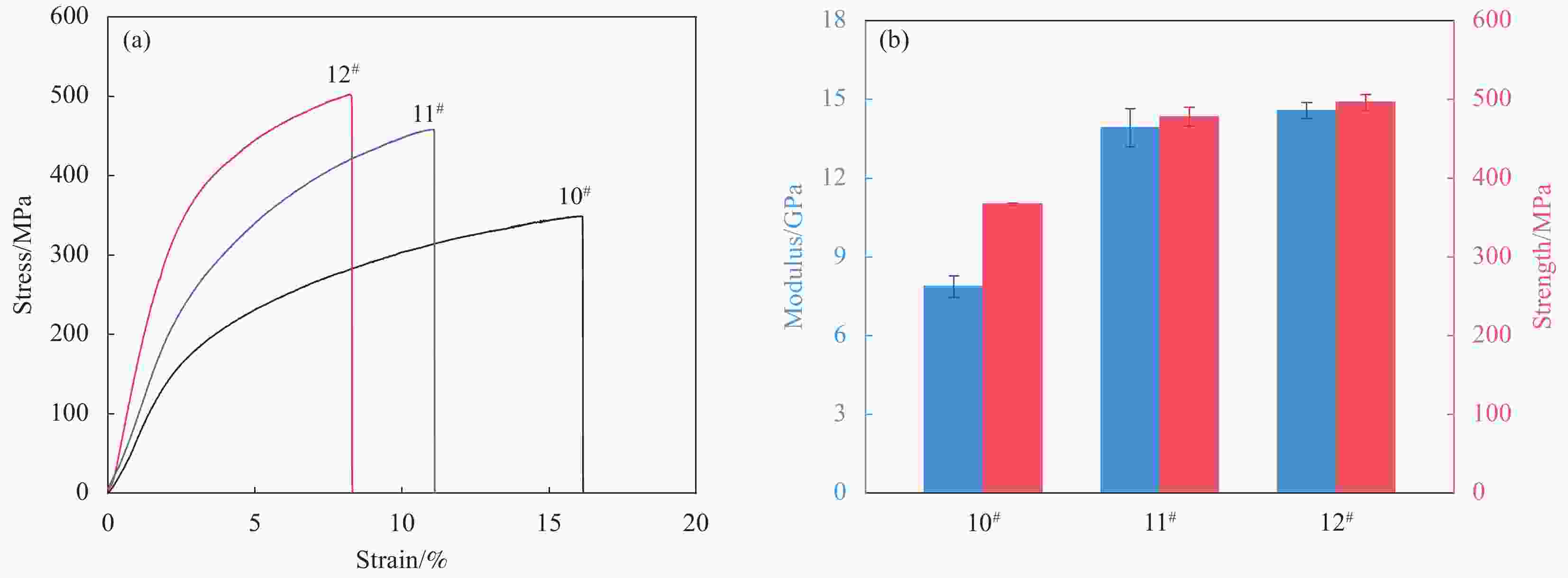

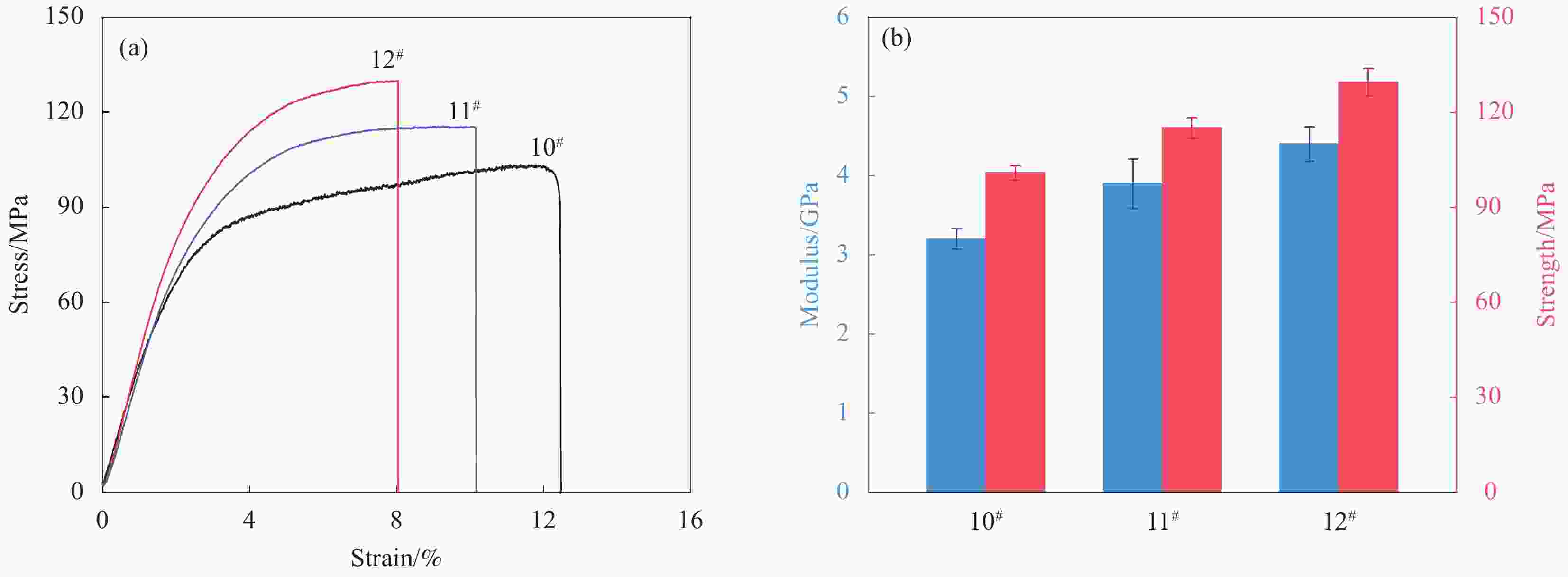

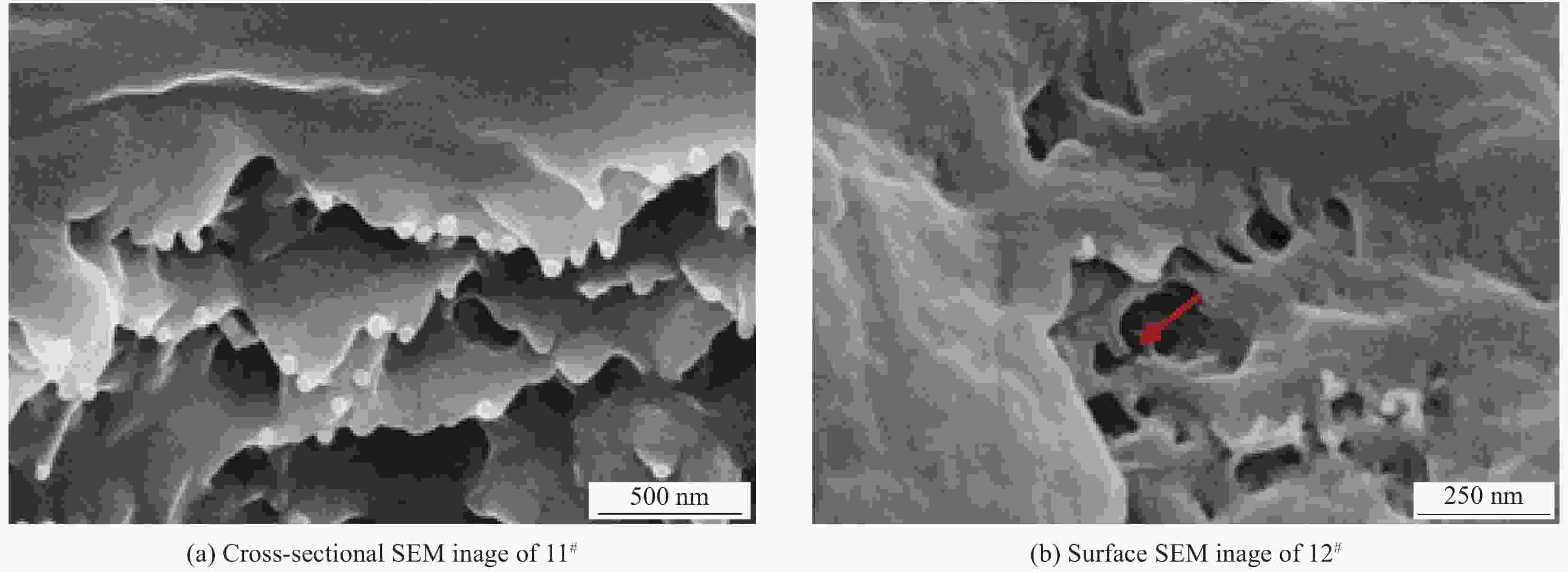

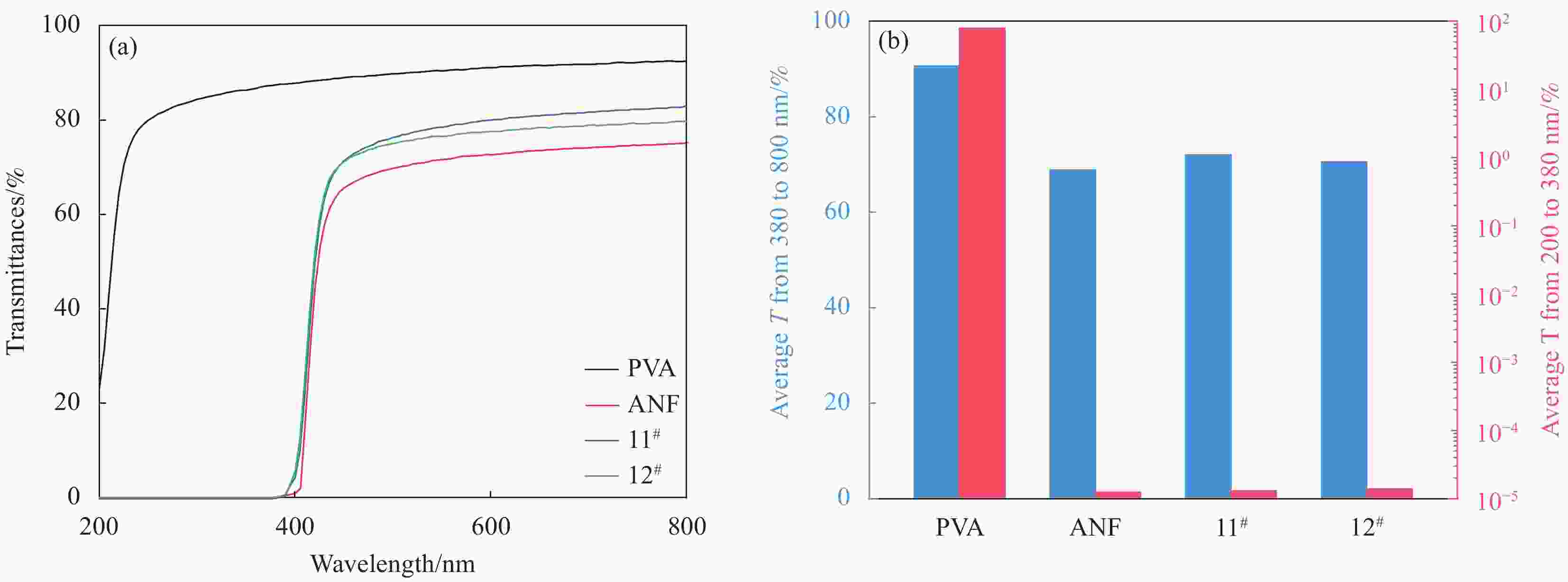

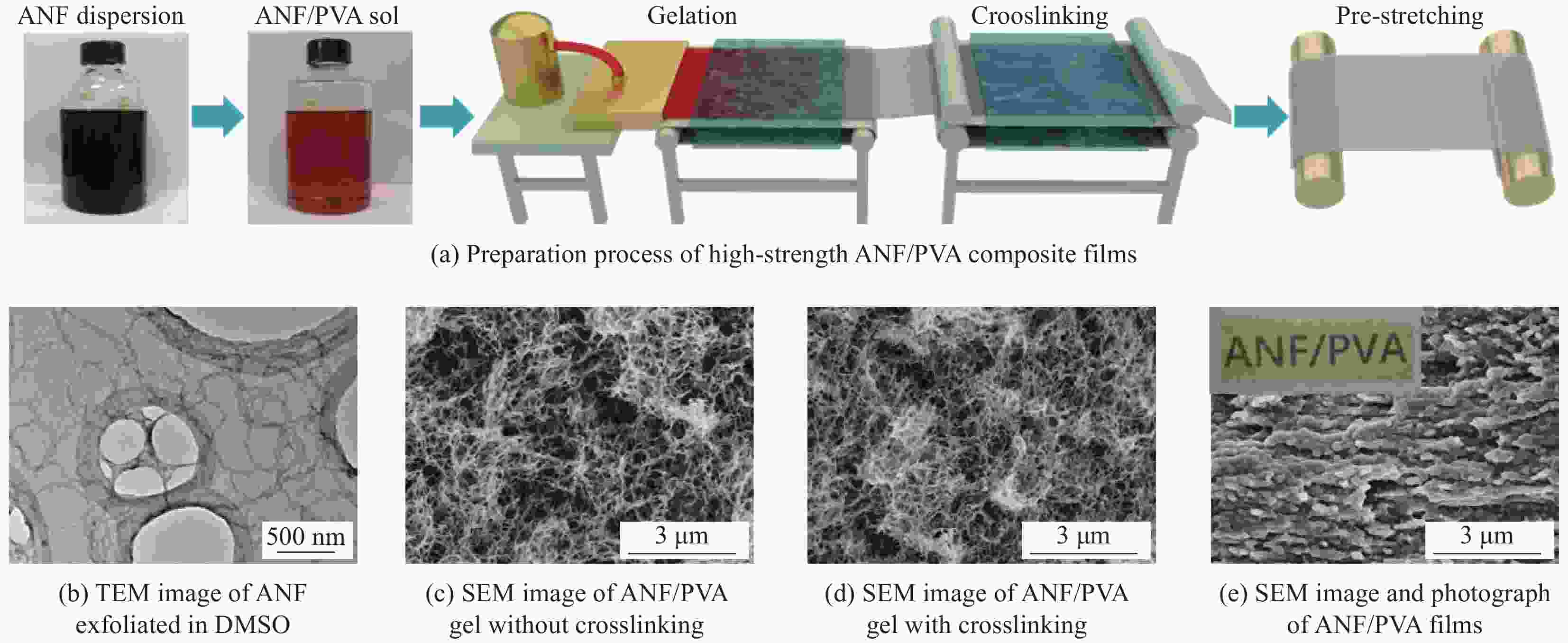

摘要: 芳纶纳米纤维(ANF)具有大长径比、高比表面积、丰富的表面酰胺官能团和优异的力学性能,是制备高强度纳米复合材料的理想构筑单元。本文开发了一种新颖的水凝胶加工策略,用于制备ANF增强聚乙烯醇(PVA)复合薄膜,逐步优化了ANF的含量、水凝胶的预拉伸比和PVA组份的化学交联,表征分析了复合薄膜中ANF的分散、取向、PVA的交联形式及ANF与PVA之间的界面氢键作用,当ANF的质量分数为25wt%、水凝胶的预拉伸比为55%和采用氯化铜交联PVA基体时,复合薄膜的力学性能最优,其杨氏模量和拉伸强度分别高达(14.6±0.3) GPa 和(496.5±10.0) MPa,远远优于文献报道的ANF增强聚合物复合材料。此外,该高强度纳米复合薄膜同时具有良好的透明性和优异的紫外屏蔽性能,透明度大于72.1%,能够屏蔽大于99.98%紫外线,可用做先进包装材料。Abstract: Aramid nanofiber (ANF) is an ideal building block for fabricating high-strength composite materials because of its large aspect ratio, high specific area, a plenty of amide group on the surface, and excellent mechanical properties. In this work, a novel hydrogel processing strategy was developed to prepare ANF-reinforced poly(vinyl alcohol) (PVA) composite films. The loading of ANF, pre-stretching ratio of ANF/PVA hydrogel and chemical crosslinking of PVA component were optimized step by step. The dispersion and orientation of ANF, the crosslinking form of PVA, and the interfacial hydrogen bond between ANF and PVA were characterized and analyzed. It is confirmed that the mechanical properties reach maximum values when ANF loading, pre-stretching ratio and the used crosslinking agent are 25wt%, 55% and CuCl2, respectively. The Young’s modulus and tensile strength of the resultant composite film are as high as (14.6±0.3) GPa and (496.5±10.0) MPa, far superior to previously reported ANF-reinforced polymer composites. Moreover, the high-strength composite film has good transparency and excellent UV light shielding property. Its transmittance is larger than 72.1%, while it can shield more than 99.98% UV light. We believe that the transparent yet UV light-blocking composite film can be applied as advanced packaging materials.

-

表 1 芳纶纳米纤维/聚乙烯醇(ANF/PVA)复合薄膜的配方

Table 1. Formula of aramid nanofiber/poly(vinyl alcohol) hydrogel (ANF/PVA) composite films

Sample ANF/

wt%PVA/

wt%Crosslinking

agentPre-stretching

ratio/%1# 0 100 No 0 2# 17 83 No 0 3# 20 80 No 0 4# 25 75 No 0 5# 33 67 No 0 6# 50 50 No 0 7# 25 75 No 15 8# 25 75 No 30 9# 25 75 No 45 10# 25 75 No 55 11# 25 75 Glutaraldehyde (GA) 55 12# 25 75 CuCl2 55 表 2 交联前后ANF/PVA中C—OH、C—O—C基团的含量变化

Table 2. Different of C—OH and C—O—C groups in ANF/PVA before and after crosslinking

Sample C—OH/% C—O—C/% 10# 4.4 2.7 11# 3.3 3.0 12# 2.1 4.2 -

[1] 雷卫华, 陈可平. 聚硅氧烷/ZDMA/短切芳纶纤维复合材料的结构与性能[J]. 复合材料学报, 2021, 38(5):1398-1406.LEI Weihua, CHEN Keping. Structure and properties of polysiloxane/ZDMA/short-cutted aramid fiber compo-sites[J]. Acta Materiae Compositae Sinica,2021,38(5):1398-1406(in Chinese). [2] LYU J, WANG X, LIU L, et al. High strength conductive composites with plasmonic nanoparticles aligned on aramid nanofibers[J]. Advanced Functional Materials,2016,26(46):8435-8445. doi: 10.1002/adfm.201603230 [3] 杨旋, 涂群章, 沈新民, 等. 双键超支化聚硅氧烷在芳纶纤维表面的原位生长[J]. 复合材料学报, 2021, 38(9):3018-3026.YANG Xuan, TU Qunzhang, SHEN Xinmin, et al. Study on the in-situ growth of hyperbranched polysioxane with double bonds on the surface of aramid fiber[J]. Acta Materiae Compositae Sinica,2021,38(9):3018-3026(in Chinese). [4] 张美云, 罗晶晶, 杨斌, 等. 芳纶纳米纤维的制备及应用研究进展[J]. 材料导报, 2020, 34(5):158-166.ZHANG Meiyun, LUO Jingjing, YANG Bin, et al. Preparation and application of aramid nanofibers[J]. Materials Guide,2020,34(5):158-166(in Chinese). [5] YANG M, CAO K Q, SUI L, et al. Dispersions of aramid nano-fibers: A new nanoscale building block[J]. ACS Nano,2011,5(9):6945-6954. doi: 10.1021/nn2014003 [6] KUANG Q X, ZHANG D, YE J C, et al. Toward record-high stiffness in polyurethane nanocomposites using aramid nanofibers[J]. Journal of Physical Chemistry C,2015,119:27467-27477. doi: 10.1021/acs.jpcc.5b08856 [7] YANG B, WANG L, ZHANG M Y, et al. Timesaving, high-efficiency approaches to fabricate aramid nanofibers (ANFs)[J]. ACS Nano,2019,13(7):7886-7897. doi: 10.1021/acsnano.9b02258 [8] 曾繁展, 陈宪宏, 王建锋. 连续制备柔性导热的氮化铝/芳纶纳米纤维复合薄膜[J]. 复合材料学报, 2020, 37(12):3043-3051.ZENG Fanzhan, CHEN Xianhong, WANG Jianfeng. Continuous fabrication of flexible, thermally conductive aluminum nitride/aramid nanofiber composite films[J]. Acta Materiae Compositae Sinica,2020,37(12):3043-3051(in Chinese). [9] MA Z L, KONG S L, MA Z J, et al. Flexible, transparent and conductive Ti3C2Tx MXene-silver nanowire films with smart acoustic sensitivity for high-performance electromagnetic interference shielding[J]. ACS Nano,2020,14(7):8368-8382. doi: 10.1021/acsnano.0c02401 [10] WU Y D, FANG W, HUANG Y D. Facile and simple fabri cation of strong, transparent and flexible aramid nano-fibers/bacterial cellulose nanocomposite membranes[J]. Composites Science and Technology,2018,159:70-76. doi: 10.1016/j.compscitech.2018.02.036 [11] KOO J M, KIM H, LEE M, et al. Nonstop monomer-to-aramid nanofiber synthesis with remarkable reinforcement ability[J]. Macromolecules,2019,52(3):923-934. doi: 10.1021/acs.macromol.8b02391 [12] ZHU J, BANG S H, MALAKOOTI M H, et al. Isolation of aramid nanofibers for high strength and toughness polymer nanocomposites[J]. ACS Applied Materials & Interfaces,2017,9(12):11167-11175. [13] LIN Z J, YANG M, EMRE A, et al. Branched aramid nanofibers[J]. Angewandte Chemie,2017,56(39):11744-11748. doi: 10.1002/anie.201703766 [14] LYU J, ZHAO X, HOU X L, et al. Electromagnetic interference shielding based on a high strength polyaniline-aramid nanocomposite[J]. Composites Science and Technology,2017,149:159-165. doi: 10.1016/j.compscitech.2017.06.026 [15] PATTERSON B A, MALAKOOTI M H, LIN J J, et al. Aramid nanofibers for multiscale fiber reinforcement of polymer composites[J]. Composites Science and Technology,2018,162:92-99. [16] ZHOU G D, WANG W T, PENG M. Functionalized aramid nanofibers prepared by polymerization induced self-assembly for simultaneously reinforcing and toughening of epoxy and carbon fiber/epoxy multiscale composite[J]. Composites Science and Technology,2018,168:312-319. doi: 10.1016/j.compscitech.2018.10.013 [17] YANG B, LIN W, ZHANG M Y, et al. Fabrication, applications, and prospects of aramid nanofiber[J]. Advanced Functional Materials,2020,30(22):2000186. doi: 10.1002/adfm.202000186 [18] MANSUR H S, SADAHIRA C M, SOUZA A N, et al. FTIR spectroscopy characterization of poly (vinyl alcohol) hydrogel with different hydrolysis degree and chemically crosslinked with glutaraldehyde[J]. Materials Science and Engineering C,2008,28(4):539-548. doi: 10.1016/j.msec.2007.10.088 [19] ALADEJANA J T, WU Z, LI D, et al. Facile approach for glutaraldehyde cross-linking of PVA/Aluminophosphate adhesives for wood-based panels[J]. ACS Sustainable Chemistry & Engineering,2019,7(22):18524-18533. [20] PODSIADLO P, KAUSHIK A K, SHIM B S, et al. Can nature's design be improved upon? High strength, transparent nacre-like nanocomposites with double network of sacrificial cross links[J]. Journal of Physical Chemistry B,2008,112(46):14359-14363. doi: 10.1021/jp801492n [21] LI H, TENG C, WANG J F, et al. A scalable hydrogel processing route to high-strength, foldable clay-based artificial nacre[J]. Composites Science and Technology,2021,201:108543. doi: 10.1016/j.compscitech.2020.108543 [22] XU L Z, ZHAO X, XU C, et al. Water-rich biomimetic composites with abiotic self-organizing nanofiber network[J]. Advanced Materials,2017,3(1):1703343. [23] LV L L, HAN X S, ZONG L, et al. Biomimetic hybridiztion of Kevlar into silk fibroin: nanofibrous strategy for improved mechanic properties of flexible composites and filtration membranes[J]. ACS Nano,2017,11(8):8178-8184. doi: 10.1021/acsnano.7b03119 [24] GUAN Y, LI W, ZHANG Y, et al. Aramid nanofibers and poly (vinyl alcohol) nanocomposites for ideal combination of strength and toughness via hydrogen bonding interactions[J]. Composites Science and Technology,2017,144:193-201. doi: 10.1016/j.compscitech.2017.03.010 [25] WANG F, WU Y, HUANG Y, et al. Strong, transparent and flexible aramid nanofiber/POSS hybrid organic/inorganic nanocomposite membranes[J]. Composites Science and Technology,2018,156:269-275. doi: 10.1016/j.compscitech.2018.01.016 [26] MREDHA M T I, GUO Y Z, NONOYAMA T, et al. A facile method to fabricate anisotropic hydrogels with perfectly aligned hierarchical fibrous structures[J]. Advanced Materials,2018,30(9):1704937. doi: 10.1002/adma.201704937 [27] YE D D, LEI X J, LI T, et al. Ultrahigh tough, super clear, and highly anisotropic nanofiber-structured regenerated cellulose films[J]. ACS Nano,2019,13(4):4843-4853. doi: 10.1021/acsnano.9b02081 [28] XUE X D, JIANG K, YIN Q, et al. Tailoring the structure of Kevlar nanofiber and its effects on the mechanical property and thermal stability of carboxylated acrylonitrile butadiene rubber[J]. Journal of Applied Polymer Science,2019,136(26):47698. doi: 10.1002/app.47698 [29] ZHANG X, CHEN Y, YIN Q, et al. Highly improved compatibility and mechanical properties of carboxylated nitrile rubber/styrene butadiene rubber by incorporating modified Kevlar nanofibers[J]. Materials Chemistry and Physics,2019,238:121926. doi: 10.1016/j.matchemphys.2019.121926 [30] YANG B, ZHANG M Y, LU Z Q, et al. Comparative study of aramid nanofiber (ANF) and cellulose nanofiber (CNF)[J]. Carbohydrate Polymers,2018,208:372-381. -

下载:

下载: