Multi-scale method for thermal conductivity of polypropylene fiber reinforced cementitious composites after high temperature

-

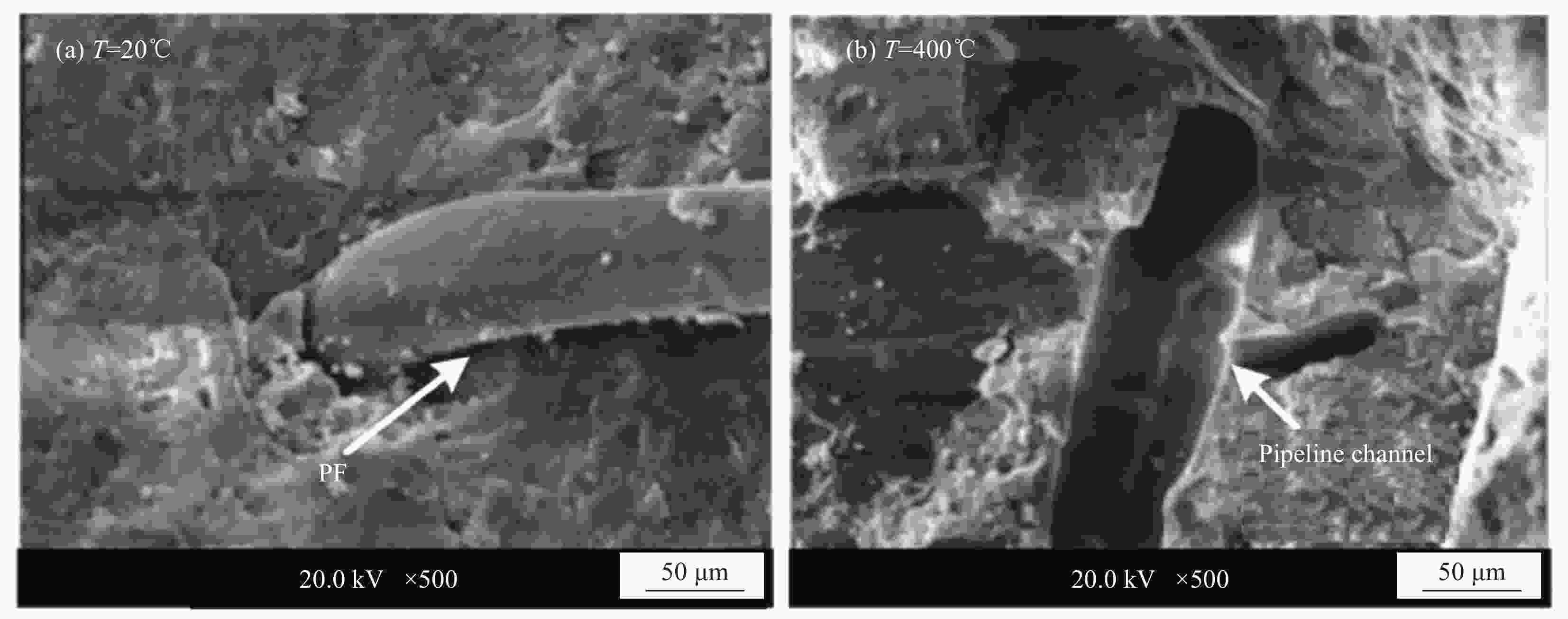

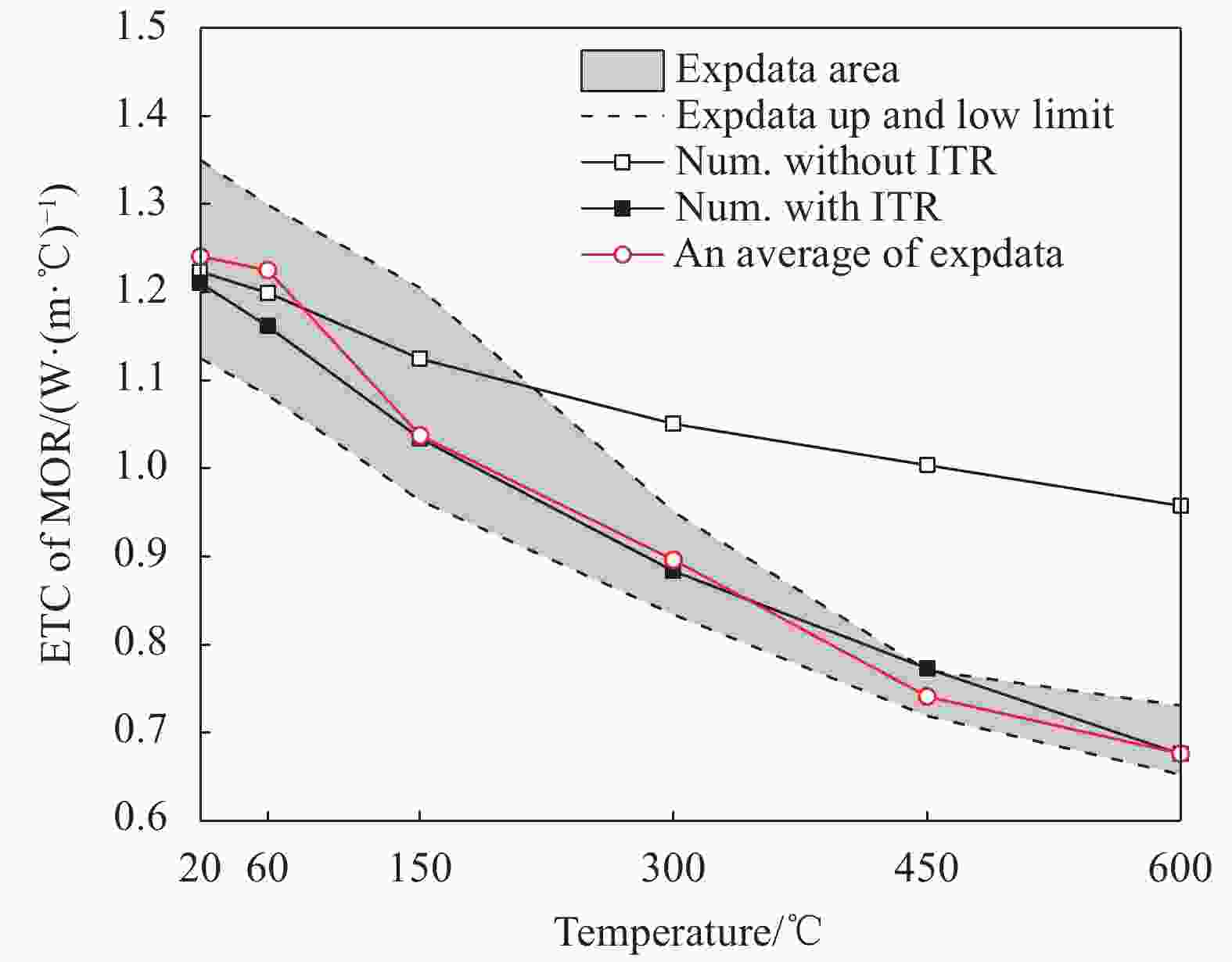

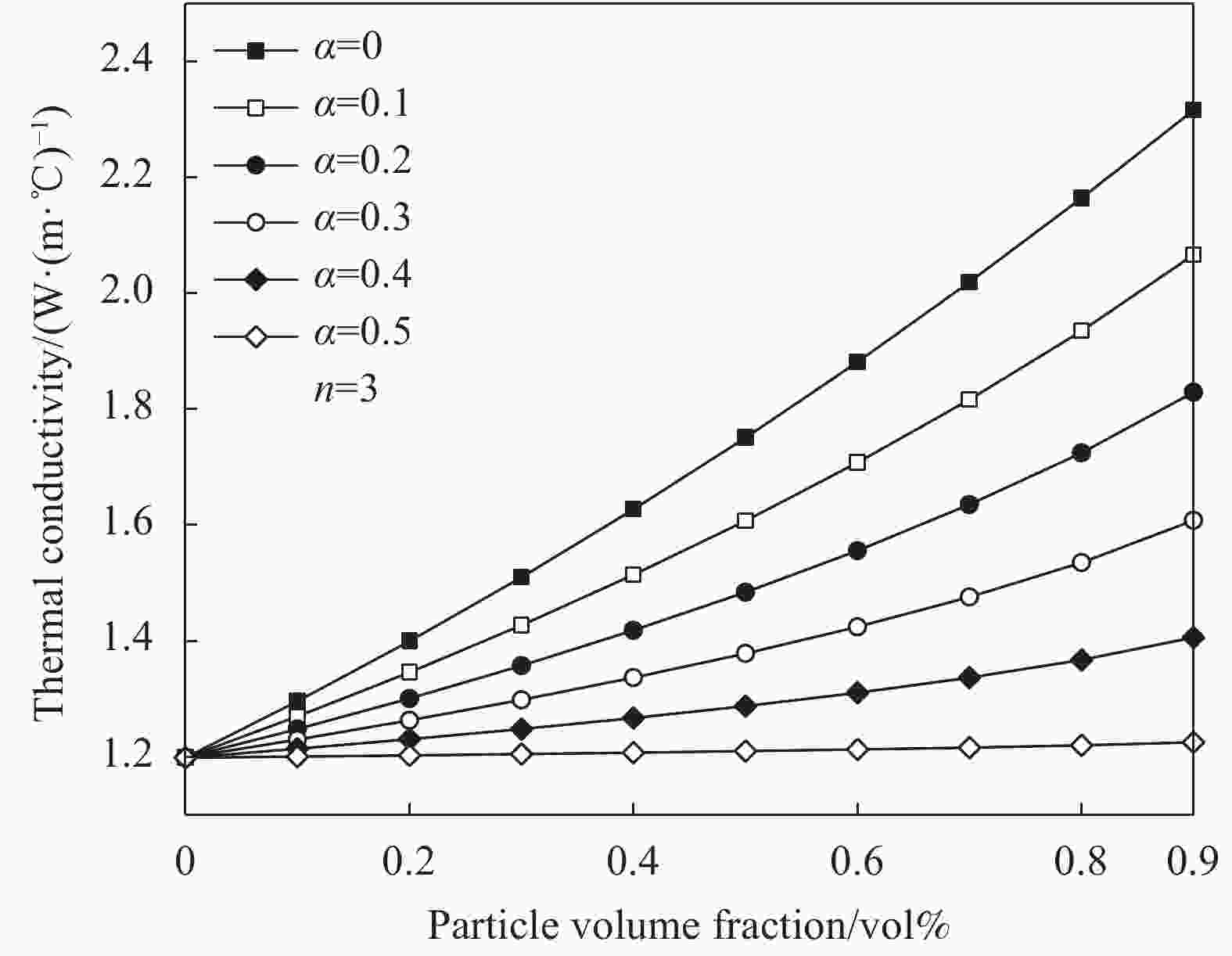

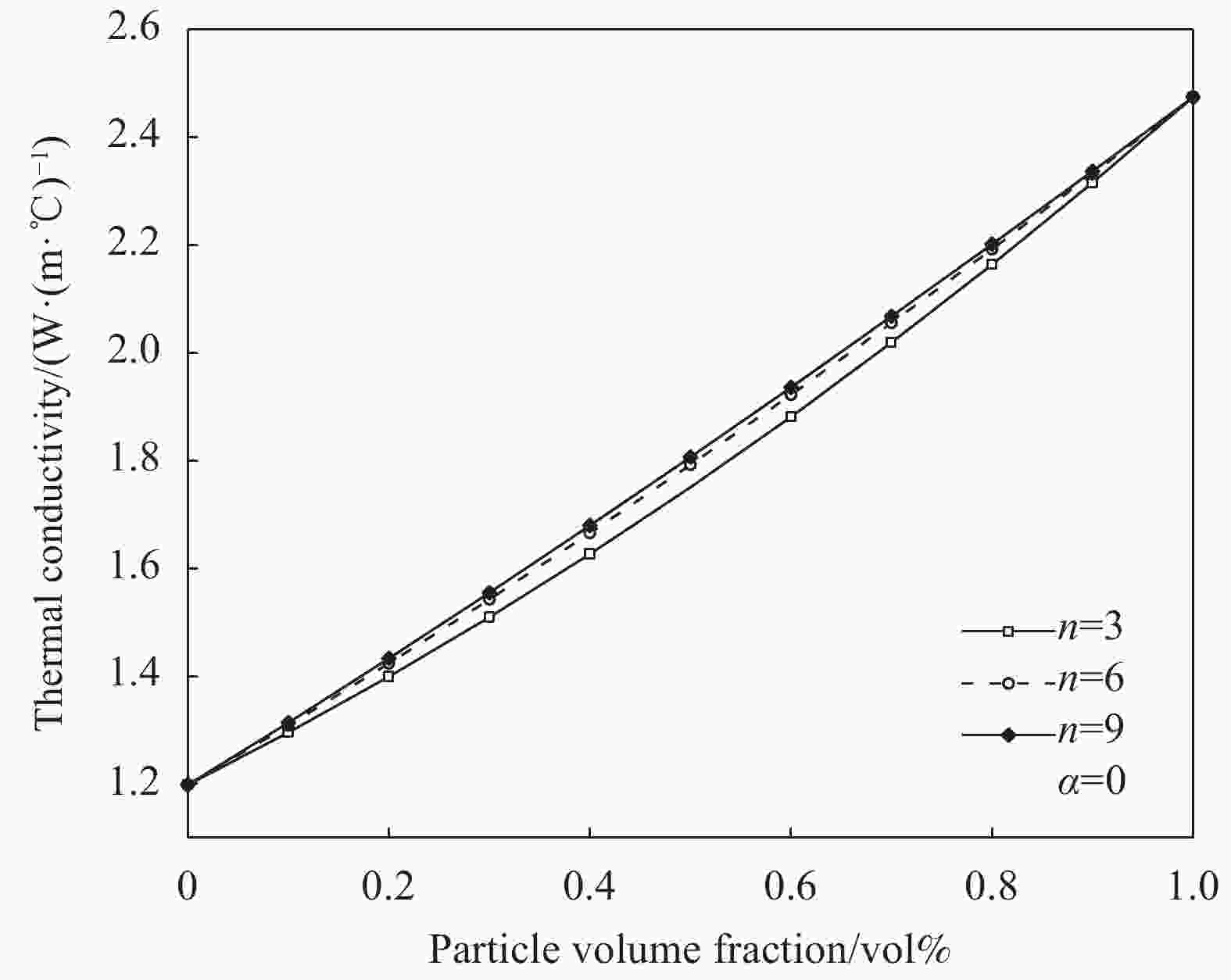

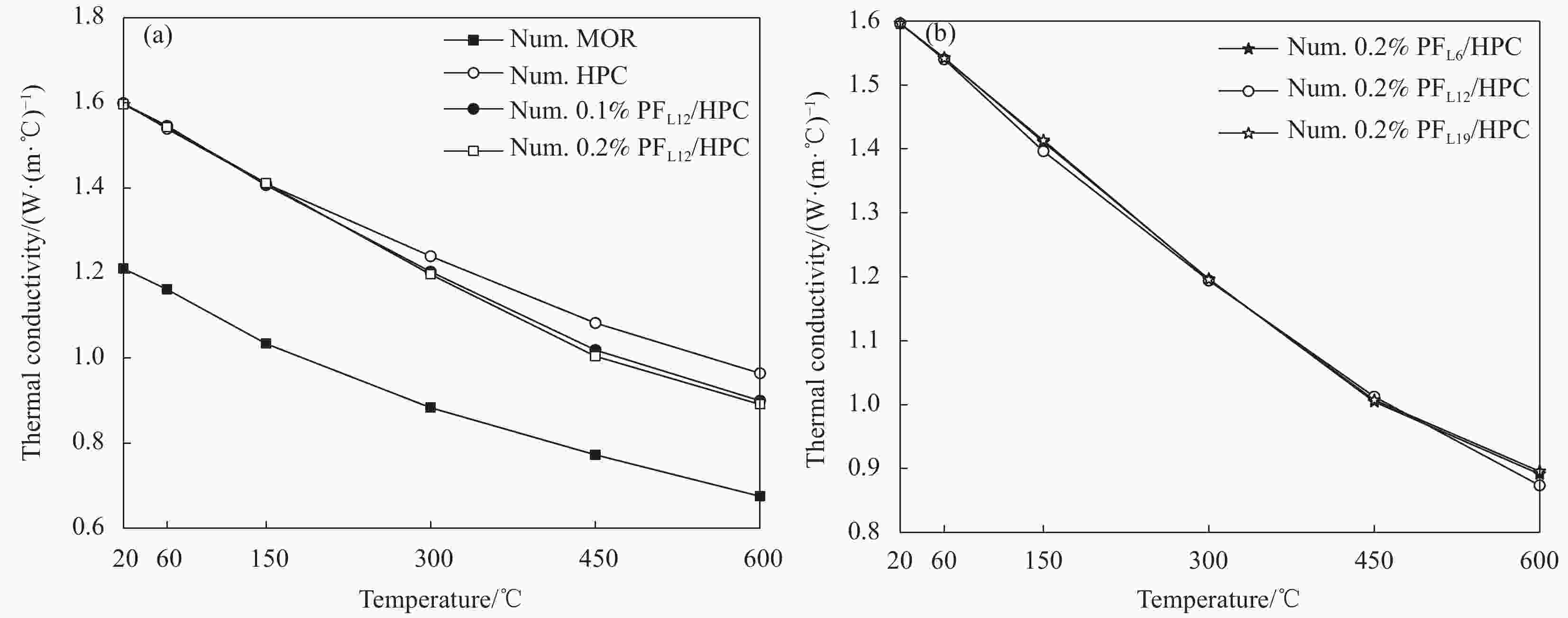

摘要: 有效导热系数(ETC)是预测火灾下混凝土结构内部温度时空分布的关键物性参数,为此提出了基于考虑界面热阻和粒子形状系数的改进Maxwell-Eucken模型的多相复合材料多尺度均质化方法,以预测高温后纤维增强水泥基复合材料的ETC。首先针对经历不同温度(20、60、150、300、450和600℃)处理后的砂浆、普通高性能混凝土和聚丙烯纤维增强混凝土开展了导热系数和孔隙率的测量试验,随后利用部分试验数据确定所提方法关键参数。最终利用所提方法预测经历不同温度处理后掺加不同含量和尺寸纤维的混凝土的ETC,方法预测结果与其余试验结果吻合良好。研究发现:粒子形状(纤维长度)对水泥基复合材料ETC的影响甚微;界面热阻(粒子与基体脱粘)对ETC的影响显著,界面热阻系数与经历温度呈线性增长关系;聚丙烯纤维熔化蒸发后干燥空气填充,形成管状裂缝热阻,同时柔软的细聚丙烯纤维在浇筑过程中附着在粗骨料表面,蒸发后进一步增加骨料与砂浆之间的界面热阻效应。Abstract: The effective thermal conductivity (ETC) is a key physical parameter for predicting the temperature distribution of concrete structure under fire. Responding to this demand, a multi-scale homogenization method based on the improved Maxwell-Eucken model, considering interfacial thermal resistance and random particle shape, was proposed to estimate the thermal conductivity of cementitious composites after high temperature. Firstly, the thermal conductivity and porosity of mortar, high performance concrete and polypropylene fiber reinforced concrete with thermal treatment at different temperatures (20, 60, 150, 300, 450 and 600℃) were measured and a part of experimental data was used to calibrate the proposed method. Finally, the method was verified by good agreement between experimental data and numerical results of concrete with different heating temperatures and different fiber contents and size. The results show that: The particle shape (fiber length) has a marginal effect on the ETC; The interfacial thermal resistance (ITR) caused by particle and matrix debonding has a significant effect on the ETC, and the ITR coefficient is in direct proportion to the heating temperature; The polypropylene fiber melts and evaporates at high temperature and then the ‘tunnel crack’ filled with dry air forms a thermal resistance. In addition, the melting and evaporation of soft fine polypropylene fiber adhering on the coarse aggregate surface enhances the ITR effect between aggregate and mortar.

-

表 1 水泥基复合材料配合比

Table 1. Mix in experiment of cementitious composites

kg/m3 Material MOR HPC 0.1%PFL12/HPC 0.2%PFL6/HPC 0.2%PFL12/HPC 0.2%PFL19/HPC Detail Cement 500 500 500 500 500 500 Poland cement 42.5 Water 150 150 150 150 150 150 Ordinary tap water Fine aggregate 713 713 713 713 713 713 Dried river sand;

Diameter: 3-2.7 mmCoarse aggregate 0 1027 1027 1027 1027 1027 Crushed limestone;

Diameter: 5-20 mmAdmixture 13.5 13.5 13.5 13.5 13.5 13.5 Polycarboxylic acid PF 0 0 0.91 1.82 1.82 1.82 Length:6,12,19 mm;

Diameter: 18-48 μmNotes: HPC—High performance concrete; 0.1%PFL12/HPC, 0.2%PFL6/HPC, 0.2%PFL12/HPC and 0.2%PFL19/HPC are different types of polypropylene fiber reinforced concretes, 0.1% and 0.2% represent the volume ratios of polypropylene fibers, PF—Polypropylene fiber; Letter L stands for fiber length, which are 6, 12 and 19 mm, respectively. 表 2 水泥基复合材料试验结果

Table 2. Experimental data of cementitious composites

Mixture T/℃ Porosity ETC/ (W∙(m∙℃)−1) Average Max Min MOR 20 0.0237 1.258 1.350 1.125 60 0.0237 1.225 1.299 1.083 150 0.1000 1.023 1.205 0.963 300 0.1737 0.896 0.951 0.834 450 0.2194 0.741 0.771 0.719 600 0.2637 0.676 0.731 0.653 HPC 20 0.0250 1.606 1.763 1.434 60 0.0250 1.452 1.672 1.371 150 0.0770 1.409 1.543 1.306 300 0.1186 1.269 1.384 1.032 450 0.1594 1.124 1.235 0.947 600 0.1729 0.964 1.053 0.867 0.1%PFL12/HPC 20 0.0149 1.599 1.695 1.470 60 0.0149 1.414 1.630 1.323 150 0.0802 1.341 1.425 1.284 300 0.1132 1.230 1.386 1.160 450 0.1514 1.045 1.175 0.924 600 0.1713 0.908 1.003 0.841 0.2%PFL6/HPC 20 0.0167 1.472 1.642 1.381 60 0.0167 1.379 1.697 1.334 150 0.0730 1.285 1.473 1.125 300 0.1076 1.187 1.346 1.036 450 0.1492 1.022 1.306 0.862 600 0.1636 0.887 1.037 0.829 0.2%PFL12/HPC 20 0.0200 1.585 1.680 1.470 60 0.0200 1.391 1.602 1.235 150 0.0907 1.255 1.489 1.177 300 0.1105 1.191 1.350 1.055 450 0.1399 1.011 1.156 1.000 600 0.1842 0.877 0.963 0.735 0.2%PFL19/HPC 20 0.0182 1.541 1.685 1.347 60 0.0182 1.445 1.654 1.247 150 0.0697 1.334 1.523 1.113 300 0.1089 1.190 1.308 1.009 450 0.1460 0.969 1.030 0.869 600 0.1585 0.874 1.024 0.807 Notes: T—Temperature; ETC—Effective thermal conductivity. 表 3 水泥基复合材料多尺度方法参数

Table 3. Parameters for multi-scale method of cementitious composites

Temperature/℃ Matrix Particles Material ${\lambda _{\rm{m}}}$/(m∙℃)−1 Material ${\lambda _{\rm{p}}}$/(m∙℃)−1 ${V_{\rm{p}}}$ $n$ $\alpha $ Step1 20-600 Cement paste solid skeleton 0.56 Identified Water dry air 0.6 0.026[31-32] Porosity

measured3 Assumed 0 Assumed Step2 20-600 Cement paste Calculated by Step1 Fine aggregate 3.1[33] 0.43 mixture 3 Assumed (0.21/600) T Identified Step3 20-600 Mortar Calculated by Step2 Coarse aggregate 2.4[33] 0.386 mixture 3 Assumed (0.27/600) T Identified Step4 20-600 Plain concrete Calculated by Step3 Polypropylene fiber 0.22[34] 1% or 2% mixture Details in the paper Details in the paper Notes: ${\lambda _{\rm{m}}}$—ETC of the matrix; ${\lambda _{\rm{p}}}$—ETC of the particles; ${V_{\rm{p}}}$—Volume fraction of the particles, $n$—Shape coefficient of the particles; $\alpha $—Interfacial thermal resistance coefficient between matrix and particles. -

[1] ZEIML M, LEITHNER D, LACKNER R, et al. How do polypropylene fibers improve the spalling behavior of in-situ concrete?[J]. Cement & Concrete Research,2006,36(5):929-942. [2] BANGI M R, HORIGUCHI T. Effect of fibre type and geometry on maximum pore pressures in fibre-reinforced high strength concrete at elevated temperatures[J]. Cement & Concrete Research,2012,42(2):459-466. [3] KODUR V, KHALIQ W. Effect of temperature on thermal properties of different types of high-strength concrete[J]. Journal of Materials in Civil Engineering,2011,23(12):1764. doi: 10.1061/(ASCE)MT.1943-5533.0000367 [4] KHALIQ W, KODUR V. Thermal and mechanical properties of fiber reinforced high performance self-consolidating concrete at elevated temperatures[J]. Cement & Concrete Research,2011,41(11):1112-1122. [5] LIANG X W, WU C Q. Investigation on thermal conductivity of steel fiber reinforced concrete using mesoscale modeling[J]. International Journal of Thermophysics,2018,39(12):1-19. [6] YANG H Z, LI Y Y, YANG Y, et al. Effective thermal conductivity of high porosity open-cell metal foams[J]. International Journal of Heat & Mass Transfer,2020,147:118974. [7] 张伟平, 童菲, 邢益善, 等. 混凝土导热系数的试验研究与预测模型[J]. 建筑材料学报, 2015, 18(2):183-189. doi: 10.3969/j.issn.1007-9629.2015.02.001ZHANG W P, TONG F, XING Y S, et al. Experimental study and prediction model of thermal conductivity of concrete[J]. Journal of Building Materials,2015,18(2):183-189(in Chinese). doi: 10.3969/j.issn.1007-9629.2015.02.001 [8] 肖建庄, 宋志文, 张枫. 混凝土导热系数试验与分析[J]. 建筑材料学报, 2010, 13(1):17-21. doi: 10.3969/j.issn.1007-9629.2010.01.004XIAO J Z, SONG Z W, ZHANG F. An experimental study on thermal conductivity of concrete[J]. Journal of Building Materials,2010,13(1):17-21(in Chinese). doi: 10.3969/j.issn.1007-9629.2010.01.004 [9] BOTTCHER C J F. Theory of electric polarization[J]. Journal of Electrostatics, 1973, 6(2): 191-197. [10] MAXWELL J. A treatise on electricity and magnetism[J]. Nature, 2014, 7(182): 478-480. [11] WANG J F, CARSON J K, NORTH M F, et al. A new approach to modelling the effective thermal conductivity of heterogeneous materials[J]. International Journal of Heat & Mass Transfer,2006,49(17-18):3075-3083. [12] 张伟平, 邢益善, 顾祥林. 基于细观复合材料的混凝土导热系数模型[J]. 结构工程师, 2012, 28(2):39-45. doi: 10.3969/j.issn.1005-0159.2012.02.007ZHANG W P, XING Y S, GU X L. Theoretical models of effective thermal conductivity of concrete based on compo-site materials in mesoscale[J]. Structural Engineers,2012,28(2):39-45(in Chinese). doi: 10.3969/j.issn.1005-0159.2012.02.007 [13] 胡新萍, 李翔宇, 韩保清, 等. GEM方程的多孔混凝土导热行为表征[J]. 硅酸盐通报, 2014, 33(10):2597-2603.HU X P, LI X Y, HAN B Q, et al. Characterization of thermal behavior of foamed concrete by GEM equation[J]. Bulletin of the Chinese Ceramic Society,2014,33(10):2597-2603(in Chinese). [14] TANG S B, TANG C A, LIANG Z Z, et al. Numerical study of the influence of material structure on effective thermal conductivity of concrete[J]. Heat Transfer Engineering,2012,33(8):732-747. doi: 10.1080/01457632.2011.635988 [15] ZHANG W P, MIN H G, GU X L, et al. Mesoscale model for thermal conductivity of concrete[J]. Construction and Building Materials,2015,98:8-16. doi: 10.1016/j.conbuildmat.2015.08.106 [16] FU Y F, WONG Y L, TANG C A, et al. Thermal induced stress and associated cracking in cement-based composite at elevated temperatures—Part Ⅱ: Thermal cracking around multiple inclusions[J]. Cement and Concrete Composites,2004,26(2):113-126. doi: 10.1016/S0958-9465(03)00087-8 [17] FU Y F, WONG Y L, TANG C A, et al. Thermal induced stress and associated cracking in cement-based composite at elevated temperatures––Part I: Thermal cracking around single inclusion[J]. Cement and Concrete Composites,2004,26(2):99-111. doi: 10.1016/S0958-9465(03)00086-6 [18] KHOURY G A, WILLOUGHBY B. Polypropylene fibres in heated concrete. Part 1: Molecular structure and materials behaviour[J]. Magazine of Concrete Research,2008,60(2):125-136. doi: 10.1680/macr.2008.60.2.125 [19] ZHENG W Z, LI H Y, WANG Y. Compressive behaviour of hybrid fiber-reinforced reactive powder concrete after high temperature[J]. Materials and Design,2012,41:403-409. doi: 10.1016/j.matdes.2012.05.026 [20] SIMPSON T K. Figures of thought: A literary appreciation of Maxwell's treatise on electricity and magnetism[M]. Santa Fe, NM: Green Lion Press, 2005. [21] HAMILTON R L, CROSSER O K. Thermal conductivity of heterogeneous two-component systems[J]. Industrial and Engineering Chemistry Research Fundamentals,1962,1(3):27-40. [22] HASSELMAN D P H, JOHNSON L F. Effective thermal conductivity of composites with interfacial thermal barrier resistance[J]. Journal of Composite Materials,1987,21(6):508-515. doi: 10.1177/002199838702100602 [23] BENVENISTE Y. Effective thermal conductivity of compo-sites with a thermal contact resistance between the constituents: Nondilute case[J]. Journal of Applied Physics,1987,61(8):2840-2843. doi: 10.1063/1.337877 [24] BRUGGEMAN D. The calculation of various physical constants of heterogeneous substances. I. The dielectric constants and conductivities of mixtures composed of isotropic substances[J]. Annals of Physics,1935:416. [25] 王家俊. 聚酰亚胺/氮化铝复合材料的制备与性能研究[D]. 杭州: 浙江大学, 2001.WANG J J. Preparation and investigation on the polyimide/AlN composite materials[D]. Hangzhou: Zhe-jiang University, 2001(in Chinese) [26] SHEN L, REN Q W, ZHANG L F, et al. Experimental and numerical study of effective thermal conductivity of cracked concrete[J]. Construction and Building Materials,2017,153:55-68. doi: 10.1016/j.conbuildmat.2017.07.038 [27] SHEN L, REN Q W, XIA N, et al. Mesoscopic numerical simulation of effective thermal conductivity of tensile cracked concrete[J]. Construction and Building Materials,2015,95:467-475. doi: 10.1016/j.conbuildmat.2015.07.117 [28] 水中和, 曹蓓蓓. 水泥混凝土材料热膨胀性能研究[C]. 广州: 第九届全国水泥和混凝土化学及应用技术会议, 2005.SHUI Z H, CAO B B. Study on thermal expan-sion performance of cement concrete[C]. Guangzhou : The 9th National Conference on Cement and Concrete Chemistry and Application Technology, 2005(in Chinese). [29] GUNEYISI E, GESOGLU M, KAREEM Q, et al. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of pervious concrete[J]. Materials and Structures,2016,49(1-2):521-536. doi: 10.1617/s11527-014-0517-y [30] 孙嘉卿, 丛干文, 刘君实, 等. 再生骨料生态混凝土预测模型抗压强度试验研究[J]. 建筑结构学报, 2020, 41(S1):381-389.SUN J Q, CONG G W, LIU J S, et al. Experimental study on compressive strength of prediction model of eco-concrete with recycled aggregate[J]. Journal of Building Structures,2020,41(S1):381-389(in Chinese). [31] CENGEL Y A. Heat and mass transfer: A practical approach[J]. Business & Economics,2006,13(2):1-8. [32] AMIRI M, MOVAHEDIRAD S, MANTEGHI F. Thermal conductivity of water and ethylene glycol nanofluids containing new modified surface SiO2-Cu nanoparticles: Experimental and modeling[J]. Applied Thermal Engineering,2016,108:48-53. doi: 10.1016/j.applthermaleng.2016.07.091 [33] BOFANG Z. Thermal stresses and temperature control of mass concrete[J]. Thermal Stresses & Temperature Control of Mass Concrete,2013:83-103. [34] 秦国锋, 张婧婧, 徐子威, 等. BN纤维对石墨烯微片/聚丙烯复合材料导热绝缘性能的影响[J]. 复合材料学报, 2020, 37(3):546-552.QIN G F, ZHANG J J, XU Z W, et al. Effect of BN fiber on thermal conductivity and insulation properties of graphene nanoplatelets/polypropylene composites[J]. Acta Materiae Compositae Sinica,2020,37(3):546-552(in Chinese). [35] 阎蕊珍, 杜红秀. 高温对C40高性能混凝土导热性能的影响[J]. 太原理工大学学报, 2013, 44(6):718-721. doi: 10.3969/j.issn.1007-9432.2013.06.010YAN R Z, DU H X. Effect of high temperature on heat conduction performance of HPC[J]. Journal of Taiyuan University of Technology,2013,44(6):718-721(in Chinese). doi: 10.3969/j.issn.1007-9432.2013.06.010 [36] 姚秀鹏, 韩阳, 沈雷, 等. 高温后聚丙烯纤维混凝土热工参数试验研究[J]. 消防科学与技术, 2020, 39(7):900-903. doi: 10.3969/j.issn.1009-0029.2020.07.003YAO X P, HAN Y, SHEN L, et al. Experimental study on thermal parameters of polypropylene fiber reinforced concrete after elevated temperature[J]. Fire Science and Technology,2020,39(7):900-903(in Chinese). doi: 10.3969/j.issn.1009-0029.2020.07.003 [37] WANG W C, WANG H Y, CHANG K H, et al. Effect of high temperature on the strength and thermal conductivity of glass fiber concrete[J]. Construction and Building Materials,2020,245:118387. [38] SHEN L, REN Q W, CUSATIS G, et al. Numeri cal study on crack thermal resistance effect on thermo-mechanical coupled behavior of concrete structure at room temperature[J]. International Journal of Solids and Structures,2020,182:141-155. -

下载:

下载: