Research progress of paper-based flexible conductive composite materials

-

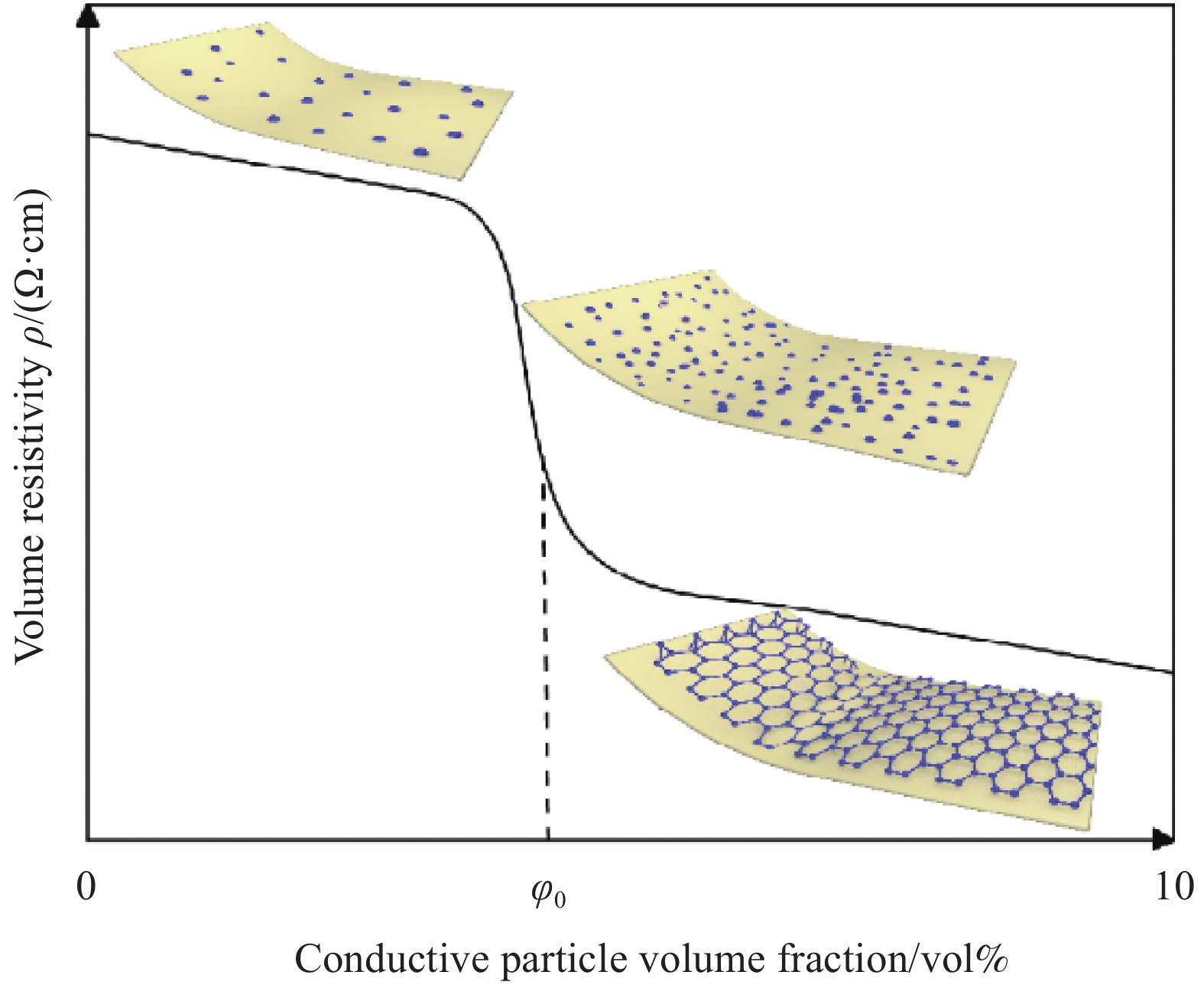

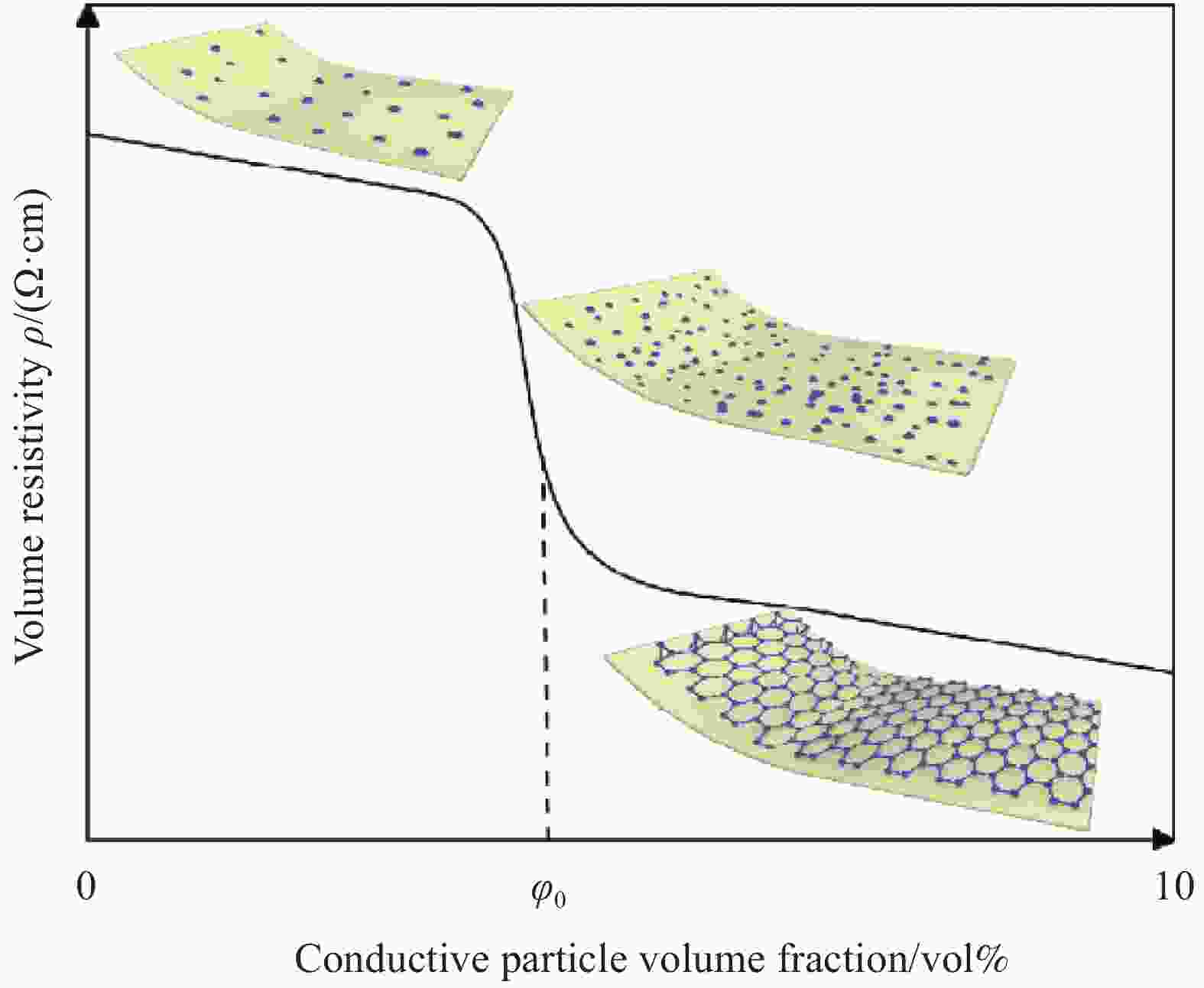

摘要: 伴随着现代电子科技领域的蓬勃发展,大量电子垃圾的产生给环境带来了巨大压力。以纤维素为主的柔性导电复合材料具有与传统石油基导电产品不可比拟的优点,如轻质、可降解、可再生、生物相容性好等。近年来,纸基柔性导电材料逐步成为该领域研究的热点。本文综述了近些年来国内外纸基柔性导电材料的研究进展,描述了柔性导电材料的工作原理,详细概述了纸基导电材料的制备方法与相关应用,对纸基柔性导电材料亟待解决的问题及未来发展趋势进行了总结和展望。Abstract: With the rapid development of modern electronic technology, a large amount of e-waste puts huge pressure on the environment. The cellulose-based flexible conductive composite material has incomparable advantages with traditional petroleum-based conductive products, such as lightweight, degradable, renewable, bio-compatible, and so on. In recent years, paper-based flexible conductive materials have gradually become a research focus in this field. This article reviews the research progress of paper-based flexible conductive materials at home and abroad in recent years, describes the working principle of flexible conductive materials, summarizes the preparation methods and related applications of paper-based flexible conductive materials in detail, and the paper-based flexible conductive materials urgently need to be solved and the future development trend is summarized and prospected.

-

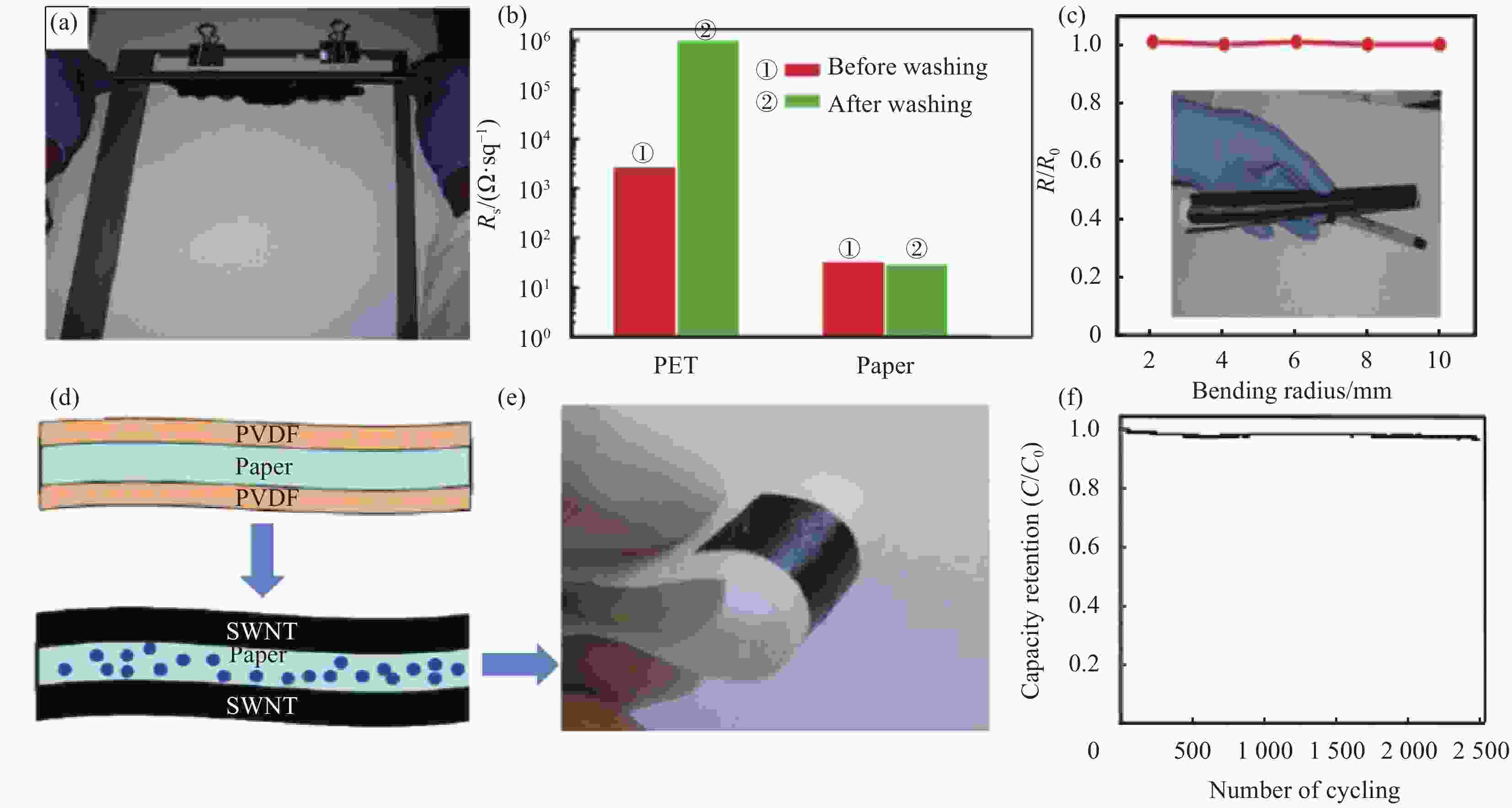

图 2 利用迈耶棒涂覆A4纸示意图 (a)、用薄层电阻变化来反映聚对苯二甲酸乙二醇酯(PET)与纸在洗涤前后活性材料附着情况 (b)、导电材料在不同弯曲半径下与电阻变化率R/R0曲线(c)[23]、利用聚偏氟乙烯(PVDF)与单壁碳纳米管(SWNT)制备导电材料的过程 (d)~(e)以及在2 500次循环下纸基超级电容器的电容保持性能曲线 (f)[24]

Figure 2. Schematic diagram of coating A4 paper with Meyer rod (a), change of sheet resistance to reflect the adhesion of the active material between polyethylene terephthalate (PET) and paper before and after washing (b), conductive material under different bending radius and the resistance change rate R/R0 curve (c)[23], process of preparing conductive materials using polyvinylidene fluoride (PVDF) and single-walled carbon nanotube (SWNT) (d)-(e), and capacitance retention performance curve of paper-based supercapacitors under 2 500 cycles (f)[24]

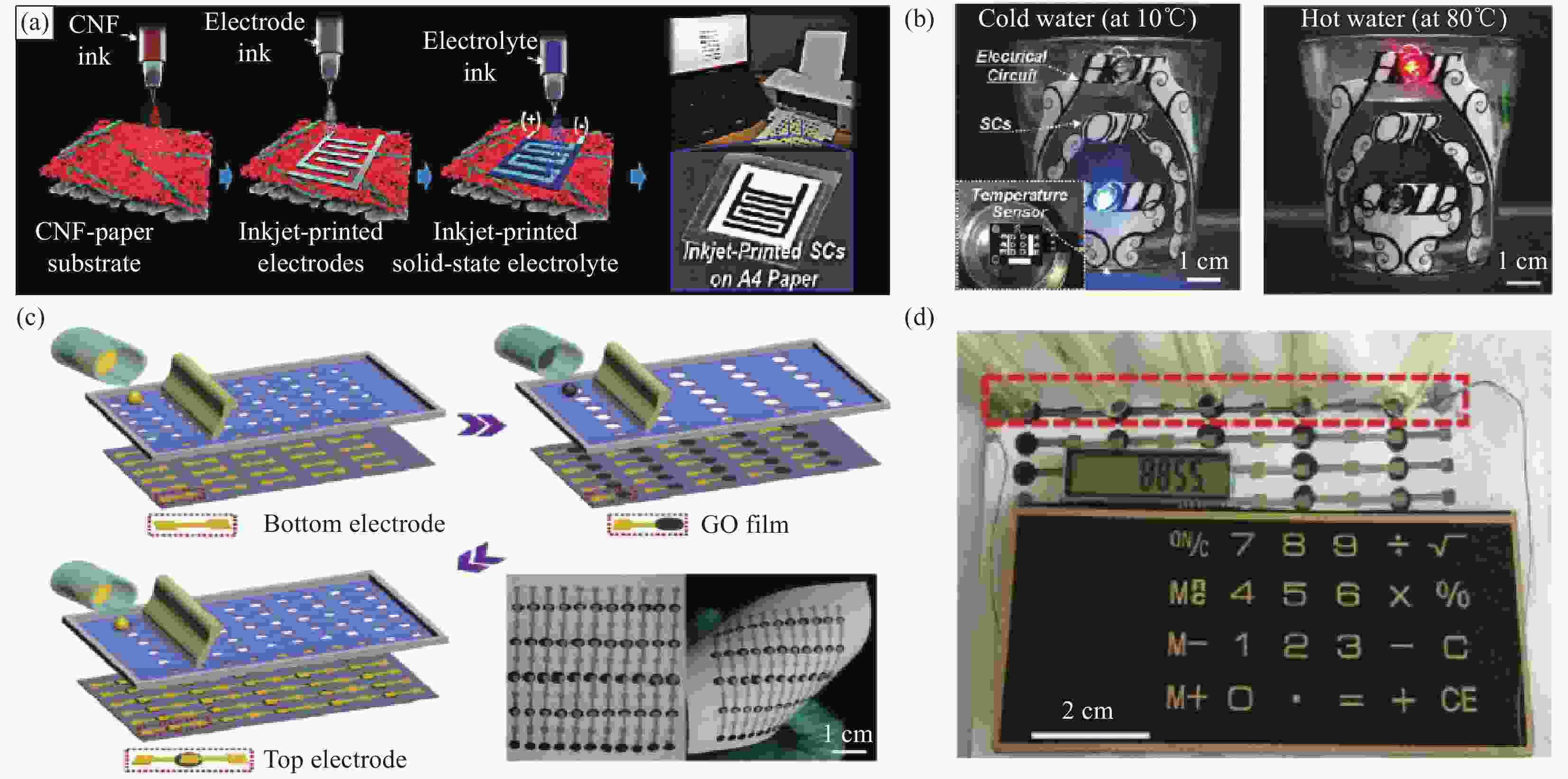

图 3 喷墨打印机打印超级电容器示意图及所用的喷墨打印机照片(a)、超级电容器与温度传感器连接制作智能温度感应杯 (b)[26]、利用丝网印刷技术制备氧化石墨烯(GO)湿度发电器件示意图 (c)、超级电容器供电示意图 (d)[28]

Figure 3. Schematic diagram of inkjet printer printing super capacitor and the photo of inkjet printer (a), connecting supercapacitors with temperature sensor to make intelligent temperature sensing cup (b)[26], schematic diagram of graphene oxide (GO) humidity power generation device prepared by screen printing technology (c), schematic diagram of super capacitors power supply for calculator (d)[28]

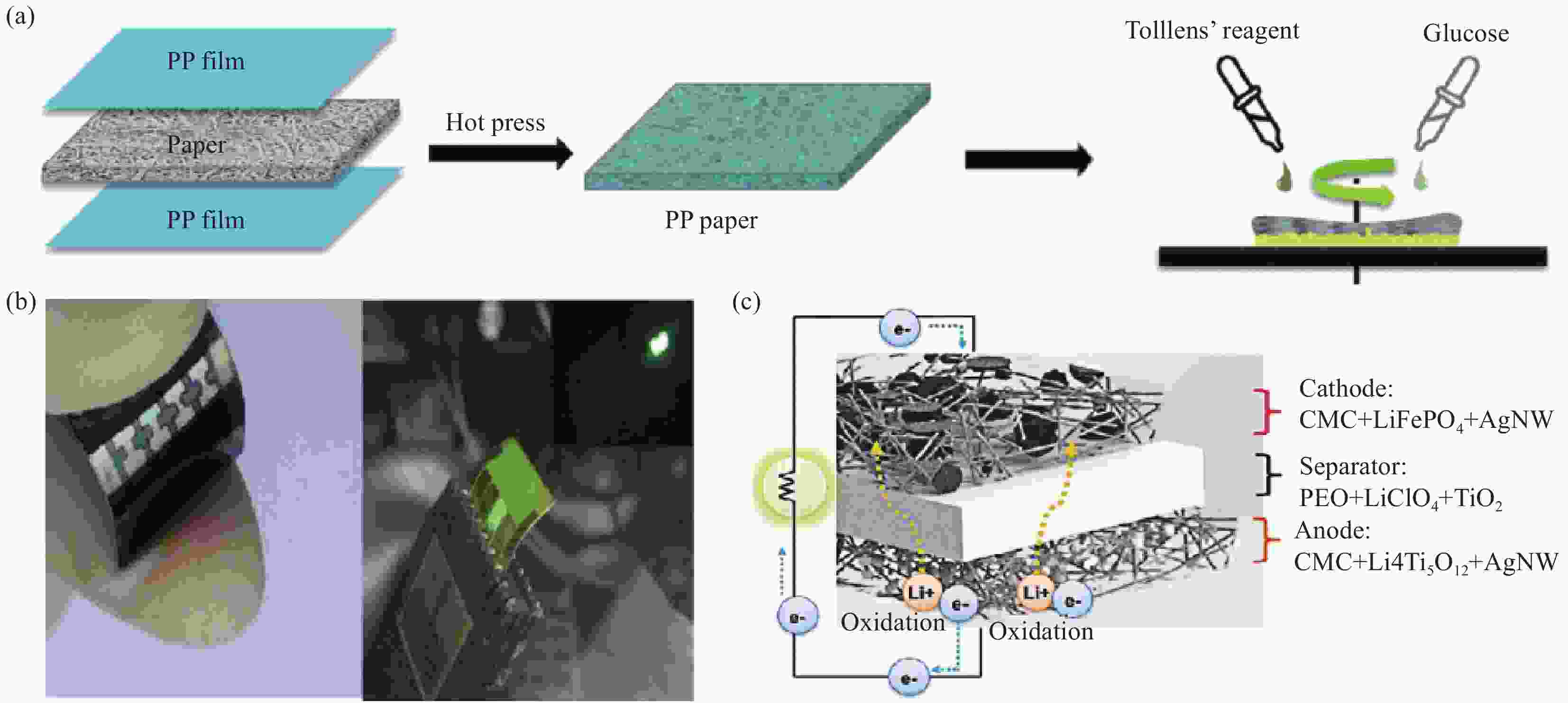

图 4 聚丙烯(PP)薄膜热压示意图及载旋涂法下的银镜反应 (a)、基于银/纸电极材料制备的有机太阳能电池(OSC)与有机发光二极管(OLED) (b)[29]、利用3D打印技术制备锂电池结构示意图 (c)[30]

Figure 4. Schematic diagram of polypropylene (PP) film hot pressing and silver mirror reaction under spin coating method (a), organic solar cells (OSC) and oganic light emitting diodes (OLED) based on silver/paper electrode material (b)[29], structure diagram of lithium battery prepared by 3D printing (c)[30]

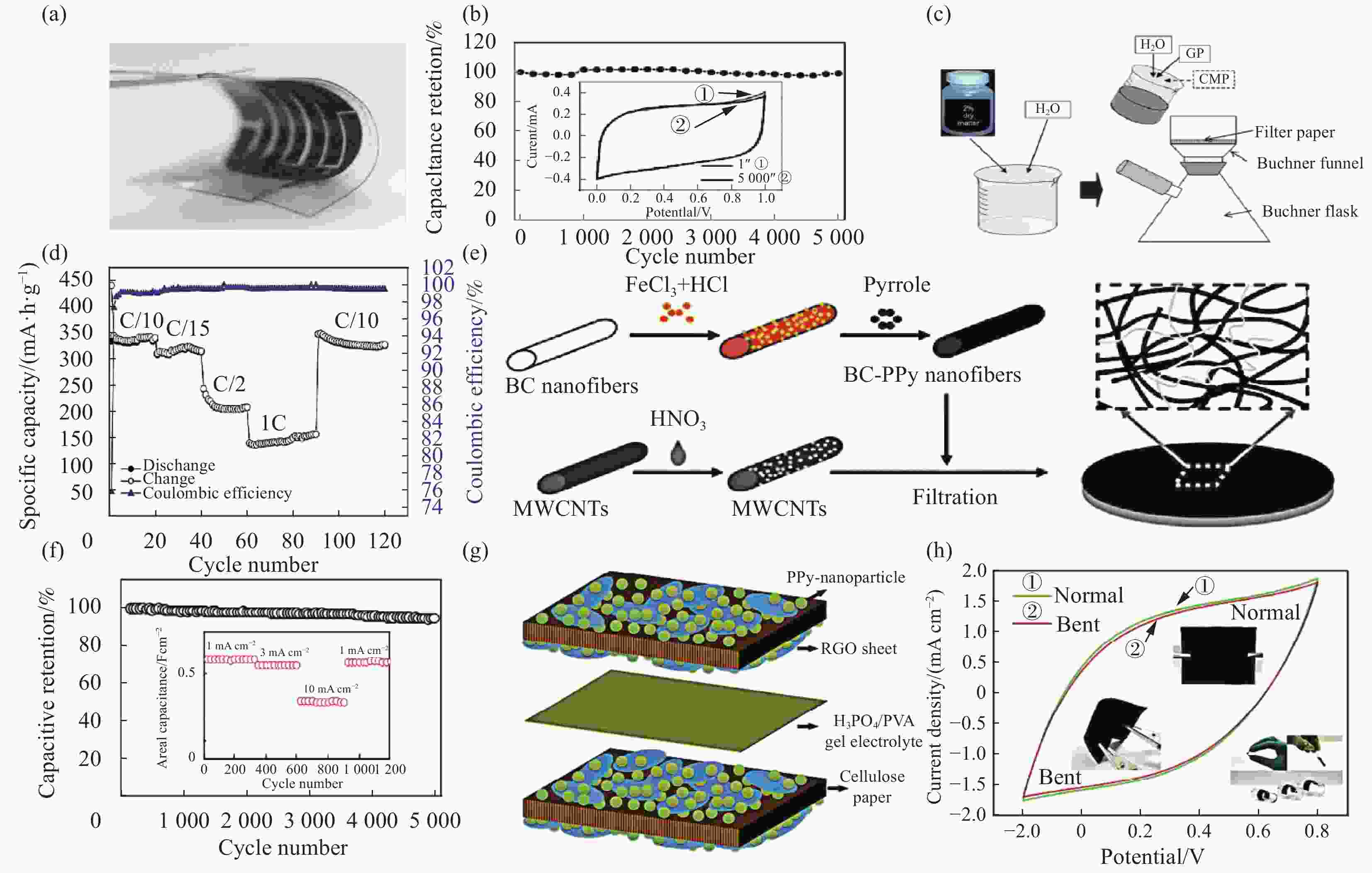

图 5 石墨烯/纤维素纸超级电容器照片 (a);在5 000次循环下超级电容器(SC)的电容保持率,嵌图显示的是SC的伏安曲线(b)[31];柔性、超薄纤维素纤维/石墨阳极制备过程示意图 (c);石墨(GP)/纤维/羧甲基纤维素(CMC)阳极的比电容与库仑效率曲线 (d)[32];细菌纤维素(BC)/聚吡咯(PPy)/多壁碳纳米管(MWCNTs)复合膜制备过程示意图 (e);电容保持率曲线 (f)[35];PPy沉积过程示意图 (g);在弯曲折叠下电压与电流密度曲线 (h)[39]

Figure 5. Photograph of graphene/cellulose paper supercapacitor (a); Capacitance retention of supercapacitor (SC) under 5000 cycles, the inset shows the CV curve under 1 and 5 000 cycles (b)[31]; Schematic diagram of the preparation process of flexible, ultra-thin cellulose fiber/graphite anode (c); Specific capacitance and coulombic efficiency profile of graphite (GP)/fiber/carboxymethylcellulose (CMC) anode (d)[32]; Preparation process of bacterial cellulose (BC)/polypyrrole (PPy)/multiwalled carbon nanotube (MWCNTs) composite membrane (e); Capacitance retention curve (f)[35]; Schematic diagram of PPy deposition process (g); Voltage and current density profile under bending and folding (h)[39]

RGO—Reduced graphene oxide; CMP—5'-cytidine acid

图 6 在不同吡咯(Py)/OH摩尔比下Py/纤维的电导率曲线,嵌图为导电纤维的TEM图像 (a);不同参数下,超级电容器的电容曲线 (b);超级电容器的充放电性能 (c)[44];还原氧化石墨烯(RGO)/PPy/碳纤维纸电极制备示意图 (d);三种复合材料电流密度对面积电容曲线 (e);超级电容器的电容保持率 (f)[45];BC/碳纳米管(CNT)超级电容器比电容变化曲线 (g)[48];锂离子电池结构示意图 (h)[49];锂离子电池电极电容保持率与库伦效率曲线 (i)[51]

Figure 6. Conductivity profile of pyrrole (Py)/fiber under different Py/OH molar ratio, inset shows the TEM image of conductive fiber (a); Capacitance profile of supercapacitor under different parameters (b); Supercapacitor charge and discharge performance (c)[44]; Schematic diagram of preparation of reduced graphene oxide (RGO)/PPy/carbon fiber paper electrode (d); Curves of current density versus area capacitance for three composite materials (e); Capacitance retention of supercapacitors (f)[45]; Specific capacitance change curves of BC/carbon nanotube (CNT) supercapacitors (g)[48]; Structure diagram of lithium ion battery (h)[49]; Curves of electrode capacitance retention and coulomb efficiency for lithium ion battery (i)[51]

LTO—Li4Ti5O12; LCO—LiCoO2; CB—Carbon black; CCFs—Chopped carbon fibers

图 7 纸基摩擦纳米发电机(P-TENG)示意图 (a)、不同堆叠层数产生的电荷数 (b)[54]、非接触式TENGs原理图(c)、不同距离下TENGs电压输出情况 (d)、TENGs为电容器充电 (e)[55]、TEGs电流与功率、电压曲线 ((f)、(g))[56]、不同基底下光透射雾度与透射率曲线 (h)[57]、电压与电流密度曲线 (i)[58]、CNP太阳能电池结构示意图 (j)、电流转换效率对比图 (k)[59]

Figure 7. Schematic diagram of P-nanogenerator (TENG) (a), number of charges generated by different stacking layers (b)[54], schematic diagram of noncontact TENGs (c), voltage output of Tengs at different distances (d), TENGs charges the capacitor (e)[55], curves of TEGs current versus power and voltage ((f), (g))[56], optical transmission haze versus transmittance for different substrates (h)[57], voltage versus current density curve (i)[58], structure diagram of CNP solar cell (j), comparison of current conversion efficiency (k)[59]

图 8 生物燃料电池工作原理 (a)、电压与电流密度曲线 (b)、葡萄糖测定可视化示意图 (c)[63]、酶基生物燃料电池纸基分析装置(µPAD-EBFC)制备过程示意图 (d)、不同葡萄糖浓度下电压与电流密度曲线 (e)、µPAD-EBFC串并联情况 (f)[64]

Figure 8. Schematic diagram of working principle of biofuel cells (a), voltage and current density curve (b), visualization of glucose determination (c)[63], schematic diagram of preparation process of paper-based analytical device for enzymatic biofuel cells (µPAD-EBFC) (d), voltage and current density curves under different glucose concentrations (e), voltage output of series and parallel connection of µPAD-EBFC (f)[64]

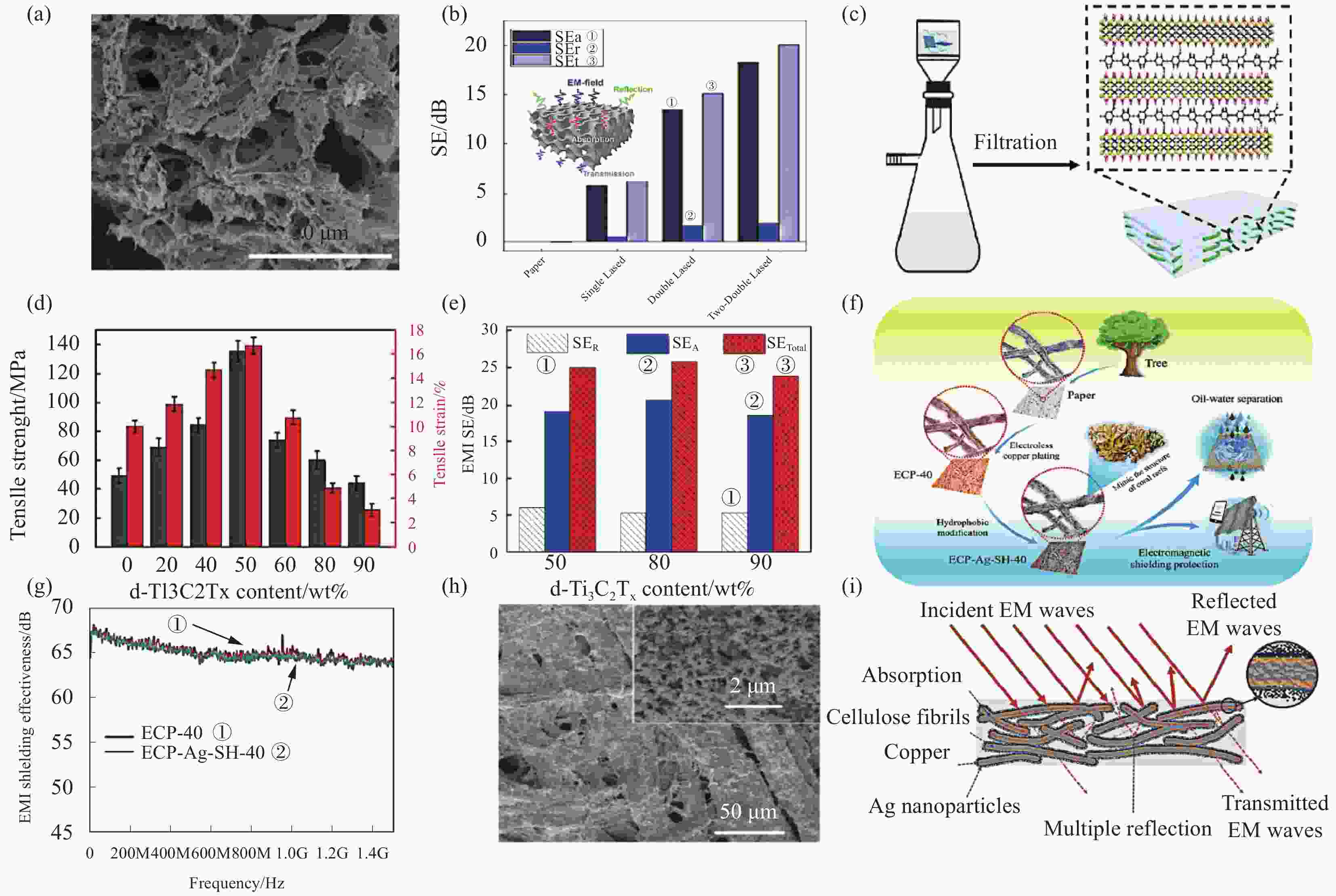

图 9 碳化钼/石墨烯(MCG)复合材料SEM图像 (a);电磁屏蔽性能图,嵌图为3D结构示意图 (b)[66];Ti3C2Tx/纳米纤维素纤维复合纸制备方法与材料结构示意图 (c);材料拉伸应变曲线 (d);电磁屏蔽性能曲线 (e)[67];导电滤纸制备流程示意图 (f);电磁屏蔽性能曲线 (g);导电滤纸表观形貌SEM图像 (h);电磁屏蔽过程示意图 (i)[68]

Figure 9. SEM image of molybdenum carbide/graphene(MCG)composites (a); Picture of electromagnetic shielding performance, the inset shows 3D structure of the MCG (b)[66]; Preparation method and material structure of Ti3C2Tx/cellulose nanofiber composite paper (c); Tensile strain curve of materials (d); Profile of electromagnetic shielding performance (e)[67]; Preparation process of conductive filter paper (f); Profile of electromagnetic shielding performance (g); SEM image of the surface morphology of conductive filter paper (h); Schematic diagram of electromagnetic shielding process (i)[68]

表 1 不同纸基复合材料制备方法分析

Table 1. Analysis of different preparation methods of paper-based conductive composites

Method Active material Substrate Index Parameter Application Reference Meyer rod coating EDOT Filter paper Conductivity 1.8 S/cm Electrode [22] Inkjet printing AgNWs, SWNTs, AC A4 paper Resistance 8 Ω/sq Supercapacitor [26] Screen printing GO A4 paper Voltage output 0.7 V Humidity generator [28] Spin coating Silver nanoparticles Cellulose paper Conductivity 1.2×107 S/m Electrode, solar cell substrate [29] Dehydration forming PPy, MWCNTs Bacterial cellulose paper Conductivity 7.78 S/cm Electrode, supercapacitor [35] Polymerization PPy, GO Cellulose paper Resistance 1.7 Ω/sq Electrode, supercapacitor [39] In-situ growth AuNP Cellulose paper Conductivity 1.15×10−5 Ω·cm Electrode [43] -

[1] HYUN W J, SECOR E B, KIM C H, et al. Scalable, self-aligned printing of flexible graphene micro-supercapacitors[J]. Advanced Energy Materials,2017,7(17):1700285.1-1700285.8. [2] NING H, PIKUL J H, ZHANG R, et al. Holographic patterning of high-performance on-chip 3D lithium-ion microbatteries[J]. Proceedings of the National Academy of Sciences of the United States of America,2015,112(21):6573-6578. doi: 10.1073/pnas.1423889112 [3] QIN K, KANG J, LI J, et al. Free-standing porous carbon nanofiber/ultrathin graphite hybrid for flexible solid-state supercapacitors[J]. Acs Nano,2015,9(1):481-487. [4] KAEMPGEN M, CHAN C K, MA J, et al. Printable thin film supercapacitors using single-walled carbon nanotubes[J]. Nano Letters,2009,9(5):1872. [5] DUFRESNE A. Nanocellulose processing properties and potential applications[J]. Current Forestry Reports,2019,5(2):76-89. doi: 10.1007/s40725-019-00088-1 [6] DU H S, LIU W, ZHANG M M, et al. Cellulose nanocrystals and cellulose nanofibrils based hydrogels for biomedical applications[J]. Carbohydrate Polymers,2019,209:130-144. [7] 马书荣, 米勤勇, 余坚, 等. 基于纤维素的气凝胶材料[J]. 化学进展, 2014, 26(5):796-809.MA S R, MI Q Y, YU J, et al. Aerogel materials based on cellulose[J]. Progress in Chemistry,2014,26(5):796-809(in Chinese). [8] LEE H M, CHOI S Y, JUNG A, et al. Highly conductive aluminum textile and paper for flexible and wearable electronics[J]. Angewandte Chemie,2013,52(30):7718-7723. doi: 10.1002/anie.201301941 [9] TOBJRK D, STERBACKA R. Paper electronics[J]. Advanced Materials,2011,23(17):1935-1961. doi: 10.1002/adma.201004692 [10] NAN C W, SHEN Y, MA J, et al. Physical properties of composites near percolation[J]. Annual Review of Materials Research,2010,40(1):131-151. doi: 10.1146/annurev-matsci-070909-104529 [11] POLLEY M H, BOONSTRA B B S T. Carbon blacks for highly conductive rubber[J]. Rubber Chemistry & Technology,1957,30(1):170-179. [12] 赵世阳, 王庆国, 卢聘, 等. 高分子基复合材料非线性导电行为和机制研究进展[J]. 材料科学与工程学报, 2018, 36(5):858-862.ZHAO S Y, WANG Q G, LU P, et al. Review on nonlinear conductive behavior and mechanisms of polymer compo-sites[J]. Journal of materials science and Engineering,2018,36(5):858-862(in Chinese). [13] MUNSON-MCGEE S H. Estimation of the critical concentration in an anisotropic percolation network[J]. Physical Review B Condensed Matter,1991,43(4):3331-3336. doi: 10.1103/PhysRevB.43.3331 [14] KIRKPATRICK S. Percolation and conduction[J]. Reviews of Modern Physics,1973,45(4):574-588. doi: 10.1103/RevModPhys.45.574 [15] JAY J. On the critical conductive filler loading in antistatic composites[J]. Journal of Applied Physics,1975,46(2):966-969. doi: 10.1063/1.321629 [16] MEDALIA, AVROM I. Electrical conduction in carbon black composites[J]. Rubber Chemistry & Technology,1986,59(3):432-454. [17] 张澎涛, 孙丽萍. 高分子导电复合材料的导电机制及其电磁屏蔽作用分析[J]. 林业机械与木工设备, 2006, 34(6):24-26. doi: 10.3969/j.issn.2095-2953.2006.06.008ZHANG P T, SUN L P. Analysis of conductive mechanism and electromagnetic shielding effect of polymer conductive composites[J]. Forestry Machinery & Woodworking Equipment,2006,34(6):24-26(in Chinese). doi: 10.3969/j.issn.2095-2953.2006.06.008 [18] BEEK L V, PUL B V. Internal field emission in carbon black-loaded natural rubber vulcanizates[J]. Rubber Chemistry and Technology,1963,36(3):740-746. doi: 10.5254/1.3539605 [19] WEN B, CAO M S, LU M M, et al. Reduced graphene oxides: Light-weight and high-efficiency electromagnetic interference shielding at elevated temperatures[J]. Advanced Materials,2014,26(21):3484-3489. doi: 10.1002/adma.201400108 [20] ZHAO M H, ZHU W, FENG X Q, et al. Role of interfacial 2D graphene in high performance 3D graphene/germanium Schottky junction humidity sensors[J]. Journal of Materials Chemistry C,2020,8(40):14196. doi: 10.1039/D0TC03853A [21] 王希晰, 曹茂盛. 特色研究报告: 低维电磁功能材料研究进展[J]. 表面技术, 2020, 49(2):18-28.WANG X X, CAO M S. Low-dimensional electromagnetic functional materials[J]. Surface Technology,2020,49(2):18-28(in Chinese). [22] KAWASHIMA H, SHINOTSUKA M, NAKANO M, et al. Fabrication of conductive paper coated with PEDOT: Preparation and characterization[J]. Journal of Coatings Technology & Research,2012,9(4):467-474. [23] HU L, CHOI J W, YANG Y, et al. Highly conductive paper for energy-storage devices[J]. Proceedings of the National Academy of Sciences,2009,106(51):21490-21494. doi: 10.1073/pnas.0908858106 [24] HU L, HUI W, YI C. Printed energy storage devices by integration of electrodes and separators into single sheets of paper[J]. Applied Physics Letters,2010,96(18):183502. doi: 10.1063/1.3425767 [25] KOGA H, NOGI M, KOMODA N, et al. Uniformly connected conductive networks on cellulose nanofiber paper for transparent paper electronics[J]. Npg Asia Materials,2014,6(3):e93. doi: 10.1038/am.2014.9 [26] CHOI K H, YOO J T, LEE C K, et al. All-inkjet-printed, solid-state flexible supercapacitors on paper[J]. Energy & Environmental Science,2016,9(9):2812-2821. [27] 张岩, 陈杰, 曹云峰. 喷墨打印纸涂层中胶黏剂配比对油墨扩散渗透的影响[J]. 中国造纸学报, 2015, 30(1):32-35.ZHANG Y, CHEN J, CAO Y F. Impact of binder composition of coatings on ink diffusion and permeation in inkjet paper[J]. Transactions of China Pulp and Paper,2015,30(1):32-35(in Chinese). [28] LIANG Y, ZHAO F, CHENG Z, et al. Electric power generation via asymmetric moisturizing of graphene oxide for flexible, printable and portable electronics[J]. Energy & Environmental Science,2018,11(7):1730-1735. [29] HUANG Q, ZHANG K, YANG Y, et al. Highly smooth, stable and reflective Ag-paper electrode enabled by silver mirror reaction for organic optoelectronics[J]. Chemical Engineering Journal,2019,370:1048-1056. doi: 10.1016/j.cej.2019.03.258 [30] PARK J S, KIM T, KIM W S. Conductive cellulose compo-sites with low percolation threshold for 3D printed electronics[J]. Scientific Reports,2017,7(1):3246. doi: 10.1038/s41598-017-03365-w [31] WENG Z, SU Y, WANG D W, et al. Graphene-cellulose paper flexible supercapacitors[J]. Advanced Energy Materials,2011,1(5):917-922. doi: 10.1002/aenm.201100312 [32] JABBOUR L, DESTRO M, GERBALDI C, et al. Aqueous processing of cellulose based paper-anodes for flexible Li-ion batteries[J]. Journal of Materials Chemistry,2012,22(7):3227-3233. doi: 10.1039/c2jm15117k [33] CHEN X, CUI J, XU X, et al. Bacterial cellulose/attapulgite magnetic composites as an efficient adsorbent for heavy metal ions and dye treatment[J]. Carbohydrate Polymers,2020,229:115512. doi: 10.1016/j.carbpol.2019.115512 [34] ZHANG X, ZHAO X Y, XUE T T, et al. Bidirectional anisotropic polyimide/bacterial cellulose aerogels by freeze-drying for super-thermal insulation[J]. Chemical Engineering Journal,2020,385:123963. doi: 10.1016/j.cej.2019.123963 [35] LI S H, HUANG D K, YANG J C, et al. Freestanding bacterial cellulose-polypyrrole nanofibres paper electrodes for advanced energy storage devices[J]. Nano Energy,2014,9:309-317. doi: 10.1016/j.nanoen.2014.08.004 [36] WANG X H, HUANG Q B, XU M M, et al. Large scale preparation of graphene oxide/cellulose paper with improved mechanical performance and gas barrier properties by conventional papermaking method[J]. Industrial Crops & Products,2016,85:198-203. [37] PHILIPOSE U, JIANG Y, FARMER G, et al. Using a novel approach to estimate packing density and related electrical resistance in multiwall carbon nanotube networks[J]. Nanomaterials,2020,10(12):2350. doi: 10.3390/nano10122350 [38] DICHIARA A B, SONG A, GOODMAN S M, et al. Smart papers comprising carbon nanotubes and cellulose microfibers for multifunctional sensing applications[J]. Journal of Materials Chemistry A,2017,5(38):20161-20169. doi: 10.1039/C7TA04329E [39] WAN C C, JIAO Y, LI J. Flexible, highly conductive, and free-standing reduced graphene oxide/polypyrrole/cellulose hybrid papers for supercapacitor electrodes[J]. Journal of Materials Chemistry A,2017,5:3819-3831. doi: 10.1039/C6TA04844G [40] 宋豪, 钱学仁, 王立娟, 等. 聚苯胺/纸浆纤维复合制造导电纸(Ⅰ)—吸聚条件对导电纸性能的影响[J]. 中国造纸学报, 2006, 21(1):43-46. doi: 10.3321/j.issn:1000-6842.2006.01.011SONG H, QIAN X R, WANG L J, et al. Conductive paper manufactured with the composite of PAN/pulp fiber(Ⅰ)−Effects of adsorption and polymerization conditions on the performances of conductive paper[J]. Transactions of China Pulp and Paper,2006,21(1):43-46(in Chinese). doi: 10.3321/j.issn:1000-6842.2006.01.011 [41] WANG Z L, ZHOU J, YUAN L Y, et al. Paper-based supercapacitors for self-powered nanosystems[J]. Angewandte Chemie International Edition,2012,51(20):4934-4938. doi: 10.1002/anie.201109142 [42] XU J M, ZHANG Y, LI L, et al. Colorimetric and electrochemiluminecence dual mode sensing of lead ion based on integrated lab-on-paper device[J]. ACS Applied Materials & Interfaces,2018,10(4):3431-3440. [43] GE L, WANG S M, YU J H, et al. Molecularly imprinted polymer grafted porous au-paper electrode for an microfluidic electro-Analytical origami device[J]. Advanced Functional Materials,2013,23(24):3115-3123. doi: 10.1002/adfm.201202785 [44] WU X Y, CHABOT V L, KIM B K, et al. Cost-effective and scalable chemical synthesis of conductive cellulose nanocrystals for high-performance supercapacitors[J]. Electrochimica Acta,2014,138:139-147. doi: 10.1016/j.electacta.2014.06.089 [45] LYU S, CHANG H, FU F, et al. Cellulose-coupled graphene/polypyrrole composite electrodes containing conducting networks built by carbon fibers as wearable supercapacitors with excellent foldability and tailorability[J]. Journal of Power Sources,2016,327:438-446. doi: 10.1016/j.jpowsour.2016.07.091 [46] KLEMM D, HEUBLEIN B, FINK H P, et al. Cellulose: Fascinating biopolymer and sustainable raw material[J]. Angewandte Chemie International Edition,2005,44(22):3358-3393. doi: 10.1002/anie.200460587 [47] KLEMM D, KRAMER F, MORITZ S, et al. Nanocelluloses: A new family of nature-based materials[J]. Angewandte Chemie International Edition,2011,50(24):5438-5466. doi: 10.1002/anie.201001273 [48] KANG Y J, CHUN S J, LEE S S, et al. All-solid-state flexible supercapacitors fabricated with bacterial nanocellulose papers, carbon nanotubes, and triblock-copolymer ion gels[J]. Acs Nano,2012,6(7):6400-6406. doi: 10.1021/nn301971r [49] CHENG Q, SONG Z, MA T, et al. Folding paper-based lithium-ion batteries for higher areal energy densities[J]. Nano Letters,2013,13(10):4969-4974. doi: 10.1021/nl4030374 [50] ALIAHMAD N, AGARWAL M, SHRESTHA S, et al. Paper-based lithium-ion batteries using carbon nanotube-coated wood microfibers[J]. Nanotechnology, IEEE Transactions on Electron Devices,2013,12(3):408-412. doi: 10.1109/TNANO.2013.2252922 [51] OU J K, ZOU L, JIN F, et al. Hierarchically porous nitrogen, oxygen-rich carbons derived from filter paper for high-performance lithium ion battery anodes[J]. Powder Technology,2020,371:64-73. doi: 10.1016/j.powtec.2020.05.060 [52] YAO L H, CAO W Q, SHU J C, et al. Tailoring adsorption for tunable lithium ion storage and devices[J]. Chemical Engineering Journal,2020,413:127428. [53] YAO L H, CAO W Q, CAO M S. Doping effect on the adsorption of Na atom onto graphenes[J]. Current Applied Physics,2016,16(5):574-580. doi: 10.1016/j.cap.2016.03.001 [54] WU C X, KIMA T W, SUNG S, et al. Ultrasoft and cuttable paper-based triboelectric nanogenerators for mechanical energy harvesting[J]. Nano Energy,2018,44:279-287. doi: 10.1016/j.nanoen.2017.11.080 [55] XI Y H, HUA J, SHI Y J. Noncontact triboelectric nanogenerator for human motion monitoring and energy harvesting[J]. Nano Energy,2020,69(11):104390. [56] ROJAS J P, CONCHOUSO D, AREVALO A, et al. Paper-based origami flexible and foldable thermoelectric nanogenerator[J]. Nano Energy,2017,31:296-301. doi: 10.1016/j.nanoen.2016.11.012 [57] FANG Z, ZHU H, YUAN Y, et al. Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells[J]. Nano Letters,2014,14(2):765. doi: 10.1021/nl404101p [58] NOGI M, KARAKAWA M, KOMODA N, et al. Transparent conductive nanofiber paper for foldable solar cells[J]. Scientific Reports,2015,5(1):17254. doi: 10.1038/srep17254 [59] WU J Y, CHE X P, HU H C, et al. Organic solar cells based on cellulose nanopaper from agroforestry residues with an efficiency of over 16% and effectively wide-angle light capturing[J]. Journal of Materials Chemistry A,2020,8(11):5442-5448. doi: 10.1039/C9TA14039E [60] WANG Y H, ZHANG L, CUI K, et al. Solar driven electrochromic photoelectrochemical fuel cells for simultaneous energy conversion, storage and self-powered sensing[J]. Nanoscale,2018,10(7):3421-3428. doi: 10.1039/C7NR09275J [61] REWATKAR P, KOTHURU A, GOEL S. PDMS-based microfluidic glucose biofuel cell integrated with optimized laser-induced flexible graphene bioelectrodes[J]. IEEE Transactions on Electron Devices,2020,67(4):1832-1838. doi: 10.1109/TED.2020.2971480 [62] WANG C, SHIM E, CHANG H K, et al. Sustainable and high-power wearable glucose biofuel cell using long-term and high-speed flow in sportswear fabrics[J]. Biosensors and Bioelectronics,2020,169:112625. [63] WANG Y H, ZHANG L N, ZHAO P N, et al. Visual distance readout to display the level of energy generation in paper-based biofuel cells: Application to enzymatic sensing of glucose[J]. Microchimica Acta,2019,186(5):283. doi: 10.1007/s00604-019-3374-0 [64] REWATKAR P, JAYAPIRIYA U S, GOEL S. Optimized shelf-stacked paper origami based glucose biofuel cell with immobilized enzymes and mediator[J]. ACS Sustainable Chemistry & Engineering,2020,8(32):12313-12320. [65] CAO M S, WANG X X, ZHANG M, et al. Electromagnetic response and energy conversion for functions and devices in low-dimensional materials[J]. Advanced Functional Materials,2019,29(25):1807398. doi: 10.1002/adfm.201807398 [66] ZANG X X, XING D, TANG W J, et al. Electromagnetic interference shielding with laser induced molybdenum carbide-graphene paper[J]. Materials Letters,2020,271:127784. doi: 10.1016/j.matlet.2020.127784 [67] CAO W T, CHEN F F, ZHU Y J, et al. Binary strengthening and toughening of mxene/cellulose nanofiber composite paper with nacre-inspired structure and superior electromagnetic interference shielding properties[J]. ACS Nano,2018,12(5):4583-4593. doi: 10.1021/acsnano.8b00997 [68] ZHANG T C, WANG D Y, LIU R T, et al. A coral reef-like structure fabricated on cellulose paper for simultaneous oil-water separation and electromagnetic shielding protection[J]. ACS Omega,2020,5(29):18105-18113. doi: 10.1021/acsomega.0c01666 [69] 刘珍红, 孙晓刚, 邱治文, 等. 多壁碳纳米管纸作正极集流体的锂硫电池性能[J]. 复合材料学报, 2017, 34(4):873-880.LIU Z H, SUN X G, QIU Z W, et al. Performance of lithium sulfur batteries using multiwalled carbon nanotube paper as cathode current collector[J]. Acta Materiae Compositae Sinica,2017,34(4):873-880(in Chinese). [70] CHAIYO S, MEHMETI E, SIANGPROH W, et al. Non-enzymatic electrochemical detection of glucose with a disposable paper-based sensor using a cobalt phthalocyanine-ionic liquid-graphene composite[J]. Biosensors & Bioelectronics,2017,102:113-120. -

下载:

下载: