Experimental study on the influence of impact positions on compression-after-impact behavior of composite stiffened panels

-

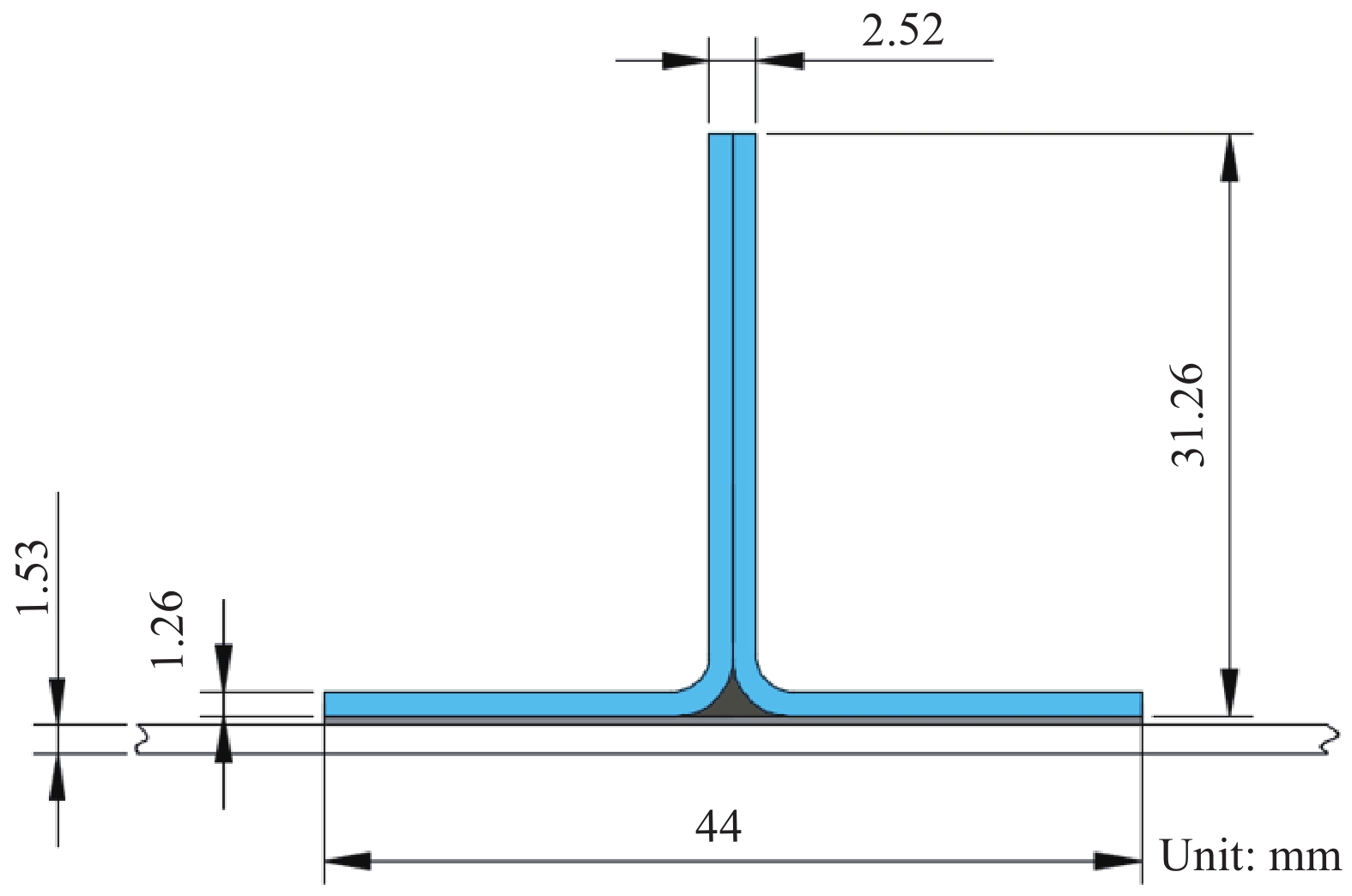

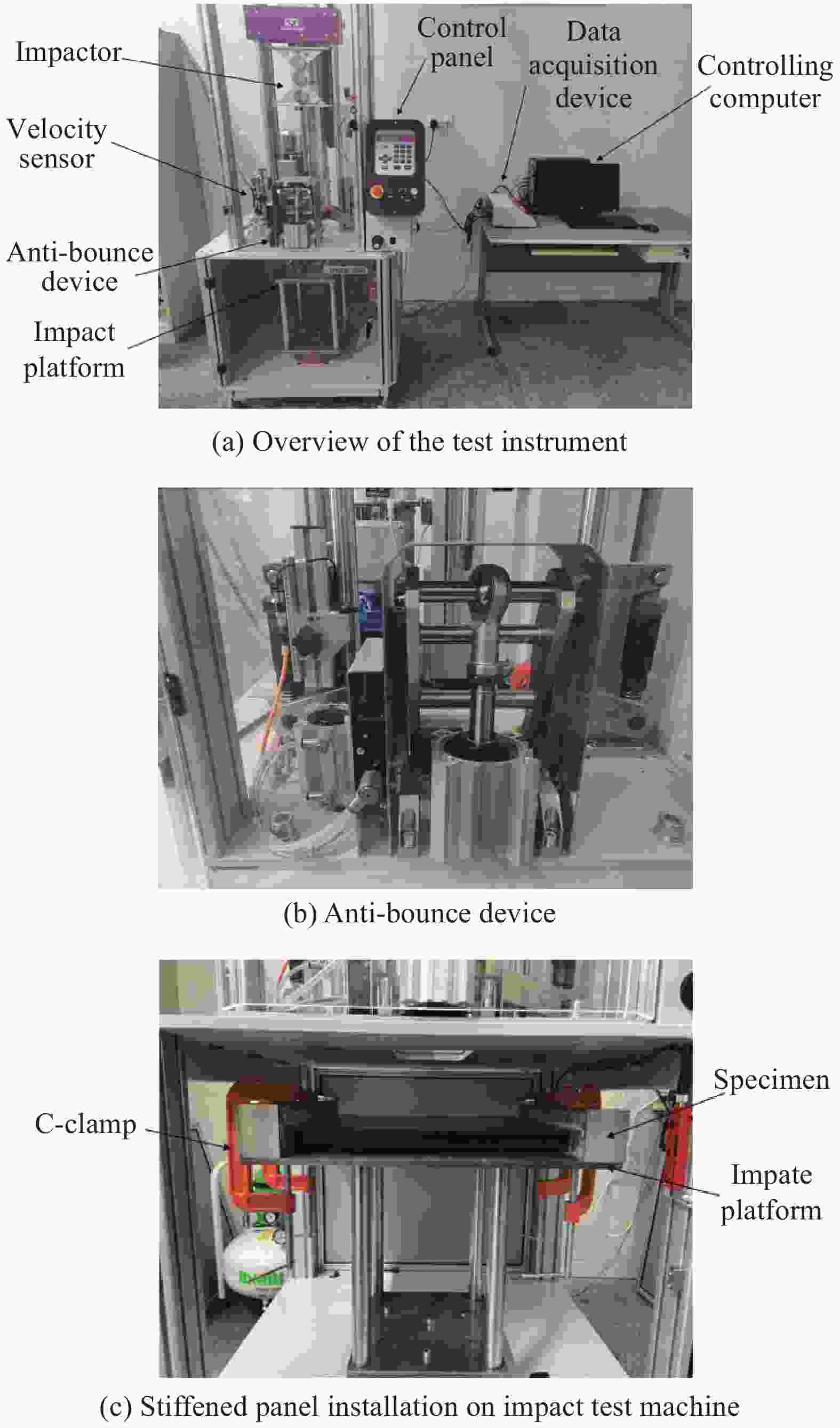

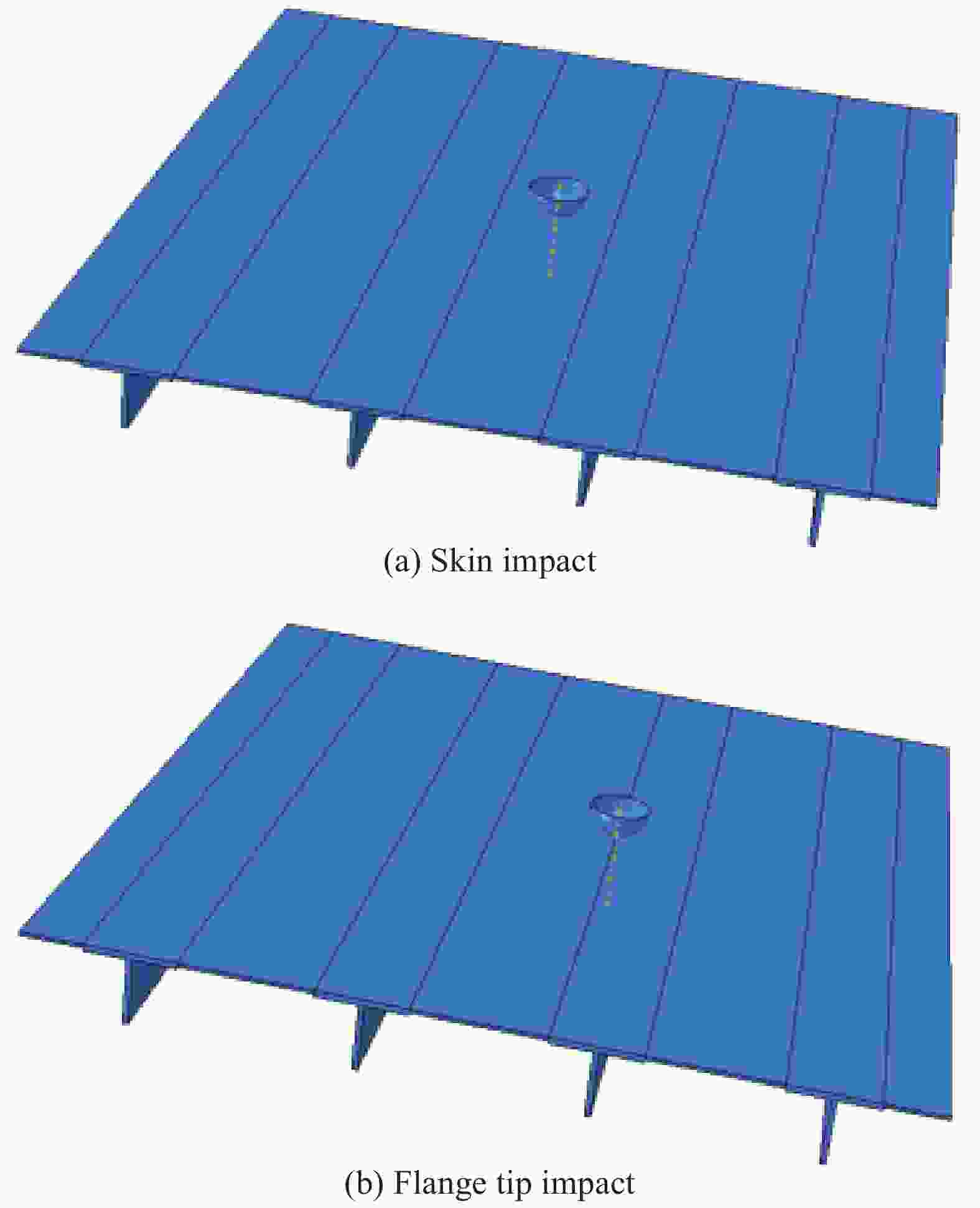

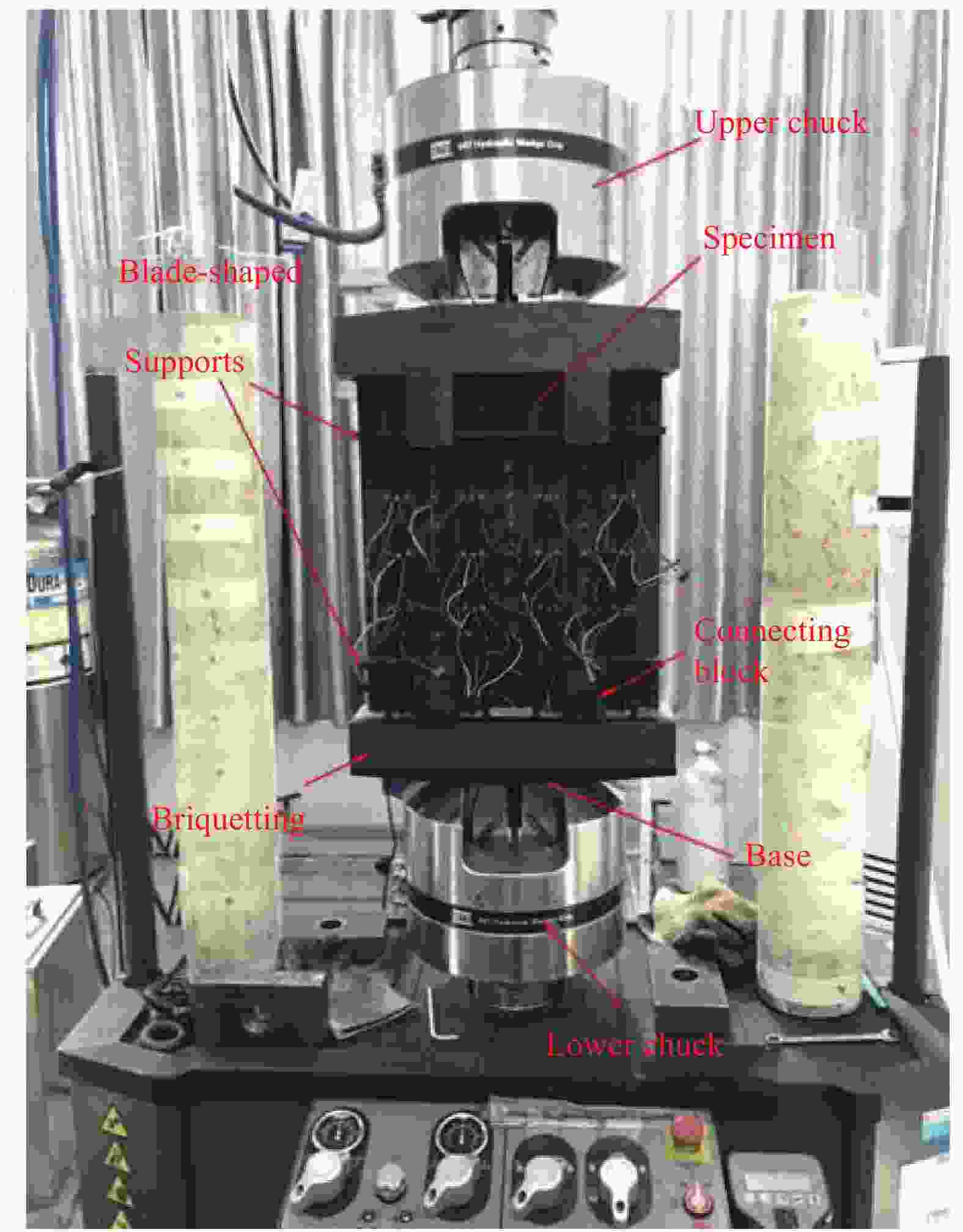

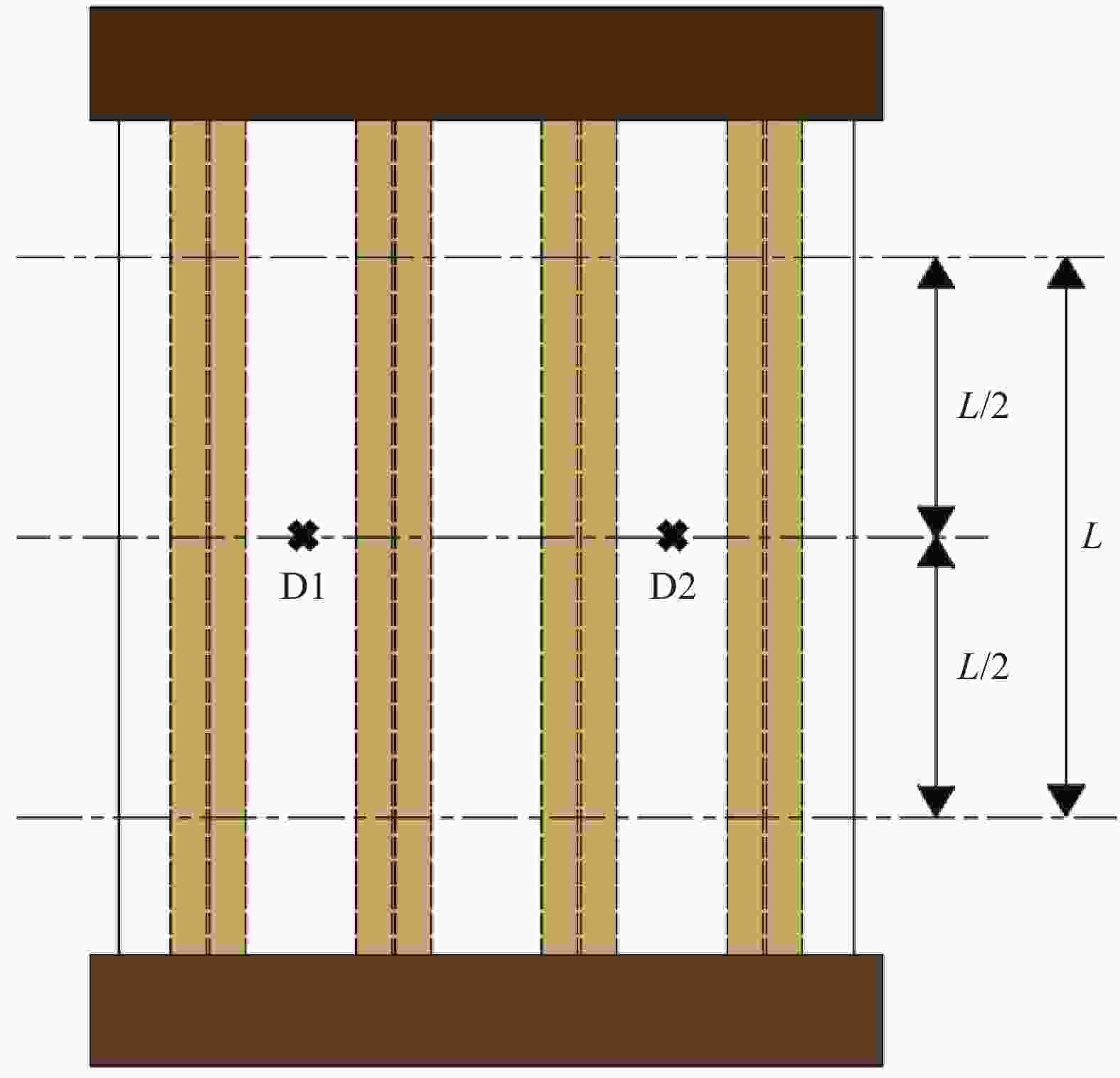

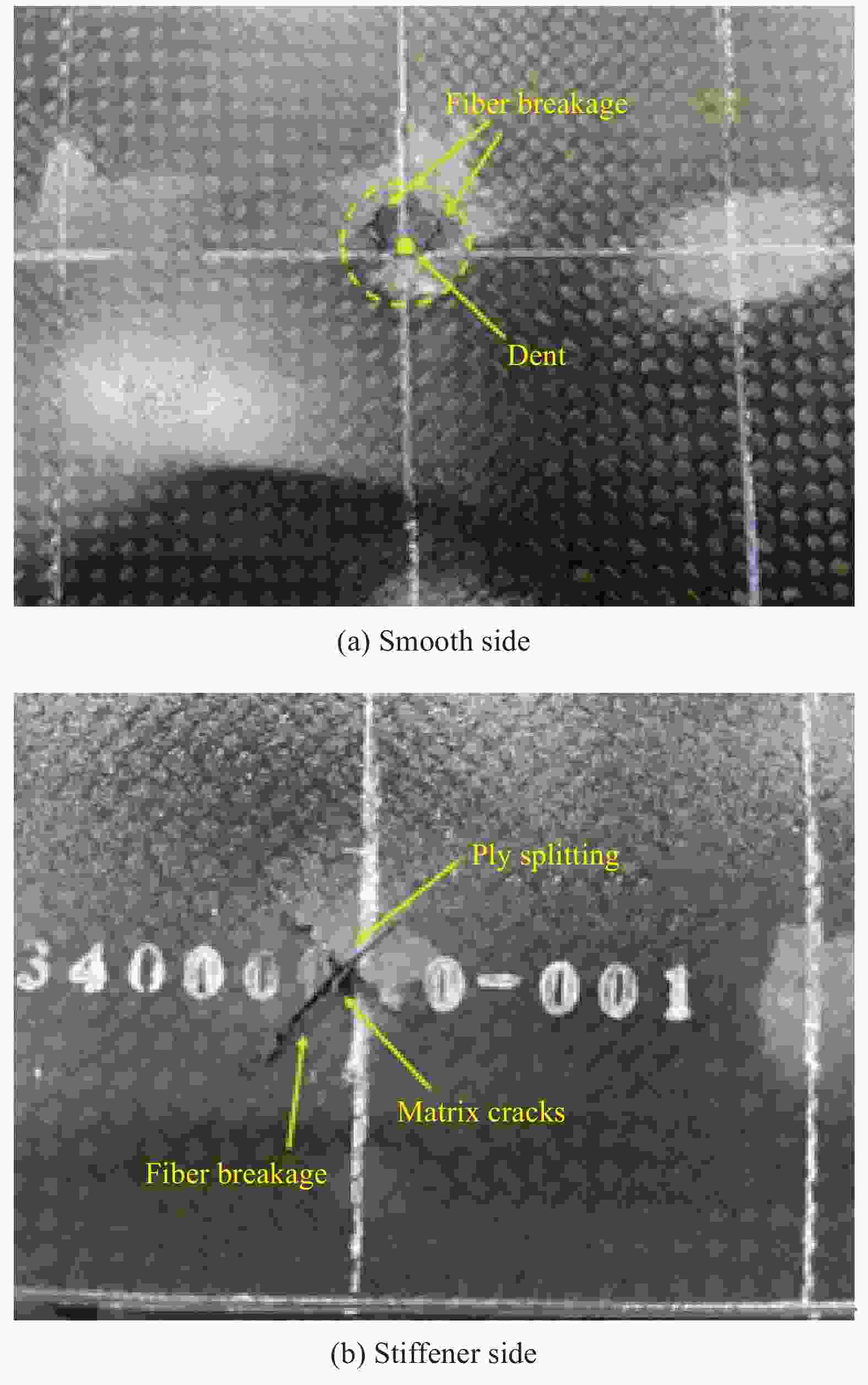

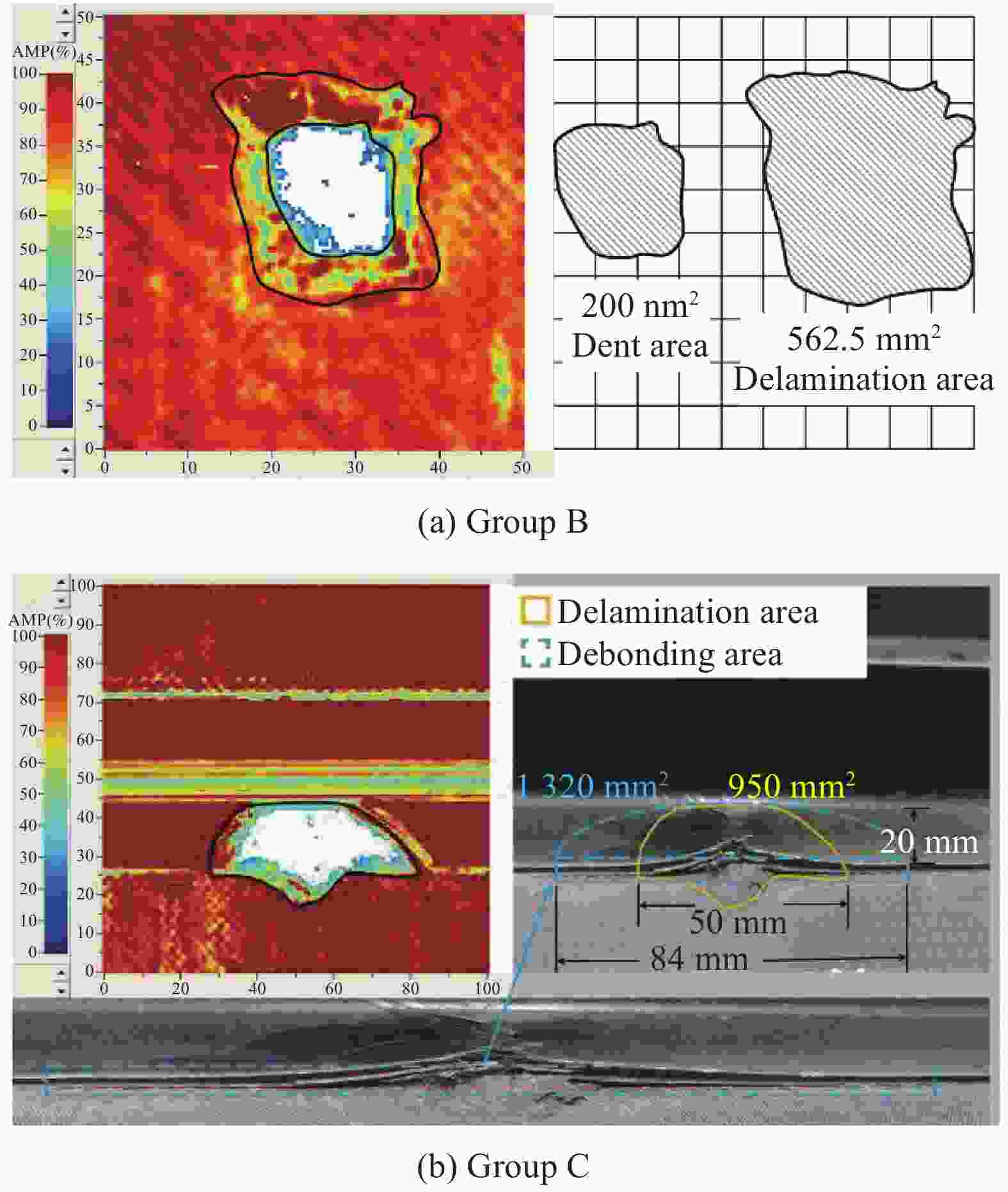

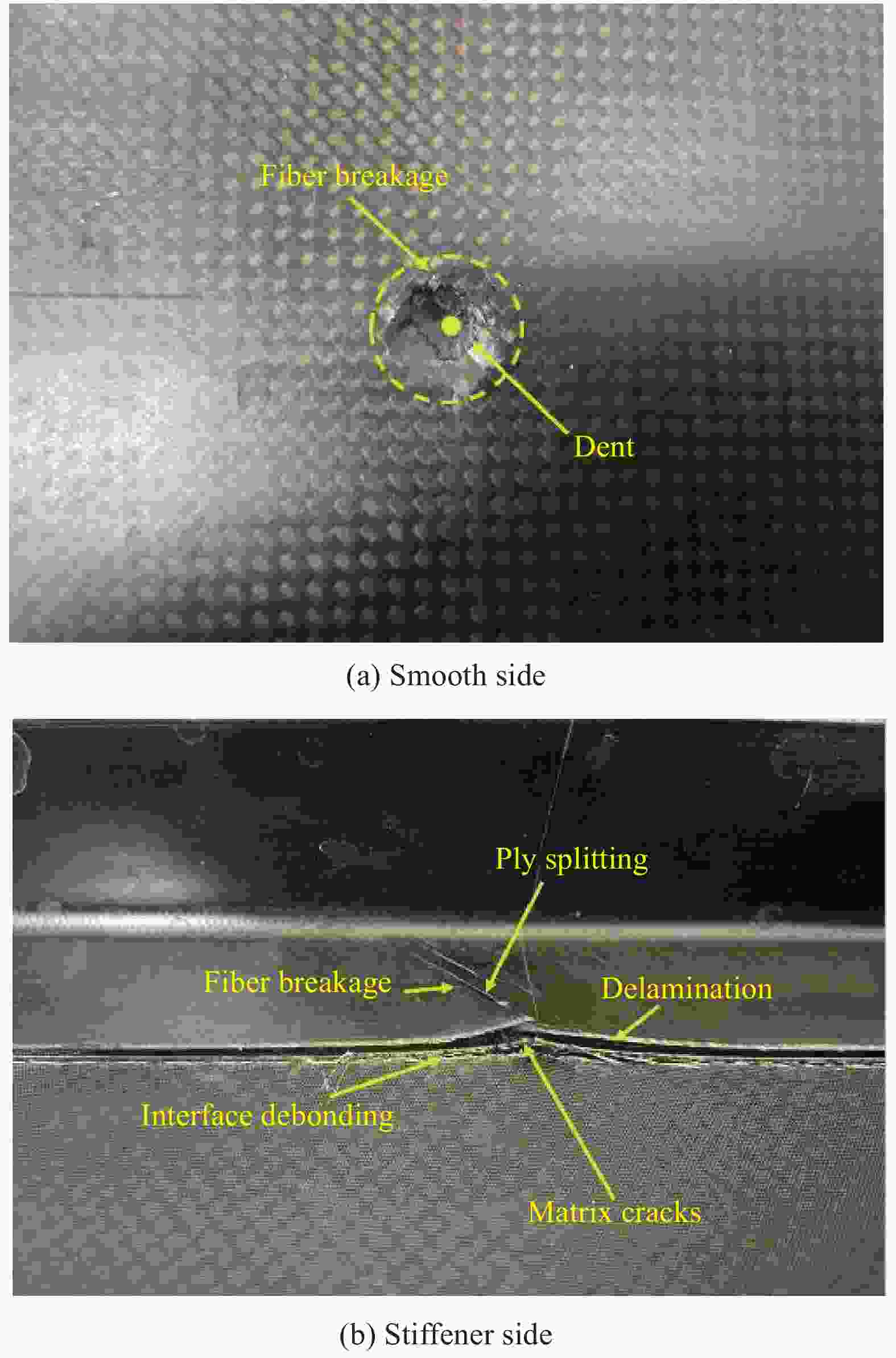

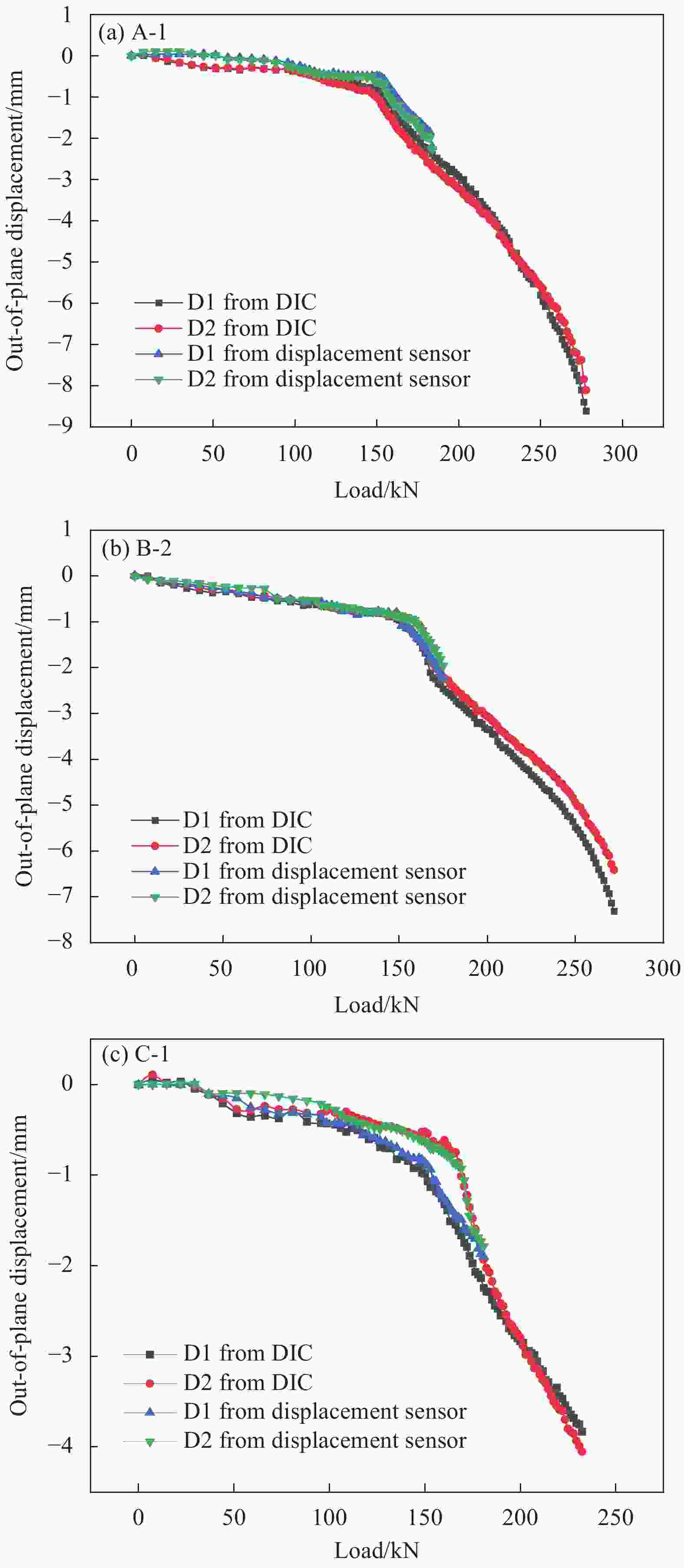

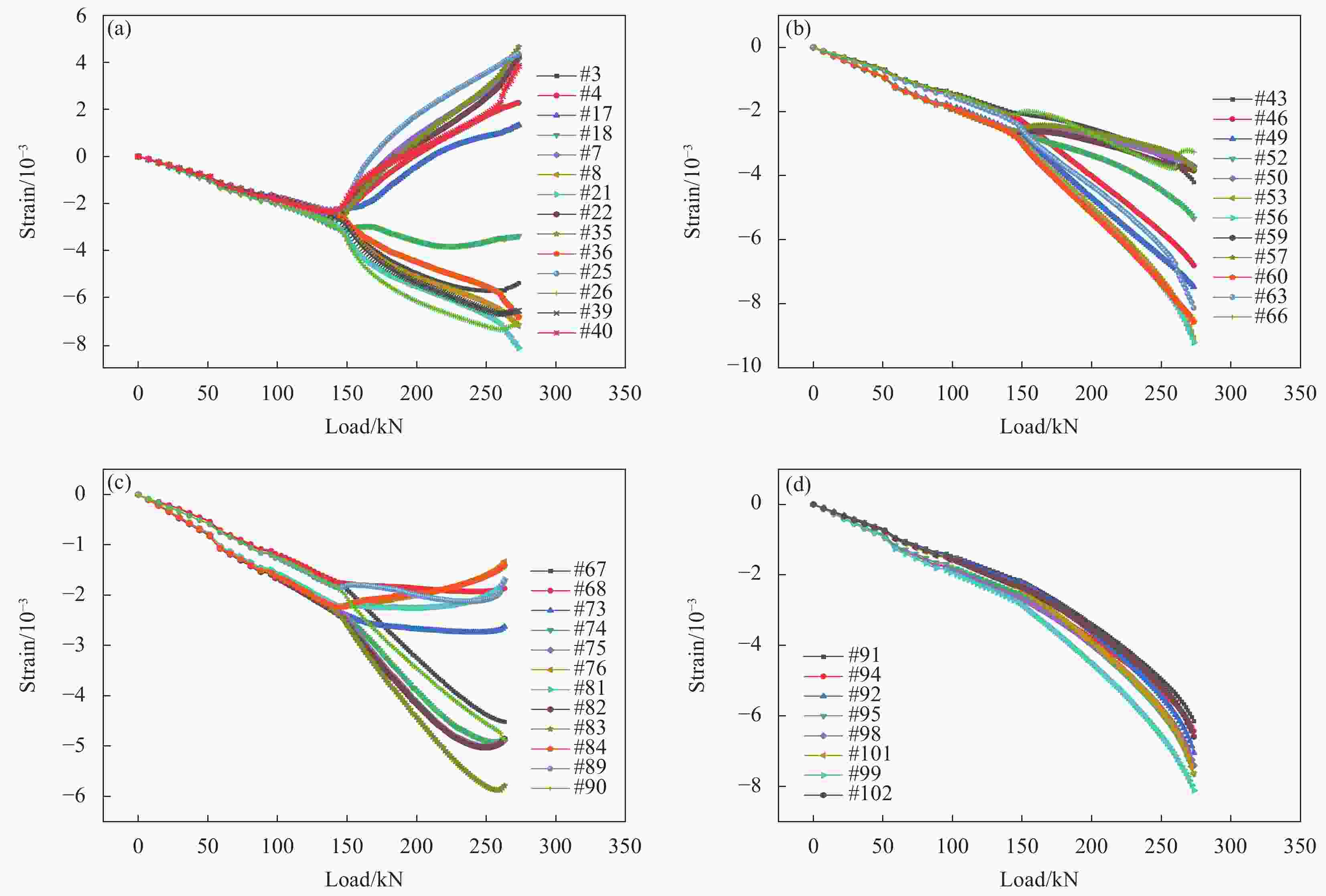

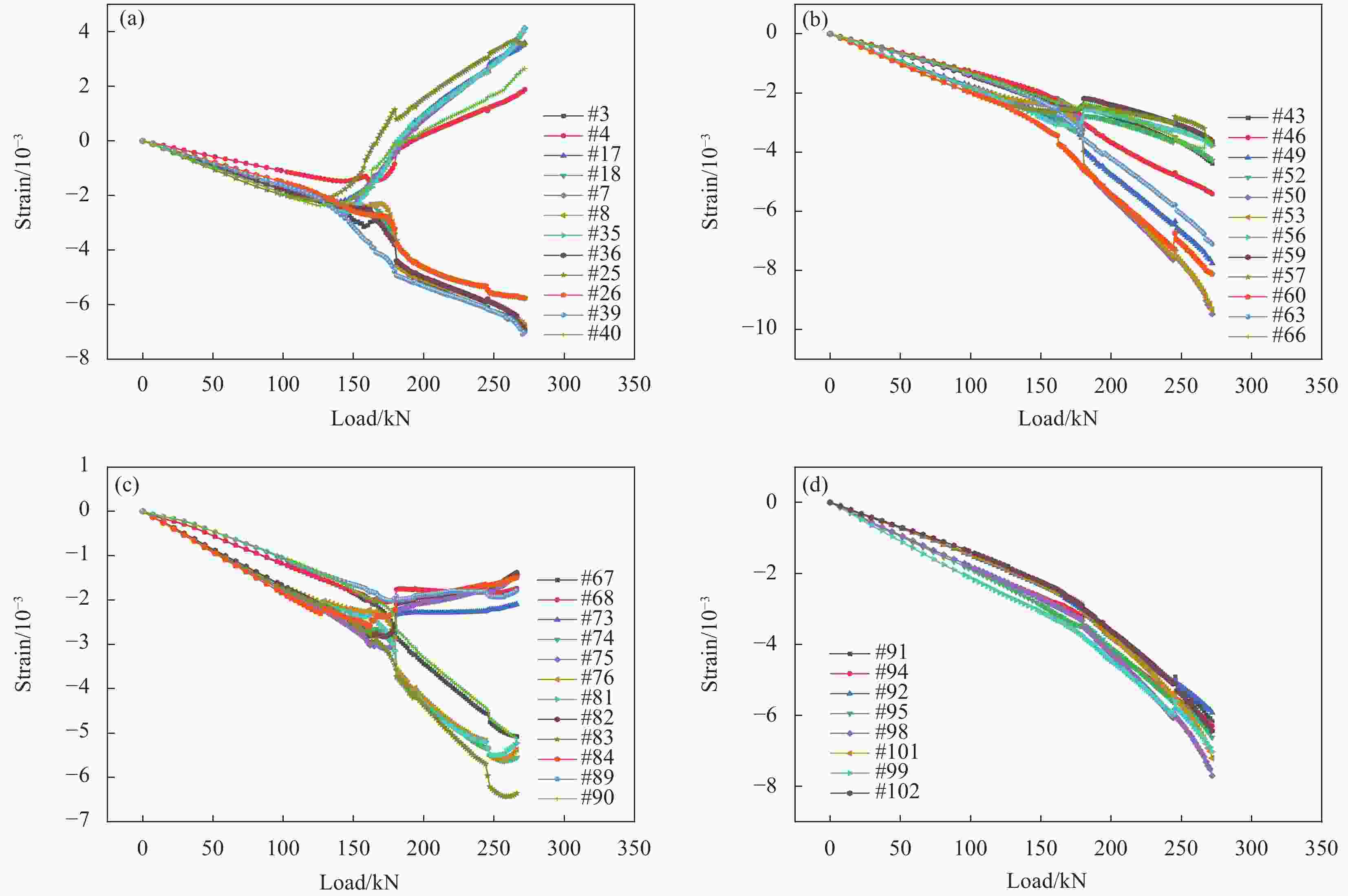

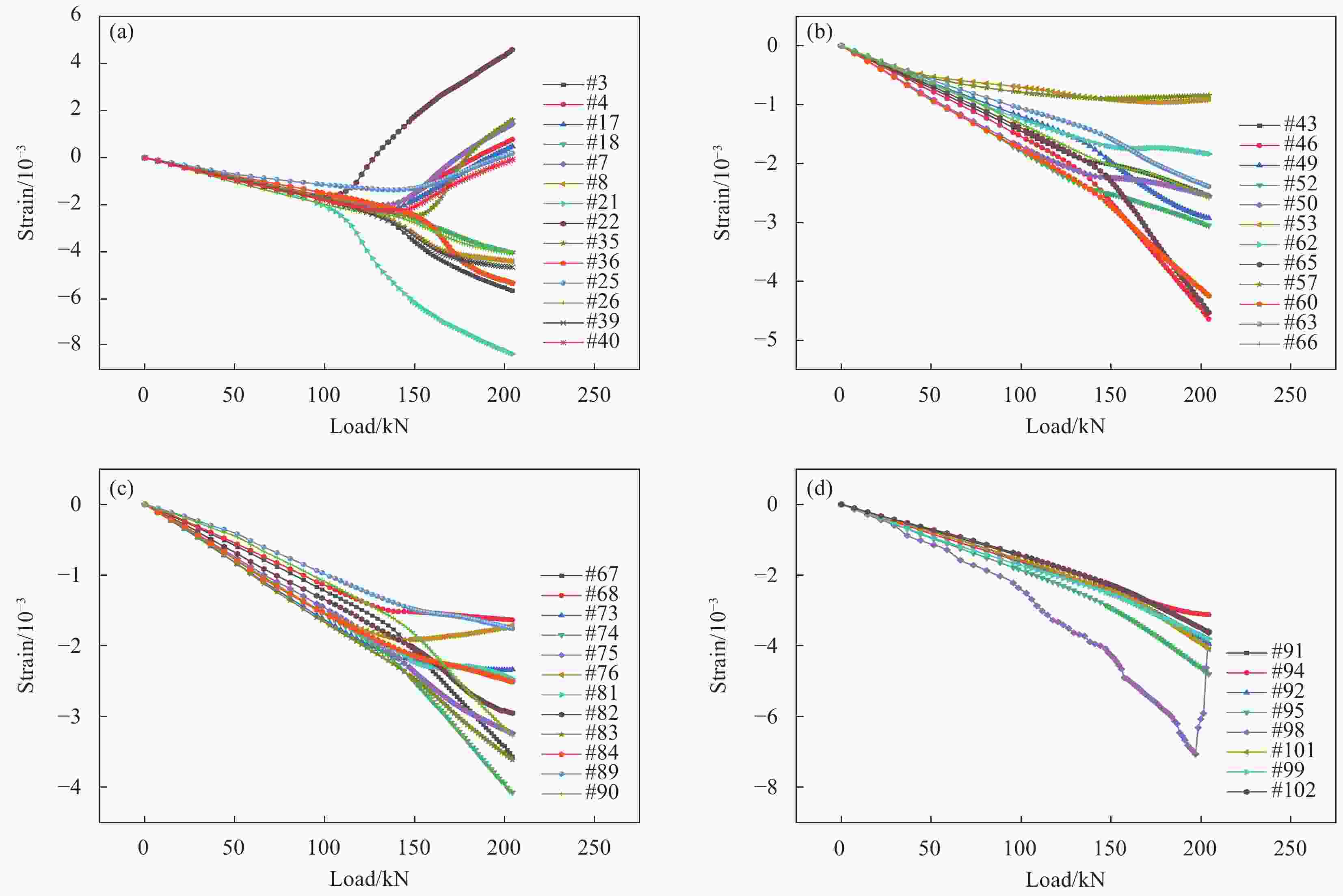

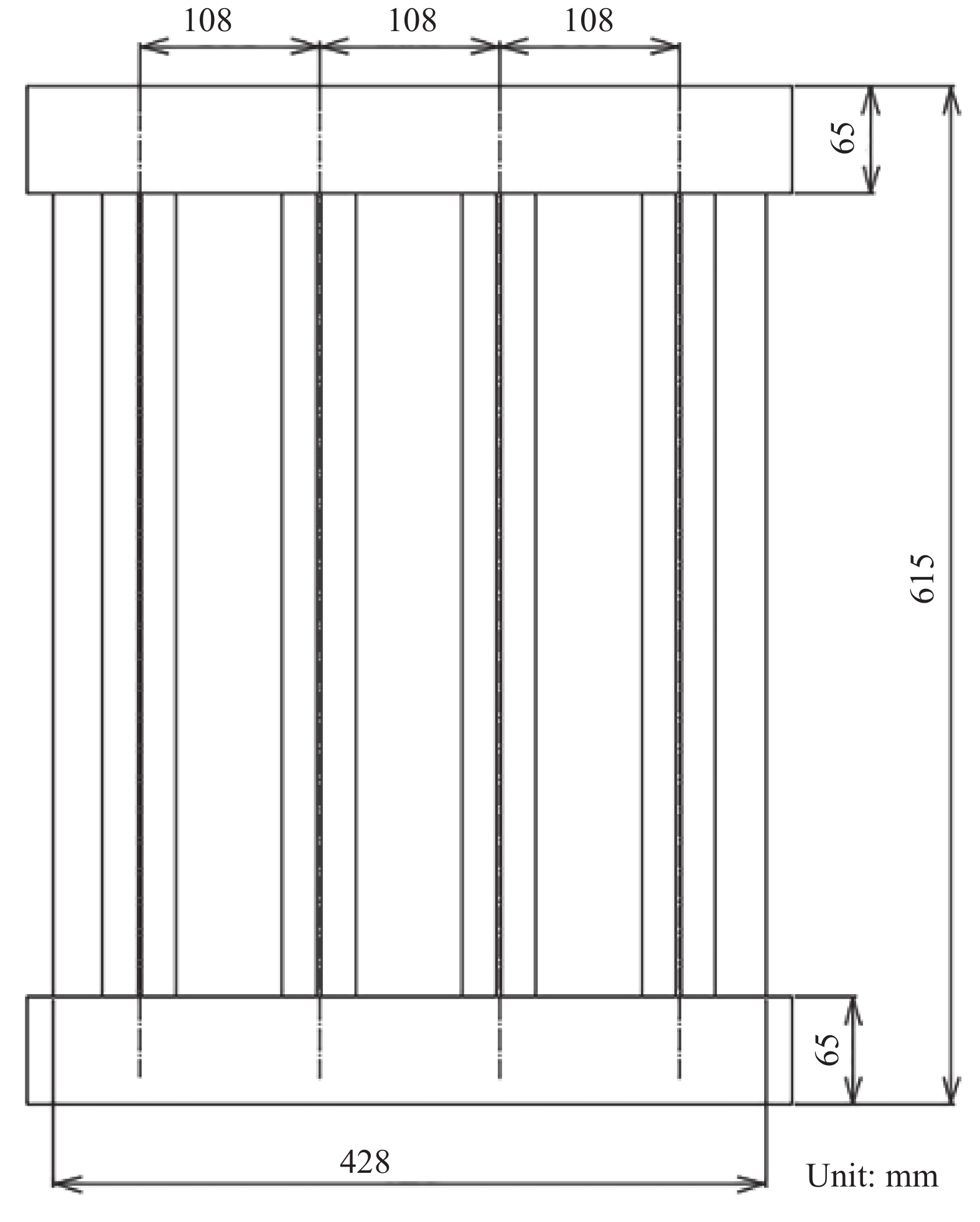

摘要: 对低速冲击 (LVI)载荷下不同冲击位置对T型复合材料加筋板损伤容限的影响进行了试验研究。选取了2个典型冲击位置,即:两筋间蒙皮和筋条长桁边缘,引入目视可检冲击损伤(VID)。借助目视及无损检测手段观察到不同冲击位置处的损伤存在显著差异。相比于蒙皮冲击,长桁边缘冲击处的损伤形式更复杂,表现为:纤维断裂、基体开裂、分层、层剥离及界面脱粘。分别对完好、蒙皮冲击和长桁冲击试件进行冲击后压缩试验(CAI)。结果表明:蒙皮冲击件与完好件失效过程极为相似,由于试验夹具刀口的存在,限制了加筋板的变形,诱发了损伤起始,导致最终的结构破坏;而长桁冲击件展示出截然不同的失效机制,损伤从冲击位置沿试件横向扩展,促使结构整体失效的提前发生,显著降低了加筋板的剩余压缩强度。此外,引入数字图像相关技术(DIC)对压缩过程中试件的变形进行监测,并与传统的接触式测量结果进行对比,验证了该测试方法应用于材料力学性能测试的可行性与优越性。Abstract: The effect of impact positions on the damage tolerance of T-stiffened composite panels was investigated by experimental methods. Low velocity impact (LVI) was carried out at two typical locations, namely the center of skin between two stiffeners and the stiffener flange tip of the panels, to introduce visible impact damage (VID). With the help of visual inspection and nondestructive detection, obvious differences in damage morphology from different impact positions were observed. Compared with the skin impact, the damage types induced by the flange tip impact were more complicated, including fiber fracture, matrix cracks, delamination, ply splitting and interface debonding. Compression-after-impact (CAI) tests were performed on the intact, skin-impacted and flange-impacted stiffened panels respectively. The experimental results show that the deformation of skin-impacted panels is restricted due to blade supports, inducing the damage initiation and causing ultimate destruction, which is extremely similar to intact panels. For the flange tip impact, whilst, damage propagation is along the transverse direction from the impact location, which is entirely different from skin impact in the damage scenario, promoting the structural failure and reducing significantly the residual compressive strength. Additionally, the digital image correlation (DIC) was used to monitor the deformation of the specimens during compression and compared with the results of contact measurement, which verified the feasibility and superiority of the test method applied to the mechanical properties of materials.

-

表 1 碳纤维增强环氧树脂复合材料特性参数

Table 1. Material property parameters of carbon fiber reinforced epoxy resin composite

Material Property Value CCF800/AC531 Longitudinal Young’s modulus E11/GPa 147 Transverse Young’s modulus E22/GPa 9.25 In-plane shear modulus G12/GPa 4.40 Poisson’s ratio ν12 0.33 CF8611/AC531 Longitudinal Young’s modulus E11/GPa 69 Transverse Young’s modulus E22/GPa 67.9 In-plane shear modulus G12/GPa 3.97 Poisson’s ratio ν12 0.047 表 2 复合材料加筋板冲击损伤的详细测量值

Table 2. Detailed measurements of impact damage of composite stiffened panels

Specimen Dent

depth/mmDent

length/mmDent

width/mmB-1 1.962 14.10 12.84 B-2 1.856 13.74 11.70 B-3 1.752 13.26 11.44 Average value 1.857 13.70 11.99 C-1 2.520 19.20 14.50 C-2 2.384 17.50 14.08 C-3 4.360 19.50 14.50 Average value 3.088 18.73 14.36 Notes: Group B—Impacted at the center of skin between two stiffeners; Group C—Impacted at the stiffener flange tip. 表 3 复合材料加筋板冲击后压缩试验结果

Table 3. Compression-after-impact test results for stiffened composite panels

Specimen Type General buckling of stiffened panels Ultimate failure of stiffened panels Load/kN Average load/kN Load/kN Average load /kN Relative change A-1 Intact 145 142.7 276.230 276.769 − A-2 143 275.689 A-3 140 278.387 B-1 The skin impact 148 143.7 267.247 271.181 −2.02% B-2 141 274.750 B-3 142 271.545 C-1 The flange tip impact 142 143.3 205.055 224.775 −18.79% C-2 145 237.844 C-3 143 231.425 -

[1] 蓝元沛, 关志东, 孟庆春. 复合材料飞机结构技术成熟度评价方法[J]. 复合材料学报, 2010, 27(3):150-154.LAN Yuanpei, GUAN Zhidong, MENG Qingchun. Evaluation method for technology maturity of composite aircraft structure[J]. Acta Materiae Compositae Sinica,2010,27(3):150-154(in Chinese). [2] ZHANG Shengming, KHAN Imtaz. Buckling and ultimate capability of plates and stiffened panels in axial compression[J]. Marine Structures,2009,22(4):791-808. doi: 10.1016/j.marstruc.2009.09.001 [3] WEAVER P M, DRIESEN J R, ROBERTS P. Anisotropic effects in the compression buckling of laminated composite cylindrical shells[J]. Composites Science and Technology,2002,62(1):91-105. doi: 10.1016/S0266-3538(01)00186-5 [4] BERTOLINI J, CASTANIE B, BARRAU J J, et al. An experimental and numerical study on omega stringer debonding[J]. Composite Structures,2008,86(1):233-242. [5] GREENHALGH E, MEEKS C, CLARKE A, et al. The effect of defects on the performance of post-buckled CFRP stringer-stiffened panels[J]. Composites Part A: Applied Science and Manufacturing,2003,34(7):623-633. doi: 10.1016/S1359-835X(03)00098-8 [6] LIU Jingze, FEI Qingguo, JIANG Dong, et al. Experimental and numerical investigation on static and dynamic characteristics for curvilinearly stiffened plates using DST–BK model[J]. International Journal of Mechanical Sciences,2020,169:105286. doi: 10.1016/j.ijmecsci.2019.105286 [7] YE Yaoyao, ZHU Weidong, JIANG Junxia, et al. Design and optimization of composite sub-stiffened panels[J]. Composite Structures,2020,240:112084. doi: 10.1016/j.compstruct.2020.112084 [8] ORIFICI A C, THOMSON R S, DEGENHARDT R, et al. Degradation investigation in a postbuckling composite stiffened fuselage panel[J]. Composite Structures,2007,82(2):217-224. [9] KONG Xiangshao, YANG Yi, GAN Jin, et al. Experimental and numerical investigation on the detailed buckling process of similar stiffened panels subjected to in-plane compressive load[J]. Thin-Walled Structures,2020,148:106620. doi: 10.1016/j.tws.2020.106620 [10] TURON A, DAVILA C G, CAMANHO P P, et al. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models[J]. Engineering Fracture Mechanics,2006,74(10):1665-1682. [11] 孔斌, 陈普会, 陈炎. 复合材料整体加筋板轴压后屈曲失效评估方法[J]. 复合材料学报, 2014, 31(3):765-771.KONG Bin, CHEN Puhui, CHEN Yan. Post-buckling failure evaluation method of integrated composite stiffened panels under uniaxial compression[J]. Acta Materiae Compo-sitae Sinica,2014,31(3):765-771(in Chinese). [12] YETMAN J E, SOBEY A J, BLAKE J I R, et al. Investigation into skin stiffener debonding of top-hat stiffened composite structures[J]. Composite Structures,2015,132:1168-1181. doi: 10.1016/j.compstruct.2015.06.061 [13] ORIFICI A C, DE ZARATE ALBERDI I O, THOMSON R S, et al. Compression and post-buckling damage growth and collapse analysis of flat composite stiffened panels[J]. Composites Science and Technology,2008,68(15):3150-3160. [14] CAPRINO G. Residual strength prediction of impacted CFRP laminates[J]. Journal of Composite Materials,1984,18(6):508-518. doi: 10.1177/002199838401800601 [15] CHOI H Y, CHANG F K. A model for predicting damage in graphite/epoxy laminated composites resulting from low-velocity point impact[J]. Journal of Composite Materials,1992,26(14):2132-2167. [16] WISHEART M, RICHARDSON M. The finite element analysis of impact induced delamination in composite materials using a novel interface element[J]. Composites Part A: Applied Science and Manufacturing,1998,29(3):301-313. doi: 10.1016/S1359-835X(97)00080-8 [17] MITREVSKI T, MARSHALL I H, THOMSON R. The influence of impactor shape on the damage to composite laminates[J]. Composite Structures,2006,76:116-122. doi: 10.1016/j.compstruct.2006.06.017 [18] OUYANG Tian, BAO Rui, SUN Wei, et al. A fast and efficient numerical prediction of compression after impact (CAI) strength of composite laminates and structures[J]. Thin-Walled Structures,2020,148:106588. doi: 10.1016/j.tws.2019.106588 [19] FENG Yu, ZHANG Haoyu, TAN Xiangfei, et al. Effect of impact damage positions on the buckling and post-buckling behaviors of stiffened composite panel[J]. Composite Structures,2016,155:184-196. doi: 10.1016/j.compstruct.2016.08.012 [20] TAN Riming, GUAN Zhidong, SUN Wei, et al. Experiment investigation on impact damage and influences on compression behaviors of single T-stiffened composite panels[J]. Composite Structures,2018,203:486-497. doi: 10.1016/j.compstruct.2018.07.038 [21] LI N, CHEN P H. Experimental investigation on edge impact damage and compression-after-impact (CAI) behavior of stiffened composite panels[J]. Composite Structures,2016,138:134-150. doi: 10.1016/j.compstruct.2015.11.060 [22] 阳奥, 陈普会, 孔斌, 等. 数字图像相关技术在复合材料加筋曲板压缩试验中的应用[J]. 复合材料学报, 2020, 37(10):2439-2451.YANG Ao, CHEN Puhui, KONG Bin, et al. Application of digital image correlation technology in compression test of stringer stiffened composite curved panels[J]. Acta Materiae Compositae Sinica,2020,37(10):2439-2451(in Chinese). [23] ZIMMERMANN R, KLEIN H, KLING A. Buckling and postbuckling of stringer stiffened fibre composite curved panels-Tests and computations[J]. Composite Structures,2005,73(2):150-161. [24] FEATHERSTON C A, MORTIMER J, EATON M, et al. The dynamic buckling of stiffened panels-A study using high speed digital image correlation[J]. Applied Mechanics and Materials,2010,972:331-336. [25] TAN Riming, XU Jifeng, GUAN Zhidong, et al. Experimental study on effect of impact locations on damage formation and compression behavior of stiffened composite panels with L-shaped stiffener[J]. Thin-Walled Structures,2020,150:106707. doi: 10.1016/j.tws.2020.106707 [26] ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D 7136[S]. West conshohocken: ASTM, 2007. -

下载:

下载: