Temperature control for induction welding of carbon fiber reinforced polyetheretherketone (CF/PEEK) composite material via thermal conduction plate

-

摘要: 研究了碳纤维增强聚醚醚酮(CF/PEEK)复合材料感应焊接中厚度方向及焊接面内的温度分布及调控。基于对温度分布结果的分析,使用导热板结合真空袋压的方式对CF/PEEK进行感应焊接,结合使用合适的功率及加热时间,测试了焊接件的单搭接强度,观测分析了焊接件的断裂形貌。结果表明,导热板对层合板表层和边缘均有良好的散热效果;焊接功率越低,焊接面的加热均匀性增加,但是会延长加热时间。在真空袋中对层合板上表面和两侧添加导热板,在输出功率示数为600时感应焊接300 s,焊接件的单搭接剪切强度达到41.57 MPa。Abstract: The temperature distribution along the thickness direction and along the weld line for carbon fiber reinforced polyetheretherketone (CF/PEEK) composite was recorded and optimized. According to the temperature distribution result, the induction welding of CF/PEEK laminates was carried out with appropriate power and heating time, with the help of vacuum bag and properly placed thermal conduction plates. The single lap strength of the welded sample was tested, and the fracture morphology of the weld area was observed and analyzed. The results show that the thermal conduction plates have a good heat dissipation effect around the surfaces of the laminates. The lower the welding power, the more uniform the heating of the welding area, but the heating time will be extended. Under the optimized processing parameters of power of 600 and heating time of 300 s in vacuum bag, and intentionally placed thermal conduction plates above the top surface and along the lateral sides, the single lap shear strength of the part reaches 41.57 MPa.

-

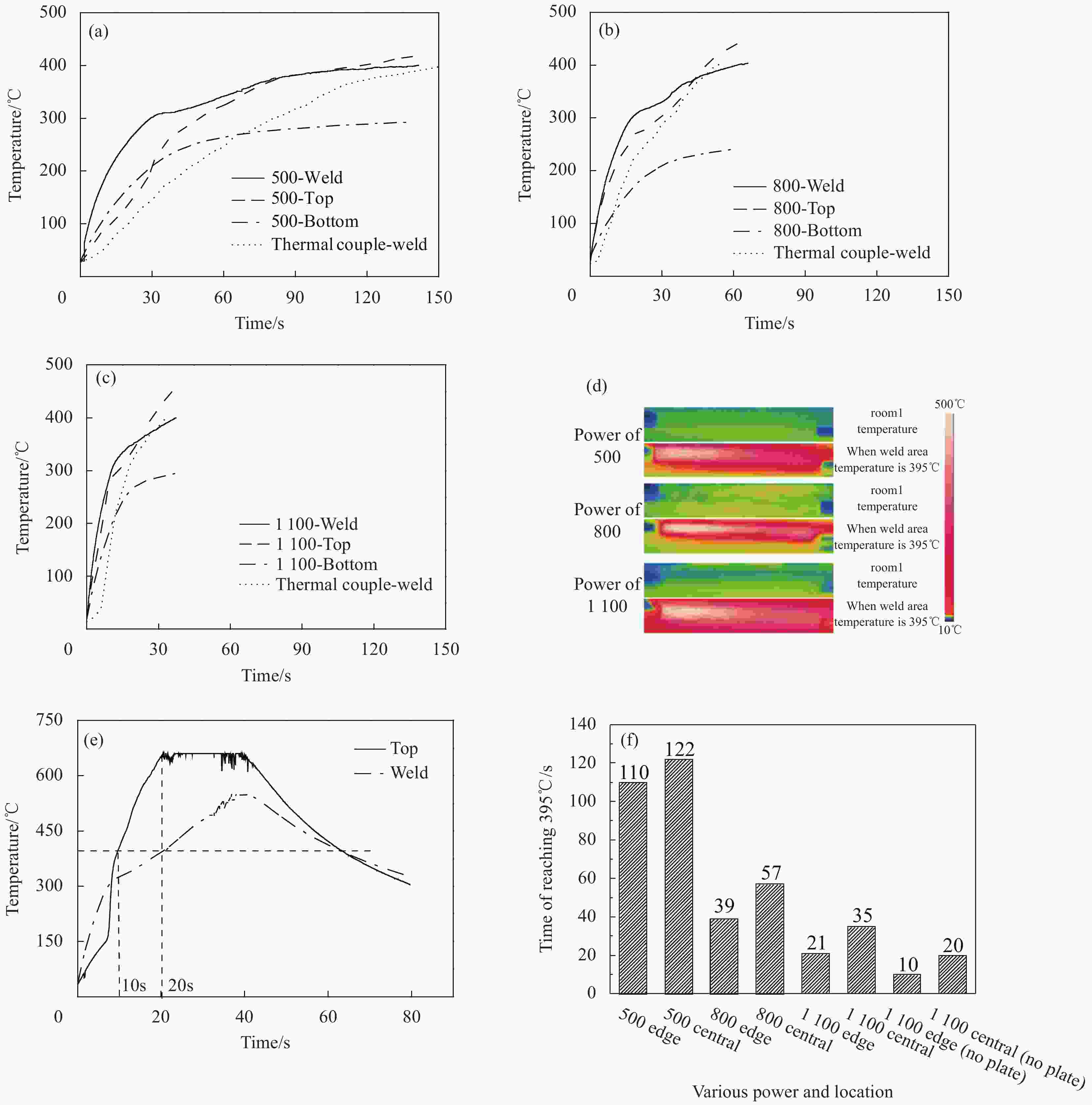

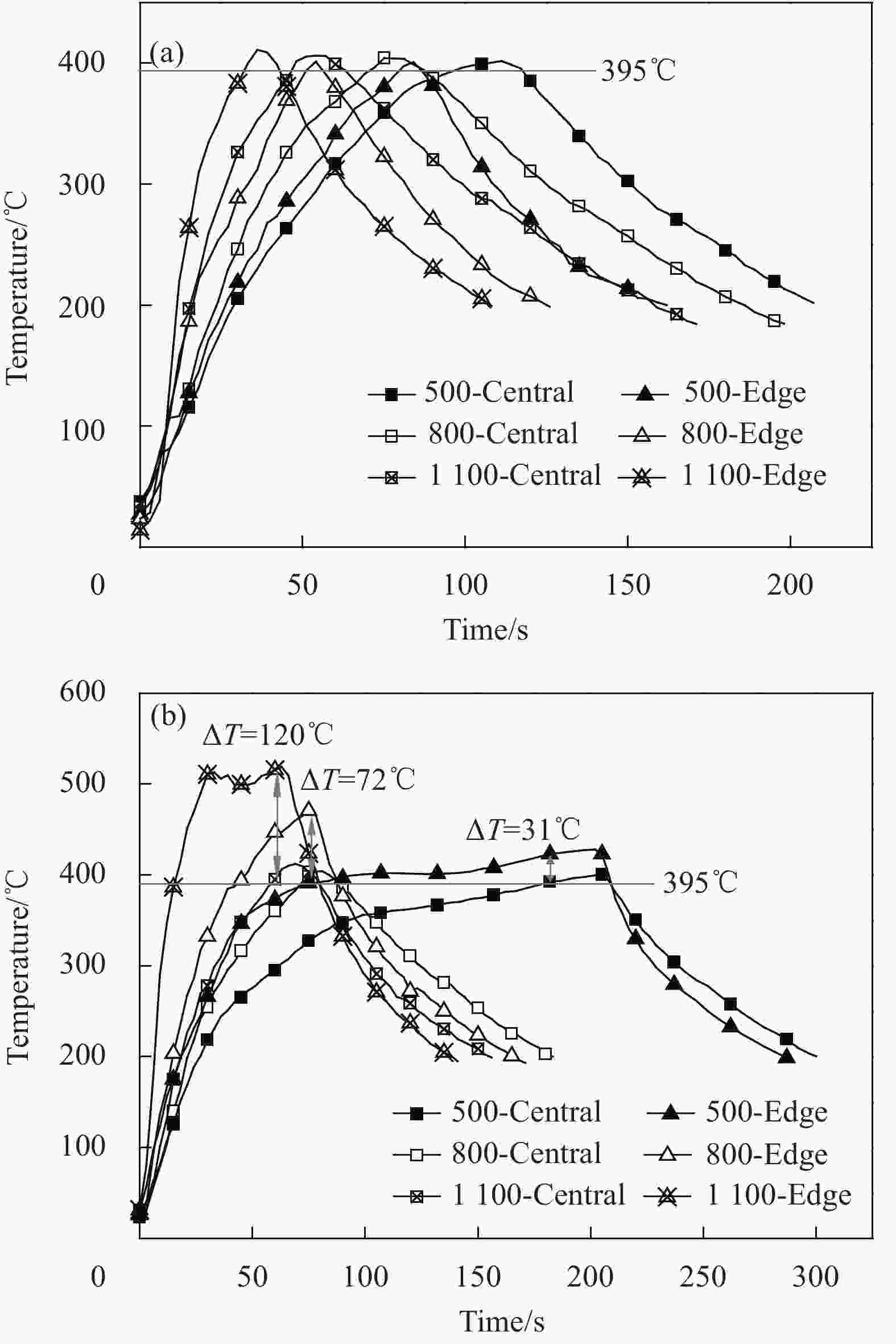

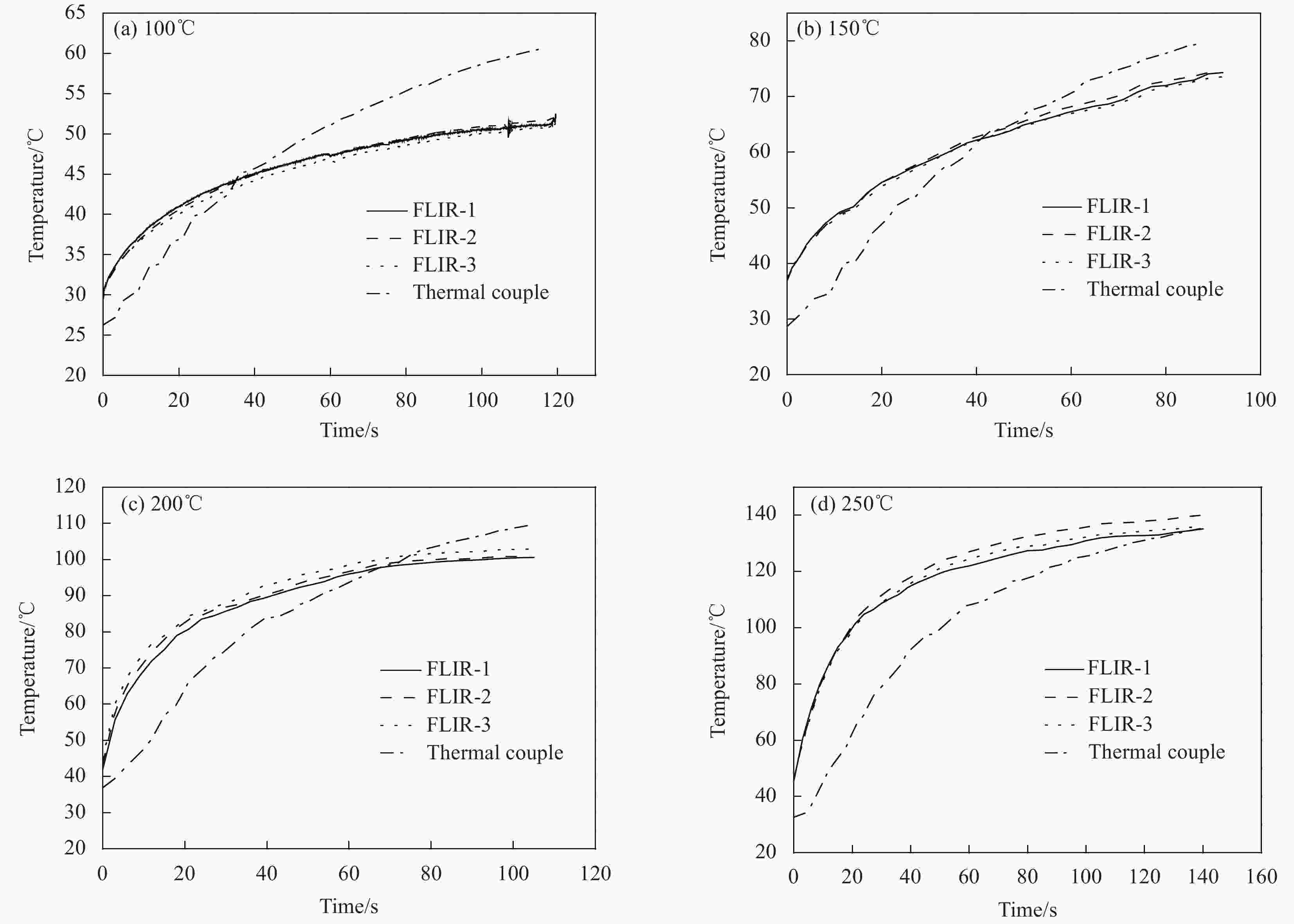

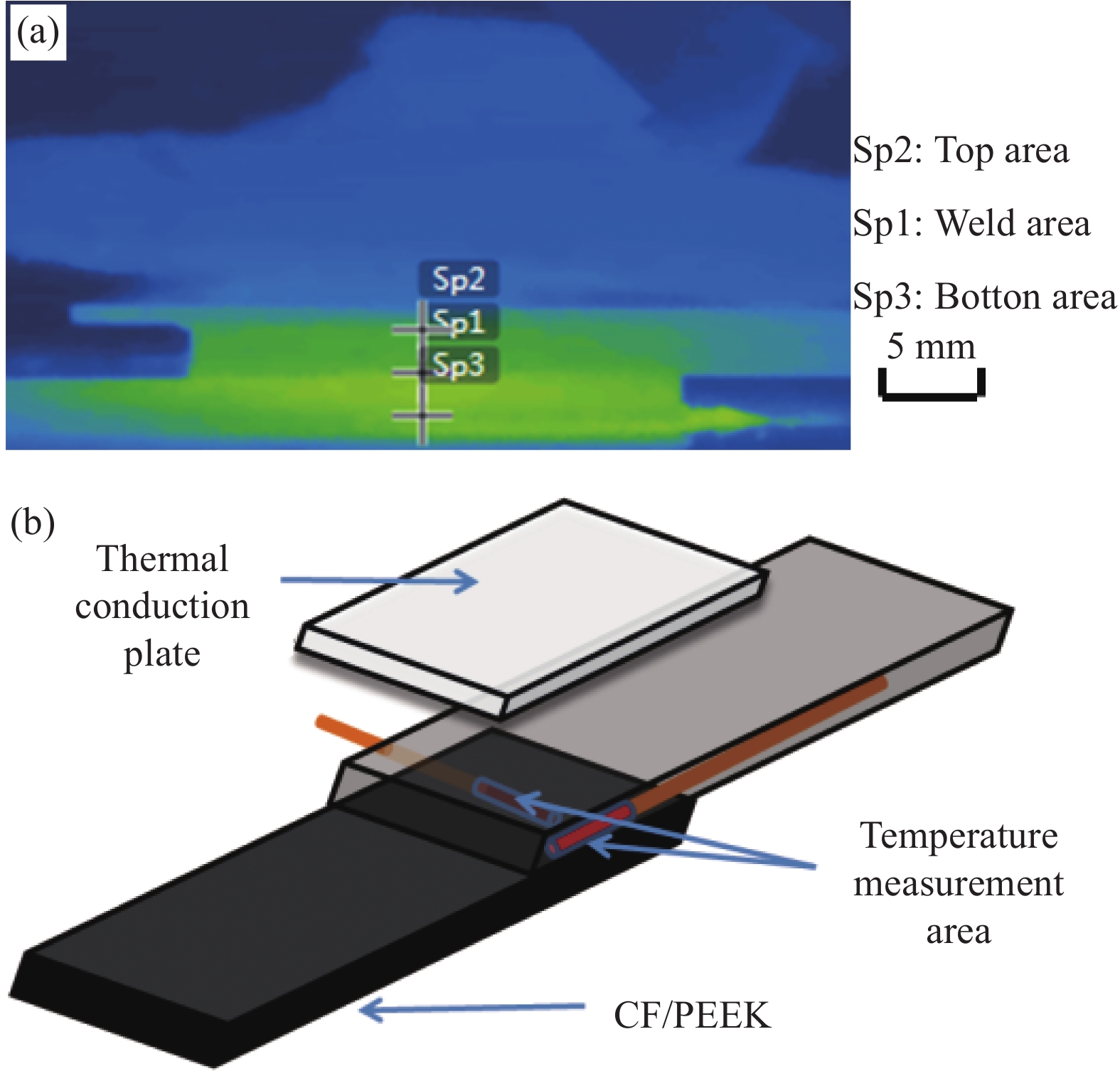

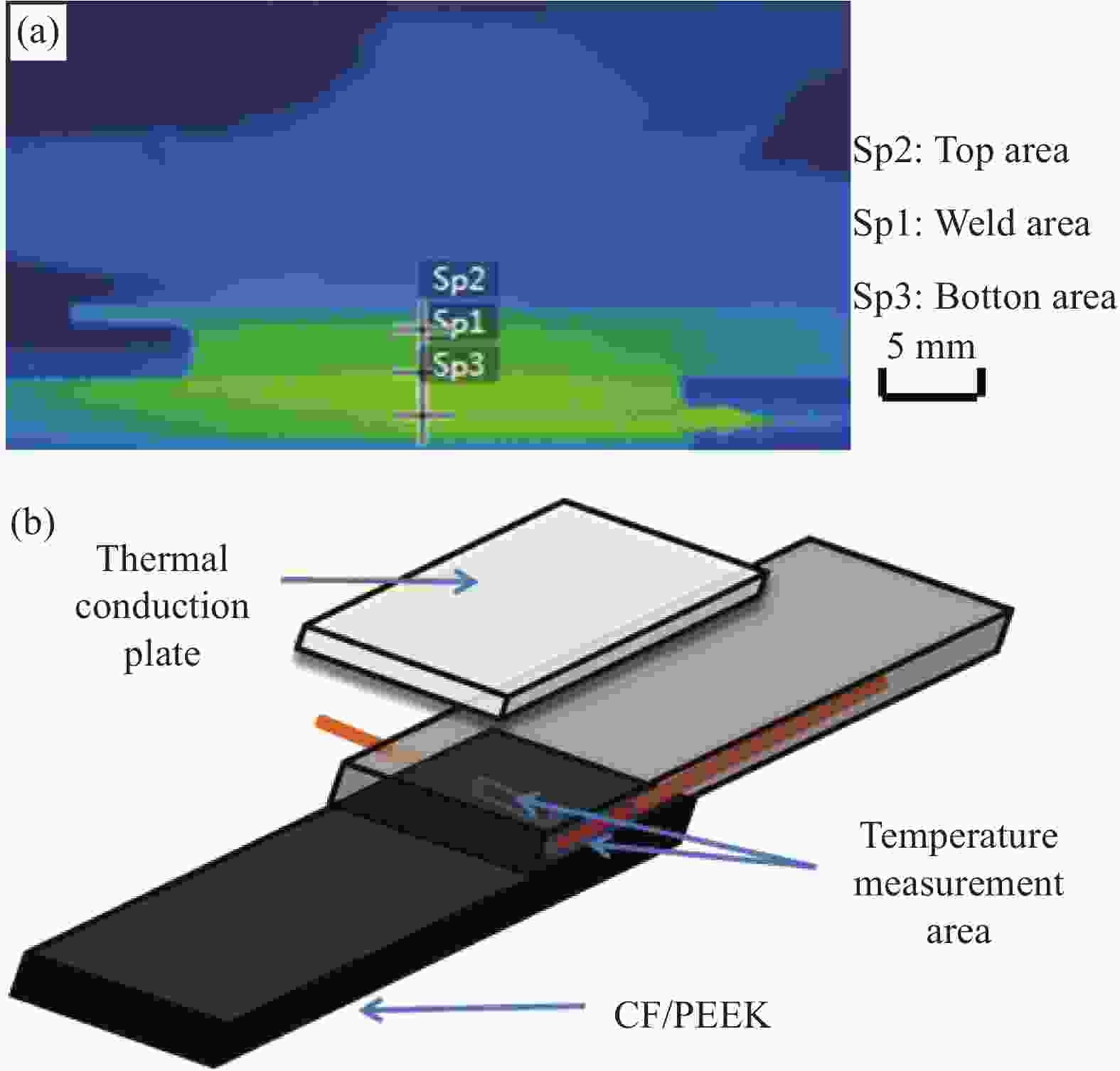

图 2 导热板下各功率CF/PEEK层合板侧面厚度方向上红外测温温度随时间变化曲线((a) 功率500;(b) 功率800;(c) 功率1100;(d) 红外热成像图;(e) 功率1 100无导热板;(f) 不同时间和位置到达395℃的时间)

Figure 2. Variation of temperature with time obtained by the infrared thermal imager for different spots along the thickness direction of CF/PEEK laminates under a heat conduction plate with different power output ((a) Power of 500; (b) Power of 800; (c) Power of 1100; (d) Infrared thermography; (e) Power of 1100 without heat conduction plate; (f) Time of reaching 395℃ at various power and position)

图 5 不同条件下CF/PEEK焊接件的断面形貌((a) 功率500、加热98 s;(b) 功率800、加热48 s;(c)功率1 100、加热19 s)和不同条件下CF/PEEK焊接件的上表面形貌((d) 功率1 100、无导热板、加热19 s;(e) 功率1 100、有导热板、加热19 s)

Figure 5. Fracture morphologies of CF/PEEK welded laminates ((a) Power of 500, heating time of 98 s; (b) Power of 800, heating time of 48 s; (c) Power of 1 100, heating time of 19 s) and top surface morphology of the welded laminates ((d) Power of 1 100, heating time of 19 s, without a heating conduction plate; (e) Power of 1 100, heating time of 19 s, with a heating conduction plate)

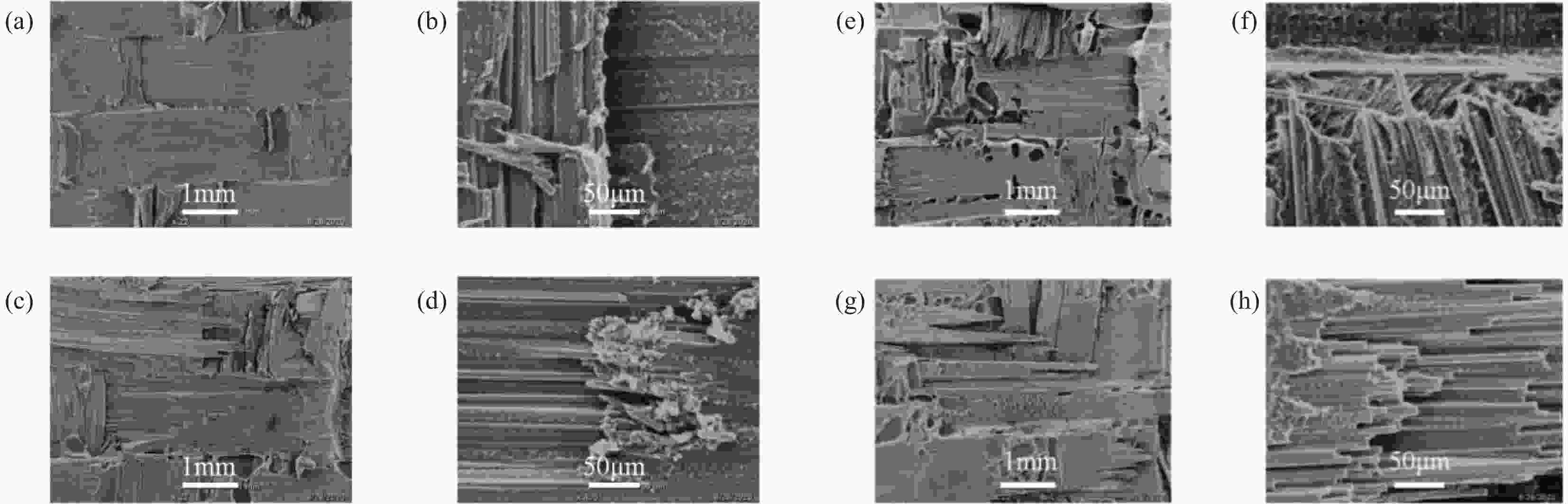

图 6 不同条件下CF/PEEK焊接件的断面SEM图像((a)~(b) 功率500中间区域;(c)~(d) 功率500边缘区域;(e)~(f) 功率800边缘区域;(g)~(h)功率1 100边缘区域)

Figure 6. SEM observation on fracture images of CF/PEEK welded laminates with a heating conduction plate and vacuum bag ((a)-(b) Power of 500, central area; (c)-(d) Power of 500, marginal area; (e)-(f) Power of 800, marginal area; (g)-(h) Power of 1 100, marginal area)

表 1 CF/PEEK焊接件接头单搭接剪切强度(LSS)

Table 1. Single lap shear strength (LSS) of CF/PEEK welded joints

Condition Average LSS/MPa Standard deviation Power of 500, 98 s 30.06 0.55 Power of 800, 48 s 22.35 1.87 Power of 1 100, 19 s 18.28 1.13 表 2 额外给层合板两侧添加导热板后CF/PEEK焊接件接头LSS

Table 2. LSS of CF/PEEK welded joints after adding heating conduction plates to both sides of the laminate

Condition Average LSS/MPa Power of 500, 200 s 26.40 Power of 600, 200 s 36.30 Power of 600, 300 s 41.57 -

[1] 杨洋, 见雪珍, 袁协尧, 等. 先进热塑性复合材料在大型客机结构零件领域的应用及其制造技术[J]. 玻璃钢, 2017(4):1-15.YANG Yang, JIAN Xuezhen, YUAN Xieyao, et al. Application and manufacturing technology of advanced thermoplastic composite materials in the field of large passenger aircraft structural parts[J]. Glass Fiber Reinforced Plastics,2017(4):1-15(in Chinese). [2] 路鹏程, 陈栋, 王志平. 碳纤维/聚苯硫醚热塑性复合材料电阻焊接工艺[J]. 复合材料学报, 2020, 37(5):1041-1048.LU Pengcheng, CHEN Dong, WANG Zhiping. Resistance welding process of carbon fiber/polyphenylene sulfide thermoplastic composite material[J]. Acta Materiae Compositae Sinica,2020,37(5):1041-1048(in Chinese). [3] 陈吉平, 李岩, 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成型技术的航空发展现状[J]. 复合材料学报, 2019, 36(4):784-794.CHEN Jiping, LI Yan, LIU Weiping, et al. Aerospace development status of continuous fiber-reinforced thermoplastic resin matrix composite material automatic placement and in-situ molding[J]. Acta Materiae Compositae Sinica,2019,36(4):784-794(in Chinese). [4] MITSCHANG P, MAURER D. Quality controlled induction welding by adapted process parameters[J]. Sampe Journal,2017,53(1):42-50. [5] CHOUDHURY M R, DEBNATH K. A review of the research and advances in electromagnetic joining of fiber-reinforced thermoplastic composites[J]. Polymer Engineering and Science,2019,59(10):1965-1985. [6] BAYERL T, DUHOVIC M, MITSCHANG P, et al. The heating of polymer composites by electromagnetic induction-A review[J]. Composites Part A: Applied Science and Manufacturing,2014,57:27-40. [7] 袁协尧, 杨洋, 见雪珍, 等. 感应焊接技术在民用飞机热塑性复合材料中的应用[J]. 玻璃钢/复合材料, 2017(5):99-104,127.YUAN Xierao, YANG Yang, JIAN Xuezhen, et al. Application of induction welding technology in thermoplastic composites of civil aircraft[J]. Glass Fiber Reinforced Plastics/Composite Materials,2017(5):99-104,127(in Chinese). [8] RUDOLF R, MITSCHANG P, NEITZEL M. Induction heating of continuous carbon-fibre-reinforced thermoplastics[J]. Composites Part A: Applied Science and Manufacturing,2000,31(11):1191-1202. [9] PALMIERI B, NELE L, GALISE F. Numerical modeling and experimental validation of thermoplastic composites induction welding[C]. Proceedings of the 21st International ESAFORM Conference on Material Forming, 2018: 050013(1-6). [10] O'SHAUGHNESSEY P G, DUBE M, VILLEGAS I F. Modeling and experimental investigation of induction welding of thermoplastic composites and comparison with other welding processes[J]. Journal of Composite Materials,2016,50(21):2895-2910. [11] FARAHANI R D, DUBÉ M. Novel heating elements for induction welding of carbon fiber/polyphenylene sulfide thermoplastic composites[J]. Advanced Engineering Materials,2017,19(11):1700294. [12] PAPPADÀ S, SALOMI A, MONTANARO J, et al. Fabrication of a thermoplastic matrix composite stiffened panel by induction welding[J]. Aerospace Science and Technology,2015,43:314-320. [13] MOSER L. Experimental analysis and modeling of susceptorless induction welding of high performance thermoplastic polymer composites[R]. Kaiserslautern: Institut für Verbundwerkstoffe GmbH, 2012. [14] FLANAGAN M, DOYLE A, DOYLE K, et al. Comparative manufacture and testing of induction- welded and adhesively bonded carbon fibre PEEK stiffened panels[J]. Journal of Thermoplastic Composite Materials,2019,32(12):1622-1649. [15] FINK B K, MCCULLOUGH R L, GILLESPIE J W. Experimental verification of models for induction heating of continuous-carbon-fiber composites[J]. Polymer Composites,1996,17(2):198-209. [16] HAGENBEEK M, VILA BRAMON J, FERNANDEZ VILLEGAS I. Controlling the edge effect using a bypass conductor for induction welding of carbon fibre thermoplastic composites[C]. ECCM18: 18th European Conference on Composite Materials, 2018: 1-6. [17] LIONETTO F, PAPPADÀ S, BUCCOLIERO G, et al. Finite element modeling of continuous induction welding of thermoplastic matrix composites[J]. Materials and Design,2017,120:212-221. [18] 钱盈, 王家锋, 宋俣诺, 等. 风冷和导热板对CF/PPS复合材料自感应焊接的影响[J]. 复合材料科学与工程, 2020, 321(10): 45-52.QIAN Ying, WANG Jiafeng, SONG Yunuo, et al. Influences of air nozzle and heat-conducting plate on the induction welding of CF/PPS composite[J]. Composites Science and Engineering, 2020, 321(10): 45-52(in Chinese). [19] 张照, 曹硕, 朱姝, 等. 纺织结构碳纤维增强聚醚醚酮基复合材料的制备及界面改性[J]. 高分子材料科学与工程, 2017, 33(10):141-148.ZHANG Zhao, CAO Shuo, ZHU Shu, et al. Preparation and interface modification of textile structure carbon fiber reinforced polyether ether ketone based composite[J]. Polymer Materials Science and Engineering,2017,33(10):141-148(in Chinese). [20] ASTM International. Standard test method for lab shear adhesion for fiber reinforced plastic (FRP) bonding: ASTM D5868-01[S]. West Conshohocken: ASTM International, 2014. [21] 熊剑, 于惠忠. 温度传感器的响应延迟[J]. 电子测量与仪器学报, 2003(4):1-3.XIONG Jian, YU Huizhong. Response delay of thermal sensors[J]. Journal of Electronic Measurement and Instrument,2003(4):1-3(in Chinese). [22] FARAHANI R D, JANIER M, DUBÉ M. Conductive films of silver nanoparticles as novel susceptors for induction welding of thermoplastic composites[J]. Nanotechnology,2018,29(12):125701. [23] 韩志勇, 陈栋, 路鹏程. 碳纤维增强聚苯硫醚复合材料感应焊接研究[J]. 塑料工业, 2019, 47(11):134-140. doi: 10.3969/j.issn.1005-5770.2019.11.032HAN Zhiyong, CHEN Dong, LU Pengcheng. Research on induction welding of carbon fiber reinforced polyphenylene sulfide composite material[J]. Plastic Industry,2019,47(11):134-140(in Chinese). doi: 10.3969/j.issn.1005-5770.2019.11.032 -

下载:

下载: