Property evolution of CFRP@GFRP hybrid composite rod exposed in the distilled water

-

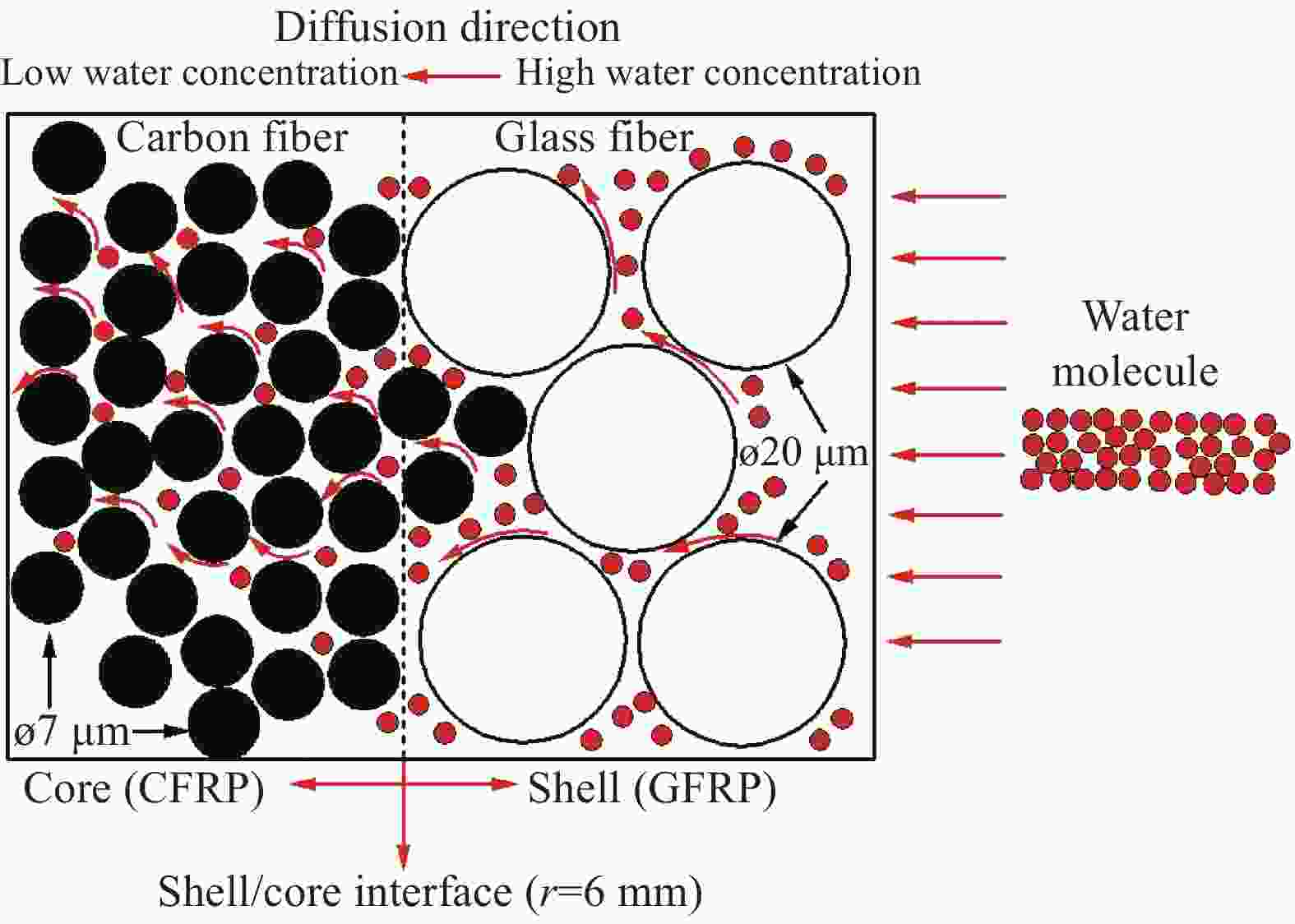

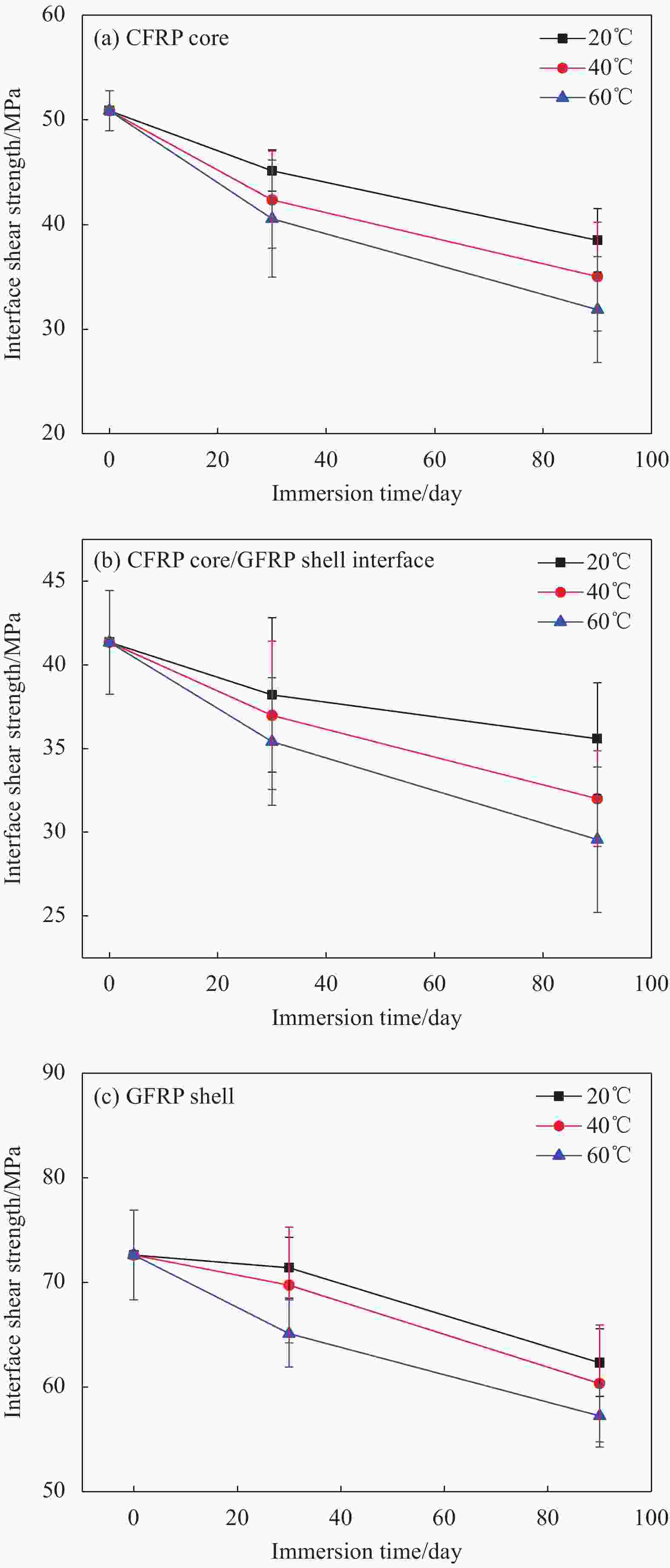

摘要: 碳纤维增强树脂复合材料(CFRP)@玻璃纤维增强树脂复合材料(GFRP)混杂复合材料杆体发挥碳纤维的高力学、疲劳性能与玻璃纤维的低成本、高变形能力等优势,在桥梁与海洋工程中具有巨大应用潜力,如跨海大桥斜拉索。针对CFRP@GFRP混杂复合材料杆体在服役环境下长期性能演化,本文采用加速试验方法研究蒸馏水环境下CFRP@GFRP混杂复合材料杆体的水吸收及界面剪切性能长期演化规律。研究结果表明:混杂复合材料杆体皮、芯层及杆体吸水行为符合Fick定律,GFRP皮层扩散系数最大,CFRP芯层次之,混杂复合材料杆体由于在皮/芯界面层形成吸水屏障而扩散系数最小。浸泡在蒸馏水环境下芯层、皮/芯界面及皮层界面剪切强度下降,这是由于浸泡过程中水分子通过氢键形式与树脂基体结合形成结合水,导致树脂基体发生水解和塑化及纤维/树脂界面脱黏。基于Arrhenius加速理论建立了混杂复合材料杆体在三座典型桥梁服役环境下的界面剪切强度预测模型。

-

关键词:

- CFRP@GFRP混杂复合材料杆体 /

- 湿热老化 /

- 吸水性能 /

- 界面剪切强度 /

- 长期寿命预测

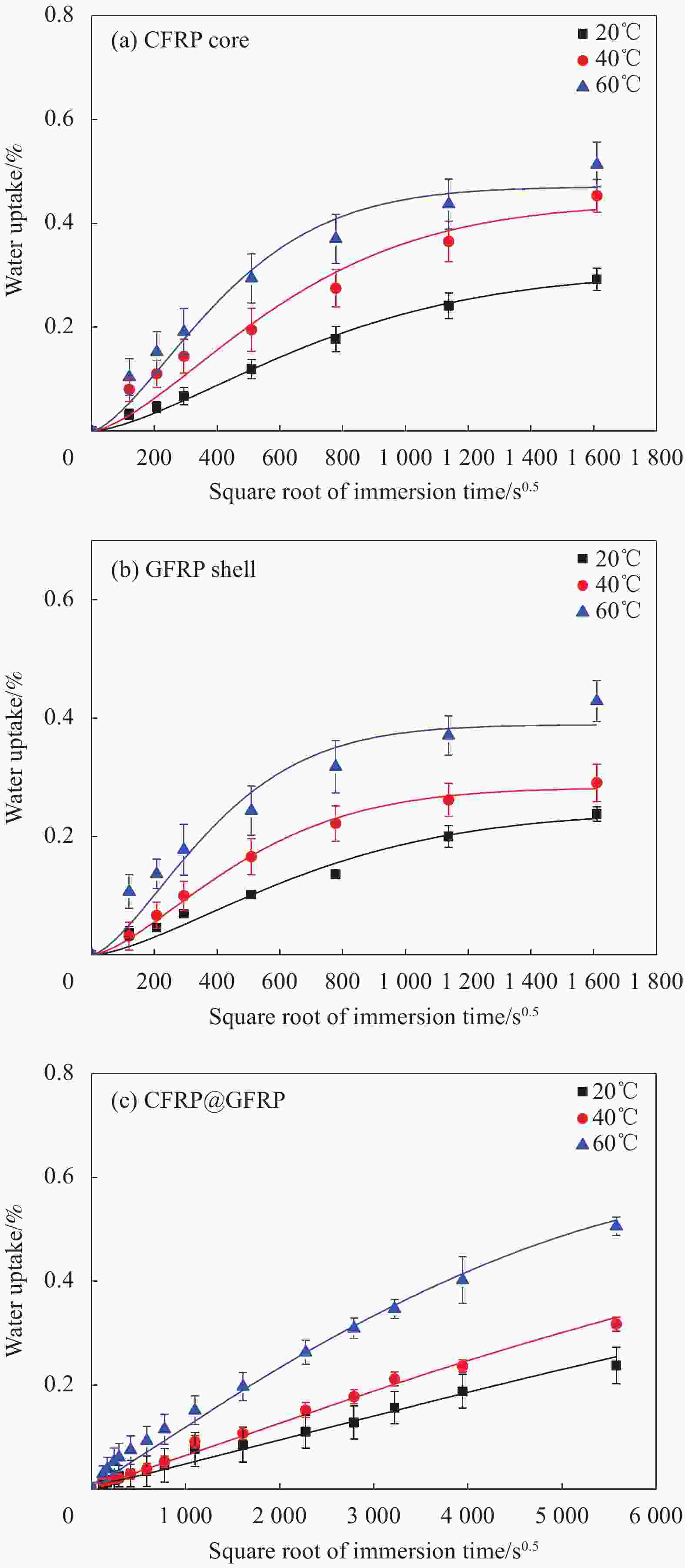

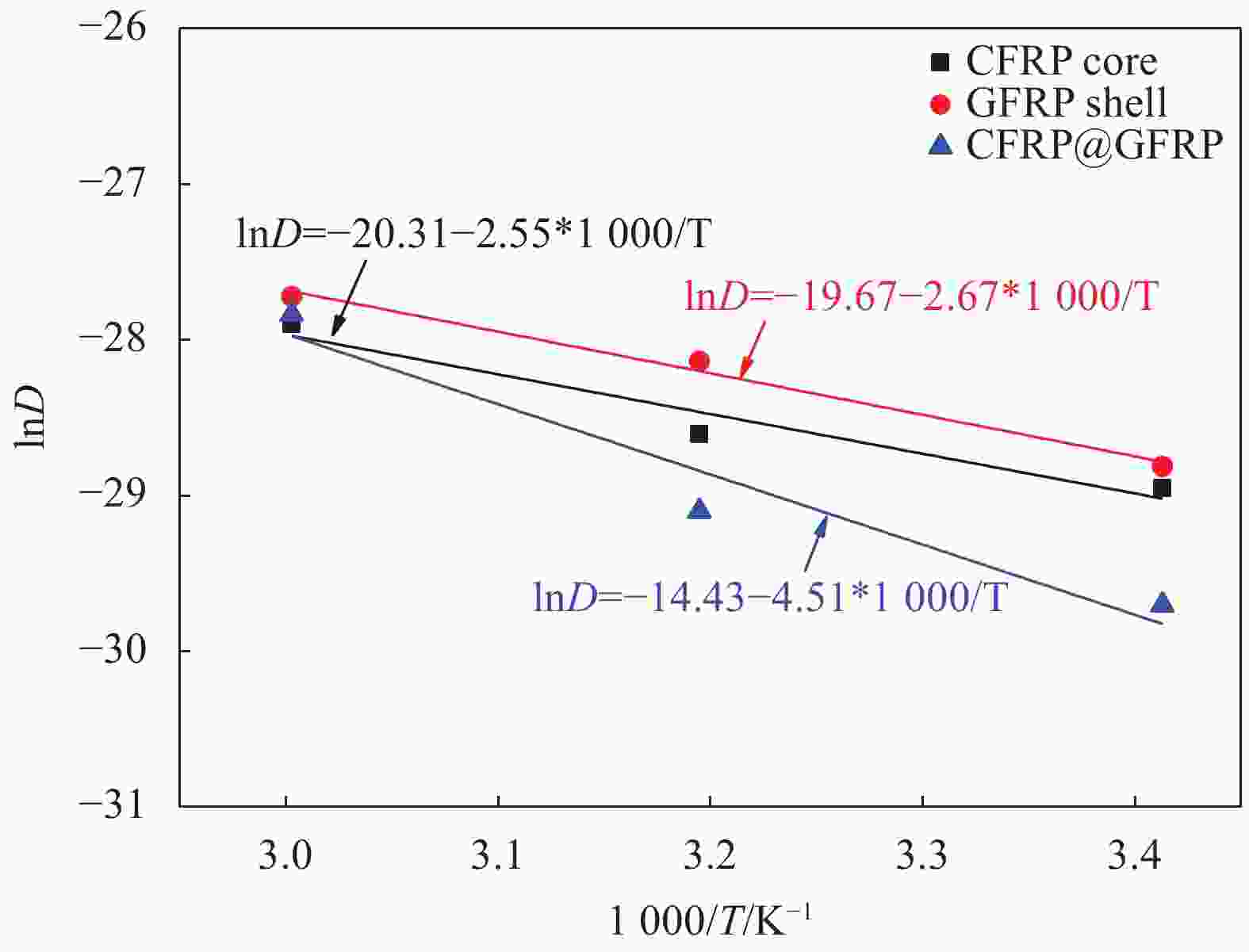

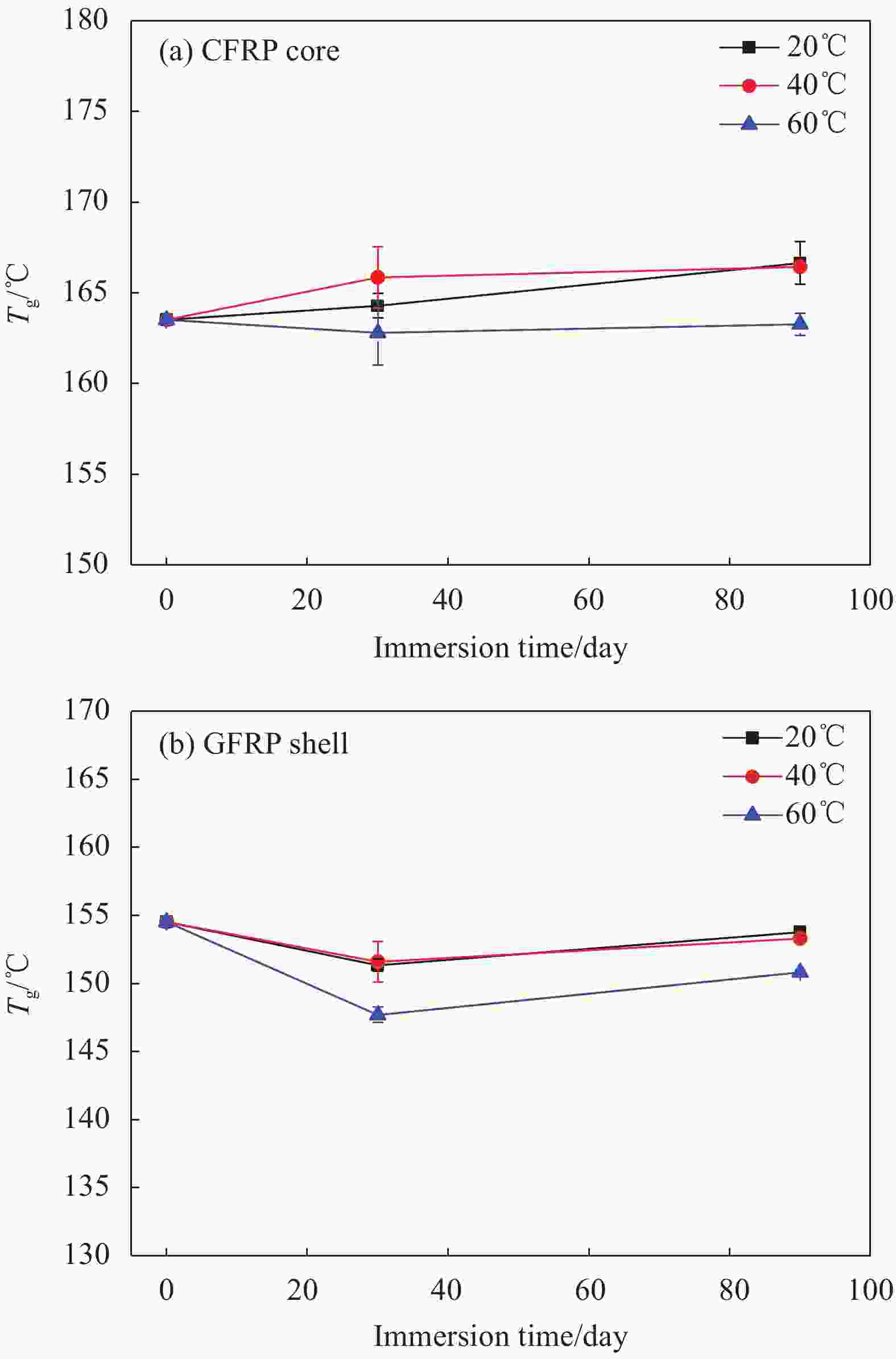

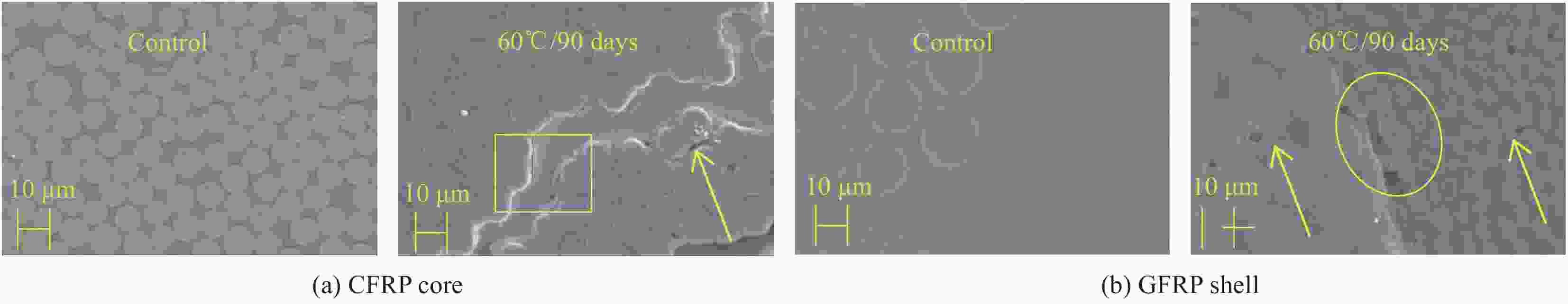

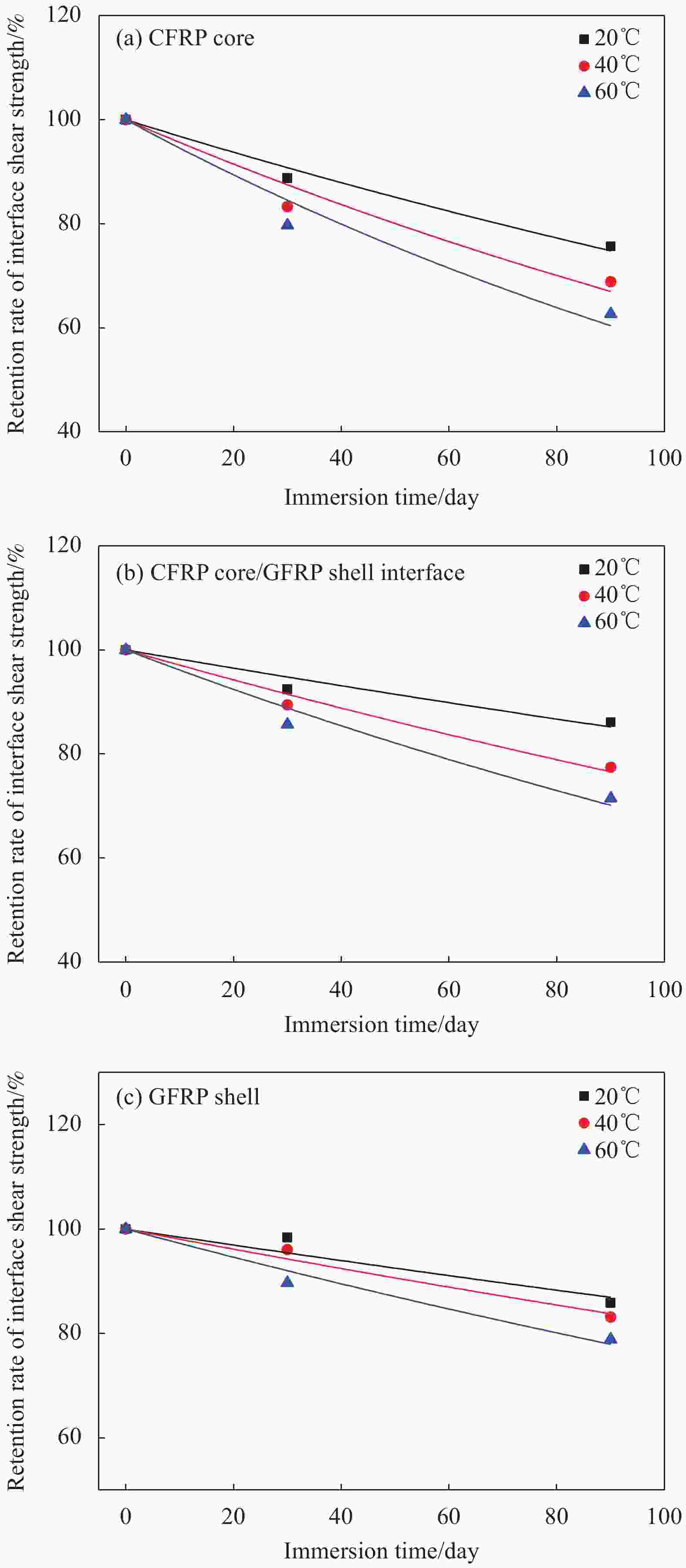

Abstract: Carbon fiber reinforced polymer (CFRP)@glass fiber reinforced polymer (GFRP) hybrid composite rod plays the advantages of carbon fiber (such as high mechanical and fatigue performances) and glass fiber (such as low cost and high deformation capacity) and has great application potential in bridge and ocean engineering, such as cross-sea bridge cable. In view of the long-term performance evolution of CFRP@GFRP hybrid composite rod under the service environment, the present paper adopted the experimental acceleration method to study the water absorption and interface shear performance evolution of CFRP@GFRP hybrid composite rod under the distilled water environment. The results show that the absorption behavior of hybrid composite rod is in accordance with Fick law. The diffusion coefficient of glass fiber shell is the largest, carbon fiber core is the second, and the hybrid composite rod is the smallest due to the water absorption barrier between the shell/core interface layer. Immersed in distilled water leads to the decrease of the interface shear strength of core, shell/core and shell layers. This is attributed to the water molecules combined with the resin matrix in the form of hydrogen bond to form the bond water, resulting in the hydrolysis and plasticization of the resin matrix and the debonding of the fiber/resin interface. The prediction model of interface shear strength of hybrid composite rod was established in three typical bridge service environments based on the accelerating theory of Arrhenius. -

表 1 CFRP芯层、GFRP皮层及CFRP@GFRP混杂复合材料杆体的扩散系数D

Table 1. Diffusion coefficients D of CFRP core, GFRP shell and CFRP@GFRP hybrid composite rod

10−7mm2/s Type 20℃ 40℃ 60℃ CFRP core 2.68 3.77 7.67 GFRP shell 3.08 6.03 9.14 CFRP@GFRP 1.26 2.30 8.14 表 2 CFRP芯层、GFRP皮层及CFRP@GFRP混杂复合材料杆体水吸收拟合度(R2)

Table 2. Degree of fitting R2 of water uptake of CFRP core, GFRP shell and CFRP@GFRP hybrid composite rod

Type 20℃ 40℃ 60℃ CFRP core 0.99 0.94 0.96 GFRP shell 0.96 0.99 0.94 CFRP@GFRP 0.98 0.99 0.99 表 3 CFRP@GFRP混杂复合材料杆体寿命预测的回归系数τ及R2

Table 3. Regression coefficient τ and R2 of life prediction for CFRP@GFRP hybrid composite rod

Type Immersion

temperature/°Cτ R2 CFRP core 20 310.2 0.98 40 224.7 0.96 60 178.6 0.96 GFRP shell 20 561.3 0.93 40 337.5 0.98 60 253.8 0.97 CFRP core/GFRP

shell interface20 641.4 0.92 40 508.1 0.98 60 360.5 0.97 表 4 CFRP@GFRP混杂复合材料杆体寿命预测的回归系数Ea/R及R2

Table 4. Regression coefficient Ea/R and R2 of life prediction for CFRP@GFRP hybrid composite rod

Type Strength

retention/%Ea/R R2 CFRP core 50 1350 0.99 60 1350 0.99 70 1350 0.99 80 1350 0.99 90 1350 0.99 GFRP shell 50 1 945 0.97 60 1 945 0.97 70 1 945 0.97 80 1 945 0.97 90 1 945 0.97 CFRP core/GFRP shell interface 50 1398 0.96 60 1398 0.96 70 1398 0.96 80 1398 0.96 90 1398 0.96 Notes: Ea—Activation energy of materials; R—Universal gas constant; R2—Degree of fitting. 表 5 CFRP@GFRP混杂复合材料杆体剪切强度寿命预测的时移因子参数

Table 5. Time-shift factor for life prediction of interface shear strength for CFRP@GFRP hybrid composite rod

Type T0/°C Time-shift factor Shenyang Youth Bridge (T=8.8°C) Jiangsu Yangtze River

Bridge (T=15.9°C)Hainan Century Bridge (T=26.9°C) CFRP core 20 1.20 1.07 0.90 40 1.61 1.43 1.21 60 2.09 1.86 1.56 GFRP shell 20 1.30 1.09 0.85 40 1.99 1.68 1.31 60 2.89 2.44 1.90 CFRP core/GFRP

shell interface20 1.21 1.07 0.90 40 1.64 1.45 1.22 60 2.14 1.90 1.59 Notes: T—Annual mean temperature data from China Meteorological Observatory (www.nmc.cn) for 2019;T0—Immersion temperature in the lab environment. -

[1] LI C G, XIAN G J. Design optimization and experimental validation of a novel wedge-shaped bond anchorage system for prestressed CFRP plates[J]. Polymer Testing,2019,75:167-174. [2] 潘云锋. 湿热与冻融作用下CFRP-混凝土界面粘结性能演化规律研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.PAN Y F. Research on evolution of the CFRP-concrete substrate bond exposed to hygrothermal condition and freeze-thaw cycles[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [3] YANG Y Q, FAHMY M F M, GUAN S J, et al. Properties and applications of FRP cable on long-span cable-supported bridges: A review[J]. Composites Part B: Engineering,2020,190:107934. [4] WANG X, ZHOU J Y, DING L N, et al. Static behavior of circumferential stress-releasing anchor for large-capacity FRP cable[J]. Journal of Bridge Engineering,2020,25:04019114. [5] LI C G, GUO R, XIAN G J, et al. Innovative compound-type anchorage system for a large-diameter pultruded carbon/glass hybrid composite rod for bridge cable[J]. Materials and Structures,2020,53:73. [6] 王自柯. FRP筋在模拟海水—海砂混凝土孔溶液浸泡下的耐久性研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.WANG Z K. Study of the durability performances of fiber reinforced polymer (FRP) bars exposed to simulated seawater and sea sand concrete pore solution[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [7] 彭哲琦, 旺昕, 吴智深. 基于随机强度的纤维增强材料拉索多尺度拉伸性能预测[J]. 工业建筑, 2019, 49(9): 1-5.PENG Z Q, WANG X, WU Z S. Multiscale tensile prediction of FRP cable considering random strength distribution[J]. Industrial Construction, 2019, 49(9): 1-5(in Chinese). [8] 陈娟娟. GFRP筋材锚杆在基坑支护中的应用前景展望[J]. 绿色环保建材, 2020, 7:5-7.CHEN J J. Application prospect of GFRP bar anchor in foundation supporting[J]. Green Building Materials,2020,7:5-7(in Chinese). [9] WANG Z K, ZHAO X L, XIAN G J, et al. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars[J]. Corrosion Science,2018,138:200-218. [10] PAN Y F, SHI J J, XIAN G J. Experimental and numerical study of the CFRP-to-concrete bonded joints after water immersion[J]. Composite Structures,2019,218:95-106. [11] LI C G, XIAN G J, LI H. Combined effects of temperature, hydraulic pressure and salty concentration on the water uptake and mechanical properties of a carbon/glass fibers hybrid composite rod in salty solutions[J]. Polymer Testing,2019,76:19-32. [12] LI C G, XIAN G J, LI H. Tension-tension fatigue performance of a large-diameter pultruded carbon/glass hybrid composite rod[J]. International Journal of Fatigue,2019,120:141-149. [13] BARJASTEH E, NUTT S R. Moisture absorption of unidirectional hybrid composite rod[J]. Composites Part A: Applied Science and Manufacturing,2012,43:158-164. [14] KAR N K, BARJASTEH E, HU Y, et al. Bending fatigue of hybrid composite rod rods[J]. Composites Part A: Applied Science and Manufacturing,2011,42:328-336. [15] 洪斌. 聚氨酯基CFRP拉挤板材的耐水碱盐性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.HONG B. Study of the resistance to water, alkali and salt solutions of pultruded polyurethane-based CFRP plates[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [16] LI C G, YIN X L, LIU Y C, et al. Long-term service evaluation of a pultruded carbon/glass hybrid composite rod exposed to elevated temperature, hydraulic pressure and fatigue load coupling[J]. International Journal of Fatigue,2020,134:105480. [17] 郝信凯, 黄胜德, 张红卫, 等. 水浸泡对碳纤维拉挤杆的水吸收与剪切强度影响[J]. 玻璃钢/复合材料, 2014, 12:68-73.HAO X K, HUANG S D, ZHANG H W, et al. Effects of water immersion on the water uptake and shear strength of pultruded carbon fiber reinforced epoxy rods[J]. Glass Reinforced Plastics/Composites,2014,12:68-73(in Chinese). [18] LI C G, XIAN G J, LI H. Water absorption and distribution in a pultruded unidirectional carbon/glass hybrid composite rod under hydraulic pressure and elevated temperatures[J]. Polymers,2018,10(6):627. [19] NISHIZAKI I, LABOSSIERE P, SARSANIUC B. Durability of CFRP sheet reinforcement through exposure tests[J]. Special Publication,2005,230:1419-1428. [20] CHEN Y, DAVALOS J F, RAY I, et al. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures[J]. Composite Structures,2007,78(1):101-111. [21] 洪斌. CFRP板材的拉挤制备工艺及其耐湿热性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2012.HONG B. Study of the pultrusion process of CFRP plate and its hygrothermal durability[D]. Harbin: Harbin Institute of Technology, 2012(in Chinese). [22] RUTKOWSKA M, KRASOWSKA K, HEIMOWSKA A, et al. Degradation of polyurethanes in sea water[J]. Polymer Degradation and Stability,2002,76(2):233-239. [23] SCHEFFLER C, FORSTER T, MAER E, et al. Aging of alkali-resistant glass and basal fibers in alkaline solutions: Evaluation of the failure stress by Weibul distribution function[J]. Journal of Non-Crystalline Solids,2009,355(52):2588-2595. [24] HONG B, XIAN G J, LI H. Effects of water or alkali solution immersion on the water uptake and physicochemical properties of a pultruded carbon fiber reinforced polyurethane plate[J]. Polymer Composites,2019,40:738-748. [25] ASTM. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D 5229[S]. West Conshohocken: ASTM, 2004. [26] ASTM. Standard test method for as-signment of the glass transition temperature by dynamic mechanical analysis: ASTM E1640—99[S]. West Conshohocken: ASTM, 1999. [27] LI C G, XIAN G J, LI H. Influence of immersion in water under hydraulic pressure on the interfacial shear strength of a unidirectional carbon/glass hybrid composite rod[J]. Polymer Testing,2018,72:164-171. [28] TSAI Y I, BOSZE E J, BARJASTEH E, et al. Influence of hygrothermal environment on thermal and mechanical properties of carbon fiber/fiberglass hybrid composite rod[J]. Composite Science and Technology,2009,69:432-437. [29] ZHOU J M, LUCAS J P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy[J]. Polymer,1999,40:5505-5512. [30] PHANI K K, BOSE N R. Hydrothermal aging of csm-laminate during water immersion-An acoustoultrasonic study[J]. Journal of Materials Science,1986,21:3633-3637. [31] WU G, DONG Z Q, WANG X, et al. Prediction of long-term performance and durability of BFRP bars under the combined effect of sustained load and corrosive solutions[J]. Journal of Composites for Construction,2015,19(3):04014058. [32] WANG Z K, ZHAO X L, XIAN G J, et al. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sandconcrete environment[J]. Construction and Building Materials,2017,156:985-1004. -

下载:

下载: