Mechanical behavior of copper-zirconium crystal/amorphous dual-phase nanocomposite based on molecular dynamics simulation

-

摘要: 金属玻璃因其较差的室温塑性限制了其广泛应用,因此提升金属玻璃的力学性能、探明金属玻璃的变形机制已经成为当前材料领域的研究热点。采用分子动力学方法研究了晶粒尺寸和分布对晶体/非晶B2-CuZr/CuZr双相复合材料力学行为的影响。研究结果表明,随着纳米晶粒的尺寸增大,复合材料变形模式发生了从相对均匀变形到单一剪切带的局部变形的转变。研究指出,增大纳米晶粒尺寸/体积分数能有效提高复合材料的峰值应力,但除了较小尺寸纳米晶粒模型外,双相复合材料的塑性没有明显增强。此外,相对于交叉排列,纳米晶粒的对齐排列导致了更严重的塑性应变局部化。本文的研究结果对于设计和制备高性能的金属玻璃材料具有重要的参考价值和指导意义。Abstract: The wide application of metallic glass is limited by its poor room temperature plasticity. Therefore, improving the mechanical properties of metallic glass and exploring the deformation mechanism of metallic glass have become the research hotspot in the field of materials. The effects of grain size and distribution on the mechanical behavior of dual-phase nanocrystalline/amorphous B2-CuZr/CuZr composites were studied by molecular dynamics method. The results show that with the increase of the size of nanocrystalline particles, the deformation mode of the composites changes from relatively uniform deformation to local deformation of single shear band. The results also indicate that the peak stress of the composites can be effectively increased by increasing the size/volume fraction of nanocrystals, but the plasticity of the composites is not significantly enhanced except for the smaller size nanocrystalline model. In addition, alignment of nanocrystals leads to more severe plastic strain localization than cross alignment. The results of this paper have important reference value and guiding significance for the design and preparation of high-performance metallic glass materials.

-

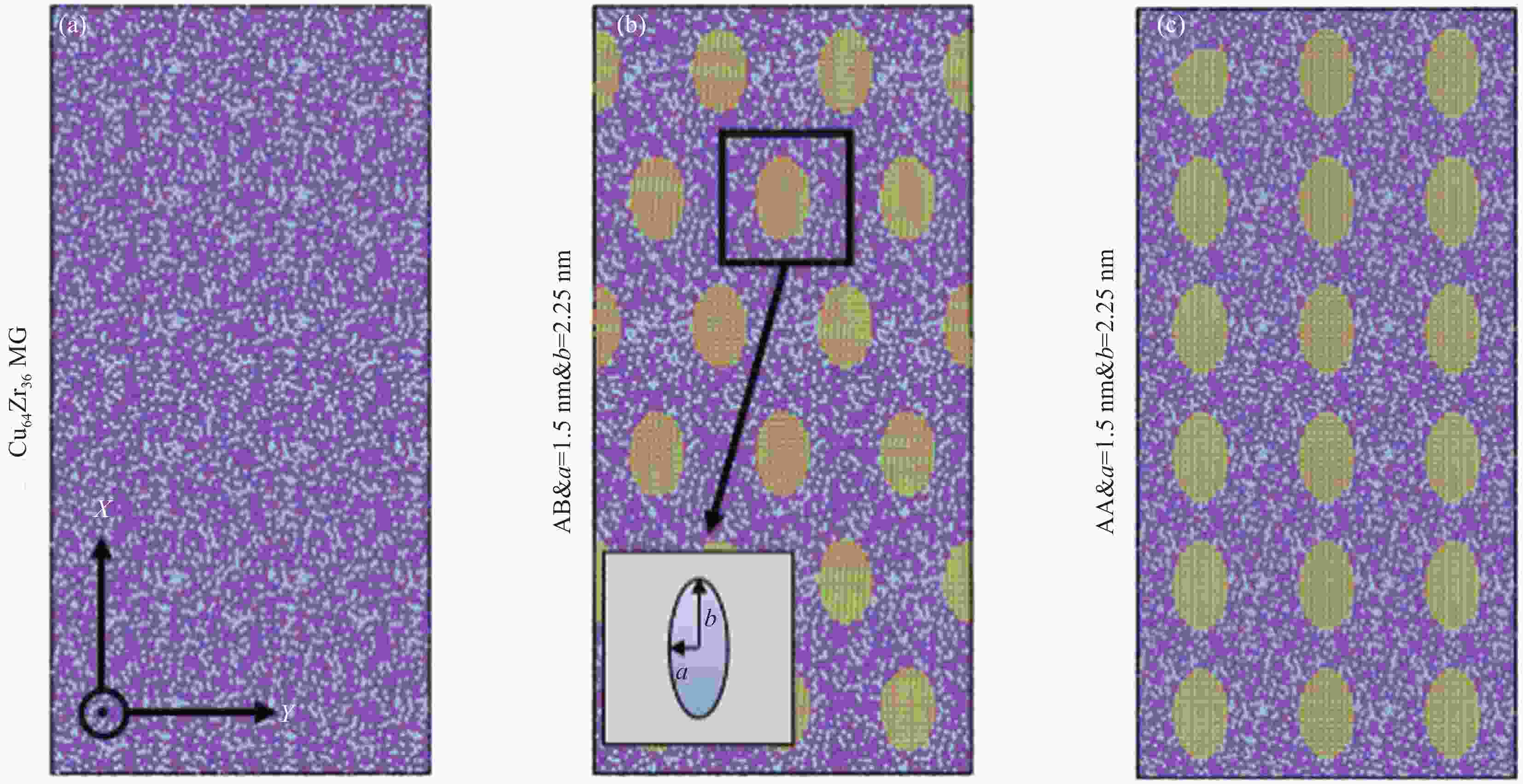

图 1 Cu64Zr36 金属玻璃(MG) (a)、AB&a=1.5 nm&b=2.25 nm B2-CuZr/Cu64Zr36 MG双相复合材料(b)、AA&a=1.5 nm&b=2.25 nm B2-CuZr/Cu64Zr36 MG双相复合材料(c)的原子模型图

Figure 1. Atomic models of Cu64Zr36 metallic glass (MG) (a), AB&a=1.5 nm&b=2.25 nm B2-CuZr/Cu64Zr36 MG dual-phase composites (b) and AA&a=1.5 nm&b=2.25 nm B2-CuZr/Cu64Zr36 MG composites (c)

YY&a= x nm&b= y nm DNMGs—DNMGs model in which the nanograins are arranged in YY mode; YY—AA or AB arrangement; Lengths of a-axis and b-axis—x nm and y nm, respectively

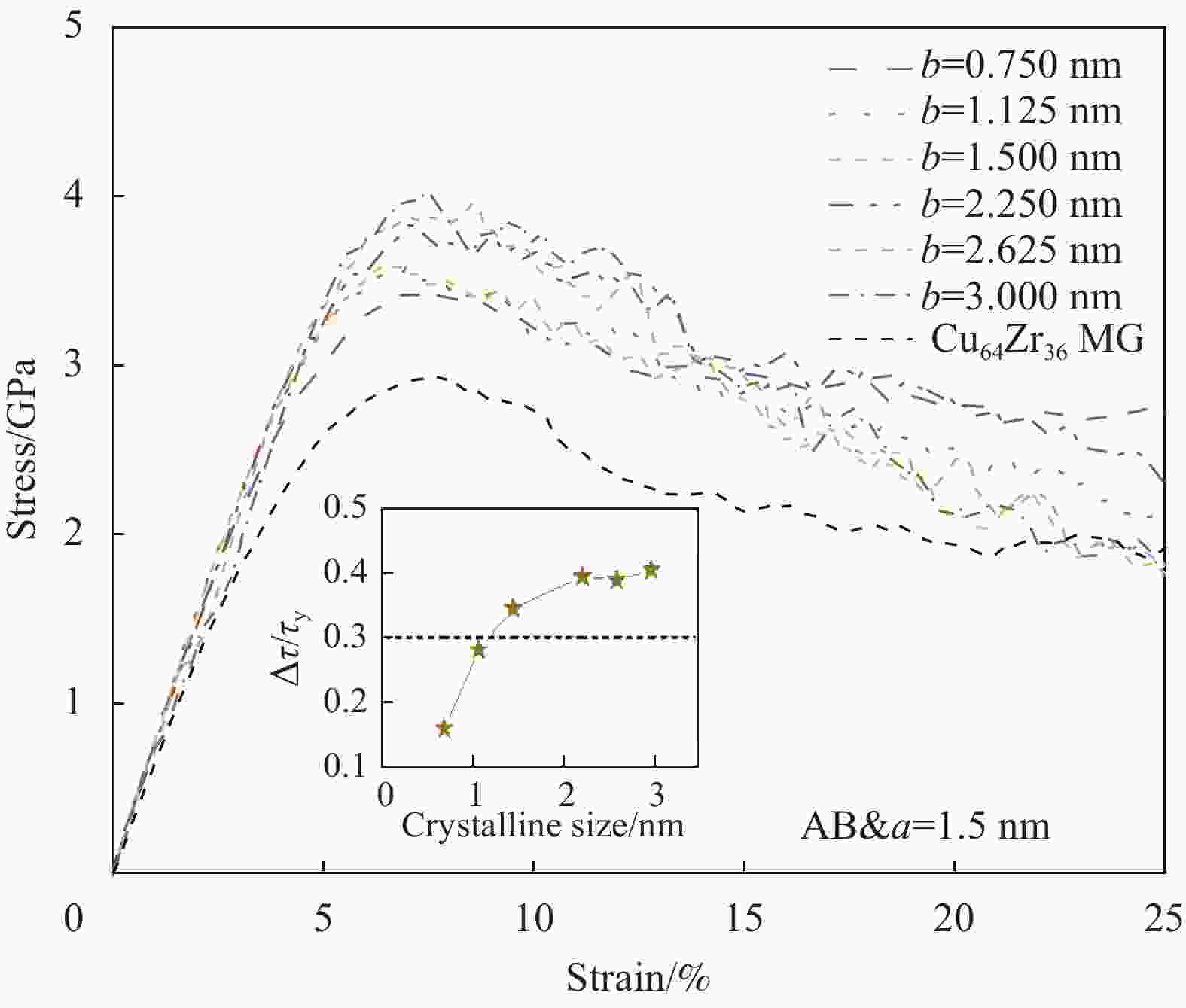

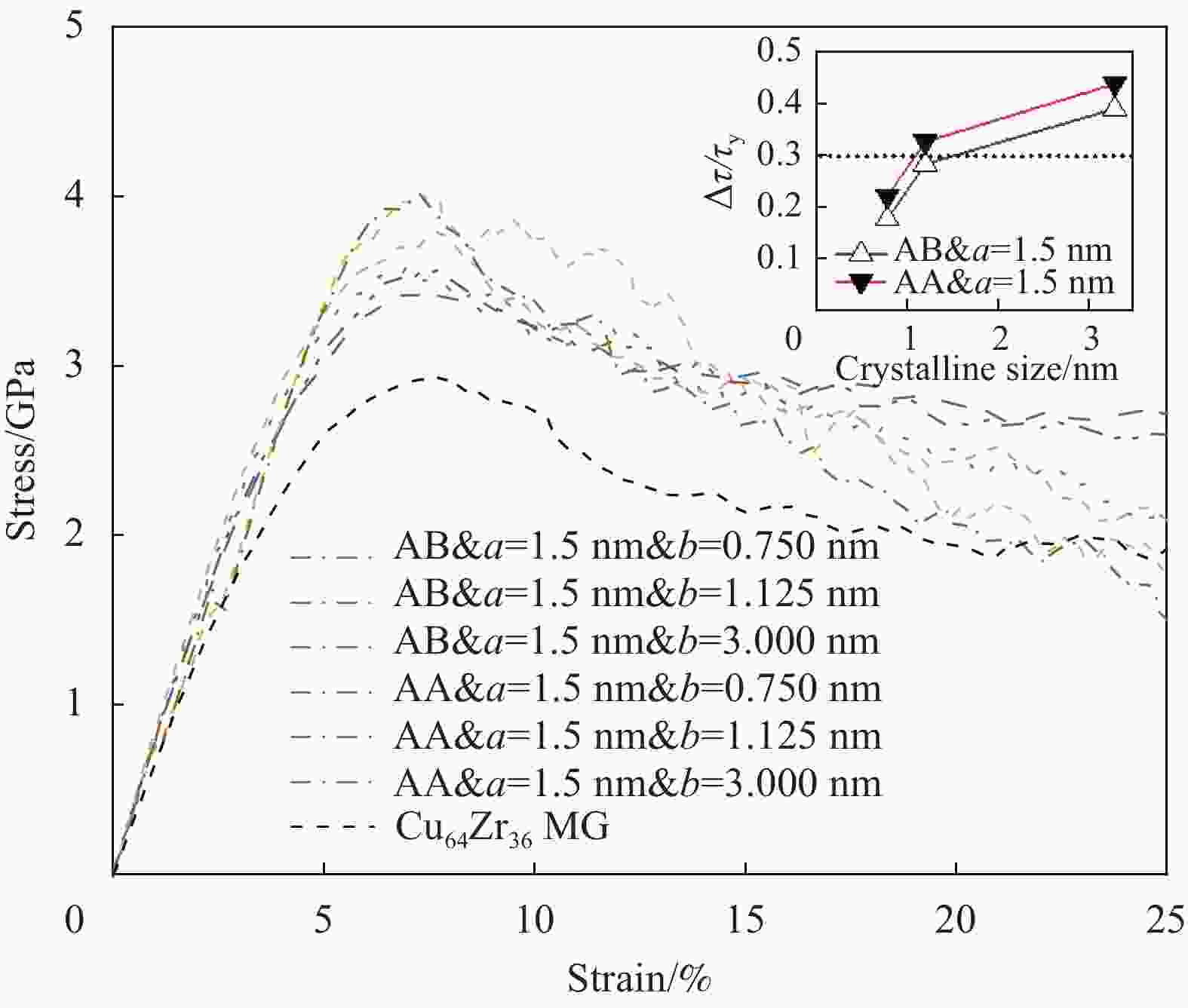

图 2 具有不同b轴尺寸纳米晶粒的AB&a=1.5 nm B2-CuZr/Cu64Zr36 MG双相复合材料应力-应变曲线(插图为ε=0.25时∆τ/τy随b轴尺寸的变化曲线,其中虚线代表Cu64Zr36 MG的∆τ/τy)

Figure 2. Stress-strain curves of the AB&a=1.5 nm B2-CuZr/Cu64Zr36 MG dual-phase composites with different b-axis lengths of nanocrystalline (Inset: Evolution of ∆τ/τy as a function of the degree of b-axis lengths at ε=0.25. Dashed line represents the ∆τ/τy value of the Cu64Zr36 MG)

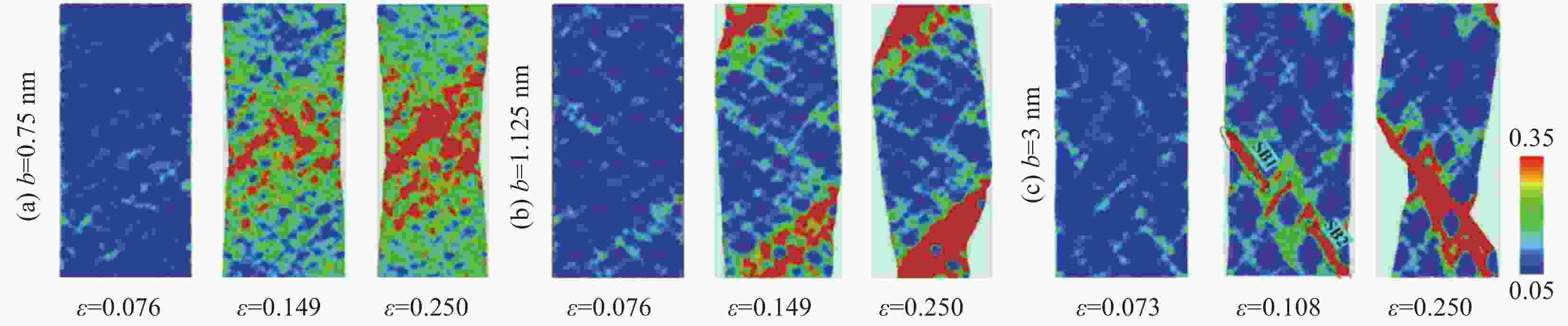

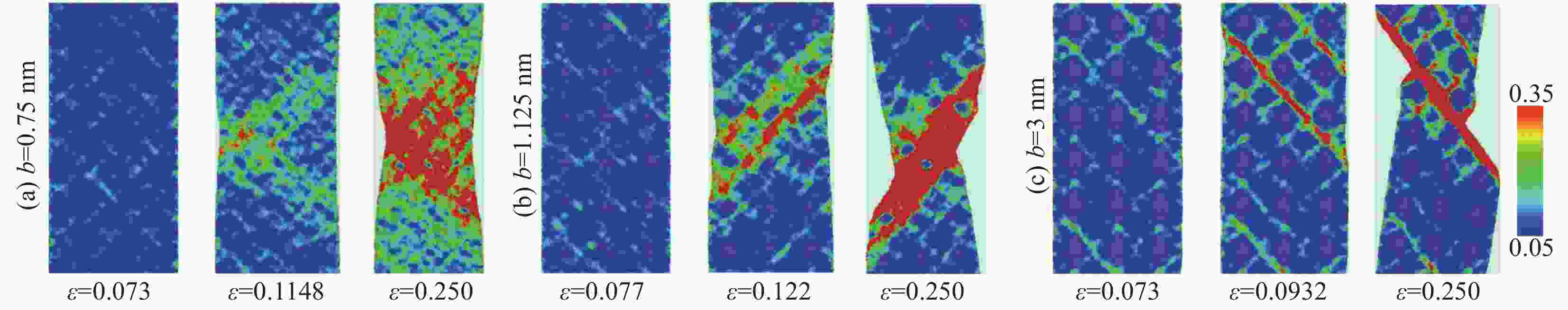

图 4 具有不同b轴尺寸纳米晶粒的AB&a=1.5 nm的B2-CuZr/Cu64Zr36 MG双相复合材料中纳米晶在0.25的拉伸应变下的原子结构图

Figure 4. Atomic diagrams of nanocrystalline in the AB&a=1.5 nm 2-CuZr/Cu64Zr36 MG dual-phase composites with different b-axis lengths under the tensile strain of 0.25((a) b=0.75 nm, (b) b=1.125 nm; and (c) b=3 nm)

Dark color atom represents the B2 structure, while the light color atoms represent disordered structure or lattice distortion

-

[1] ZHANG J C, CHEN C, PEI Q X, et al. Ab initio molecular dynamics study of the local atomic structures in monatomic metallic liquid and glass[J]. Materials & Design,2015,77:1-5. [2] QIAO J W, JIA H L, LIAW P K. Metallic glass matrix compo-sites[J]. Materials Science and Engineering R,2016,100:1-69. doi: 10.1016/j.mser.2015.12.001 [3] 武振伟, 汪卫华. 非晶态物质原子局域连接度与弛豫动力学[J]. 物理学报, 2020, 69(6):066101. doi: 10.7498/aps.69.20191870WU Zhenwei, WANG Weihua. Linking local connectivity to atomic-scale relaxation dynamics in metallic glass-forming systems[J]. Acta Physica Sinica,2020,69(6):066101(in Chinese). doi: 10.7498/aps.69.20191870 [4] EBNER C, ESCHER B, GAMMER C, et al. Structural and mechanical characterization of heterogeneities in a CuZr-based bulk metallic glass processed by high pressure torsion[J]. Acta Materialia,2018,160:147-157. doi: 10.1016/j.actamat.2018.08.032 [5] JIANG S, GUO S, HUANG Y, et al. In situ study of the shear band features of a CuZr-based bulk metallic glass compo-site[J]. Intermetallics,2019,112:106523. doi: 10.1016/j.intermet.2019.106523 [6] 吴飞飞, 余鹏, 卞西磊, 等. 金属玻璃的断裂机理与其断裂韧度的关系[J]. 物理学报, 2014, 63(5):058101. doi: 10.7498/aps.63.058101WU Feifei, YU Peng, BIAN Xilei, et al. Correlation between fracture mechanism and fracture toughness in metallic glasses[J]. Acta Physica Sinica,2014,63(5):058101(in Chinese). doi: 10.7498/aps.63.058101 [7] WU G, CHAN K C, ZHU L, et al. Dual-phase nanostructuring as a route to high-strength magnesium alloys[J]. Nature,2017,545(7652):80-83. doi: 10.1038/nature21691 [8] SONG K K, PAULY S, ZHANG Y, et al. Triple yielding and deformation mechanisms in metastable Cu47.5Zr47.5Al5 composites[J]. Acta Materialia,2012,60:6000-6012. doi: 10.1016/j.actamat.2012.07.015 [9] GUO W, SHAO Y, ZHAO M, et al. Varying the treating conditions to rejuvenate metallic glass by deep cryogenic cycling treatment[J]. Journal of Alloys and Composites,2020,819:152997. doi: 10.1016/j.jallcom.2019.152997 [10] 吴青青, 姜云鹏, 孙龙港, 等. 梯度微结构对金属玻璃拉伸增韧的影响[J]. 复合材料学报, 2018, 35(5):1227-1235.WU Qingqing, JIANG Yunpeng, SUN Longgang, et al. Effect of gradient microstructure on the tensile toughening of metallic glasses[J]. Acta Materiae Compositae Sinica,2018,35(5):1227-1235(in Chinese). [11] CUI Y, SHIBUTANI Y, LI S, et al. Plastic deformation behaviors of amorphous-Cu50Zr50/crystalline-Cu nanolaminated structures by molecular dynamics simulations[J]. Journal of Alloys and Compounds,2017,693:285-290. doi: 10.1016/j.jallcom.2016.09.184 [12] JHOU W T, WANG C, II S, et al. Nanoscaled superelastic behavior of shape memory alloy/metallic glass multilayered films[J]. Composites Part B: Engineering,2018,142(1):193-199. [13] 邱昆, 姜云鹏, 史雪萍, 等. 新型金属玻璃复合材料的拉伸增韧机制[J]. 复合材料学报, 2018, 35(1):124-131.QIU Kun, JIANG Yunpeng, SHI Xueping, et al. Tensile toughening mechanism of new particle reinforced metallic glass composites[J]. Acta Materiae Compositae Sinica,2018,35(1):124-131(in Chinese). [14] GUO W, JAGLE E, YAO J, et al. Intrinsic and extrinsic size effects in the deformation of amorphous CuZr/nanocrystalline Cu nanolaminates[J]. Acta Materialia,2014,80:94-106. doi: 10.1016/j.actamat.2014.07.027 [15] WANG Y Q, FRITZ R, KIENER D, et al. Fracture behavior and deformation mechanisms in nanolaminated crystalline/amorphous micro-cantilevers[J]. Acta Materialia,2019,180:73-83. doi: 10.1016/j.actamat.2019.09.002 [16] HU J, SHI Y N, SAUVAGE X, et al. Grain boundary stability governs hardening and softening in extremely fine nanograined metals[J]. Science,2017,355(6331):1292-1296. doi: 10.1126/science.aal5166 [17] WU G, LIU C, SUN L, et al. Hierarchical nanostructured aluminum alloy with ultrahigh strength and large plasticity[J]. Nature Communications,2019,10(1):1-8. doi: 10.1038/s41467-018-07882-8 [18] FENG S D, LI L, CHAN K C, et al. Control of shear band dynamics in Cu50Zr50 metallic glass by introducing amorphous-crystalline interfaces[J]. Journal of Alloys and Compounds,2019,770:896-905. doi: 10.1016/j.jallcom.2018.08.192 [19] SONG H Y, LIS, AN M R, et al. Effect of crystal phase on shear bands initiation and propagation behavior in metallic glass matrix composites[J]. Computational Materials Science,2018,150:42-46. doi: 10.1016/j.commatsci.2018.03.069 [20] 张茹远, 阚前华, 张娟, 等. 形状记忆合金的力学及界面参数和体积分数对大块金属玻璃基复合材料增韧的影响[J]. 复合材料学报, 2015, 32(1):188-195.ZHANG Ruyuan, KAN Qianhua, ZHANG Juan, et al. Effects of mechanics and interface parameters and volume fraction of shape memory alloys on toughening of bulk metalic glass matrix composites[J]. Acta Materiae Compositae Sinica,2015,32(1):188-195(in Chinese). [21] SONG K K, HAN X L, PAULY S, et al. Rapid and partial crystallization to design ductile CuZr-based bulk metallic glass composites[J]. Materials and Design,2018,139:132-140. doi: 10.1016/j.matdes.2017.11.008 [22] MENG Y H, DUAN F H, PAN J, et al. Phase stability of B2-ordered ZrTiHfCuNiFe high entropy alloy[J]. Intermetallics,2019,111:106515. doi: 10.1016/j.intermet.2019.106515 [23] YUAN X, ZHAO Y, KOU S, et al. Microstructure and micro-mechanical properties of Cu based amorphous composites with shape-memory crystals[J]. Rare Metal Materials and Engineering,2017,46(1):35-38. doi: 10.1016/S1875-5372(17)30073-5 [24] WEI R, CHEN L B, LI H P, et al. Compression-compression fatigue behavior of CuZr-based bulk metallic glass compo-site containing B2 phase[J]. Intermetallics,2017,85:54-58. doi: 10.1016/j.intermet.2017.02.001 [25] ŞOPU D, ALBE K, ECKERT J. Metallic glass nanolaminates with shape memory alloys[J]. Acta Materialia,2018,159:344-351. doi: 10.1016/j.actamat.2018.08.034 [26] ŞOPU D, STOICA M, ECKERT J. Deformation behavior of metallic glass composites reinforced with shape memory nanowires studied via molecular dynamics simulations[J]. Applied Physics Letters,2015,106(21):33. [27] ZHAO L, CHAN K C, CHEN S H. Atomistic deformation mechanisms of amorphous/polycrystalline metallic nanolaminates[J]. Intermetallics,2018,95:102-109. doi: 10.1016/j.intermet.2018.01.023 [28] AMIGO N, SEPULVEDA-MACIAS M, GUTIERREZ G, et al. Enhancement of mechanical properties of metallic glass nanolaminates via martensitic transformation: Atomistic deformation mechanism[J]. Materials Chemistry and Physics,2019,225:159-168. doi: 10.1016/j.matchemphys.2018.12.050 [29] MENDELEV M I, SORDELET D J, KRAMER M J, et al. Using atomistic computer simulations to analyze X-ray diffraction data from metallic glasses[J]. Journal of Applied Physics,2007,102(4):043501. doi: 10.1063/1.2769157 [30] SUTRAKAR V K, MAHAPATRA D R, et al. Single and multi-step phase transformation in CuZr nanowire under compressive/tensile loading[J]. Intermetallics,2010,18(4):679-687. doi: 10.1016/j.intermet.2009.11.006 [31] AMIGO N, SEPÚLVEDA-MACÍAS M, GUTIÉRREZ G, et al. Martensitic transformation to monoclinic phase in bulk B2-CuZr[J]. Intermetallics,2017,91:16-21. doi: 10.1016/j.intermet.2017.08.003 [32] SONG H Y, XU J J, ZHANG Y G, et al. Molecular dynamics study of deformation behavior of crystalline Cu/amorphous Cu50Zr50 nanolaminates[J]. Materials & Design,2017,127:173-182. [33] STUKOWSKI A. Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool[J]. Modelling and Simulation in Materials Science and Engineering,2010,18(1):2154-2162. [34] PENG C X, ŞOPU D, CHENG Y, et al. Deformation behavior of designed dual-phase CuZr metallic glasses[J]. Materials and Design,2019,168:107662. doi: 10.1016/j.matdes.2019.107662 [35] KIM H K, LEE M, LEE K R, et al. How can a minor element added to a binary amorphous alloy simultaneously improve the plasticity and glass-forming ability?[J]. Acta Materialia,2013,61(17):6597-6608. doi: 10.1016/j.actamat.2013.07.044 [36] SEPULVEDA-M M, AMIGO N, GUTIERREZ G. Tensile behavior of Cu50Zr50 metallic glass nanowire with a B2 crystalline precipitate[J]. Physica B: Condensed Matter,2018,531:64-69. doi: 10.1016/j.physb.2017.12.005 -

下载:

下载: