Preparation and damage healing behavior of intrinsic self-repairing polymeric bonded explosives

-

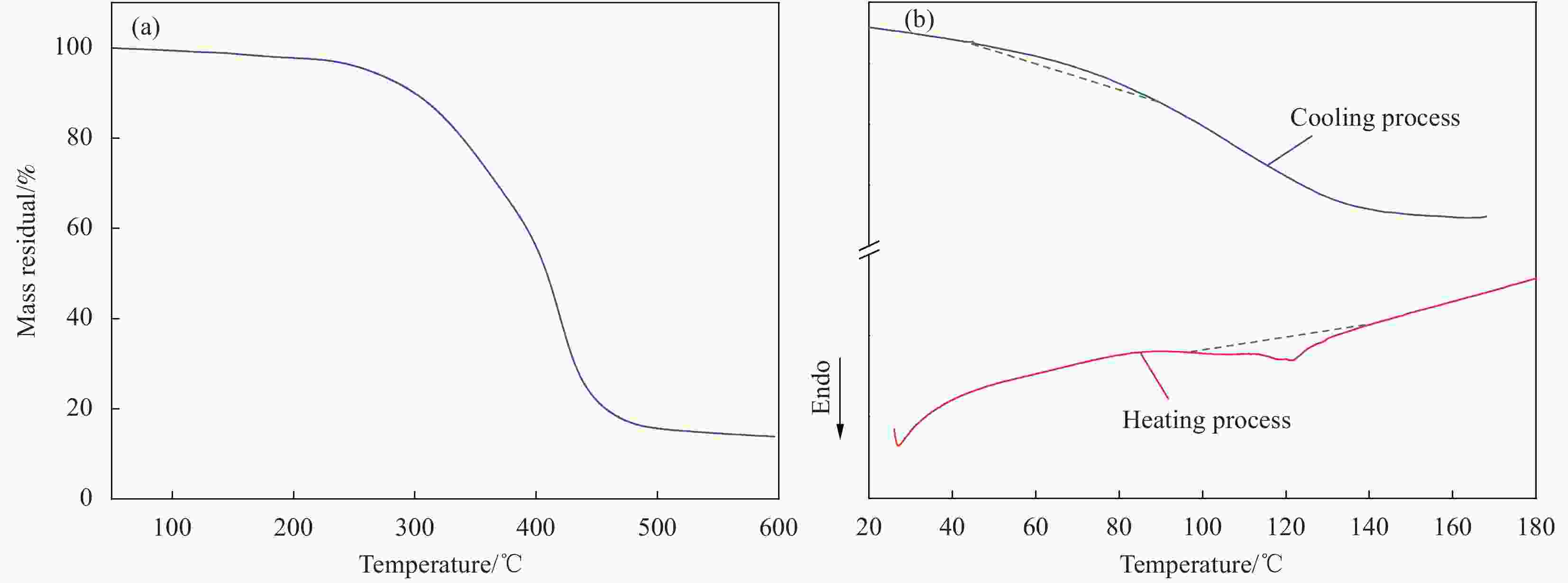

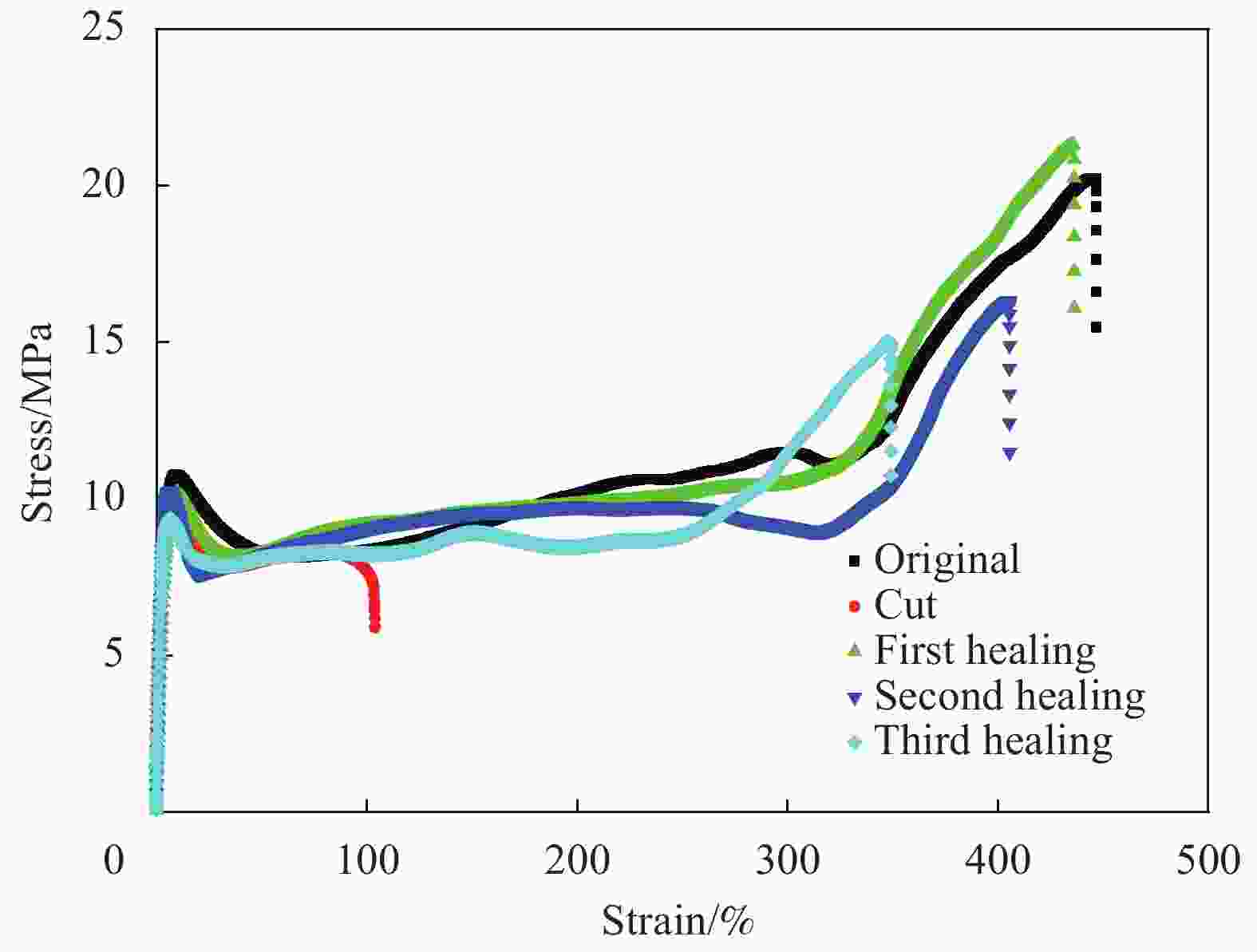

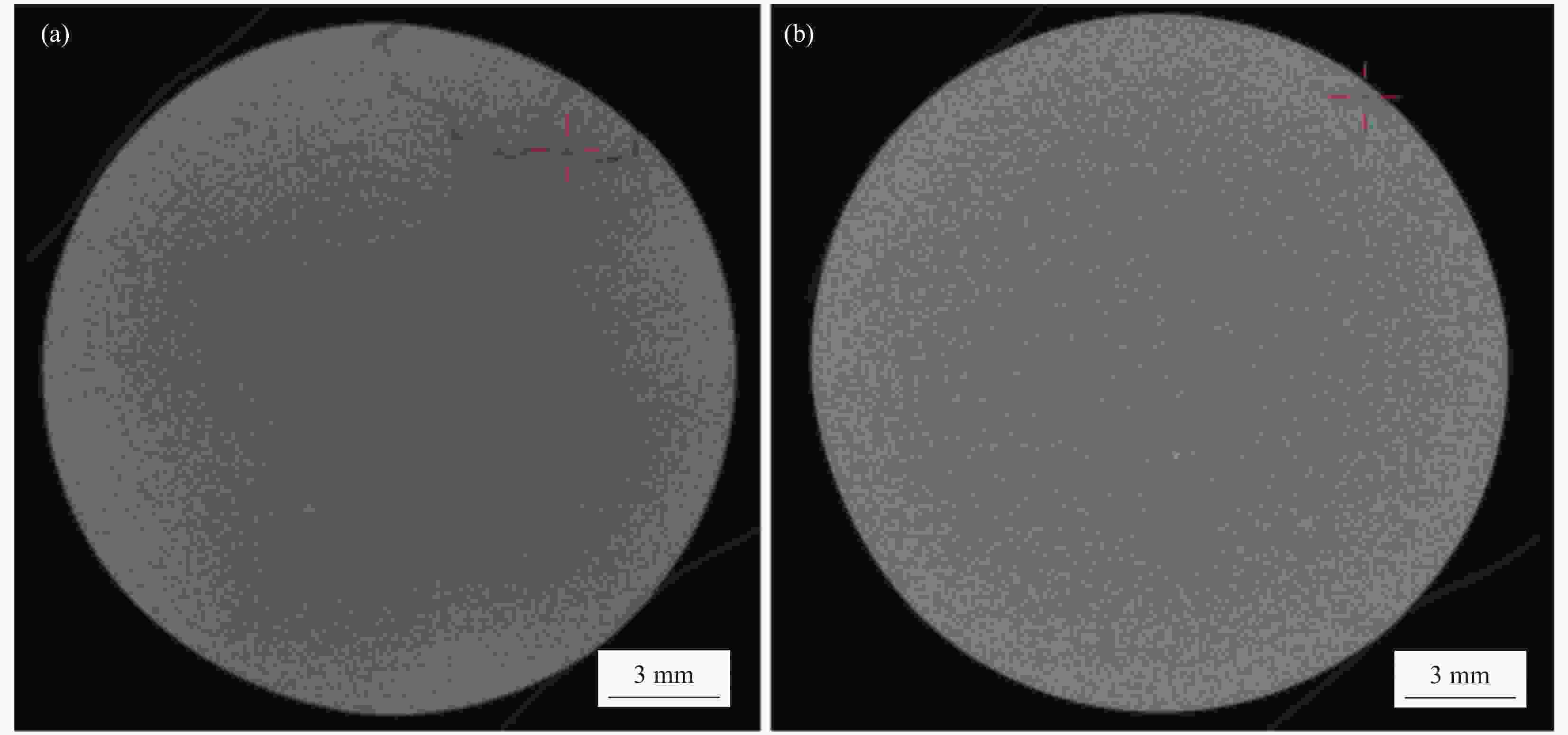

摘要: 为减轻高聚物粘结炸药(PBX)由于力、热等环境因素所产生的微裂纹等损伤对于其性能与使用寿命的影响,根据颗粒填充高分子复合材料的结构特性,设计合成了含DA键的本征型自修复高聚物粘结剂,以期实现PBX内部损伤的自主修复。研究结果表明,采用含可逆DA共价键的TAPE-DAPU为粘结剂,设计制备的PBX材料具有较强的损伤愈合能力,当损伤较轻时,该PBX的强度恢复率超过95%,对于较严重的贯穿性损伤,其修复效率也在65%以上。

-

关键词:

- 复合材料 /

- 高聚物粘结炸药(PBX) /

- 损伤 /

- 自修复 /

- DA反应

Abstract: In order to reduce the influence of microcracks and other damages caused by environmental factors such as force and heat on the performance and service life of polymeric bonded explosives (PBX), an intrinsic self-repairing polymer binder containing DA bonds was designed and synthesized to realize autonomous healing of PBX internal damage according to the structural characteristic of particle filled polymer composites. The research results show that using TAPE-DAPU containing reversible DA covalent bonds as binder, the designed and prepared PBX material has good damage-healing ability. When the damage in PBX is slight, the strength recovery rate of the PBX exceeds 95%, while the repair efficiency is also above 65% for relatively severe penetrating damage.-

Key words:

- composite materials /

- polymeric bonded explosives (PBX) /

- damage /

- self-repairing /

- Diels-Alder reaction

-

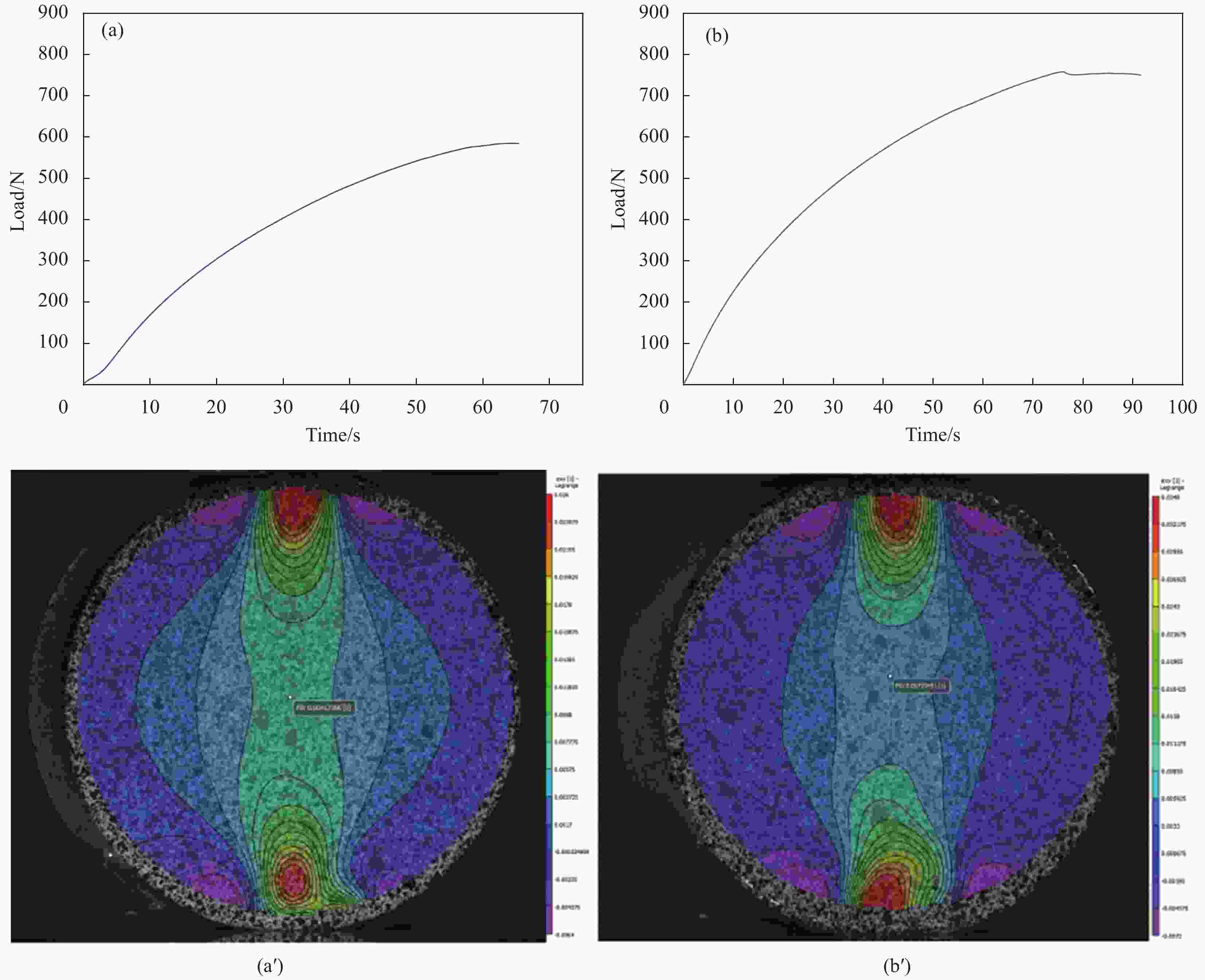

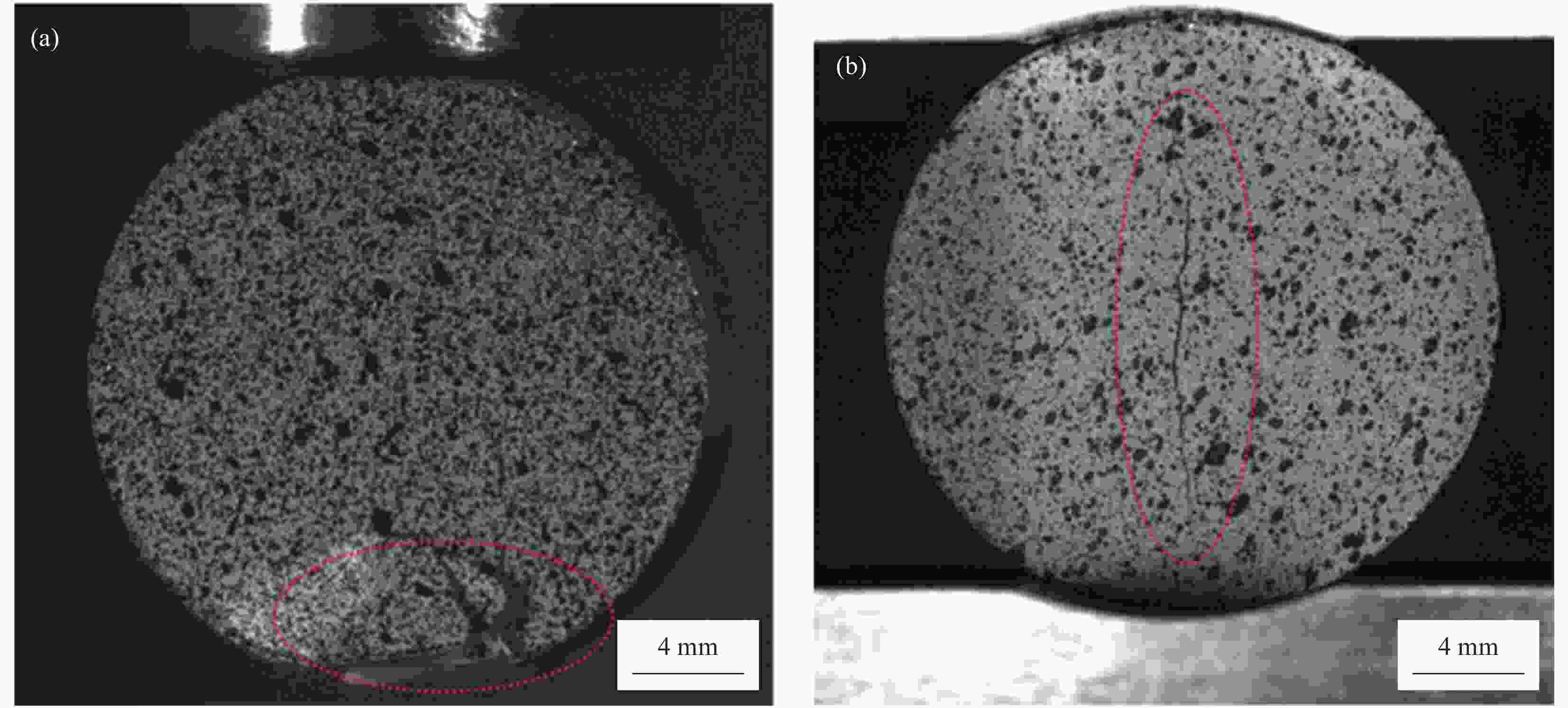

表 1 三氨基三硝基苯(TATB)/含DA键的四氨基苯基乙烯基聚氨酯(TAPE-DAPU)的高聚物粘结炸药(PBX)的损伤预制与修复处理方式

Table 1. Damage prefabrication and healing methods of Triaminotrinitrobenzene(TATB)/ Tetrakis(4-aminophenyl)ethene polyurethane with Diels-Alder bonds (TAPE-DAPU) based polymer bonded explosive (PBX)

Sample Mode of damage-prefabrication Serial number Method of healing-treatment A Plane-head clamp, loading to 550 N A1 Heating at 125℃ for 1 h and keeping at 65℃ for 4 h A2 Heating at 125℃ for 2 h and keeping at 65℃ for 3 h B Arc-head clamp, loading to 950 N and keeping 100 s B1 Heating at 125℃ for 1 h and keeping at 65℃ for 4 h B2 Heating at 125℃ for 2 h and keeping at 65℃ for 3 h C Arc-head clamp, loading to 1000 N C1 Heating at 125℃ for 1 h and keeping at 65℃ for 4 h C2 Heating at 125℃ for 2 h and keeping at 65℃ for 3 h D Arc-head clamp, loading to form perforative crack D1 Heating at 125℃ for 1 h and keeping at 65℃ for 4 h D2 Heating at 125℃ for 2 h and keeping at 65℃ for 3 h 表 2 TATB-DAPU基PBX不同损伤修复试样的巴西性能

Table 2. Brazilian properties of TATB-DAPU based PBX after different damage-healing process

Sample Serial

numberBrazilian

strength/MPaElongation/% Original sample P0 6.45±0.15 1.173±0.020 A A1 6.28±0.11 0.857±0.015 A2 4.86±0.10 0.517±0.013 B B1 4.99±0.06 0.777±0.013 B2 4.79±0.09 0.627±0.014 C C1 4.78±0.09 0.617±0.016 C2 4.50±0.10 0.397±0.011 D D1 4.45±0.07 0.557±0.012 D2 4.25±0.09 0.635±0.011 -

[1] BERGMAN S D, WUDL F. Mendable polymers[J]. Journal of Materials Chemistry,2008,18(1):41-62. doi: 10.1039/B713953P [2] ZHANG M Q, RONG M Z. Self-healing polymers and polymer composites[M]. Hoboken: John Wiley & Sons, Inc, 2011. [3] HIA I L, VAHEDI V, PASBAKHSH P. Self-healing polymer composites: prospects, challenges, and applications[J]. Polymer Reviews,2016,56:225-261. doi: 10.1080/15583724.2015.1106555 [4] ZHANG Q, LIU L B, PAN C G, et al. Review of recent achievements in self-healing conductive materials and their applications[J]. Journal of Materials Science,2018,53(1):27-46. doi: 10.1007/s10853-017-1388-8 [5] WHITE S R, SOTTOS N R, GEUBELLE P H, et al. Autonomic healing of polymer composites[J]. Nature,2001,409:794-797. doi: 10.1038/35057232 [6] LI C, TAN J, GU J, et al. Rapid and efficient synthesis of isocyanate microcapsules via thiol-ene photopolymerization in Pickering emulsion and its application in self-healing coating[J]. Composite Science and Technology,2016,123:250-258. doi: 10.1016/j.compscitech.2016.01.001 [7] GU J, YANG X, LI C, et al. Synthesis of cyanate ester microcapsules via solvent evaporation technique and its application in epoxy resins as a healing agent[J]. Industrial & Engineering Chemistry Research,2016,55:10941-10946. [8] GARCIA S J. Effect of polymer architecture on the intrinsic self-healing character of polymers[J]. European Polymer Journal,2014,53:118-125. doi: 10.1016/j.eurpolymj.2014.01.026 [9] CHEN Y, KUSHNER A M, WILLIAMS G A, et al. Multiphase design of autonomic self-healing thermoplastic elastomers[J]. Nature Chemistry,2012,4:467-472. doi: 10.1038/nchem.1314 [10] STEWART S A, BACKHOLM M, BURKE N A D, et al. Cross-linked hydrogels formed through Diels-Alder coupling of furan-and maleimide-modified poly(methyl vinyl ether-alt-maleic acid)[J]. Langmuir,2016,32:1863-1870. doi: 10.1021/acs.langmuir.5b04450 [11] CASUSO P, ODRIOZOLA I, VICENTE A P, et al. Injectable and selfhealing dynamic hydrogels based on metal(I)-thiolate/disulfide exchange as biomaterials with tunable mechanical properties[J]. Biomacromolecules,2015,16:3552-3561. doi: 10.1021/acs.biomac.5b00980 [12] ROWAN S J, CANTRILL S J, COUSINS G R L, et al. Dynamic covalent chemistry[J]. Angewandte Chemie International Edition,2002,41:598-952. [13] LAI J C, MEI J F, JIA X Y, et al. A stiff and healable polymer based on dynamic-covalent boroxine bonds[J]. Advanced Materials,2016,28:8277-8282. doi: 10.1002/adma.201602332 [14] CORDIER P, TOURNILHAC F, SOULIE-ZIAKOVIC C, et al. Self-healing and thermoreversible rubber from supramolecular assembly[J]. Nature,2008,451:977-980. doi: 10.1038/nature06669 [15] BURNWORTH M, TANG L, KUMPFER J R, et al. Optically healable supramolecular polymers[J]. Nature,2011,472:334-337. doi: 10.1038/nature09963 [16] BODE S, ZEDLER L, SCHACHER F H, et al. Self-healing polymer coatings based on crosslinked metallosupramolecular copolymers[J]. Advanced Materials,2013,25:1634-1638. doi: 10.1002/adma.201203865 [17] LI C H, WANG C, KEPLINGER C, et al. A highly stretchable autonomous self-healing elastomer[J]. Nature Chemistry,2016,8:618-624. doi: 10.1038/nchem.2492 [18] CHEN X, DAM M A, ONO K, et al. A thermally re-mendable crosslinked polymeric material[J]. Science,2002,295:1698-1702. doi: 10.1126/science.1065879 [19] 梁楚尧. Diels-Alder反应在自修复端呋喃甲酯基聚丁二烯黏合剂中的应用[D]. 北京: 北京理工大学, 2017.LIANG C. Application of Diels-Alder reaction in self-repairing furo-methyl polybutadiene adhesive[D]. Beijing: Beijing Institute of Technology, 2017(in Chinese). [20] 菅晓霞, 宋育芳, 赵盟辉. GAP基自修复黏结剂的制备及性能[J]. 含能材料, 2019, 27(2):131-136. doi: 10.11943/CJEM2018169JIAN X, SONG Y, ZHAO M. Preparation and properties of GAP-based self-repairing Binder[J]. Energetic Materials,2019,27(2):131-136(in Chinese). doi: 10.11943/CJEM2018169 [21] LI Y, YANG Z, ZHANG J, et al. Novel polyurethane with high self-healing efficiency for functional energetic composites[J]. Polymer Testing, 2019, 76: 82-89. [22] KOTTERITZSCH J, HAGER M D, SCHUBERT U S. Tuning the self-healing behavior of one-component intrinsic polymers[J]. Polymer, 2015, 69: 321-329. [23] DU P, JIA H, CHEN Q, et al. Slightly crosslinked polyurethane with Diels-Alder adducts from trimethylolpropane[J]. Journal Applied Polymer Science,2016,133:43971. [24] 何晴, 白静, 史子兴, 印杰. 基于Diels-Alder反应的热可逆交联聚醚胺的制备和表征[J]. 功能高分子学报, 2018, 31(2):140-146.HE Q, BAI J, SHI Z, YIN J. Preparation and characterization of thermal reversible polyetheramine based on Diels-Alder reaction[J]. Journal of Functional Polymer,2018,31(2):140-146(in Chinese). -

下载:

下载: