Inversion study on the correlation between the mesh size and the adhesive properties

-

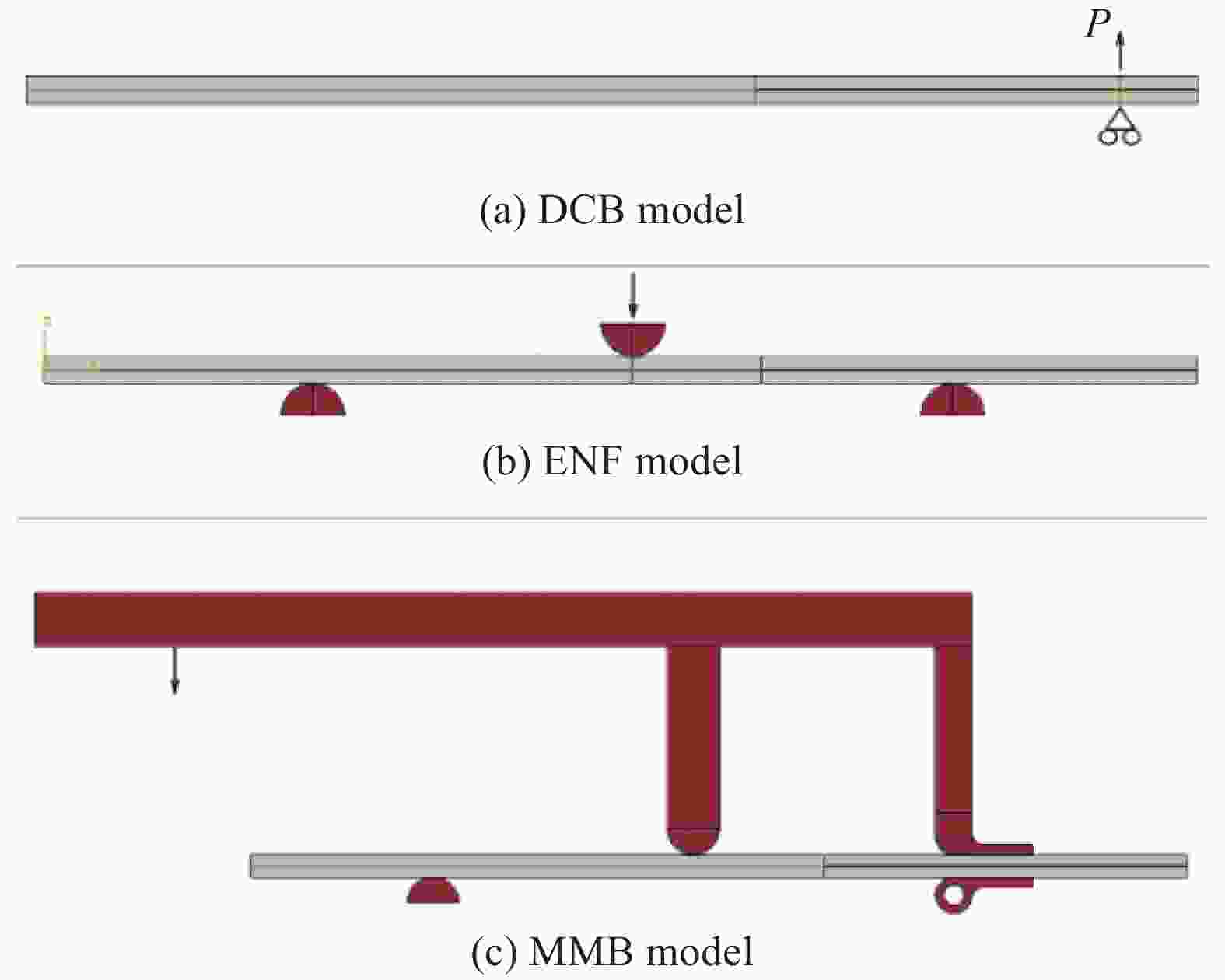

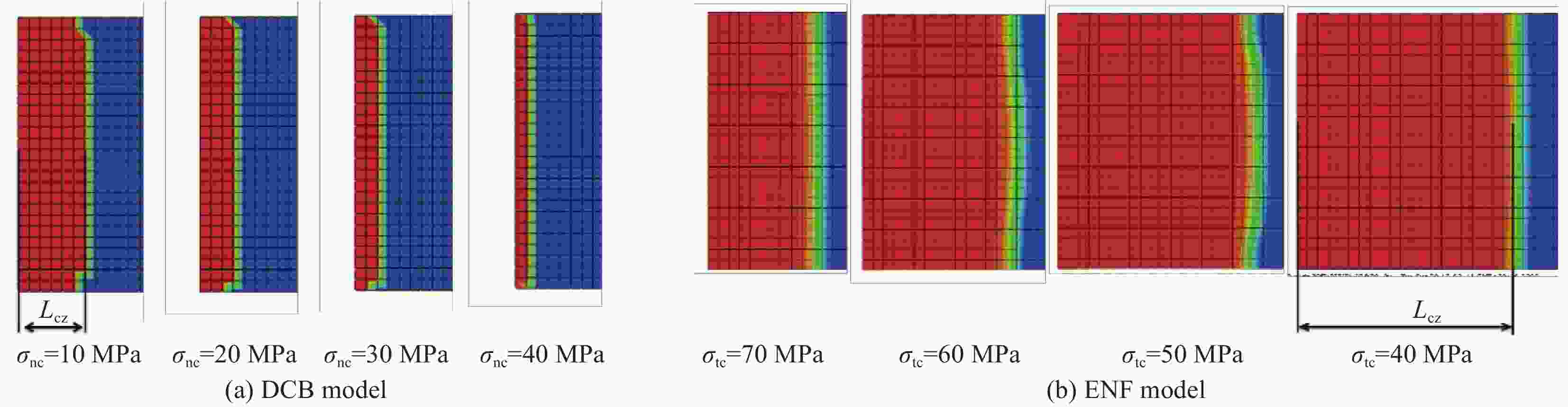

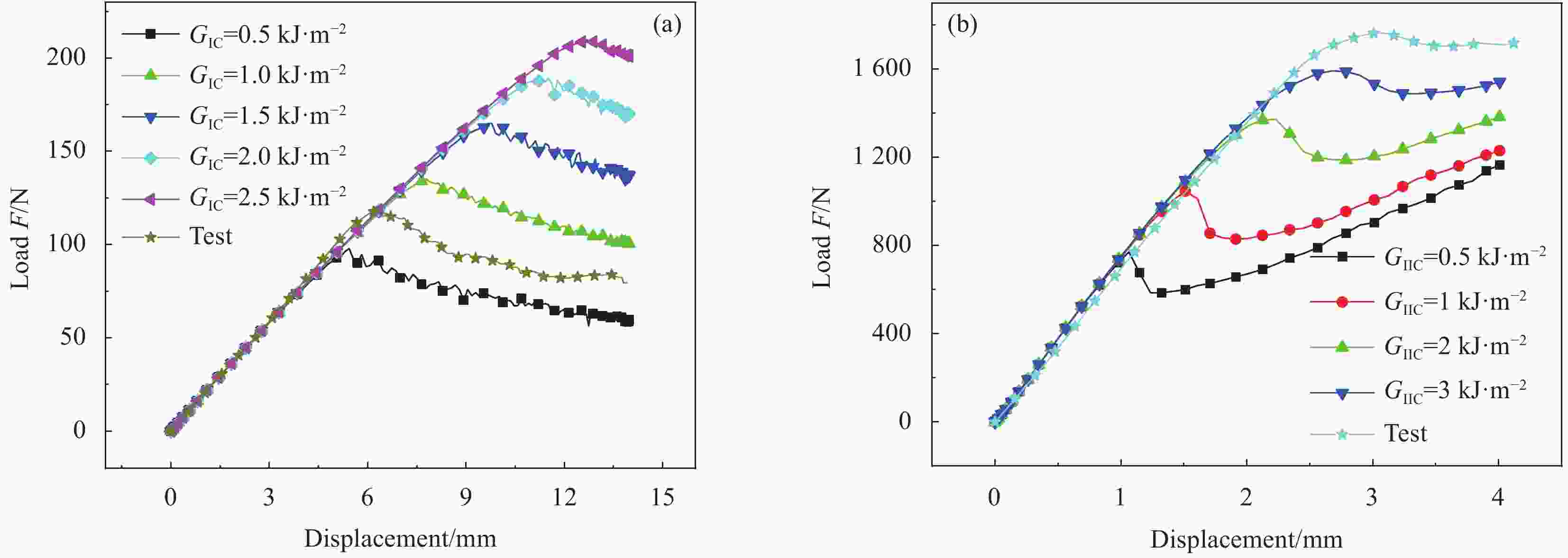

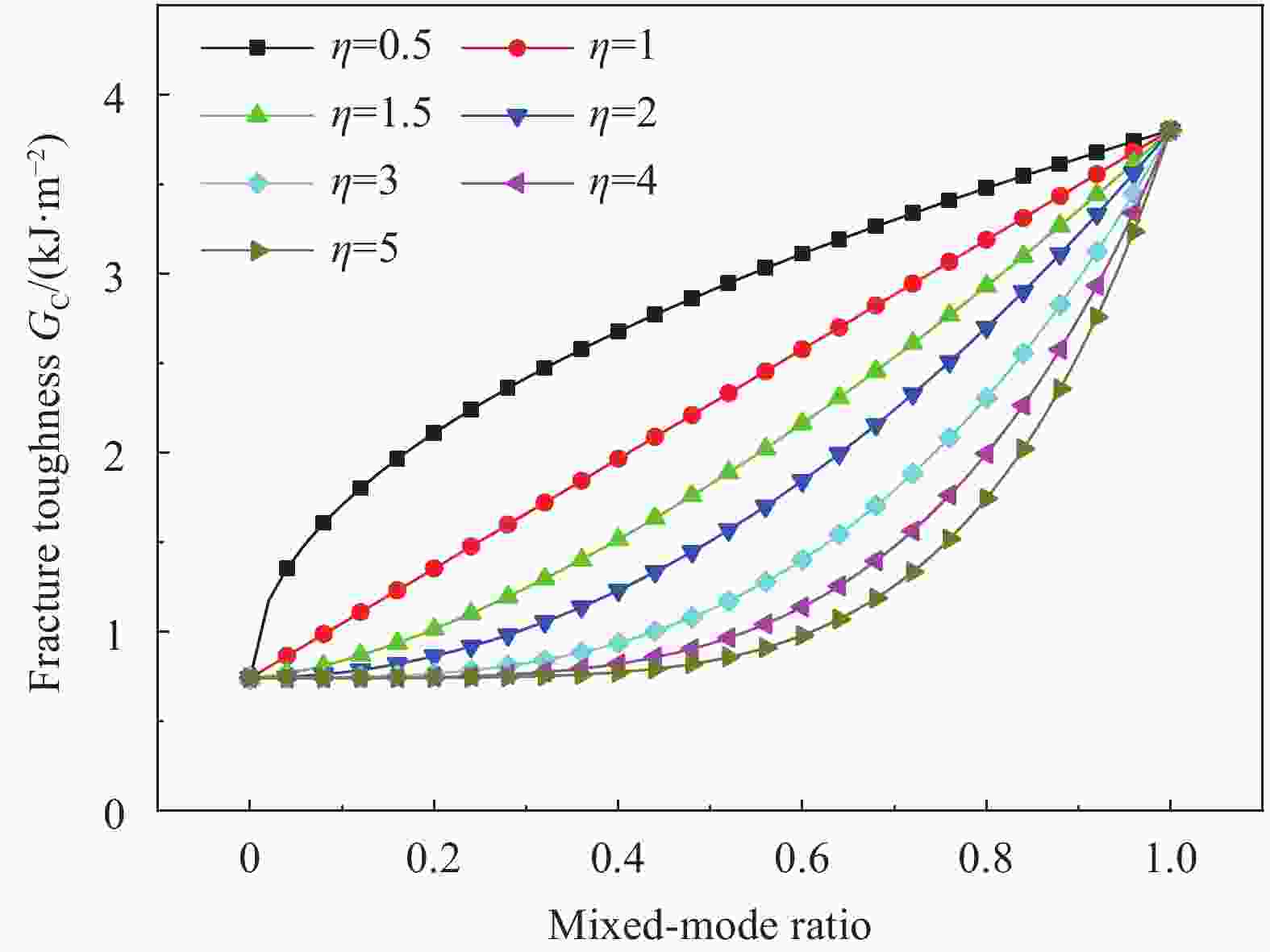

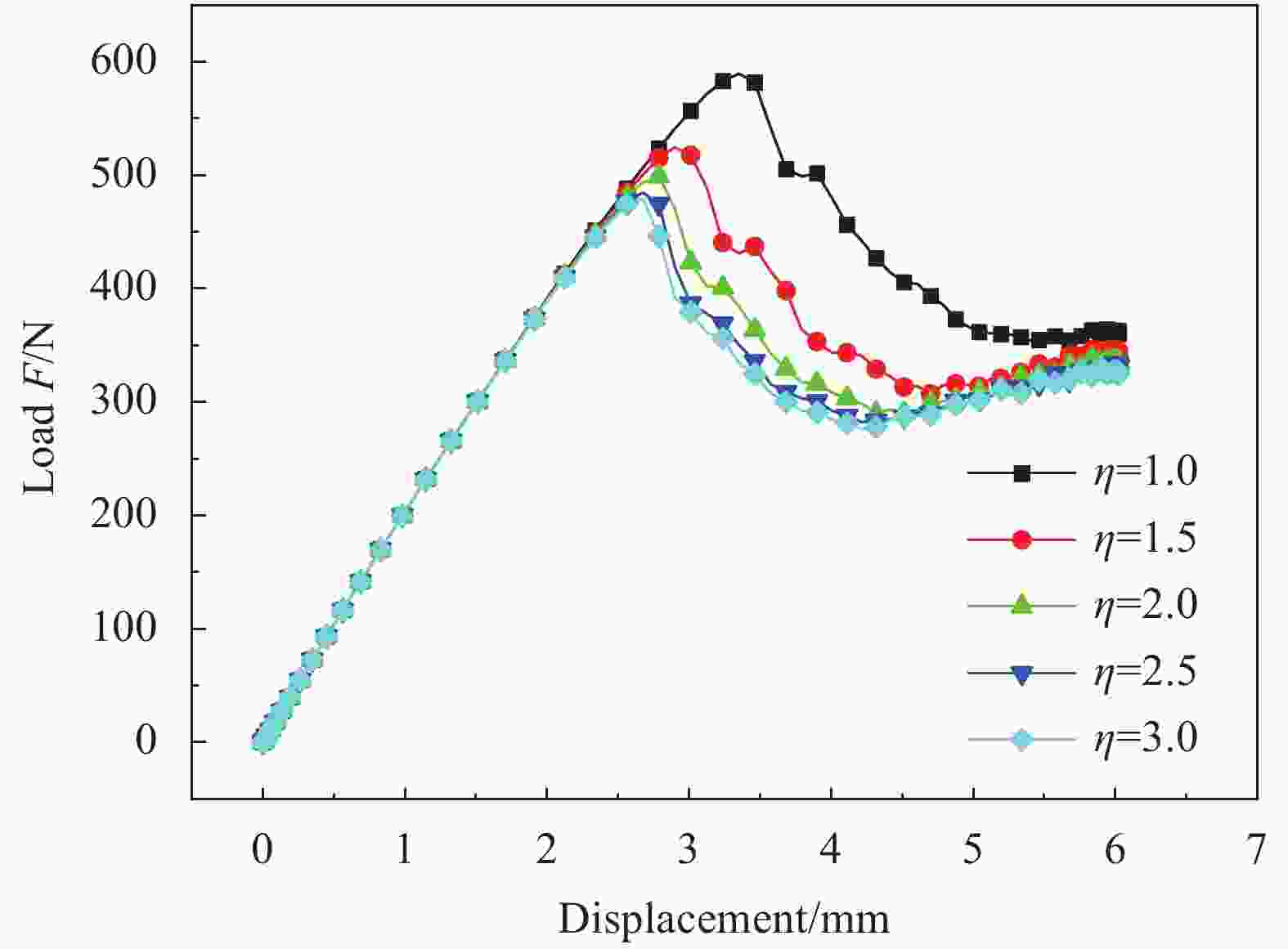

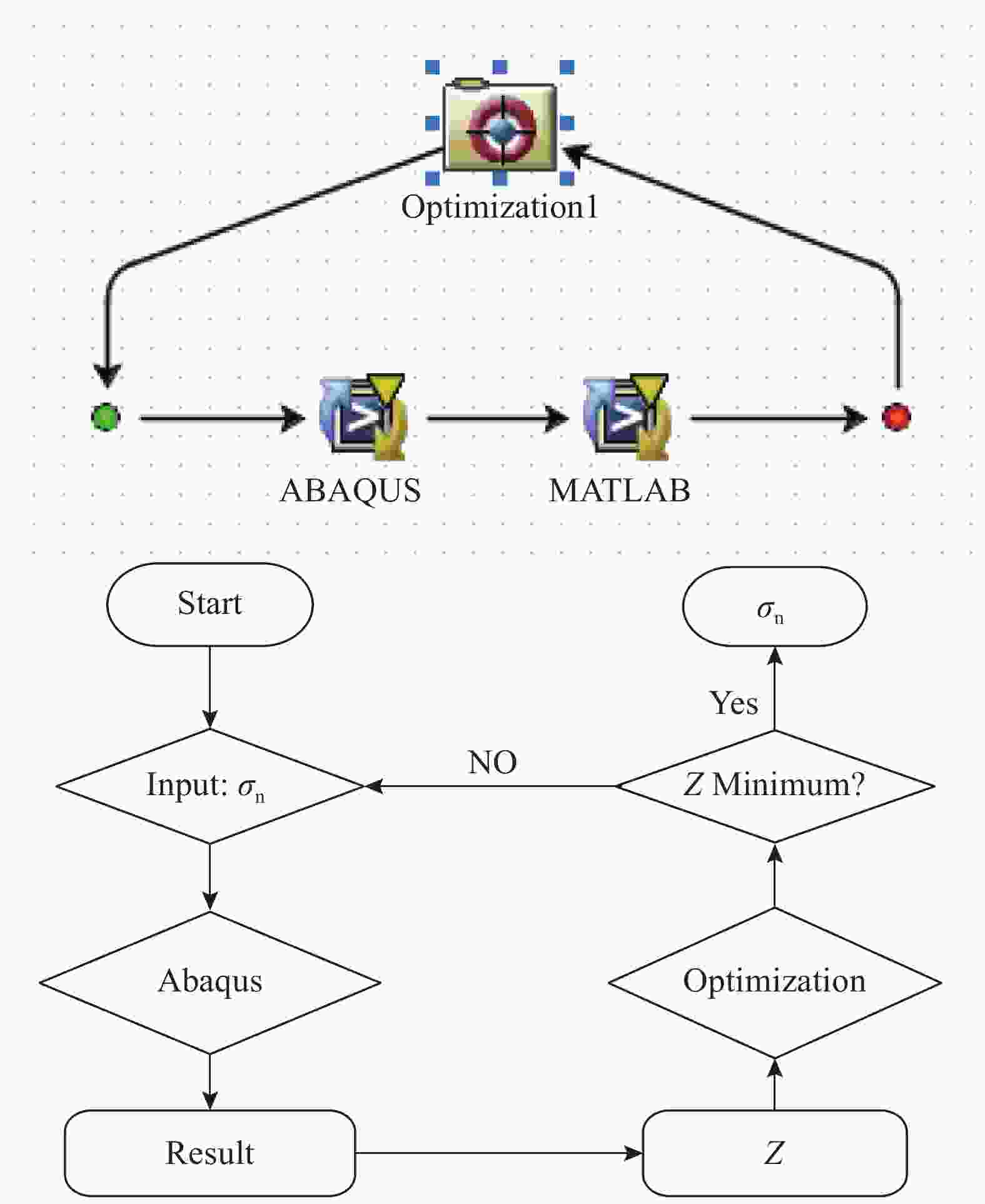

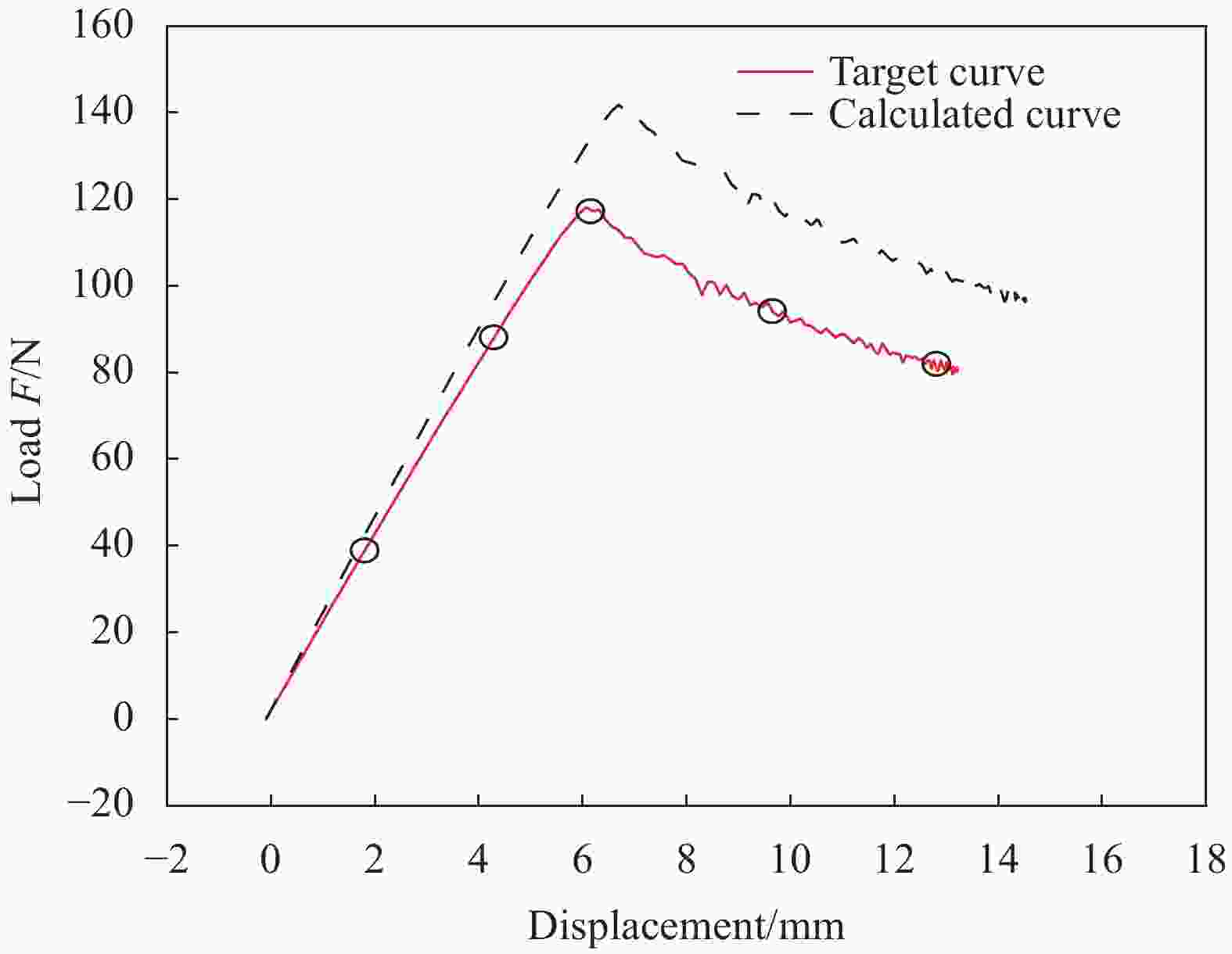

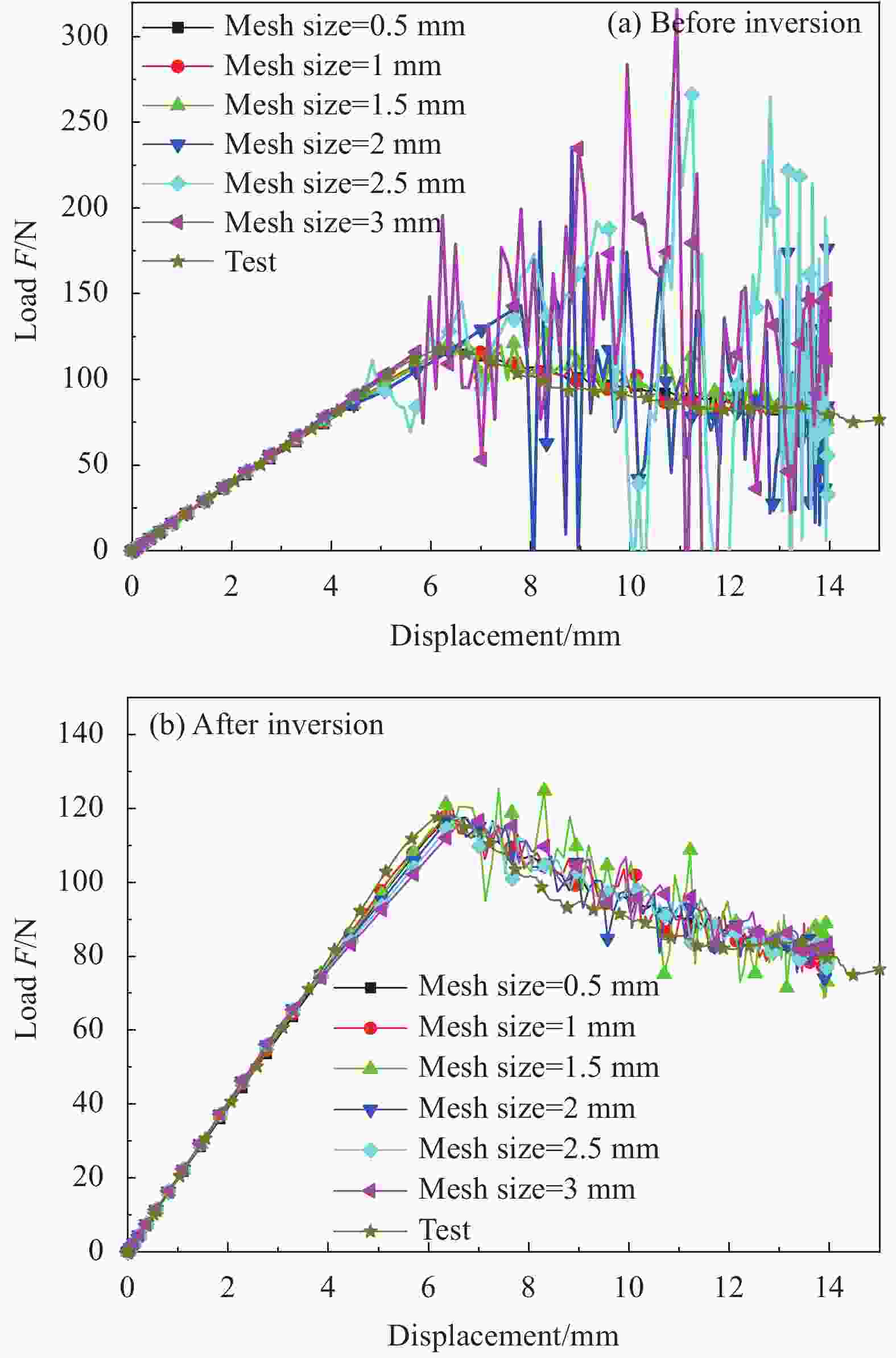

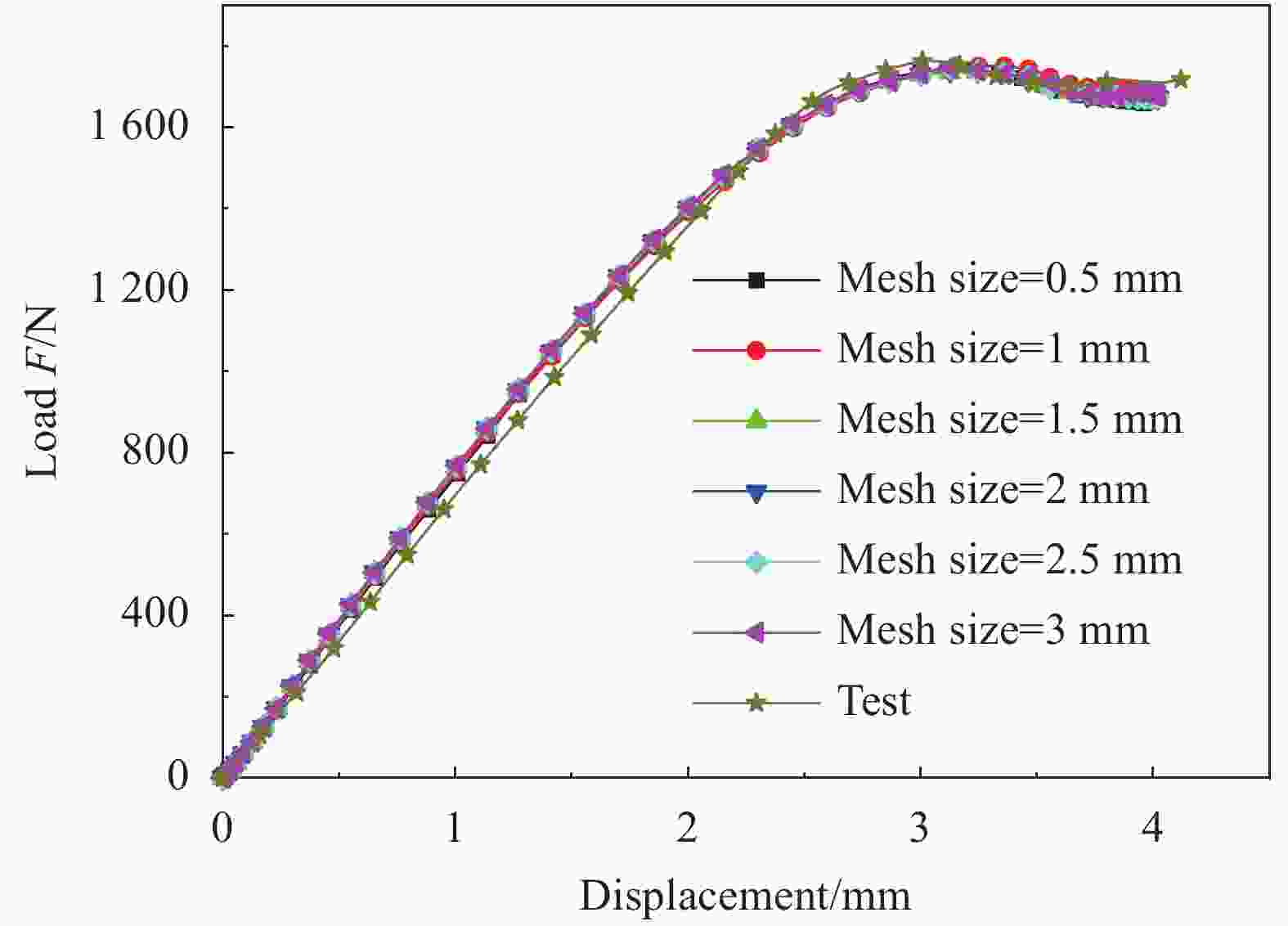

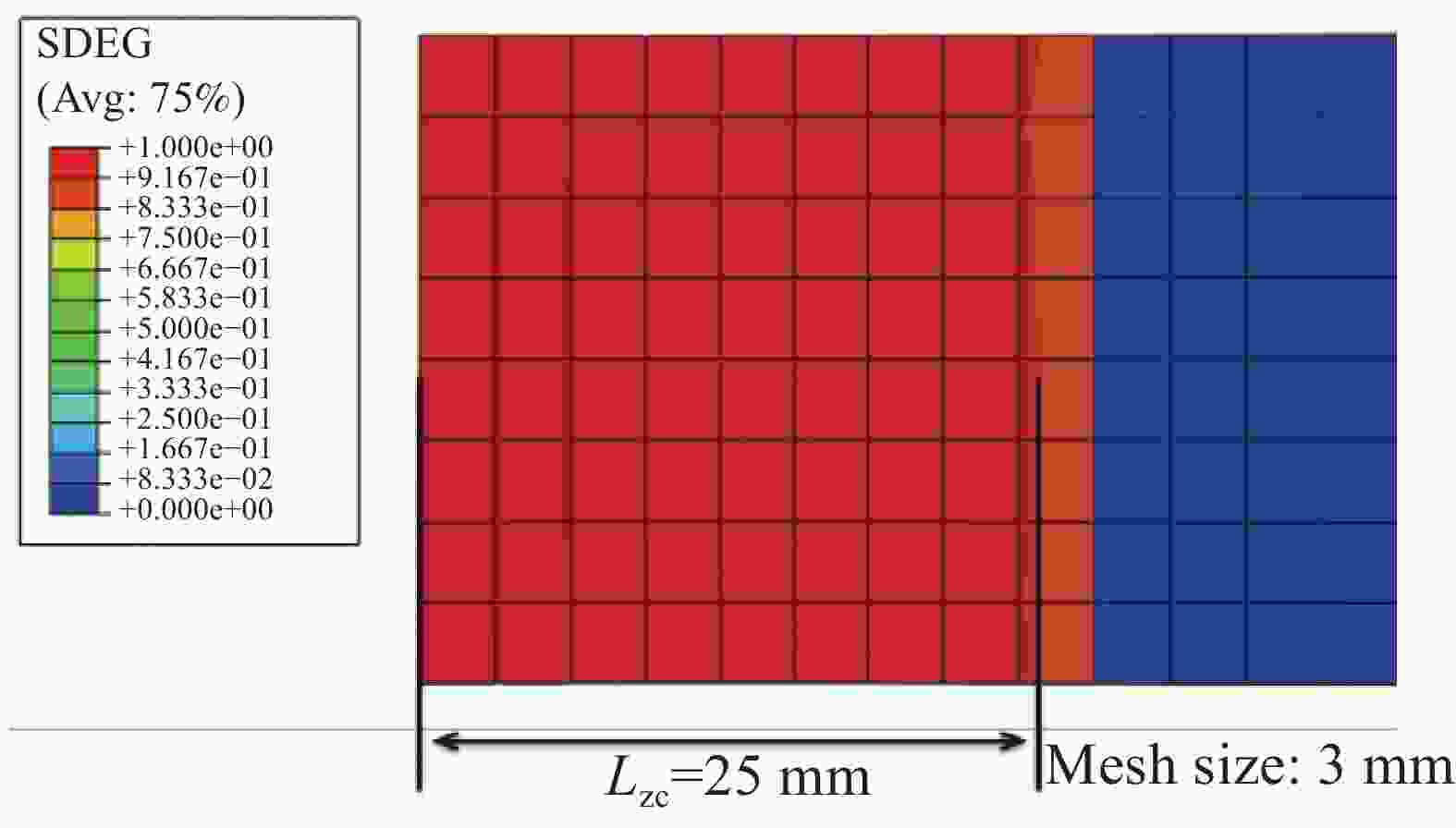

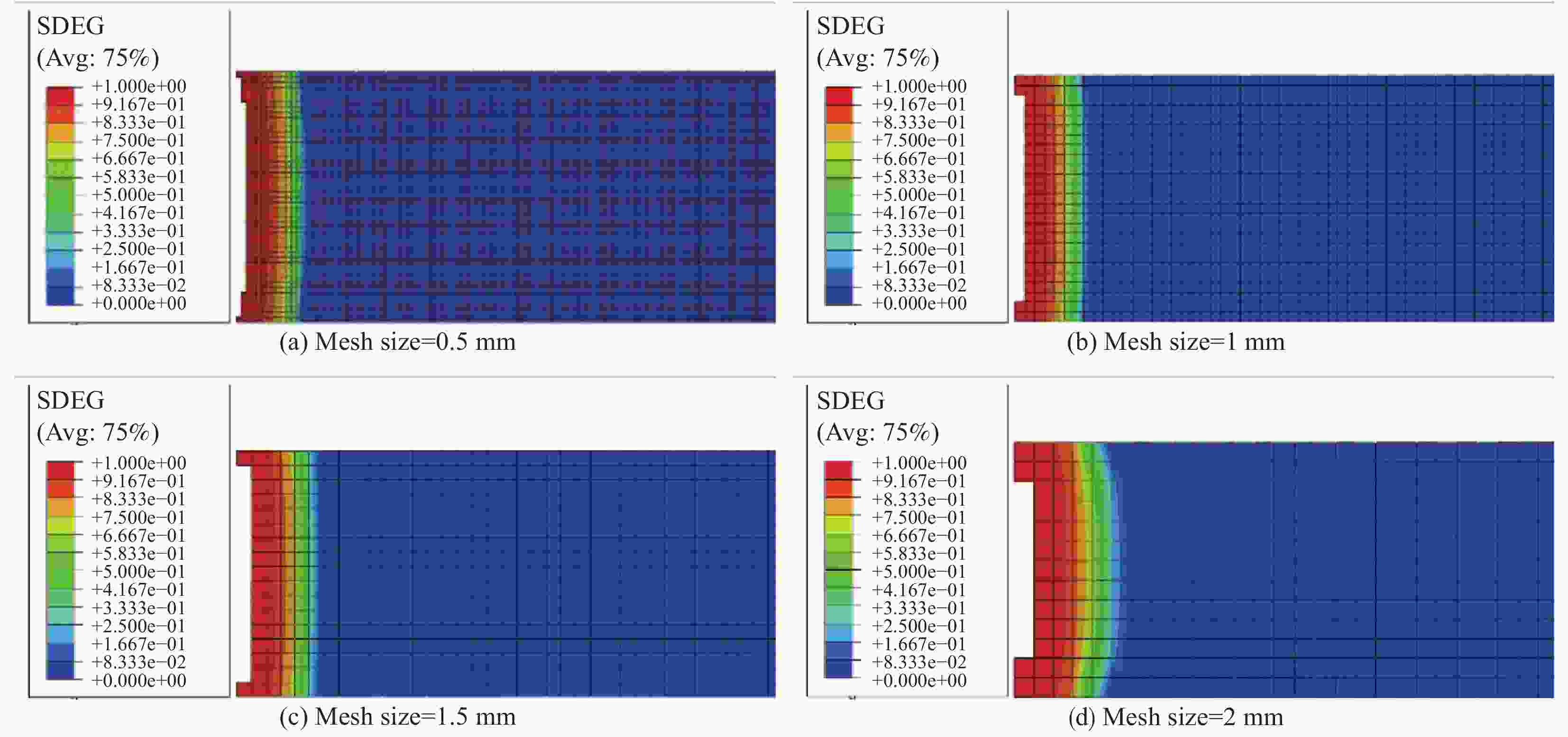

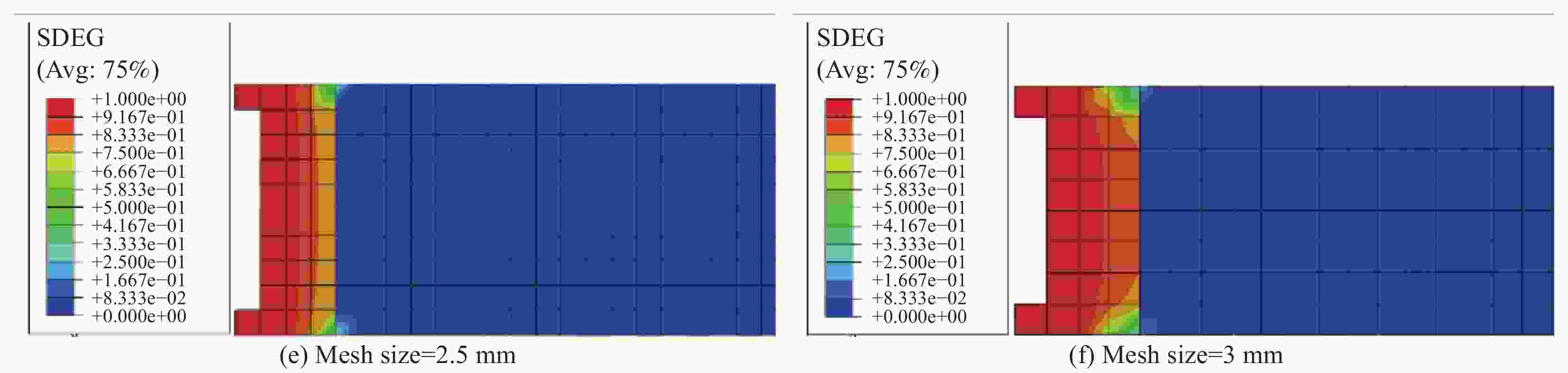

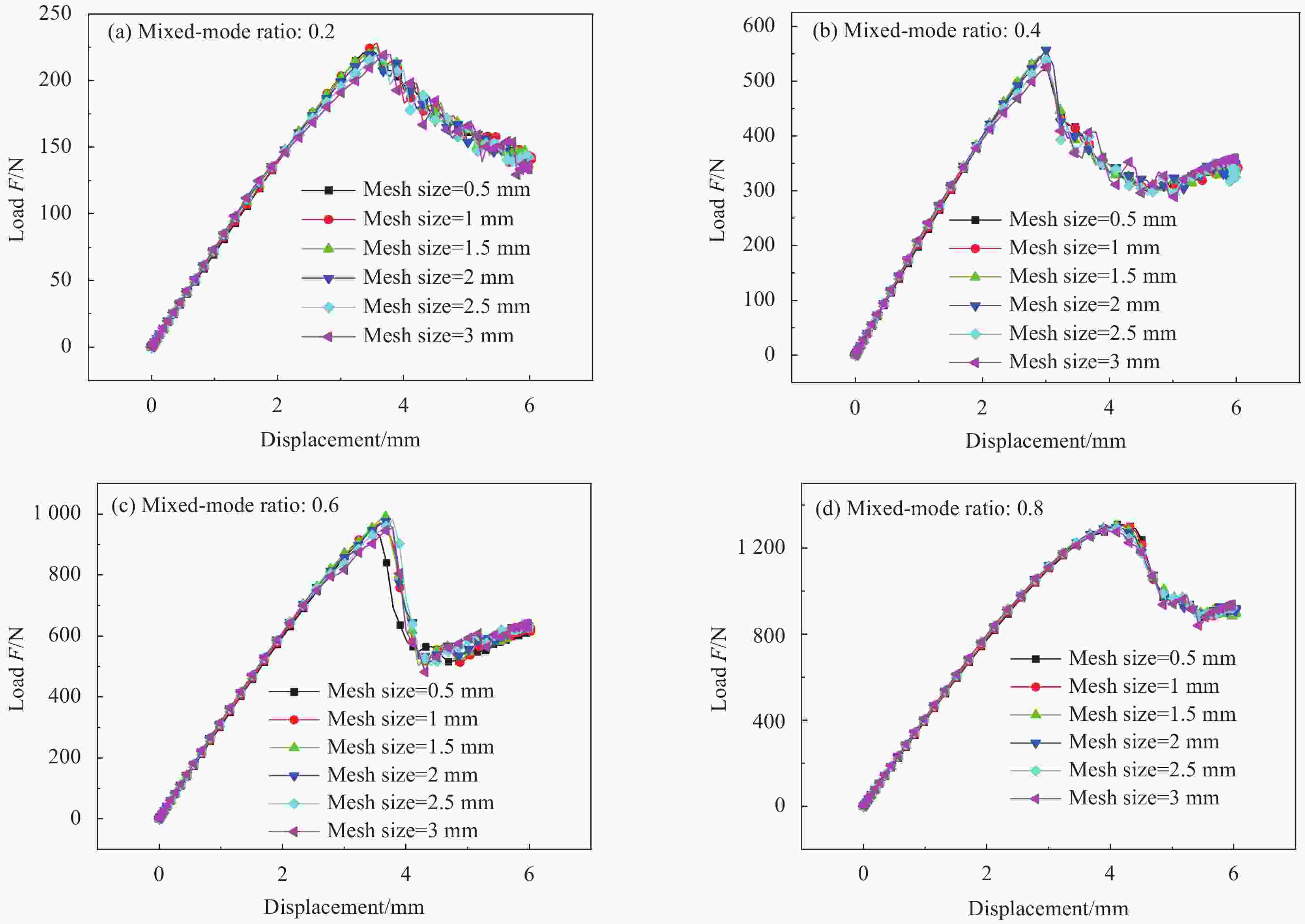

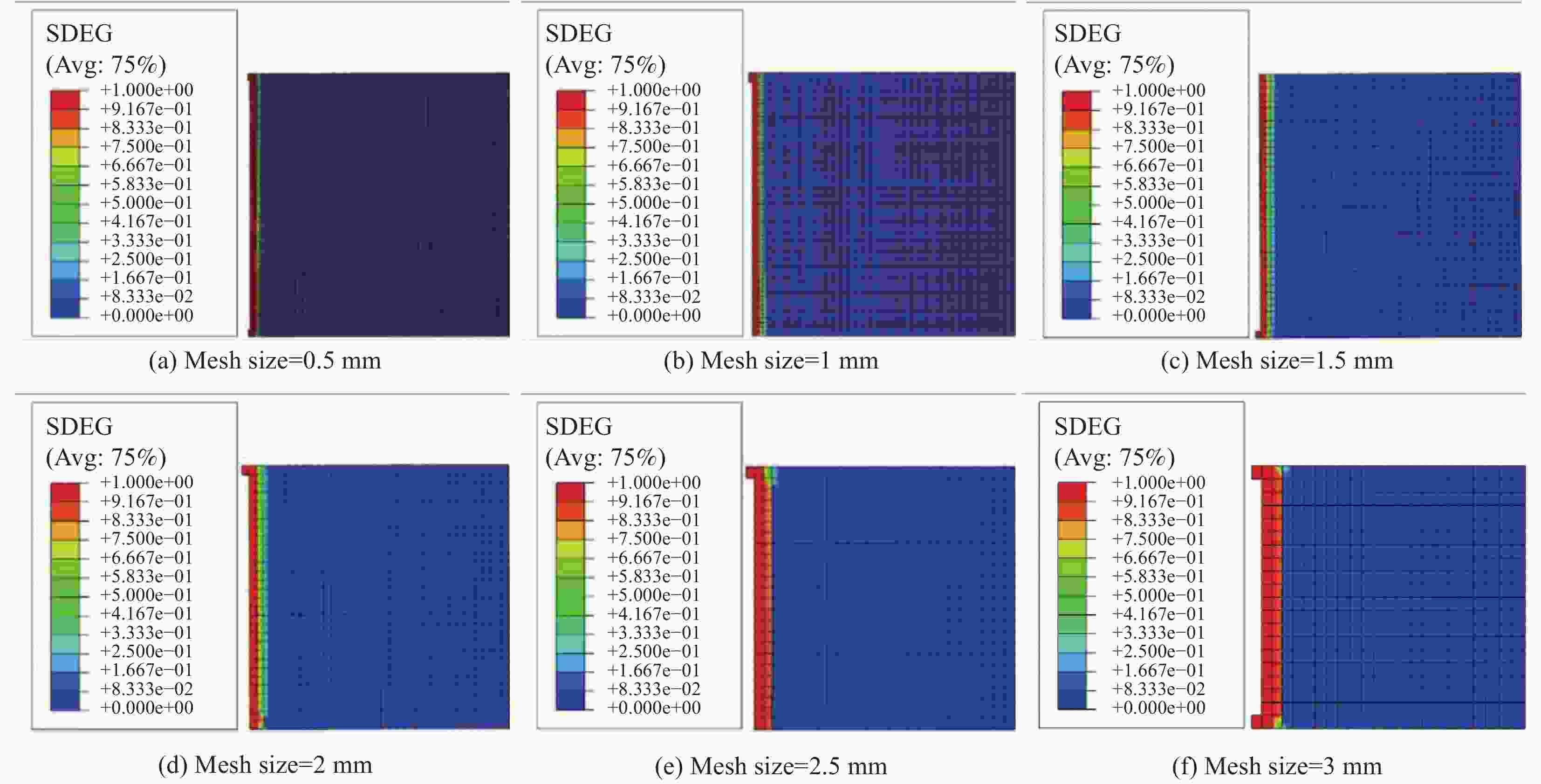

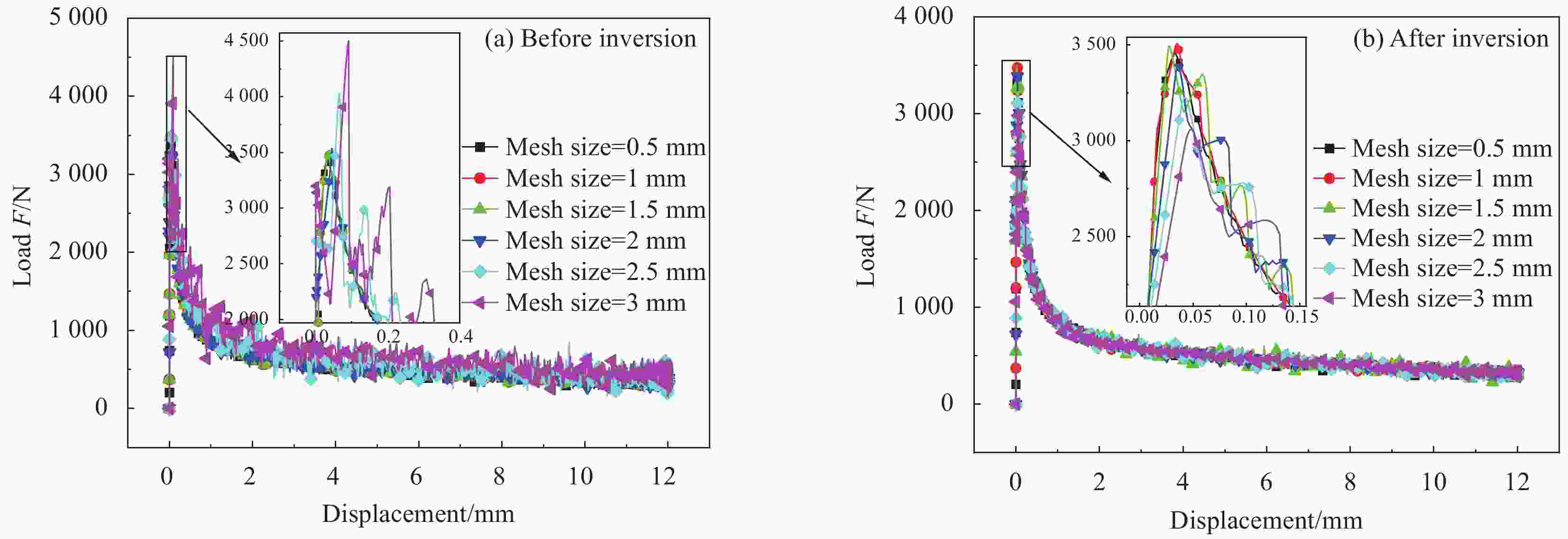

摘要: 在使用内聚力模型对复合材料胶层进行有限元失效分析时,为了保证计算结果的准确性和收敛性,胶层网格尺寸应小于1 mm。然而当使用内聚力模型对飞机上的大型复合材料结构进行有限元分析时,模型将会产生上百万的有限元单元,这将耗费大量的计算资源。本文在研究胶层参数对胶层失效分析影响的基础上,通过对不同网格尺寸下胶层参数进行反演,提出了一种修改胶层参数的方法以适用于不同网格尺寸下胶层失效分析。使用此方法对不同网格尺寸的混合型弯曲(MMB)有限元模型和复合材料圆壳模型进行了有限元仿真。结果表明:所提出的方法能够大幅降低模型的网格数量,减小计算规模,快速准确地计算出混合加载条件下胶层损伤演化和破坏情况。Abstract: In order to ensure the accuracy and convergence of the calculation results, the mesh size of the adhesive layer should be less than 1 mm for the failure analysis of composite adhesive layer using the cohesive zone model. However, when the cohesive zone model is used to analysis a large composite material structure in the aircraft, the model will generate millions of finite elements, which will consume numerous computing resources. Based on the research of the influence of the adhesive properties on the adhesive layer failure analysis, by inversion of the adhesive properties with different mesh sizes, the method that can accurately describe the failure behavior of the adhesive layer by changing the parameters of the adhesive layer to adapt to different mesh sizes was proposed. This method was used to simulate the mixed-mode-bending (MMB) model and composite cylindrical shell model with different mesh sizes. The results show that the method proposed can greatly reduce the number of meshes in the model and the calculation scale, and quickly and accurately calculate the damage evolution and failure of the adhesive layer under mixed loading conditions.

-

Key words:

- cohesive zone model /

- adhesive properties /

- mesh size /

- cohesive zone length /

- parameter inversion

-

表 1 碳纤维增强环氧树脂复合材料层合板TC350-1/IM7-12K材料参数[29]

Table 1. Material parameters of TC350-1/TM7-12K carbon fiber reinforced epoxy composite laminates [29]

E1/MPa E2/MPa E3/MPa ${\mu _{12}}$ ${\mu _{13}}$ ${\mu _{23}}$ G12/MPa G13/MPa G23/MPa 158600 9700 9700 0.32 0.32 0.461 5000 5000 3319 Notes: Ei (i=1,2,3)—Elastic modulus in material principle directions; Gij (1≤i<j≤3)—Shear elastic modulus in material principle directions; ${\mu _{ij}}$(1≤i<j≤3)—Poison’s ratio in material principal directions. ${\sigma _{{\rm{nc}}}}$/MPa ${\sigma _{{\rm{tc}}}}$/MPa GIC/(kJ·m−2) GIIC/(kJ·m−2) $\eta $ K/(N·mm−3) 36 37 0.741 3.8 1.5 106 Notes: ${\sigma _{{\rm{nc}}}}$—Tensile strength; ${\sigma _{{\rm{tc}}}}$—Shear strength; GIC—Type I fracture toughness; GIIC—Type II fracture toughness; $\eta $—B-K criterion parameter; K—Interface stiffness. 表 3 TC350-1/IM7-12K复合材料层合板DCB有限元模型J-271胶层参数反演结果

Table 3. Inversion results of J-271 adhesive properties in DCB model of TC350-1/IM7-12K composite laminates

Mesh size/mm ${\sigma _{{\rm{nc}}}}$/MPa GIC/(kJ·m−2) Computation time/s 0.5 36.00 0.741 15 795 1 36.00 0.741 2 160 1.5 35.96 0.741 904 2 29.34 0.741 590 2.5 23.21 0.741 415 3 18.64 0.741 258 表 4 TC350-1/IM7-12K复合材料层合板不同网格尺寸下的J-271胶层参数

Table 4. Mechanical properties of J-271 adhesive layer of TC350-1/IM7-12K composite laminates with different mesh sizes

Mesh size/mm ${\sigma _{{\rm{nc}}}}$/MPa ${\sigma _{{\rm{tc}}}}$/MPa GIC/(kJ·m−2) GIIC/(kJ·m−2) $\eta $ 0.5 36.00 37 0.741 3.8 1.5 1 36.00 37 0.741 3.8 1.5 1.5 35.96 37 0.741 3.8 1.5 2 29.34 37 0.741 3.8 1.5 2.5 23.21 37 0.741 3.8 1.5 3 18.64 37 0.741 3.8 1.5 表 5 反演后圆壳模型不同尺寸网格下计算时间

Table 5. Calculation time of circular shell model with different mesh sizes after inversion

Mesh size/mm 0.5 1 1.5 2 2.5 3 Computation time/s 7730 1010 395 238 172 127 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU Shanyi, GUAN Zhidong. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica,2008,25(1):1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [3] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322.MA Limin, ZHANG Jiazhen, YUE Guangquan, et al. Application of composites in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese). [4] 杨乃宾. 新一代大型客机复合材料结构[J]. 航空学报, 2008, 3:596-604. doi: 10.3321/j.issn:1000-6893.2008.03.010YANG Naibin. Composite structures for new generation large commercial jet[J]. Acta Aeronautica et Astronautica Sinica,2008,3:596-604(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.010 [5] WAAS V D, HIDAYAT M I P, NOEROCHIM L. Finite element simulation of delamination in carbon fiber/epoxy laminate using cohesive zone model: Effect of meshing variation[J]. Materials Science Forum,2019,964:257-262. doi: 10.4028/www.scientific.net/MSF.964.257 [6] GUAN Z, GUO Y, MENG Q, et al. Comparision of damage characterization of composite laminates under quasi-static indentation and low-velocity impact[C]. 17th International Conference on Composite Materials, 2009. [7] 李西宁, 王悦舜, 周新房. 复合材料层合板分层损伤数值模拟方法现状[J]. 复合材料学报, 2021, 38(4):1076-1086.LI Xining, WANG Yueshun, ZHOU Xinfang. Status of numerical simulation methods for delamination damage of composite laminates[J]. Acta Materiae Compositae Sinica,2021,38(4):1076-1086(in Chinese). [8] DUGDALE D S. Yielding of steel sheets containing slits[J]. Journal of the Mechanics and Physics of Solids,1960,8(2):100-104. doi: 10.1016/0022-5096(60)90013-2 [9] BARENBLATT G I. The mathematical theory of equilibrium cracks in brittle fracture[J]. Advances in Applied Mechanics,1962,7(1):55-129. [10] MI Y, CRISFIELD M A, DAVIES G A O, et al. Progressive delamination using interface elements[J]. Journal of Composite Materials,1998,32(14):1246-1272. doi: 10.1177/002199839803201401 [11] SADIQ M A, ZAFAR N, BUTT H S U, et al. An efficient approach to the design of damage tolerant CFRP stiffened panels[C]//2017 14th International Bhurban Conference on Applied Sciences and Technology (IBCAST). IEEE, 2017: 58-65. [12] LIU B, XU F, FENG W, et al. Experiment and design methods of composite scarf repair for primary-load bearing structures[J]. Composites Part A: Applied Science and Manufacturing,2016,88:27-38. doi: 10.1016/j.compositesa.2016.05.011 [13] 冯威, 徐绯, 袁佳雷. 双斜接修补复合材料层合板的拉伸行为及影响因素[J]. 复合材料学报, 2019, 36(6):1421-1427.FENG Wei, XU Fei, YUAN Jialei. Tensile behavior and effect factors of double scarf-repaired composite laminates[J]. Acta Materiae Compositae Sinica,2019,36(6):1421-1427(in Chinese). [14] 冯威, 徐绯. 冲击作用下斜接修补CFRP层间分层和胶层的损伤机制及参数分析[J]. 复合材料学报, 2018, 35(4):1024-1031.FENG Wei, XU Fei. Damage mechanism of laminates delamination and bondline for scarf repaired CFRP under impact and parameter study[J]. Acta Materiae Compositae Sinica,2018,35(4):1024-1031(in Chinese). [15] 冯威, 徐绯, 由昊, 等. 扩展有限元方法与内聚力模型耦合下斜接修补复合材料的胶层损伤和缺陷[J]. 复合材料学报, 2018, 35(5):1354-1360.FENG Wei, XU Fei, YOU Hao, et al. Adhesive damage and defect analysis of scarf-repaired composite by combining extended finite element method and cohesive zone model[J]. Acta Materiae Compositae Sinica,2018,35(5):1354-1360(in Chinese). [16] LI S, THOULESS M D, WAAS A M, et al. Use of a cohesive-zone model to analyze the fracture of a fiber-reinforced polymer-matrix composite[J]. Composites Science and Technology,2005,65(3-4):537-549. doi: 10.1016/j.compscitech.2004.08.004 [17] LI S, THOULESS M D, WAAS A M, et al. Mixed-mode cohesive-zone models for fracture of an adhesively bonded polymer-matrix composite[J]. Engineering Fracture Mechanics,2006,73(1):64-78. doi: 10.1016/j.engfracmech.2005.07.004 [18] 屈琼. 基于实验的复合材料层合板的界面损伤分析及界面力学性能研究[D]. 福州: 福州大学, 2010.QU Qiong. Experiment-based analysis of interfacial damage in laminates and study on interfacial mechanical properties[D]. Fuzhou: Fuzhou University, 2010 (in Chinese). [19] BOLZON G, GHILOTTI D, MAIER G. Strength of periodic elastic–brittle composites evaluated through homogenization and parameter identification[J]. European Journal of Mechanics-A/Solids,2002,21(3):355-378. doi: 10.1016/S0997-7538(02)01216-0 [20] HARPER P W, HALLETT S R. Cohesive zone length in numerical simulations of composite delamination[J]. Engineering Fracture Mechanics,2008,75(16):4774-4792. doi: 10.1016/j.engfracmech.2008.06.004 [21] TURON A, DAVILA C G, CAMANHO P P, et al. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models[J]. Engineering Fracture Mechanics,2007,74(10):1665-1682. doi: 10.1016/j.engfracmech.2006.08.025 [22] DAVILA C, CAMANHO P, MOURA D M. Mixed-mode decohesion elements for analyses of progressive delamination[C]//19th AIAA Applied Aerodynamics Conference, 2001: 1486. [23] FALK M L, NEEDLEMAN A, RICE J R. A critical evaluation of cohesive zone models of dynamic fracture[J]. Journal De Physique IV,2001,11(Pr5):43-50. [24] ASTM. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528—13[S]. West Conshohocken: ASTM International, 2013. [25] ASTM. Standard test method for determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D7905/D7905M—14[S]. West Conshohocken: ASTM International, 2014. [26] ASTM. Standard test method for mixed mode I-mode II interlaminar fracture toughness of unidirectional fiber reinforced polymer matrix composites: ASTM D6671/D6671M—13[S]. West Conshohocken: ASTM International, 2013. [27] 袁佳雷. 复合材料胶接修复结构的参数化建模研究[D]. 西安: 西北工业大学, 2018.YUAN Jialei. Study on the parameterization modeling of composite bonding structure[D]. Xi'an: Northwestern Polytechnical University, 2018 (in Chinese). [28] ASTM. Standard test method for tensile strength of adhesives by means of bar and rod specimens: ASTM D2095—96[S]. West Conshohocken: ASTM International, 2015. [29] ASTM. Standard test method for strength properties of adhesives in shear by tension loading of single-lap-joint laminated assemblies: ASTM D3165—07[S]. West Conshohocken: ASTM International, 2014. [30] RICE J R. The mechanics of earthquake rupture[M]. Providence: Division of Engineering, Brown University, 1979. [31] HILLERBORG A, MODÉER M, PETERSSON P E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements[J]. Cement and Concrete Research,1976,6(6):773-781. doi: 10.1016/0008-8846(76)90007-7 -

下载:

下载: