Creep model of GFRP composites considering interface effect

-

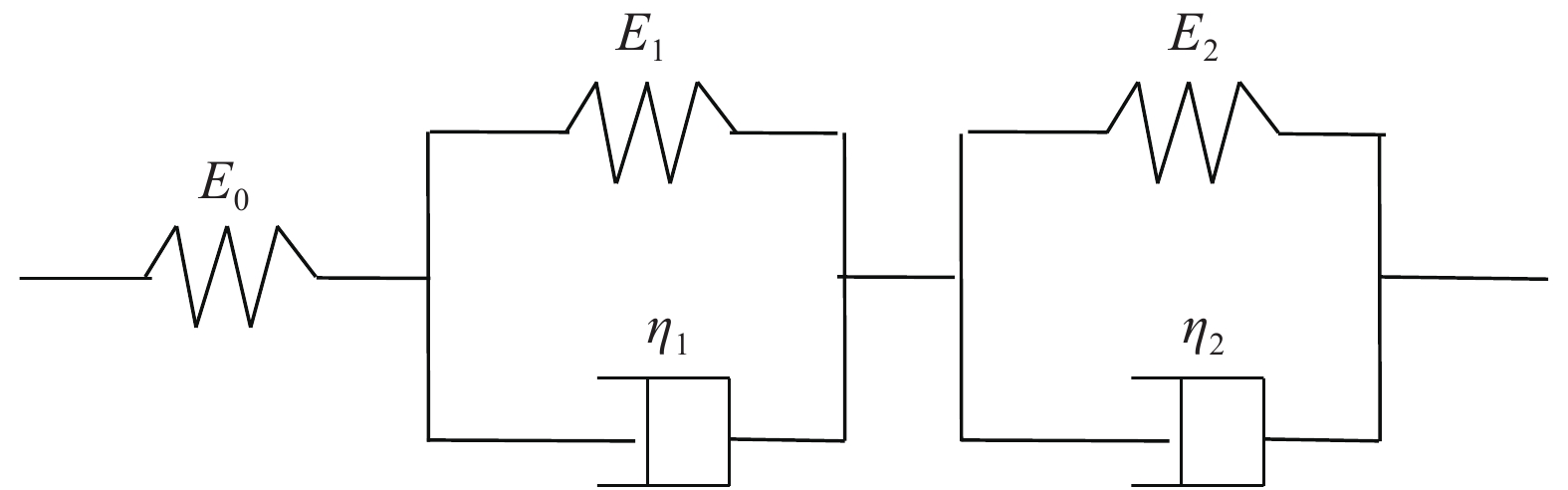

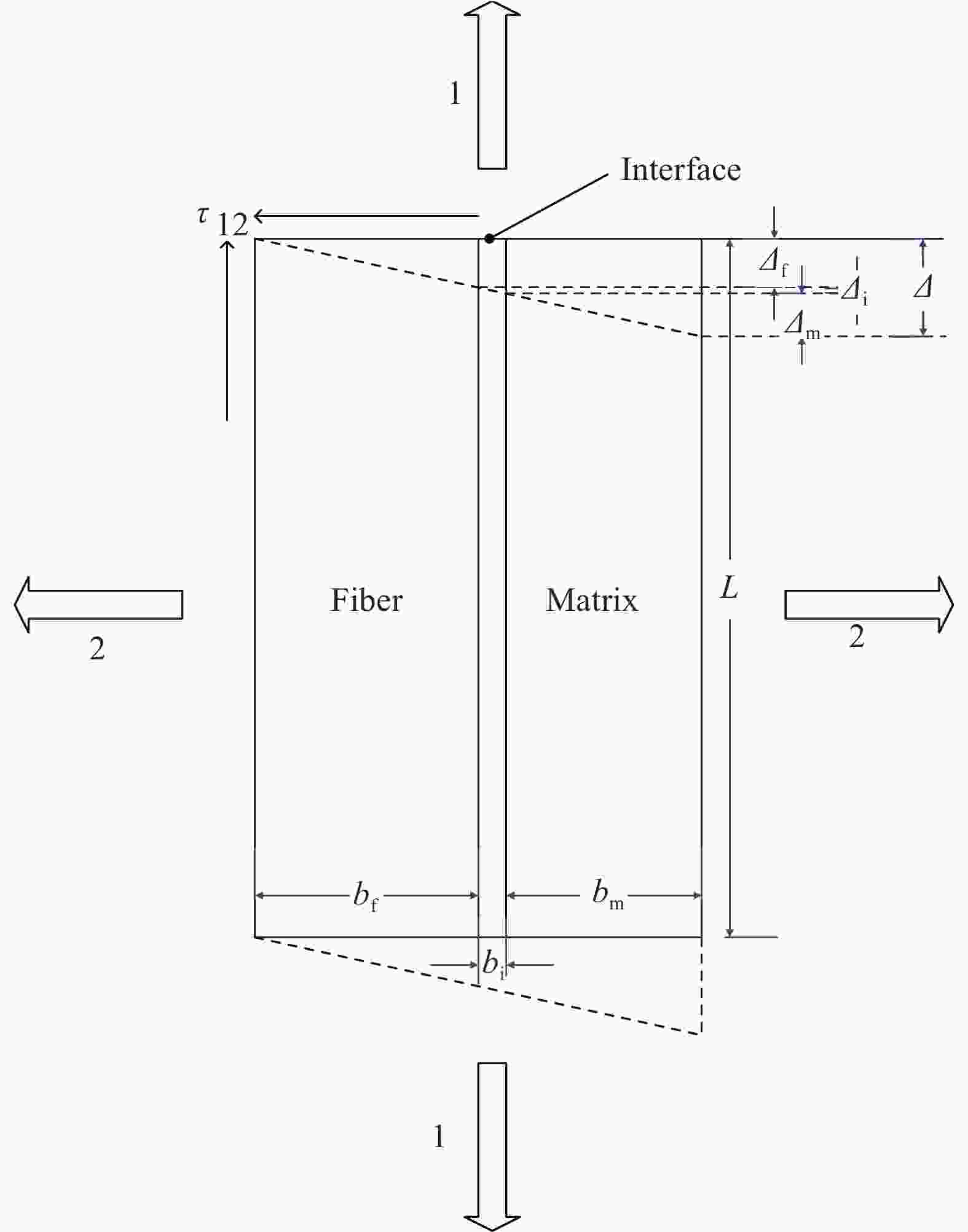

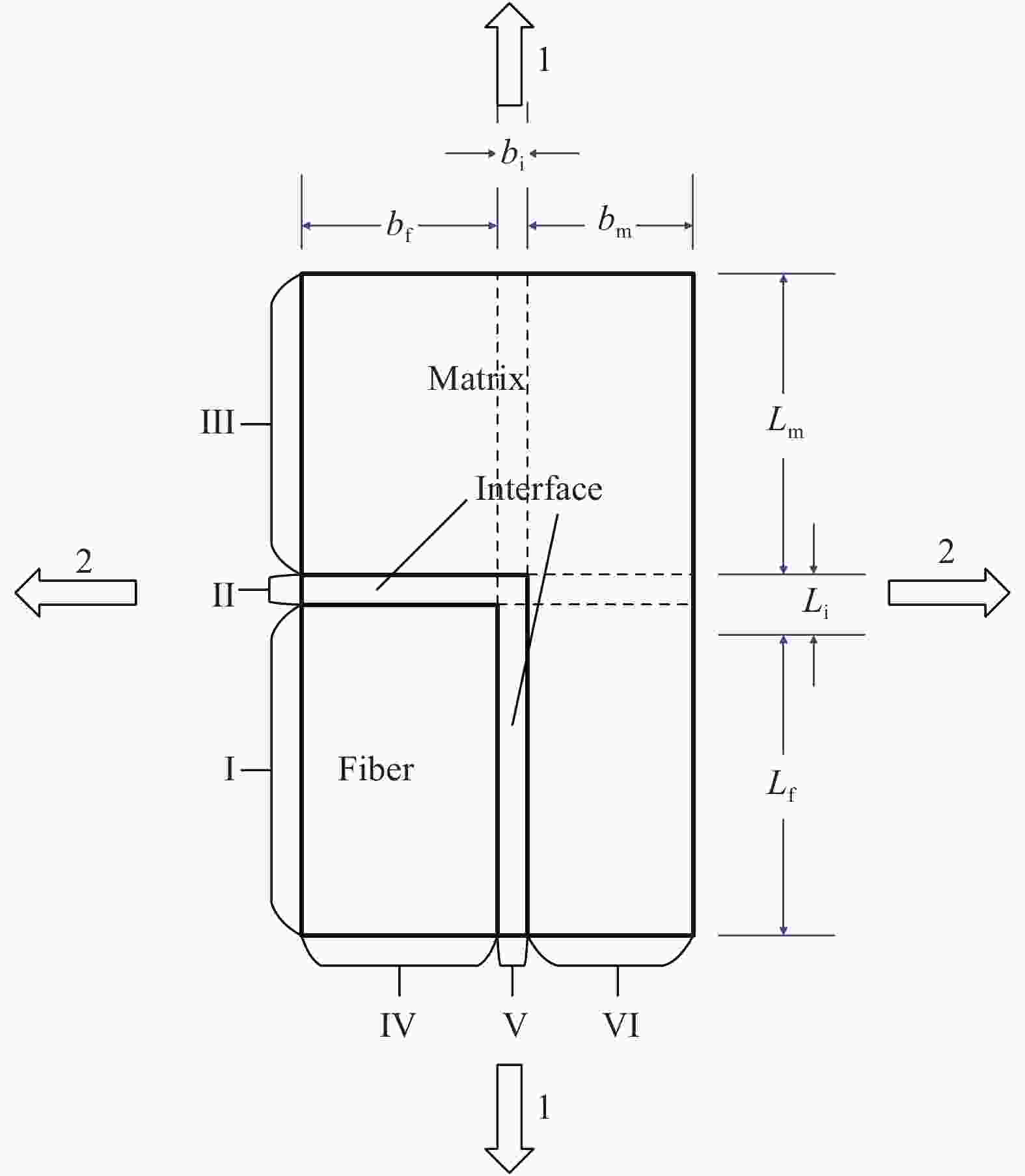

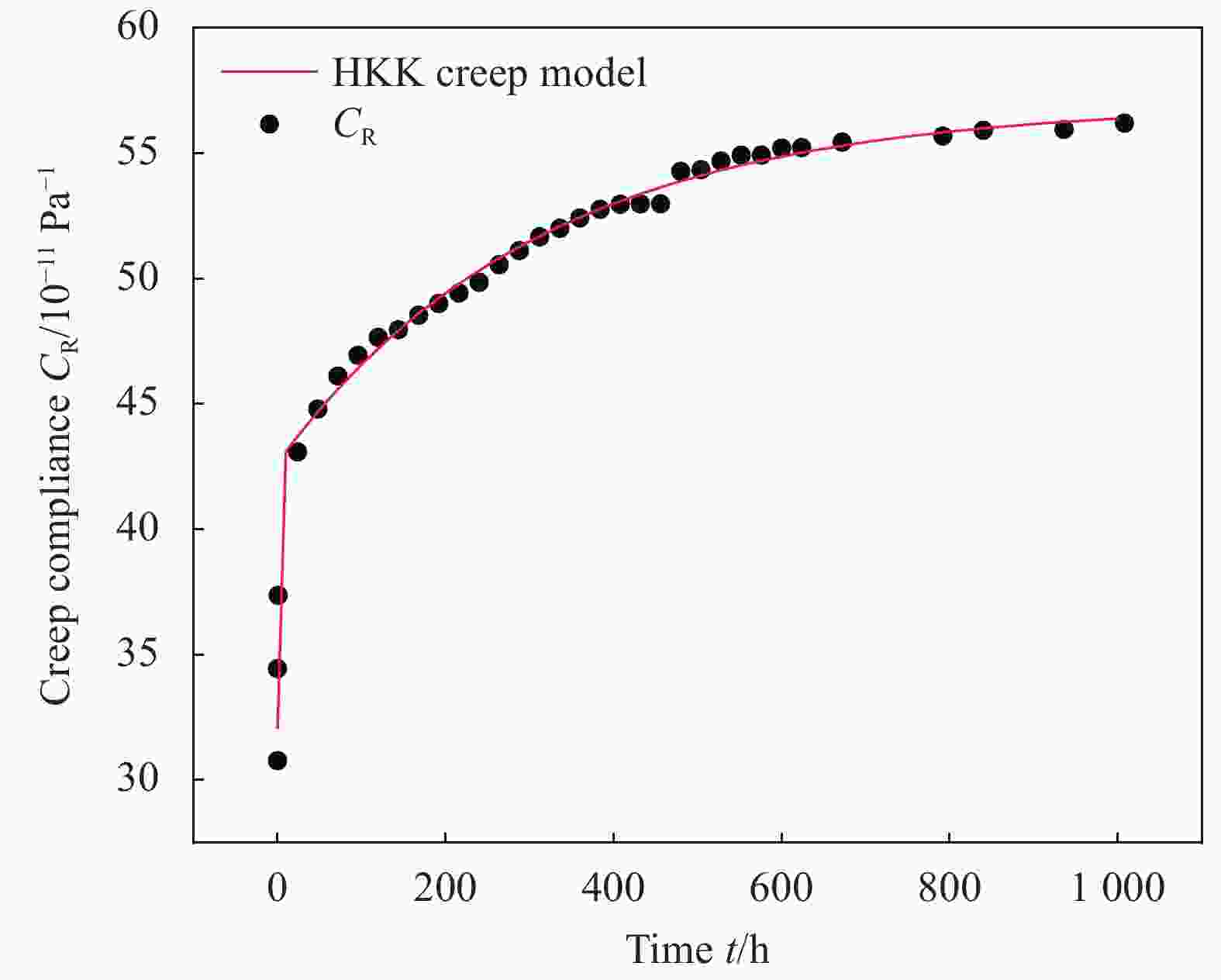

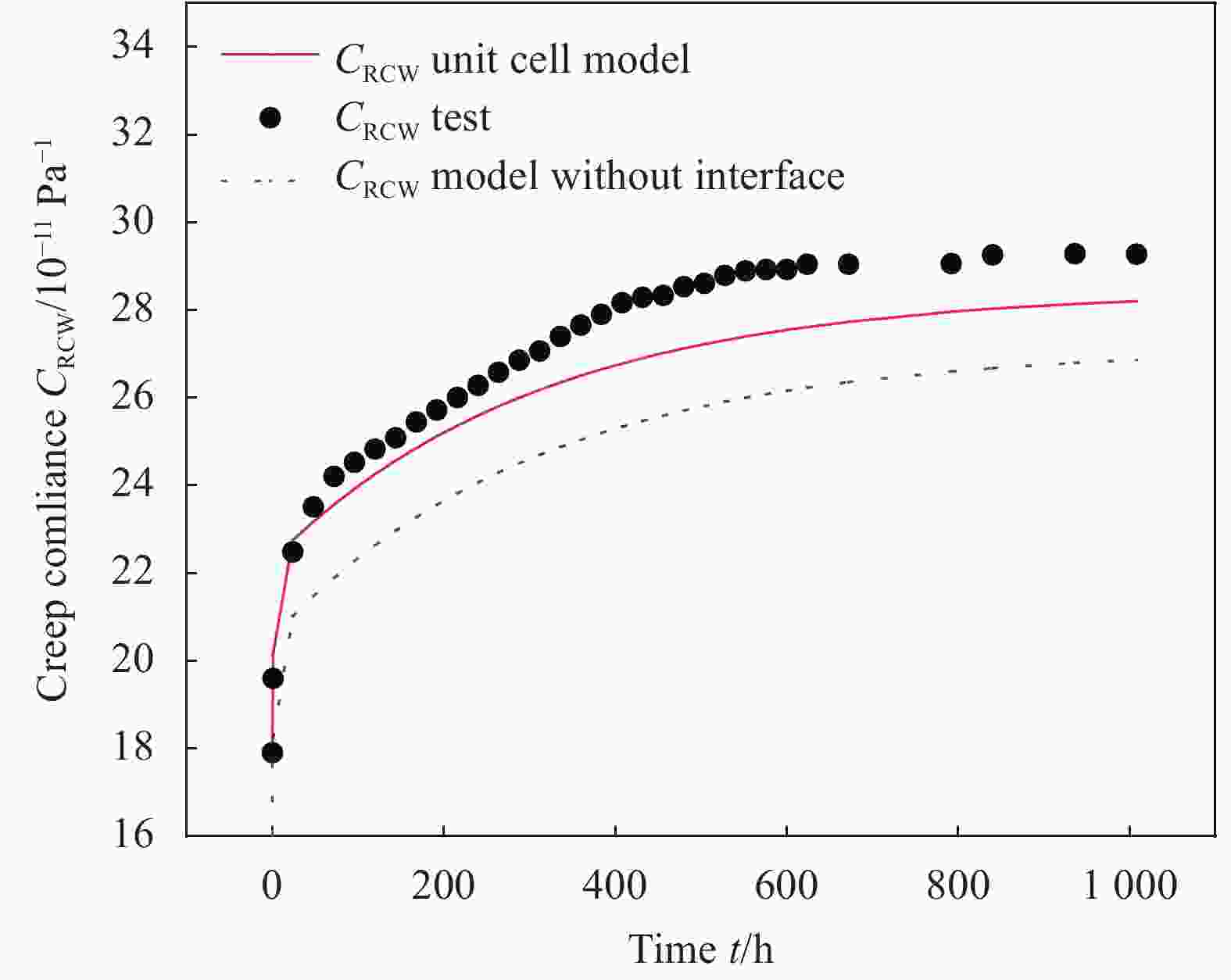

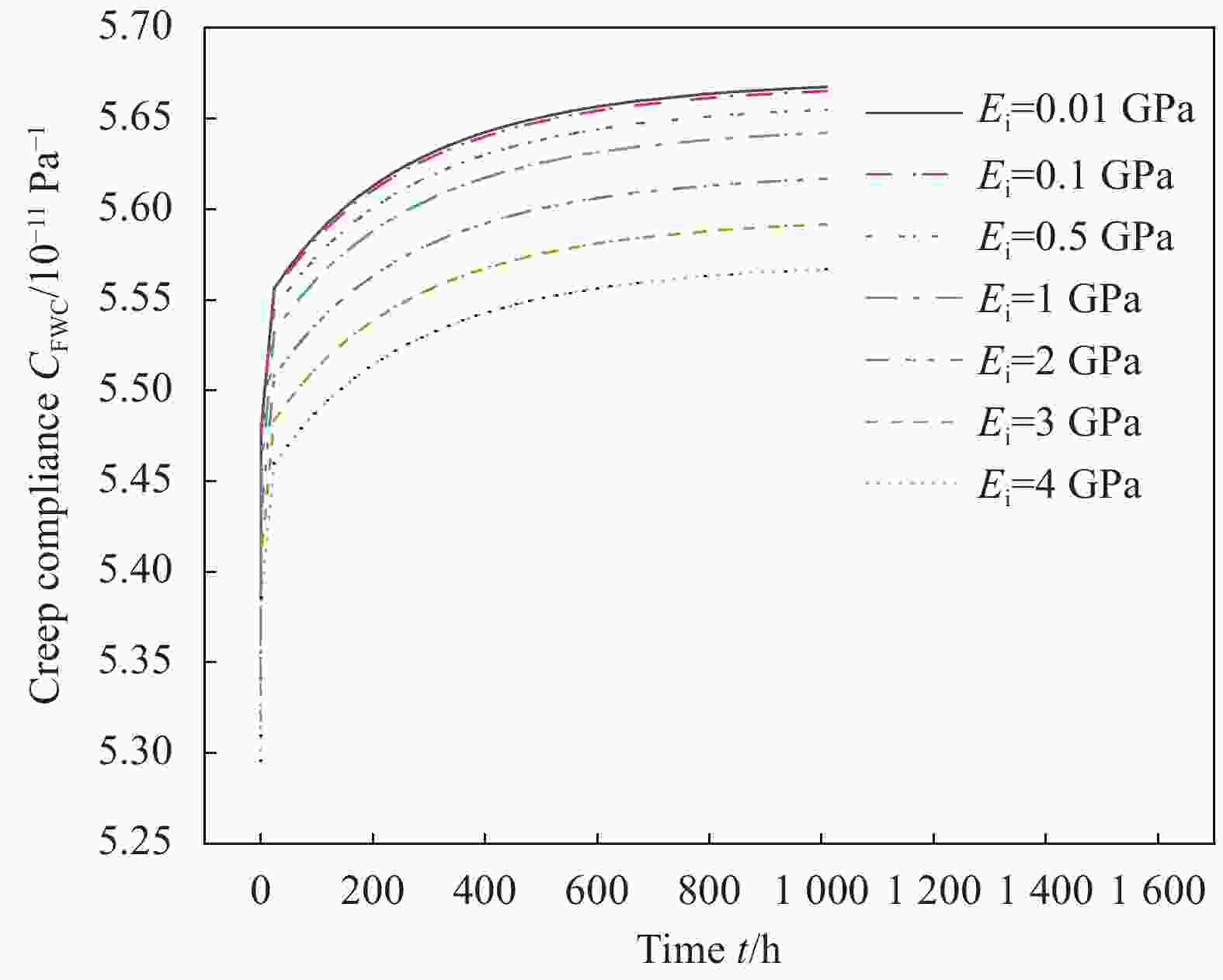

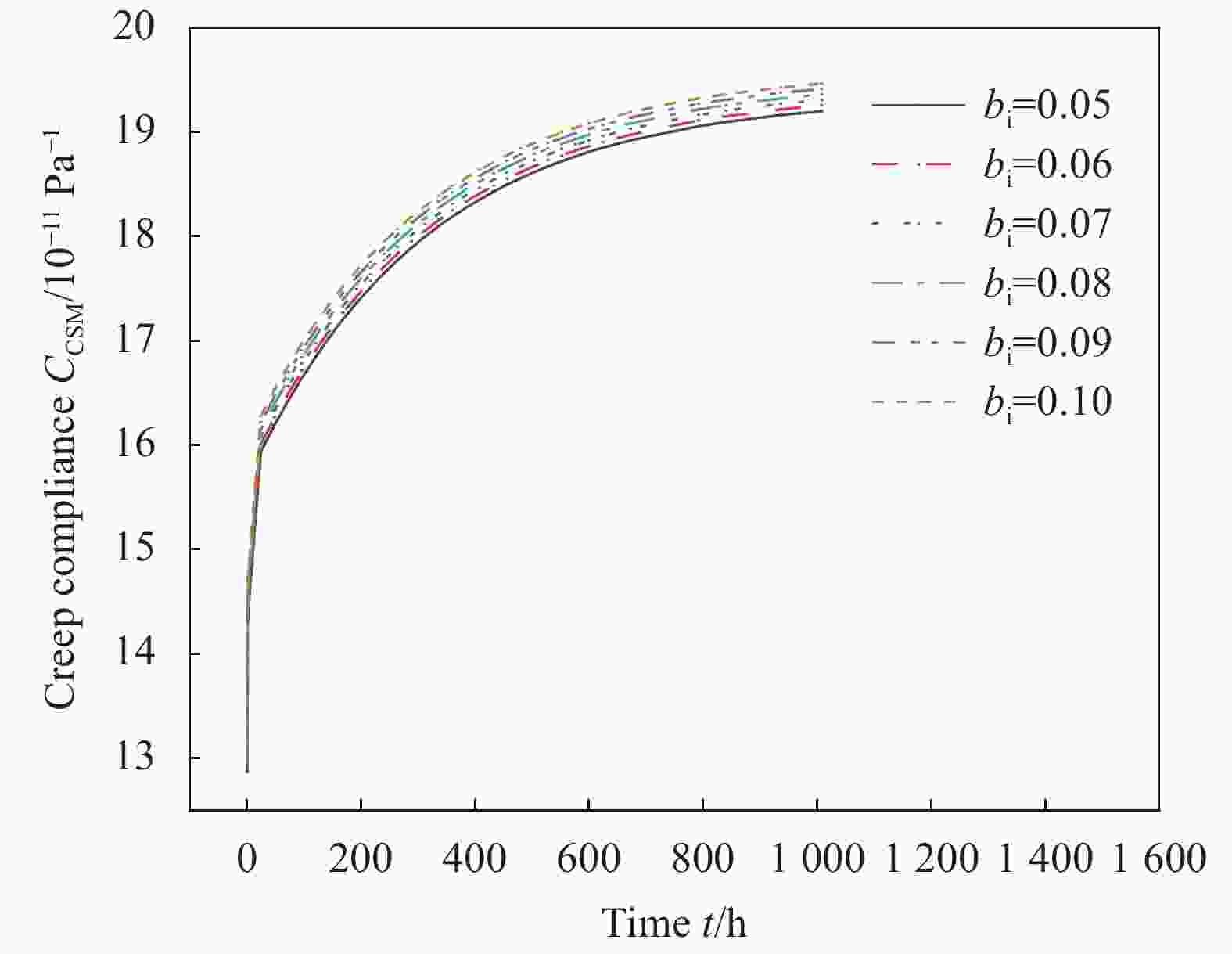

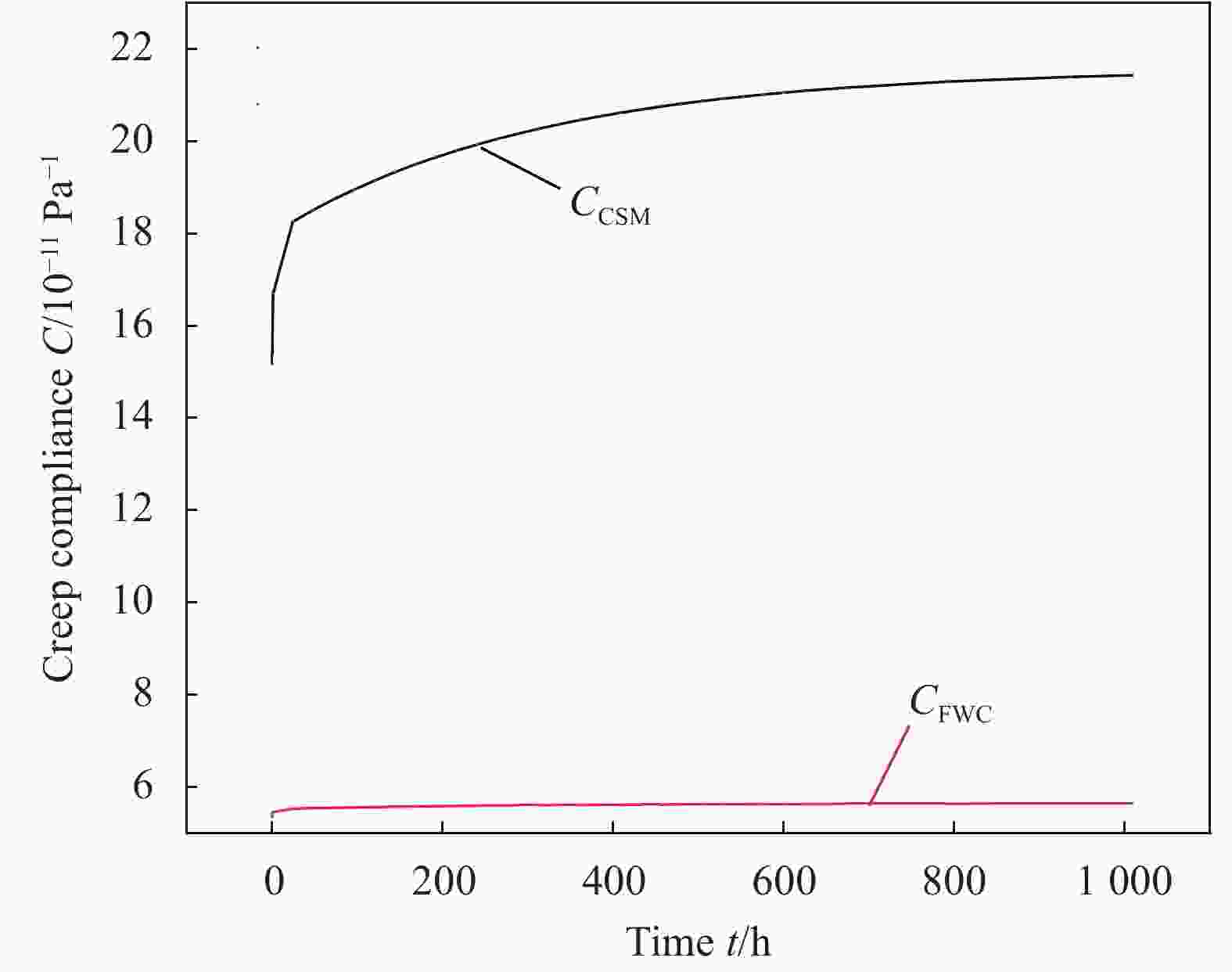

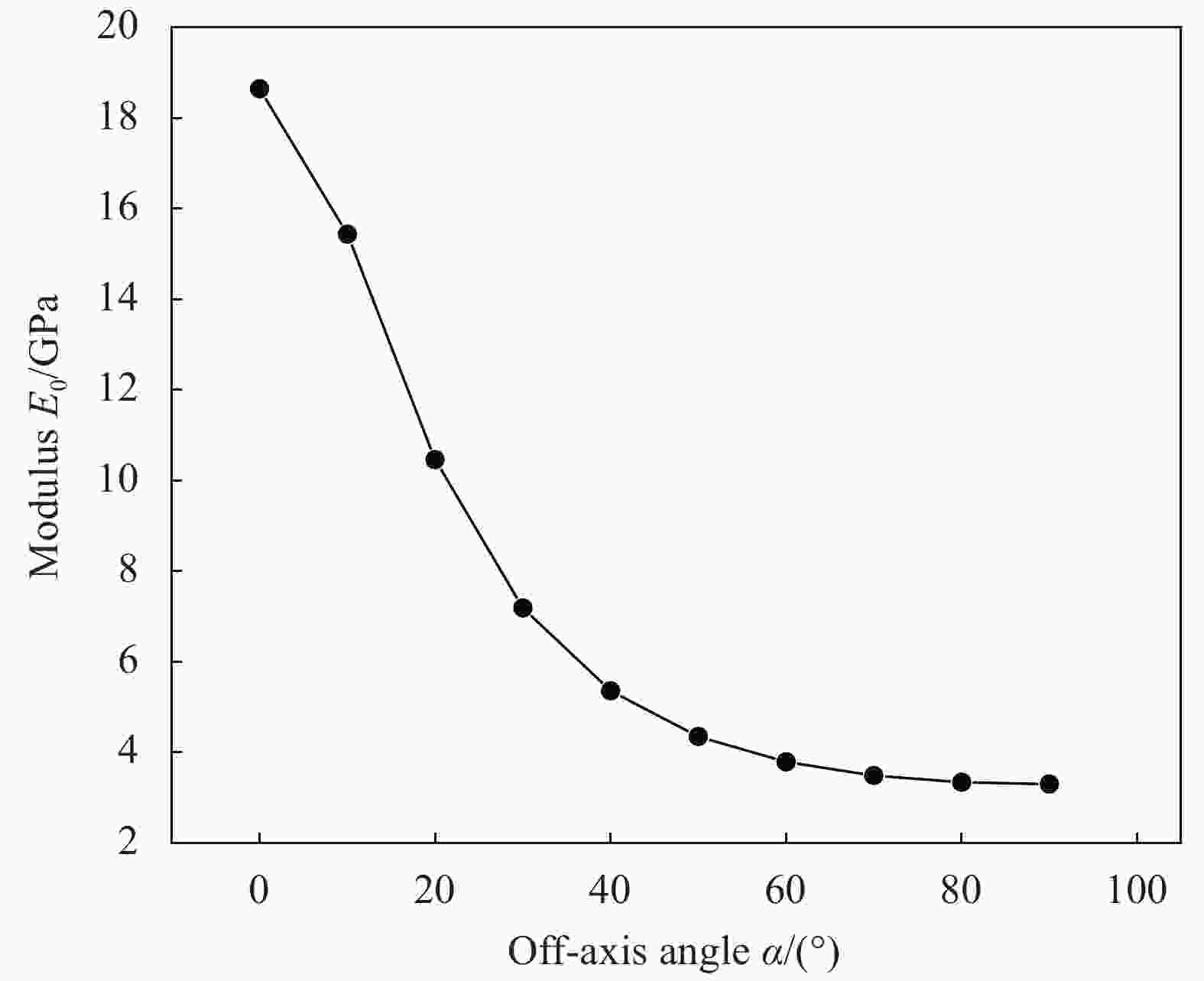

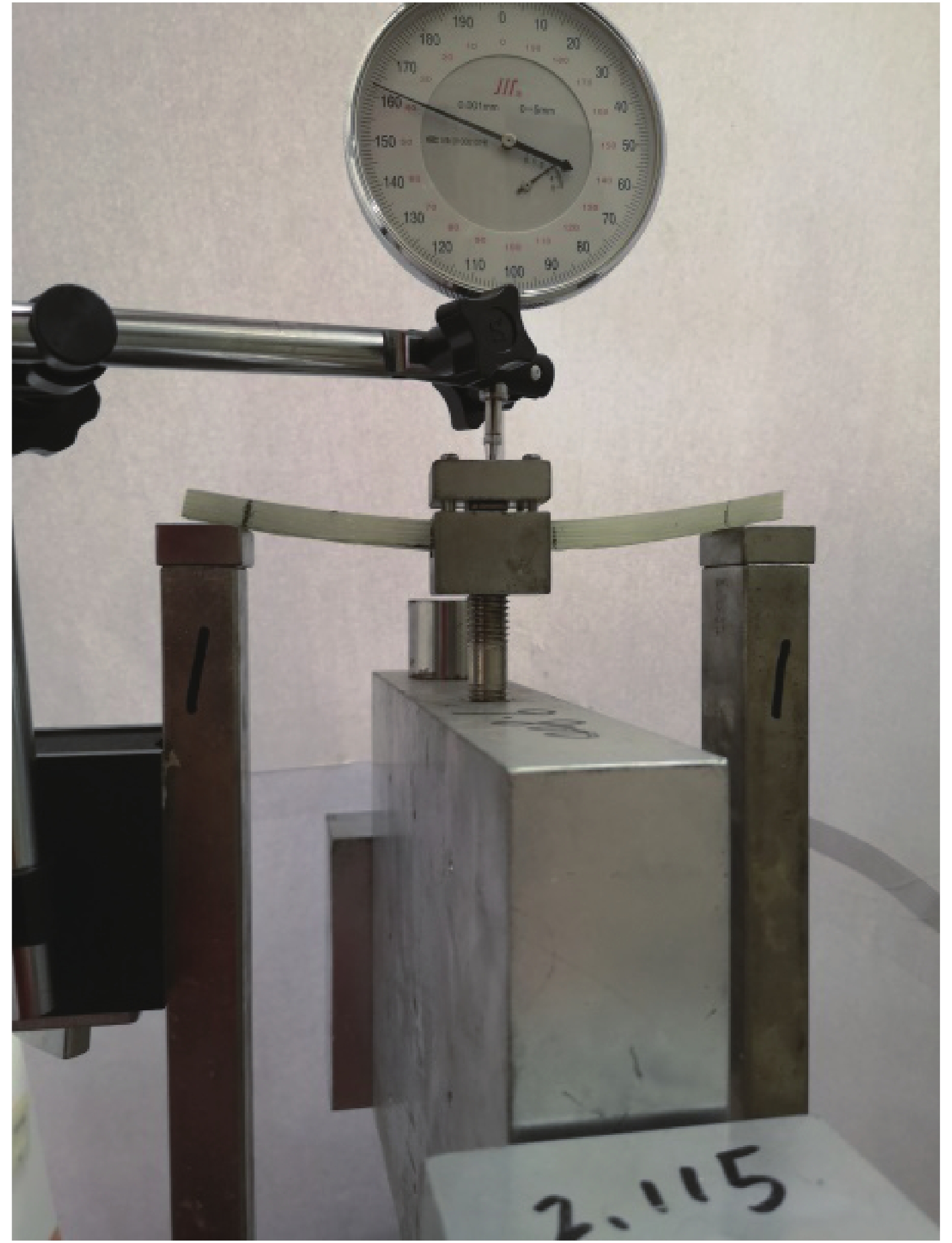

摘要: 建立了包含界面的玻璃纤维增强树脂复合材料(GFRP)蠕变混合率单胞模型,对GFRP的蠕变性能进行分析;并与GFRP在应力水平为初始弯曲强度的20%所对应的载荷下的弯曲蠕变实验结果进行对比。分析了界面模量、界面厚度、纤维连续性与形态以及位向等因素对复合材料蠕变性能的影响。结果表明:相较于不考虑界面效应的混合率模型,本模型具有更高的准确性,与实验结果更为吻合;界面模量反应了纤维与基体的结合程度,对复合材料的蠕变性能产生影响,其蠕变柔量随着界面模量的增大而减小;界面厚度的增大会导致复合材料的蠕变柔量略微增大;相较于连续纤维增强树脂复合材料,短切纤维毡增强树脂复合材料的蠕变性能更易受到界面效应的影响;纤维方向对复合材料蠕变性能有显著影响,随着纤维方向角的增大,复合材料蠕变柔量增大,但当纤维方向角达到60°后,纤维已基本失去载荷传递和增强能力,复合材料蠕变柔量不再继续随着纤维方向角的增大而增大。Abstract: A unit cell model of creep mixing rate containing interface for glass fiber/resin composite (GFRP) was established to analyze the long-term creep property of GFRP. The experimental results of bending creep of GFRP under loads with the stress level of 20% of the initial bending strength were compared. The effects of interfacial modulus, interfacial thickness, fiber continuity, morphology and orientation on the long-term creep properties of composites were analyzed. The results show that this model is more accurate and more consistent with the experimental results compared with the mixing rate model without considering the interface effect. Interfacial modulus reflects the degree of binding between fiber and matrix, and affects the creep property of composite. The creep compliance decreases with the increase of interface modulus. The creep compliance of the composite increases slightly with the increase of the interfacial thickness. Compared with continuous fiber reinforced resin composites, the creep properties of chopped strand mat reinforced resin composite are more easily affected by interfacial effects. The fiber direction has a significant influence on the creep performance of composite materials. With the increase of fiber direction angle, the creep compliance of composite increases. However, when the fiber direction angle reaches 60°, the fiber has basically lost the load transfer and reinforcing ability, and the creep compliance of composite materials no longer increases with the increase of fiber direction angle.

-

Key words:

- composite /

- interface effect /

- creep /

- unit cell model /

- mixing ratio

-

表 1 玻璃纤维增强树脂复合材料(GFRP)试样初始强度及树脂质量分数

Table 1. Initial strength and resin mass fraction of glass fiber reinforced polymer (GFRP) samples

Sample σb/MPa Wt/% FWC/R 932.8 28 FWA/R 40 28 RCW/R 74.5 32 CSM/R 165.8 70 Notes: FWC/R—Filament wound (circumferential)/resin composites; FWA/R—Filament wound (axial)/resin composites; RCW/R—Reciprocating cross wound/resin composites; CSM/R—Chopped strand mat/resin composites; σb—Initial strength; Wt—Resin mass fraction. -

[1] 刘伟庆, 方海, 方园. 纤维增强复合材料及其结构研究进展[J]. 建筑结构学报, 2019, 40(4):1-16.LIU W Q, FANG H, FANG Y. Research progress of fiber-reinforced composites and structures[J]. Journal of Building Structures,2019,40(4):1-16(in Chinese). [2] BERARDI V P, PERRELLA M, FEO L, et al. Creep behavior of GFRP laminates and their phases: Experimental investigation and analytical modeling[J]. Composites Part B: Engineering,2017,122B(8):136-144. [3] ZHANG X, HUANG Q, CHEN J, et al. Prediction of viscoelastic behavior of unidirectional polymer matrix composites[J]. Journal of Wuhan University of Technology (Materials Science),2016,31(3):695-699. doi: 10.1007/s11595-016-1431-7 [4] 梁军, 杜善义. 黏弹性复合材料力学性能的细观研究[J]. 复合材料学报, 2001, 18 (1):97-100. doi: 10.3321/j.issn:1000-3851.2001.01.023LIANG J, DU S Y. Study of mechanical properties of viscoelastic matrix composite by micromechanics[J]. Acta Materiae Compositae Sinica,2001,18 (1):97-100(in Chinese). doi: 10.3321/j.issn:1000-3851.2001.01.023 [5] 钟轶峰, 杨旦旦, 周小平, 等. 聚合物基复合材料有效蠕变响应与单轴拉伸行为的细观力学模拟[J]. 复合材料学报, 2016, 33(12):2911-2917.ZHONG Y F, YANG D D, ZHOU X P, et al. Effective creep response and uniaxial tension behavior of polymer matrix composites simulated by mesomechanics[J]. Acta Materiae Compositae Sinica,2016,33(12):2911-2917(in Chinese). [6] NEDJAR B. Modeling long-term creep rupture by debonding in unidirectional fibre-reinforced composites[J]. International Journal of Solids Structure 2014, 51(10): 1962-1969. [7] BERARDI V P, MANCUSI G. A mechanical model for predicting the long term behavior of reinforced polymer concretes[J]. Mechanics Research Communications,2013,50:1-7. doi: 10.1016/j.mechrescom.2013.02.001 [8] NEDJAR B. Directional damage gradient modeling of fiber/matrix debonding in viscoelastic UD composites[J]. Composite Structures,2016,153(10):895-901. [9] CHEVALI V S, JANOWSKI G M. Flexural creep of long fiber-reinforced thermoplastic composites: Effect of processing-dependent fiber variables on creep response[J]. Composites Part A: Applied Science and Manufacturing,2010,41(9):1253-1262. doi: 10.1016/j.compositesa.2010.05.008 [10] PULNGERN T, CHITSAMRAN T, CHUCHEEP-SAKUL S, et al. Effect of temperature on mechanical properties and creep responses for wood/PVC composites[J]. Construction and Building Materials,2016,111:191-198. doi: 10.1016/j.conbuildmat.2016.02.051 [11] 梁娜, 朱四荣, 陈建中. 一种新的聚合物基复合材料应力松弛经验模型[J]. 复合材料学报, 2017, 34(10):2205-2210.LIANG N, ZHU S R, CHAN J Z, et, al. A new empirical model for stress relaxation of polymer matrix[J]. Acta Materiae Compositae Sinica,2017,34(10):2205-2210(in Chinese). [12] 张小玉, 黄乾钰, 陈建中, 等. 聚合物基复合材料单向板黏弹性模型[J]. 华中科技大学学报: 自然科学版, 2015, 43(01):30-33.ZHANG X Y, HUANG Q Y, CHEN J Z, et al. The viscoelastic model of PMC unidirectional plates[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2015,43(01):30-33(in Chinese). [13] MIYANO Y, NAKADA M, ICHIMURA J, et al. Accelerated testing for long-term strength of innovative CFRP laminates for marine use[J]. Composites Part B: Engineering, 2008, 39(1): 5-12. [14] MASOUMI S, SALEHI M, AKHLAGHI M. Nonlinear viscoelastic analysis of laminated composite plates-a multi scale approach[J]. International Journal of Recent Advances in Mechanical Engineering,2013,2(2):11-18. [15] 梁基照. 聚合物复合材料界面层厚度的估算[J]. 合成橡胶工业, 1999(05):285-287.LIANG J Z. Estimation of interlayer thickness of polymer composites[J]. China Synthetic Rubber Industry,1999(05):285-287(in Chinese). [16] TOTRY E, MOLINA-ALDAREGUÍA J M, GONZÁLEZ C, et al. Effect of fiber, matrix and interface properties on the in-plane shear deformation of carbon-fiber reinforced composites[J]. Composites Science and Technology,2010,70(6):970-980. doi: 10.1016/j.compscitech.2010.02.014 [17] WANG J, BEYERLEIN I J, MARA N A, et al. Interface-facilitated deformation twinning in copper within submicron Ag–Cu multilayered composites[J]. Scripta Materialia,2011,64(12):1083-1086. doi: 10.1016/j.scriptamat.2011.02.025 [18] ZHANG Y, WU G. Comparative study on the interface and mechanical properties of T700/Al and M40/Al composites[J]. Rare Metals,2010,29(1):102-107. doi: 10.1007/s12598-010-0018-2 [19] ZHANG R L, HUANG Y D, LIU L, et al. Effect of the molecular weight of sizing agent on the surface of carbon fibres and interface of its composites[J]. Applied Surface Science,2011,257(6):1840-1844. doi: 10.1016/j.apsusc.2010.08.102 [20] ZHANG Y H, WU G H. Interface and thermal expansion of carbon fiber reinforced aluminum matrix composites[J]. Transactions of Nonferrous Metals Society of China,2010,20(11):2148-2151. doi: 10.1016/S1003-6326(09)60433-7 [21] UDAYAKUMAR A, BALASUBRAMANIAN M, GOPALA H B, et al. Influence of the type of interface on the tribological characteristics of ICVI generated SiCf/SiC composites[J]. Wear,2011,271(5-6):859-865. doi: 10.1016/j.wear.2011.03.029 [22] 田君, 钟守炎, 石子琼, 等. 界面对硅酸铝短纤维增强AZ91D镁基复合材料蠕变性能的影响[J]. 复合材料学报, 2014, 31(04):955-962.TIAN J, ZHONG S Y, SHI Z Q, et al. Interface effects on creep properties of aluminum silicate short fiber reinforced AZ91D magnesium matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(04):955-962(in Chinese). [23] 姜云鹏, 岳珠峰, 万建松. 界面特性对短纤维金属基复合材料蠕变行为的影响[J]. 计算力学学报, 2003(6):743-748. doi: 10.3969/j.issn.1007-4708.2003.06.016JIANG Y P, YUE Z F, WAN J S. On the study of the influence of the interphase properties on the creep behavior of short fiber enforced metal matrix composites[J]. Chinese Journal of Computational Mechanics,2003(6):743-748(in Chinese). doi: 10.3969/j.issn.1007-4708.2003.06.016 [24] 梁娜, 朱四荣, 陈建中. 聚合物基复合材料在低应力下的蠕变模型[C]//第二十一届全国玻璃钢/复合材料学术年会论文集(《玻璃钢/复合材料》2016增刊). 玻璃钢/复合材料, 2016: 4.LIANG N, ZHU S R, CHEN J Z. Creep model of polymer matrix composites under low stress[C]//21th Annual Academic Conference on FRP/CM. Fiber Reinforced Plastics/Composites, 2016: 4(in Chinese). [25] 王耀先. 复合材料力学与结构设计[M]. 上海: 华东理工大学出版社, 2012: 28-38.WANG Y X. Echanics and structural design of composite materials[M]. Shanghai: East China University of Science and Technology Press, 2012: 28-38(in Chinese). [26] MAI K, MDÄER E, MÜHLE M. Interphase characterization in composites with new non-destructive methods[J]. Composites Part A: Applied Science and Manufacturing, 1998, 29: 1111-1119. -

下载:

下载: