Bisphenol A type o-phthalonitrile resin modified silicoalkyne hybrid resin and its composite properties

-

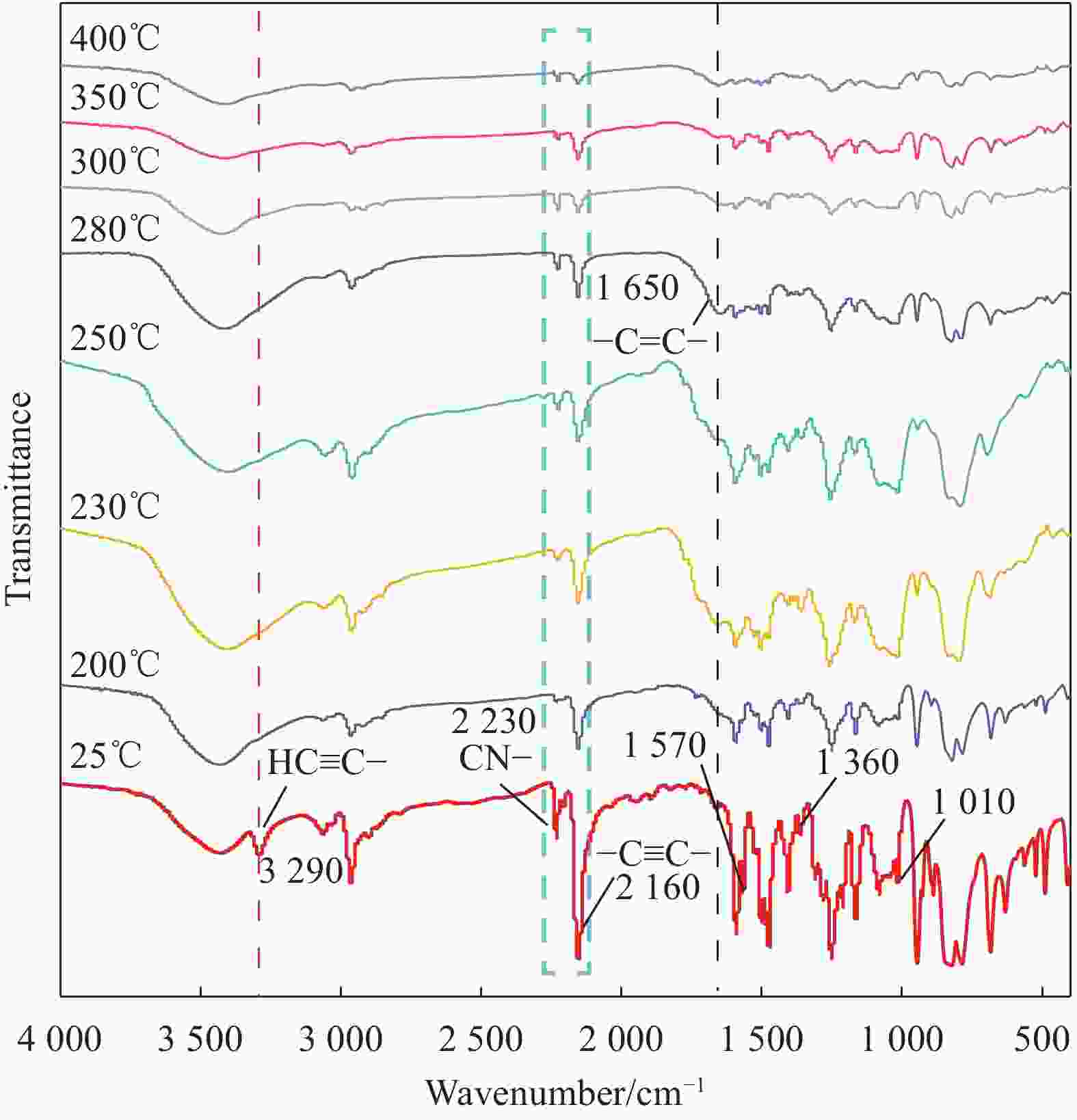

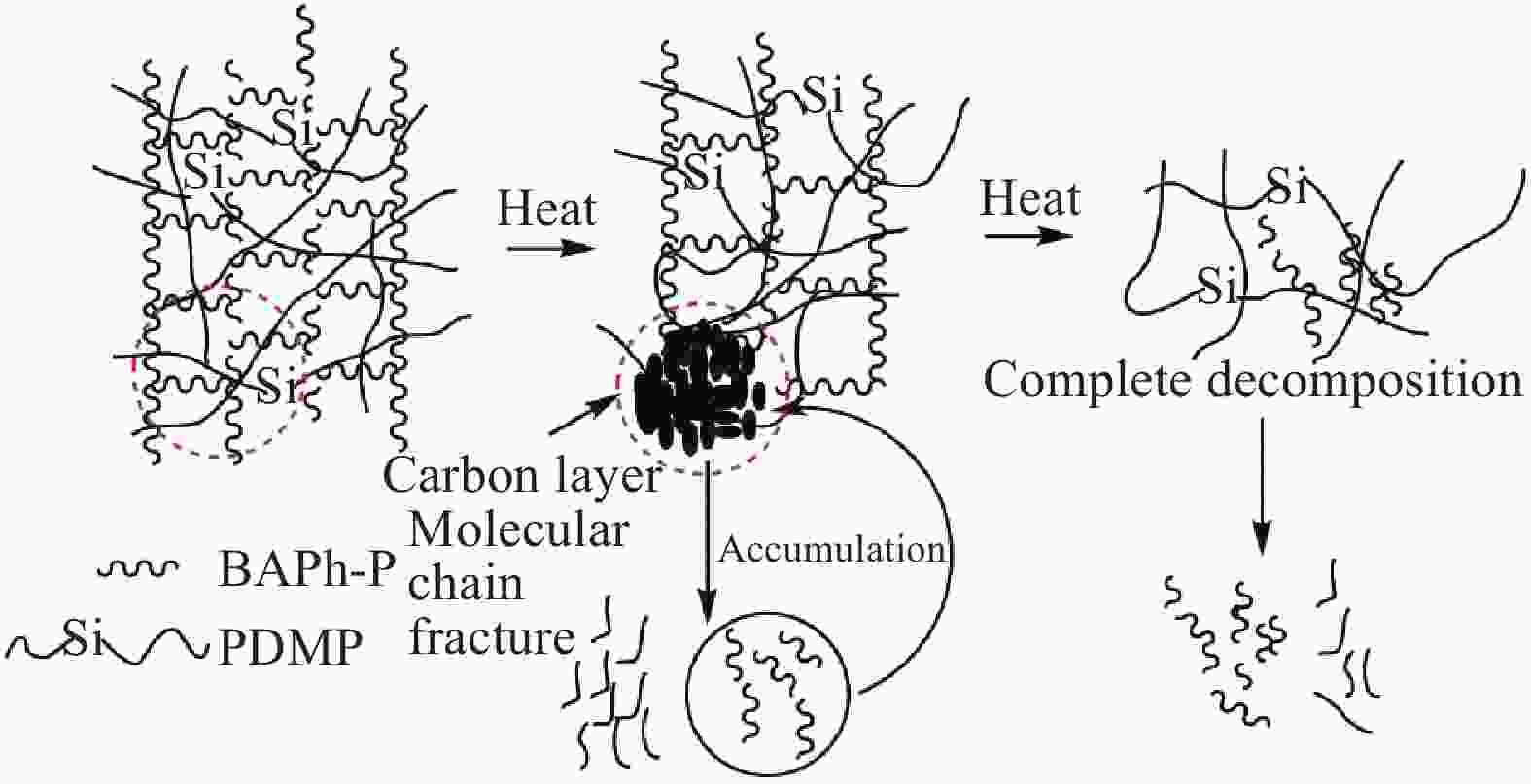

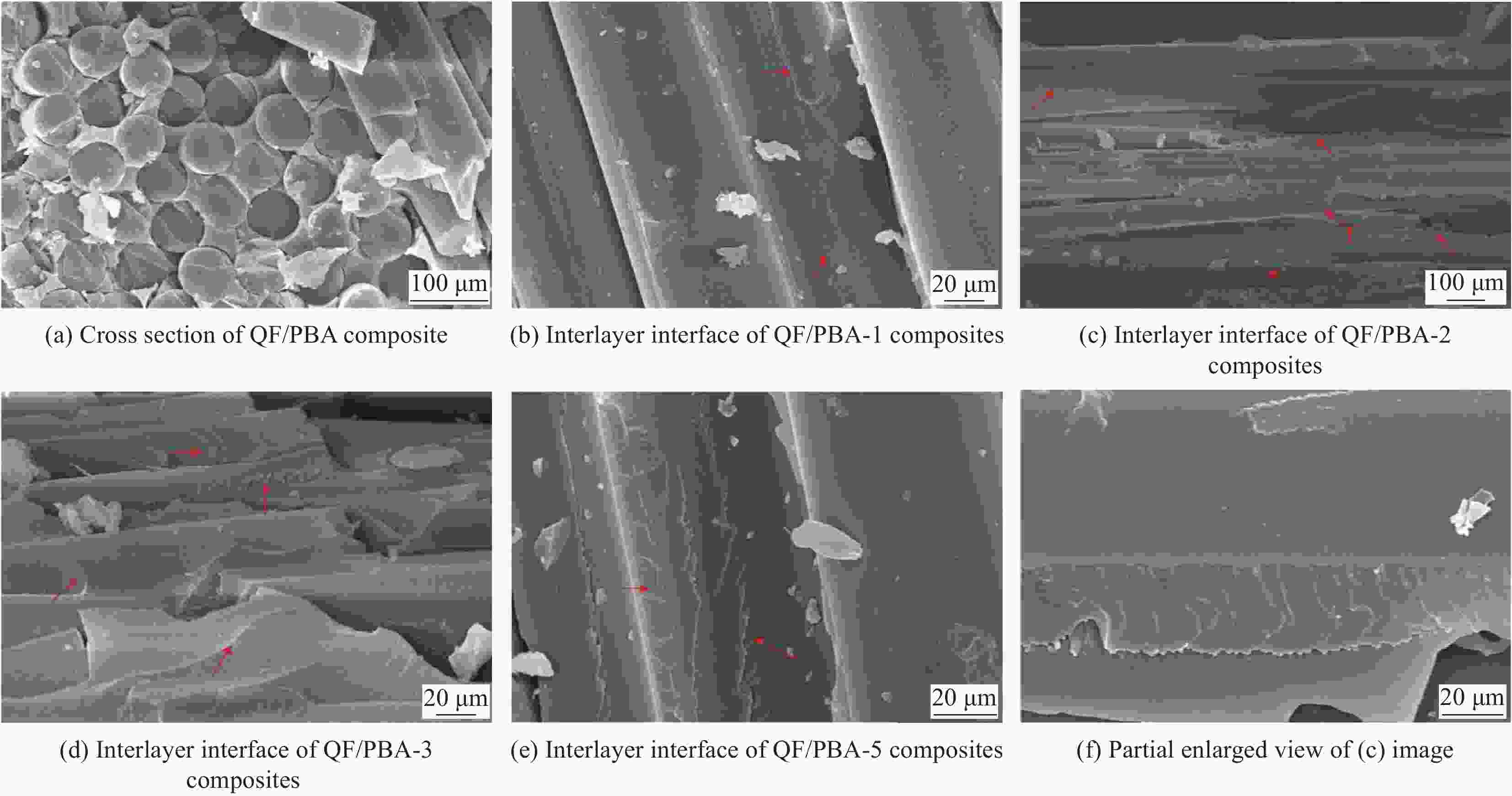

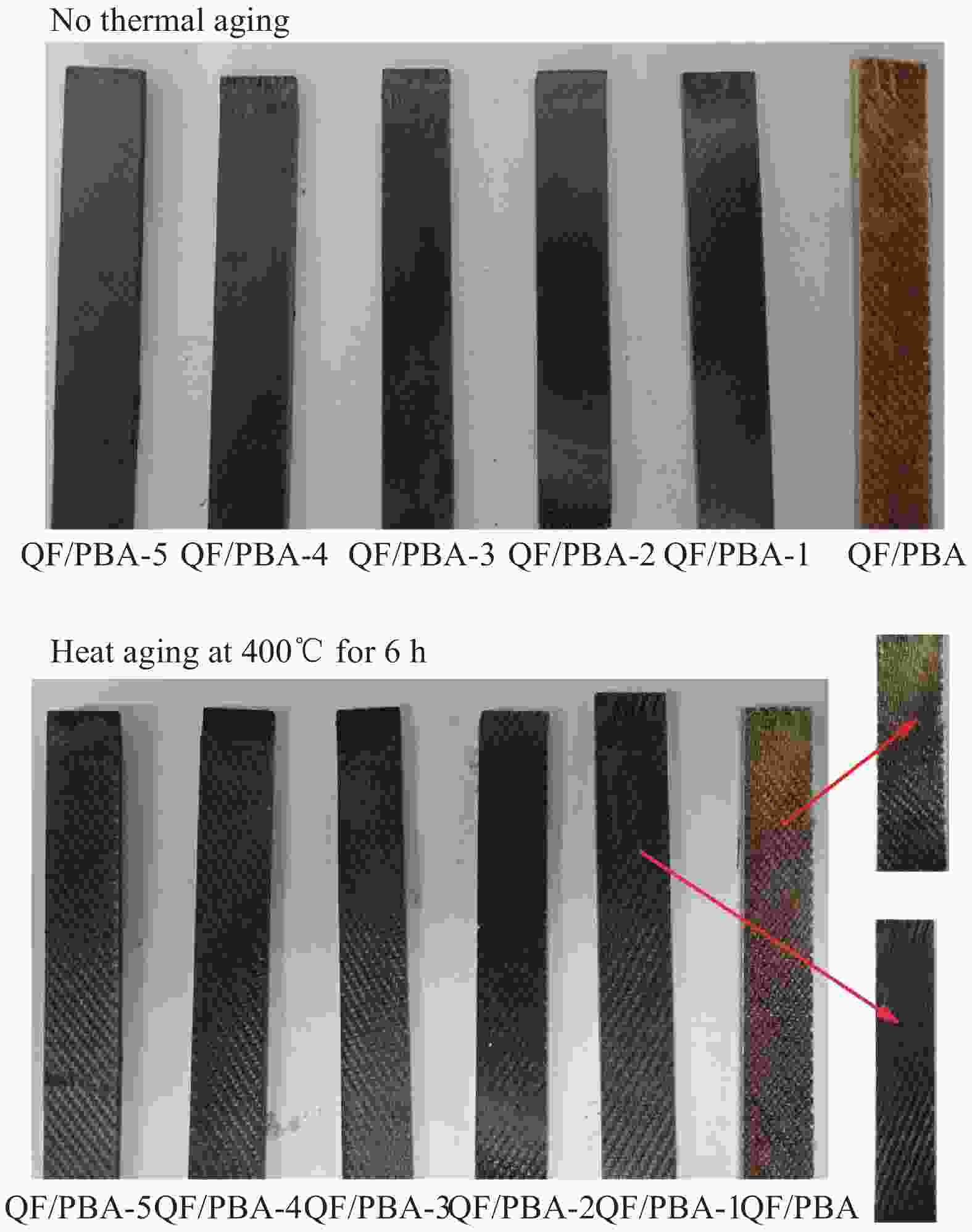

摘要: 采用双酚A型邻苯二甲腈预聚树脂(BAPh-P)改性聚(间二乙炔基苯-二甲基硅烷)树脂(PDMP)制备了双酚A型邻苯二甲腈/聚(间二乙炔基苯-二甲基硅烷)树脂(PBA),利用DSC、FTIR、流变分析、TGA等技术分析其固化行为、黏度以及耐热性变化。结果表明,PBA树脂固化峰值温度较PDMP升高;固化反应主要为炔基的Diels-Alder和加成反应、氰基进一步交联生成三嗪环和酞菁环等结构反应;BAPh-P的加入提升了PDMP在空气下的耐热性,PBA-1(PDMP:BAPh-P质量比为5∶1)树脂固化物在N2和空气氛围质量损失5%的温度(Td5)分别为640.6℃和591℃,1000℃质量保留率为89.0%和26.9%;随着BAPh-P质量增加,PBA树脂固化物Td5呈下降趋势,但空气中Td5均高于PDMP;石英纤维增强PBA树脂基(QF/PBA)复合材料随BAPh-P质量增加室温弯曲强度逐渐升高,高温弯曲强度先升高后降低;其中QF/PBA-2复合材料室温和400℃弯曲强度分别为363 MPa和330 MPa,较PDMP分别提升91%和214%,室温和400℃的层间剪切强度(ILSS)分别为37.5 MPa和22.2 MPa。Abstract: Bisphenol A-type phthalonitrile/poly (dimethylsilane-m-diacetylenyl phenyl) resin (PBA) was prepared by modifying Poly (dimethylsilane-m-diacetylenyl phenyl) resin (PDMP) with bisphenol A-type phthalonitrile prepolymer (BAPh-P). The curing behavior, viscosity and heat resistance were analyzed by DSC, FTIR, rheological analysis and TGA. The results show that the curing peak temperature of PBA resin is higher than that of PDMP; the curing reaction is mainly Diels alder and addition reaction of alkynyl group, triazine ring and phthalocyanine ring formed by cyano further crosslinking; heat resistance of PDMP in air is improved by the addition of BAPh-P, and temperature with mass loss of 5% (Td5) of PBA-1 (PDMP: BAPh-P mass ratio of 5∶1) in N2 and air is 640.6℃ and 591℃, respectively, and mass retention rates at 1000℃ is 89.0% and 26.9%; with the increase of BAPh-P mass, the Td5 of PBA resin curing compound decreases, but the Td5 in air is higher than that of PDMP; The bending strength of quartz fiber reinforced PBA resin matrix (QF/PBA) composites increases gradually at room temperature with the increase of BAPh-P mass, and then decreases at high temperature; flexural strength of QF/PBA-2 composite at room temperature and 400℃ is 363 MPa and 330 MPa, respectively, which is higher than that of PDMP, interlaminar shear strength (ILSS) at room temperature and 400℃ is 37.5 MPa and 22.2 MPa, respectively.

-

表 1 双酚 A 型邻苯二甲腈/聚 (间二乙炔基苯-二甲基硅烷)树脂(PBA)树脂配方

Table 1. Bisphenol A-type phthalonitrile/poly (dimethylsilane-m-diacetylenyl phenyl) resin (PBA) resin formula

Sample Resin mass ratio PDMP BAPh-P PBA-1 5 1 PBA-2 5 2 PBA-3 5 3 PBA-4 5 4 PBA-5 5 5 Notes: PDMP—Poly (dimethylsilane-m-diacetylenyl phenyl) resin; BAPh-P—Bisphenol A-type phthalonitrile prepolymer. 表 2 PDMP和BAPh树脂溶解性

Table 2. Solubility of PDMP and BAPh resin

Solvent BAPh BAPh-P15 PDMP Acetone − +− − THF +− ++ ++ Toluene − +− ++ Dioxane − ++ ++ Ethyl acetate − +− − DMF ++ ++ − Notes:++—Soluble; +-—Partial soluble; −—Insoluble; BAPh-P15—BAPh-P after 4,4-diaminodiphenyl sulfone (DDS) prepoly−merization was added; THF—Tetrahydrofuran; DMF—Dimethyl formamide. 表 3 400℃固化2 h后PBA树脂固化度

Table 3. Curing degree of PBA resin after 2 h curing at 400℃

Sample Curing degree/% PBA-1 98.80 PBA-2 98.78 PBA-3 98.53 PBA-4 97.40 PBA-5 97.25 表 4 PBA树脂固化物的TGA数据

Table 4. TGA data of PBA resin curing compound

Sample Td5 /℃ Mass residue/% N2 Air N2 Air PDMP 641.1 532.0 88.9 31.6 PBA-1 640.6 591.0 89.0 26.9 PBA-2 603.3 582.7 87.7 27.7 PBA-3 586.4 571.6 87.1 19.7 PBA-4 575.5 572.2 87.0 17.4 PBA-5 569.3 571.9 85.6 17.7 Note: Td5—Temperature with mass loss of 5% 表 5 QF/PBA复合材料400℃热老化6 h质量损失

Table 5. QF/PBA composite material thermal aging at 400℃ for 6 h mass loss

Sample Mass loss/% QF/PDMP 4.80 QF/PBA-1 1.70 QF/PBA-2 1.40 QF/PBA-3 1.09 QF/PBA-4 0.70 QF/PBA-5 0.68 -

[1] 徐彬, 周权, 倪礼忠. 硅炔杂化树脂改性有机硅树脂及其复合材料的性能[J]. 功能高分子学报, 2012, 25(2):148-151.XU Bin, ZHOU Quan, NI Lizhong. Properties of modified organosilicone resin and its composite[J]. Journal of Functional Polymers,2012,25(2):148-151(in Chinese). [2] KORSHAK V V, SLADKOV A M, LUNEVA L K. Synthesis of heteroorganic polymers with acetylenic bonds in the chain[J]. Russian Chemical Bulletin,1962,11:677. [3] ITOH M, MITSUZUKA M, IWATA K, et al. A novel synthesis and extremely high thermal stability of poly [(phenylsilylene)ethynylene-1,3-phenyleneethynylene][J]. Macromolecules,1994,27(26):7917-7919. doi: 10.1021/ma00104a056 [4] ITOH M, INOUE K, IWATA K, et al. New highly heat-resistant polymers containing silicon: poly(silyleneethynylenephenyleneethynylene)s[J]. Macromolecules,1997,30(4):694-701. doi: 10.1021/ma961081f [5] 沈学宁, 肖刚, 田鑫. 含硅芳炔醚树脂的合成及表征[J]. 精细石油化工, 2013, 30(4):62-65. doi: 10.3969/j.issn.1003-9384.2013.04.016SHEN X N, XIAO G, TIAN X. Synthesis and characterization of silicon-containing aryl ether resins[J]. Fine Petrochemical Engineering,2013,30(4):62-65(in Chinese). doi: 10.3969/j.issn.1003-9384.2013.04.016 [6] 楚明, 朱峻立, 王立权, 等. 基于材料基因组方法的含硅芳炔树脂的设计与合成[J]. 高分子学报, 2019, 50(11):1211-1219. doi: 10.11777/j.issn1000-3304.2019.19076CHU Ming, ZHU Junli, WANG Liquan, et al. Design and synthesis of silicon-containing aryl resin based on material genome method[J]. Acta Macromolecular Sinica,2019,50(11):1211-1219(in Chinese). doi: 10.11777/j.issn1000-3304.2019.19076 [7] 马满平, 戴妮娉, 李传, 等. 侧氰基芳醚硅芳炔树脂的制备与表征[J]. 复合材料学报, 2020, 37(12):1-8.MA Manping, DAI Niping, LI Chuan, et al. Preparation and characterization of lateral cyanoyl ether silicoaryl alkyne resin[J]. Acta Materiae Compositae Sinica,2020,37(12):1-8(in Chinese). [8] 胡永彬, 王帆, 朱亚平, 等. SiO2中空微球改性含硅芳炔树脂及其复合材料的结构与性能[J]. 复合材料学报, 2019, 36(3):592-601.HU Yongbin, WANG Fan, ZHU Yaping, et al. Structure and properties of SiO2 hollow microspheres modified silicone-containing aryl resin and its composites[J]. Acta Materiae Compositae Sinica,2019,36(3):592-601(in Chinese). [9] HUANG J X , DU W, ZHANG J, et al. Study on the copolymers of silicon-containing arylacetylene resin and acetylene-functional benzoxazine[J]. Polymer Bulletin,2008,62(2):127-138. [10] 束长朋, 王茂源, 周权, 等. 苯并噁嗪-氨基稀释剂改性硅炔杂化树脂及其复合材料性能[J]. 复合材料学报, 2020, 37(11):1-8.SHU Changpeng, WANG Maoyuan, ZHOU Quan, et al. Properties of silicoalkyne hybrid resin modified with benzoxazine-amino diluent[J]. Acta Materiae Compositae Sinica,2020,37(11):1-8(in Chinese). [11] 汤乐旻, 周燕, 田鑫, 等. 改性含硅芳炔树脂及其复合材料性能研究[J]. 玻璃钢/复合材料, 2012(6):41-46.TANG Lemin, ZHOU Yan, TIAN Xin, et al. Properties of modified silicon-Aryl resin and its composites[J]. Glass steel/composite material,2012(6):41-46(in Chinese). [12] 杜峰可, 袁荞龙, 黄发荣. 含硅芳炔树脂/苯并噁嗪/氰酸酯三元聚合体系研究[J]. 高分子学报, 2018(3):410-418. doi: 10.11777/j.issn1000-3304.2017.17099DU Fengke, YUAN Qiaolong, HUANG Farong. Study on ternary polymerization system of silicon containing aromatic alkyne resin/Benzoxazine/cyanate ester[J]. Acta polymer Sinica,2018(3):410-418(in Chinese). doi: 10.11777/j.issn1000-3304.2017.17099 [13] KELLER T M . The synthesis of a fluorinated phthalocyanine[J]. Journal of Fluorine Chemistry,1979,13(1):73-77. [14] KELLER T M, GRIFFITH J R. The synthesis of highly fluorinated phthalonitrile resins and cure studies[J]. Journal of Fluorine Chemistry,1979,13(4):315-324. [15] KELLER T M, PRICE T R, GRIFFITH J R. Synthesis of phthalonitriles by nitro displacement[J]. Chemischer Informationsdiens,1980,8:613. [16] KELLER T M. Phthalonitrile-based high temperature resin[J]. Journal of Polymer Science: Part A — Polymer Chemistry,1988,26(12):3199-3212. doi: 10.1002/pola.1988.080261207 [17] KELLER T M. Imide-containing phthalonitrile resin[J]. Polymer,1992,34(5):952-955. [18] ZHANG Z B, LI Z, ZHOU H, et al. Self-catalyzed silicon-containing phthalonitrile resins with low melting point, excellent solubility and thermal stability[J]. Journal of Applied Polymer Science,2014,131(20):40911-40917. [19] XU S S, HAN Y, GUO Y, et al. Allyl phenolic-phthalonitrile resins with tunable properties: Curing, processability and thermal stability[J]. European Polymer Journal,2017,95:394-405. [20] WANG G X, GUO Y, LI Z, et al. Synthesis and properties of phthalonitrile terminated polyaryl ether nitrile containing fluorene group[J]. Journal of Applied Polymer Science,2018,135(34):46601-46608. [21] SUN B G, LEI Q, GUO Y, et al. Enhanced mechanical properties at 400℃ of carbon fabric reinforced phthalonitrile composites by high temperature postcure[J]. Composites Part B: Engineering,2019,166:681-687. [22] WANG G X, HAN Y, GUO Y, et al. Phthalonitrile terminated fluorene based copolymer with outstanding thermal and mechanical properties[J]. European Polymer Journal,2019,113:1-11. [23] YANG X L, LEI Y J, ZHONG J C, et al. Preparation and thermal properties of novel phthalonitrile oligomer containing biphenyl ethernitrile/bisphthalonitrile blends[J]. Journal of Applied Polymer Science,2011,119(2):882-887. doi: 10.1002/app.32783 [24] YANG X L, ZHANG Z B, LEI Y J, et al. Effect of different aromatic amines on the crosslinking behavior and thermal properties of phthalonitrile oligomer containing biphenyl ethernitrile[J]. Journal of Applied Polymer Science,2011,121(4):2331-2337. doi: 10.1002/app.33949 [25] HU J H, YUAN P, ZENG K, et al. Study of the curing kinetics of a benzimidazole/phthalonitrile resin system[J]. Thermochimica Acta,2014,590:30-39. [26] HU J H, WU D M, LU D K, et al. Study on thermal behaviors of a novel cruciform amide-containing phthalonitrile monomer[J]. Designed Monomers and Polymers,2015,18(7):620-626. doi: 10.1080/15685551.2015.1045331 [27] YUAN P, LIU Y C, ZENG K, et al. Synthesis and characterization of a new imide compound containing phthalonitrile and phenylethynyl end-groups[J]. Designed Monomers and Polymers,2015,18(4):343-349. doi: 10.1080/15685551.2015.1012623 [28] 欧国荣, 张德震. 高分子科学与工程实验[M]. 上海: 华东理工大学出版社, 1998.OU Guorong, ZHANG Dezhen, polymer science and engineering experiment[M]. Shanghai: East China University of science and Technology Press, 1998.(in Chinese) [29] 中国国家标准化管理委员会. 纤维增强塑料树脂不可溶分含量试验方法: GB/T 2576—2005[S]. 北京: 中国标准出版社, 2005.National Standardization Administration of China. Test method for insoluble content of fiber reinforced plastics resins: GB/T 2576—2005[S]. Beijing: China Standard Press, 2005.(in Chinese) [30] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.National Standardization Administration of China. Test method for flexural properties of fiber reinforced plastics: GB/T 1449—2005[S]. Beijing: China Standard Press, 2005.(in Chinese) [31] 中国国家标准化管理委员会. 纤维增强塑料层间剪切强度试验方法: GB/T 1450.1—2005[S]. 北京: 中国标准出版社, 2005.National Standardization Administration of China. Test method for interlaminar shear strength of fiber reinforced plastics: GB/T 1450.1—2005[S]. Beijing: China Standard Press, 2005.(in Chinese) [32] SHIMKIN A A, PONOMARENKO S A, MUKHAMETOV R R. Curing of diphthalonitrile resin[J]. Russian Journal of Applied Chemistry,2016,89(2):263-270. doi: 10.1134/S1070427216020166 [33] WILKIE C A. Fire properties of future material candidates. Improved fire-and smoke-resistant materials for commercial aircraft interiors: A proceedings[J]. Polymer,1995,115:123-126. -

下载:

下载: