Compressive strength of carbon fiber reinforced epoxy composites with various carbon fiber cross section characteristics

-

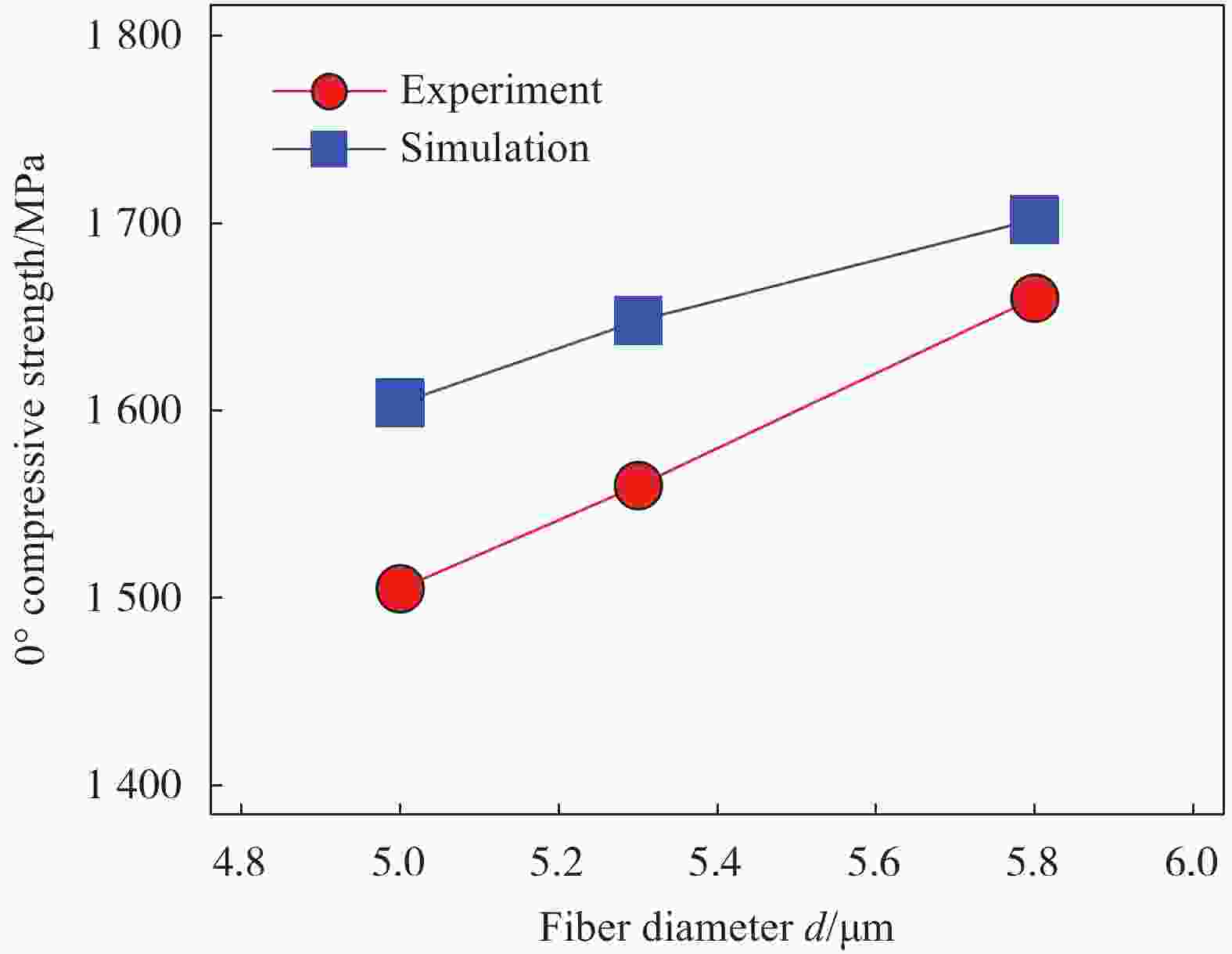

摘要: 基于压拉平衡为特征的新一代先进复合材料的需求,开展了碳纤维截面形状和尺寸对碳纤维/环氧树脂复合材料压缩强度的影响研究。有限元模拟和试验结果均表明,增大碳纤维直径可以提高复合材料压缩强度。另外碳纤维截面形状也对复合材料压缩强度有影响,圆形截面优于椭圆形截面。

-

关键词:

- 碳纤维增强树脂基复合材料 /

- 压缩强度 /

- 纤维直径 /

- 截面形状 /

- 有限元模拟

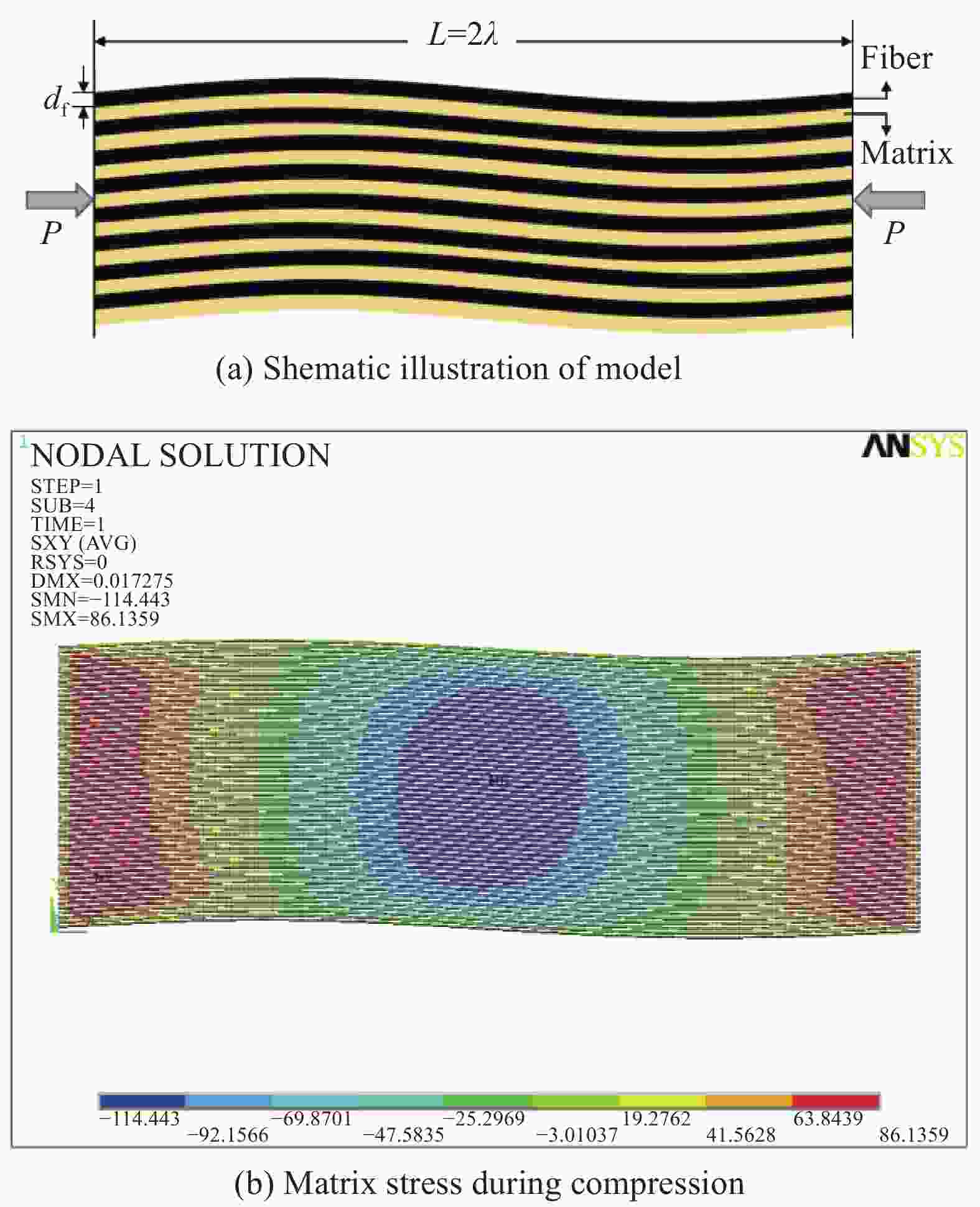

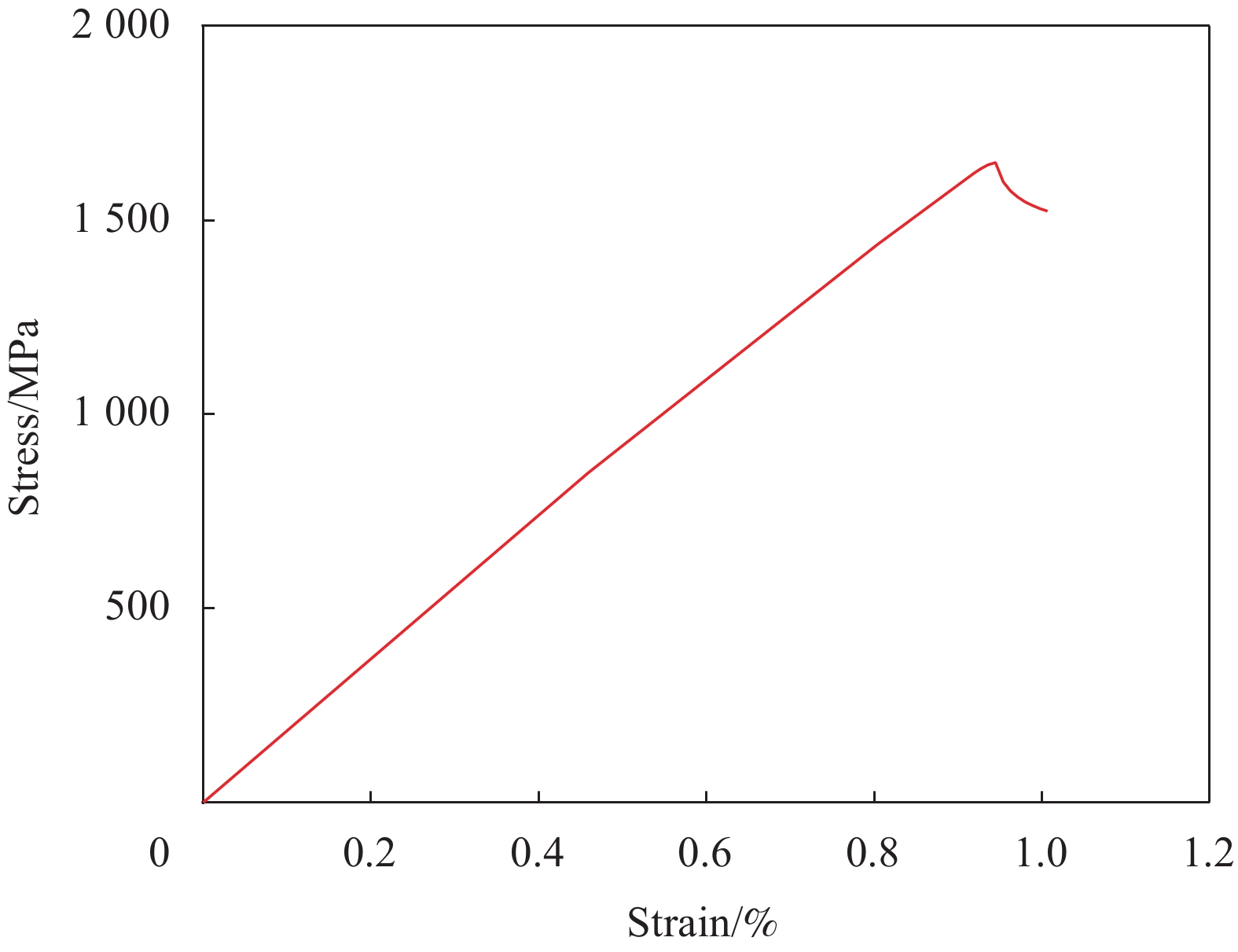

Abstract: Based on the demand of new generation advanced composites characterized by the balance of com-pressive and tensile strength, the compressive strength of carbon fiber/epoxy composites with various cross section characteristics of carbon fibers was studied by finite element simulation and experiment. Results show that the compressive strength of carbon fiber/epoxy composite increases with the increasing fiber diameter, and round is better than ellipse regarding to the fiber cross section shape. -

表 1 4种碳纤维性能

Table 1. Properties of 4 types of carbon fibers

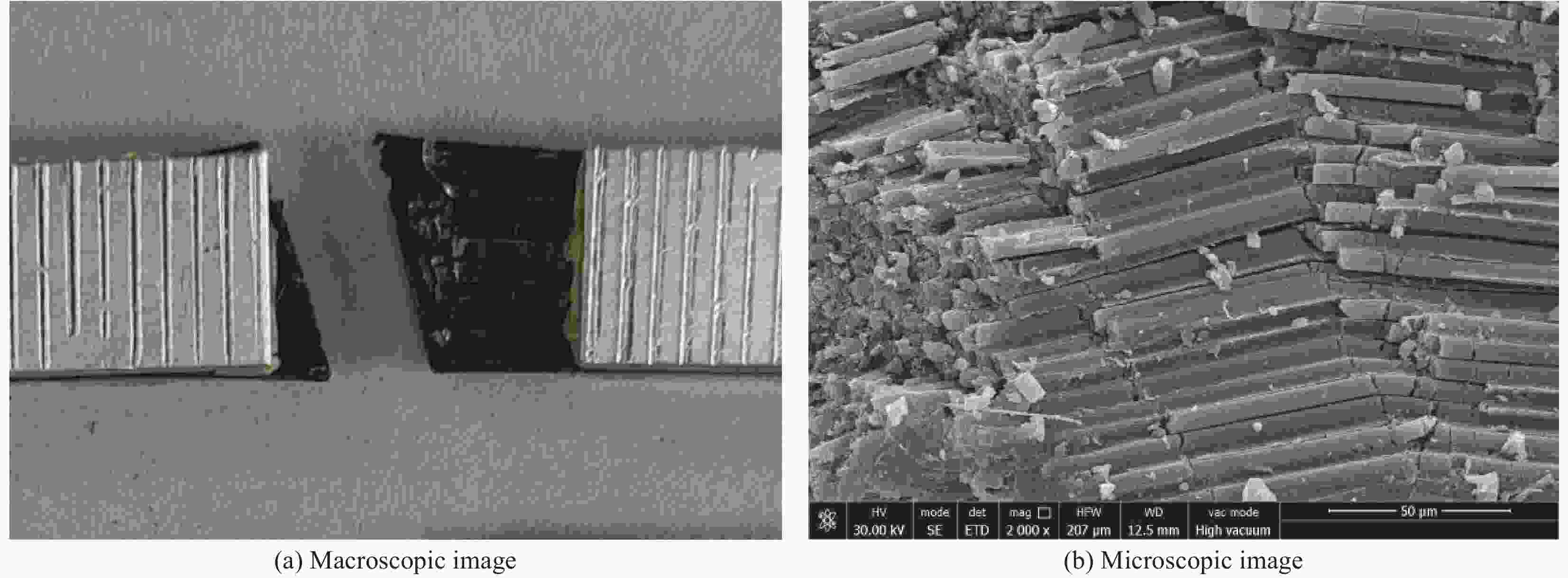

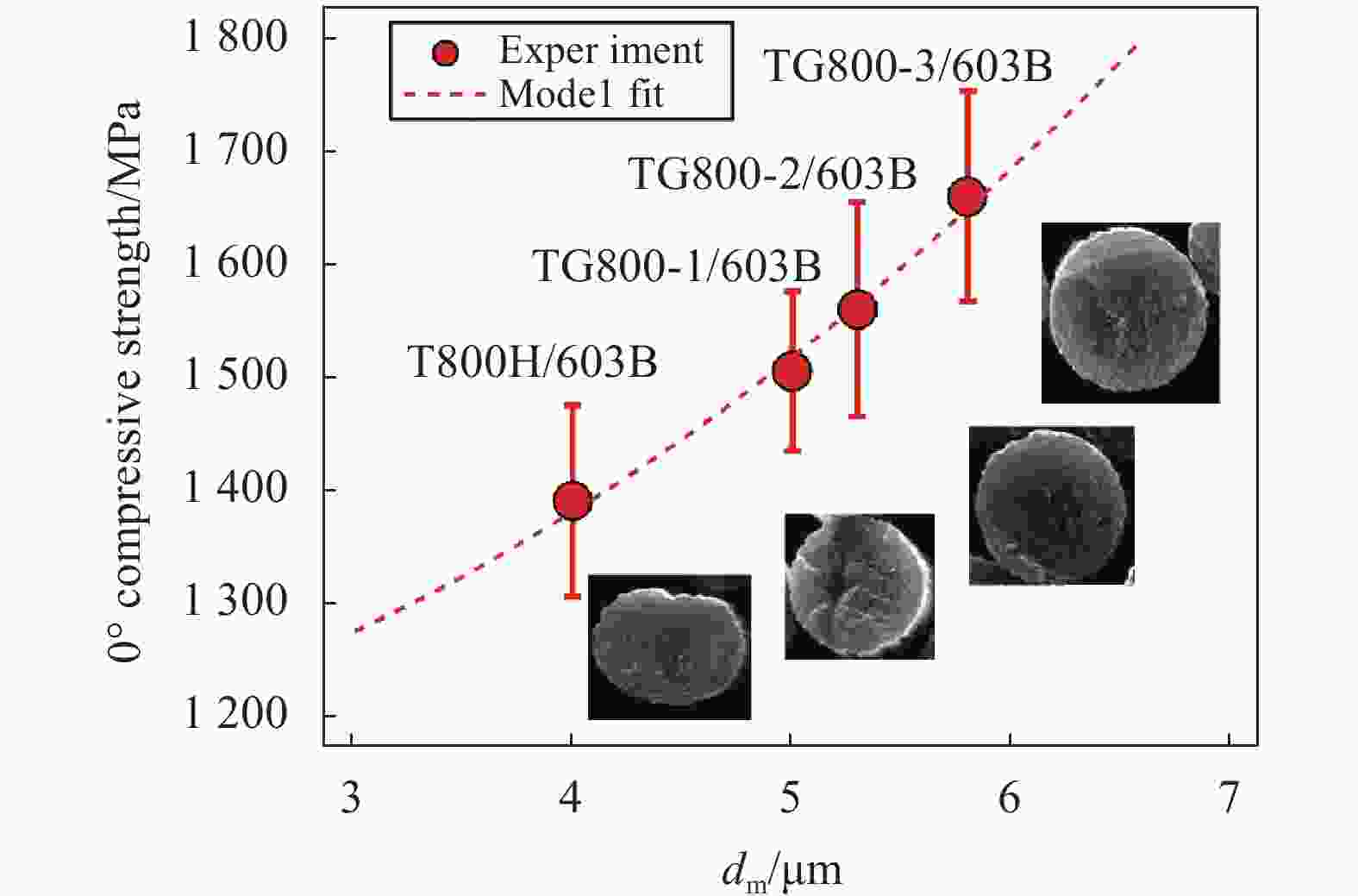

Type Strength σ/MPa Modulus E/GPa Diameter/μm Section shape Surface roughness T800H 5790 294 5.0 Ellipse Obvious TG800-1 5820 292 5.0 Round Obvious TG800-2 5860 292 5.3 Round Obvious TG800-3 5830 294 5.8 Round Obvious 表 2 4种碳纤维/环氧复合材料力学性能

Table 2. Mechanical properties of 4 types of carbon fiber/epoxy composites

Type 0° tensile strength/MPa 0° compressive strength/MPa Compressive/tensile strength ratio T800H/603B 2770±180 1390±85 0.50 TG800-1/603B 2750±170 1505±71 0.55 TG800-2/603B 2805±210 1560±95 0.56 TG800-3/603B 2790±180 1660±93 0.60 表 3 3种典型碳纤维截面惯性矩计算

Table 3. Sectional inertia moments of 3 typical section shapes of carbon fibers

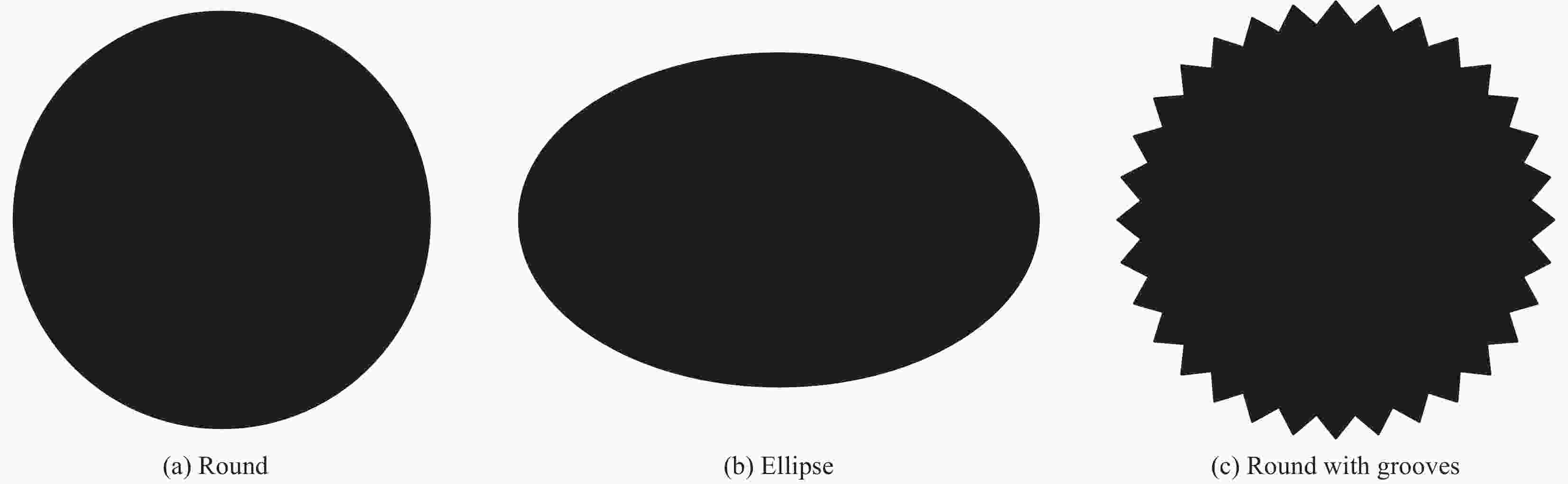

Shape Round Ellipse Round with grooves I (Equation)/μm4 $ {\mathrm{{\text{π}} }d}^{4}/64 $ $ \mathrm{{\text{π}} }a{b}^{3}/64 $ $ {\mathrm{{\text{π}} }d}^{4}/64+{\mathrm{{\text{π}} }d}^{2}{t}^{2}/192 $ S (Equation)/μm2 $ {\mathrm{{\text{π}} }d}^{2}/4 $ $ \mathrm{{\text{π}} }ab/4 $ $ {\mathrm{{\text{π}} }d}^{2}/4 $ Parameters/μm d=5 a=6.25, b=4 d=5, t=0.5 S (Value)/μm2 6.25π 6.25π 6.25π I (Value)/μm4 9.76π 6.25π 9.80π Notes: I—Minimum moment of inertia; S—Section area d—Diameter for round section; a—Long axis of ellipse; b—Short axis of ellipse; t—Groove depth. -

[1] 朱文墨, 李刚, 杨小平, 等. 连续纤维增强树脂复合材料纵向压缩强度预测模型的发展及其影响因素[J]. 复合材料学报, 2020, 37(1):1-15.ZHU W M, LI G, YANG X P, et al. Development of prediction model and influencing factors of longitudinal compressive strength for continuous fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2020,37(1):1-15(in Chinese). [2] 张弥, 关志东, 黎增山, 等. 考虑纤维初始位错的复合材料轴向压缩性能[J]. 复合材料学报, 2017, 34(8):1754-1763.ZHANG M, GUAN Z D, LI Z S, et al. Longitudinal com-pressive properties of composites considering fiber initial misalignment[J]. Acta Materiae Compositae Sinica,2017,34(8):1754-1763(in Chinese). [3] ZHANG M, WANG X D, LI W D, et al. Compressive strength determined for ultrahigh modulus fiber reinforced composites by [90/0]ns laminates[J]. Composite Structures,2018,191:24-35. doi: 10.1016/j.compstruct.2018.02.033 [4] ROBINSON P, GREENHALGH E, PINHO S. Failure mechanisms in polymer matrix composites: Criteria, testing and industrial applications[M]. Sawston: Woodhead Publishing Limited, 2012. [5] BUDIANSKY B, FLECK N A. Compressive failure of fiber composites[J]. Journal of the Mechanics and Physics of Solids,1993,41(1):183-211. doi: 10.1016/0022-5096(93)90068-Q [6] DE-MORAIS A B. Prediction of the layer longitudinal compression strength[J]. Journal of Composite Materials,2000,34(21):1808-1820. doi: 10.1106/9XG6-F8T7-079T-YAHC [7] LO K H, CHIM E S M. Compressive strength of unidirectional composites[J]. Journal of Reinforced Plastics and Composites,1992,11(8):838-896. doi: 10.1177/073168449201100801 [8] XU Y L, REIFSNIDER K L. Micromechanical modeling of composite compressive strength[J]. Journal of Composite Materials,1993,27(6):572-588. doi: 10.1177/002199839302700602 [9] MAMALIS D, FLANAGAN T, CONCHÚR M O. Effect of fibre straightness and sizing in carbon fibre reinforced powder epoxy composites[J]. Composites Part A: Applied Science and Manufacturing,2018,110:93-105. doi: 10.1016/j.compositesa.2018.04.013 [10] GUO H, HUANG Y, LIU L, et al. Effect of epoxy coatings on carbon fibers during manufacture of carbon fiber reinforced resin matrix composites[J]. Materials & Design,2010,31(3):1186-1190. [11] SHARMA M, GAO S, MDER E, et al. Carbon fiber surfaces and composite interphases[J]. Composites Science and Technology,2014,102:35-50. doi: 10.1016/j.compscitech.2014.07.005 [12] SONG W, GU A, LIANG G, et al. Effect of the surface roughness on interfacial properties of carbon fibers reinforced epoxy resin composites[J]. Applied Surface Science,2011,257(9):4069-4074. doi: 10.1016/j.apsusc.2010.11.177 [13] 李龙, 潘月秀, 朱世鹏, 等. 炭纤维毛丝评价表征研究[J]. 新型炭材料, 2018, 33(4):97-104.LI L, PAN Y X, ZHU S P, et al. A comparative study of the fuzz produced by friction and tension in China T800 and Toray T800H carbon fiber tows[J]. New Carbon Materials,2018,33(4):97-104(in Chinese). [14] ZHANG H J, SELLAIYAN S, KAKIZAKI T, et al. Effect of free-volume holes on dynamic mechanical properties of epoxy resins for carbon-fiber-reinforced polymers[J]. Macromolecules,2017,50:3933-3942. doi: 10.1021/acs.macromol.7b00472 [15] 石佩洛, 王月友, 郭鸿俊, 等. 炭纤维/鳞片石墨/氰酸酯复合材料的导热和力学性能(英文)[J]. 新型炭材料, 2019, 34(1):110-114. doi: 10.1016/S1872-5805(19)60005-3SHI P L, WANG Y Y, GUO H J, et al. The thermal and mechanical properties of carbon fiber/flake graphite/cyanate ester composites[J]. New Carbon Materials,2019,34(1):110-114(in Chinese). doi: 10.1016/S1872-5805(19)60005-3 [16] BAZHENOV S L, KUPERMAN A M, ZELENSKII E S, et al. Compression failure of unidirectional glass-fibre-reinforced plastics[J]. Composites Science & Technology,1992,26(3):201-208. [17] BRUNBAUER J, STADLER H, PINTER G. Mechanical properties, fatigue damage and microstructure of carbon/epoxy laminates depending on fibre volume content[J]. International Journal of Fatigue,2015,70:85-92. [18] VERPOEST I, SPRINGER G S. Effects of moisture on the compressive and interlaminar shear strengths of aramid-epoxy composites[J]. Journal of Reinforced Plastics & Composites,1988,7(1):23-32. [19] XU P, YU Y, LIU D, et al. Enhanced interfacial and mechanical properties of high-modulus carbon fiber composites: Establishing modulus intermediate layer between fiber and matrix based on tailored-modulus epoxy[J]. Compo-sites Science and Technology,2018,163:26-33. [20] BERBINAU P, SOUTIS C, GUZ I A. Compressive failure of 0° unidirectional carbon-fibre-reinforced plastic (CFRP) laminates by fibre microbuckling[J]. Composites Science & Technology,1999,59(9):1451-1455. [21] NAIK N K, KUMAR R S. Compressive strength of unidirectional composites: Evaluation and comparison of prediction models[J]. Composite Structures,1999,46(3):299-308. doi: 10.1016/S0263-8223(99)00098-7 [22] CARLOS G, LORCA J. Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modeling[J]. Compo-sites Science and Technology,2007,67(13):2795-2806. doi: 10.1016/j.compscitech.2007.02.001 [23] VAUGHAN T J, MCCARTHY C T. Micromechanical modelling of the transverse damage behaviour in fibre reinforced composites[J]. Composites Science & Technology,2011,71(3):388-396. [24] YANG L, YAN Y, LIU Y, et al. Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression[J]. Composites Science & Technology,2012,72(15):1818-1825. [25] BRU T, ASP L E, OLSSON R, et al. Biaxial transverse compression testing for a fibre reinforced polymer material[C]. 18th European Conference on Composite Materials (ECCM18), 2018. [26] ZUMAQUERO P L, CORREA E, JUSTO J, et al. Microscopical observations of interface cracks from inter-fibre failure under compression in composite laminates[J]. Compo-sites Part A: Applied Science and Manufacturing,2018,110:76-83. doi: 10.1016/j.compositesa.2018.04.004 [27] 李梦龙, 朱世鹏, 欧阳琴, 等. 不同直径国产高强中模型碳纤维结构及其轴向压缩强度关系的研究[J]. 高科技纤维与应用, 2018, 55(6):33-39. doi: 10.3969/j.issn.1007-9815.2018.06.004LI M L, ZHU S P, OUYANG Q. Structure and unidirectional compressive properties of fibres with different diameters[J]. HiTech Fiber Application,2018,55(6):33-39(in Chinese). doi: 10.3969/j.issn.1007-9815.2018.06.004 [28] 中国国家标准化管理委员会. 碳纤维直径和根数试验方法: GB/T 3364—2008[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test methods for diameter of carbon fiber and filament number in carbon fiber strand: GB/T 3364—2008[S]. Beijing: China Standards Press, 2005(in Chinese). [29] 中国国家标准化管理委员会. 碳纤维复丝拉伸性能试验方法: GB/T 3362—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test methods for tensile properties of carbon fiber multifilament: GB/T 3362—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [30] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: China Standards Press, 2005(in Chinese). [31] American Society for Testing and Materials. Standard test method for compressive properties of polymer matrix composite materials with unsupported gage section by shear loading: ASTM D3410—16[S]. West Conshohocken: ASTM, 2016. -

下载:

下载: