| [1] |

MEROLA M, ESCOURBIAC F, RAFFRAY R, et al. Overview and status of ITER internal components[J]. Fusion Engineering and Design,2014,89(7-8):890-895. doi: 10.1016/j.fusengdes.2014.01.055

|

| [2] |

SHIMOMURA Y. ITER and plasma surface interaction issues in a fusion reactor[J]. Journal of Nuclear Materials,2007,363-365:467-475. doi: 10.1016/j.jnucmat.2007.01.215

|

| [3] |

吴玉程. 面向等离子体W材料改善韧性的方法与机制[J]. 金属学报, 2019, 55(2):171-180. doi: 10.11900/0412.1961.2018.00404WU Yucheng. The routes and mechanism of plasma facing tungstenmaterials to improve ductility[J]. Acta Metallurgica Sinica,2019,55(2):171-180(in Chinese). doi: 10.11900/0412.1961.2018.00404

|

| [4] |

吴玉程. 核聚变堆用W及其合金辐照损伤行为研究进展[J]. 金属学报, 2019, 55(8):939-950. doi: 10.11900/0412.1961.2018.00405WU Yucheng. Research progress in irradiation damage behavior of tungsten and its alloys for nuclear fusion reactor[J]. Acta Metallurgica Sinica,2019,55(8):939-950(in Chinese). doi: 10.11900/0412.1961.2018.00405

|

| [5] |

沈晓, 程继贵, 李剑峰, 等. 轧膜成形制备W-Cu层状功能梯度材料及其性能研究[J]. 粉末冶金工业, 2016, 26(6):8-14.SHEN Xiao, CHENG Jigui, LI Jianfeng, et al. Fabrication and properties of W-Cu functionally graded materials by tapecalendaring method[J]. Powder Metallurgy Industry,2016,26(6):8-14(in Chinese).

|

| [6] |

雷纯鹏, 程继贵, 夏永红. 新型钨铜复合材料的制备和性能研究的新进展[J]. 金属功能材料, 2003, 10(4):24-27. doi: 10.3969/j.issn.1005-8192.2003.04.007LEI Chunpeng, CHENG Jigui, XIA Yonghong. The latest developments in preparation and property study of W-Cu composites[J]. Metallic Functional Materials,2003,10(4):24-27(in Chinese). doi: 10.3969/j.issn.1005-8192.2003.04.007

|

| [7] |

种法力, 周张建, 陈俊凌, 等. 核聚变钨铜面对等离子体材料研究[J]. 功能材料, 2018, 49(3):3109-3112.CHONG Fali, ZHOU Zhangjian, CHEN Junling, et al. W/Cu plasma facing component for fusion device[J]. Journal of Functional Materials,2018,49(3):3109-3112(in Chinese).

|

| [8] |

CHAPA J, REIMANIS I. Modeling of thermal stresses in a graded Cu/W joint[J]. Journal of Nuclear Materials,2002,303(2):131-136.

|

| [9] |

LIU X, YANG L, TAMURA S, et al. Thermal response of plasma sprayed tungsten coating to high heat flux[J]. Fusion Engineering and Design,2004,70(4):341-349. doi: 10.1016/j.fusengdes.2004.06.002

|

| [10] |

RICCARDI B, MONTANARI R, CASADEI M, et al. Optimisation and characterisation of tungsten thick coatings on copper based alloy substrates[J]. Journal of Nuclear Materials,2006,352(1-3):29-35. doi: 10.1016/j.jnucmat.2006.02.069

|

| [11] |

TEJADO E, MÜLLER A V, YOU J H, et al. The thermo-mechanical behaviour of W-Cu metal matrix composites for fusion heat sink applications: The influence of the Cu content[J]. Journal of Nuclear Materials,2018,498:468-475. doi: 10.1016/j.jnucmat.2017.08.020

|

| [12] |

YOU J H, BOLT H. Analytical method for thermal stress analysis of plasma facing materials[J]. Journal of Nuclear Materials,2001,299(1):9-19. doi: 10.1016/S0022-3115(01)00674-2

|

| [13] |

RICHOU M, GALLAY F, BSWIRTH B, et al. Performance assessment of thick W/Cu graded interlayer for DEMO divertor target[J]. Fusion Engineering and Design,2020,157:1-6.

|

| [14] |

LOEWENHOFF T, LINKE J, PINTSUK G, et al. Tungsten and CFC degradation under combined high cycle transient and steady state heat loads[J]. Fusion Engineering and Design,2012,87(7-8):1201-1205. doi: 10.1016/j.fusengdes.2012.02.106

|

| [15] |

吴玉程, 姚刚, 罗来马, 等. 核聚变堆用钨及钨基材料热负荷损伤行为的研究进展[J]. 中国有色金属学报, 2018, 28(4):719-731.WU Yucheng, YAO Gang, LUO Laima, et al. Research progress in heat load damage behavior of tungsten and tungsten base materials for nuclear fusion reactor[J]. The Chinese Journal of Nonferrous Metals,2018,28(4):719-731(in Chinese).

|

| [16] |

汪峰涛, 吴玉程, 王涂根, 等. W-Cu面对等离子体梯度热沉材料的制备和性能[J]. 复合材料学报, 2008, 25(2):25-30. doi: 10.3321/j.issn:1000-3851.2008.02.005WANG Fengtao, WU Yucheng, WANG Tugen, et al. Fabrication and properties of the W-Cu gradient heat sink materials for plasma facing materials[J]. Acta Materiae Compo-sitae Sinica,2008,25(2):25-30(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.005

|

| [17] |

陶光勇, 郑子樵, 刘孙和. W/Cu功能梯度材料的制备及热循环应力分析[J]. 复合材料学报, 2006, 23(4):72-77. doi: 10.3321/j.issn:1000-3851.2006.04.013TAO Guangyong, ZHENG Ziqiao, LIU Sunhe. Fabrication of W/Cu functionally graded material and analysis of thermal cycle stress[J]. Acta Materiae Compositae Sinica,2006,23(4):72-77(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.04.013

|

| [18] |

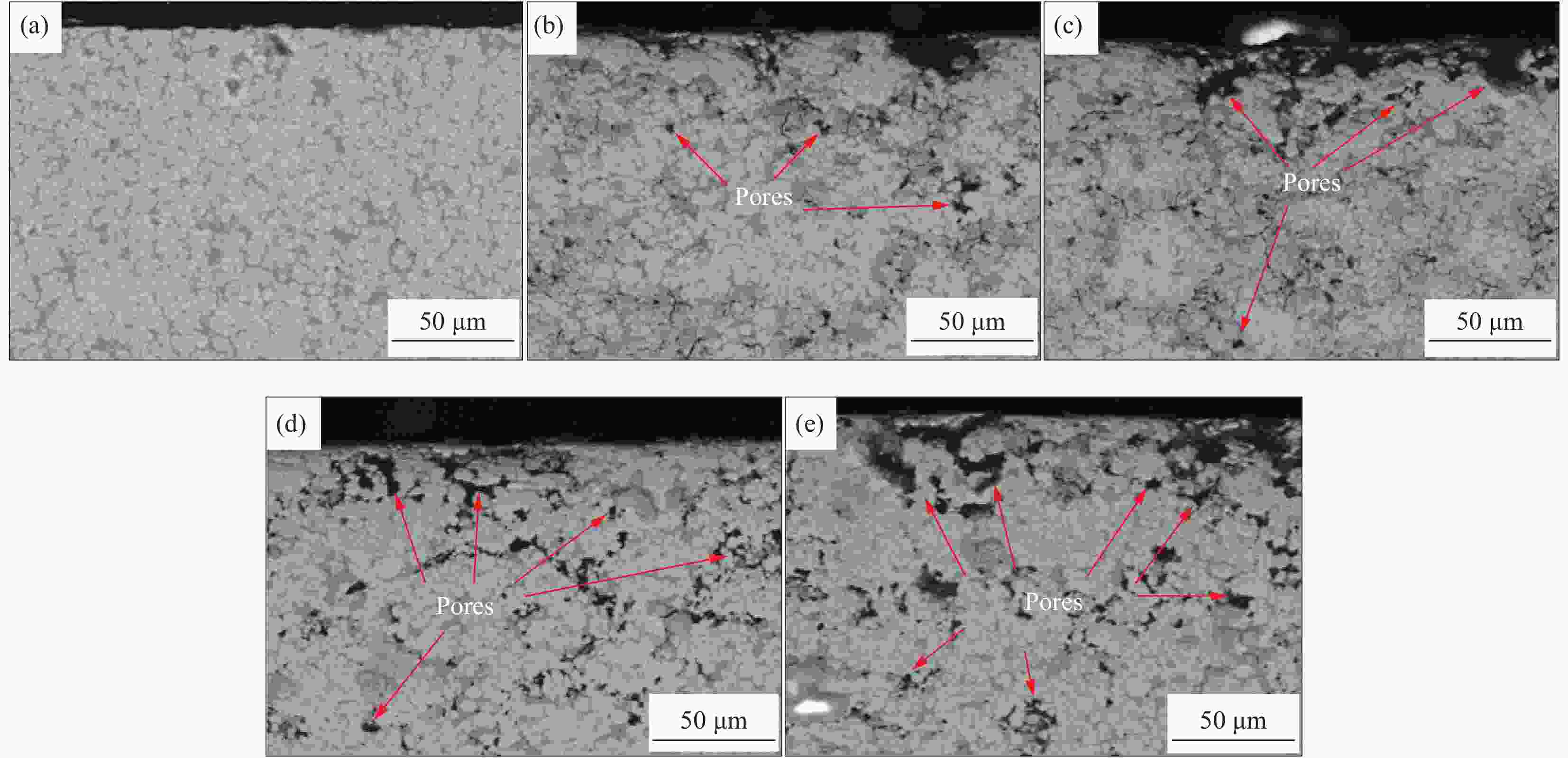

ZHOU Z J, SONG S X, DU J, et al. Performance of W/Cu FGM based plasma facing components under high heat load test[J]. Journal of Nuclear Materials,2007,363-365:1309-1314. doi: 10.1016/j.jnucmat.2007.01.184

|

| [19] |

WANG B G, ZHU D H, LI C J, et al. Performance of full compositional W/Cu functionally gradient materials under quasi-steady-stateheat loads[J]. IEEE Transactions on Plasma Science,2018,46(5):1551-1555. doi: 10.1109/TPS.2018.2803898

|

| [20] |

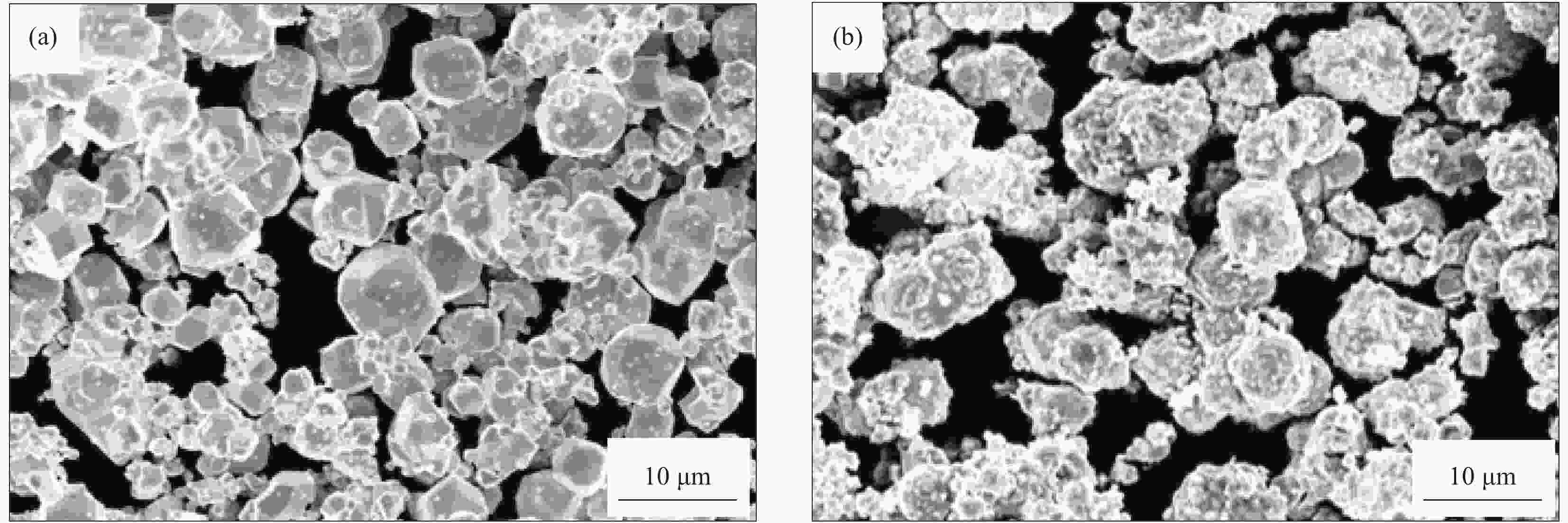

CHEN W C, CHEN P Q, LI J F, et al. Functionally graded W-Cu materials prepared from Cu-coated W powders by microwave sintering[J]. Journal of Materials Engineering and Performance,2019,28(10):6135-6144. doi: 10.1007/s11665-019-04321-7

|

| [21] |

WANG Y L, LIANG S H, XIAO P, et al. Experimental and simulation analysis of thermal shock with rapid heating followed by water quenching for CuW70 alloys[J]. Rare Metal Materials and Engineering,2012,41(3):393-396. doi: 10.1016/S1875-5372(12)60034-4

|

| [22] |

WANG Y L, LIANG S H, REN J T. Analysis of meso-scale damage and crack for CuW alloys induced by thermal shock[J]. Materials Science and Engineering: A,2012,534:542-546. doi: 10.1016/j.msea.2011.12.005

|

| [23] |

CHAWLA K K. Grain boundary cavitation and sliding in copper/tungsten composites due to thermal stresses[J]. Philosophical Magazine,1973,28(2):401-413. doi: 10.1080/14786437308217462

|

| [24] |

陈平安. Cu-W体系复合材料的热压烧结、结构调控与性能增强[D]. 武汉: 武汉理工大学, 2014.CHEN Ping’an. Hot-press sintering, structure regulation and properties improvement of Cu-W system composites[D]. Wuhan: Wuhan University of Technology, 2014(in Chinese)

|

下载:

下载: