Axial compression performance of pultruded GFRP tube based on casing buckling restraint

-

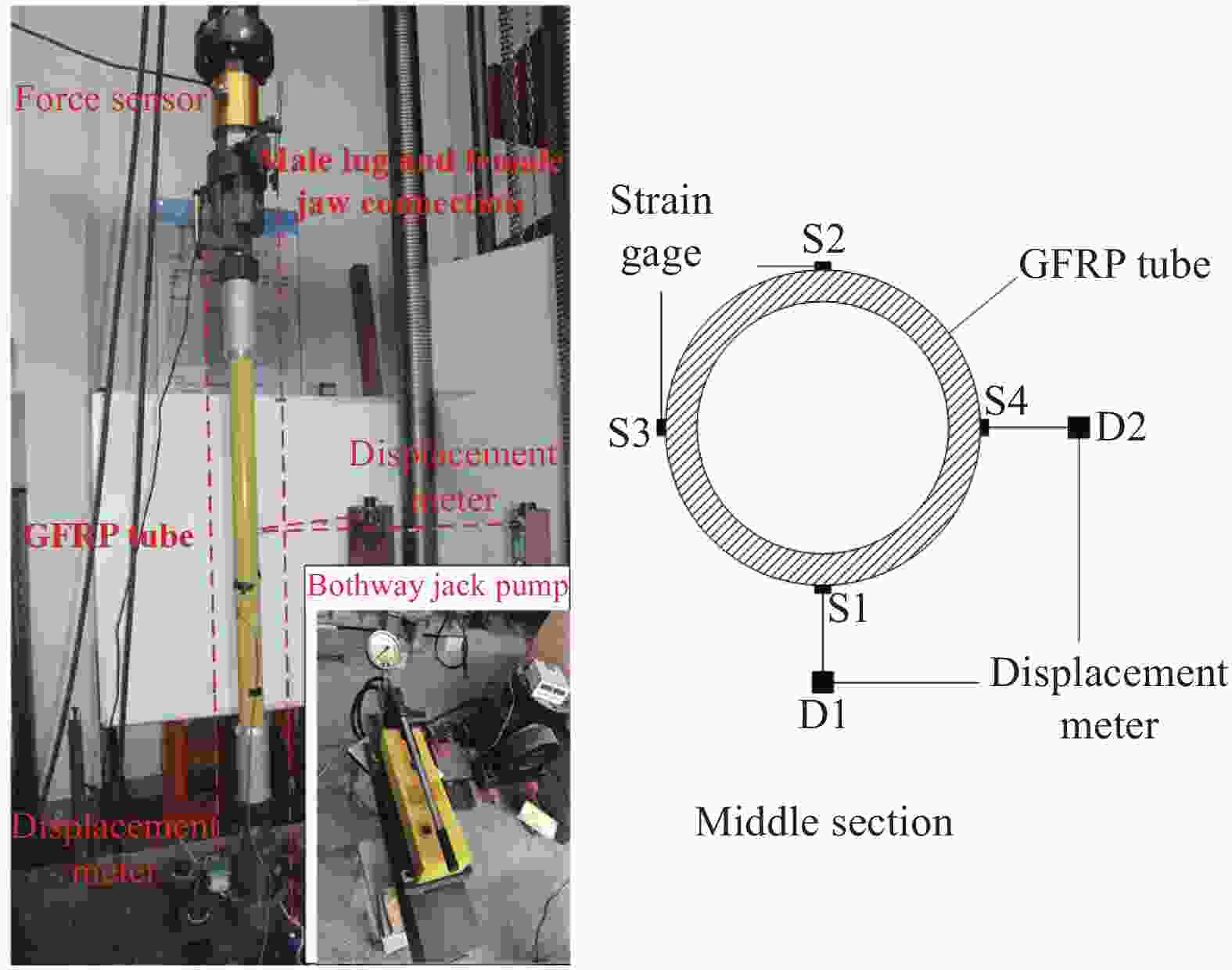

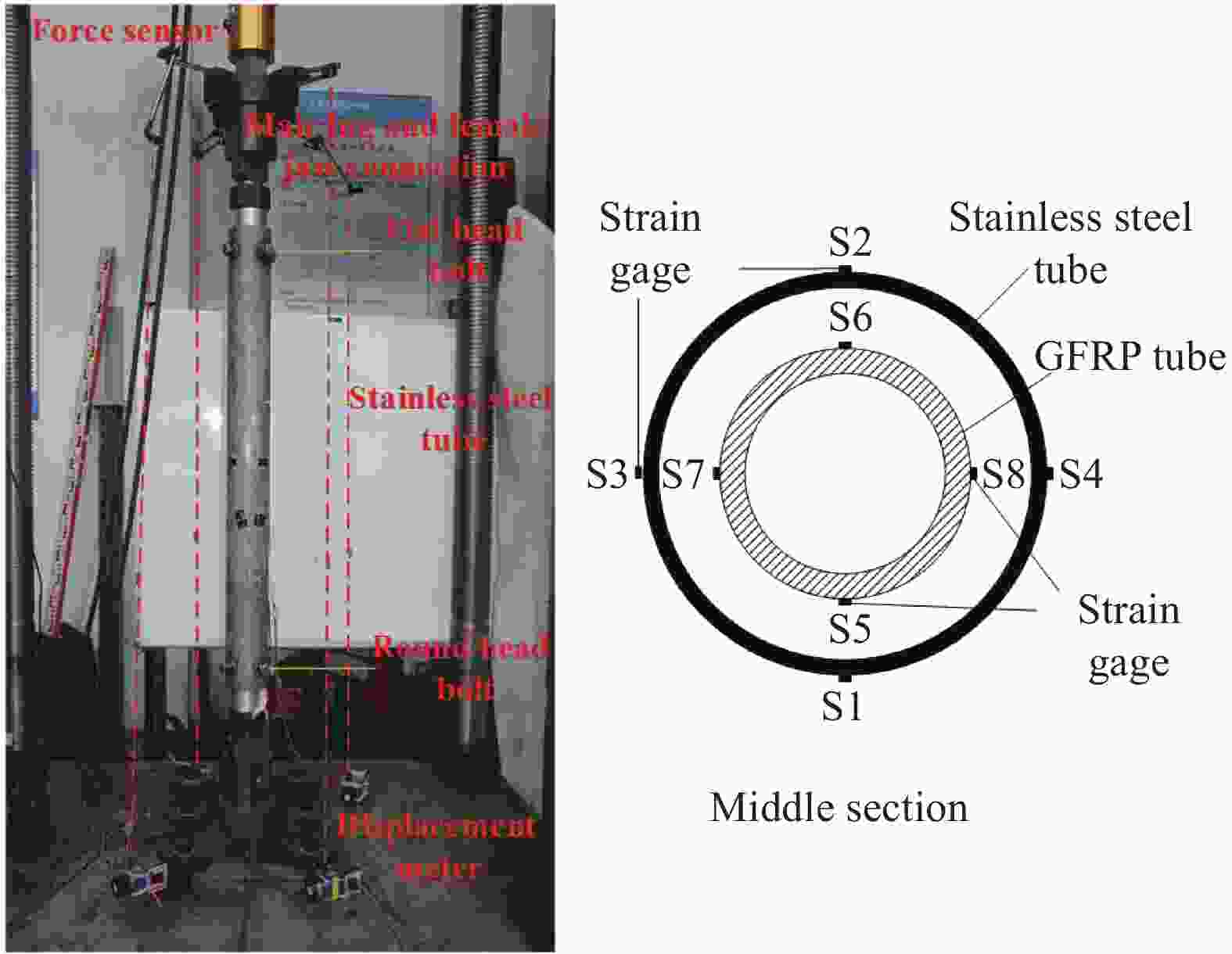

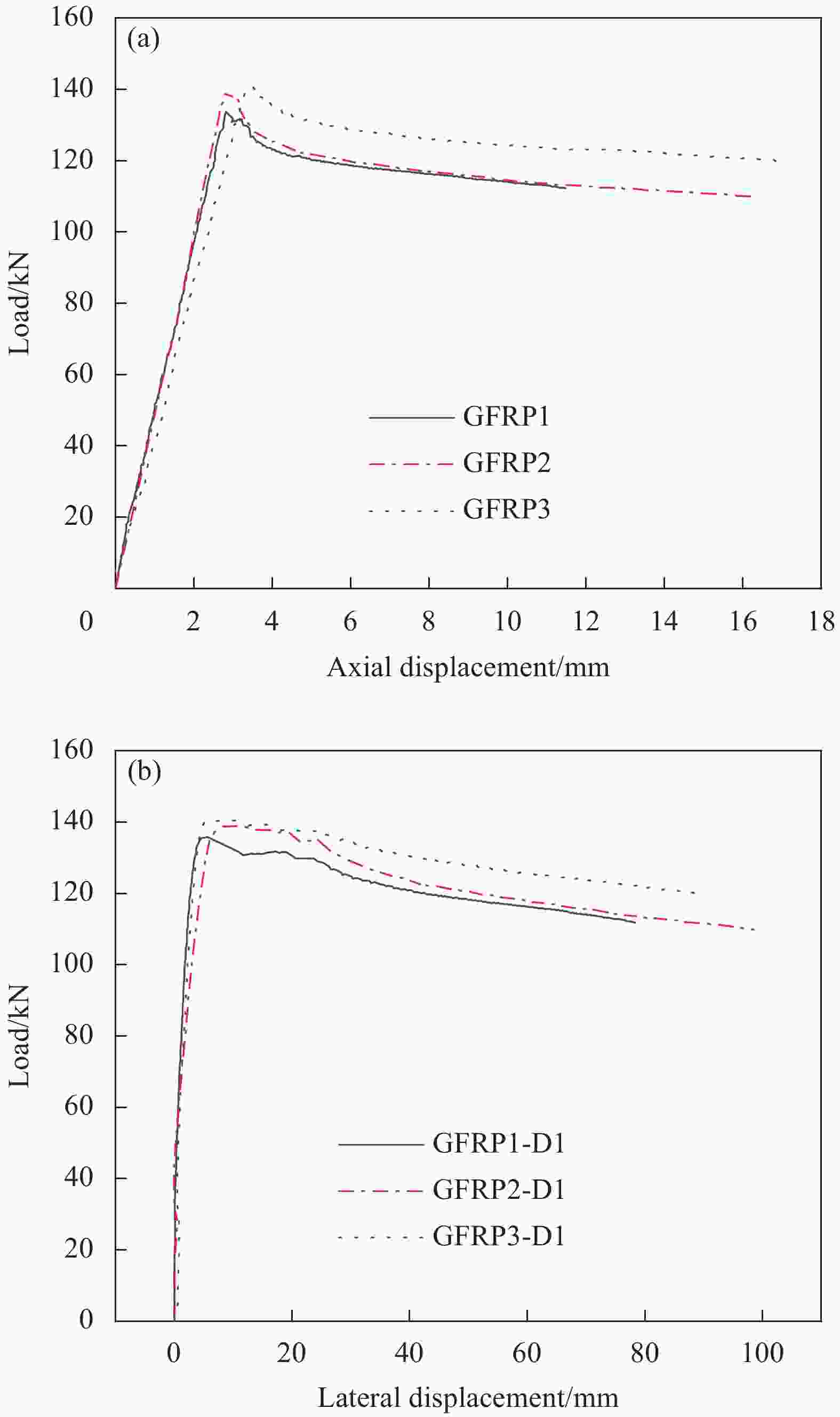

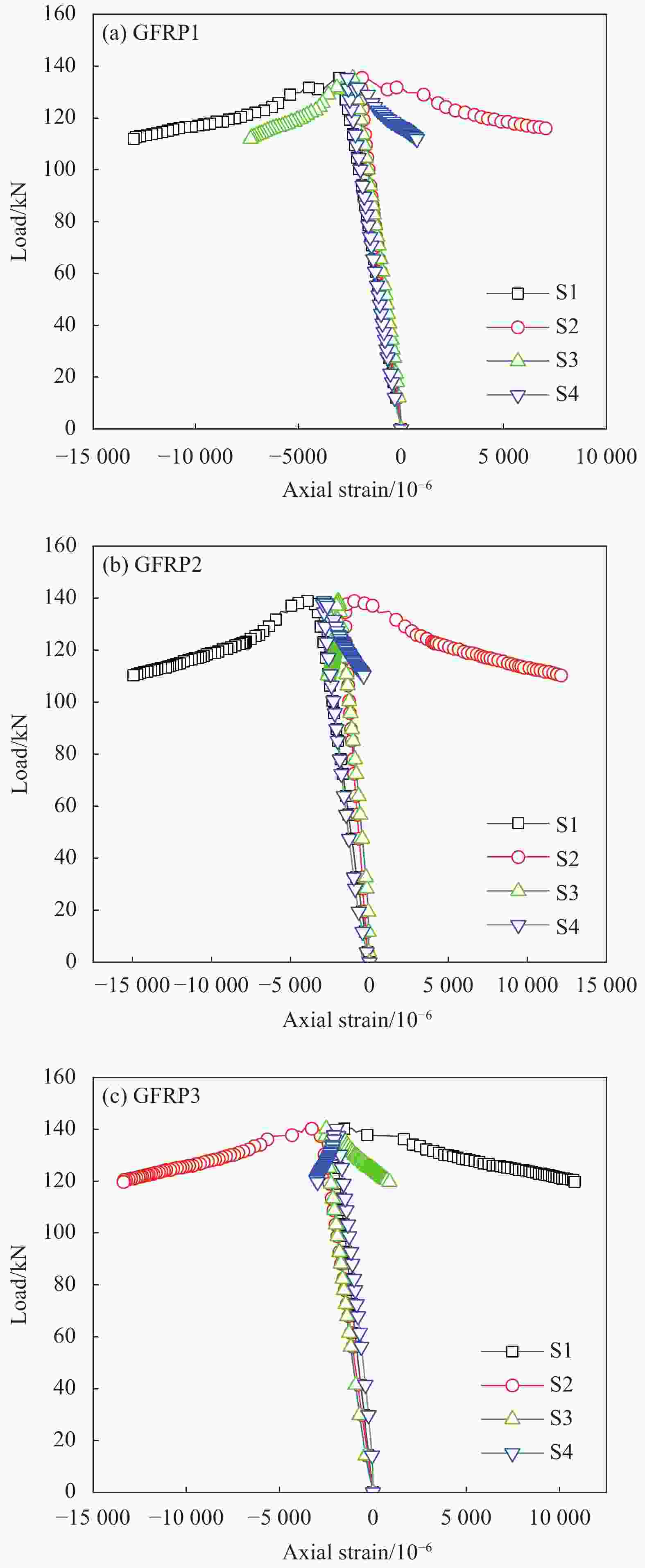

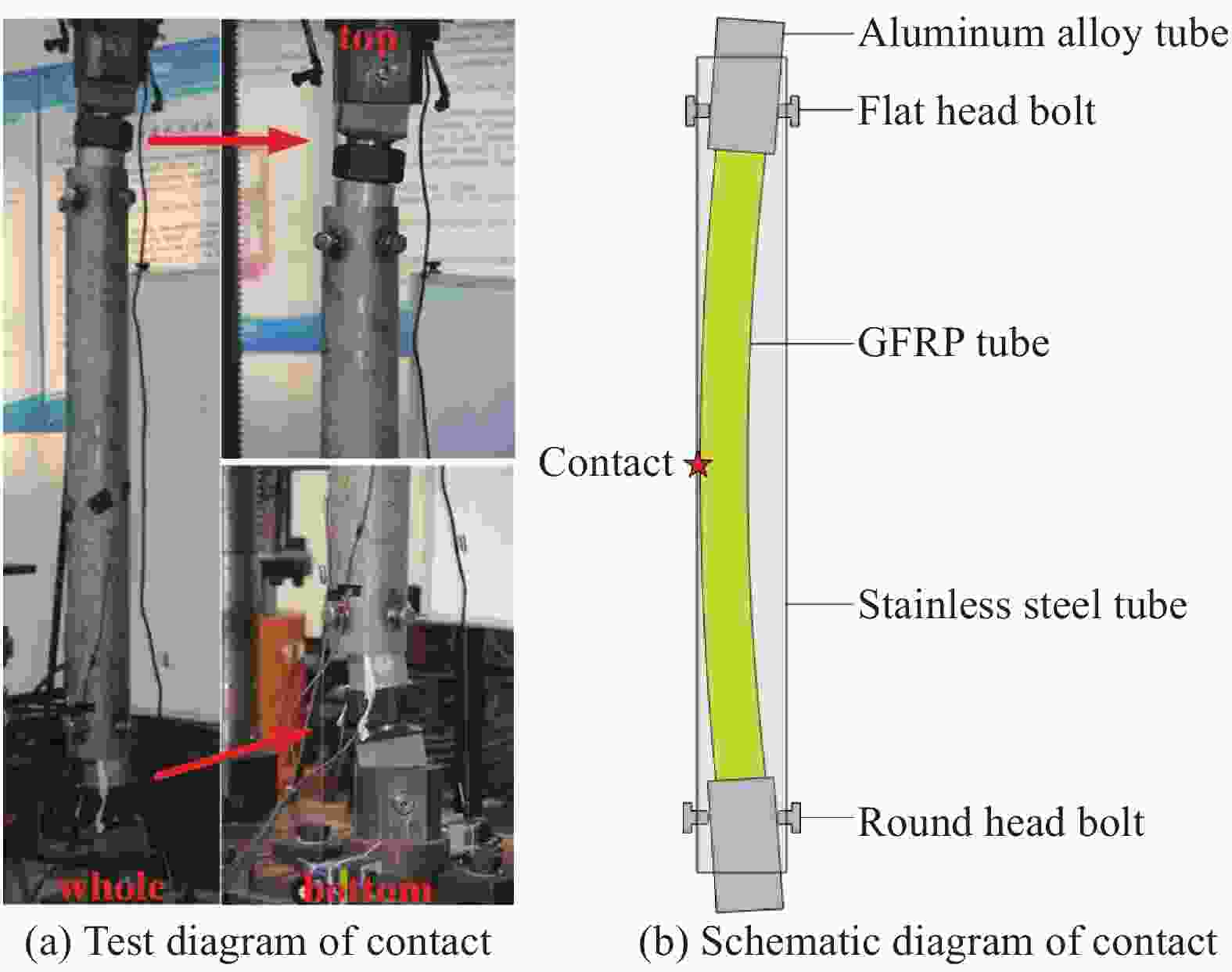

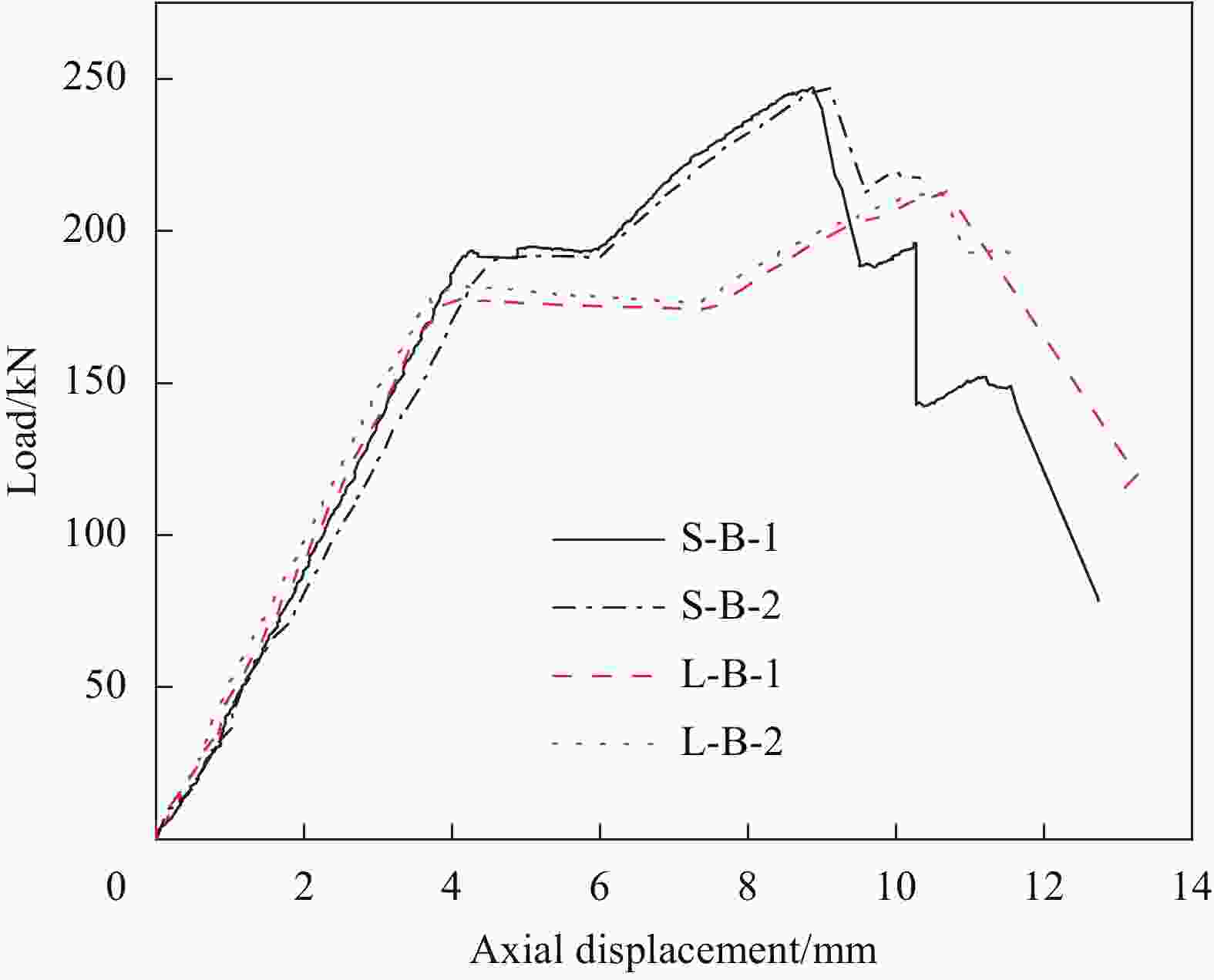

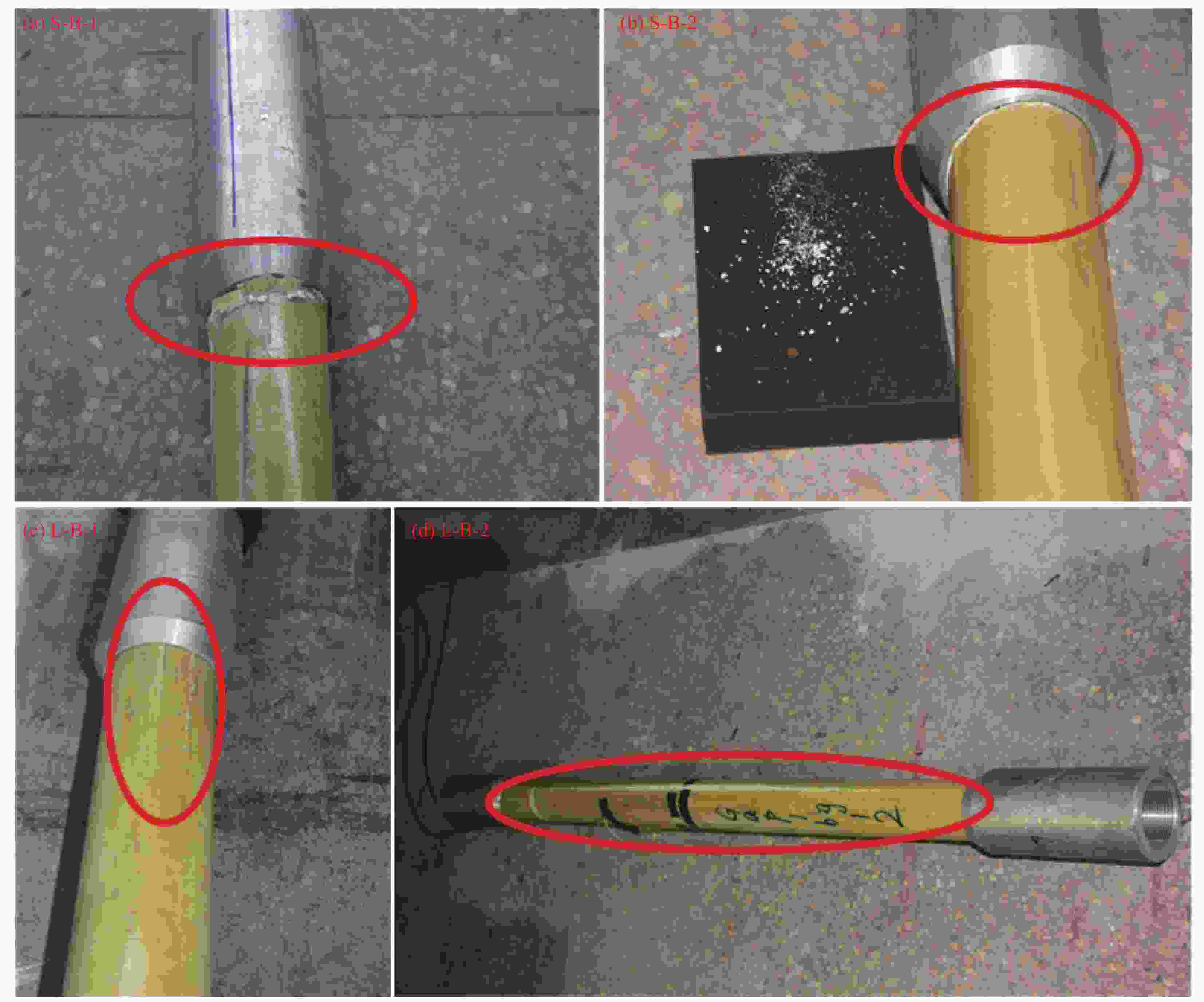

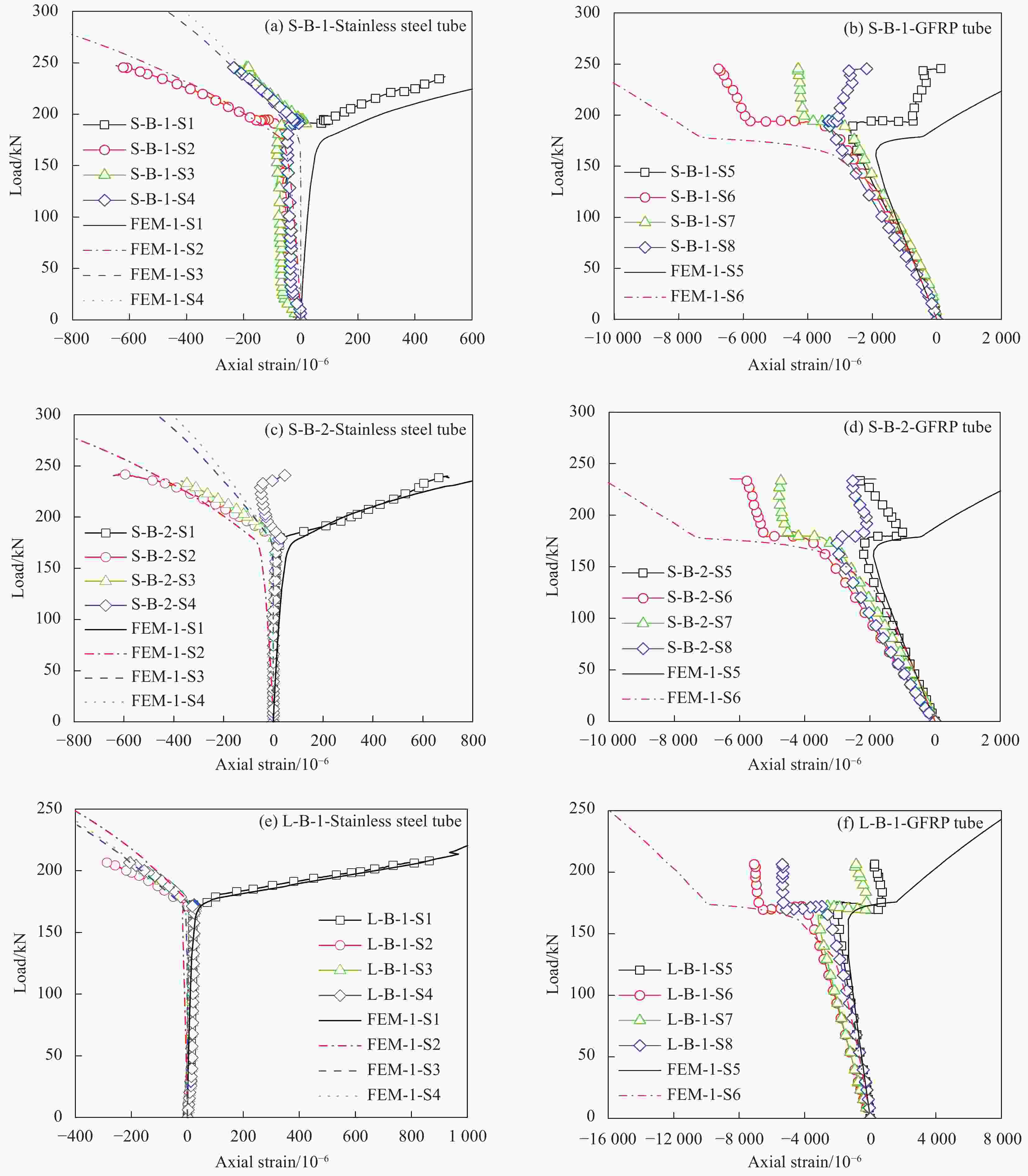

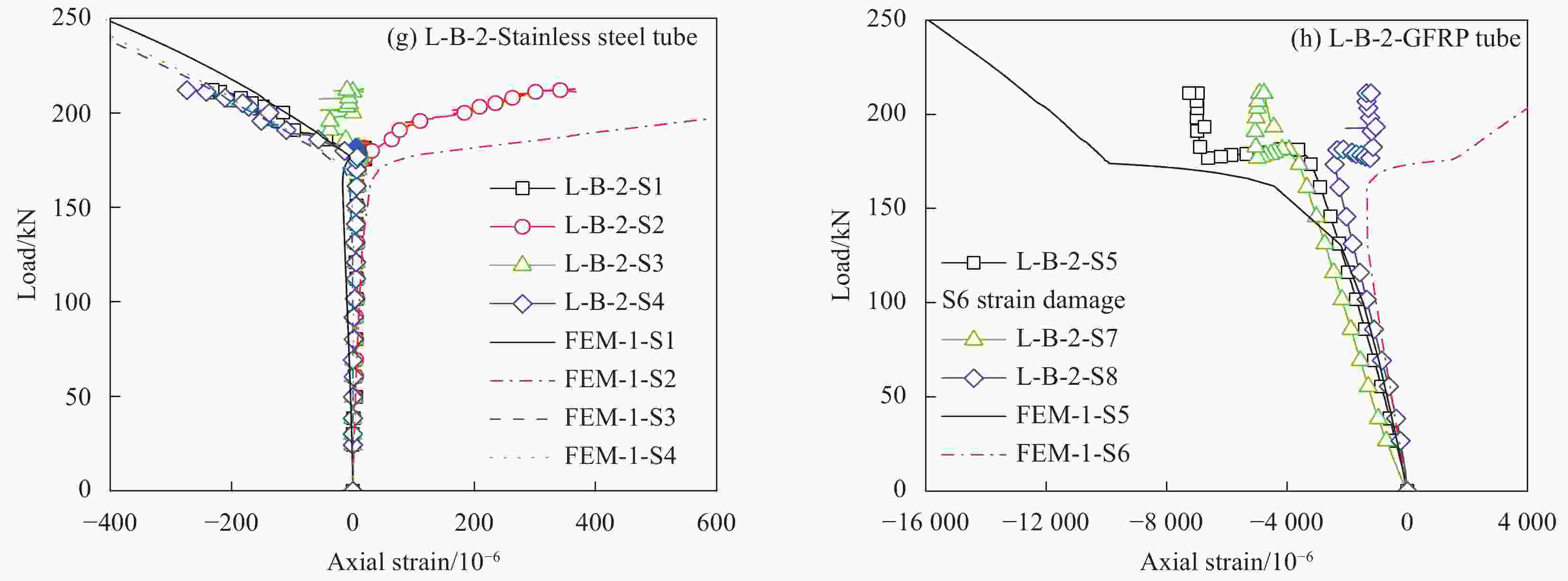

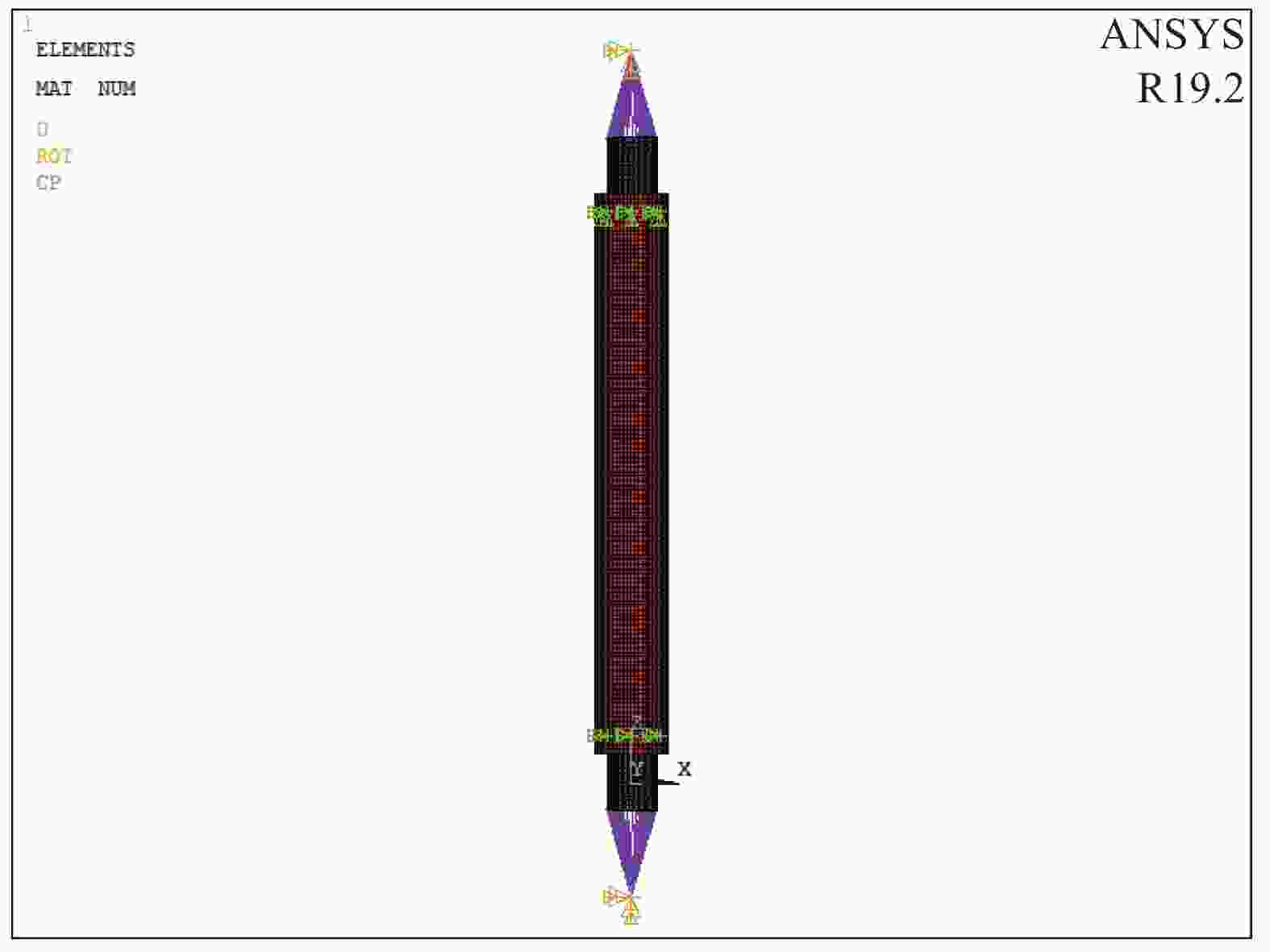

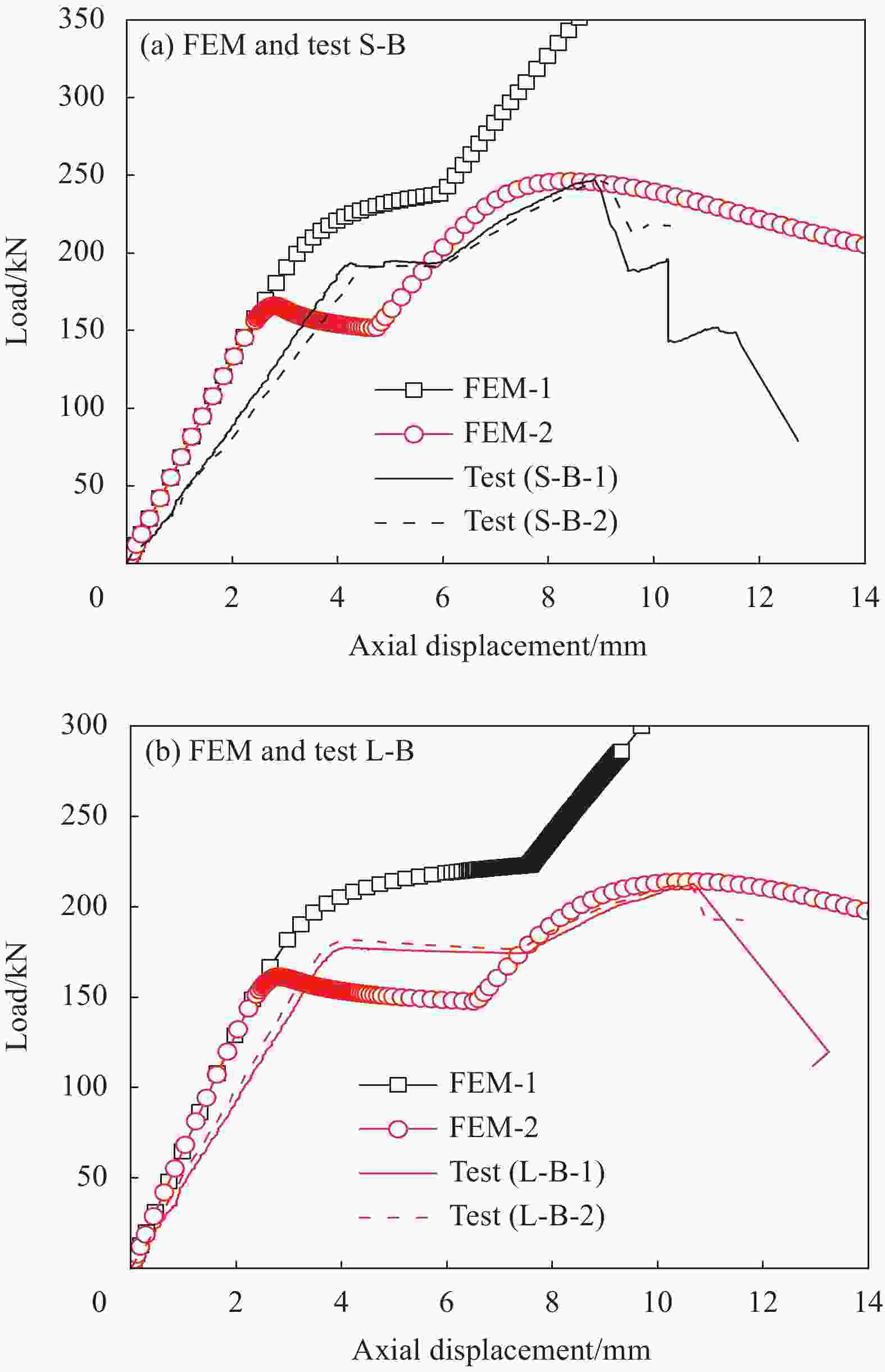

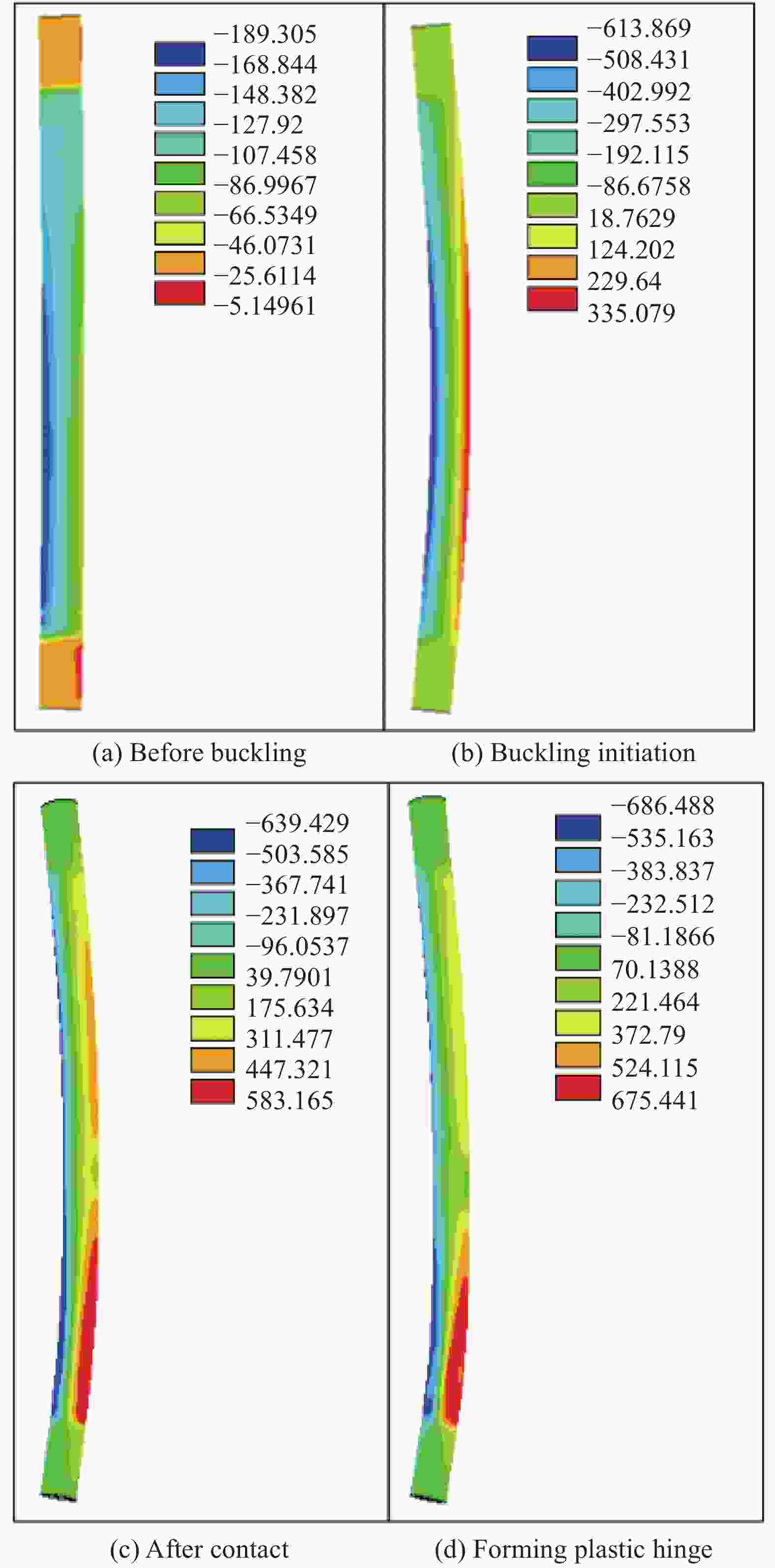

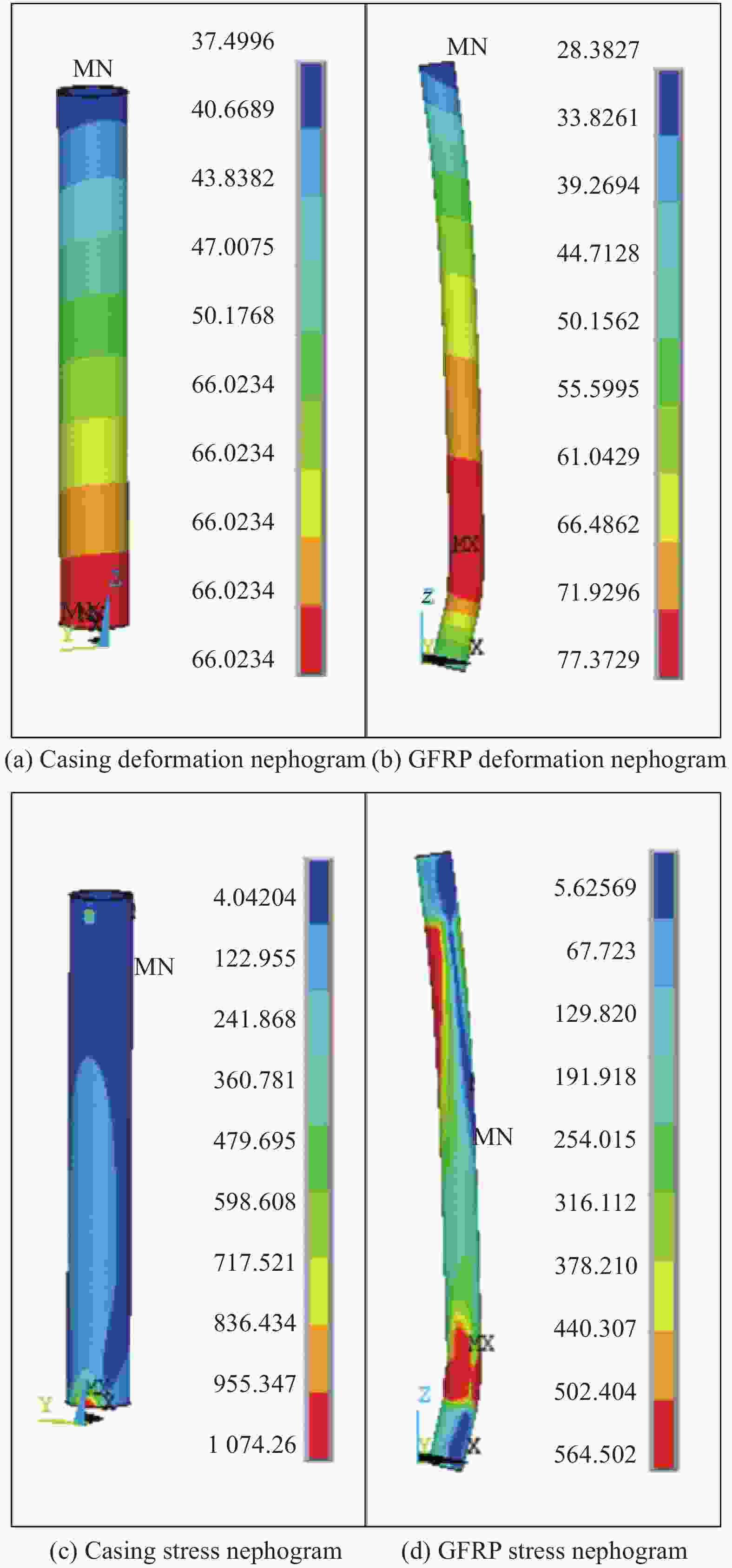

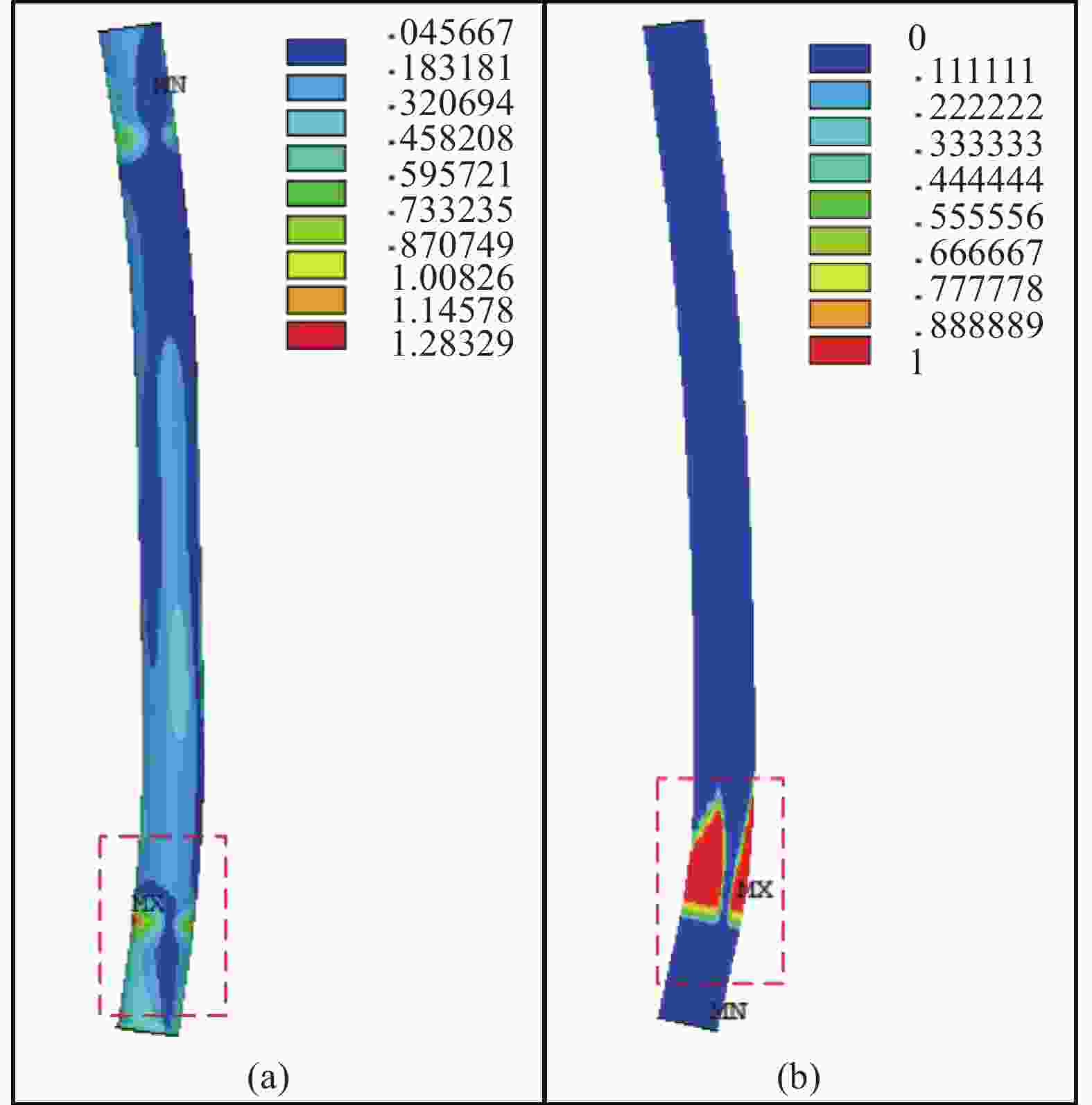

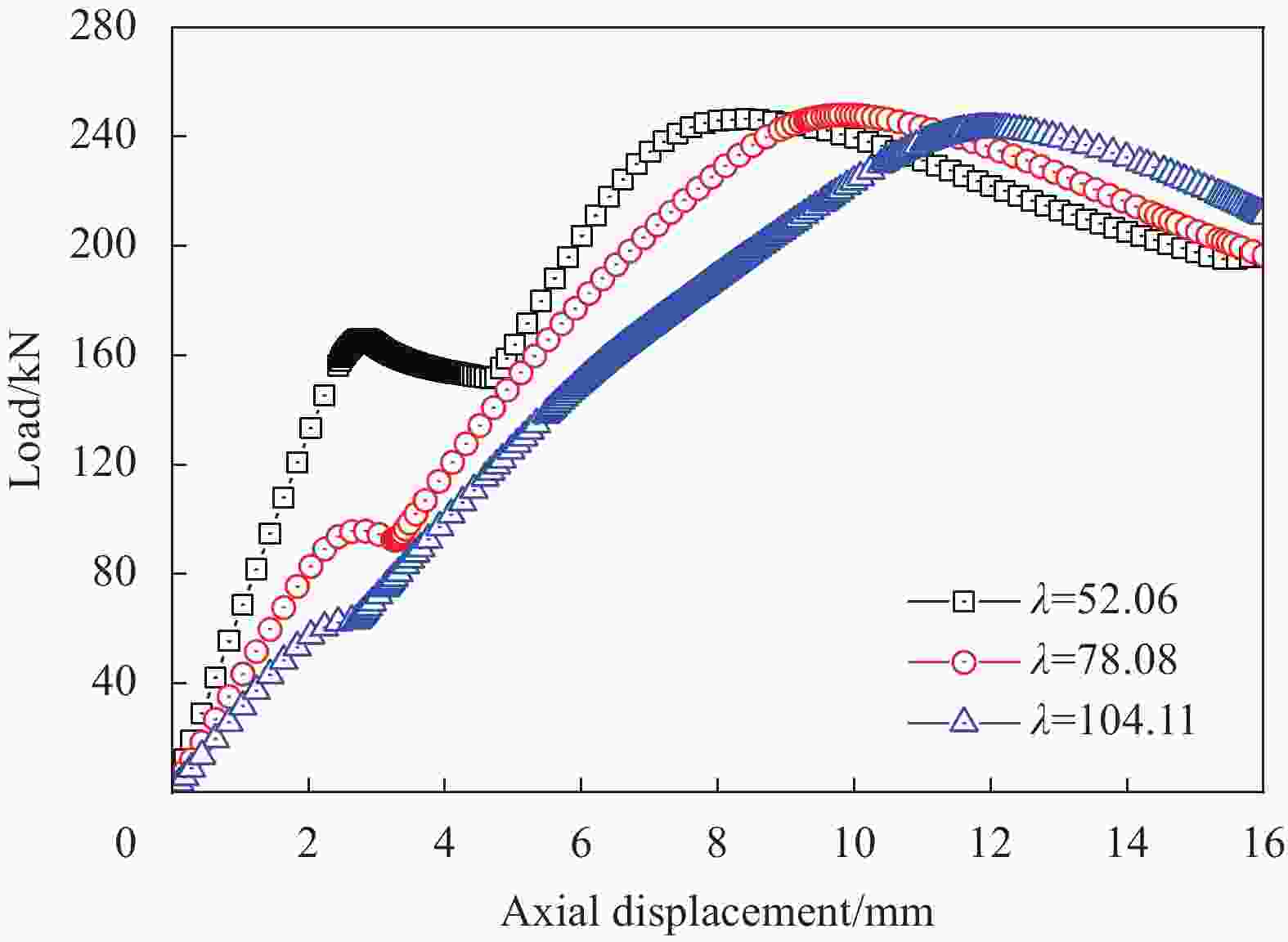

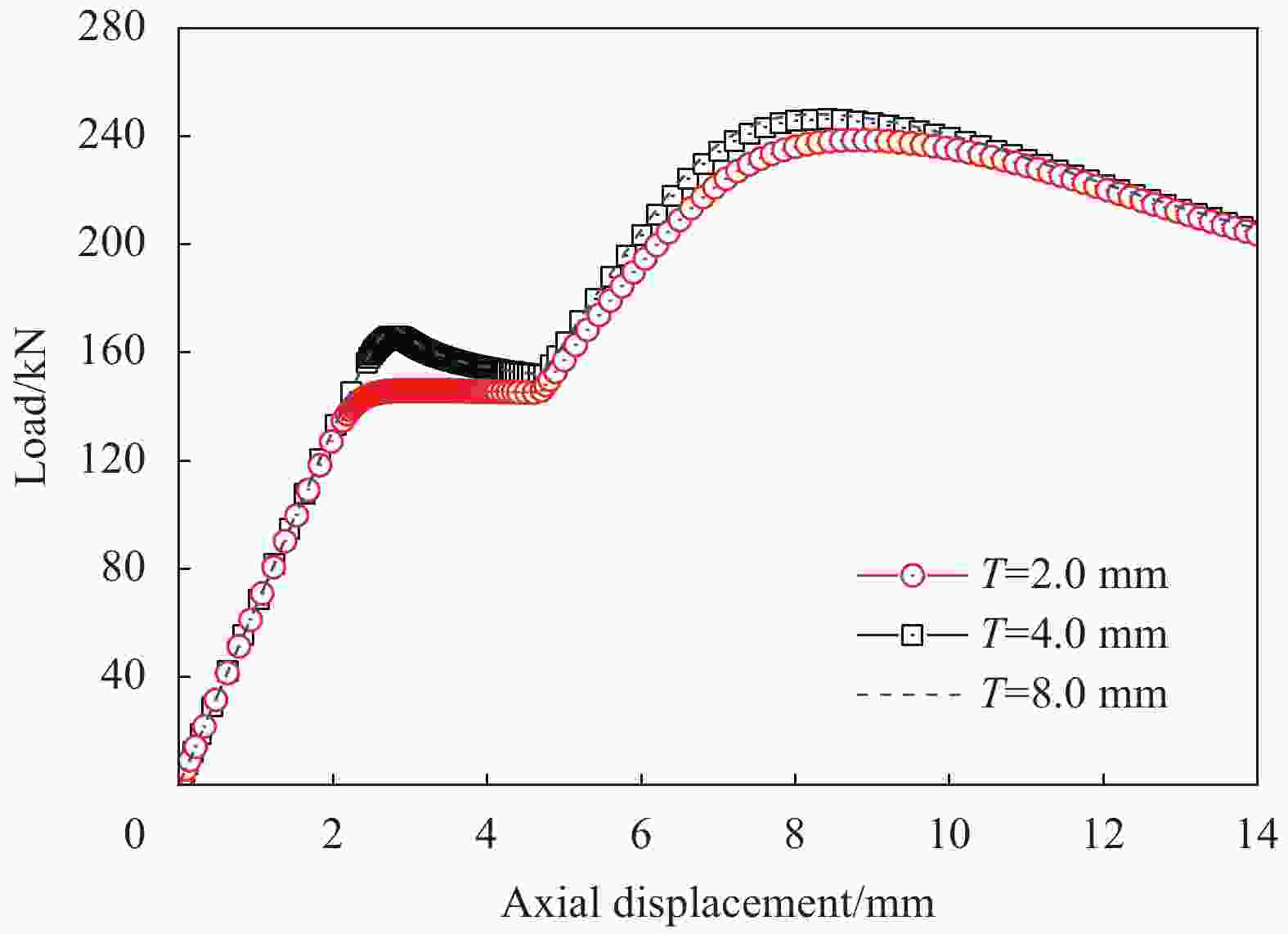

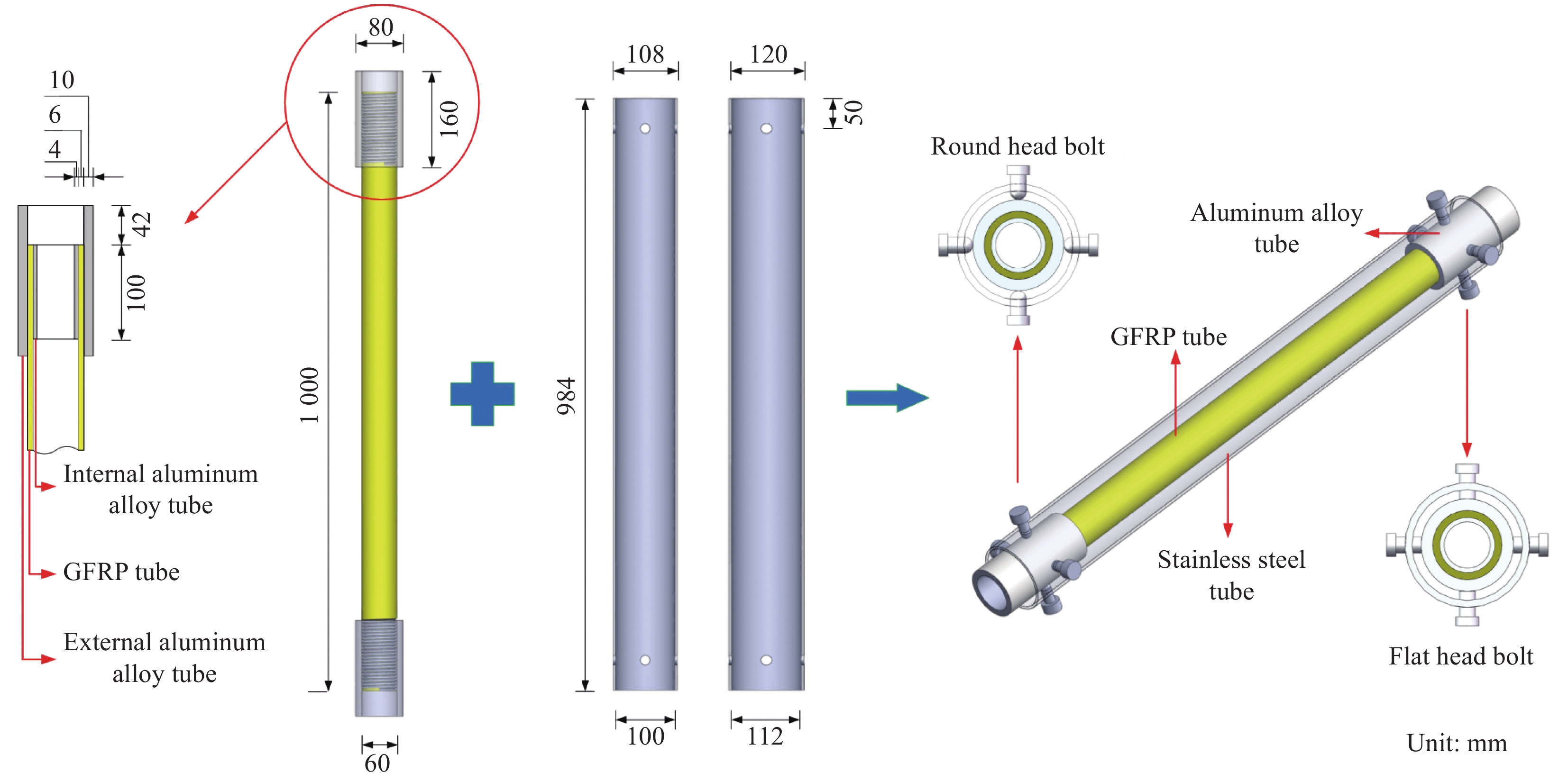

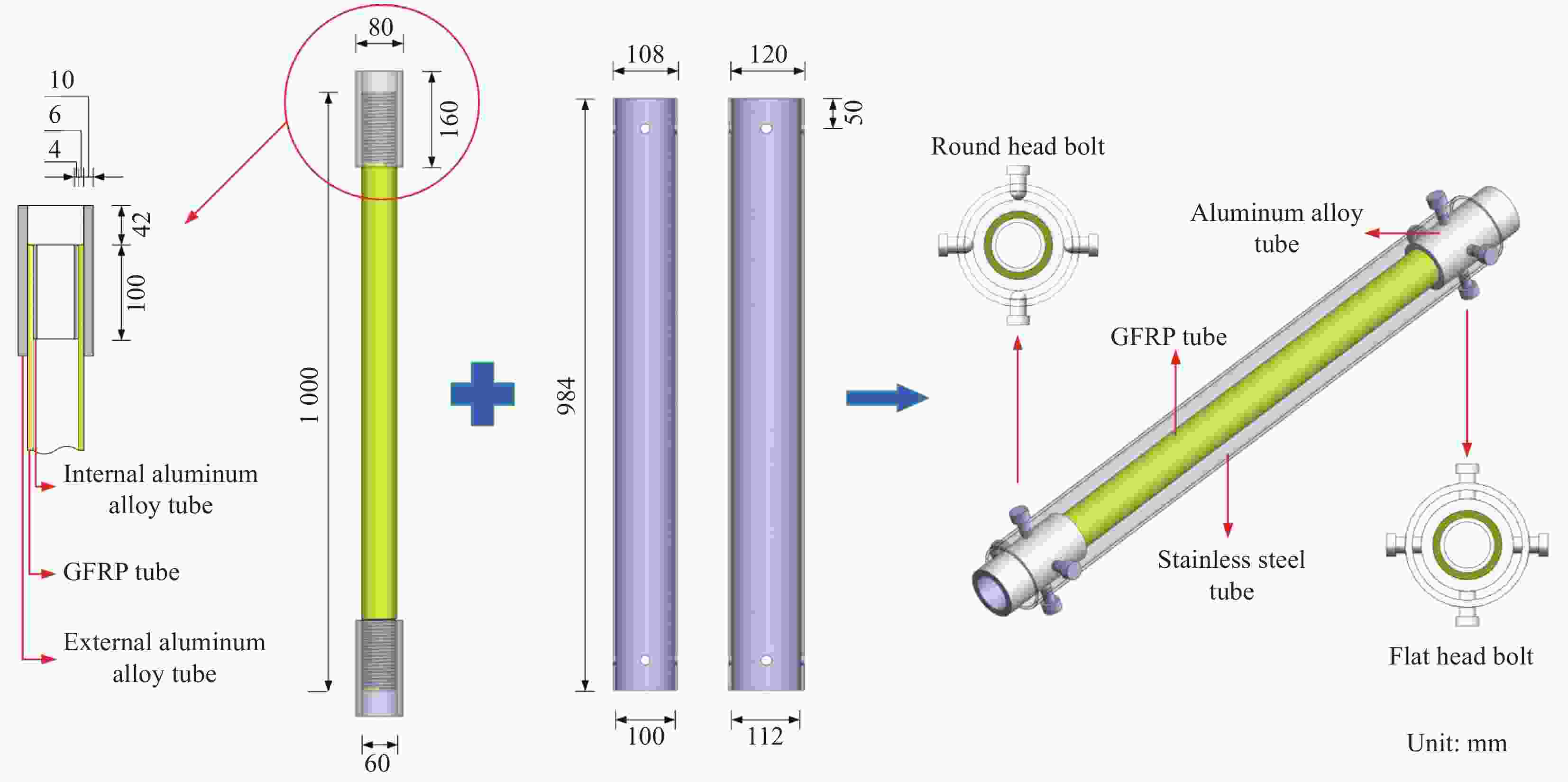

摘要: 为解决复合材料空间桁架结构部分关键压杆失稳引发的连续性倒塌问题,提出了一种由不锈钢套管及螺栓连接系组成的玻璃纤维增强树脂复合材料(GFRP)管整体失稳套管屈曲约束装置。为分析该套管屈曲约束装置对拉挤型GFRP管轴压性能的影响,对3个GFRP管试件和4个套管屈曲约束GFRP管试件进行了轴压试验,观察了试件的受力过程和破坏形态,获得了荷载-位移曲线和荷载-应变曲线,对比研究了两者的极限承载力和破坏模式,同时利用有限元模型分析了不同内核长细比、内核与套管间隙及套管壁厚对GFRP管轴压性能的影响。结果表明:该套管屈曲约束装置能有效约束GFRP管整体失稳变形,其极限承载力和延性均得到提升,并使GFRP管从失稳破坏向材料强度破坏发展;内核长细比越大,套管屈曲约束GFRP管极限承载力相比于内核失稳临界荷载的相对提升幅值越高,约束效果越好;内核与套管间隙越大,GFRP管延性越好,但其极限承载力会降低;套管壁厚过薄会降低GFRP管极限承载力,过厚则约束效果不明显。Abstract: In order to solve the problem of continuous collapse caused by the instability of the key compression struts in fiber reinforced polymer (FRP) space truss structure, a casing buckling restrained brace for the overall instability of glass fiber reinforced polymer (GFRP) tubes composed of stainless steel casing and bolt connection system was proposed. In order to analyze the influence of the casing buckling restrained brace on the axial compression performance of pultruded GFRP tubes, axial compression tests were carried out on three GFRP tube specimens and four GFRP tube specimens with casing buckling-restrained brace. The loading course and failure form of specimens were observed, and the load-displacement curves and load-strain curves were obtained, and the ultimate bearing capacity and failure mode were compared. At the same time, the finite element model was used to analyze the influence of different slenderness ratios of GFRP tubes, core and casing gaps and casing thicknesses on the axial compression performance of GFRP tubes. The results show that: the casing buckling restrained brace can effectively restrain the overall instability deformation of GFRP tubes, its ultimate bearing capacity and ductility are improved, and the GFRP tubes develop from instability failure to material strength failure; the larger the slenderness ratio of the core, the higher the ultimate bearing capacity of the GFRP tubes due to buckling of the casing compared with the critical load of the core instability, and the better the restraint effect; the greater the gap between the inner core and the casing, the better the ductility of the GFRP tube, but its ultimate bearing capacity will be reduced; too thin casing thickness will reduce the ultimate bearing capacity of GFRP tubes, but too thick will have no obvious restraint effect.

-

表 1 玻璃纤维增强树脂复合材料(GFRP)、铝合金及不锈钢的材料力学参数

Table 1. Mechanical parameters of glass fiber reinforced polymer (GFRP), aluminum alloy and stainless steel

Material Elastic modulus/GPa Poisson’s ratio GFRP ${E_1} = 63.0$, ${E_{\rm{2}}}{\rm{ = }}{E_{\rm{3}}}{\rm{ = 14}}{\rm{.2}}$, ${G_{{\rm{12}}}}{\rm{ = }}{G_{{\rm{13}}}}{\rm{ = 13}}{\rm{.0}}$, ${G_{{\rm{23}}}}{\rm{ = 9}}{\rm{.4}}$ ${v_{12}} = {v_{13}} = 0.25$, ${v_{23}} = 0.27$ Al alloy ${E_{{\rm{Al}}}}{\rm{ = 65}}{\rm{.0}}$ ${v_{{\rm{Al}}}} = 0.{\rm{3}}$ Stainless steel ${E_{{\rm{SS}}}}{\rm{ = 200}}{\rm{.0}}$ ${v_{{\rm{SS}}}} = 0.{\rm{3}}$ Notes: ${E_{\rm{1}}}$—Elastic modulus of 1-axis; ${E_{\rm{2}}}$—Elastic modulus of 2-axis; ${E_{\rm{3}}}$—Elastic modulus of 3-axis; ${G_{{\rm{12}}}}$—Shear modulus of plane 12; ${G_{{\rm{13}}}}$—Shear modulus of plane 13; ${G_{{\rm{23}}}}$—Shear modulus of plane 23; ${v_{12}},{v_{13}}$—Major Poisson’s ratio; ${v_{23}}$—Minor Poisson’s ratio; ${E_{{\rm{Al}}}}$—Elastic modulus of Al alloy; ${v_{{\rm{Al}}}}$—Poisson’s ratio of Al alloy; ${E_{{\rm{SS}}}}$—Elastic modulus of stainless steel; ${v_{{\rm{SS}}}}$—Poisson’s ratio of stainless steel. 表 2 GFRP管及带套管屈曲约束装置(BRB)管试件的编号及尺寸

Table 2. Number and size of GFRP and buckling restrained brace (BRB) tubes

mm Number Outer sleeve GFRP tube DO L T DO L T GFRP1 — — — 60 1000 6 GFRP2 GFRP3 L-B-1 120 984 4 60 1000 6 L-B-2 S-B-1 108 S-B-2 Notes: L—Length; DO—Outer diameter; T—Thickness; L-B—Large gap BRB; S-B—Small gap BRB. 表 3 GFRP管与带屈曲约束装置GFRP管轴压试验结果对比

Table 3. Comparison of the axial compression test results between GFRP tubes and GFRP tubes with BRB

Specimen Ultimate load/kN Average load/kN Increase coefficient/% Variation/% Failure mode GFRP1 133.7 137.7 — 1.85 Buckling failure GFRP2 138.9 GFRP3 140.6 S-B-1 247.4 247.4 79.66 0.02 Strength failure S-B-2 247.3 L-B-1 212.9 212.8 54.54 0.05 L-B-2 212.6 -

[1] ZHANG D D, ZHAO Q L, HUANG Y X, et al. Flexural properties of a lightweight hybrid FRP-aluminum modular space truss bridge system[J]. Composite Structures,2014,108:600-615. doi: 10.1016/j.compstruct.2013.09.058 [2] 冯鹏, 田野, 覃兆平. 纤维增强复合材料拉挤型材桁架桥静动力性能研究[J]. 工业建筑, 2013, 43(6):36-41.FENG P, TIAN Y, QIN Z P. Static and dynamic behavior of a truss bridge made of FRP pultruded profiles[J]. Industrial Construction,2013,43(6):36-41(in Chinese). [3] ALEXANDER V, ALEXANDER S, FAUSTO T, et al. Pultruded materials and structures: A review[J]. Journal of Composite Materials,2020,54(26):1-37. [4] 周龙伟, 赵丽滨. 基于失效机制的单向纤维增强树脂复合材料退化模型[J]. 复合材料学报, 2019, 36(6):1389-1397.ZHOU L W, ZHAO L B. Failure mechanisms based degradation model of unidirectional fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2019,36(6):1389-1397(in Chinese). [5] 朱锐杰, 李峰, 刘加顺. 基于能量法的变截面层合管整体稳定承载力计算方法[J]. 复合材料学报, 2017, 34(10):2211-2219.ZHU R J, LI F, LIU J S. A method for calculating bearing capacity of laminated tube with variable cross section based on energy method[J]. Acta Materiae Compositae Sinica,2017,34(10):2211-2219(in Chinese). [6] GOODMAN J W, GISKSMAN J A. Structural evaluation of long boron composite column[J]. Composite Materials: Testing and Designing,1969,460:460-469. [7] HASHEM Z A, YUAN R L. Short vs. long column behavior of pultruded glass-fiber reinforced polymer composites[J]. Construction and Building Materials,2001,15(8):369-378. doi: 10.1016/S0950-0618(01)00018-6 [8] HEWSON P. Buckling of pultruded glass fiber-reinforced channel sections[J]. Composites Structures,1978,9(1):56-60. [9] ZUREICK A H, SCOTT D W. Short-Term behavior and design of fiber-reinforced polymeric slender members under axial compression[J]. Journal of Composites for Construction,1997,1(4):140-149. doi: 10.1061/(ASCE)1090-0268(1997)1:4(140) [10] 南波, 武岳, 孙浩田. 拉挤型CFRP管轴压性能[J]. 哈尔滨工程大学学报, 2015, 36(6):779-783.NAN B, WU Y, SUN H T. Buckling behavior of pultruded carbon fiber reinforced polymer pipes under axial compressive load[J]. Journal of Harbin Engineering University,2015,36(6):779-783(in Chinese). [11] 陈静芬. 基于弹塑性损伤本构模型的复合材料层合板破坏荷载预测[J]. 复合材料学报, 2017, 36(4):773-785.CHEN J F. Failure loads prediction of composite laminates using a combined elastoplastic damage model[J]. Acta Materiae Compositae Sinica,2017,36(4):773-785(in Chinese). [12] 郭小农, 王丽, 罗永峰, 等. CFRP增强铝合金叠层复合材料短柱力学性能[J]. 复合材料学报, 2021, 38(4): 1115-1127.GUO X N, WANG L, LUO Y F, et al. Mechanical properties of CFRP reinforced aluminum alloy laminated composite stub column[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1115-1127(in Chinese). [13] 金福松, 薛江红, 夏飞, 等. 考虑多尺度界面力学特性的损伤复合材料层合板分岔屈曲性能的等代化[J]. 复合材料学报, 2019, 36(5):1132-1142.JIN F S, XUE J H, XIA F, et al. An equivalent model on bifurcation buckling of delaminated composite laminates with multiscale interfacial behaviors[J]. Acta Materiae Compositae Sinica,2019,36(5):1132-1142(in Chinese). [14] FÜLÖP A, IVÁNYI M. Experimentally analyzed stability and ductility behaviour of a space-truss roof system[J]. Thin-Walled Structures,2004,42(2):309-320. doi: 10.1016/S0263-8231(03)00062-4 [15] YANG X, BAI Y, DING F X. Structural performance of a large-scale space frame assembled using pultruded GFRP composites[J]. Composites Structures,2015,133:986-996. doi: 10.1016/j.compstruct.2015.07.120 [16] PRASAD B K. Experimental investigation of sleeved column[C]. Proc. 33rd AIAA/ASCE Structures, Structural Dynamics and Materials Conference, Dallas USA: AIAA/ASCE, 1992: 991-999. [17] SRIDHARA B N. Sleeved compression member: USA, 5175972[P]. 1993-5-1. [18] 申波, 马克俭, 邓长根. 轴压套管构件静力稳定的理论与试验研究[J]. 工程力学, 2013, 30(3):8-16.SHEN B, MA K J, DENG C G. Theoretical and experimental investigations on the static stability of a sleeved column[J]. Engineering Mechanics,2013,30(3):8-16(in Chinese). [19] 申波. 轴压套管构件静力稳定性能的理论与试验研究[D]. 上海: 同济大学, 2007.SHEN B. Theoretical and experimental investigations on the static stability of sleeved compression members[D]. Shanghai: Tongji University, 2007(in Chinese). [20] 张晨辉, 邓长根, 应武挡. 轴压套管构件的典型破坏模式与极限承载力[J]. 东南大学学报(自然科学版), 2019, 49(2):311-320. doi: 10.3969/j.issn.1001-0505.2019.02.016ZHANG C H, DENG C G, YING W D. Typical failure mode and ultimate bearing capacity of sleeved compression member under axial compression[J]. Journal of Southeast University(Natural Science Edition),2019,49(2):311-320(in Chinese). doi: 10.3969/j.issn.1001-0505.2019.02.016 [21] 黄炳生, 崔海涛, 杨放, 等. 套管加固圆钢管轴心受压性能试验研究[J]. 建筑结构学报, 2020, 41(9):198-206.HUANG B S, CUI H T, YANG F, et al. Experimental study on axial compressive behavior of circular steel tubes strengthened by sleeved pipe[J]. Journal of Building Structures,2020,41(9):198-206(in Chinese). [22] 李峰, 朱锐杰, 刘建邦, 等. 一种复合材料管屈曲约束装置: 中国, 201921953198[P]. 2020-7-21.LI F, ZHU R J, LIU J B, et al. A buckling restrained brace for composite tube: China, 201921953198[P]. 2020-7-21(in Chinese). [23] LI F, ZHAO Q L, GAO Y F, et al. A prediction method of the failure load and failure mode for composite pre-tightened tooth connections based on the characteristic lengths[J]. Composite Structures,2016,154:684-693. doi: 10.1016/j.compstruct.2016.06.036 [24] ZHU R J, LI F, SHAO F, et al. Static and dynamic behaviour of a hybrid PFRP-aluminium space truss girder: Experimental and numerical study[J]. Composite Structures,2020,243:112226. doi: 10.1016/j.compstruct.2020.112226 [25] ASCE. Pre-standard for load and resistance factor design of pultruded fiber reinforced polymer structures[S]. Arlington: American Composites Manufacturers Association, 2010. -

下载:

下载: