Experimental study on tensile and bending properties of sea sand ECC reinforced by BFRP bars under chloride salt erosion

-

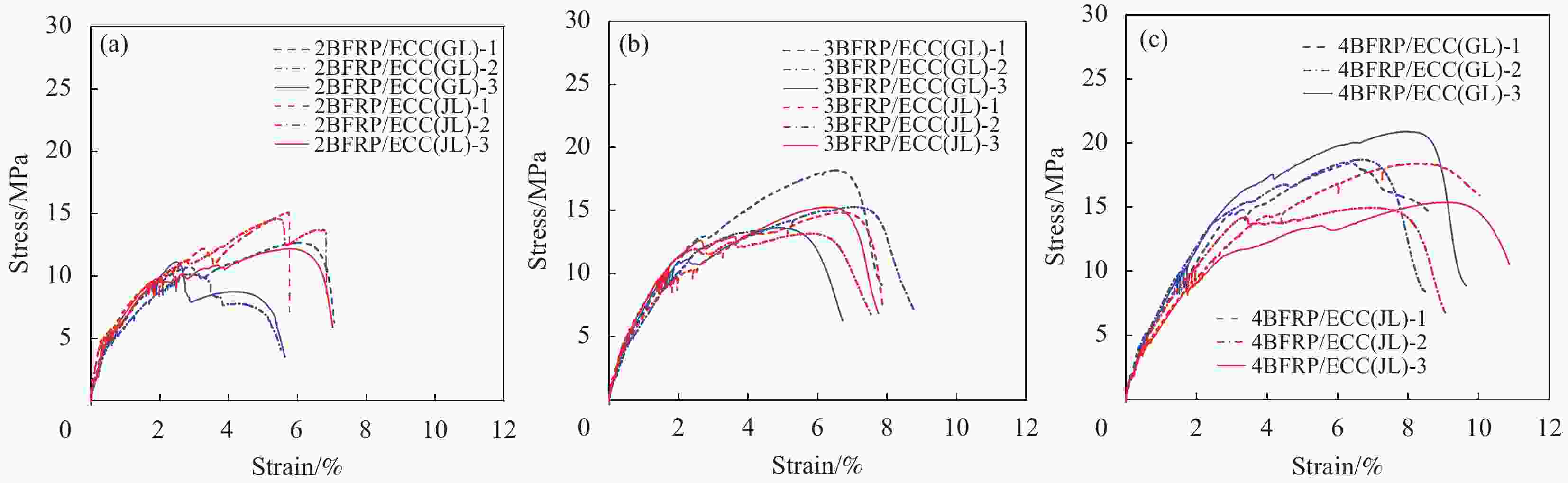

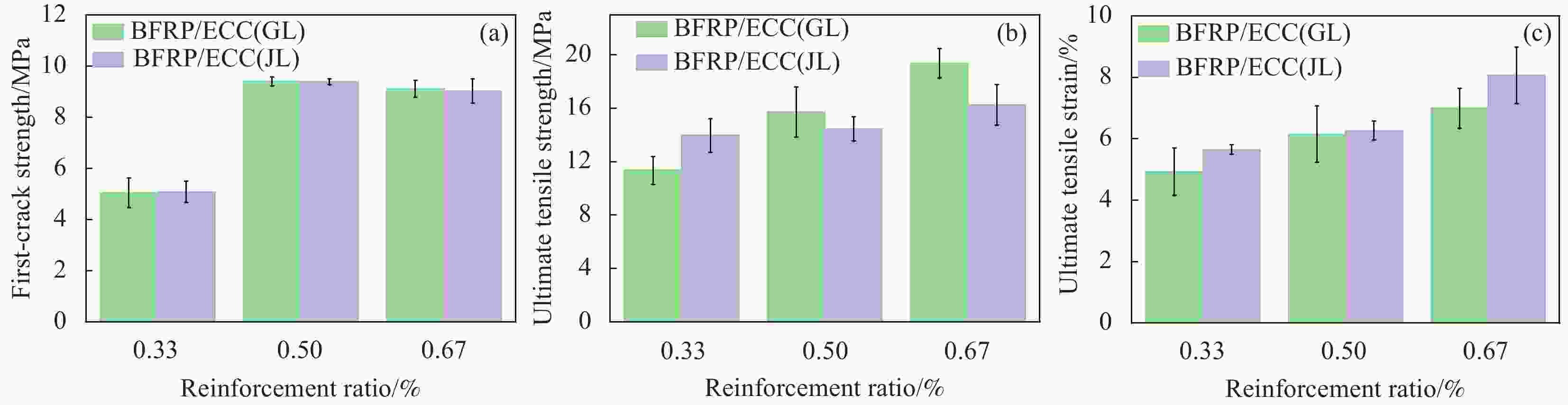

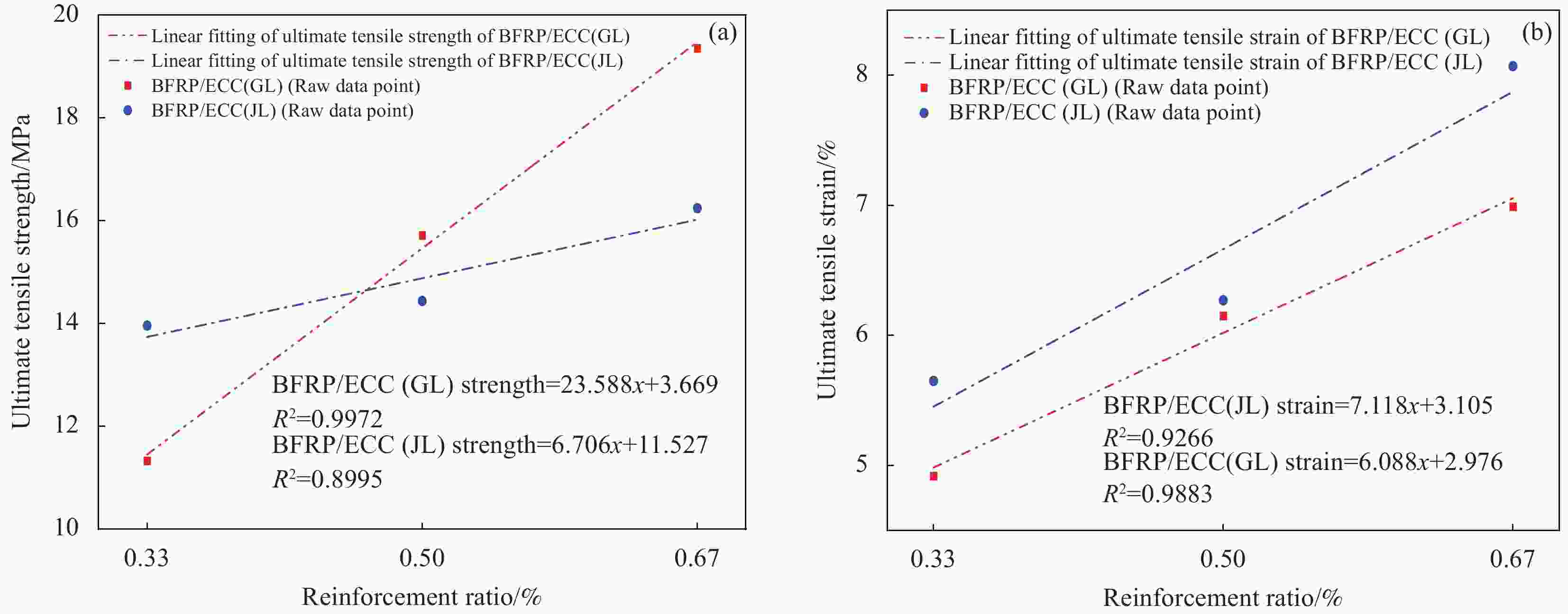

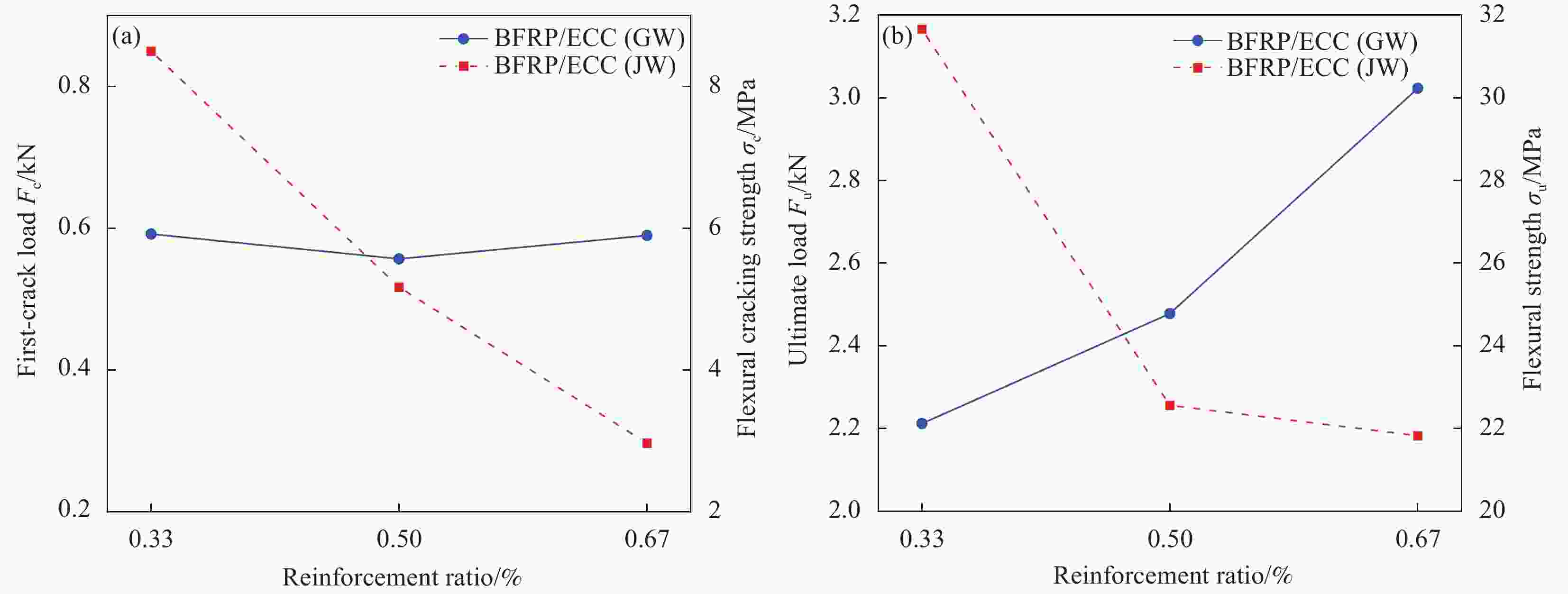

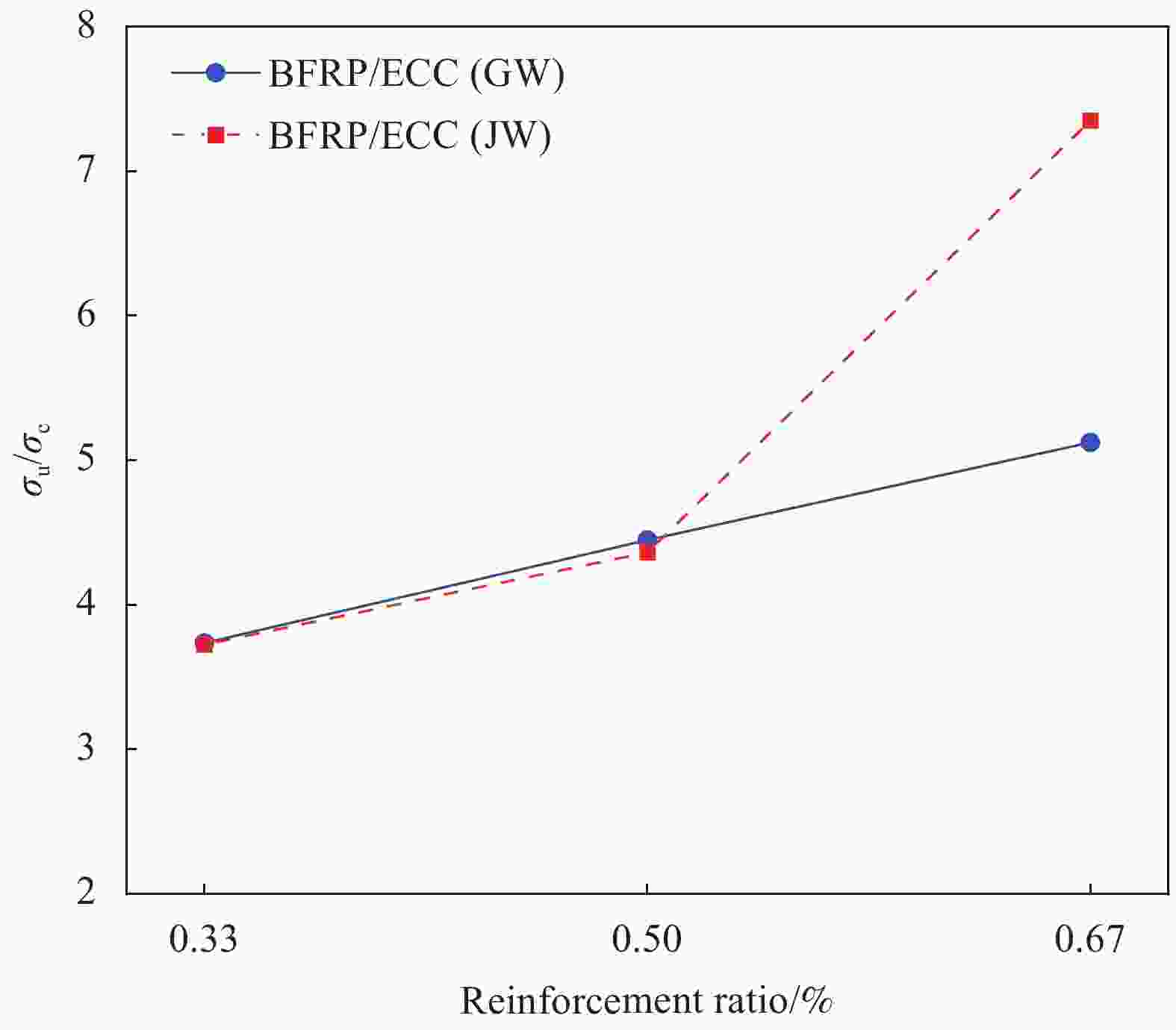

摘要: 为推广使用海洋资源,采用海砂代替硅砂制备工程水泥基复合材料(Engineering cementitious composites, ECC)。将海砂ECC与玄武岩纤维增强树脂复合材料(Basalt fiber reinforced polymer, BFRP) 筋结合,充分发挥两种材料的优点,以获得更强的耐腐蚀性能及更为优异的拉伸性能。通过单轴拉伸及四点弯曲试验,研究了不同侵蚀制度及配筋率对BFRP筋增强海砂ECC的拉伸性能及弯曲性能的影响,并与未配筋的海砂ECC作比较。结果表明,BFRP筋增强海砂ECC的极限拉应力与海砂ECC相比提升了2.46~4.92倍,极限拉应变提升了1.40~2.94倍,干湿循环作用下BFRP筋增强海砂ECC的极限荷载是海砂ECC极限荷载的3.14~4.29倍。不同侵蚀制度下,BFRP筋增强海砂ECC的最佳配筋率均为0.67%。研究的BFRP筋增强海砂ECC可为桥面无缝连接板等设计提供参考。Abstract: In order to popularize the use of marine resources, sea sand was used to prepare engineering cementitious composite (ECC) instead of silica sand. By combining sea sand ECC with basalt fiber reinforced polymer (BFRP) bars, the advantages of the two kinds of materials can be fully exploited to obtain higher corrosion resistance and better tensile properties. Through uniaxial tensile and four-point bending tests, the effects of different erosion systems and reinforcement ratio on the tensile and bending properties of BFRP reinforced sea sand ECC were studied, and compared with the sea sand ECC without BFRP reinforcement. The results show that the ultimate tensile stress of BFRP reinforced sea sand ECC is increased by 2.46-4.92 times and the ultimate tensile strain is increased by 1.40-2.94 times compared with the sea sand ECC. The ultimate load of BFRP reinforced sea sand ECC is 3.14-4.29 times of the sea sand ECC without BFRP reinforcement under the effect of dry-wetting cycling. Under different erosion systems, the optimal reinforcement ratio of BFRP reinforced sea sand ECC is 0.67%. The BFRP reinforced sea sand ECC can provide reference for the design of seamless bridge deck.

-

Key words:

- Friedel’s salt /

- bending performance /

- tensile performance /

- BFRP bars /

- sea sand /

- chlorine salt erosion

-

表 1 水泥、粉煤灰和偏高岭土的化学成分

Table 1. Chemical composition of cement, fly ash and metakaolin

wt% Material CaO SiO2 Al2O3 Fe2O3 MgO SO3 Na2O K2O TiO2 P2O5 Cement 63.21 18.48 6.74 3.45 3.24 3.16 0.171 0.533 0.35 0.158 Fly ash 2.58 32.54 24.76 4.92 0.397 1.17 0.523 0.589 0.717 0.251 Metakaolin 0.04 53.29 43.11 0.68 0.22 0.11 0.44 0.42 0.28 0.52 表 2 聚乙烯醇(PVA)纤维的物理力学性能

Table 2. Physical and mechanical characteristics of polyvinyl alcohol (PVA) fiber

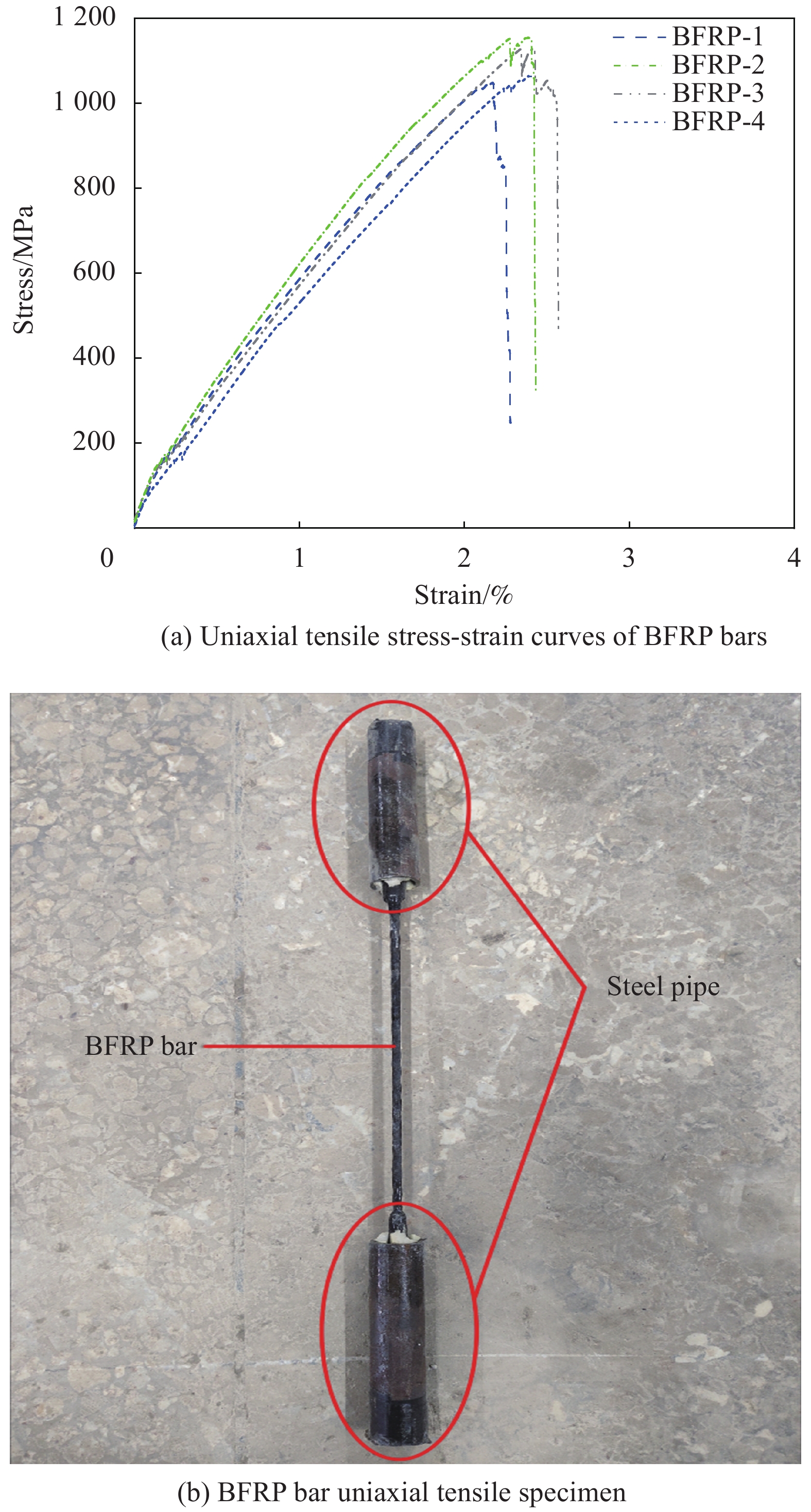

Length/mm Diameter/μm Tensile strength/MPa Elongation/% Elastic modulus/GPa Density /(g·cm−3) 12 39 1620 7 42.8 1.3 表 3 玄武岩纤维增强树脂复合材料(BFRP)筋的物理力学性能

Table 3. Physical and mechanical characteristics of basalt fiber reinforced polymer (BFRP) bars

Diameter/

mmPeak tensile

strength/MPaElongation/

%Elastic

modulus/GPaDensity/

(g·cm−3)Longitudinal linear expansion

coefficient/(10−6℃−1)4 1099.52(44.08) 2.36(0.14) 57.28(2.18) 1.9 9.0 Notes: Data in brackets are standard deviations. 表 4 海砂工程水泥基复合材料(ECC)配合比

Table 4. Mixture proportion of sea sand engineering cementitious composite (ECC)

kg/m3 Cement Fly ash Metakaolin Silica sand Sea sand Water Fiber 278 890 56 178 267 330 26 表 5 BFRP筋增强海砂ECC复合板试件明细

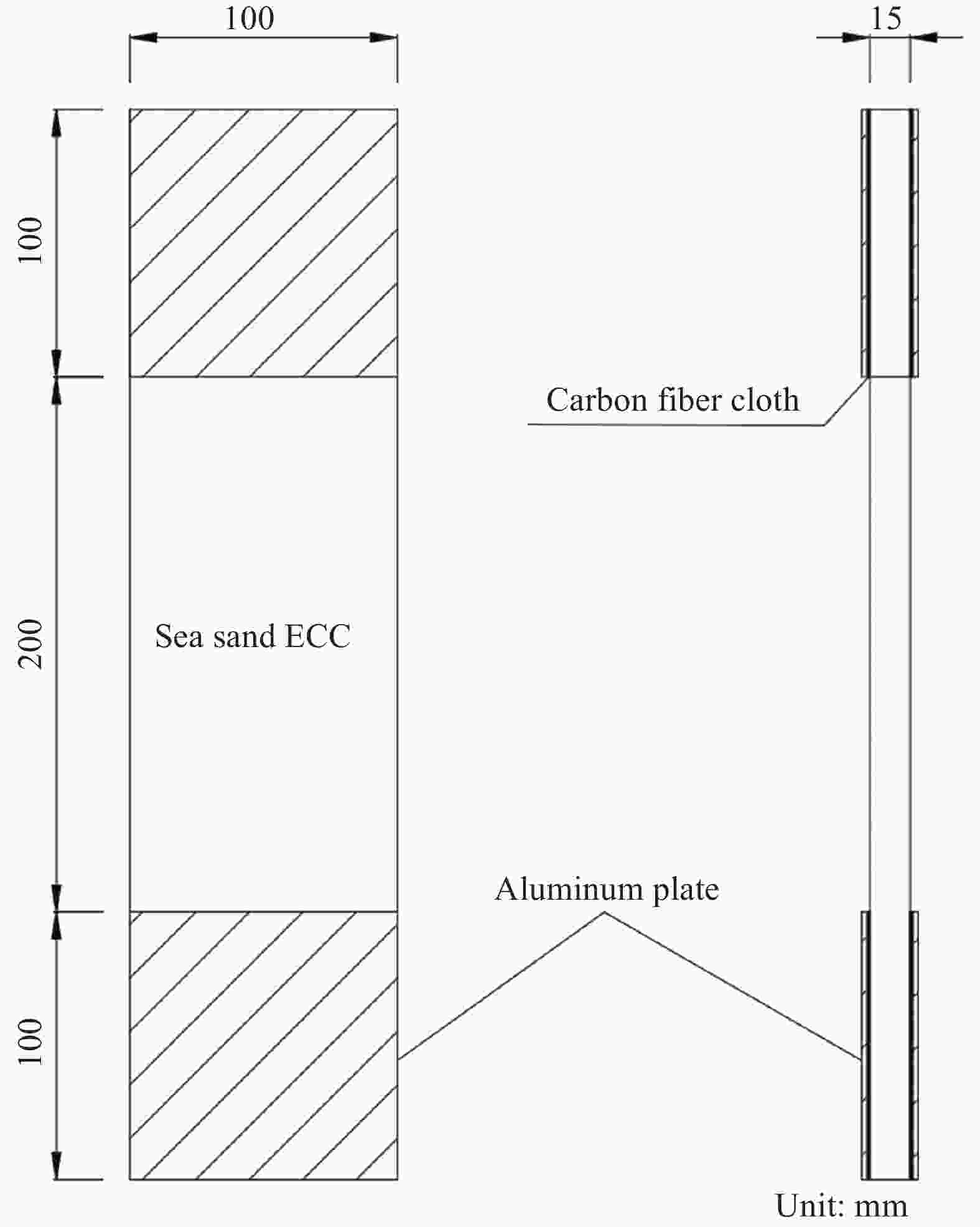

Table 5. Specimen detail of BFRP reinforced sea sand ECC

Specimen ID Erosion

systemNumber of

BFRP bars4BFRP/ECC(GL, GW) Wetting-drying cycling in NaCl solution 4 3BFRP/ECC(GL, GW) 3 2BFRP/ECC(GL, GW) 2 4BFRP/ECC(JL, JW) Soaking in NaCl solution 4 3BFRP/ECC(JL, JW) 3 2BFRP/ECC(JL, JW) 2 Notes: In specimen ID, "G"—Wetting-drying cycling in NaCl solution; "J"—Soaking in NaCl solution; "L"—Uniaxial tensile test; "W"—Four-point bending test. 表 6 不同侵蚀制度及配筋率下BFRP筋增强海砂ECC复合板的单轴拉伸试验结果

Table 6. Uniaxial tensile test results of BFRP reinforced sea sand ECC under different erosion systems and reinforcement ratios

Specimen

IDFirst-crack

strength/

MPaUltimate

tensile

strength/

MPaUltimate

tensile

strain/

%2BFRP/ECC(GL) 5.04 11.33 4.92 3BFRP/ECC(GL) 9.40 15.71 6.15 4BFRP/ECC(GL) 9.11 19.35 6.99 2BFRP/ECC(JL) 5.08 13.96 5.65 3BFRP/ECC(JL) 9.38 14.44 6.27 4BFRP/ECC(JL) 9.02 16.24 8.07 表 7 不同侵蚀制度下BFRP筋增强海砂ECC复合板的四点弯曲试验结果

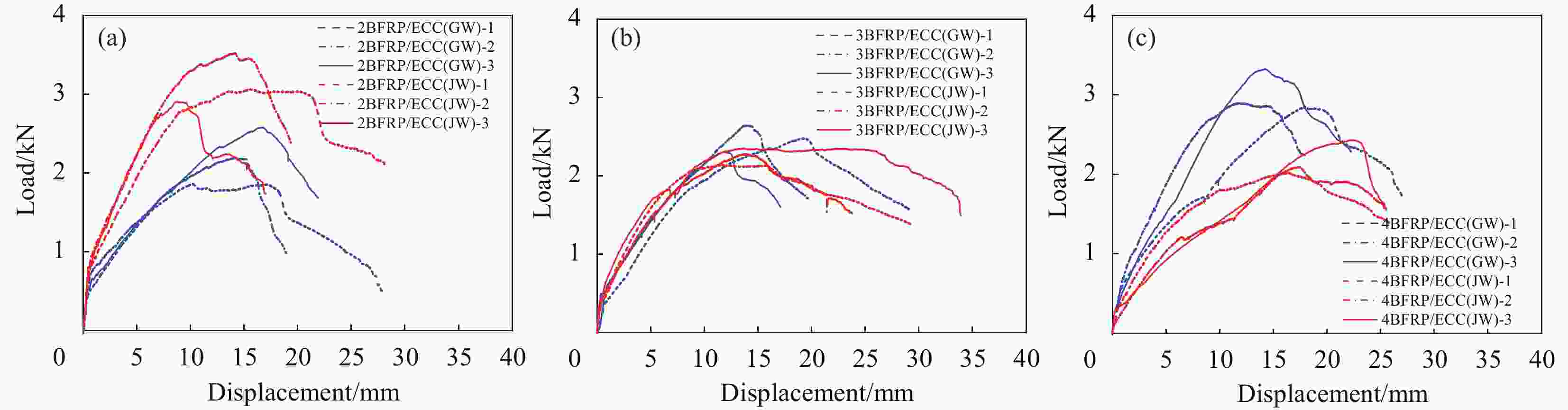

Table 7. Four-point bending test results of BFRP reinforced sea sand ECC under different erosion systems

Specimen ID First-crack load/N First-crack deflection/mm Ultimate load/N Ultimate deflection/mm 2BFRP/ECC(GW) 592 0.55 2212 15.47 3BFRP/ECC(GW) 557 0.45 2478 15.00 4BFRP/ECC(GW) 590 0.88 3023 15.60 2BFRP/ECC(JW) 850 0.67 3166 11.03 3BFRP/ECC(JW) 517 0.60 2256 12.97 4BFRP/ECC(JW) 297 0.30 2183 18.70 表 8 BFRP筋增强海砂ECC弯曲韧性指标

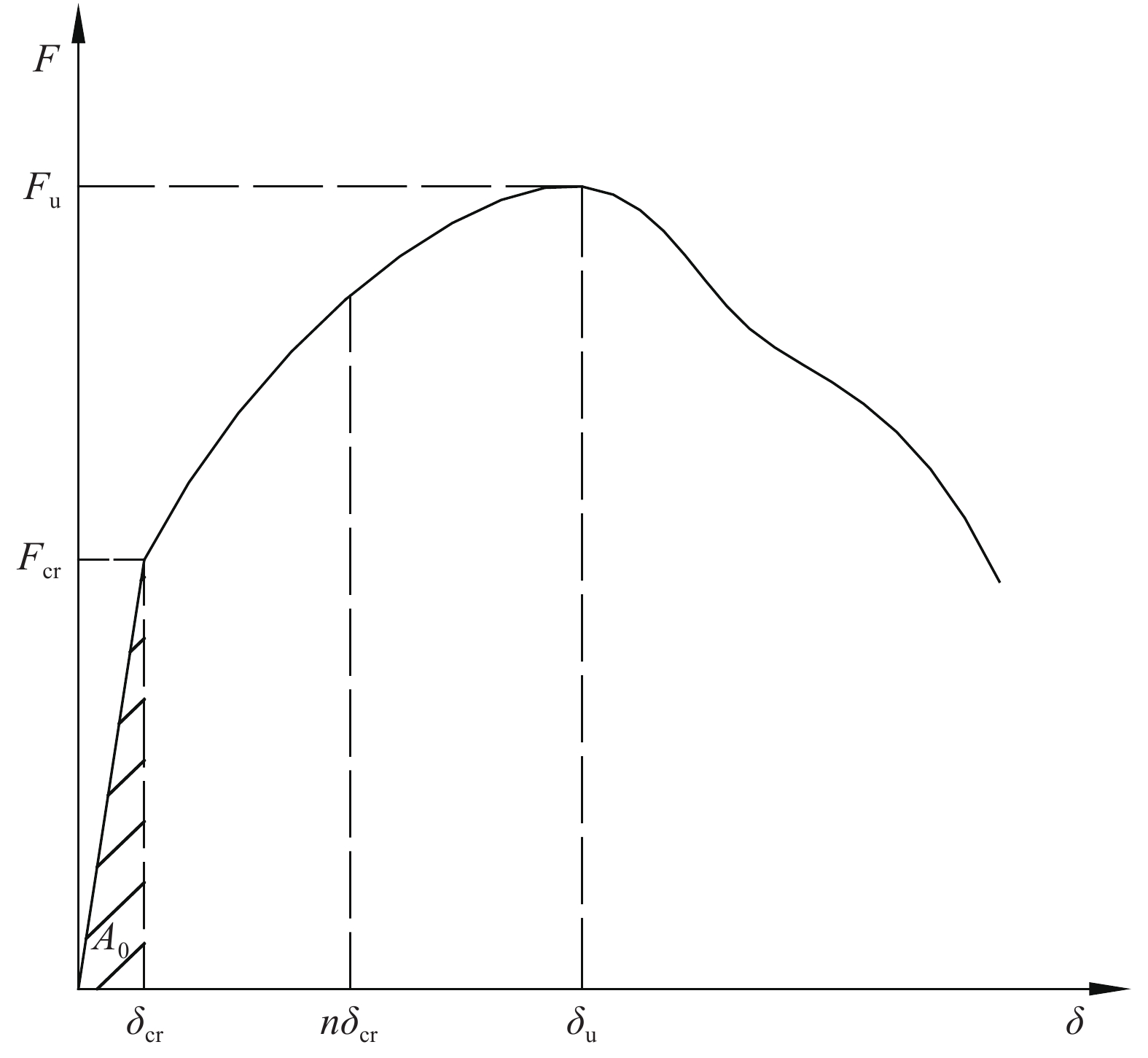

Table 8. Flexural toughness indexes of BFRP bars reinforced sea sand ECC

Specimen ID I5 I10 I20 I30 Iu 2BFRP/ECC(GW) 6 12 33 60 162 3BFRP/ECC(GW) 9 23 66 128 613 4BFRP/ECC(GW) 6 16 47 89 108 2BFRP/ECC(JW) 6 14 38 69 95 3BFRP/ECC(JW) 6 14 37 68 131 4BFRP/ECC(JW) 6 13 37 73 840 Note: I5, I10, I20, I30 and Iu—Flexural toughness indexes of BFRP bars reinforced sea sand ECC. -

[1] 李庆华, 徐世烺. 超高韧性水泥基复合材料基本性能和结构应用研究进展[J]. 工程力学, 2009(S2):23-67.LI Qinghua, XU Shilang. Performance and application of ultra high toughness cementitious composite: A review[J]. Engineering Mechanics,2009(S2):23-67(in Chinese). [2] HUANG B T, YU J, WU J, et al. Seawater sea-sand engineered cementitious composites (SS-ECC) for marine and coastal applications[J]. Composites Communications,2020(20):100353. [3] 徐世烺, 李庆华, 李贺东. 碳纤维编织网增强超高韧性水泥基复合材料弯曲性能的试验研究[J]. 土木工程学报, 2007(12):69-76. doi: 10.3321/j.issn:1000-131x.2007.12.009XU Shilang, LI Qinghua, LI Hedong. An experiment study on the flexural properties of carbon textile reinforced ECC[J]. China Civil Engineering Journal,2007(12):69-76(in Chinese). doi: 10.3321/j.issn:1000-131x.2007.12.009 [4] 葛文杰, 陈俊钰, 戴强, 等. 钢筋增强ECC-混凝土复合梁受弯性能试验研究[J]. 混凝土, 2017(11):35-39. doi: 10.3969/j.issn.1002-3550.2017.11.009GE Wenjie, CHEN Junyu, DAI Qiang, et al. Experimental study on the flexural behavior of ECC-concrete composite beams reinforced of steel bars[J]. Concrete,2017(11):35-39(in Chinese). doi: 10.3969/j.issn.1002-3550.2017.11.009 [5] 范建伟, 李可, 王新玲, 等. 不锈钢绞线工程用水泥基复合材料的拉伸试验分析[J]. 工业建筑, 2020, 50(9):94-98.FAN Jianwei, LI Ke, WANG Xinling, et al. Experimental analysis of stainless steel strand reinforce ECC under tension[J]. Industrial Construction,2020,50(9):94-98(in Chinese). [6] 王新玲, 杨广华, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料受拉应力-应变关系[J]. 复合材料学报, 2020, 37(12):3220-3228.WANG Xinling, YANG Guanghua, QIAN Wenwen, et al. Tensile stress-strain relationship of engineered cementitious composites reinforced by high-strength stainless steel wire mesh[J]. Acta Materiae Compositae Sinica,2020,37(12):3220-3228(in Chinese). [7] 王新玲, 陈永杰, 钱文文, 等. 高强不锈钢绞线网增强工程水泥基复合材料弯曲性能试验[J]. 复合材料学报, 2021, 38(4): 1292-1301.WANG Xinling, CHEN Yongjie, QIAN Wenwen, et al. Experiment on bending performance of engineered cementitious composites reinforced by high-strength stainless steel wire strand mesh [J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1292-1301(in Chinese). [8] 夏立鹏, 张黎飞, 郑愚. CFRP增强工程水泥基复合材料桥面连接板的结构和性能[J]. 复合材料学报, 2019, 36(4):848-859.XIA Lipeng, ZHANG Lifei, ZHENG Yu. Structural performance of CFRP reinforced ECC link slabs in jointless bridge decks[J]. Acta Materiae Compositae Sinica,2019,36(4):848-859(in Chinese). [9] 尹世平, 华云涛, 徐世烺. FRP配筋混凝土结构研究进展及其应用[J]. 建筑结构学报, 2021, 42(1):134-150.YIN Shiping, HUA Yuntao, XU Shilang. A review on research progress and application of concrete structures internally reinforced with FRP bars[J]. Journal of Building Structures,2021,42(1):134-150(in Chinese). [10] 周甲佳, 姚少科, 景川, 等. FRP筋-ECC梁受弯性能[J]. 建筑科学与工程学报, 2020, 37(6):46-54.ZHOU Jiajia, YAO Shaoke, JING Chuan, et al. Flexural behavior of FRP-reinforced ECC beam[J]. Journal of Architecture and Civil Engineering,2020,37(6):46-54(in Chinese). [11] ZHENG Y, ZHANG L F, XIA L P. Investigation of the behaviour of flexible and ductile ECC link slab reinforced with FRP[J]. Construction and Building Materials,2018,166:694-711. doi: 10.1016/j.conbuildmat.2018.01.188 [12] 葛文杰, 冯肖, 季翔, 等. 纤维增强复材筋增强工程用水泥基复合材料-混凝土复合梁受弯性能试验研究[J]. 工业建筑, 2017, 47(11):23-27, 94.GE Wenjie, FENG Xiao, JI Xiang, et al. Experimental research on the flexural behavior of ECC-concrete composite beam reinforce with FRP bars[J]. Industrial Construction,2017,47(11):23-27, 94(in Chinese). [13] 中华人民共和国国家质量监督检验检疫总局. GB/T 14684—2011 建设用砂[S]. 北京: 中国标准出版社, 2011.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 14684—2011 Sand for construction[S]. Beijing: China Standards Press, 2011(in Chinese). [14] 中华人民共和国住房和城乡建设部. JG/T 406—2013 土木工程用玻璃纤维增强筋[S]. 北京: 中国标准出版社, 2013.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. JG/T 406—2013 Class fibre reinforced plastics rebar for civil engineering[S]. Beijing: China Standards Press, 2013(in Chinese). [15] LI V C, WANG S, WU C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC)[J]. ACI Materials Journal,2001(6):483-492. [16] 吴智深, 汪昕, 吴刚. FRP增强工程结构体系[M]. 北京: 科学出版社, 2017: 317.WU Zhishen, WANG Xin, WU Gang. FRP reinforced engineering structural systems[M]. Beijing: Science Press, 2017: 317(in Chinese). [17] 张庆章, 黄庆华, 张伟平, 等. 海水潮汐区混凝土氯盐侵蚀加速试验方法研究[J]. 结构工程师, 2010, 26(3):145-153. doi: 10.3969/j.issn.1005-0159.2010.03.024ZHANG Qingzhang, HUANG Qinghua, ZHANG Weiping, et al. Study on accelerated chloride penetration testing methods for concrete in tidal zone[J]. Structural Engineers,2010,26(3):145-153(in Chinese). doi: 10.3969/j.issn.1005-0159.2010.03.024 [18] 曾俊杰, 王胜年, 范志宏, 等. 偏高岭土改善海工混凝土抗氯离子侵蚀性的效果及机理[J]. 武汉理工大学学报, 2015, 37(4): 22-28.ZENG Junjie, WANG Shengnian, FAN Zhihong, et al. Improvement effect and mechanism of metakaolin on marine concrete chloride penetration resistance[J]. Journal of Wuhan University of Technology, 2015, 37(4): 22-28(in Chinese). [19] LI V C. Tailoring ECC for special attributes: A review[J]. International Journal of Concrete Structures and Materials,2012(9):135-144. [20] 高杰, 张暄, 韩乐冰, 等. 超高韧性水泥基复合材料弯曲韧性研究[J]. 硅酸盐通报, 2020, 39(4):1050-1056.GAO Jie, ZHANG Xuan, HAN Lebing, et al. Study on bending toughness of ultra-high toughness cementitious composites[J]. Bulletin of the Chinese Ceramic Society,2020,39(4):1050-1056(in Chinese). [21] 史占崇, 苏庆田, 邵长宇, 等. 粗骨料UHPC的基本力学性能及弯曲韧性评价方法[J]. 土木工程学报, 2020, 53(12):86-97.SHI Zhanchong, SU Qingtian, SHAO Changyu, et al. Basic mechanical behavior and flexural toughness evaluation method of coarse aggregate UHPC[J]. China Civil Engineering Journal,2020,53(12):86-97(in Chinese). [22] American Society of Testing Materials. ASTM-C1018-98 Standard test method for flexural toughness and first-crack strength of fiber reinforced concrete[S]. Philadelphia, America: Book of ASTM Standard, 1997. -

下载:

下载: