Bond behavior of deformed steel bars lap-splice in ultra high performance concrete

-

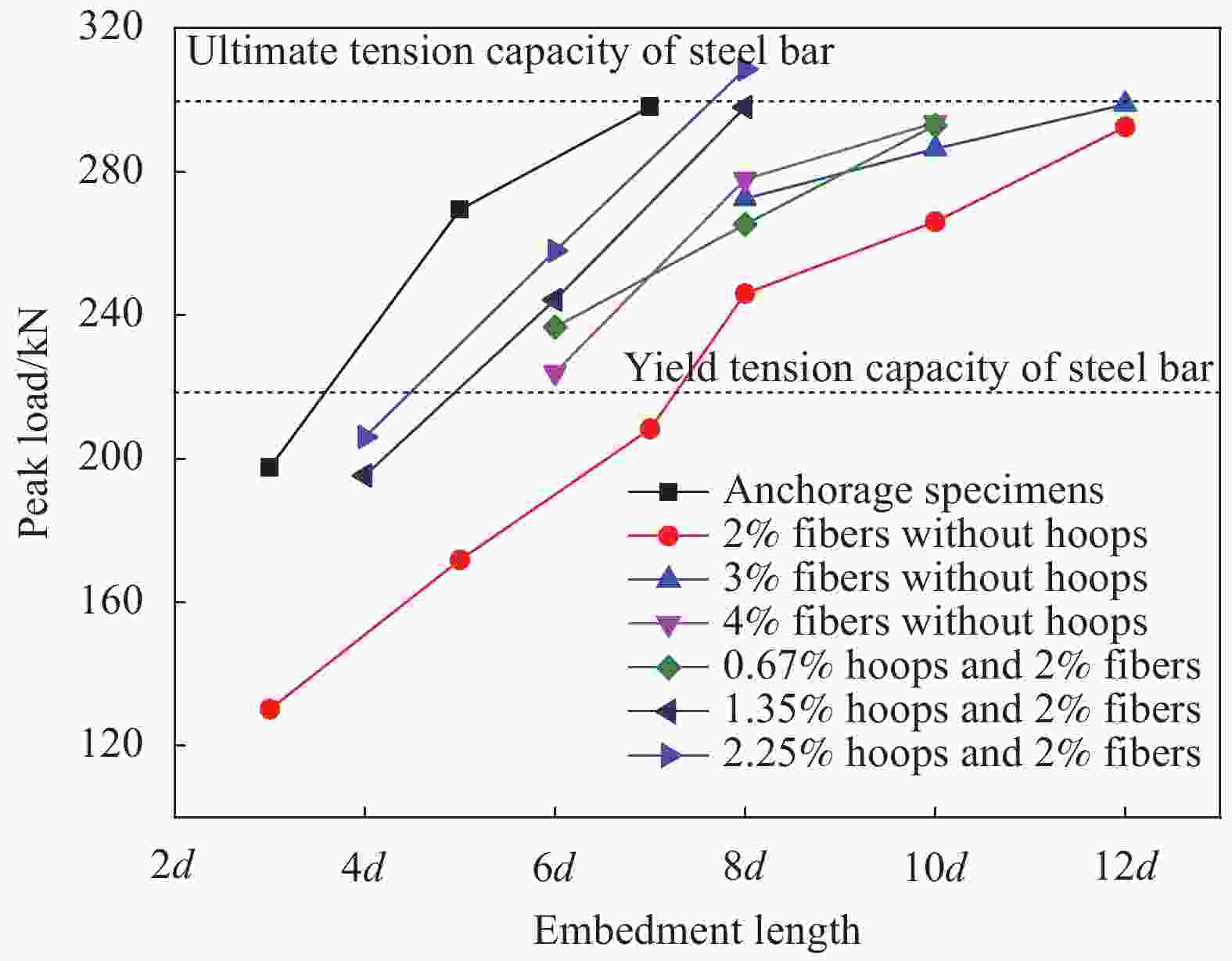

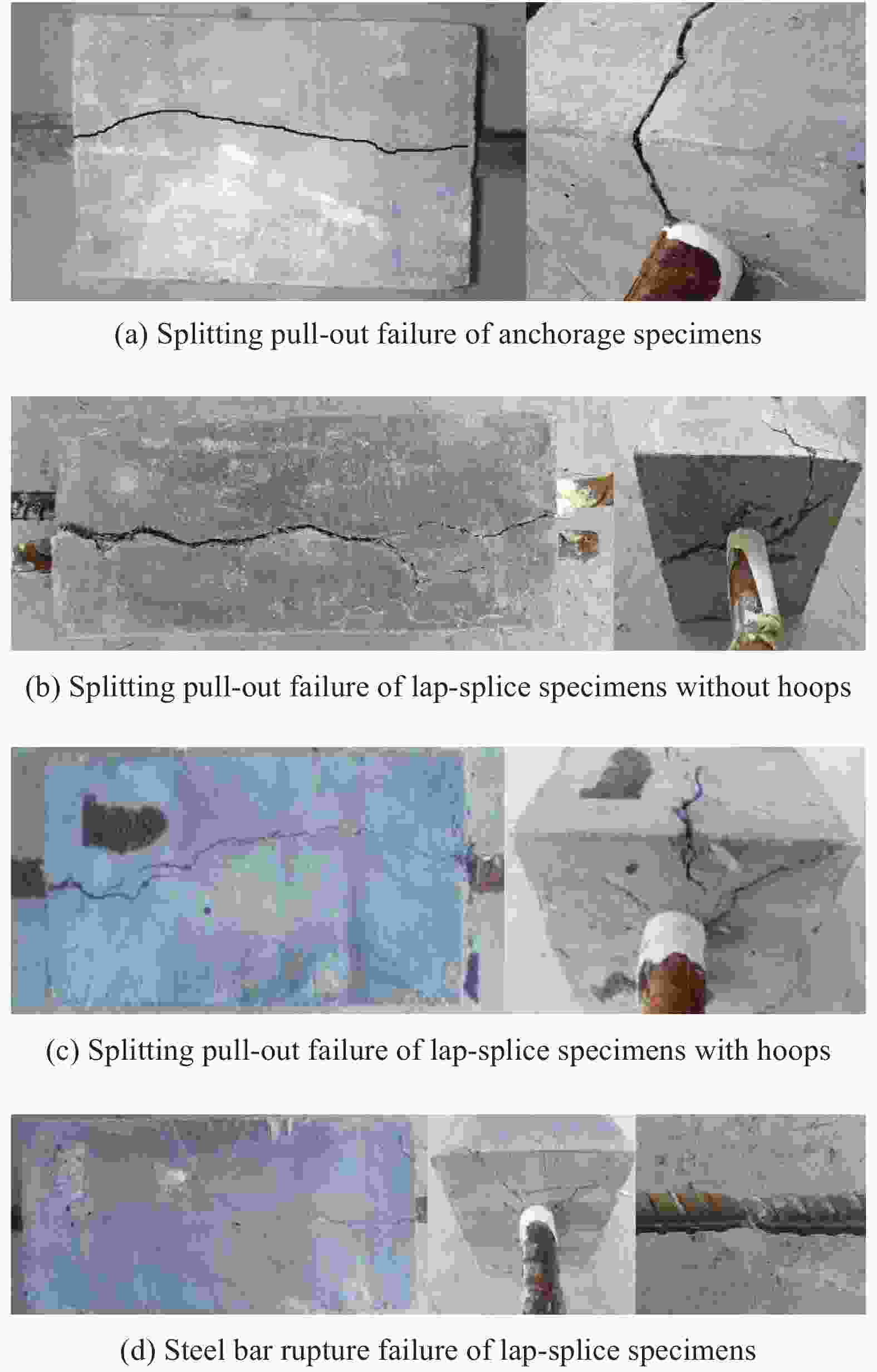

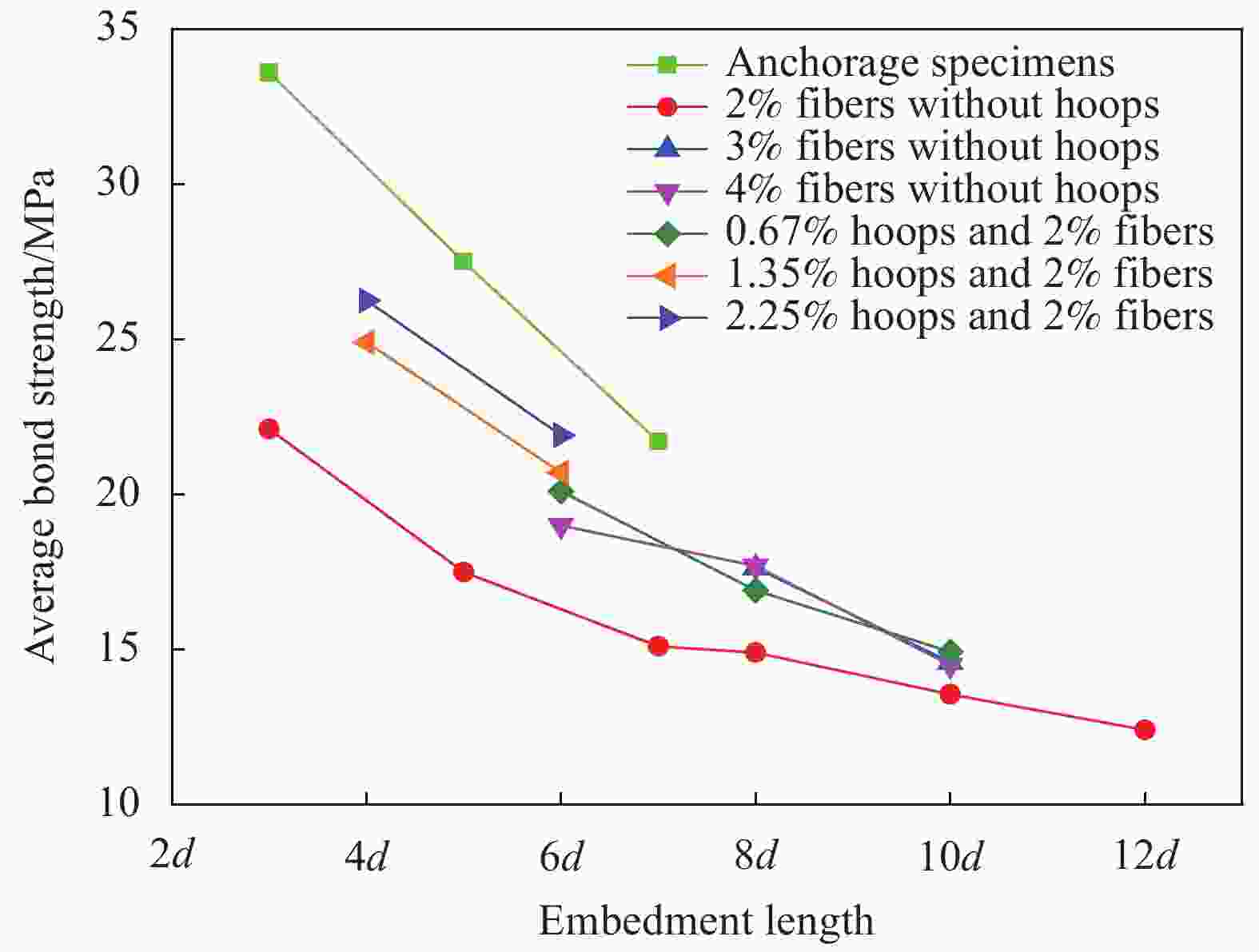

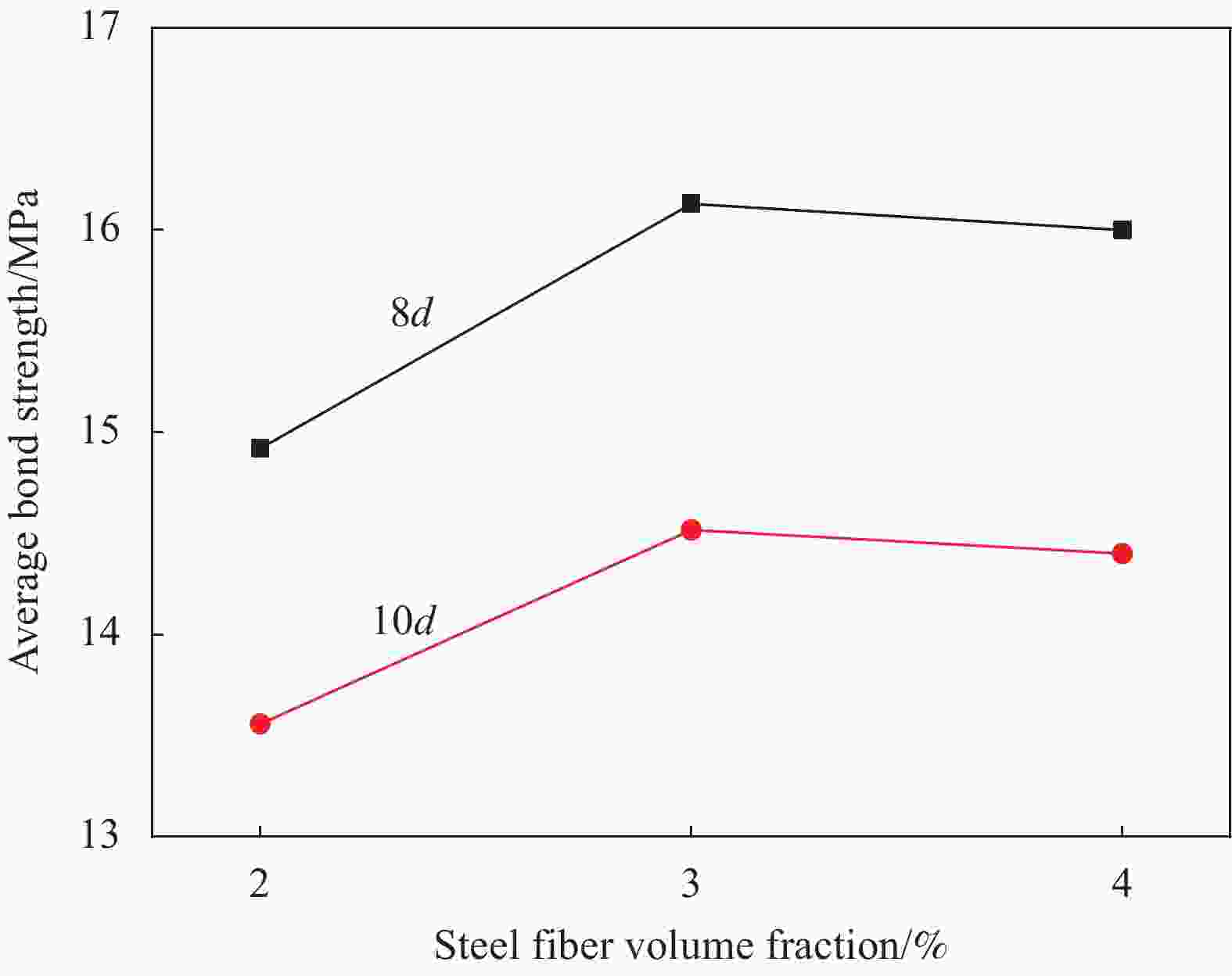

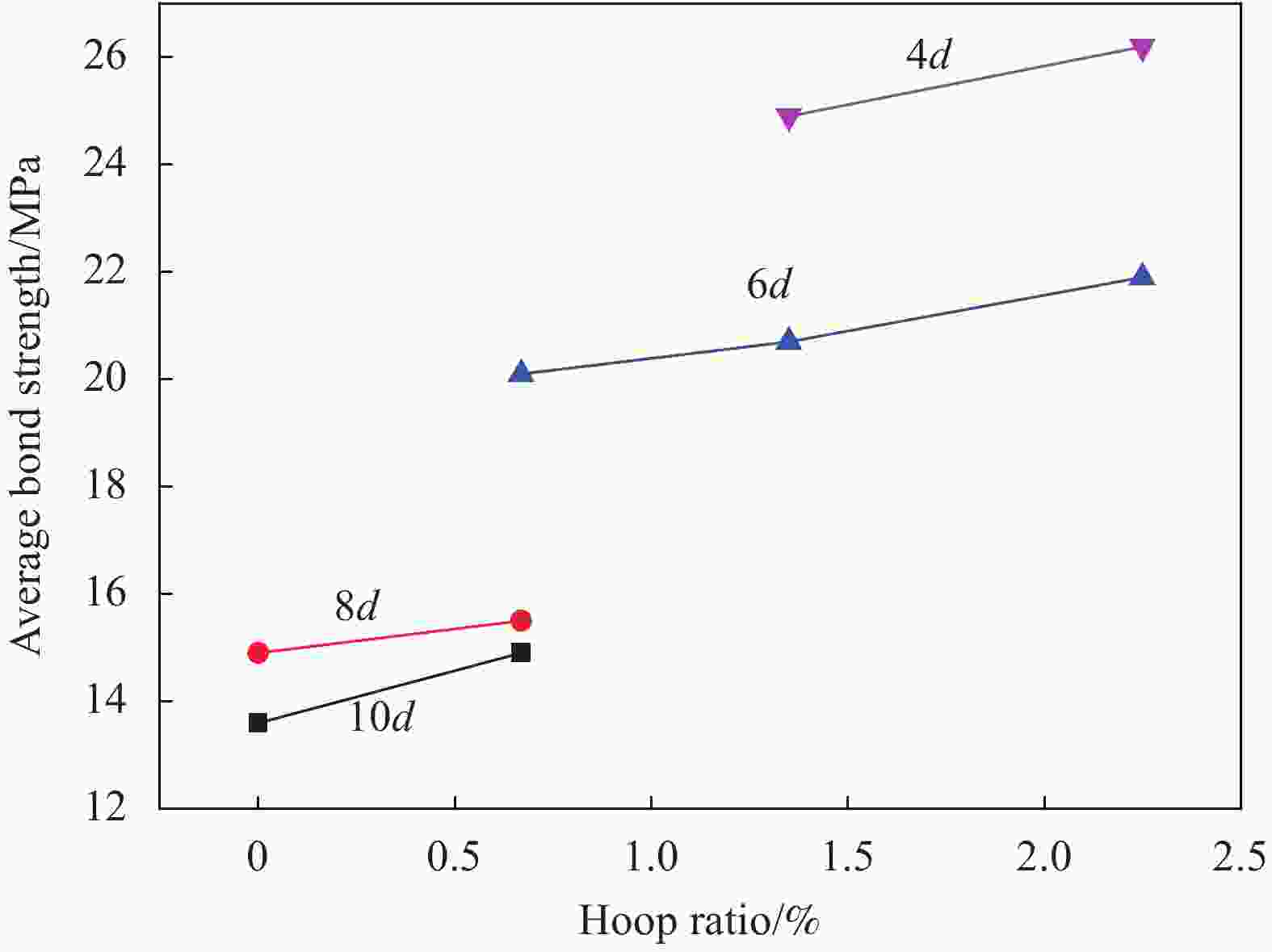

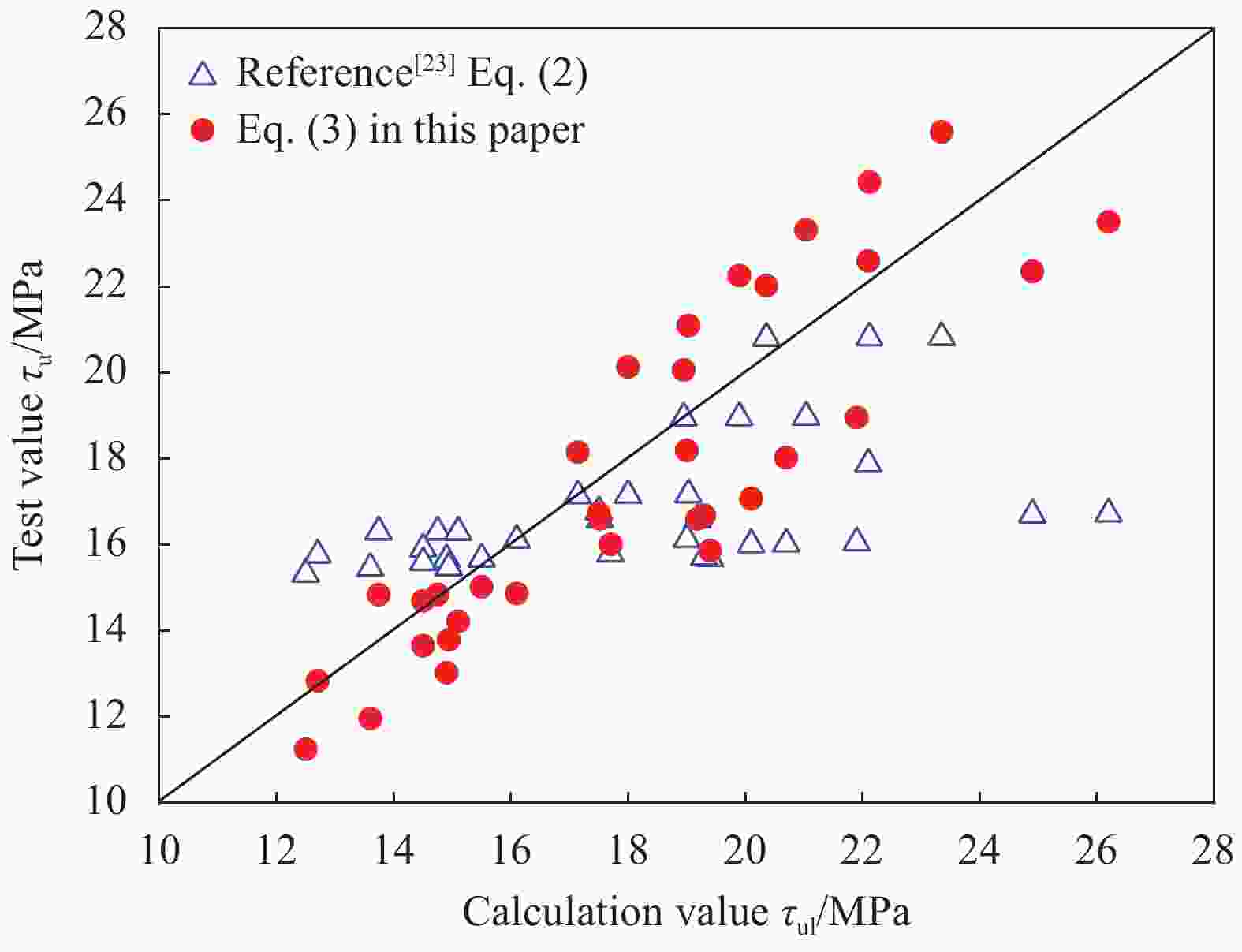

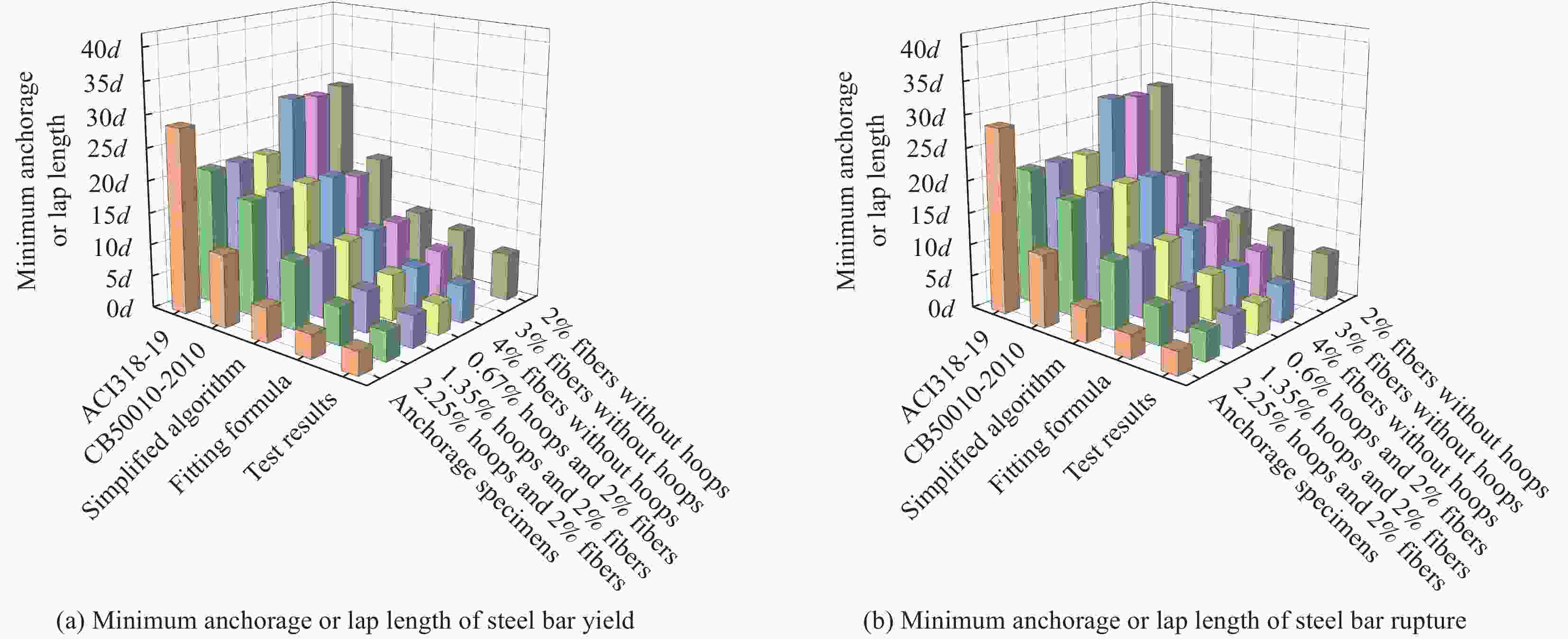

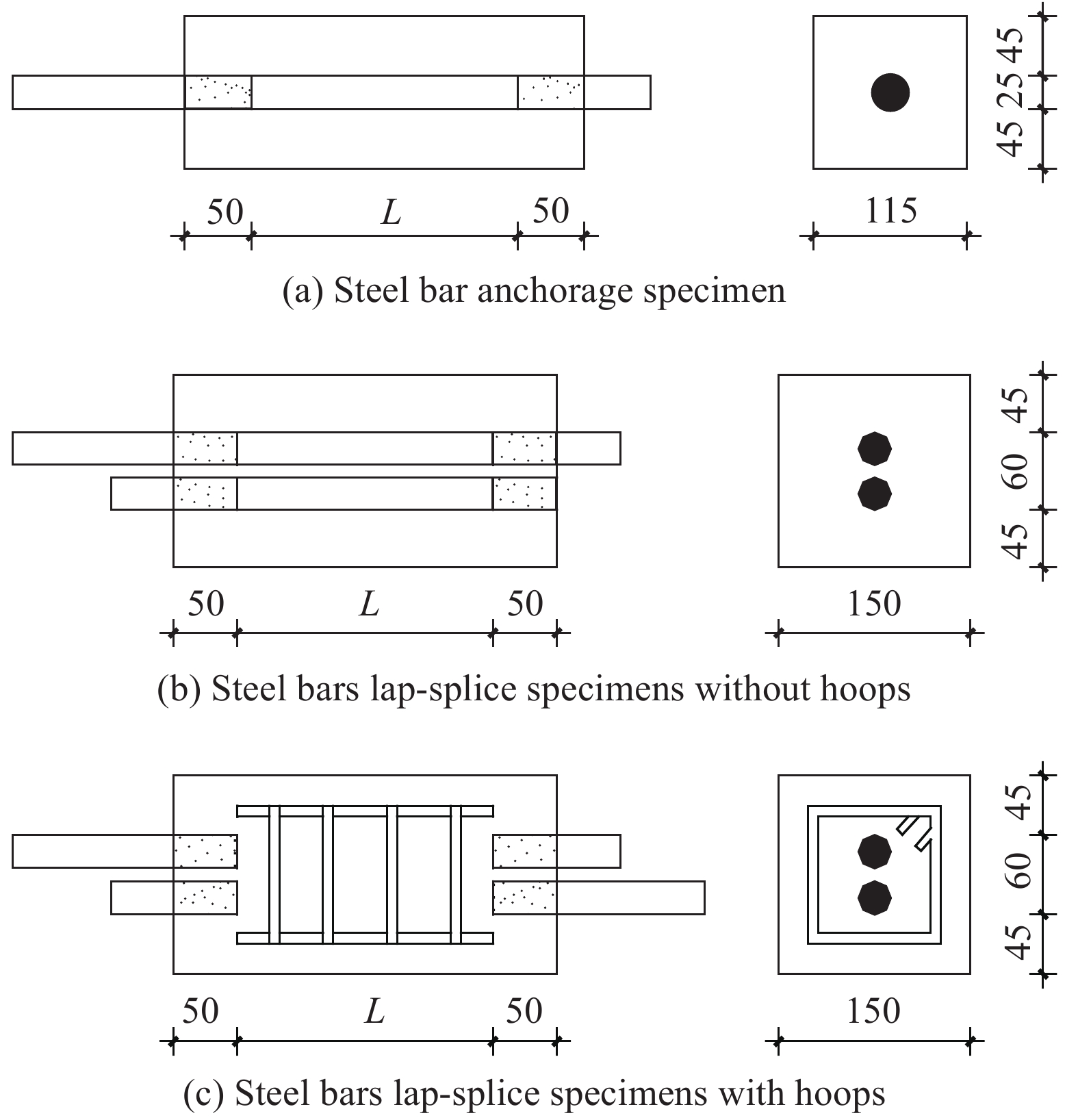

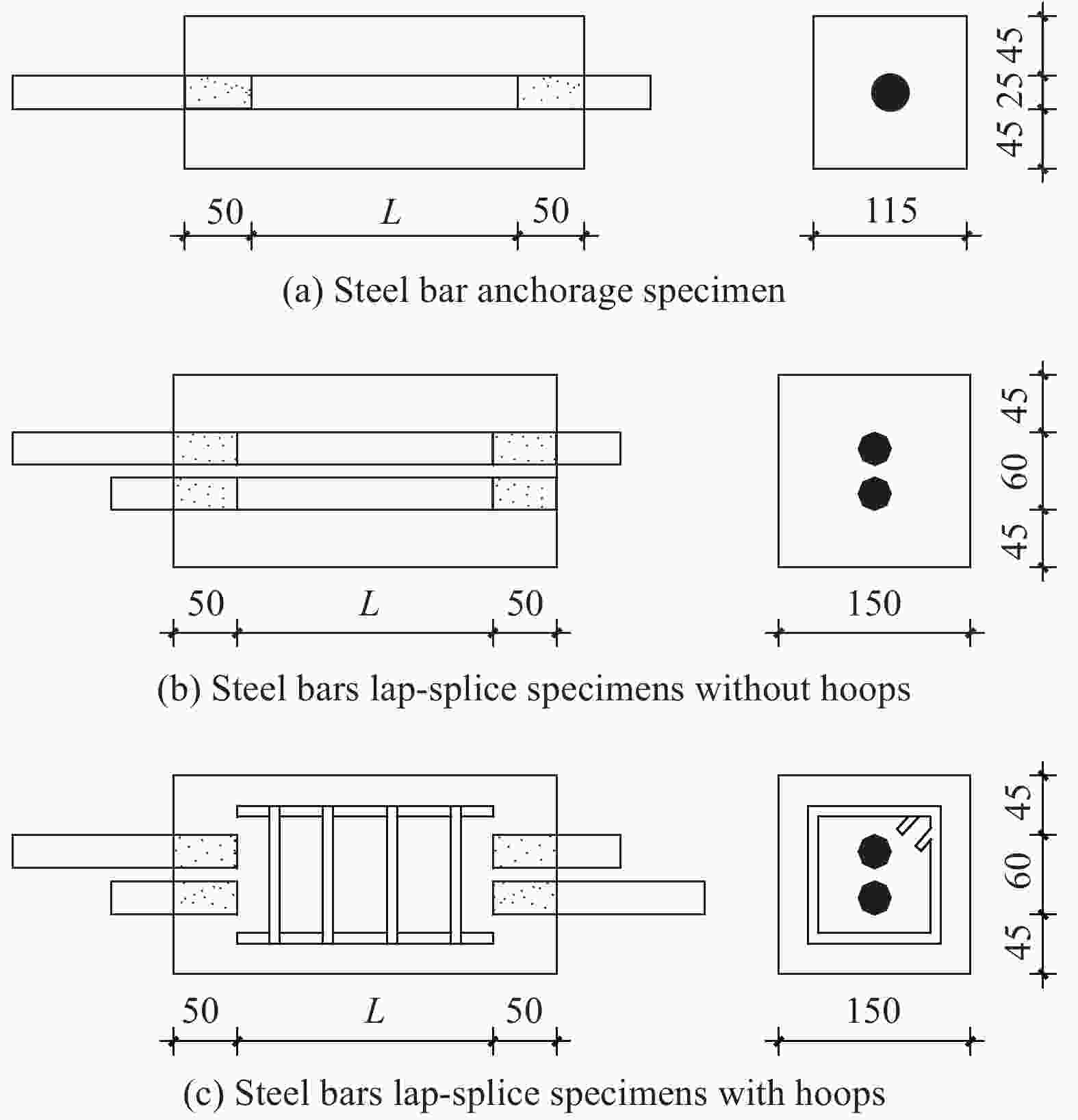

摘要: 超高性能混凝土(UHPC)是一种高强度、高韧性和高耐久性的水泥基复合材料。为了研究钢筋/UHPC的搭接黏结性能,进行了21组考虑搭接长度、纤维掺量和配箍率影响的钢筋搭接对拉拔出试验,3组考虑锚固长度影响的钢筋直接拔出锚固试验;试验出现了劈裂拔出破坏和钢筋拉断破坏2种破坏模式;钢筋/UHPC平均黏结强度随钢筋埋置长度的增大而减小,随配箍率的增大而增大;钢纤维掺量的增大,有利于增大对UHPC的约束作用,增加配箍率和适当增大纤维掺量均能减小钢筋/UHPC的临界搭接长度;结合前人的试验结果,拟合得到平均锚固和搭接黏结强度计算公式及临界锚固和搭接长度计算公式,根据混凝土结构设计规范,建立了钢筋/UHPC锚固和搭接长度简化算法,计算结果较为准确。Abstract: Ultra high performance concrete (UHPC) is a kind of cement-based material with high strength, high toughness and high durability. To study the lap-spliced bond performance of steel bars in UHPC, 21 groups of lap-spliced specimens were tested considering the parameters of lap length, fibers content and stirrups ratio. 3 groups of pull-out specimens considering a parameter of anchorage length were conducted to be control groups. Two failure modes, those are splitting-pull-out failure and steel-bar-rupture failure appear. The average bond strength decreases with the increase of embedded length and increases with the increase of stirrup ratio. The steel fibers enhance the confinement for UHPC. Increasing the stirrup ratio and fiber content can reduce the lap-spliced length of the steel bars in UHPC. Combining with the previous research, average bond strength and development length as well as splice length formulas were fitted. Simplified algorithms of development length and splice length were proposed according to the Code for Design of Concrete Stuctures, and the results agree well with the test results.

-

表 1 钢筋锚固和搭接钢筋/UHPC试件参数及试验结果

Table 1. Parameters and test results of anchorage and lap-splice steel bars/UHPC specimens

Number Notation Vf/% ${\rho _{{\rm{sv}}}}$/% L fcu/MPa fc/MPa Py/kN Ps/kN Pu/kN τmt/MPa Failure mode 1 A-2-0-3d 2 0 3d 117.1 103.6 — 190.4 197.6 33.6 SPF 2 A-2-0-5d 5d 218.6 265.2 269.5 27.5 SPF 3 A-2-0-7d 7d 220.4 284.6 298.1 21.7 SPF 4 LS-2-0-3d 2 0 3d 117.1 103.6 — 111.9 130.2 22.1 SPF 5 LS-2-0-5d 5d — 143.4 171.8 17.5 SPF 6 LS-2-0-7d 7d — 173.3 208.3 15.1 SPF 7 LS-2-0-8d 2 0 8d 110.1 100.9 219.1 223.4 234.2 14.9 SPF 8 LS-2-0-10d 10d 215.6 246.9 266.0 13.6 SPF 9 LS-2-0-12d 12d 217.6 272.8 293.7 12.5 SPF 10 LS-3-0-8d 3 0 8d 116.6 105.5 217.2 245.8 253.2 16.1 SPF 11 LS-3-0-10d 10d 219.1 265.7 284.8 14.5 SPF 12 LS-3-0-12d 12d 216.3 285.9 298.8 12.7 RF 13 LS-4-0-6d 4 0 6d 112 102 217.1 201.3 224.0 19.0 SPF 14 LS-4-0-8d 8d 215.3 244.9 250.1 16.0 SPF 15 LS-4-0-10d 10d 217.1 276.3 282.2 14.4 SPF 16 LS-2-0.67-6d 2 0.67 6d 110.1 100.9 218.2 164.9 236.6 20.1 SPF 17 LS-2-0.67-8d 8d 218.4 180.5 243.5 15.5 SPF 18 LS-2-0.67-10d 10d 215.8 201.3 292.9 14.94 SPF 19 LS-2-1.35-4d 2 1.35 4d 110.1 100.9 — 122.6 195.3 24.9 SPF 20 LS-2-1.35-6d 6d 218.8 146.6 244.3 20.7 SPF 21 LS-2-1.35-8d 8d 219.4 202.4 304.2 19.4 RF 22 LS-2-2.25-4d 2 2.25 4d 110.1 100.9 — 128.1 206.0 26.2 SPF 23 LS-2-2.25-6d 6d 219.4 167.7 257.9 21.9 SPF 24 LS-2-2.25-8d 8d 214.5 216.0 302.8 19.3 RF Notes: d—Steel bar diameter; Vf—Fibre volume fraction; ρsv—Hoop ratio; L—Embedment length; fcu—Compressive strength of cube; fc—Compressive strength of prism; Py, Ps and Pu—Yield, slippage and peak loads in the test, respectively; τmt—Mean bond strength measured in the test; SPF and RF represent the splitting pull-out failure and steel bar rupture failure, respectively. The “A” and “LS” in notation system—Anchorage specimen and lap-splice specimen, respectively. The figures in the second, third and fourth symbol—Fibre volume fraction (%), stirrup ratio (%) and embedment length, respectively. For example, the notation of “LS-2-0-3d”—Splice specimen with 2% of fibre volume fraction, 0% of stirrup ratio and 3 bar diameters embedment. 表 2 UHPC配合比

Table 2. Mix proportions of UHPC

Number Water to

binder ratioCement Fly

ashSilica

fumeMineral

powderQuartz

sandSuperplasticizer Volume fraction of

steel fiber Vf1 0.18 1.00 0.30 0.30 0.30 1.3 0.05 0.02 2 0.18 1.00 0.30 0.30 0.30 1.3 0.05 0.03 3 0.18 1.00 0.30 0.30 0.30 1.3 0.05 0.04 表 3 钢筋力学性能

Table 3. Mechanical properties of steel bars

Diameter/mm Strength grade Yield strength/MPa Ultimate strength/MPa 25 HRB400 447 611 18 HRB400 436 608 8 HPB300 364 540 表 4 钢筋/UHPC锚固和对拉拔出搭接试件试验数据

Table 4. Test data of anchorage specimens and pull out lap-splice specimens of steel bars in UHPC

Reference Notation d/mm L/mm c/mm ρsv fcu/MPa Vf τut/MPa Anchorage specimen [15] φ14-50 14 50 68 0 147.78 0.023 37.07 φ15-50 16 50 67 0 147.78 0.023 33.28 φ16-50 18 50 66 0 147.78 0.023 29.87 φ17-50 18 75 66 0 147.78 0.023 28.94 [16] H1-LZ-8-24 8 24 71 0 121.77 0.02 55.3 H1-LZ-8-32 8 32 71 0 121.77 0.02 45.7 H1-LZ-10-30 10 30 70 0 121.77 0.02 46.1 H1-LZ-10-40 10 40 70 0 121.77 0.02 42.9 H2-LZ-16-48 16 48 67 0 132.39 0.02 52.7 H2-LZ-16-64 16 64 67 0 132.39 0.02 42.9 H2-LZ-16-80 16 80 67 0 132.39 0.02 34.1 H2-LZ-18-54 18 54 66 0 132.39 0.02 55 H2-LZ-18-72 18 72 66 0 132.39 0.02 42.3 H3-LZ-6-18 6 18 72 0 153.09 0.03 51.1 H3-LZ-8-24 8 24 71 0 153.09 0.03 70.5 H3-LZ-8-32 8 32 71 0 153.09 0.03 52.8 H3-LZ-10-30 10 30 70 0 153.09 0.03 62.2 H2-NZ-16-12 16 48 12 0 132.39 0.02 31.1 H2-NZ-16-22 16 48 22 0 132.39 0.02 36 H2-NZ-16-32 16 48 32 0 132.39 0.02 41.9 H2-NZ-16-42 16 48 42 0 132.39 0.02 47.7 H2-NZ-16-52 16 48 52 0 132.39 0.02 48.8 H2-NZ-16-62 16 48 62 0 132.39 0.02 52.8 H3-LP-8-10 8 40 10 0 153.09 0.03 29.9 H3-LP-8-15 8 40 15 0 153.09 0.03 29.1 [17] P0.0 16 50 67 0 79.81 0 29.7 P0.5 16 50 67 0 92.27 0.005 31.18 P1.0 16 50 67 0 114.30 0.01 32.05 P1.5 16 50 67 0 117.02 0.015 36.72 P2.0 16 50 67 0 128.58 0.02 38.12 Lap-splice specimen [23] L100-R100-D1-S0 20 100 45 0 96.03 0.02 17.14 L100-R100-D1-S34 20 100 45 0.0034 96.03 0.02 18 L100-R100-D1-S75 20 100 45 0.0075 96.03 0.02 19.03 L100-R120-D1-S0 20 100 45 0 117.36 0.02 18.95 L100-R120-D1-S34 20 100 45 0.0034 117.36 0.02 19.9 L100-R120-D1-S75 20 100 45 0.0075 117.36 0.02 21.04 L100-R150-D1-S0 20 100 45 0 141.39 0.02 20.36 L100-R150-D1-S34 20 100 45 0.0034 141.39 0.02 22.12 L100-R150-D1-S75 20 100 45 0.0075 141.39 0.02 23.35 L150-R100-D1-S34 20 150 45 0.0034 96.03 0.02 17.52 L150-R120-D1-S34 20 150 45 0.0034 96.03 0.02 19.18 L200-R100-D1-S34 20 200 45 0.0034 96.03 0.02 14.75 L200-R100-D1-S34 20 200 45 0.0034 96.03 0.02 13.74 Notes: d—Steel bar diameter; L—Embedment length; c—Thickness of UHPC cover; ρsv—Hoop ratio; fcu—Compressive strength of cube; Vf—Fibre volume fraction; τut—Test value of ultimate average bond strength. 表 5 钢筋/UHPC搭接梁式试件黏结强度拟合公式验证

Table 5. Verification of the fitting formula for lap-splice bond strength of beam lap-splice steel bars/UHPC specimens

Reference Notation d/mm L/mm c/mm fc/MPa Vf τut/MPa τuf/MPa τuf/τut Beam lap-splice specimen [6] 1-12-25-L 25 300 45 130 0.03 10.8 13.40 1.26 2-12-25-L 25 300 45 130 0.03 9.8 13.40 1.39 1-18-25-L 25 450 45 130 0.03 6.8 11.98 1.96 1-12-35-L 35 420 45 130 0.03 9.8 11.32 1.15 1-18-35-L 35 630 45 130 0.03 6.11 10.12 1.81 1-6-25-L 25 150 45 130 0.03 19.6 17.67 0.74 1-6-25-L1 25 150 45 130 0.03 19.6 17.67 0.74 1-12-25-L1 25 300 45 130 0.03 9.8 13.40 1.39 1-6-35-L 35 210 45 130 0.03 16.23 14.92 0.74 1-6-35-L½ 35 210 45 130 0.03 12.32 14.92 0.97 1-12-35-L½ 35 420 45 130 0.03 9.16 11.32 1.24 [18] 25-12-L-1% 25 300 25 125 0.01 9.5 8.00 1.04 25-12-L-2% 25 300 25 124 0.02 10.4 8.94 0.94 25-12-L-3% 25 300 25 114 0.03 10.5 9.51 0.90 25-12-R-3% 25 300 25 114 0.03 10 9.51 0.94 35-18-L-3% 35 630 35 114 0.03 8.2 8.50 1.13 35-18-R-3% 35 630 35 114 0.03 7.2 8.50 1.28 Average value 1.15 Variation coefficient 0.29 Notes: fc—Uniaxial compressive strength; τut—Test value of ultimate average bond strength; τuf—Value of ultimate average bond strength calculated by the Eq. (3). 表 6 钢筋/UHPC锚固和搭接长度试验值与计算值

Table 6. Test values and calculated values of development length and splice length of steel bars/UHPC

Type Minimum anchorage or lap length of steel bar yield Minimum anchorage or lap length of steel bar rupture lsyACI lsyGB lsys lsyf lsyt lsuACI lsuGB lsus lsuf lsut Anchorage specimen 28.6d 11.2d 5.3d 3.7d 3.6d 39.1d 15.3d 7.2d 6.6d 7.1d 2.25vol% hoops 20.9d 17.9d 10.5d 5.8d 4.5d 28.6d 24.4d 14.4d 10.1d 7.6d 1.35vol% hoops 20.9d 17.9d 10.5d 6.4d 4.9d 28.6d 24.4d 14.4d 11.0d 8.1d 0.67vol% hoops 20.9d 17.9d 10.5d 7.1d 4.8d 28.6d 24.4d 14.4d 11.9d 10.6d 4vol% fibers 28.9d 17.6d 10.6d 6.5d 5.8d 39.4d 24.0d 14.5d 11.1d 13.2d 3vol% fibers 28.3d 16.4d 10.4d 7.5d — 38.7d 22.4d 14.3d 12.5d 12.1d 2vol% fibers 29.0d 17.9d 10.5d 9.3d 7.3d 39.7d 24.4d 14.4d 15.0d 12.6d Notes: lsyACI, lsyGB, lsys and lsyf—Minimum anchorage or lap length of steel bar yield calculated by the ACI 318—19[27], GB 50010—2010[26], simplified algorithm and fitting formula, respectively; lsuACI, lsuGB, lsus, and lsuf—Minimum anchorage or lap length of steel bar rupture calculated by the ACI 318—19[27], GB 50010—2010[26], simplified algorithm and fitting formula, respectively; lsyt—Test value of minimum anchorage or lap length of steel bar yield; lsut—Test value of minimum anchorage or lap length of steel bar rupture. As,p/As,r Maximum percent of As spliced

within required lap length/%Splice type Lap splice lengths ls ≥2 50 A Greater of: 1.0ld and 304.8 mm 100 B Greater of: 1.3ld and 304.8 mm <2 All cases B Note: As,p/As,r—Ratio of area of reinforcement provided to area of reinforcement required by analysis at splice location. -

[1] 中国国家标准化管理委员会. 活性粉末混凝土: CB/T 31387—2015[S]. 中国标准出版社, 2015National Standardization Administration of China. Reactive powder concrete: CB/T 31387—2015[S]. China Standard Press, 2015 (in Chinese). [2] YUAN J, GRAYBEAL B. Bond of reinforcement in ultra-high-performance concrete[J]. ACI Structural Journal,2015,112(6):851. [3] GRAYBEAL B. Design and construction of field-cast UHPC connections[R]. United States: Federal Highway Administration, 2014. [4] SHAFIEIFAR M, FARZAD M, AZIZINAMINI A. Alternative ABC connection utilizing UHPC[R]. Washington DC, United States: Transportation Research Board 96th Annual Meeting, 2017. [5] AARUP B, JENSEN B C. Bond properties of high-strength fiber reinforced concrete[J]. Special Publication,1998,180:459-472. [6] DAGENAIS M A, MASSICOTTE B. Tension lap splices strengthened with ultrahigh-performance fiber-reinforced concrete[J]. Journal of Materials in Civil Engineering,2014,27(7):04014206. [7] GRAYBEAL B. Behavior of field-cast ultra-high performance concrete bridge deck connections under cyclic and static structural loading[R]. US: Department of Transportation, 2010. [8] SWENTY M, GRAYBEAL B. Influence of differential deflection on staged construction deck-level connections[R]. US: Department of Transportation, 2012. [9] HOLSCHEMACHER K, WEIBE D, KLOTZ S. Bond of reinforcement in ultra high strength concrete[C]//SCHMIDT M, FEHLING E, GEISENHANSLÜKE C. Proceedings of the International Symposium on Ultra High Performance Concrete, 2004: 375–387. [10] JUNGWIRTH J, MUTTONI A. Structural behavior of tension memebers in UHPC[R]. Kassel, Germany: Proceedings of the International Symposium on Ultra High Performance Concrete, 2004. [11] ALKAYSI M, El-TAWIL S. Factors affecting bond development between ultra high performance concrete (UHPC) and steel bar reinforcement[J]. Construction and Building Materials,2017,144:412-422. doi: 10.1016/j.conbuildmat.2017.03.091 [12] GRAYBEAL B. Bond behavior of reinforcing steel in ultra high performance concrete[R]. United States: Federal Highway Administration, 2014. [13] BAE B I, CHOI H K, CHOI C S. Bond stress between conventional reinforcement and steel fibre reinforced reactive powder concrete[J]. Construction and Building Materials,2016,112:825-835. doi: 10.1016/j.conbuildmat.2016.02.118 [14] SALEEM M A, MIRMIRAN A, XIA J, et al. Development length of high-strength steel rebar in ultrahigh performance concrete[J]. Journal of Materials in Civil Engineering,2012,25(8):991-998. [15] 安明喆, 张盟. 变形钢筋与活性粉末混凝土的黏结性能试验研究[J]. 中国铁道科学, 2007, 28(2):50-54.AN M Z, ZHANG M. Experimental research of bond capability between deformed bars and reactive powder concrete[J]. China Railway Science,2007,28(2):50-54(in Chinese). [16] 邓宗才, 袁常兴. 高强钢筋与活性粉末混凝土黏结性能的试验研究[J]. 土木工程学报, 2014, 47(3):69-78.DENG Z C, YUAN C X. Experimental study on bond capability between high strength rebar and reactive powder concrete[J]. China Civil Engineering Journal,2014,47(3):69-78(in Chinese). [17] 贾方方. 钢筋与活性粉末混凝土黏结性能的试验研究[D]. 北京: 北京交通大学, 2013.JIA F F, Experimental study on bonding properties of steel bars and reactive powder concrete[D]. Beijing: Beijing Jiaotong University, 2013 (in Chinese). [18] DAGENAIS M A, MASSICOTTE B. Cyclic behavior of lap splices strengthened with ultrahigh performance fiber-reinforced concrete[J]. Journal of Structural Engineering,2016,143(2):04016163. [19] Al-QURAISHI H, Al-FARTTOOSI M, ABDUL K R. Tension lap splice length of reinforcing bars embedded in reactive powder concrete (RPC)[J]. Structures,2019,19:362-368. doi: 10.1016/j.istruc.2018.12.011 [20] 徐有邻, 汪洪, 沈文都. 钢筋搭接传力性能的试验研究[J]. 建筑结构, 1993(4):20-24.XU Youlin, WANG Hong, SHEN Wendu. Experimental study on the force transmission performance of steel bars[J]. Building Structure,1993(4):20-24(in Chinese). [21] GRAYBEAL B. Splice Length of prestressing strand in field-cast ultra-high performance concrete connections[R]. No. FHWA-HRT-14-041, 2014. [22] LAGIER F, MASSICOTTE B, CHARRON J P. Experimental investigation of bond stress distribution and bond strength in unconfined UHPFRC lap splices under direct tension[J]. Cement and Concrete Composites,2016,74:26-38. doi: 10.1016/j.cemconcomp.2016.08.004 [23] 方志, 陈潇, 张门哲, 等. 活性粉末混凝土中带肋钢筋搭接性能试验研究[J]. 土木工程学报, 2019, 52(3):20-28.FANG Z, CHEN X, ZHANG M Z, et al. Experimental study on bond capability between high strength rebar and reactive powder concrete[J]. Journal of Civil Engineering,2019,52(3):20-28(in Chinese). [24] CHAO S H, NAAMAN A E, PARRA-MONTESINOS G J. Bond behavior of reinforcing bars in tensile strain-hardening fiber-reinforced cement composites[J]. ACI Structural Journal,2009,106(6):897. [25] LI X, WU Z, ZHENG J, et al. Effect of loading rate on bond behavior of deformed reinforcing bars in concrete under biaxial lateral pressures[J]. Journal of Structural Engineering,2016,142(6):04016027. doi: 10.1061/(ASCE)ST.1943-541X.0001479 [26] 中国国家标准化管理委员会. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2011.Standardization Administration of China. Concrete structure design specification: GB 50010—2010[S]. Beijing: China Building Industry Press, 2011 (in Chinese) [27] COMMITTEE A. Building code requirements for structural concrete and commentary: 318M—19[S]. USA: American Concrete Institute, 2019. [28] AZIZINAMINI A, CHISALA M, GHOSH S K. Tension development length of reinforcing bars embedded in high-strength concrete[J]. Engineering Structures,1995,17(7):512-522. doi: 10.1016/0141-0296(95)00096-P [29] HAMAD B S, ITANI M S. Bond strength of reinforcement in high performance concrete: Role of silica fume, casting position, and superplasticizer dosage[J]. Materials Journal,1998,95(5):499-511. [30] 袁伦一. 关于钢筋搭接[J]. 重庆交通大学学报(自然科学版), 1988, 7(1):102-108.YUAN L Y. On lapping of bar[J]. Journal of Chongqing Jiaotong University (Natural Science Edition),1988,7(1):102-108(in Chinese). [31] 原海燕. 配筋活性粉末混凝土受拉性能试验研究及理论分析[D]. 北京: 北京交通大学, 2009.YUAN H Y. Theoretical analysis and experimental research on tensile performance of reinforced reactive powder concrete[D]. Beijing: Beijing Jiaotong University, 2009 (in Chinese). -

下载:

下载: