Reduced order homogenization of graphene nanocomposites and its numerical implementation

-

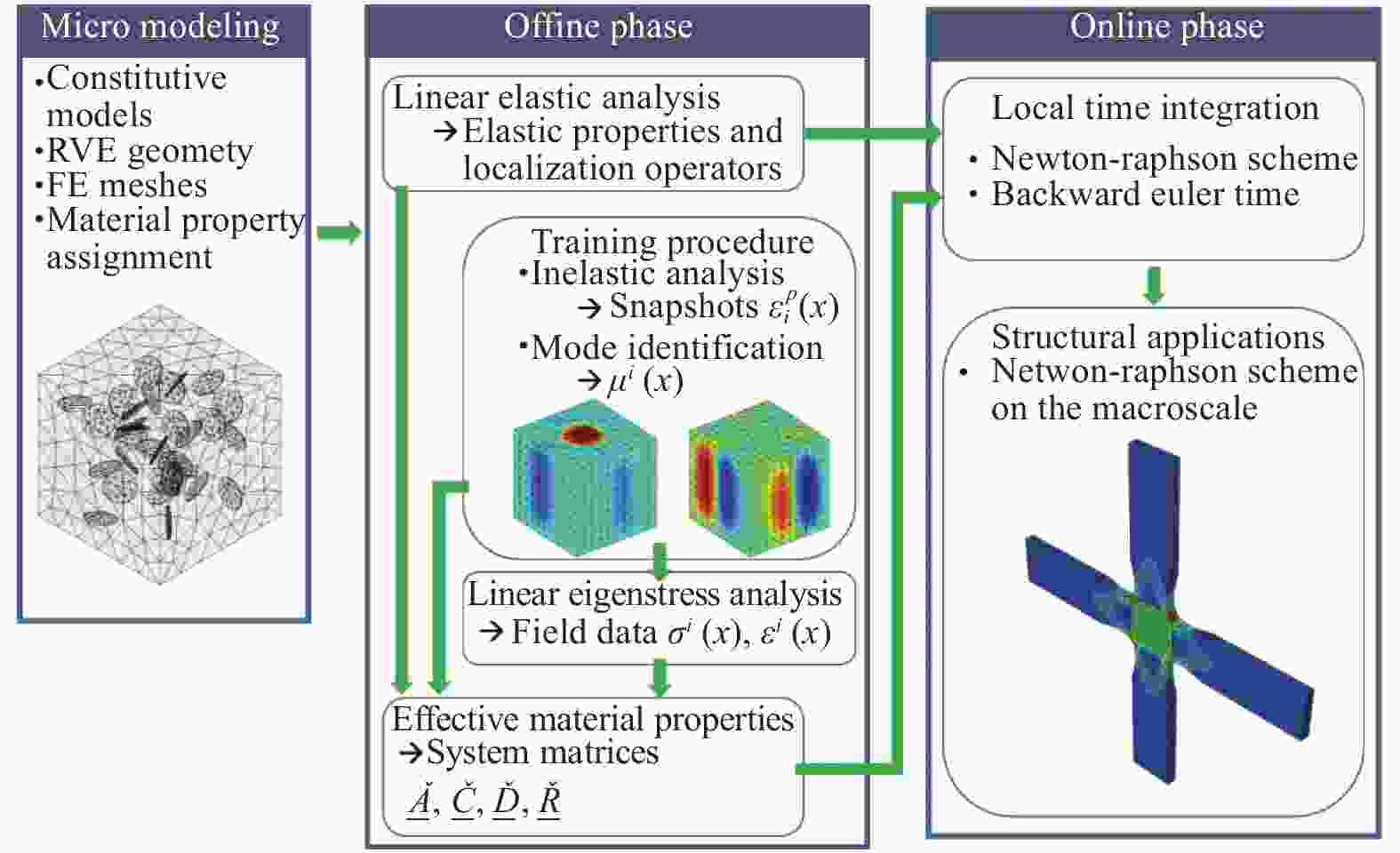

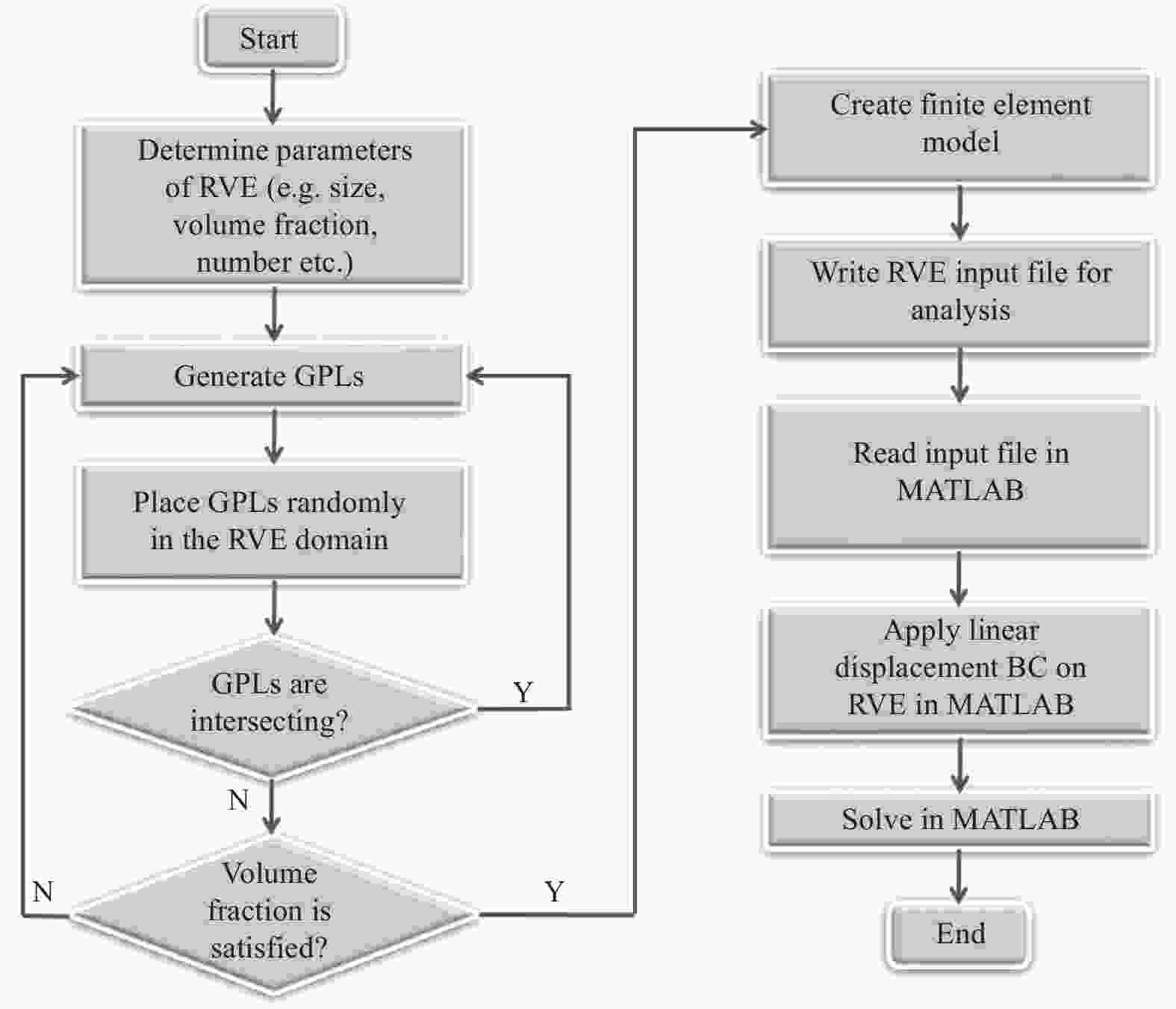

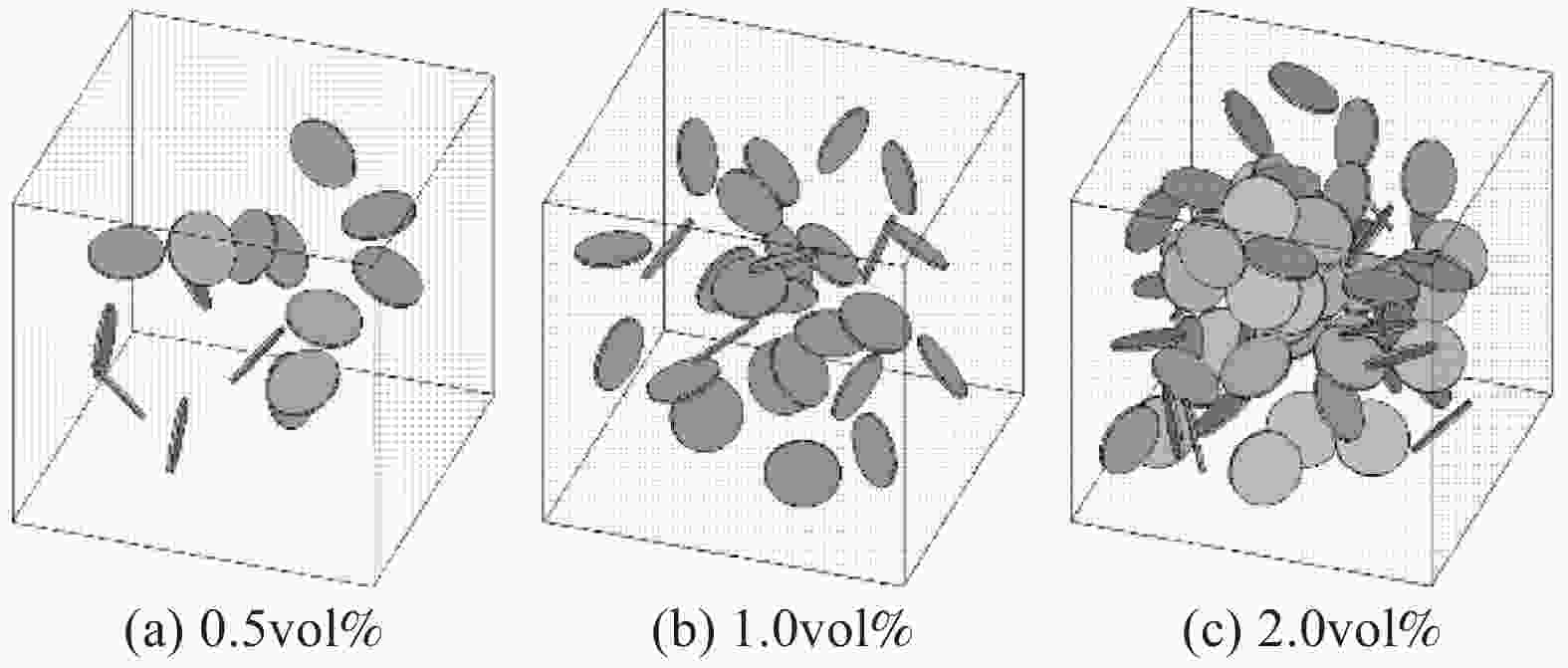

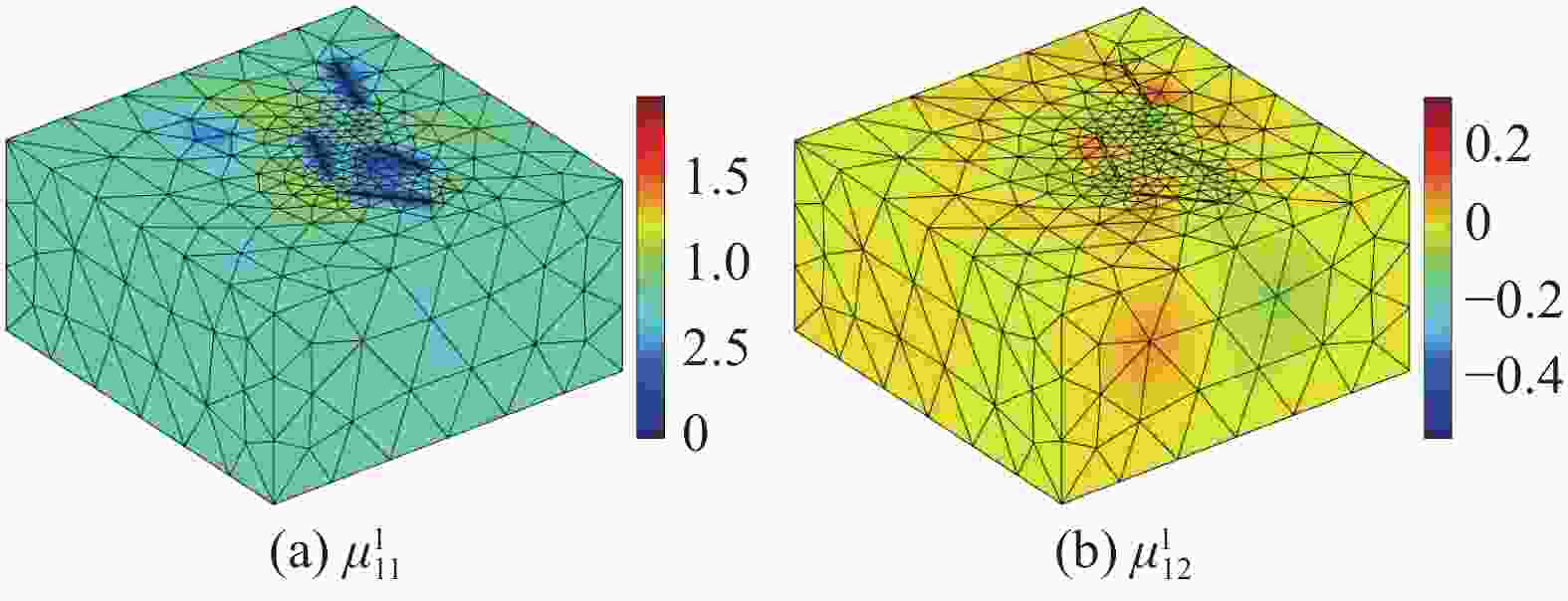

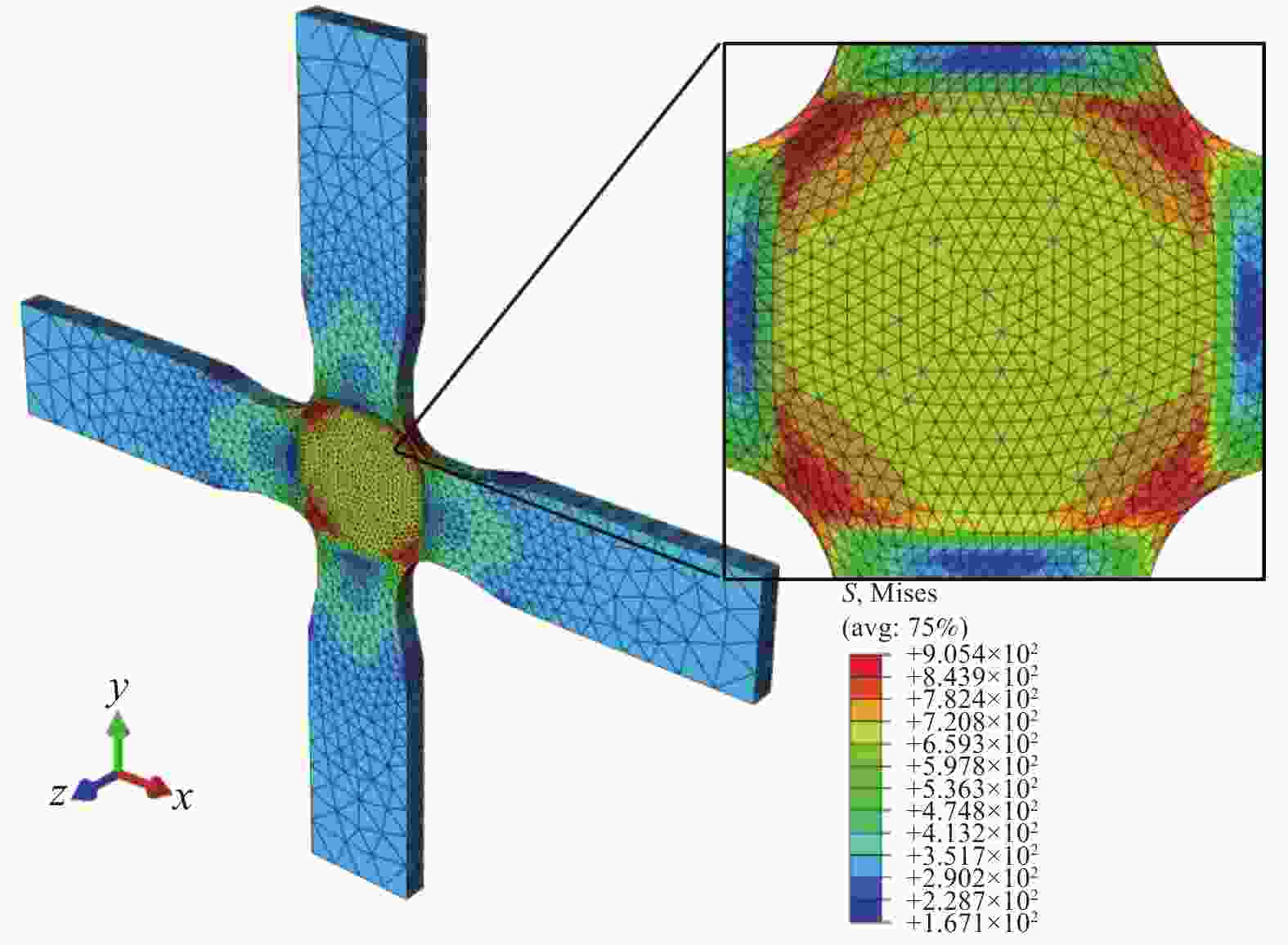

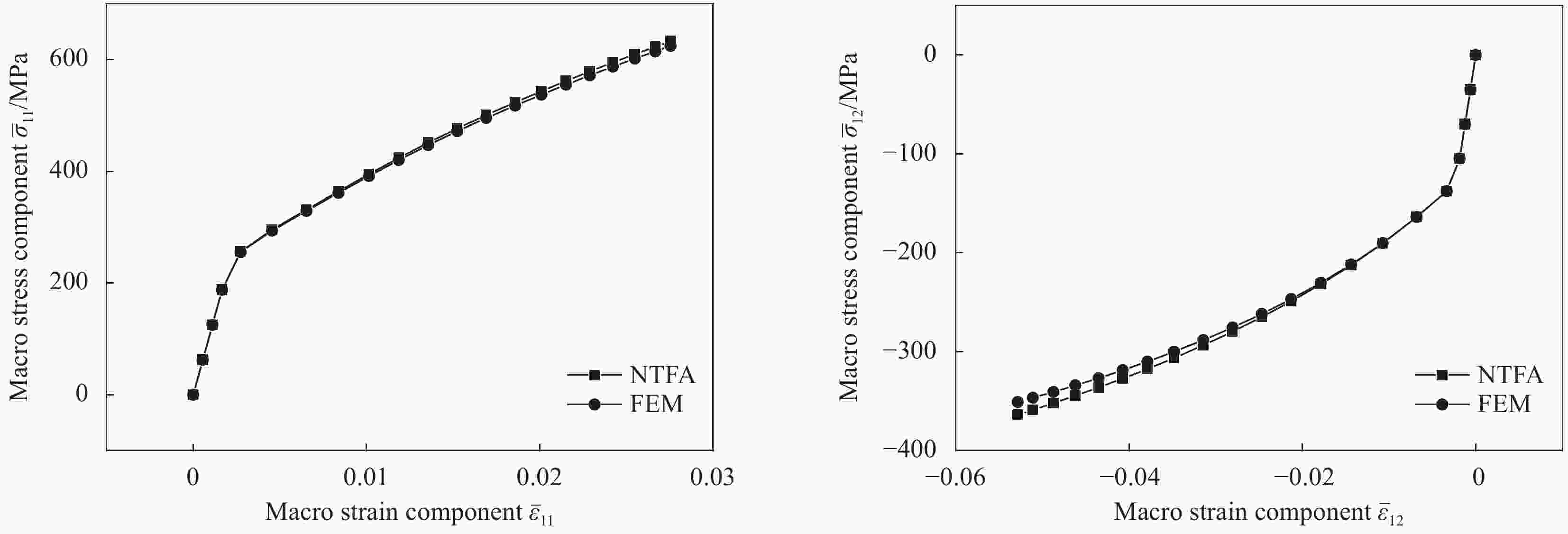

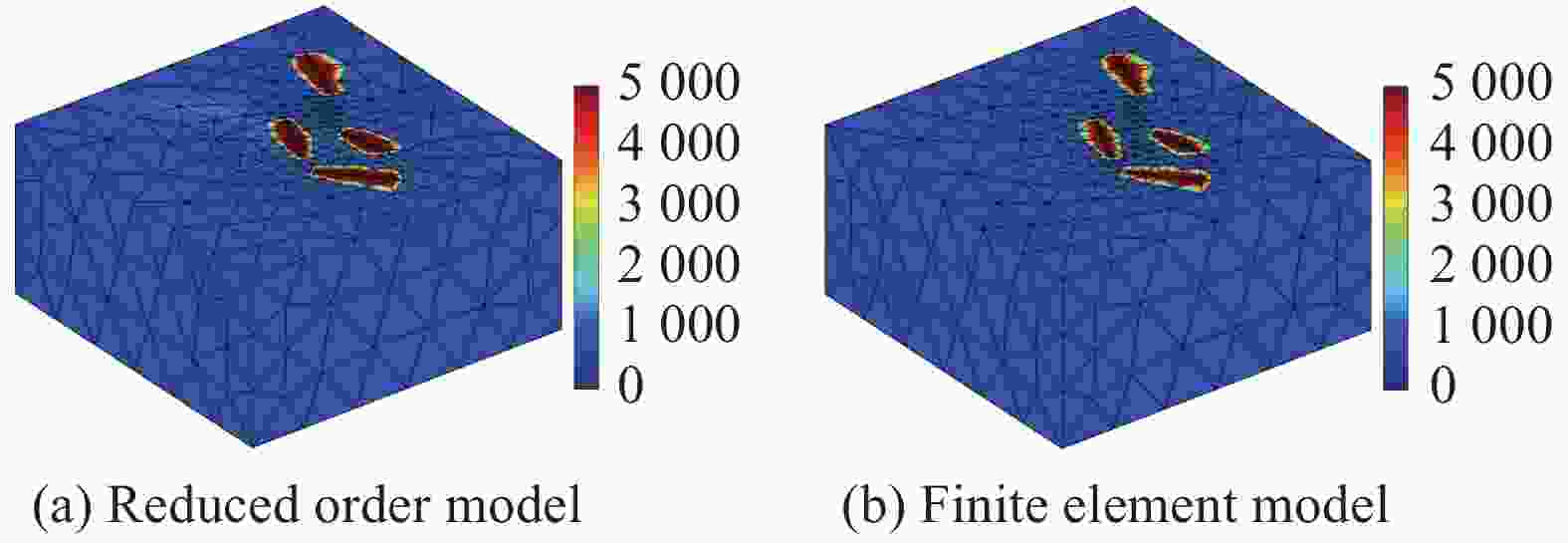

摘要: 对石墨烯纳米复合材料进行三维有限元建模通常需极其精细的网格。在考虑塑性演变的情况下,细观代表性单元体模型的计算效率极其低下。为此,基于非均匀变换场分析理论,提出了石墨烯纳米复合材料的降阶均匀化方法。首先,针对不同加载路径进行预分析,提取细观塑性应变场信息;然后对这些信息进行本征正交分解,从而得到若干个塑性模态,用作降阶模型的基函数;基于宏、细观耗散功的等效原理,导出降阶变量的本构模型。该方法的离线分析部分通过MATLAB编程实现。为了便于工程计算,在线分析部分则由商业有限元软件ABAQUS的UMAT用户子程序接口实现。基于三维算例分析,验证了所提方法的有效性。结果显示,在保证较高精度的前提下,针对三维代表性单元体计算的加速率可达103~104量级。Abstract: A three-dimensional finite element modeling for graphene nanocomposites usually requires very fine meshes. In case of plasticity, the computational efficiency of a micro representative volume element model is extremely low. For a remedy, based on the theory of nonuniform transformation field analysis, a reduced order homogenization method for graphene nanocomposites was proposed. First, we performed a pre-analysis for different loading paths to extract micro plastic strain fields; then a proper orthogonal decomposition of those field information was performed to obtain several plastic modes, which were used as basis functions for model order reduction. A constitutive model of reduced variables was derived from the equivalence of macro and micro dissipation power. The offline analysis of this method was implemented in MATLAB. For engineering computations, the online analysis was implemented by the user subroutine interface UMAT of the commercial finite element software ABAQUS. The effectiveness of the proposed method was illustrated by three-dimensional numerical examples. The results show that the acceleration rate for 3D representative volume element computations is of the order of 103~104, while maintaining a sufficient accuracy level.

-

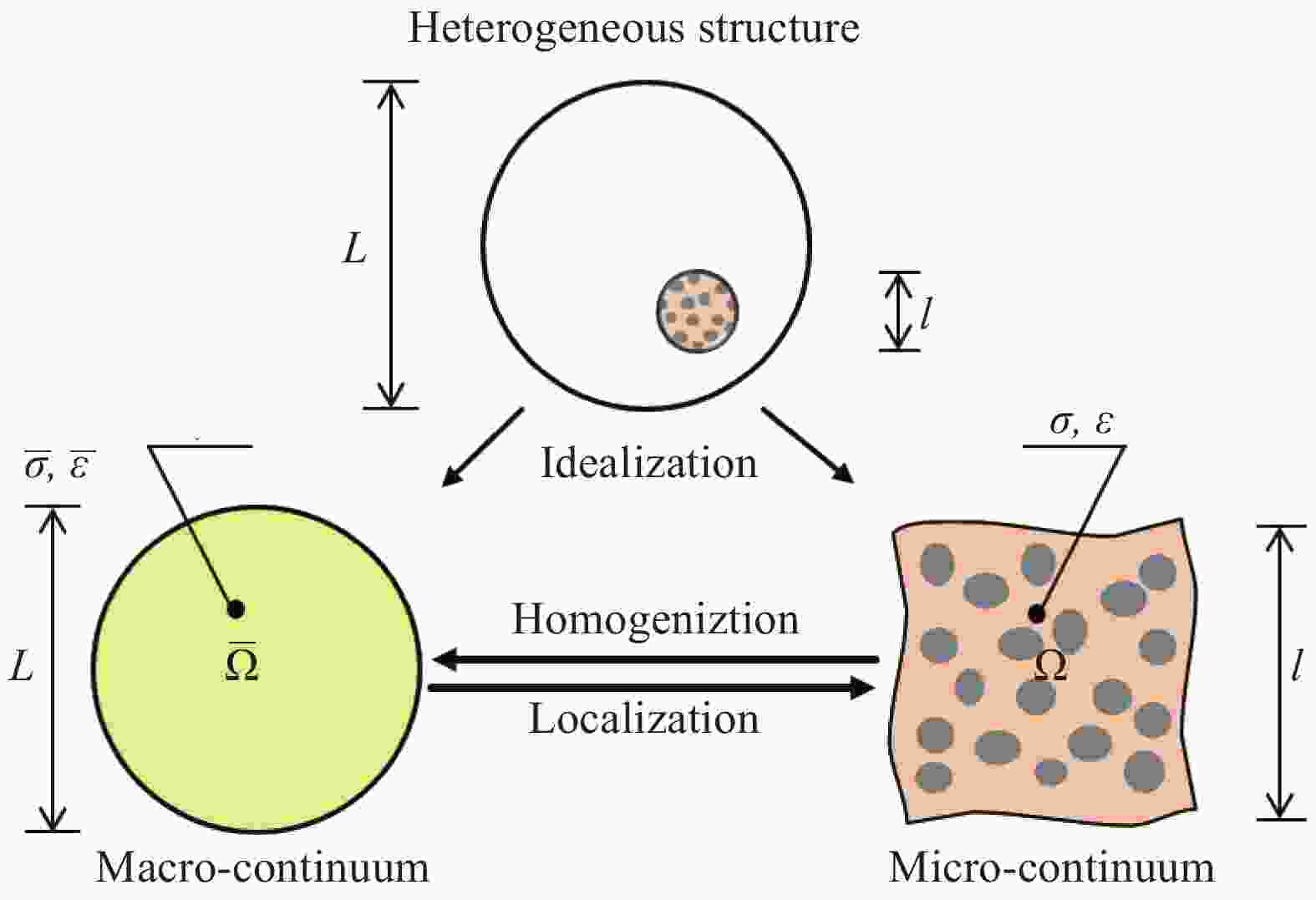

图 1 宏-细观双尺度问题

Figure 1. Illustration of a two scale (macro-micro) problem

L—Macro characteristic length; l—Micro characteristic length;$\overline{\varOmega } $—Macro domain; ${\varOmega } $—Micro domain; $\overline\sigma $—Macro stress tensor;$\sigma $—Micro stress tensor; $\overline\varepsilon $—Macro strain tensor; $\varepsilon $—Micro strain tensor

表 1 石墨烯纳米复合材料的材料属性

Table 1. Material properties of a graphene nanocomposite

Material Young’s modulus/GPa Poisson's ratio Yield stress/MPa H/MPa b c/MPa Matrix 70 0.3 350 1500 25 360 GPLs 1050 0.186 — — — — Notes: H, b and c—Material parameters in Eq.(22); GPLs—Graphene nanoplates. -

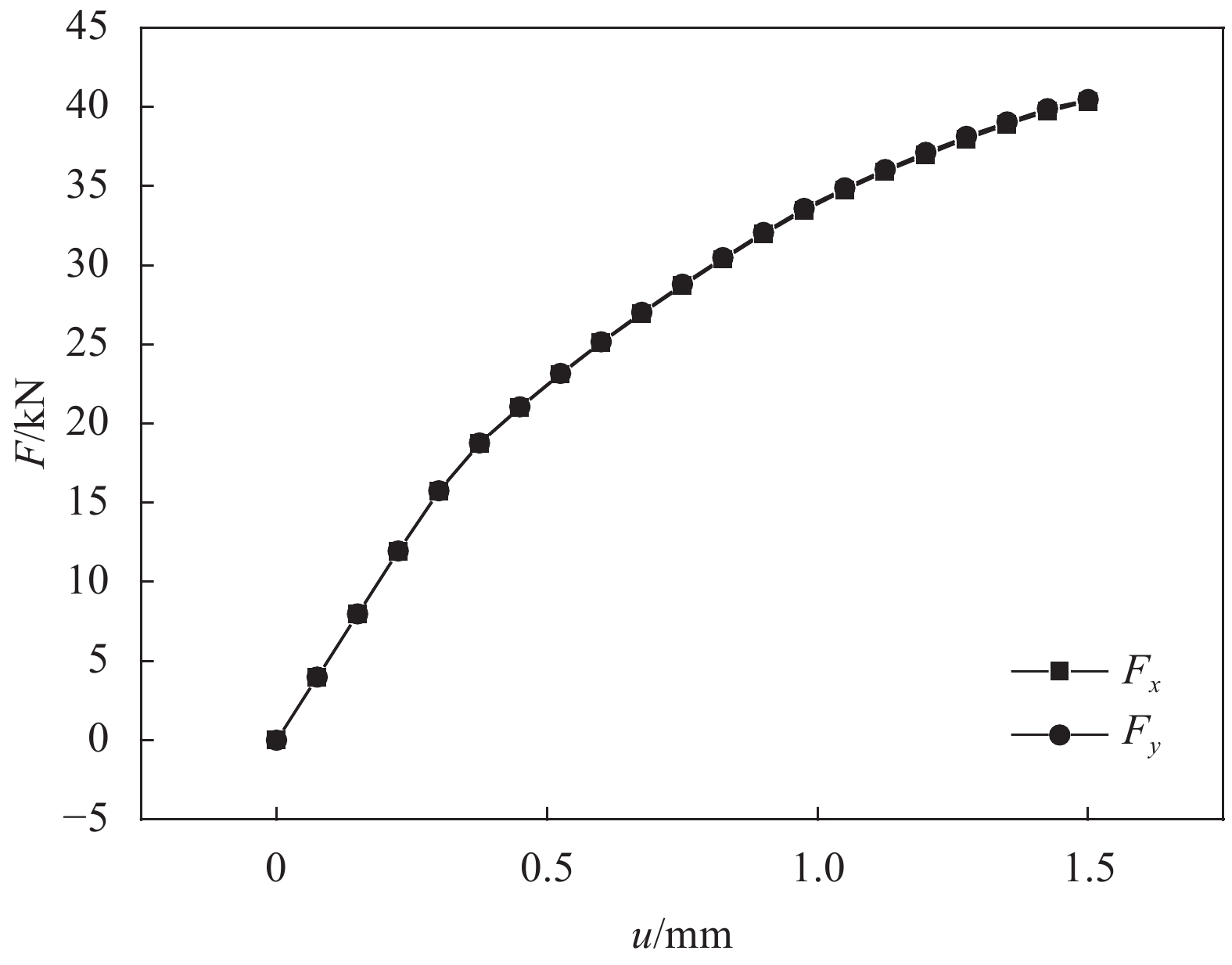

[1] LEE C, WEI X, KYSAR J, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. Science,2008,321(5887):385-388. doi: 10.1126/science.1157996 [2] RAFIEE M A, RAFIEE J, WANG Z, et al. Enhanced mechanical properties of nanocomposites at low graphene content[J]. ACS Nano,2009,3(12):3884-3890. doi: 10.1021/nn9010472 [3] HUANG X, QI X, BOEY F, et al. Graphene-based composites[J]. Chemical Society Reviews,2012,41(2):666-686. doi: 10.1039/C1CS15078B [4] 杨卫. 细观力学和细观损伤力学[J]. 力学进展, 1992, 22(1):1-9. doi: 10.6052/1000-0992-1992-1-J1992-001YANG W. Meso-mechanics and meso-damage mechanics[J]. Advances in Mechanics,1992,22(1):1-9(in Chinese). doi: 10.6052/1000-0992-1992-1-J1992-001 [5] GEERS M G, KOUZNETSOVA V G, MATOUŠ K, et al. Homogenization methods and multiscale modeling: Nonlinear problems[J]. Encyclopedia of Computational Mechanics Second Edition,2017:1-34. [6] GEERS M G D, KOUZNETSOVA V G, BREKELMANNS W A M. Multi-scale computational homogenization: Trends and challenges[J]. Journal of Computational and Applied Mathematics,2010,234:2175-2182. doi: 10.1016/j.cam.2009.08.077 [7] FEYNMAN R P. There’s plenty of room at the bottom[data storage][J]. Journal of Microelectromechanical Systems,1992,1(1):60-66. doi: 10.1109/84.128057 [8] FEYEL F, CHABOCHE J L. FE2 multiscale approach for modelling the elastoviscoplastic behaviour of long fibre SiC/Ti composite materials[J]. Computer Methods in Applied Mechanics and Engineering,2000,183(3-4):309-330. doi: 10.1016/S0045-7825(99)00224-8 [9] 许杨剑, 武鹏伟, 赵帅, 等. 弹塑性多尺度分析的实现及其在颗粒增强复合材料中的应用[J]. 复合材料学报, 2017, 34(9):1934-1943.XU Y J, WU P W, ZHAO S, et al. Implementation of elastic-plastic multi-scale analysis and application in particle reinforced composites[J]. Acta Materiae Compositae Sinica,2017,34(9):1934-1943(in Chinese). [10] DVORAK G J, BENVENSITE Y. On transformation strains and uniform fields in multiphase elastic media[J]. Proceedings of the Royal Society of London,1992,437(A):291-310. [11] MICHEL J C, SUQUET P. Nonuniform transformation field analysis[J]. International Journal for Solids and Structures,2003,40:6937-6955. doi: 10.1016/S0020-7683(03)00346-9 [12] MICHEL J C, SUQUET P. Computational analysis of nonlinear composite structures using the nonuniform transformation field analysis[J]. Computer Methods in Applied Mechanics and Engineering,2004,193:5477-5502. doi: 10.1016/j.cma.2003.12.071 [13] FRITZEN F, LEUSCHNER M. Reduced basis hybrid com-putational homogenization based on a mixed incremental formulation[J]. Computer Methods in Applied Mechanics and Engineering,2013,260:143-154. doi: 10.1016/j.cma.2013.03.007 [14] YVONNET J, HE Q C. The reduced model multiscale method (R3M) for the non-linear homogenization of hyperelastic media at finite strains[J]. Journal of Computational Physics,2007,223(1):341-368. doi: 10.1016/j.jcp.2006.09.019 [15] FISH J, FILONOVA V, YUAN Z. Hybrid impotent-incompatible eigenstrain based homogenization[J]. International Journal for Numerical Methods in Engineering,2013,95(1):1-32. doi: 10.1002/nme.4473 [16] JU X, MAHNKEN R. An NTFA-based homogenization framework considering softening effects[J]. Mechanics of Materials,2016,96:106-125. doi: 10.1016/j.mechmat.2016.01.007 [17] GAO C Y, ZHAN B, CHEN L, et al. A micromechanical model of graphene-reinforced metal matrix nanocomposites with consideration of graphene orientations[J]. Compo-sites Science and Technology,2017,152:120-128. doi: 10.1016/j.compscitech.2017.09.010 [18] DAI G, MISHNAEVSKY L. Graphene reinforced nanocomposites: 3D simulation of damage and fracture[J]. Com-putational Materials Science,2014,95:684-692. doi: 10.1016/j.commatsci.2014.08.011 [19] SPANOS K N, GEORGANTZINOS S K, ANIFANTIS N K. Mechanical properties of graphene nanocomposites: A multiscale finite element prediction[J]. Composite Structures,2015,132:536-544. doi: 10.1016/j.compstruct.2015.05.078 [20] HILL R. Elastic properties of reinforced solids: Some theoretical principles[J]. Journal of the Mechanics and Physics of Solids,1963,11:357-372. doi: 10.1016/0022-5096(63)90036-X [21] KOCH A, MIEHE C. Computational micro-to-macro tran-sitions of discretized microstructures undergoing small strains[J]. Archive of Applied Mechanics,2002,72(2002):300-317. [22] DVORAK G J, BAHEI-EL-DIN Y A, WAFA A M. The modeling of inelastic composite material with the transformation field analysis[J]. Modelling and Simulation in Materials Science and Engineering,1994,2:571-586. doi: 10.1088/0965-0393/2/3A/011 [23] MAHNKEN R, SCHLIMMER M. Simulation of strength difference in elasto-plasticity for adhesive materials[J]. International Journal for Numerical Methods in Engineering,2005,63:1461-1477. doi: 10.1002/nme.1315 [24] LIU F, MING P, LI J. Ab initio calculation of ideal strength and phonon instability of graphene under tension[J]. Physical Review B,2007,76:064120-1-7. [25] FEDEROV F. Theory of elastic waves in crystals[M]. New York: Plenum Press, 1968. [26] FRITZEN F, BÖHLKE T. Three-dimensional finite element implementation of the nonuniform transformation field analysis[J]. International Journal for Numerical Methods in Engineering,2010,84:803-829. doi: 10.1002/nme.2920 [27] 肖瑞, 李晓星, 李荣锋, 等. 十字形试样双向拉伸试验[J]. 理化检验:物理分册, 2017, 53(8):538-543.XIAO R, LI X X, LI R F, et al. Biaxial tensile testing of cruciform specimens[J]. Physical Testing and Chemical Analysis Part A: Physical Testing,2017,53(8):538-543(in Chinese). -

下载:

下载: