Effect of carboxymethyl cellulose on the properties of multi-wall carbon nanotube conductive ink

-

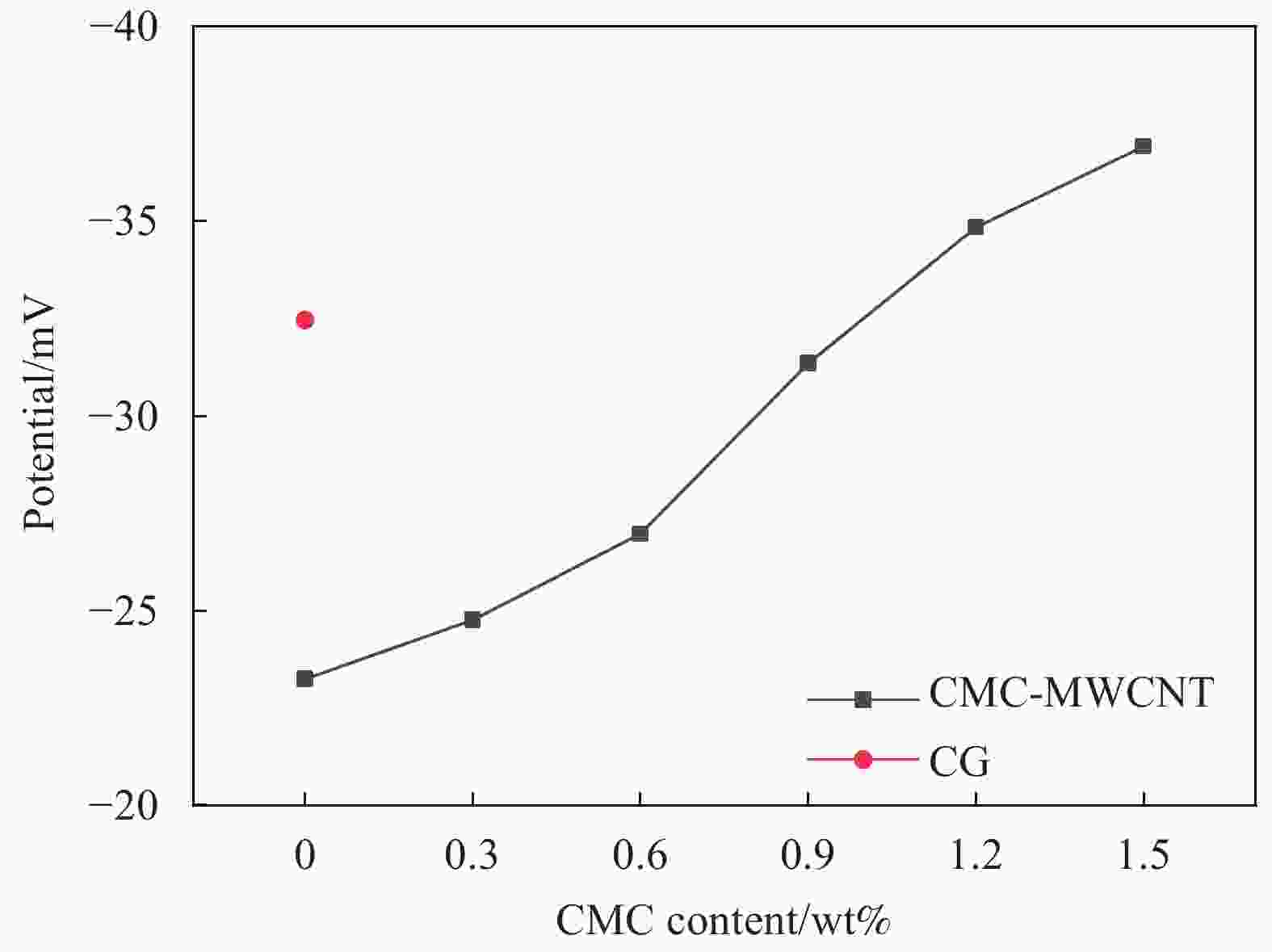

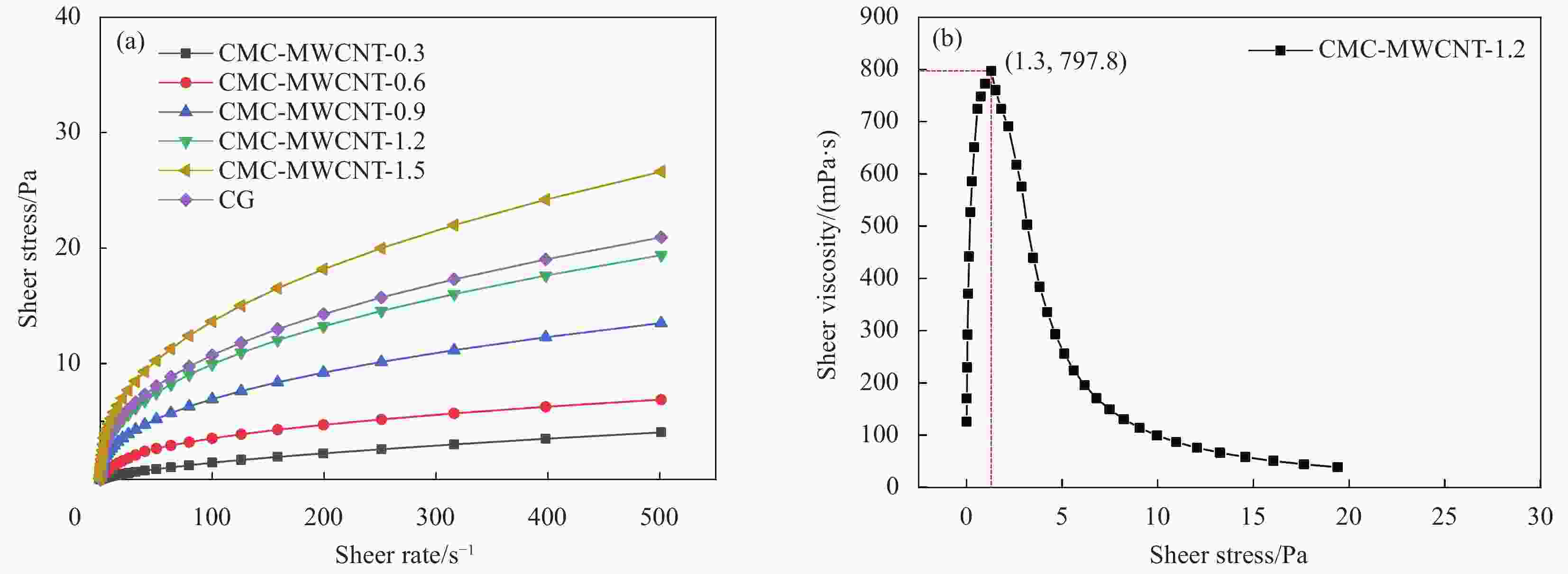

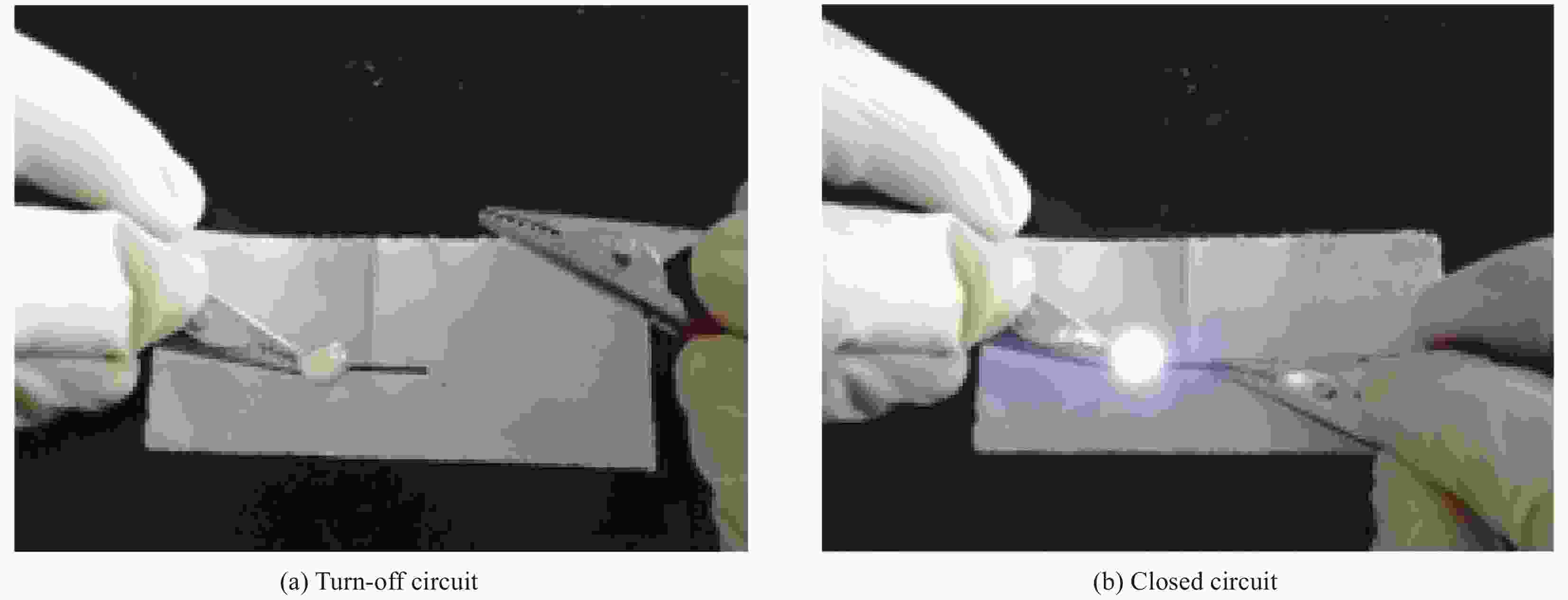

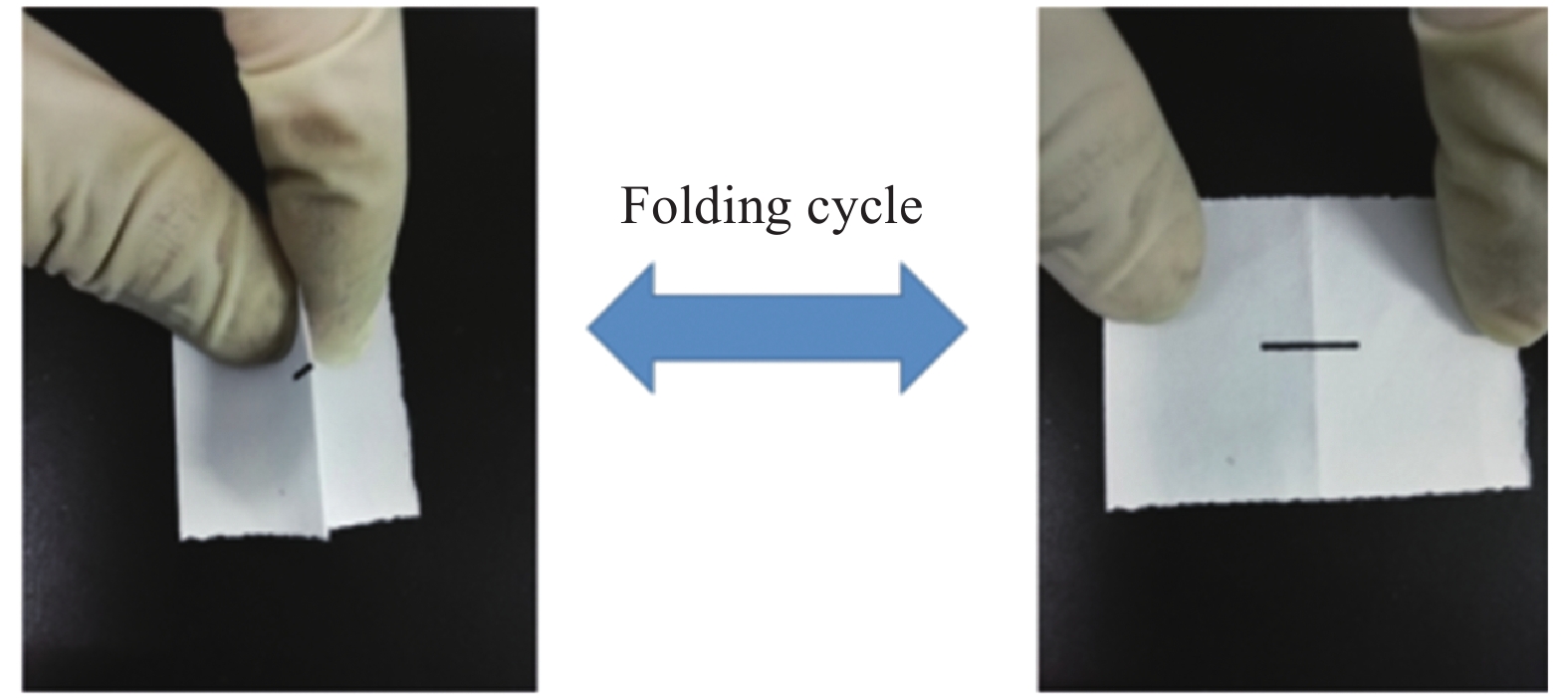

摘要: 传统中性墨水多用丙烯酸树脂做增稠剂,且不具备导电能力,因此将羧甲基纤维素(CMC)与多壁碳纳米管(MWCNT)混合,使制备墨水书写后具备导电能力。采用超声制得CMC-MWCNT导电墨水,通过中性笔书写于纸上,对制备导电墨水的稳定性能、流变性能、书写性能和书写字迹的耐腐蚀性能、导电性能、折叠稳定性能进行分析,并与市场上晨光中性笔墨水(CG)进行对比。当添加CMC为0.3wt%、0.6wt%时,导电墨水的Zeta电位、屈服应力、屈服黏度均较低,书写时出现漏墨,书写后电阻较小,但折叠一百次后电阻增大较多,分别增大32.3%、17.9%。当添加CMC为0.9wt%、1.2wt%、1.5wt%时,导电墨水的Zeta电位绝对值均大于30 mV,体系处于稳定态;屈服应力与屈服黏度随CMC添加量增大而增大;CMC为0.9wt%和1.2wt%的导电墨水书写正常,书写后电阻分别为14.9 kΩ/cm、15.6 kΩ/cm,折叠100次后电阻分别增大8.7%、7.8%;1.5wt%CMC的导电墨水书写时有断墨,书写后电阻为28.3 kΩ/cm,折叠100次后电阻增大9.5%。与CG相比,1.2wt%CMC的导电墨水具有相似的稳定性能、流变性能、书写性能,并具备导电能力,可点亮LED灯。Abstract: Thetraditional neutral ink is mostly made of acrylic resin as thickener, and does not have the ability to conduct electricity. Therefore, this study explored the mixing of carboxymethyl cellulose (CMC) and multi-wall carbon nanotubes (MWCNT) to make the prepared ink conductive after writing. CMC-MWCNT conductive ink was prepared by ultrasonic and written on paper with a neutral pen. The stability, rheological property, writing property, corrosion resistance, electrical conductivity, and folding stability of the prepared conductive ink were analyzed, and compared with Chenguang neutral ink (CG) on the market. When the amount of CMC is 0.3wt% and 0.6wt% respectively, the Zeta potential, yield stress and yield viscosity of conductive ink are all low, ink leakage occurred during writing. And the line resistance of writing is small, but the resistance increases a lot after 100 times of folding, increasing by 32.3% and 17.9%, respectively. When CMC is added at 0.9wt%, 1.2wt% and 1.5wt%, respectively, the absolute value of Zeta potential of conductive ink is greater than 30 mV, and the system is in a stable state. The yield stress and viscosity increased with the increase of CMC. When CMC content is 0.9wt% and 1.2wt%, respectively, the conductive ink writing is normal, the resistance of the writing lines are 14.9 kΩ/cm, 15.6 kΩ/cm, and the resistance increases by 8.7% and 7.8% after 100 times of folding. The conductive ink of 1.5wt% CMC content is broken when writing, the resistance after writing is 28.3 kΩ/cm, and the resistance increases by 9.5% after 100 times of folding. Compared with CG, conductive ink of 1.2wt% CMC has similar stable performance, rheological performance, and writing performance. In addition, conductive ink of 1.2wt% CMC has electrical conductivity and can light up LED lights.

-

Key words:

- conductive ink /

- carboxymethyl cellulose /

- multi-wall carbon nanotubes /

- rheological /

- conductivity /

- folding stabality

-

表 1 耐腐蚀测试条件

Table 1. Corrosion resistance test conditions

Testing agent Accepting surface Immersion time H2O A4 paper 24 h 50wt%C2H5OH 10 min 10wt%HCl 24 h 10wt%NH3·H2O 24 h -

[1] KURRA N, KULKARNI G U. Pencil-on-paper: electronic devices[J]. Lab on a Chip,2013,13(15):2866-2873. doi: 10.1039/c3lc50406a [2] RUSSO A, AHN B Y, ADAMS J J, et al. Pen-on-paper flexible electronics.[J]. Advanced Materials,2011,23(30):3426-3430. doi: 10.1002/adma.201101328 [3] 姜皎洁, 刘文涛, 黄灵阁, 等. 无线射频识别技术用导电油墨的研究[J]. 材料导报, 2015, 29(1):121-126. doi: 10.11896/j.issn.1005-023X.2015.01.021JIANG J J, LIU W T, HUANG L G, et al. State-of-the-art of the studies on conductive ink for radio frequency identification antenna[J]. Materials Review,2015,29(1):121-126(in Chinese). doi: 10.11896/j.issn.1005-023X.2015.01.021 [4] LIU S, LI J, SHI X, et al. Roller ball-pen-drawing technology for extremely foldable paper-based electronics[J]. Advanced Electronic Materials,2017,3(7):1700098. [5] LI Y, ZHU H, WANG Y, et al. Cellulose-nanofiber-enabled 3D printing of a carbon-nanotube microfiber network[J]. Small Methods,2017,1:1-8. [6] EVAN Q, MATHIS T S, NARENDRA K, et al. Direct writing of additive-free mxene-in-water ink for electronics and energy storage[J]. Advanced Materials Technologies,2019,4:1800256. doi: 10.1002/admt.201800256 [7] 姜欣, 赵轩亮, 李晶, 等. 石墨烯导电墨水研究进展: 制备方法、印刷技术及应用[J]. 科学通报, 2017, 62(27):3217-3235. doi: 10.1360/N972017-00288JIANG X, ZHAO X L, LI J, et al. Recent developments in graphene conductive ink: Preparation, printing technology and application[J]. Chinese Science Bulletin,2017,62(27):3217-3235(in Chinese). doi: 10.1360/N972017-00288 [8] JIA H, WANG J, ZHANG X, et al. Pen-writing polypyrrole arrays on paper for versatile cheap sensors[J]. ACS Macro Letters,2014,3(1):86-90. doi: 10.1021/mz400523x [9] 陶国良, 陆小璐, 李海, 等. 填充银纳米棒新型导电油墨[J]. 复合材料学报, 2012, 29(4):143-147.TAO G L, LU X L, LI H, et al. A novel kind of conductive inkjet filled with Ag nanorods[J]. Acta Materiae Compositae Sinica,2012,29(4):143-147(in Chinese). [10] 王望, 郭彦峰, 孙振锋, 等. 碳系导电油墨填料的研究进展[J]. 化工进展, 2015, 34(12):4259-4264.WANG W, GUO Y F, SUN Z W, et al. Research progress of carbon-based conductive ink fillers[J]. Chemical Industry and Engineering Progress,2015,34(12):4259-4264(in Chinese). [11] BLANCH A J, LENEHAN C E, QUINTON J S. Optimizing surfactant concentrations for dispersion of single-walled carbon nanotubes in aqueous solution[J]. Journal of Physical Chemistry B,2010,114(30):9805. doi: 10.1021/jp104113d [12] HAN J W, KIM B, LI J, et al. Carbon nanotube ink for writing on cellulose paper[J]. Materials Research Bulletin,2014,50(feb):249-253. [13] 李健, 刘雅南, 刘宁, 等. 羧甲基纤维素的制备研究及应用现状[J]. 食品工业科技, 2014, 35(8):379-382.LI J, LIU Y N, LIU N, et al. Study on the preparation and application status of carboxymethyl cellulose[J]. Science and Technology of Food Industry,2014,35(8):379-382(in Chinese). [14] SINAR D, KNOPF G K. Disposable piezoelectric vibration sensors with PDMS/ZnO transducers on printed graphene-cellulose electrodes[J]. Sensors and Actuators A: Physical,2019,302:111800. [15] 何军, 李莎, 王虹, 等. 羧甲基纤维素钠对纳米银导电墨水性能的影响[J]. 化学工业与工程, 2012(4):1-5. doi: 10.3969/j.issn.1004-9533.2012.04.001HE J, LI S, WANG H, et al. Effect of caboxymethyl cellulose sodium on the properties of nano-silver conductive ink[J]. Chemical Industry and Engineering,2012(4):1-5(in Chinese). doi: 10.3969/j.issn.1004-9533.2012.04.001 [16] 中华人民共和国工业和信息化部. 中性墨水: QB/T 4434—2012[S]. 北京: 中国标准出版社, 2012.Ministry of Industry and Information Technology of the People’s Republic of China. Gel inks: QB/T 4434—2012[S]. Beijing: China Standards Press, 2012 (in Chinese). [17] 何北海, 张春梅, 伍红. 纸浆悬浮液Zeta电位分析的初步研究[J]. 中国造纸学报, 1999(00):69-74.HE B H, ZHANG C M, WU H. Preliminary study on Zeta potential analysis in pulp suspension[J]. Transactions of China Pulp and Paper,1999(00):69-74(in Chinese). [18] 黄苏萍, 肖奇. 十二烷基硫酸钠对碳纳米管悬浮液分散性能的影响[J]. 粉末冶金材料科学与工程, 2012, 17(1):133-138.HUANG S P, XIAO Q. Effect of sodium dodecyl sulfate on dispersion properties of carbon nanotubes[J]. Materials Science and Engineering of Powder Metallurgy,2012,17(1):133-138(in Chinese). [19] 刘海燕, 庞明军, 魏进家. 非牛顿流体研究进展及发展趋势[J]. 应用化工, 2010, 39(5):740-746.LIU H Y, PANG M J, WEI J J. A progress and trend of the non-Newtonian fluids[J]. Applied Chemical Industry,2010,39(5):740-746(in Chinese). [20] 陈晓明, 张璟焱, 徐文总, 等. 关于高分子液体"高黏度"和"剪切变稀"的讨论[J]. 高分子通报, 2019(6):68-71.CHEN X M, ZHANG J Y, XU W Z, et al. Discussion on “high viscosity” and “sheer thinning” of polymer liquid[J]. Polymer Bulletin,2019(6):68-71(in Chinese). [21] 刘守军, 贺晨霞, 冯博洪, 等. 中性墨水流变性与书写性能相关性研究[J]. 太原理工大学学报, 2013(3):259-263. doi: 10.3969/j.issn.1007-9432.2013.03.001LIU S J, HE C X, FENG B H, et al. Study on the correlation between gel ink rheological property and writing performance[J]. Journal of Taiyuan University of Technology,2013(3):259-263(in Chinese). doi: 10.3969/j.issn.1007-9432.2013.03.001 [22] 钱纪军, 陈爱平, 刘众鑫, 等. 炭黑中性笔墨水书写性能的流变学表征[J]. 精细化工, 2009, 26(5):506-508.QIAN J J, CHEN A P, LIU Z X, et al. The rheological characterization of the writing performance of carbon black gel ink[J]. Fine Chemicals,2009,26(5):506-508(in Chinese). [23] 杨昕宇, 向卫东, 潘明初. 粘度对中性墨水书写性能的影响[J]. 温州大学学报(自然科学版), 2007(4):42-45.YANG X Y, XIANG W D, PAN M C. Viscosity influence on gel ink writing property[J]. Journal of Wenzhou University (Natural Science Edition),2007(4):42-45(in Chinese). [24] WANG W, FU S. Manufacture of a super-stable green gel pen ink based on CNC-indigo[J]. Cellulose,2020,27(16):1009-1020. [25] 孙亮权, 安兵, 李健, 等. 用纳米铜油墨印刷RFID标签天线[J]. 电子工艺技术, 2013, 000(1):6-9.SUN L Q, AN B, LI J, et al. Nano copper conductive ink printed RFID tag[J]. Electronics Process Technology,2013,000(1):6-9(in Chinese). [26] CHEN Y, ZHOU L, WEI J, et al. Direct ink writing of flexible electronics on paper substrate with graphene/polypyrrole/carbon black ink[J]. Journal of Electronics Materials,2019,48:3157-3168. doi: 10.1007/s11664-019-07085-x -

下载:

下载: