Experimental study on the influence of ultra-low temperature on compressive toughness of ultra high toughness cementitious composites

-

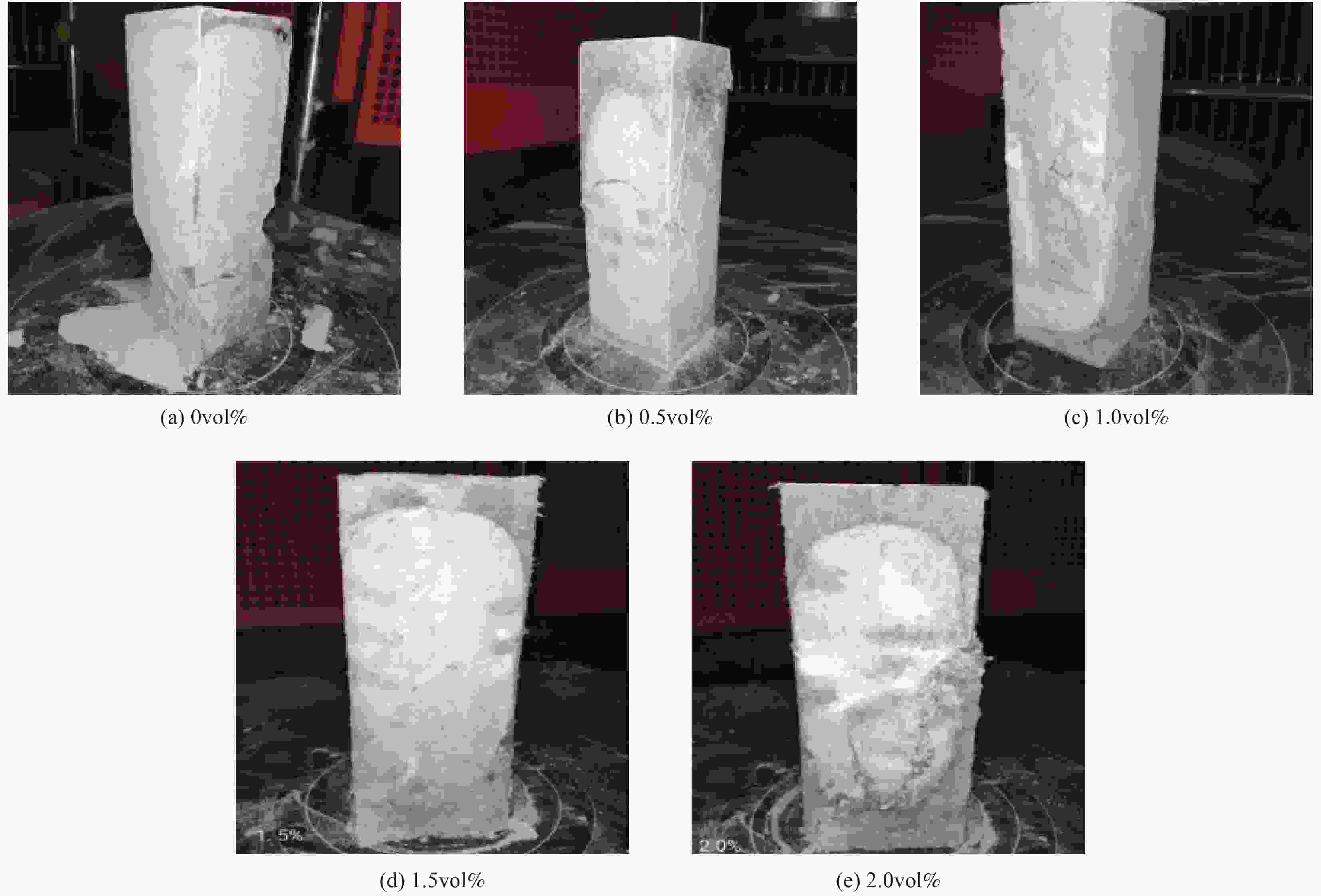

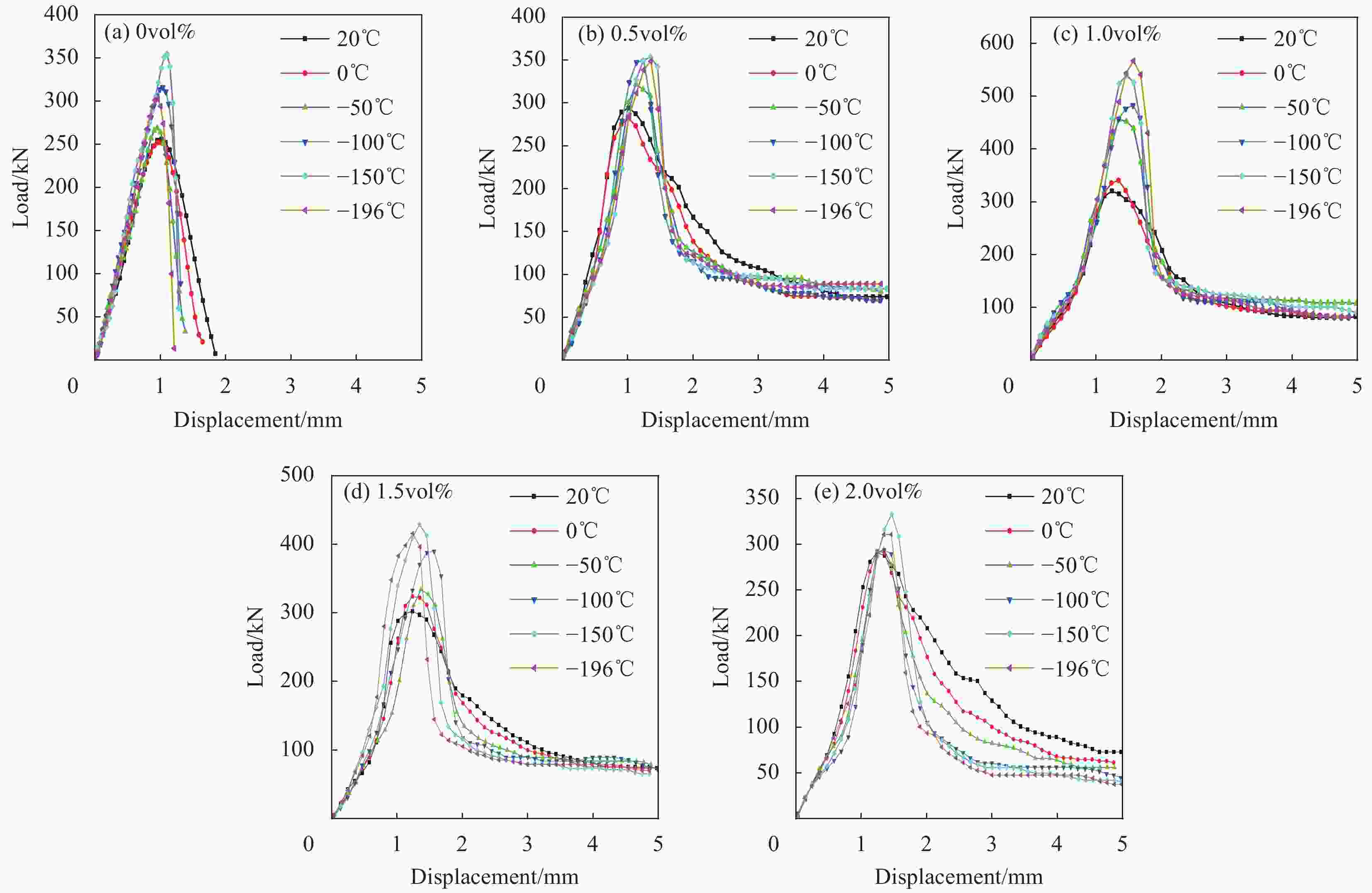

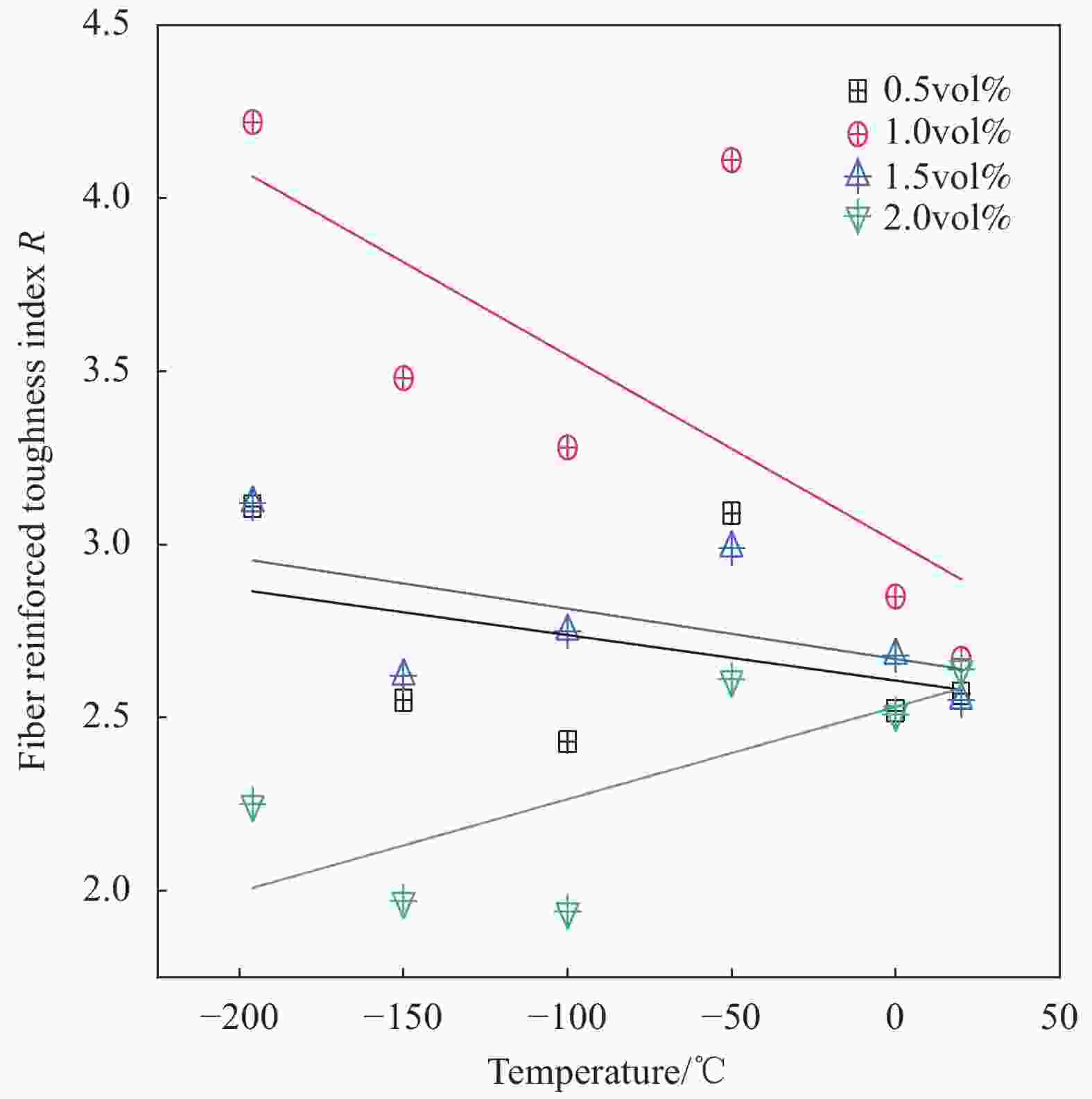

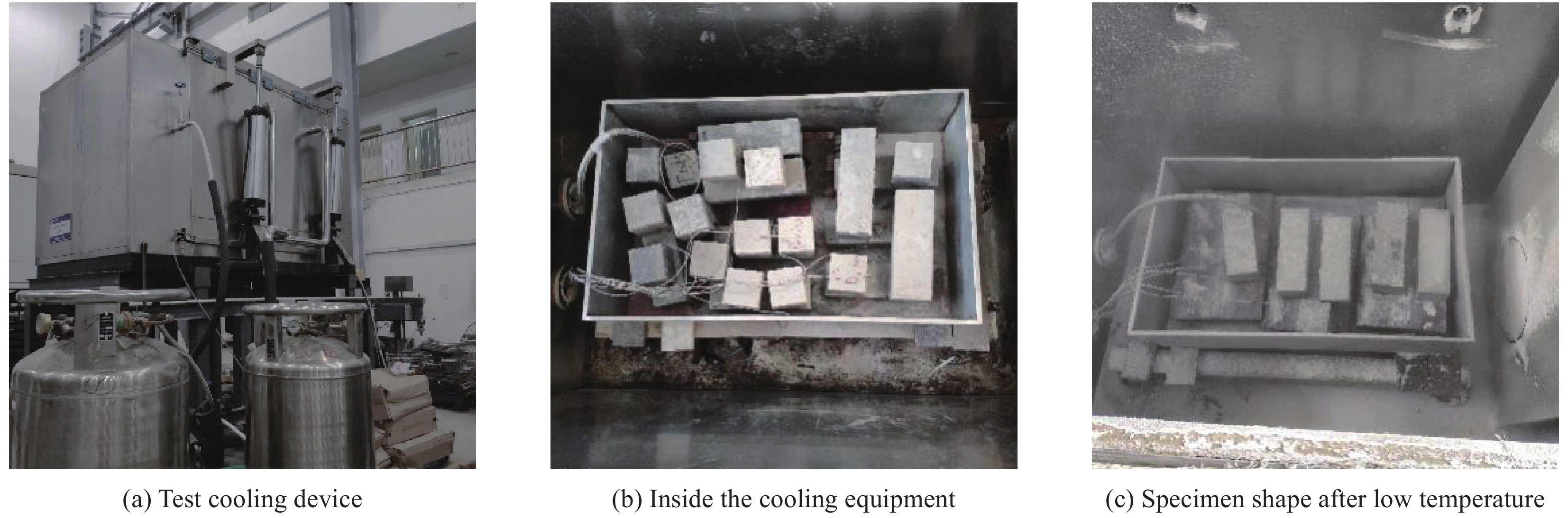

摘要: 超高韧性水泥基复合材料(UHTCC)是一种具有超高韧性及良好耐久性能的新型复合材料,其抗压韧性是评价其工作性能的重要指标。通过对5组不同纤维掺量的UHTCC在超低温作用后的单轴受压试验,研究超低温作用下UHTCC的抗压韧性评价指标,并对其变形能力进行等效分析,为UHTCC在超低温环境下的工程应用提供理论支持。研究结果表明:在一定范围内,随着纤维体积掺量的增加,UHTCC的抗压强度、抗压韧性均有明显提升,而超出最优掺量后性能反而略有下降;超低温对于UHTCC的抗压强度具有一定的提升作用,当温度降低至−196℃,其轴向抗压强度最大可提升约74.42%,但其脆性性能更明显。Abstract: Ultra high toughness cementitious composites (UHTCC) is a new material with ultra-high toughness and good durability. Its compressive toughness index is an important index to evaluate the toughness of UHTCC. 5 groups of UHTCC with different fiber contents were tested under uniaxial compression after ultra-low temperature, and the evaluation index of compressive toughness of UHTCC under ultra-low temperature was studied, and its deformation capacity was equivalent analyzed. The experimental results show that within a certain range, with the increase of fiber content, the compressive strength and toughness of UHTCC are significantly improved, but beyond the optimal content range, the performances are not improved, but are slightly decreased; ultra-low temperature has a certain improvement on the compressive strength of UHTCC, when the temperature is reduced to −196℃, the axial compressive strength can be increased by 74.42%, but it shows obvious fragility.

-

Key words:

- ultra low temperature /

- UHTCC /

- uniaxial compression /

- compressive toughness /

- fiber volume content

-

表 1 聚乙烯醇(PVA)纤维性能指标

Table 1. Polyvinyl alcohol (PVA) fiber performance index

Name Density/(g·cm−3) Diameter/mm Length/mm Elastic modulus/MPa Tensile strength/MPa Elongation/% REC15×12 1.3 0.04 12 120 526 6 表 2 超高韧性水泥基复合材料(UHTCC)配合比及试验分组

Table 2. Ultra high toughness cementitious composites (UHTCC) mix proportion and test grouping

Specimen Volume fraction of

PVA fiber/vol%Temperature/℃ Fly ash/

(kg·m−3)Cement/

(kg·m−3)Sand/

(kg·m−3)Silica fume/

(kg·m−3)C30 0 20/0/−50/−100/−150/−196 533.3 120 133.3 13.3 0.5vol%PVA/C30 0.5 20/0/−50/−100/−150/−196 533.3 120 133.3 13.3 1.0vol%PVA/C30 1.0 20/0/−50/−100/−150/−196 533.3 120 133.3 13.3 1.5vol%PVA/C30 1.5 20/0/−50/−100/−150/−196 533.3 120 133.3 13.3 2.0vol%PVA/C30 2.0 20/0/−50/−100/−150/−196 533.3 120 133.3 13.3 表 3 各UHTCC试件平均抗压强度试验值

Table 3. Average compressive strength test values of UHTCC specimens

MPa Action temperature 20℃ 0℃ −50℃ −100℃ −150℃ −196℃ Measured temperature 20℃ 0℃ −50℃ −98.2℃ −132.2℃ −162.8℃ C30 27.648 27.080 28.904 32.984 34.584 31.384 0.5vol%PVA/C30 29.288 28.976 32.968 35.296 36.168 35.464 1.0vol%PVA/C30 32.920 34.048 46.840 48.984 54.864 57.424 1.5vol%PVA/C30 30.352 32.312 33.688 39.760 43.368 42.552 2.0vol%PVA/C30 29.152 29.448 29.920 33.696 35.792 31.456 表 4 各阶段荷载及UHTCC相应变形

Table 4. Load and corresponding deformation of UHTCC at each stage

Specimen Temperature/℃ Cracking deformation δc/mm Cracking load/kN Peak deformation/mm Peak load/kN C30 20 − − 1.01 276.48 0 − − 1.02 270.80 −50 − − 1.02 289.04 −100 − − 1.08 329.84 −150 − − 1.14 345.84 −196 − − 1.01 313.84 0.5vol%PVA/C30 20 0.452 112.72 1.01 292.88 0 0.483 105.86 1.01 289.76 −50 0.574 129.43 1.12 329.68 −100 0.694 152.31 1.24 352.96 −150 0.691 136.19 1.34 361.68 −196 0.694 146.58 1.35 354.64 1.0vol%PVA/C30 20 0.582 107.45 1.24 329.20 0 0.683 128.04 1.34 340.48 −50 0.716 156.30 1.35 468.40 −100 0.793 169.63 1.56 489.84 −150 0.804 174.05 1.46 548.64 −196 0.911 245.98 1.57 574.24 1.5vol%PVA/C30 20 0.683 111.13 1.23 303.52 0 0.684 113.92 1.23 323.12 −50 0.815 129.48 1.36 336.88 −100 0.784 157.38 1.56 397.60 −150 0.682 162.77 1.45 433.68 −196 0.622 158.41 1.24 425.52 2.0vol%PVA/C30 20 0.582 92.68 1.24 291.52 0 0.692 105.48 1.24 294.48 −50 0.794 111.88 1.35 299.20 −100 0.911 122.42 1.35 336.96 −150 0.914 141.10 1.46 357.92 −196 0.816 115.73 1.46 314.56 表 5 不同影响因素下的UHTCC等效抗压强度及变形能

Table 5. UHTCC equivalent compressive strength and deformation energy under different influencing factors

Specimen Temperature/℃ Equivalent compressive

strength/MPaModified equivalent

compressive strengthDeformation energy u=0.85 u=0.5 u=0.2 u=0.85 u=0.5 u=0.2 $ {A}_{1} $ $ {A}_{3}^{1} $ $ {A}_{5.5}^{1} $ $ {A}_{10}^{1} $ C30 20 15.99 16.09 15.14 0.069 0.080 0.086 262.62 − − − 0 15.95 15.99 15.19 0.065 0.074 0.078 238.36 − − − −50 15.36 15.65 15.12 0.057 0.063 0.067 203.23 − − − −100 18.28 18.49 18.32 0.071 0.078 0.081 239.75 − − − −150 19.10 19.27 19.25 0.076 0.080 0.081 244.80 − − − −196 16.64 16.84 16.63 0.059 0.064 0.066 198.57 − − − 0.5vol%PVA/C30 20 18.54 18.67 13.59 0.091 0.138 0.225 20.38 203.54 410.9 601.35 0 16.94 17.69 12.38 0.077 0.120 0.200 23.07 228.13 381.51 575.90 −50 17.89 18.28 12.90 0.085 0.107 0.209 38.22 277.60 410.58 590.23 −100 17.53 18.26 11.96 0.078 0.096 0.194 46.42 306.29 432.35 536.75 −150 18.21 18.52 12.61 0.092 0.101 0.208 45.92 313.43 451.58 578.76 −196 17.93 18.44 12.67 0.088 0.100 0.206 49.81 310.54 444.52 567.76 1.0vol%PVA/C30 20 18.73 19.25 14.12 0.108 0.147 0.234 32.83 295.87 487.26 687.56 0 18.25 19.25 14.00 0.095 0.135 0.227 42.06 353.44 511.43 638.39 −50 23.79 24.25 16.80 0.133 0.150 0.278 55.94 448.87 623.95 779.93 −100 24.40 24.71 16.17 0.141 0.153 0.262 71.49 463.85 637.40 714.27 −150 25.28 26.05 17.08 0.141 0.153 0.284 70.92 492.25 684.66 779.96 −196 26.58 27.30 17.22 0.154 0.168 0.279 89.00 541.76 722.85 748.39 1.5vol%PVA/C30 20 17.59 17.79 13.49 0.098 0.142 0.223 35.78 333.70 509.73 634.45 0 17.06 17.81 13.11 0.090 0.126 0.212 35.85 330.93 489.98 602.15 −50 16.57 17.08 12.46 0.093 0.108 0.203 51.53 341.55 489.28 556.85 −100 19.93 20.10 13.23 0.114 0.121 0.220 51.80 378.65 517.2 606.98 −150 21.67 22.07 13.18 0.110 0.119 0.214 48.06 368.91 488.51 592.85 −196 21.16 21.55 12.74 0.098 0.106 0.206 36.96 334.42 446.67 582.21 2.0vol%PVA/C30 20 16.73 17.38 13.93 0.095 0.162 0.231 25.32 269.03 476.88 667.32 0 14.98 16.47 12.33 0.077 0.124 0.200 34.96 308.68 467.12 564.32 −50 14.20 15.19 10.90 0.073 0.099 0.177 44.67 306.16 433.97 486.11 −100 13.64 14.28 9.37 0.071 0.085 0.155 49.49 291.86 395.82 416.37 −150 15.15 15.93 9.67 0.082 0.096 0.160 55.82 315.77 408.47 425.75 −196 14.37 15.04 8.97 0.073 0.085 0.149 50.75 274.66 356.86 396.01 Notes:u—Load when the load drops to u times the ultimate load; $ {A}_{n}^{1} $—Absorbed energy after cracking of UHTCC with different deformation degrees. 表 6 UHTCC纤维增强韧性指标R与残余韧性指标Rc

Table 6. Fiber reinforced toughness index R and residual toughness index Rc in UHTCC

Specimen Temperature/℃ AUHTCC AJT Afz Fiber reinforced

toughness index RResidual toughness

index RcC30 20 − − − − − 0 − − − − − −50 − − − − − −100 − − − − − −150 − − − − − −196 − − − − − 0.5vol%PVA/C30 20 675.32 262.62 155.56 2.57 2.94 0 601.23 238.36 140.43 2.52 2.28 −50 628.45 203.24 164.44 3.09 1.86 −100 583.17 239.76 201.31 2.43 1.03 −150 624.68 244.81 221.98 2.55 1.43 −196 617.57 198.58 225.82 3.11 0.98 1.0vol%PVA/C30 20 702.39 262.62 176.86 2.67 2.97 0 680.45 238.36 217.17 2.85 2.13 −50 835.87 203.24 258.82 4.11 2.23 −100 785.76 239.76 343.27 3.28 1.29 −150 850.88 244.81 320.75 3.48 1.65 −196 837.39 198.58 369.19 4.22 1.27 1.5vol%PVA/C30 20 670.23 262.62 166.64 2.55 3.02 0 638.00 238.36 159.47 2.68 3.00 −50 608.38 203.24 179.57 2.99 2.39 −100 658.78 239.76 286.30 2.75 1.30 −150 640.90 244.81 259.05 2.62 1.47 −196 619.17 198.58 235.09 3.12 1.63 2.0vol%PVA/C30 20 692.64 262.62 159.78 2.64 3.33 0 599.28 238.36 147.07 2.51 3.07 −50 530.78 203.24 163.73 2.61 2.24 −100 465.86 239.76 152.17 1.94 2.06 −150 481.57 244.81 197.89 1.97 1.43 −196 446.76 198.58 165.76 2.25 1.70 Notes:AUHTCC—Area under the curve calculated from the peak load corresponding to five times the deformation as the limit point of the residual toughness; AJT—Toughness after ignoring the peak of the matrix, and the area under the load-deformation curve corresponding to the peak point is taken as the energy absorption value of the matrix; Afz—Area under the corresponding curve when the load-deformation curve reaches the peak load. -

[1] CAVERZAN A, CADONI E, PRISCO M D. Dynamic tensile behaviour of high performance fibre reinforced cementitious composites after high temperature exposure[J]. Mechanics of Materials, 2013, 59: 87-109. [2] TOUTANJI H A, EVANS S, GRUGEL R N. Performance of lunar sulfur concrete in lunar environments[J]. Construction and Building Materials,2012,29:444-448. doi: 10.1016/j.conbuildmat.2011.10.041 [3] LI V C, LEUNG C. Steady-state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics, 1992, 118(11): 2246-2264. [4] 徐世烺, 李贺东. 超高韧性水泥基复合材料研究进展及其工程应用[J]. 土木工程学报, 2008(6):45-60. doi: 10.3321/j.issn:1000-131X.2008.06.008XU Shilang, LI Hedong. Research progress and engineering application of ultra-high toughness cement-based composites[J]. China Civil Engineering Journal,2008(6):45-60(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.06.008 [5] 吴泽媚. 超高性能混凝土中纤维与基体界面粘结性能多尺度研究[D]. 长沙: 湖南大学, 2017.WU Zemei. Multi-scale study on the bonding properties of fiber and matrix interface in ultra-high performance concrete[D]. Changsha: Hunan University, 2017(in Chinese). [6] 宁逢伟, 陈波,张丰. PVA纤维掺量对水工混凝土抗裂性能的影响[J]. 水利水电技术, 2017, 48(2): 125-129.NING Fengwei, CHEN Bo, ZHANG Feng. Effect of PVA fiber content on crack resistance of hydraulic concrete[J]. Water Conservancy and Hydropower Technology, 2017, 48 (2): 125-129(in Chinese). [7] LIU W, HAN J. Experimental investigation on compressive toughness of the PVA-steel hybrid fiber reinforced cementitious composites[J]. Frontiers in Materials, 2019, 6: 108 [8] 牛龙龙, 张士萍, 韦有信. 钢纤维掺量对混凝土力学性能的影响[J]. 混凝土与水泥制品, 2019(3):51-54.NIU Longlong, ZHANG Shiping, WEI Youxin. The effect of steel fiber content on the mechanical properties of concrete[J]. China Concrete and Cement Products,2019(3):51-54(in Chinese). [9] 张秀芳, 徐世烺, 侯利军. 采用超高韧性水泥基复合材料提高钢筋混凝土梁弯曲抗裂性能研究(II): 试验研究[J]. 土木工程学报, 2009, 42(10):53-66. doi: 10.3321/j.issn:1000-131X.2009.10.008ZHANG Xiufang, XU Shilang, HOU Lijun. Research on using ultra-high toughness cement-based composites to improve the flexural crack resistance of reinforced concrete beams (II): Experimental research[J]. China Civil Engineering Journal,2009,42(10):53-66(in Chinese). doi: 10.3321/j.issn:1000-131X.2009.10.008 [10] KIM J W, LEE J J, LEE D G. Effect of fiber orientation on the tensile strength in fiber-reinforced polymeric composite materials[J]. Key Engineering Materials,2005,297-300:2897-2902. doi: 10.4028/www.scientific.net/KEM.297-300.2897 [11] 罗才松. 聚丙烯纤维掺量对混凝土强度的影响[J]. 科学技术与工程, 2011, 11(4):874-876. doi: 10.3969/j.issn.1671-1815.2011.04.045LUO Caisong. The influence of polypropylene fiber content on concrete strength[J]. Science Technology and Engineering,2011,11(4):874-876(in Chinese). doi: 10.3969/j.issn.1671-1815.2011.04.045 [12] KOGBARA R B, IYENGAR S R, GRASLEY Z C, et al. A review of concrete properties at cryogenic temperatures: Towards direct LNG containment[J]. Construction and Building Materials,2013,47:760-770. [13] SHEN D, JIANG J, SHEN J, et al. Influence of curing tem-perature on autogenous shrinkage and cracking resistance of high-performance concrete at an early age[J]. Construction & Building Materials,2016,103:67-76. [14] DEROSA D, HOULT N A, GREEN M F. Effects of varying temperature on the performance of reinforced concrete[J]. Materials & Structures,2015,48(4):1109-1123. [15] 王庆, 王艳云, 邢海峰. 聚丙烯纤维混凝土在低温条件下力学性能的研究[J]. 石河子大学学报(自然科学版), 2007(2):229-231.WANG Qing, WANG Yanyun, XING Haifeng. Research on the mechanical properties of polypropylene fiber concrete under low temperature conditions[J]. Journal of Shihezi University (Natural Science),2007(2):229-231(in Chinese). [16] LIU X, ZHANG M H, CHIA K S, et al. Mechanical properties of ultra-lightweight cement composite at low tempera-tures of 0 to 60°C[J]. Cement & Concrete Composites,2016,73:289-298. [17] DAHMANI L, KHENANE A, KACI S. Behavior of the reinforced concrete at cryogenic temperatures[J]. Cryogenics,2007,47(9-10):517-525. doi: 10.1016/j.cryogenics.2007.07.001 [18] XIE J, LI X, WU H. Experimental study on the axial-compression performance of concrete at cryogenic tempera-tures[J]. Construction & Building Materials,2014,72(dec. 15):380-388. [19] CAI X P, YANG W C, YUAN J, et al. Mechanics properties of concrete at low temperature[J]. Advanced Materials Research,2011,261-263:389-393. doi: 10.4028/www.scientific.net/AMR.261-263.389 [20] 中国工程建设协会标准. 纤维混凝土试验方法标准: CECS13: 2009[S]. 北京: 中国计划出版社, 2010.China Association for Engineering Construction Standardization. Test method standard for fiber reinforced concrete: CECS13: 2009[S]. Beijing: China Planning Press, 2010(in Chinese). [21] YAMANA S, KASAMI H, OKUNO T. Properties of concrete at very low temperatures[J]. Publication SP 55,1978,55:1-12. [22] MIURA T. The properties of concrete at very low tempera-tures[J]. Materials and Structures,1989,22(4):243-254. doi: 10.1007/BF02472556 -

下载:

下载: