Micro-characterization and mechanical properties of pseudo-boehmite stone-coated graphene oxide/epoxy resin-cyanate composites

-

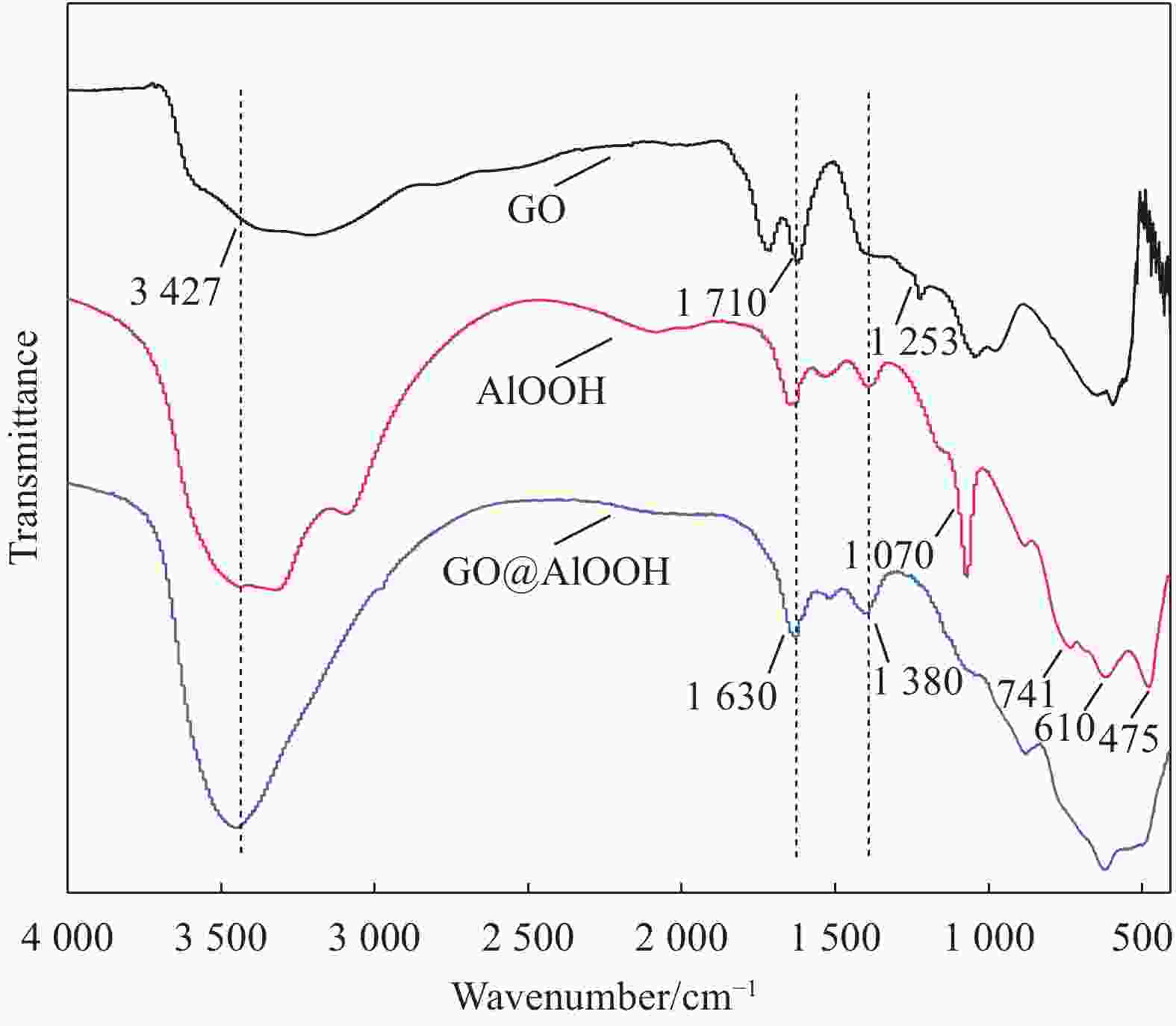

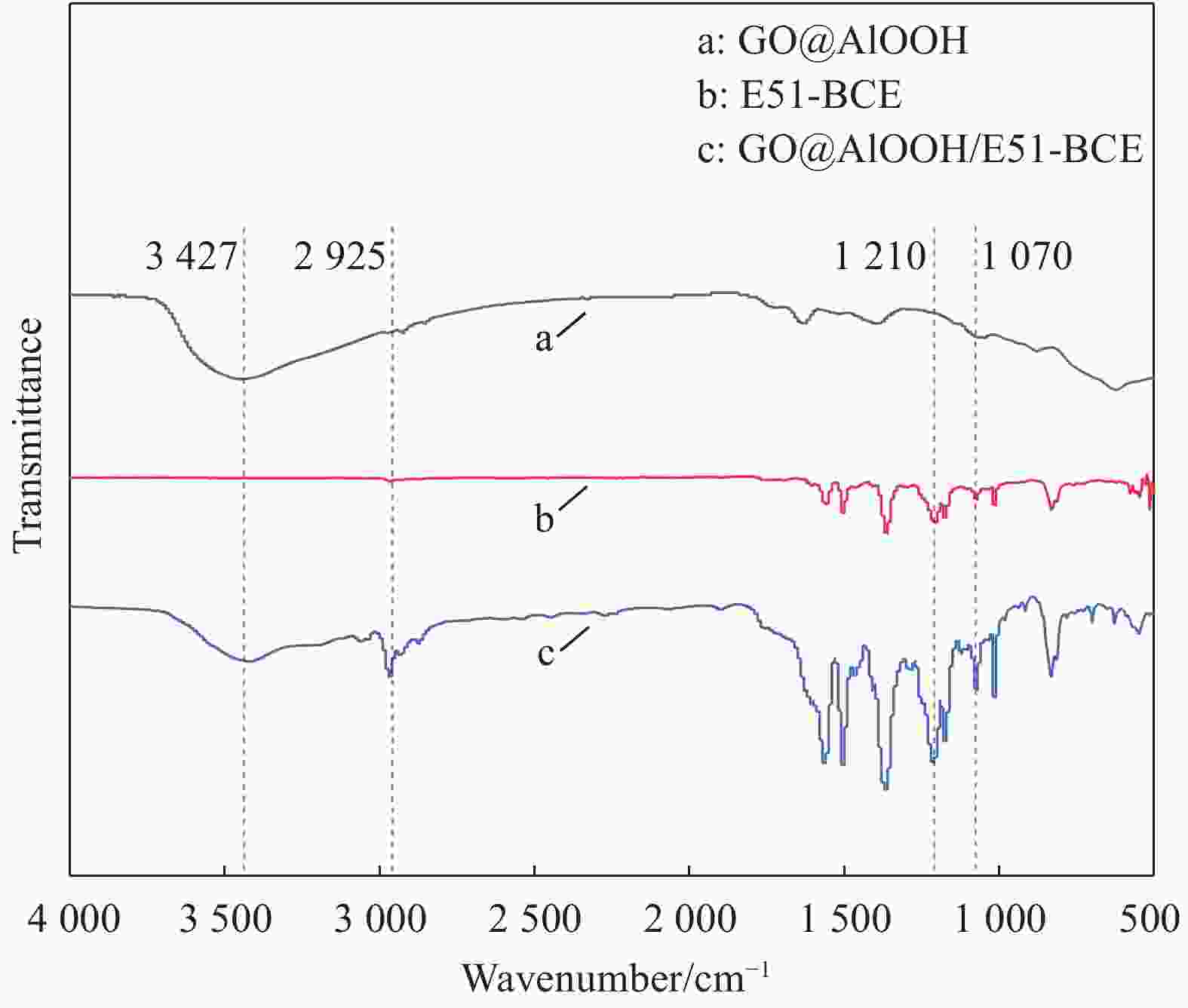

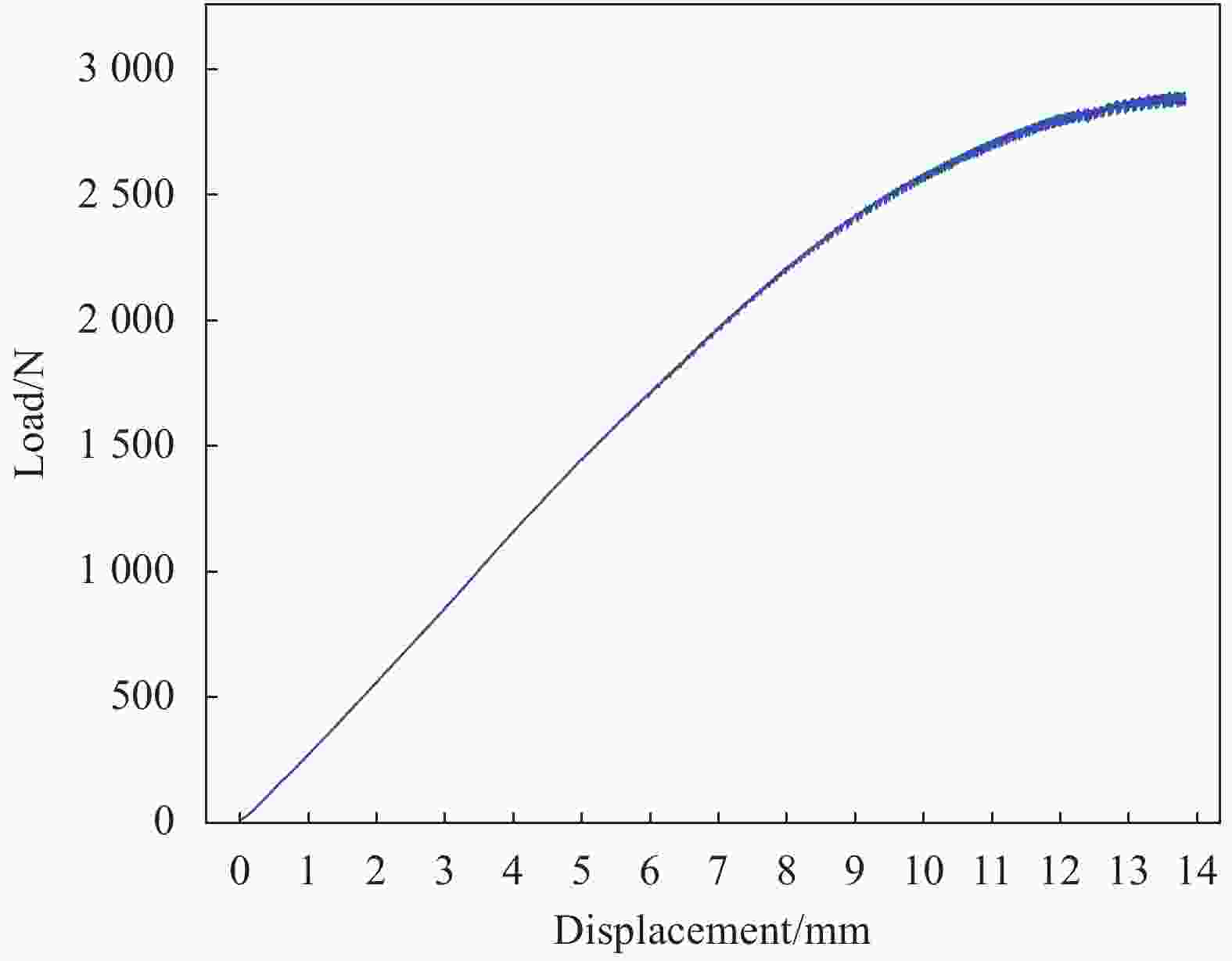

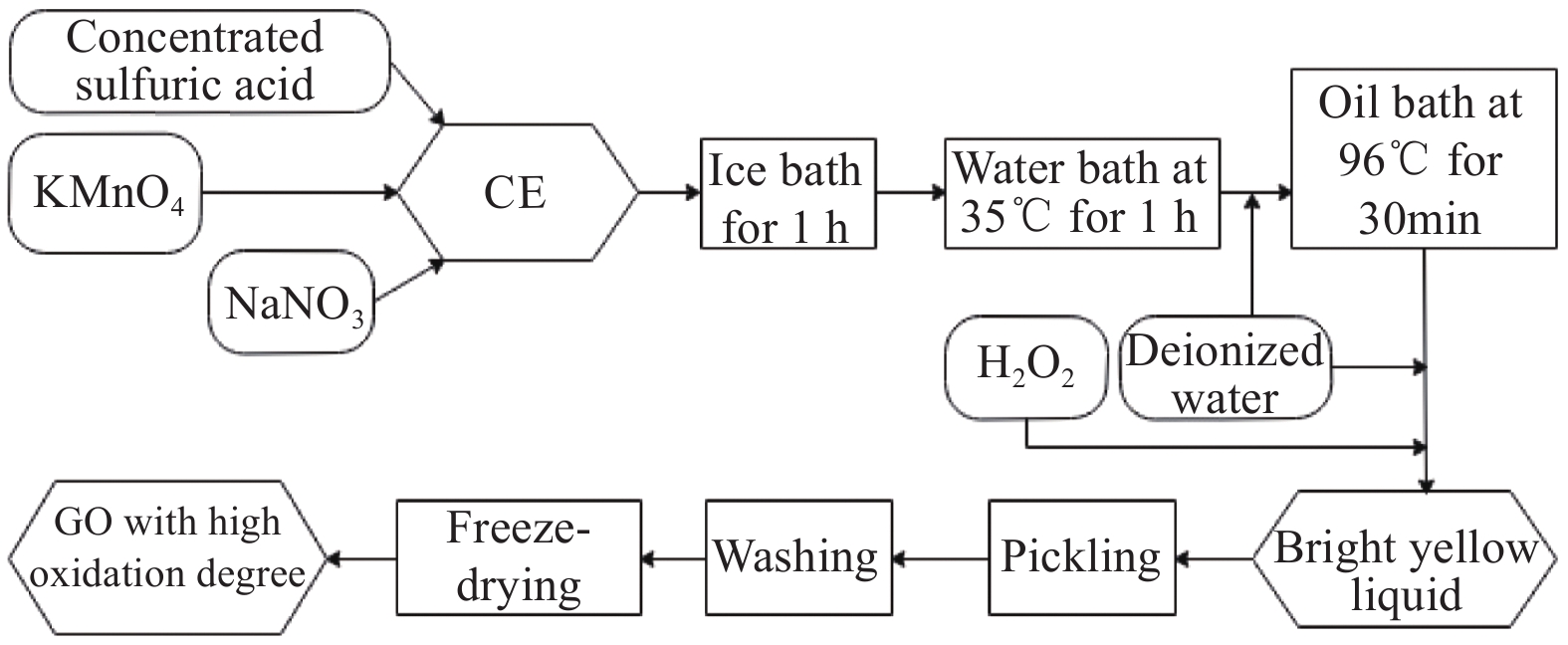

摘要: 以物理法石墨烯为原料,采用改进的Hummers法制备了氧化石墨烯(GO),通过溶胶-凝胶法在氧化石墨烯表面生长拟薄水铝石(AlOOH)纳米颗粒,得到拟薄水铝石包覆氧化石墨烯(GO@AlOOH),以环氧树脂(E51)和双酚A型氰酸酯(BCE)为原料,GO@AlOOH作为增强体,制备GO@AlOOH/E51-BCE复合材料。采用红外光谱和X射线表征GO@AlOOH,结果表明:AlOOH和GO存在着相互作用,且其表面含有羟基活性基团。复合材料的SEM结果显示:GO@AlOOH的加入使得树脂断裂面明显改变,性能得到提升。当掺杂量为0.6wt%时,复合材料的弯曲强度、弯曲模量以及冲击强度达到最大,分别为158.23 MPa、2.37 GPa和46.96 kJ/m2。该复合材料具有优异的力学性能,具有一定的发展潜力。Abstract: Graphite oxide (GO) was prepared by using a modified layer of graphite powder as the raw material, and pseudoboehmite (AlOOH) nanoparticles were grown on the surface of GO by a sol-gel method to obtain pseudo-boehmite stone-coated graphene oxide (GO@AlOOH). The matrix (E51-BCE) was synthesized from epoxy resin (E51) and bisphenol A cyanate (BCE), and GO@AlOOH as reinforcement to prepare the GO@AlOOH modified epoxy resin-cyanate composites (GO@AlOOH/E51-BCE) composites. Infrared analysis and X-ray characterization of GO coating materials shows that AlOOH and GO particles have a particular interaction, and there are certain hydroxyl groups on the surface of the material after coating. The composite samples were characterized by SEM showing that the addition of GO@AlOOH significantly changes the fracture surface of the resin and improves the performance. When the doping amount is 0.6wt%, the bending strength, bending modulus and impact strength of the composite material reach the maximum, which are 158.23 MPa, 2.37 GPa and 46.96 kJ/m2, respectively. The composite material has excellent mechanical properties and specific development potential.

-

表 1 拟薄水铝石包覆氧化石墨烯改性环氧树脂-氰酸酯(GO@AlOOH/E51-BCE)复合材料的样品编号

Table 1. Components of pseudo-boehmite stone-coated graphene oxide/epoxy resin-cyanate (GO@AlOOH/E51-BCE) composites

No. Component GO@AlOOH mass fraction/wt% A0 E51-BCE 0 A1 GO@AlOOH/E51-BCE 0.2 A2 GO@AlOOH/E51-BCE 0.4 A3 GO@AlOOH/E51-BCE 0.6 A4 GO@AlOOH/E51-BCE 0.8 A5 GO@AlOOH/E51-BCE 1.0 A6 GO@AlOOH/E51-BCE 1.5 -

[1] 张立颖, 于国良, 孙东洲, 等. 氰酸酯树脂改性的研究进展[J]. 化学与黏合, 2018, 40(4):298-302.ZHANG Liying, YU Guoliang, SUN Dongzhou, et al. Research progress of cyanate ester resin modification[J]. Chemistry and Adhesion,2018,40(4):298-302(in Chinese). [2] 闫福胜, 梁国正, 秦华宇, 等. 双酚A型氰酸酯树脂的性能[J]. 高分子材料科学与工程, 2000, 16(4):170-172. doi: 10.3321/j.issn:1000-7555.2000.04.048YAN Fusheng, LIANG Guozheng, QIN Huayu, et al. Properties of bisphenol-A dicyanate resin[J]. Polymer Materials Science and Engineering,2000,16(4):170-172(in Chinese). doi: 10.3321/j.issn:1000-7555.2000.04.048 [3] TIAN Na, HUANG Hongwei, HE Ying, et, al. Mediator-free direct Zscheme photocatalytic system: BiVO4/g-C3N4 organic-inorganic hybrid photocatalyst with highly efficient visible-light-induced photocatalytic activity[J]. Dalton Transactions,2015,44(9):4297. doi: 10.1039/C4DT03905J [4] 秦滢杰, 韩建平, 陈书华. 一种氰酸酯-环氧树脂作为卫星结构件复合材料基体的评价[J]. 复合材料学报, 2018, 35(3):528-536.QIN Yingjie, HAN Jianping, CHEN Shuhua. Evaluation of a cyanate ester-epoxy resin as the matrix of composites used for structural components of satellites[J]. Acta Materiae Compositae Sinica,2018,35(3):528-536(in Chinese). [5] 陶凌云. 热固性树脂改性氰酸酯树脂的研究进展[J]. 绝缘材料, 2019, 52(12):10-13.TAO Lingyun. Research progress of cyanate ester resin modified by thermosetting resin[J]. Insulating Materials,2019,52(12):10-13(in Chinese). [6] 陈宇飞, 武耘仲, 郭红缘, 等. 功能化石墨烯改性双马来酰亚胺复合材料的微观表征及性能[J]. 化工学报, 2018, 69(10):4456-4463.CHEN Yufei, WU Yunzhong, GUO Hongyuan, et al. Micro characteristic and properties of bismaleimide modified by functionalized graphene composites[J]. Journal of Chemical Industry,2018,69(10):4456-4463(in Chinese). [7] 叶国锐, 晏义伍, 曹海琳. 氧化石墨烯改性玄武岩纤维及其增强环氧树脂复合材料性能[J]. 复合材料学报, 2014, 31(6):1402-1408.YE Guorui, YAN Yiwu, CAO Hailin. Basalt fiber modified with graphene oxide and properties of its reinforced epoxy composite[J]. Acta Materiae Compositae Sinica,2014,31(6):1402-1408(in Chinese). [8] ZAMORATEGUI A, MARTÍNEZ J M, TANAKA S. Maximum solid loading dispersion of pseudo-boehmite nanofiber[J]. Journal of the Australian Ceramic Society,2015,51(2):40-46. [9] 张欣, 陈建章, 唐安山, 等. 拟薄水铝石胶溶过程研究[J]. 人工晶体学报, 2018, 47(11):2393-2397. doi: 10.3969/j.issn.1000-985X.2018.11.029ZHANG Xin, CHEN Jianzhang, TANG Anshan, et al. Study on the gelation process of pseudo boehmite[J]. Journal of Synyhetic Crystals,2018,47(11):2393-2397(in Chinese). doi: 10.3969/j.issn.1000-985X.2018.11.029 [10] REN Fang, ZHU Guangming, REN Penggang, et al. In situ polymerization of graphene oxide and cyanate ester–epoxy with enhanced mechanical and thermal properties[J]. Applied Surface Science,2014,316:549-557. doi: 10.1016/j.apsusc.2014.07.159 [11] RAMEZANZADEH B, HAERI Z, RAMEZANZADEH M. A facile route of making silica nanoparticles-covered graphene oxide nanohybrids (SiO2-GO); fabrication of SiO2-GO/epoxy composite coating with superior barrier and corrosion protection performance[J]. Chemical Engineering Journal,2016,303:511-528. doi: 10.1016/j.cej.2016.06.028 [12] 杨建召, 孙红娟, 彭同江, 等. 不同氧化程度氧化石墨烯氨气敏感性能及机理[J]. 精细化工, 2019, 36(3):380-386+436.YANG Jianzhao, SUN Hongjuan, PENG Tongjiang, et al. Sensitivity and mechanism of graphene oxide ammonia gas with different oxidation degree[J]. Fine Chemicals,2019,36(3):380-386+436(in Chinese). [13] 国家质量技术监督局. 塑料试样状态调节和实验的标准环境: GB/T 2918—1998[S]. 北京: 中国标准出版社, 1998.Nation Bureau of Technical Supervision. Standard environment for state regulation and testing of plastic samples: GB/T 2918—1998[S]. Beijing: China Standard Press, 1998(in Chinese). [14] 国家质量监督检验检疫总局. 树脂浇铸体性能实验方法: GB/T 2567—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine. Test methods for properties of resin casting boby: GB/T 2567—2008[S]. Beijing: China Standard Press, 2008(in Chinese). [15] SHI Tao, GUO Xingzhong, YANG Hui. Preparation and characterization of boehmite (γ-AlOOH) sol[J]. Rare Metal Materials and Engineering,2008,37(S2):73-75. [16] 朱强, 周峰. 醇铝水解法制备高纯拟薄水铝石工艺实践[J]. 山东冶金, 2019, 41(6):76-77.ZHU Qiang, ZHOU Feng. Preparation of high purity grade pseudo-boehmite by aluminium alkoxide hydrolysis[J]. Shandong Metallurgy,2019,41(6):76-77(in Chinese). [17] 李波. α-氧化铝的X射线定量分析[J]. 理化检验: 物理分册, 2008, 44(2):79-81.LI Bo. X-ray quantitative analysis of alpha-alumina[J]. PTAC Part A: Phys Test,2008,44(2):79-81(in Chinese). [18] 商宇飞, 孙晶川, 李齐方. 低介电笼型倍半硅氧烷改性氰酸酯-环氧树脂复合材料[J]. 功能材料, 2008(11):1817-1820. doi: 10.3321/j.issn:1001-9731.2008.11.015SHANG Yufei, SUN Jingchuan, LI Qifang. Cyanate ester epoxy composite modified by low dielectric cage silsesquioxane[J]. Functional Materials,2008(11):1817-1820(in Chinese). doi: 10.3321/j.issn:1001-9731.2008.11.015 [19] 王文一. 无机纳米粒子/聚合物复合材料研究[D]. 北京化工大学, 2007.WANG Wenyi. Study on inorganic nano particles/polymer composites[D]. Beijing University of Chemical Technology, 2007(in Chinese). [20] 于倩倩, 陈刚, 郑志才, 等. 酸化石墨烯改性环氧树脂及其碳纤维复合材料力学性能研究[J]. 玻璃钢/复合材料, 2018(5):33-40.YU Qianqian, CHEN Gang, ZHENG Zhicai, et al. Study on the mechanical properties of graphene modified epoxy resin and carbon fiber composite[J]. Fiber Reinforced Plastics/Composites,2018(5):33-40(in Chinese). -

下载:

下载: