Preparation and properties of novel silicon-containing polyarylacetylene resin based wave-transparent composite

-

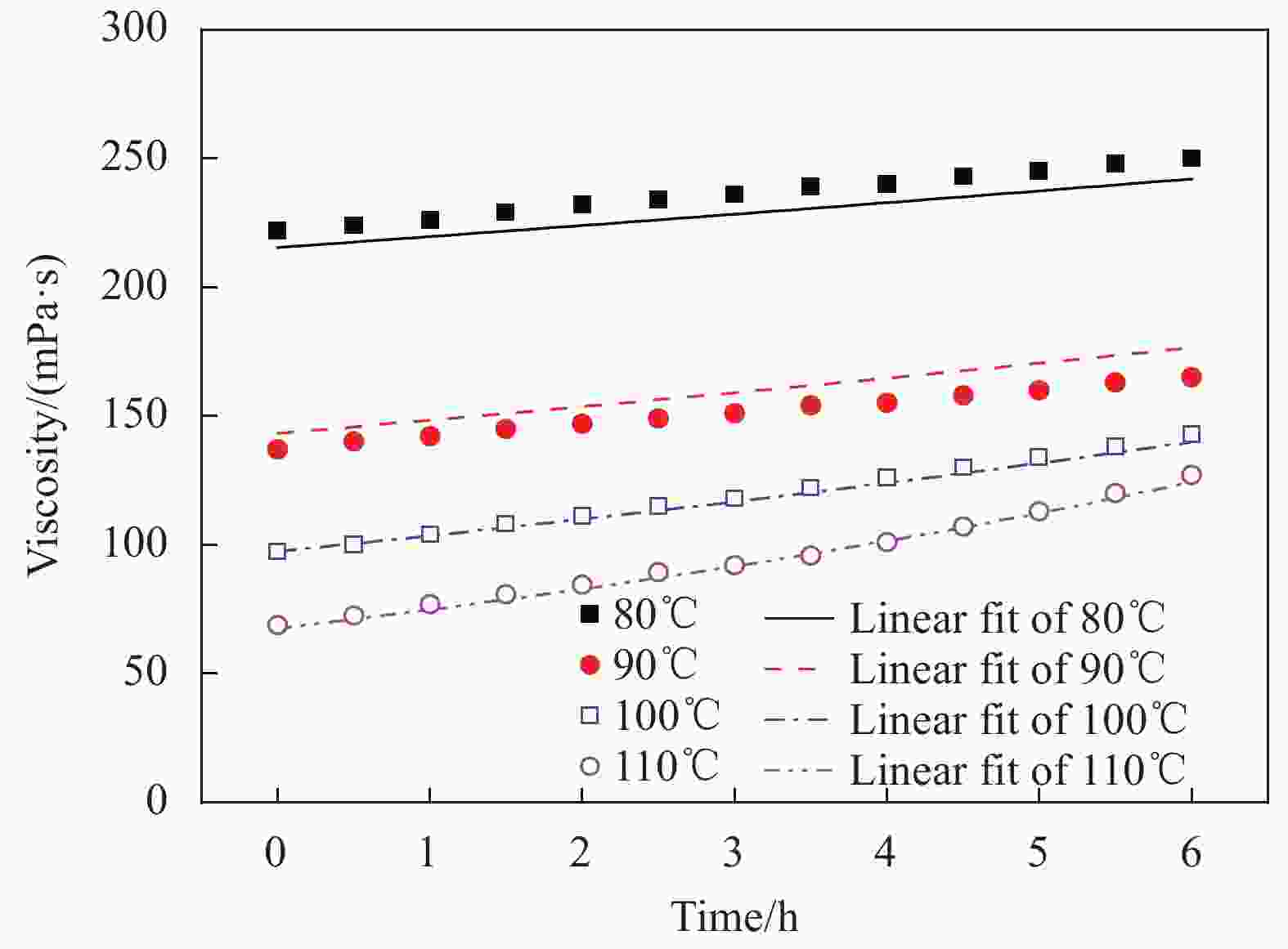

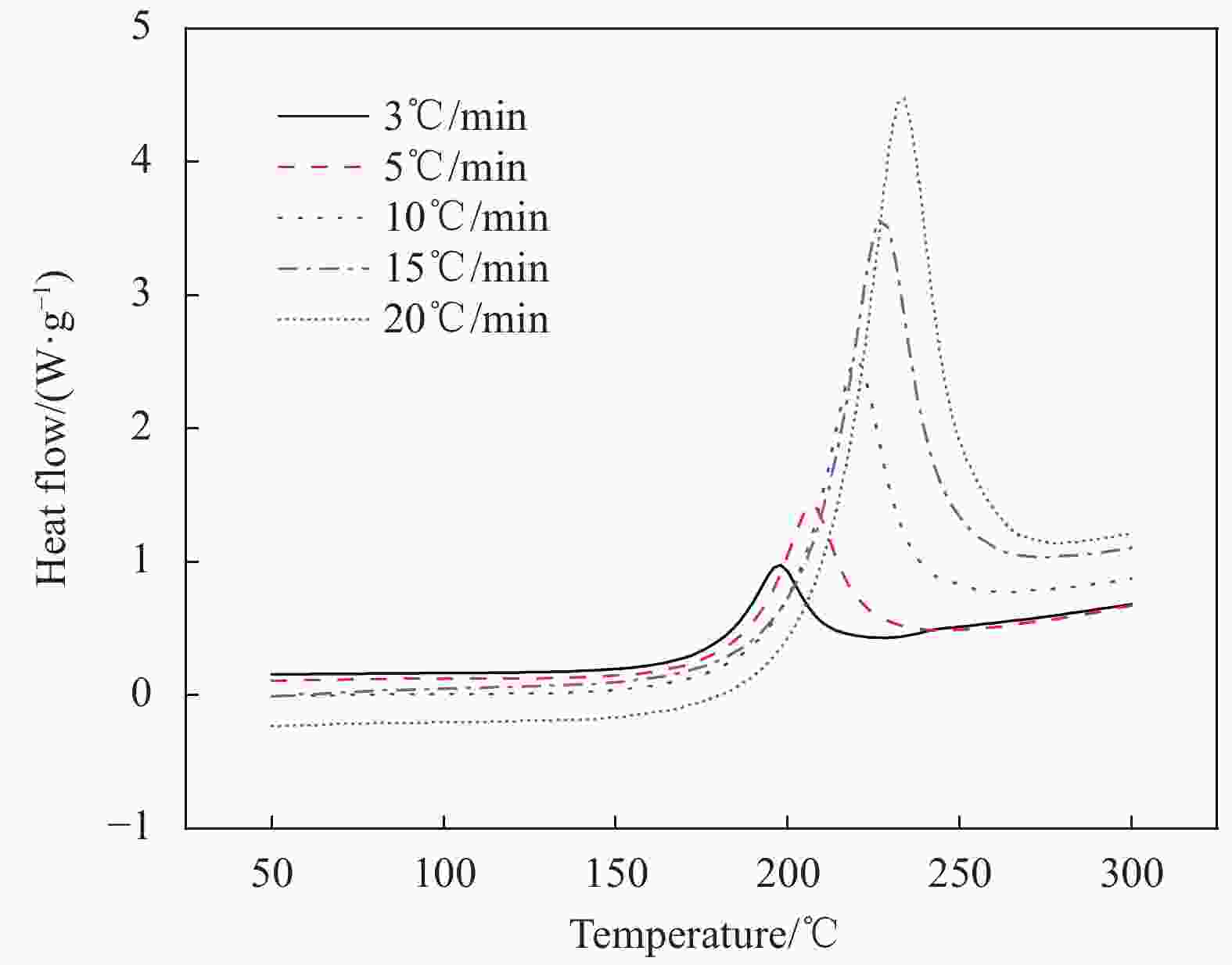

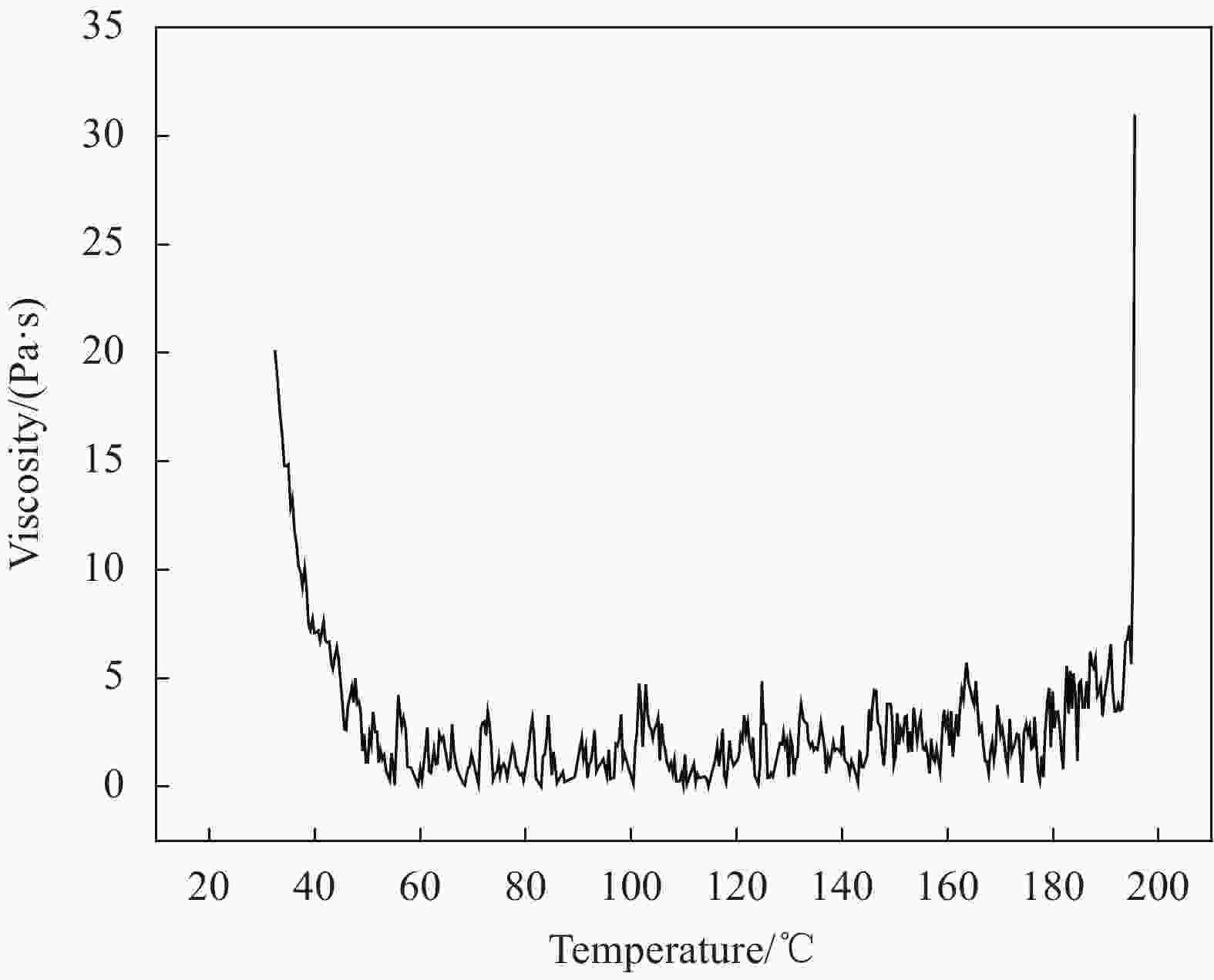

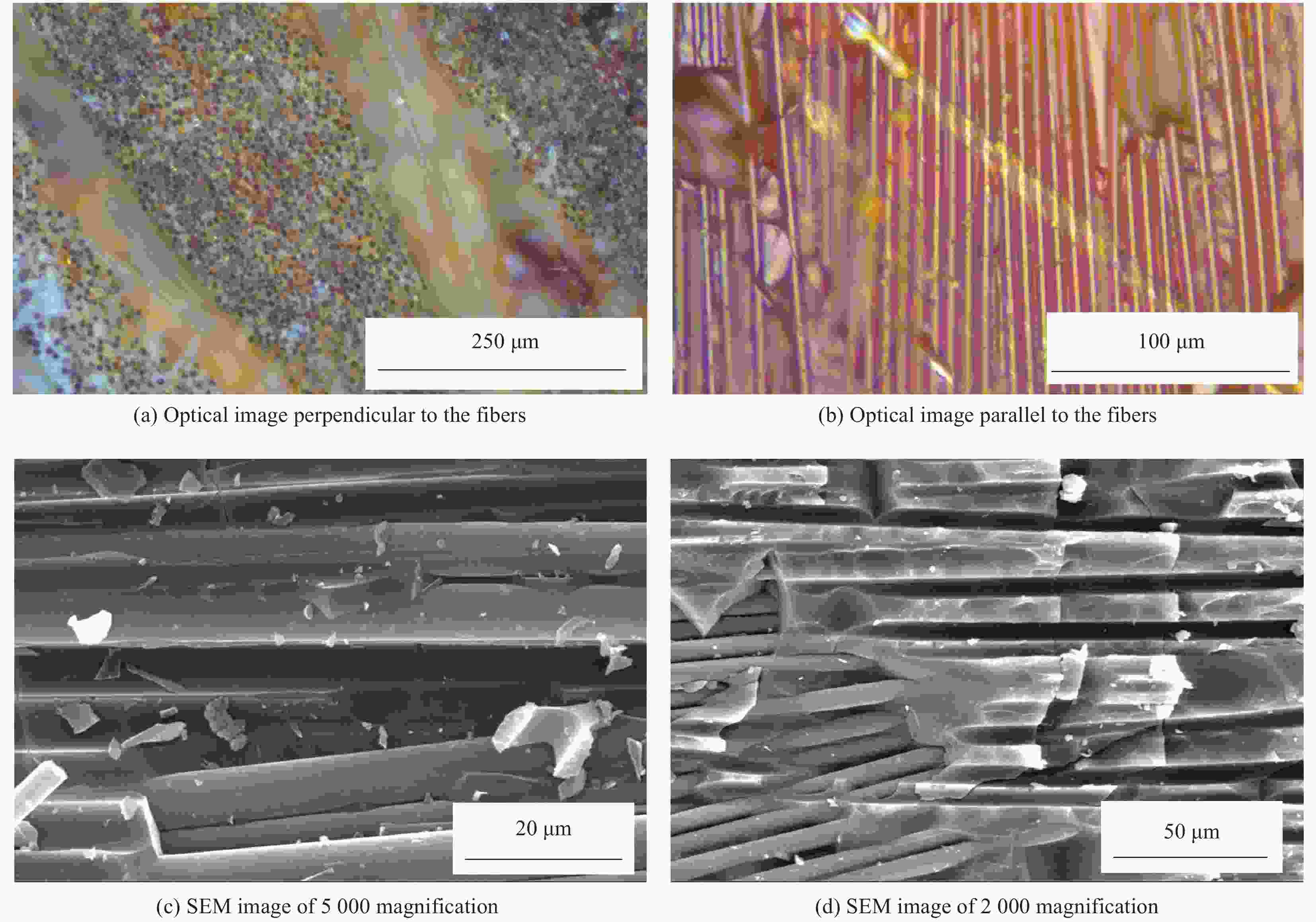

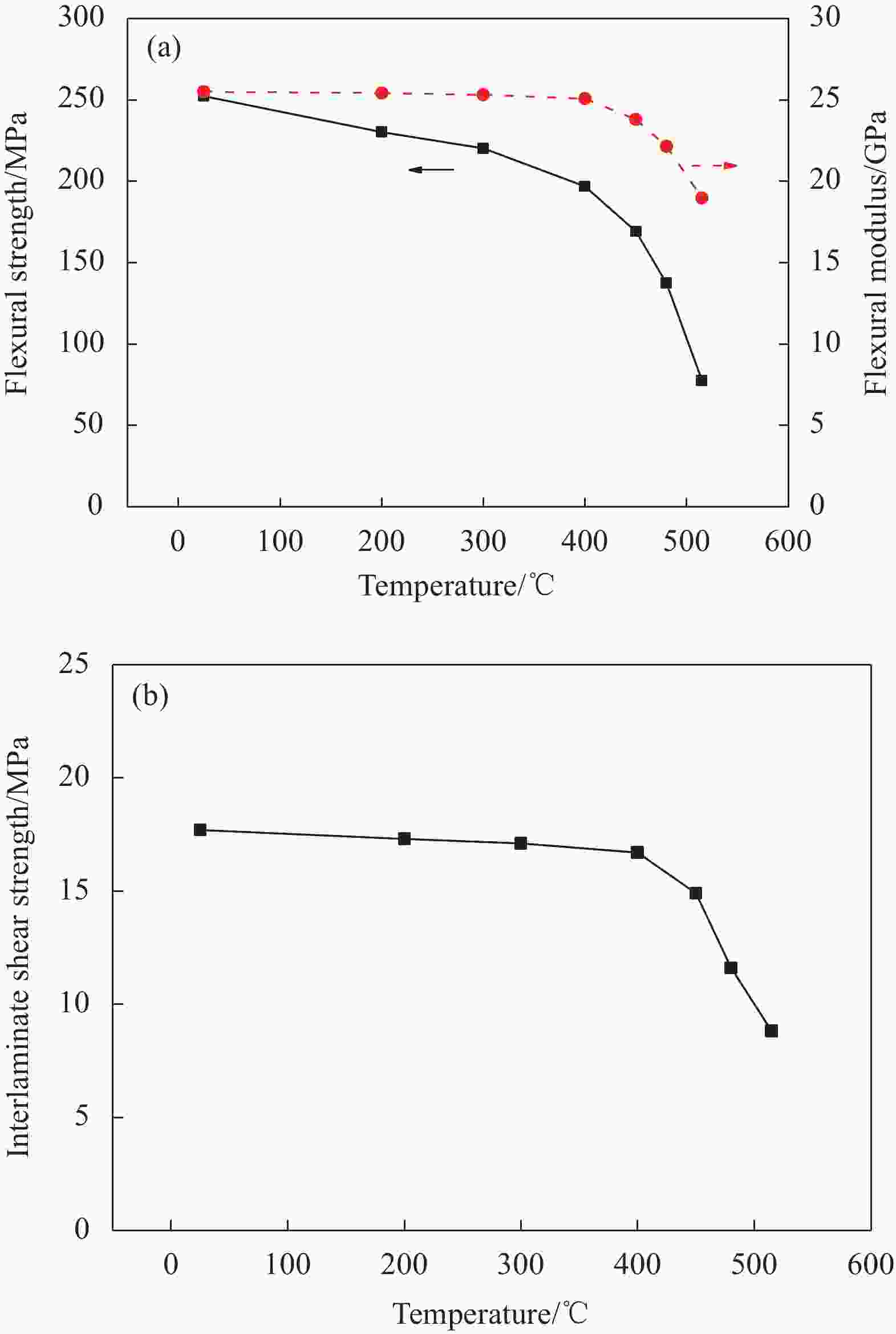

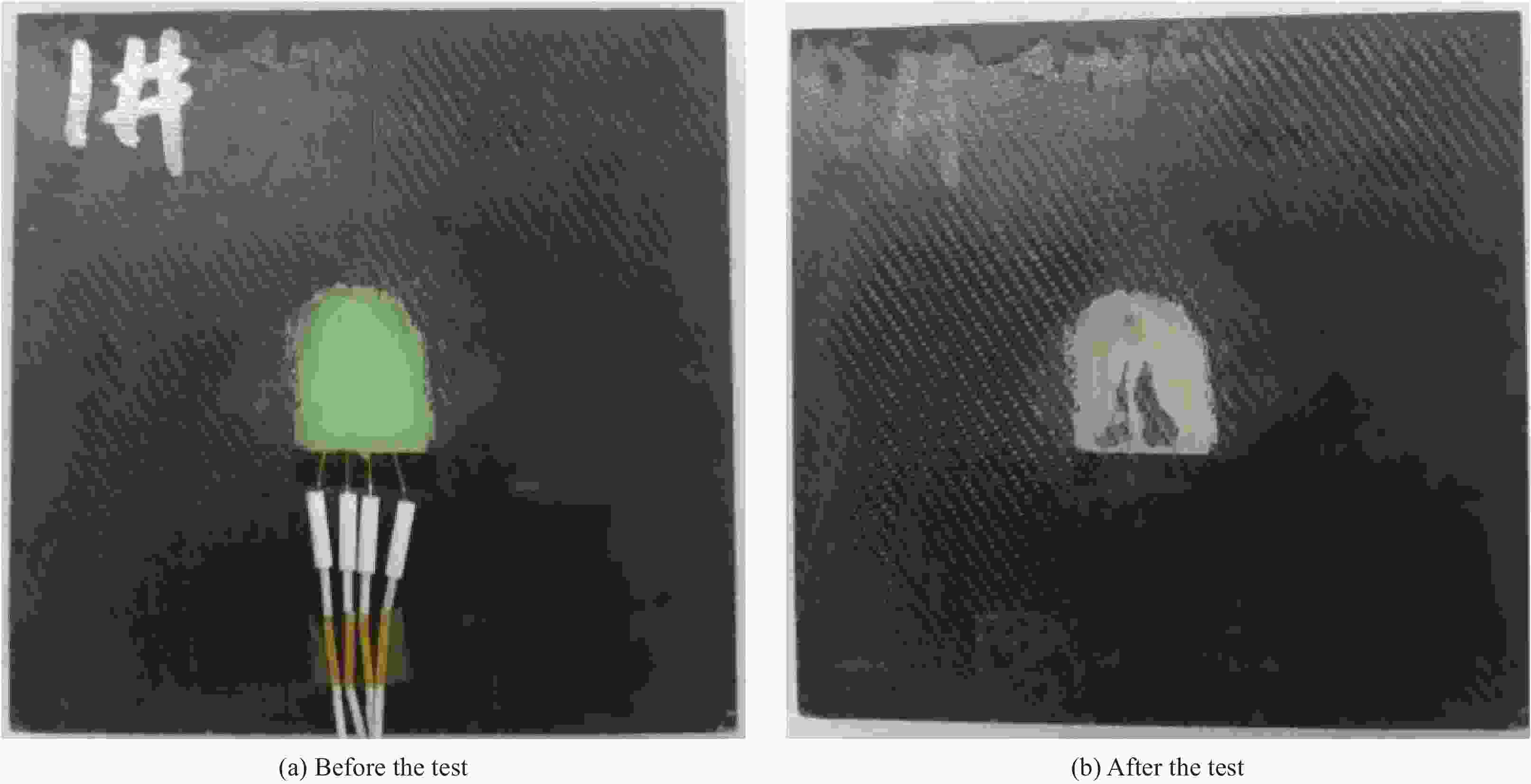

摘要: 为满足工程领域对耐高温树脂基透波复合材料的需求,研究石英纤维(QF)增强新型含硅改性聚芳炔(PSA)树脂基复合材料(QF/PSA)的制备方法及其性能。首先对树脂的黏度进行分析,确定了树脂在不同温度和时间下的黏度变化预测模型,适宜的树脂传递模塑工艺(Resin Transfer Molding, RTM)注胶温度在70~100℃范围;对树脂固化过程中的放热量、红外光谱和流变特性进行分析,确定了树脂的固化温度和固化过程,在250℃可以实现树脂的固化。基于上述分析进行了复合材料的高质量制备,并进一步对复合材料的微观形貌、力学性能、热膨胀性能、介电性能和耐高温性能进行分析和试验验证。材料的玻璃化转变温度(Tg)大于500℃,5%热失重温度(T5%)高达625℃,石英灯试验表明耐高温能力可达520℃/1000 s;介电常数稳定在3.1~3.2,介电损耗稳定在0.003以下;力学性能满足功能材料的使用要求。上述研究表明,该新型含硅聚芳炔树脂基透波复合材料在航空航天领域具有重要的应用价值。Abstract: In order to satisfy the requirement of high-temperature resistant wave-transparent composite in project field, a quartz fiber (QF) reinforced novel silicon-containing polyarylacetylene (PSA) resin based composite (QF/PSA) was researched and characterized. Firstly, viscosity prediction model of different temperature and time was established based on the viscosity-time curves of the resin, the model indicates that the resin can be injected between 70~100℃ for resin transfer molding (RTM) process. The curing heat, FT-IR spectra and rheological behavior of the resin were analysized, then the curing temperature and process were revealed. The results show that the resin can be curved at 250℃. Based on the above research, the high-quality preparation of the composite was achieved. Furthermore, the micro-morphology, mechanical properties, thermal expansion performance, dielectric properties as well as high temperature resistant performance of the composite were investigated and verified by experiments. The composite exhibits excellent thermal stability with Tg above 500℃ and T5% up to 625℃, and quartz lamp experiment further indicates that the high temperature resistant ability is up to 520℃/1000 s. The dielectric constant is 3.1~3.2 and dielectric loss is less than 0.003. In addition, the mechanical property is enough for functional composite. The above research indicates that the novel silicon-containing polyarylacetylene resin based wave-transparent composite has high potentials in the fields of aeronautics and astronautics.

-

表 1 PSA树脂不同温度下的模型参数

$n$ 值Table 1. Fitting values of viscosity model parameter

$n$ of PSATemperature/℃ Model parameter $n$ 80 0.0201 90 0.0318 100 0.0646 110 0.0998 表 2 PSA树脂不同温度下的RTM注胶工艺窗口

Table 2. The PSA resin RTM injection processing window of different temperature

Temperature/℃ RTM injection time/h 60 0 70 0-17.8 80 0-31.8 90 0-29.5 100 0.5-23.4 110 3.9-17.5 120 4.5-12.7 130 4.1-9.1 表 3 QF/PSA复合材料与QF/聚芳炔(PAA)复合材料的室温力学性能

Table 3. Mechanical properties of the QF/PSA composite and QF/aromatic alkyne (PAA) composite at room temperature

Composite Tensile strength/MPa Tensile modulus/GPa Compressive strength/MPa Compressive modulus/GPa Flexural strength/MPa Flexural Modulus/GPa Interlaminate shear strength/MPa QF/PSA 388 23.4 152 28.4 252 25.5 17.7 QF/PAA 161 16.0 92 14.4 172 16.5 14.5 -

[1] 张雄, 王义, 程海峰, 等. 石英纤维透波复合材料的研究进展[J]. 材料导报, 2012, 26(S1):96-100.ZHANG Xiong, WANG Yi, CHENG Haifeng, et al. Research and development of wave-transparent composites reinforced by silica fibers[J]. Materials Review,2012,26(S1):96-100(in Chinese). [2] 裴晓园, 陈利, 李嘉禄, 等. 天线罩材料的研究进展[J]. 纺织学报, 2016, 37(12):153-159.PEI Xiaoyuan, CHEN Li, LI Jialu, et al. Research progress in radome material[J]. Journal of Textile Research,2016,37(12):153-159(in Chinese). [3] 孙周强, 顾嫒娟, 袁莉, 等. 耐高温有机透波复合材料用基体树脂的研究进展[J]. 材料导报, 2008, 22(11):43-50. doi: 10.3321/j.issn:1005-023X.2008.11.010SUN Zhouqiang, GU Aijuan, YUAN Li, et al. Research progress in resin matrices of heat-resistant wave-transparent organic composites[J]. Materials Review,2008,22(11):43-50(in Chinese). doi: 10.3321/j.issn:1005-023X.2008.11.010 [4] HOU Z L, CAO M S, YUAN J, et al. High-temperature conductance loss dominated defect level in h-BN: Experiments and first principles calculations[J]. Journal of App-lied Physics,2009,105(7):076103. doi: 10.1063/1.3086388 [5] CAO M S, HOU Z L, YUAN J, et al. Low dielectric loss and non-Debye relaxation of gamma-Y2Si2O7 ceramic at ele-vated temperature in X-band[J]. Journal of Applied Phy-sics,2009,105(10):106012. [6] 郭慧, 黄玉东, 刘丽, 等. 聚芳基乙炔树脂及其复合材料的研究现状[J]. 化学与黏合, 2008, 30(3):37-41.GUO Hui, HUANG Yudong, LIU Li, et al. Progress in research on polyarylacetylene and carbon fiber/poly-arylacetylene composites[J]. Chemistry and Adhesion,2008,30(3):37-41(in Chinese). [7] 吴晓青, 李嘉禄, 杨彩云, 等. 聚芳基乙炔在RTM工艺中的应用探索[J]. 航空制造技术, 2004, 47(7):65-67. doi: 10.3969/j.issn.1671-833X.2004.07.012WU Xiaoqing, LI Jialu, YANG Caiyun, et al. Preliminary app-lication of polyarylacetylene resin in RTM[J]. Aeronauti-cal Manufacturing Technology,2004,47(7):65-67(in Chinese). doi: 10.3969/j.issn.1671-833X.2004.07.012 [8] 赵伟栋, 王磊, 潘玲英, 等. 聚酰亚胺复合材料研究进展[J]. 宇航材料工艺, 2013, 43(4):14-19. doi: 10.3969/j.issn.1007-2330.2013.04.004ZHAO Weidong, WANG Lei, PAN Lingying, et al. Recent advances in polyimides matrix structural composites[J]. Aerospace Materials & Technology,2013,43(4):14-19(in Chinese). doi: 10.3969/j.issn.1007-2330.2013.04.004 [9] 陈建升, 左红军, 范琳, 等. 耐高温聚酰亚胺材料研究进展[J]. 宇航材料工艺, 2006, 36(2):7-12. doi: 10.3969/j.issn.1007-2330.2006.02.002CHEN Jiansheng, ZUO Hongjun, FAN Lin, et al. Development of high temperature polyimide[J]. Aerospace Ma-terials & Technology,2006,36(2):7-12(in Chinese). doi: 10.3969/j.issn.1007-2330.2006.02.002 [10] 孟祥胜, 李洪深, 杨慧丽, 等. 耐高温异构聚酰亚胺树脂及其复合材料[J]. 复合材料学报, 2011, 28(6):23-27.MENG Xiangsheng, LI Hongshen, YANG Huili, et al. High-temperature resistant isomeric polyimide resins and their composites[J]. Acta Materiae Compositae Sinica,2011,28(6):23-27(in Chinese). [11] 余瑞莲, 汪明, 李弘瑜, 等. RTM 成型聚酰亚胺复合材料研究[J]. 宇航材料工艺, 2008, 38(2):6-8. doi: 10.3969/j.issn.1007-2330.2008.02.002YU Ruilian, WANG Ming, LI Hongyu, et al. Polyimide composite fabricated by RTM[J]. Aerospace Materials & Technology,2008,38(2):6-8(in Chinese). doi: 10.3969/j.issn.1007-2330.2008.02.002 [12] 魏建峰, 李宏涛, 孟祥胜, 等. 含苯炔基侧链的聚酰亚胺树脂及其复合材料[J]. 热固性树脂, 2011, 26(3):1-5.WEI Jianfeng, LI Hongtao, MENG Xiangsheng, et al. Polyimide resins containing phenylethynyl side chain and their composites[J]. Thermosetting Resin,2011,26(3):1-5(in Chinese). [13] 贾坤, 徐明珍, 潘海, 等. 耐高温腈基聚合物及复合材料研究进展[J]. 中国材料进展, 2015, 34(12):897-905.JIA Kun, XU Mingzhen, PAN Hai, et al. Research progress of high temperature resistant phthalonitrile-based polymers and composites[J]. Materials China,2015,34(12):897-905(in Chinese). [14] 钟正祥, 耿立艳, 祝晶晶, 等. 含炔基、氰基耐高温树脂的研究进展[J]. 化学与黏合, 2018, 50(5):357-361.ZHONG Zhengxiang, GENG Liyan, ZHU Jingjing, et al. Research progress in high temperature resin containing alkyne and nitrile[J]. Chemistry and Adhesion,2018,50(5):357-361(in Chinese). [15] 周恒, 刘锋, 李小丽, 等. 新型自催化氰基树脂的制备及其初步热性能[J]. 宇航材料工艺, 2010, 40(2):45-48. doi: 10.3969/j.issn.1007-2330.2010.02.012ZHOU Heng, LIU Feng, LI Xiaoli, et al. Preparation and thermal properties of novel self-catalyst resin with cyano group[J]. Aerospace Materials & Technology,2010,40(2):45-48(in Chinese). doi: 10.3969/j.issn.1007-2330.2010.02.012 [16] MASAYOSHI I, KOHJI I, KENJI I, et al. New highly heat-resistant polymers containing silicon: Poly (silyleneethynylenephenyleneethynylene)s[J]. Macromolecules,1997,30(4):694-701. doi: 10.1021/ma961081f [17] MASAYOSHI I, KENJI I, JUN-ICHI I, et al. Various silicon-containing polymers with Si(H)CC units[J]. Journal of Polymer Science Part A: Polymer Chemistry,2001,39(15):2658-2669. doi: 10.1002/pola.1242 [18] TSENG W C, CHEN Y, CHANG G W. Curing conditions of polyarylacetylene prepolymers to obtain thermally resistant materials[J]. Polymer Degradation and Stability,2009,94(12):2149-2156. doi: 10.1016/j.polymdegradstab.2009.09.008 [19] MING C W, MING Y, TONG Z, et al. Acetylene-grafted re-sins derived from phenolics via azo coupling reaction[J]. European Polymer Journal,2008,44(3):842-848. doi: 10.1016/j.eurpolymj.2008.01.002 [20] SATYA B S, TEDDY M K, KENNETH M J, et al. Studies on cure chemistry of new acetylenic resins[J]. Macromole-cules,1993,26(23):6171-6174. doi: 10.1021/ma00075a005 [21] XINTONG Y, SHIFENG D, YANCHUN H, et al. Thermosetting mechanism study of silicon-containing polyarylacetylene via in situ FTIR and solid-state NMR spectro-scopy[J]. Journal of Applied Polymer Science,2019,136(13):47301. doi: 10.1002/app.47301 [22] GUTOWSKI T G. Advanced composites manufacturing[M]. New York: John Wiley & Sons Inc. 1997: 393-457. [23] 汪明, 余瑞莲, 李卫方, 等. 改性聚芳基乙炔树脂性能研究[J]. 宇航材料工艺, 2013, 43(4):43-48.WANG Ming, YU Ruilian, LI Weifang, et al. Study on performance of modified polyarylacetylene Resins[J]. Aerospace Materials & Technology,2013,43(4):43-48(in Chinese). [24] WANG Shaokai , LI Min, GU Yizhuo, et al. Experimental study on crack defects formation in polyarylacetylene composites and modification improvement of resin[J]. Journal of Composite Materials,2010,44(25):3017-3032. doi: 10.1177/0021998310371539 [25] 雷景轩. 石英纤维增强石英陶瓷复合材料制备研究进展[J]. 陶瓷学报, 2019, 40(3):277-282.LEI Jingxuan. The research progress in preparation of silica fiber reinforced silica ceramic composites[J]. Journal of Ceramics,2019,40(3):277-282(in Chinese). [26] 邹铭, 肖凤艳, 郭香, 等. 石英纤维/含乙烯基聚硅氮烷耐高温透波复合材料的制备与性能[J]. 复合材料学报, 2019, 36(8):1813-1821.ZOU Ming, XIAO Fengyan, GUO Xiang, et al. Preparation and properties of quartz fiber cloth/vinyl-containing polysilazane high temperature wave-penetrating composites[J]. Acta Materiae Compositae Sinica,2019,36(8):1813-1821(in Chinese). [27] HOU Z L, ZHANG L, YUAN J, et al. High-temperature dielectric response and multiscale mechanism of SiO2/Si3N4 nanocomposites[J]. Chinese Physics Letters,2008,25(6):2249-2252. doi: 10.1088/0256-307X/25/6/090 [28] 张亮, 金海波, 曹茂盛. SiO2陶瓷复合材料高温介电性能研究[J]. 稀有金属材料与工程, 2007, 9(36):515-518.ZHANG L, JIN H B, CAO M S. Investigation on high-tem-perature dielectric properties of SiO2 composite materials[J]. Rare Metal Materials and Engineering,2007,9(36):515-518(in Chinese). -

下载:

下载: