Influence of thermo-oxidative aging on the mechanical performance of three-dimensional braided carbon fiber-glass fiber/bismaleimide composites

-

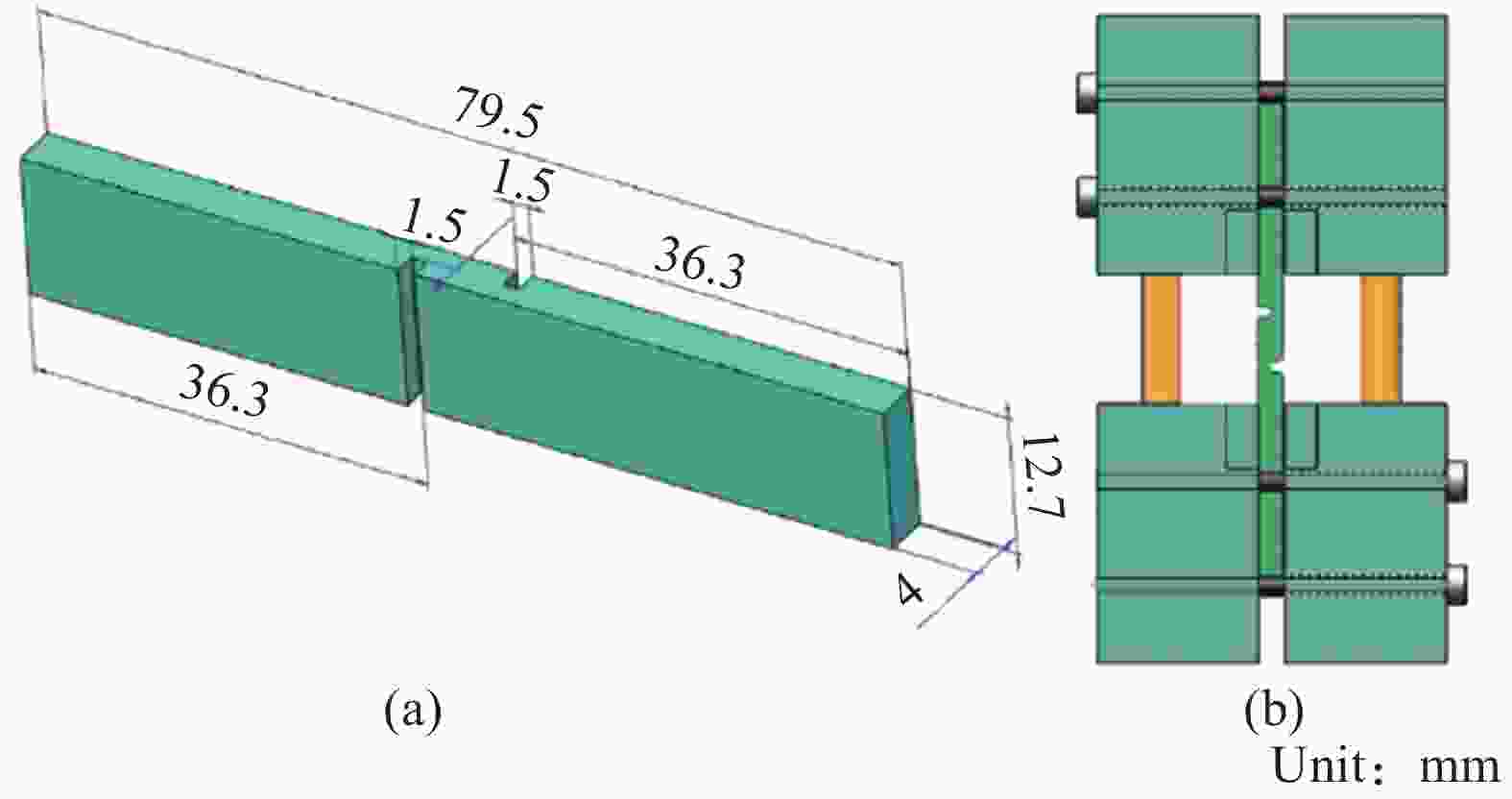

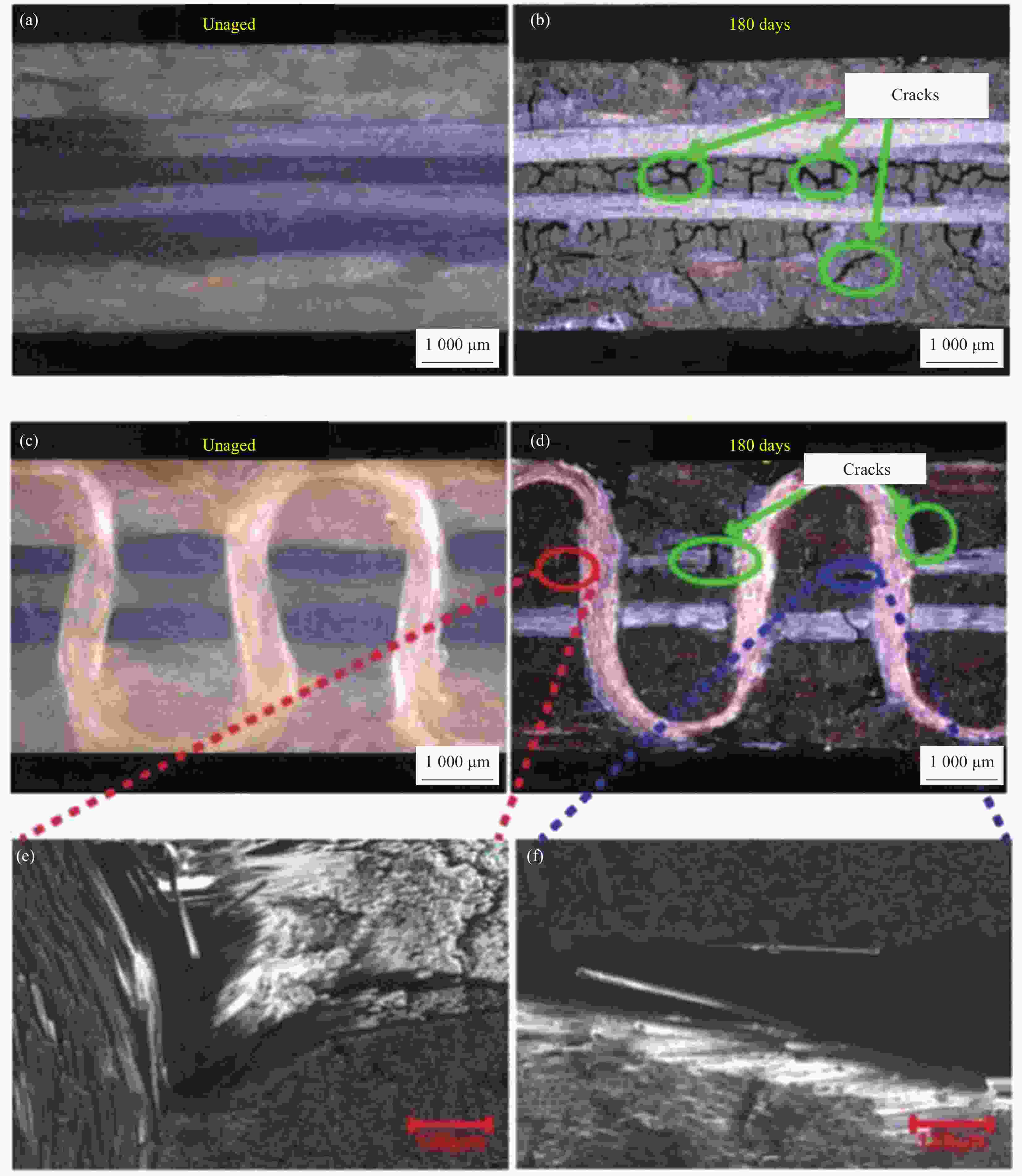

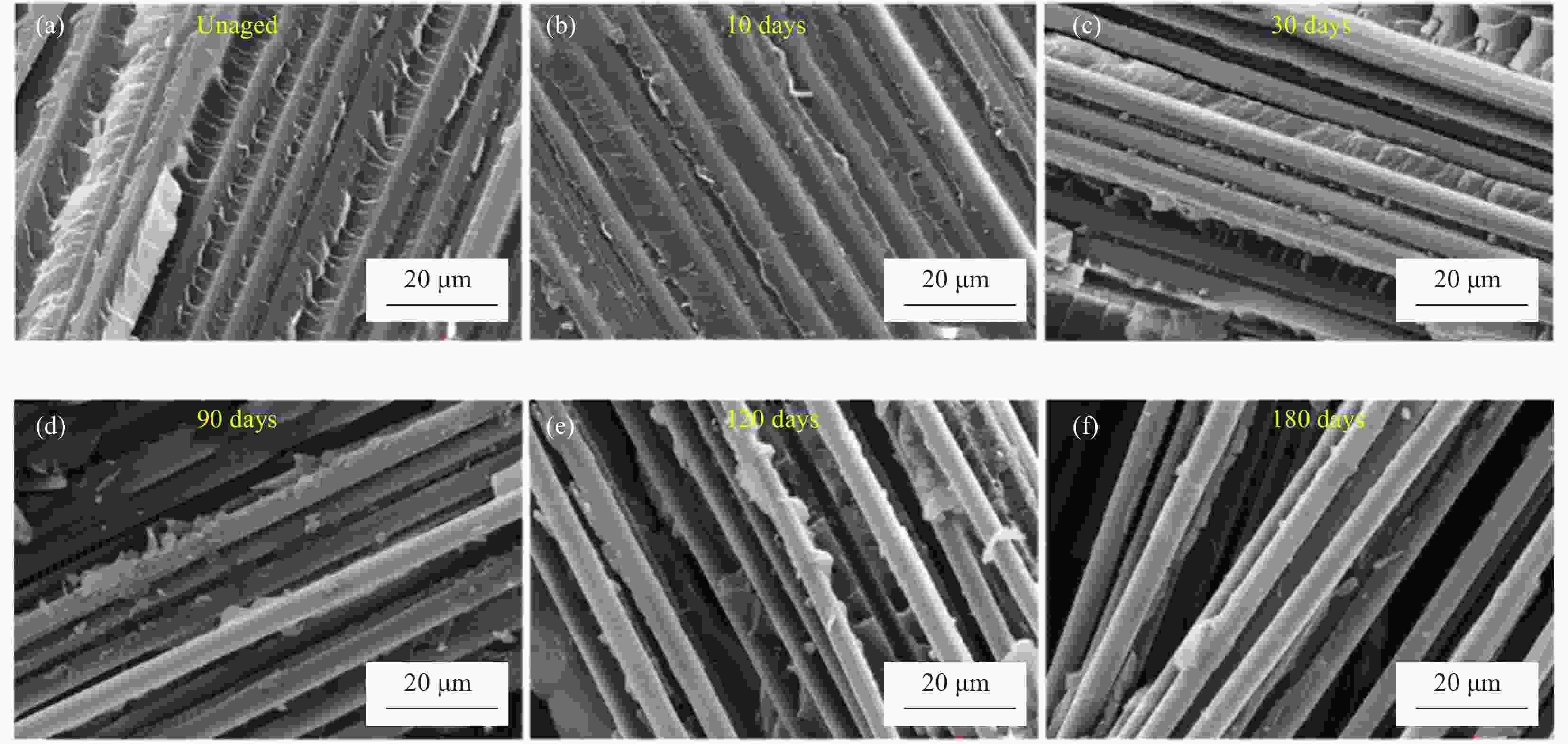

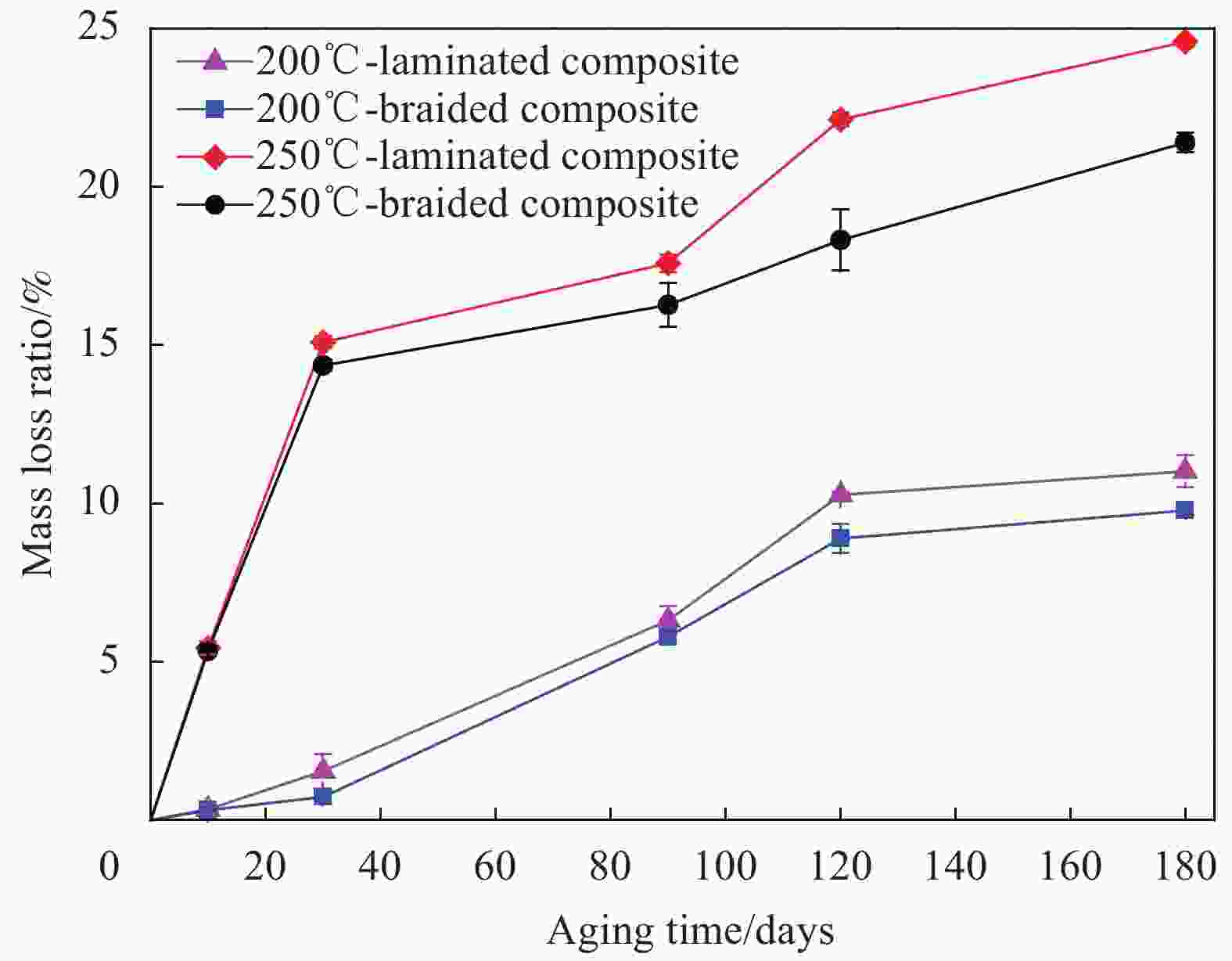

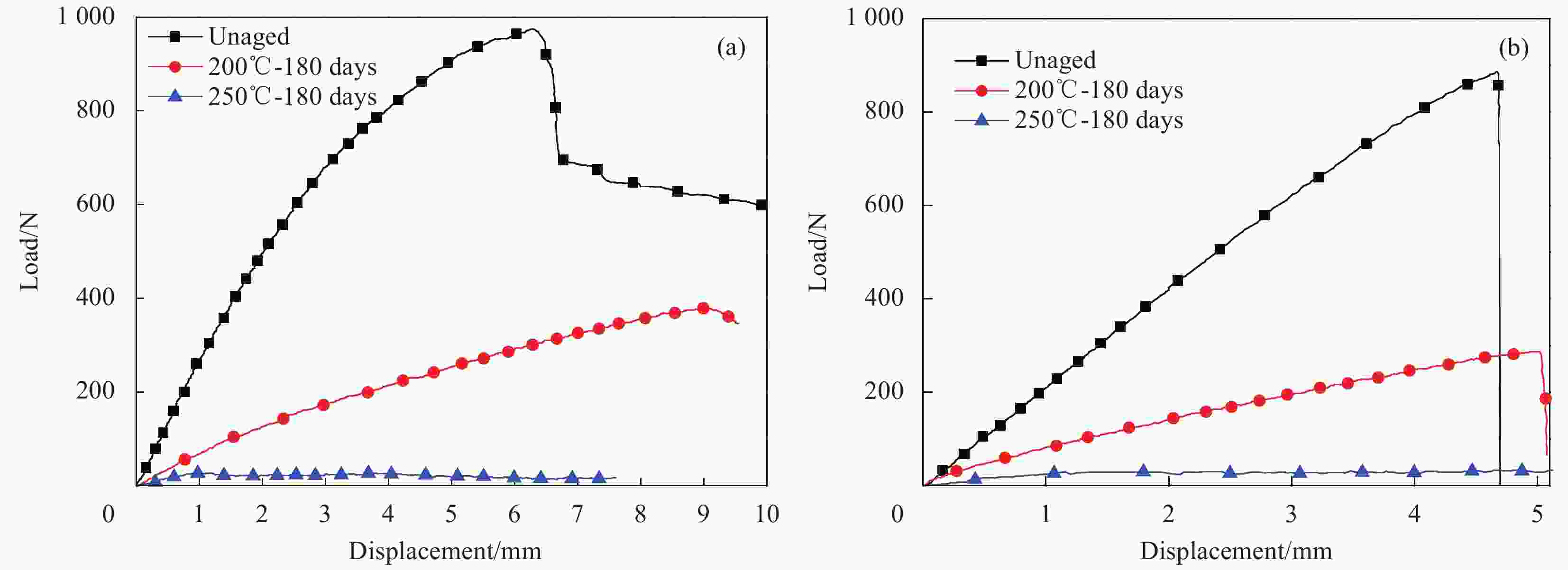

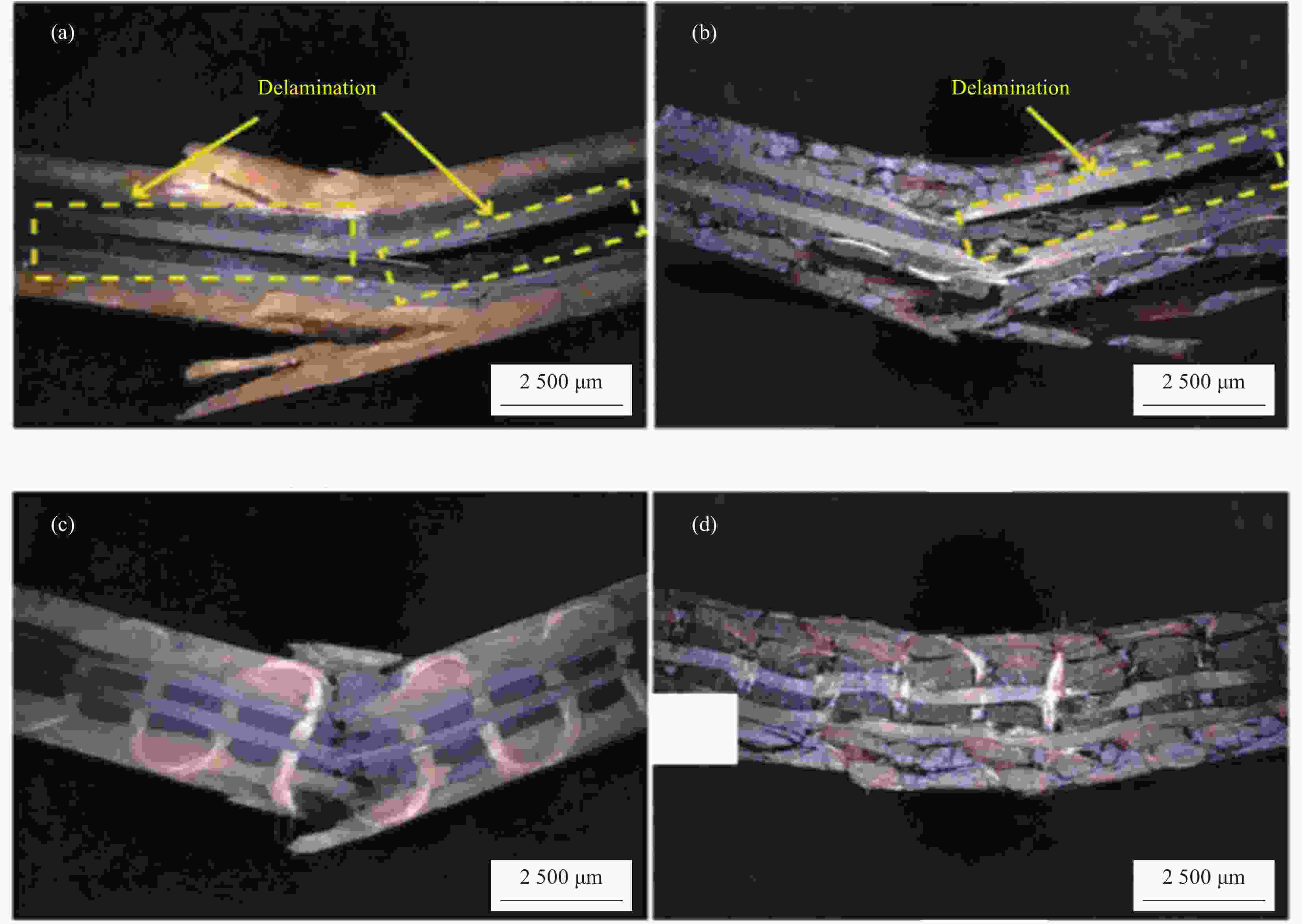

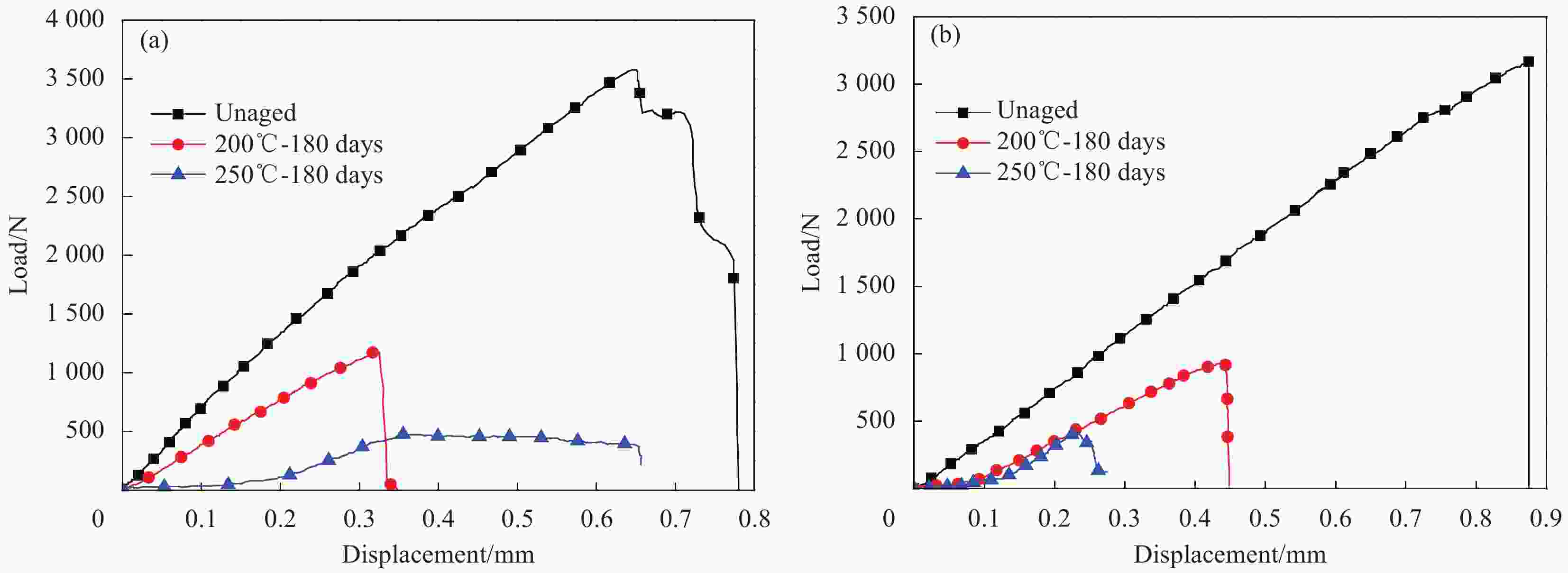

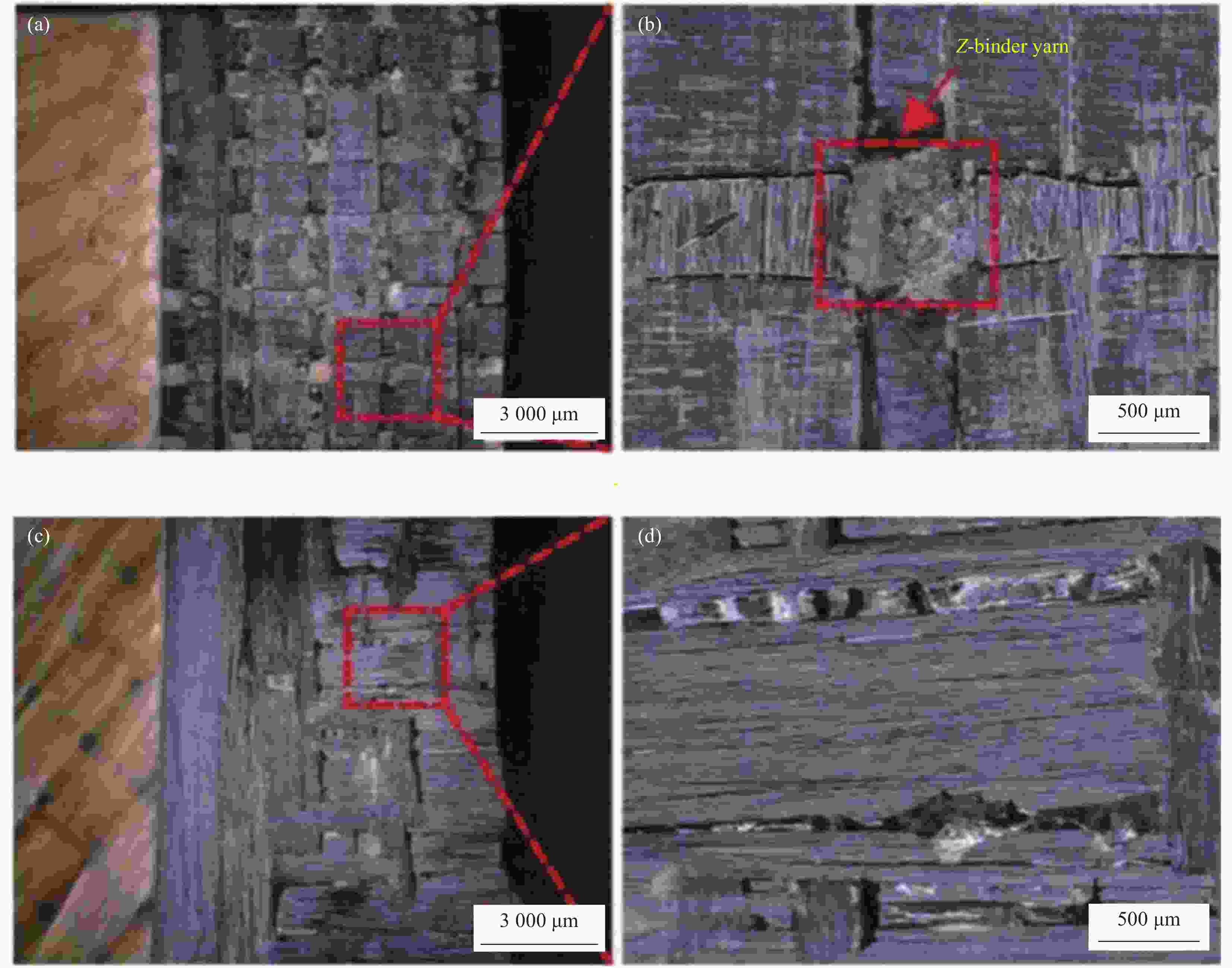

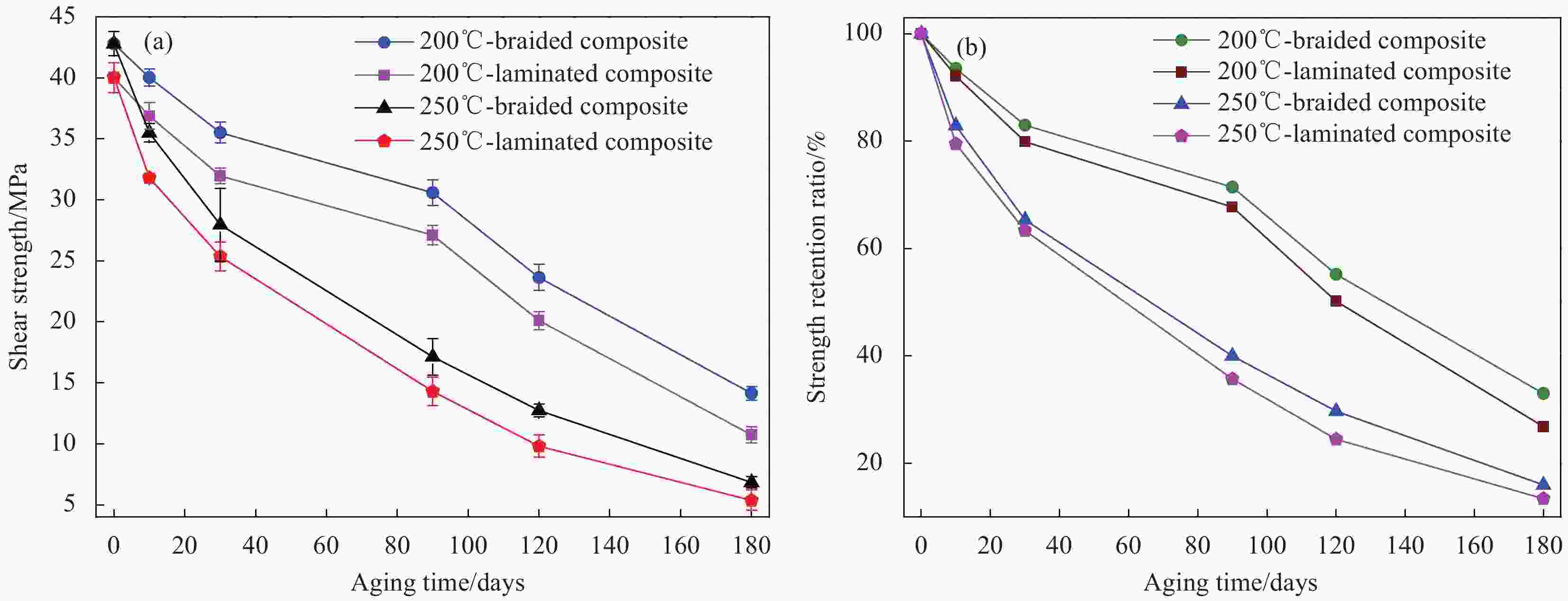

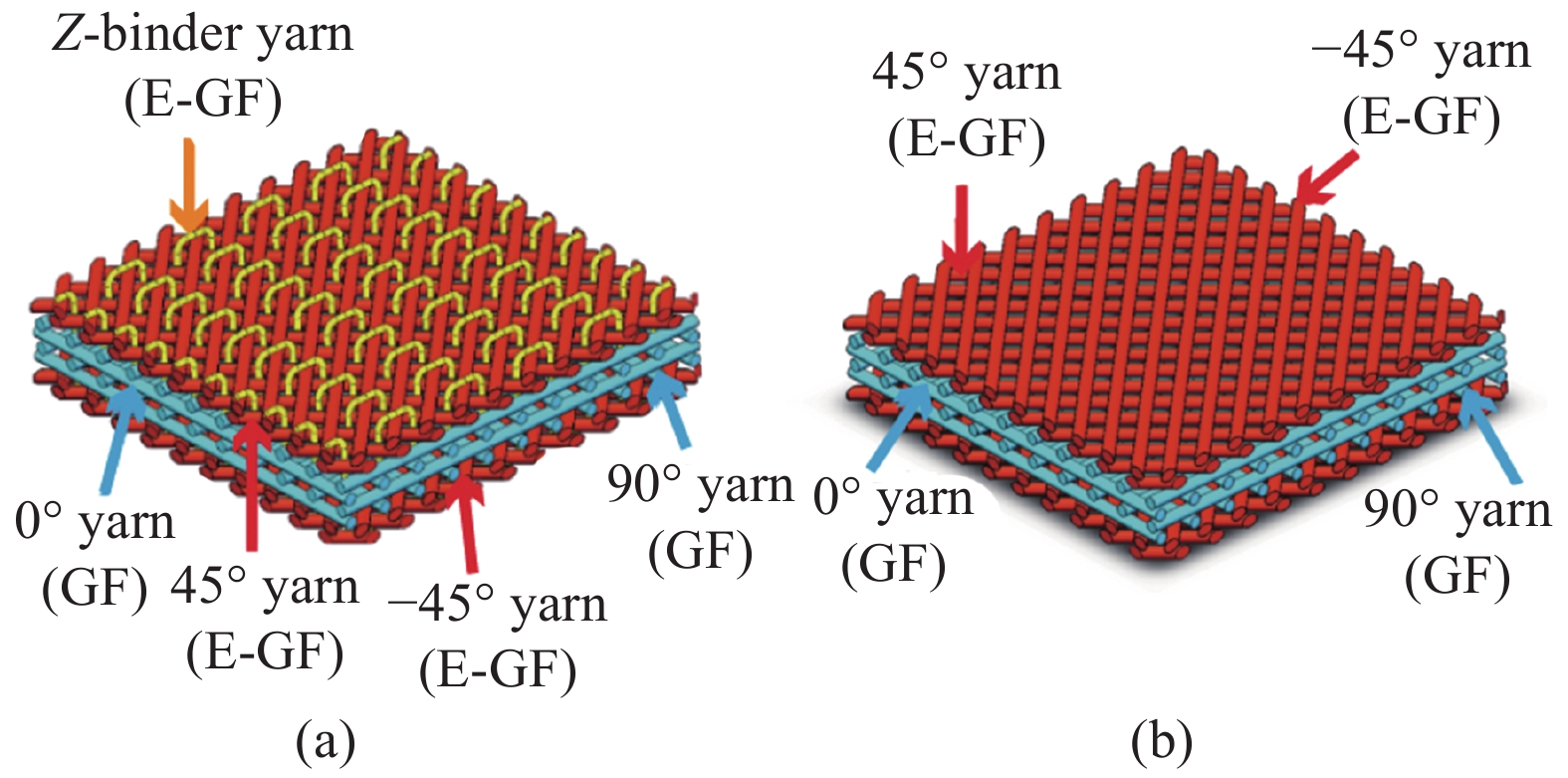

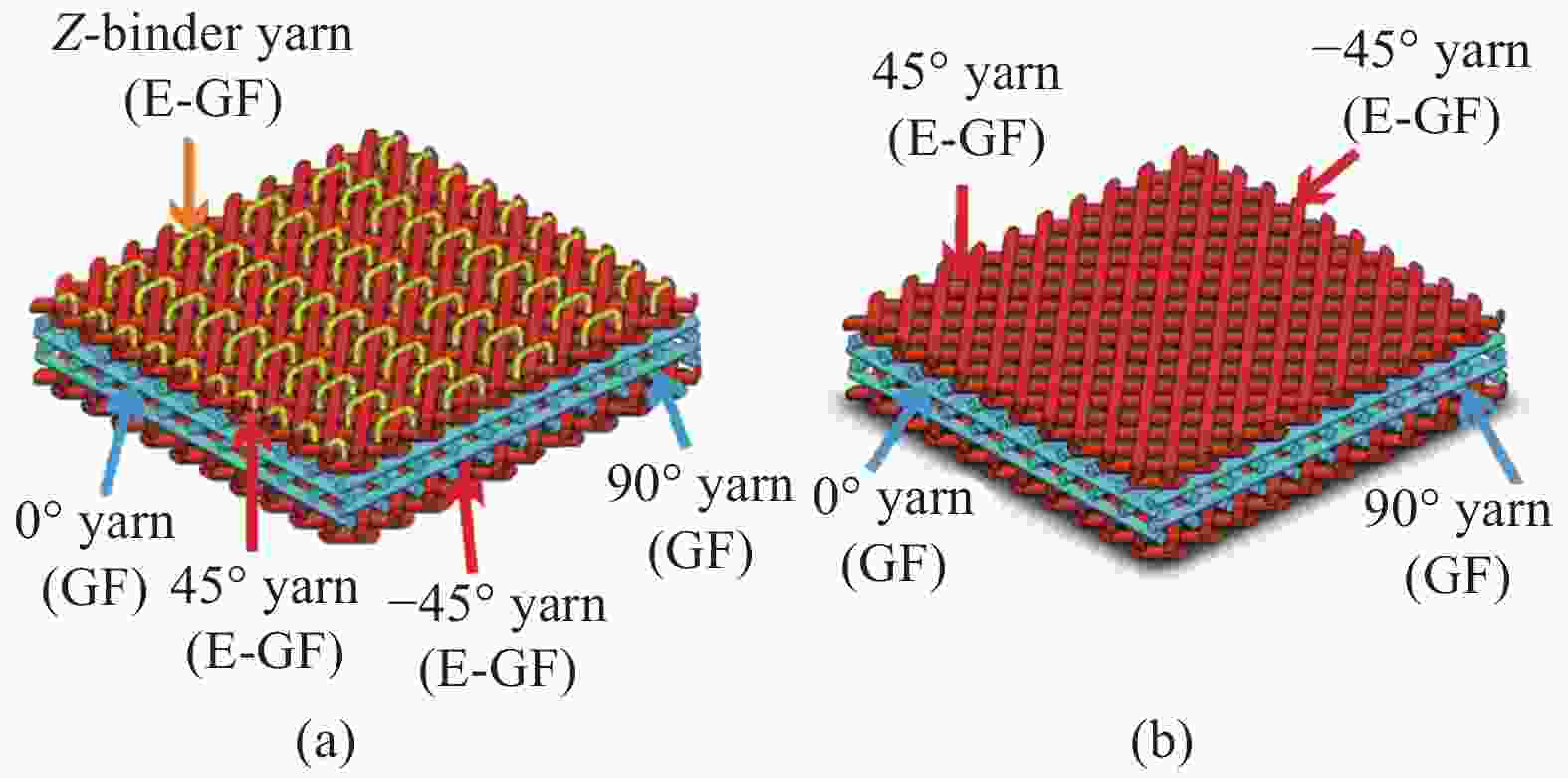

摘要: 研究了三维编织碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料和层合碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料在200℃和250℃分别老化10、30、90、120和180天后的弯曲和剪切性能的变化。结果显示热氧环境下,纤维/双马来酰亚胺树脂基体界面性能随着老化时间的延长而显著下降,且编织复合材料老化后的弯曲和剪切性能保留率大于层合复合材料。这是由于编织复合材料中沿厚度方向的Z向纱将所有纱线捆绑为一个整体结构抵抗外力,且在热氧老化造成复合材料之间产生裂纹时,Z向纱的存在可以阻挡裂纹的扩展,减缓材料的老化速率。这说明与层合复合材料相比,编织复合材料的整体结构能够起到补偿由热氧老化导致的力学性能下降的作用。Abstract: The bending and shear properties of the three-dimensional braided carbon fiber-glass fiber/bismaleimide composite and the laminated carbon fiber-glass fiber/bismaleimide composite were investigated aging at 200℃ and 250℃ for 10, 30, 90, 120, and 180 days, respectively. The results show that the interfacial performance of the fiber/matrix decreases significantly with the prolonged aging time in a hot oxygen environment, and the bending and shear retention rates of braided composite are better than the laminated composite. This is because Z-binder yarns in the thickness direction of braided composite bundle all yarns into an integral structure to resist external load, and the existence of Z-binder yarns can prevent the expansion of cracks and slow down the aging rate of composites when cracks occur between composites due to thermal-oxidative aging. This means that the integrated structure of braided composite can compensate the mechanical performance degradation caused by hot oxygen aging compared with the laminated composite.

-

表 1 组成材料的性能参数

Table 1. Properties of constituent materials

Material Type Tensile strength/MPa Tensile modulus/GPa Elongation at break/% Density/(g·cm−3) Carbon fiber T700 4 900 240 2.1 1.80 Glass fiber E 3 430 73 4.8 2.54 Bismaleimide BH301 92 4.5 2.4 1.25 表 2 三维编织碳纤维(CF)-玻璃纤维(GF)混杂织物和层合CF-GF混杂织物的织造工艺参数

Table 2. Technological parameters of the three-dimensional braided carbon fiber(CF)-glass fibers (GF) hybrid fabric and the laminated CF-GF hybrid fabric

Reinforced

structureYarns liner density/tex Preformed unit density/(yarn·cm−1) Layers Fiber volume

fraction/vol%0°/90° ±45° Z-binder yarns 0°/90° ±45° Z-binder yarns Braided fabric 800 400×2 400 5 6 5 8 47.74±1.16 Laminated fabric 800 400×2 — 6 6 — 8 46.23±1.42 表 3 老化BMI的红外特征峰位置对照

Table 3. Comparison of infrared characteristic peak position of aged BMI

Wavenumber/cm−1 Characteristic peak Functional group 2922 Asymmetric CH2 —CH2— 2851 Symmetric CH3 —CH3— 1710 Asymmetric imides —C=O— 1602 Combined production of C=C and C=O —C=C–C=O 1510 C—C of the benzene ring —C—C— 1365 Aliphatic groups and imines CH, CH2, CH3 1180 Generated by C=C C—N—C 1098 Succinimide or ether —C—O—C— 934 Maleimide deformation C=C -

[1] 王云英, 刘杰, 孟江燕, 等. 纤维增强聚合物基复合材料老化研究进展[J]. 材料工程, 2011(7):85-89.WANG Yunying, LIU Jie, MENG Jiangyan, et al. A review on aging behaviors of fiber reinforced polymer-matrix composites[J]. Journal of Materials Engineering,2011(7):85-89(in Chinese). [2] CHIN W S, LEE D G. Binary mixture rule for predicting the dielectric properties of unidirectional E-glass/epoxy composite[J]. Composite Structures,2006,74(2):153-162. doi: 10.1016/j.compstruct.2005.04.008 [3] FAN W, YUAN L J, D'SOUZA N, et al. Enhanced mechanical and radar absorbing properties of carbon/glass fiber hybrid composites with unique 3D orthogonal structure[J]. Polymer Testing,2018,69:71-79. doi: 10.1016/j.polymertesting.2018.05.007 [4] PAPA I, BOCCARUSSO L, LANGELLA A, et al. Carbon/glass hybrid composite laminates in vinylester resin: Bending and low velocity impact tests[J]. Composite Structures,2019,232:1-11. [5] LIU X, WU Z J, YAN J. Experimental study of the electrical resistivity of glass-carbon-epoxy hybrid composite[J]. Polymers and Polymer Composites,2014,22(3):289-292. doi: 10.1177/096739111402200310 [6] TSOTSIS T K, KELLER S, LEE K, et al. Aging of polymeric composite specimens for 5000 hours at elevated pressure and temperature[J]. Composites Science and Technology,2001,61:75-86. doi: 10.1016/S0266-3538(00)00196-2 [7] GATES T, GRAYSON M. On the use of accelerated aging methods for screening high temperature polymeric composite materials[C]//40th Structures, Structural Dynamics, and Materials Conference and Exhibit, 1999, 925-935. [8] BURKS B, KUMOSA M. The effects of atmospheric aging on a hybrid polymer matrix composite[J]. Composites Science& Technology,2012,72(15):1803-1811. [9] BURKS B, MIDDLETON J, KUMOSA M. Micromechanics modeling of fatigue failure mechanisms in a hybrid polymer matrix composite[J]. Composites Science & Technology,2012,72(15):1863-1869. [10] VU D Q, GIGLIOTTI M, LAFARIE-FRENOT M C. The effect of thermo-oxidation on matrix cracking of cross-ply [0/90]S composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2013,44:114-121. doi: 10.1016/j.compositesa.2012.08.013 [11] ZHAO Y, LIU W, SEAH L K, et al. Delamination growth behavior of a woven E-glass/bismaleimide composite in seawater environment[J]. Composites Part B: Engineering,2016,106:332-343. doi: 10.1016/j.compositesb.2016.09.045 [12] FAN W, LI J L, WANG H, et al. Influence of thermo-oxidative aging on the impact property of conventional and graphene-based carbon fabric composites[J]. Journal of Reinforced Plastics and Composites,2015,34(2):116-130. doi: 10.1177/0731684414565225 [13] 左翠平, 孙宝忠. 三维正交机织玄武岩/环氧树脂复合材料高温老化后低速冲击性质[J]. 复合材料学报, 2015, 33(3):545-550.ZUO Cuiping, SUN Baozhong. Low velocity impact behaviors of 3D orthogonal woven basalt/epoxy composites after high-temperature aging[J]. Acta Materiae Compositae Sinica,2015,33(3):545-550(in Chinese). [14] HOSOI A, KAWADA H. Fatigue life prediction for transverse crack initiation of CFRP cross-ply and quasi-isotropic laminates[J]. Materials,2018,11(7):1-16. [15] BULLEGAS G, BENOLIEL J, FENELLI P L, et al. Towards quasi isotropic laminates with engineered fracture behaviour for industrial applications[J]. Composites Science and Technology,2018,165:290-306. doi: 10.1016/j.compscitech.2018.07.004 [16] 李嘉禄, 孙颖, 李学明. 二步法方型三维编织复合材料力学性能及影响因素[J]. 复合材料学报, 2004(1):90-94.LI Jialu, SUN Ying, LI Xueming. Research on the mechanical properties and the effectors of the two -step 3D braided composites[J]. Acta Materiae Compositae Sinica,2004(1):90-94(in Chinese). [17] 马少华, 费昺强, 许良, 等. 热氧老化对碳纤维双马树脂基复合材料性能的影响[J]. 材料工程, 2017, 45(12):50-57.MA Shaohua, FEI Bingqiang, XU Liang, et al. Influence of thethermal-oxidative aging on property of carbon fiber bismaleimide resin composites[J]. Journal of Materials Engineering,2017,45(12):50-57(in Chinese). [18] BULLIONS T A, MCGRATH J E, LOOS A C. Thermal-oxidative aging effects on the properties of a carbon fiber-reinforced phenylethynyl-terminated poly(etherimide)[J]. Composites Science and Technology,2003,63:1737-1748. doi: 10.1016/S0266-3538(03)00089-7 [19] AKAY M, SPRATT G R, MEENAN B. The effects of long-term exposure to high temperatures on the ILSS and impact performance of carbon fibre reinforced bismaleimide[J]. Composites Science and Technology,2003,63(7):1053-1059. doi: 10.1016/S0266-3538(03)00018-6 [20] SHINDO Y, WANG R, HORIGUCHI K, et al. Theoretical and experimental evaluation of double-notch shear strength of G-10CR glass-cloth/epoxy laminates at cryogenic tempera-tures[J]. Journal of Engineering Materials and Technology,1999,121:367-373. doi: 10.1115/1.2816002 [21] XUE L L, FAN W, WU F, et al. The influence of thermo-oxidative aging on the electromagnetic absorbing properties of 3D quasi-isotropic braided carbon/glass bismaleimide composite[J]. Polymer Degradation and Stability,2019,168:1-8. [22] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.The China National Standardization Management Committee. Fibre-reinforced plastic composites-Dertermination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [23] American Society For Testing and Materials. Standard test method for in-plane shear strength of reinforced plastics: ASTM D3846[S]. West Conshohocken: American Society for Testing and Materials, 2015. [24] LI J Z, FAN W, MA Y L, et al. Influence of reinforcement structures and hybrid types on inter-laminar shear performance of carbon-glass hybrid fibers/bismaleimide composites under long-term thermo-oxidative aging[J]. Polymers,2019,11(8):1-11. [25] WANG S Q, DONG S L, GAO Y, et al. Thermal ageing effects on mechanical properties and barely visible impact damage behavior of a carbon fiber reinforced bismaleimide composite[J]. Materials & Design,2017,115:213-223. [26] CYSNE B A P, FULCO A P P, GUERRA E S S, et al. Accelerated aging effects on carbon fiber/epoxy composites[J]. Composites Part B: Engineering,2017,110:298-306. doi: 10.1016/j.compositesb.2016.11.004 [27] YANG B F, YUE Z F, GENG X L, et al. Temperature effects on transverse failure modes of carbon fiber/bismaleimides composites[J]. Journal of Composite Materials,2016,51(2):261-272. [28] FAN W, LI J L, ZHENG Y Y, et al. The effect of reinforced structure on thermo-oxidative stability of polymer-matrix composites[J]. Journal of Industrial Textiles,2015,46(1):237-255. -

下载:

下载: