Experiment study on mechanical properties of ultra-high performance concrete under ambient temperature change

-

摘要: 应用四点抗弯、轴压、轴拉实验,研究环境温度变化(−30℃、0℃、30℃、60℃、90℃)对超高性能混凝土(UHPC)力学性能的影响,通过数字图像技术(DIC)表征受弯过程中裂缝的发展,并结合SEM、压汞(MIP)对其微观结构进行分析。结果表明:经历不同环境温度变化后,UHPC弯拉、抗压、轴拉强度分别处于13.4~16.3 MPa、121.5~133 MPa、6.6~7.0 MPa范围,轴拉应变约为0.2%;与基准温度(30℃)相比,低温作用对其力学性能几乎无影响,随温度的升高性能有一定降低,但仍处于较高的水平;弯拉强度和轴拉强度在不同环境温度下都大致存在比例系数约为2.3的线性关系;30℃下基体更加致密,拥有最优的力学性能。

-

关键词:

- 超高性能混凝土(UHPC) /

- 环境温度变化 /

- 力学性能 /

- 数字图像技术(DIC) /

- 微观结构

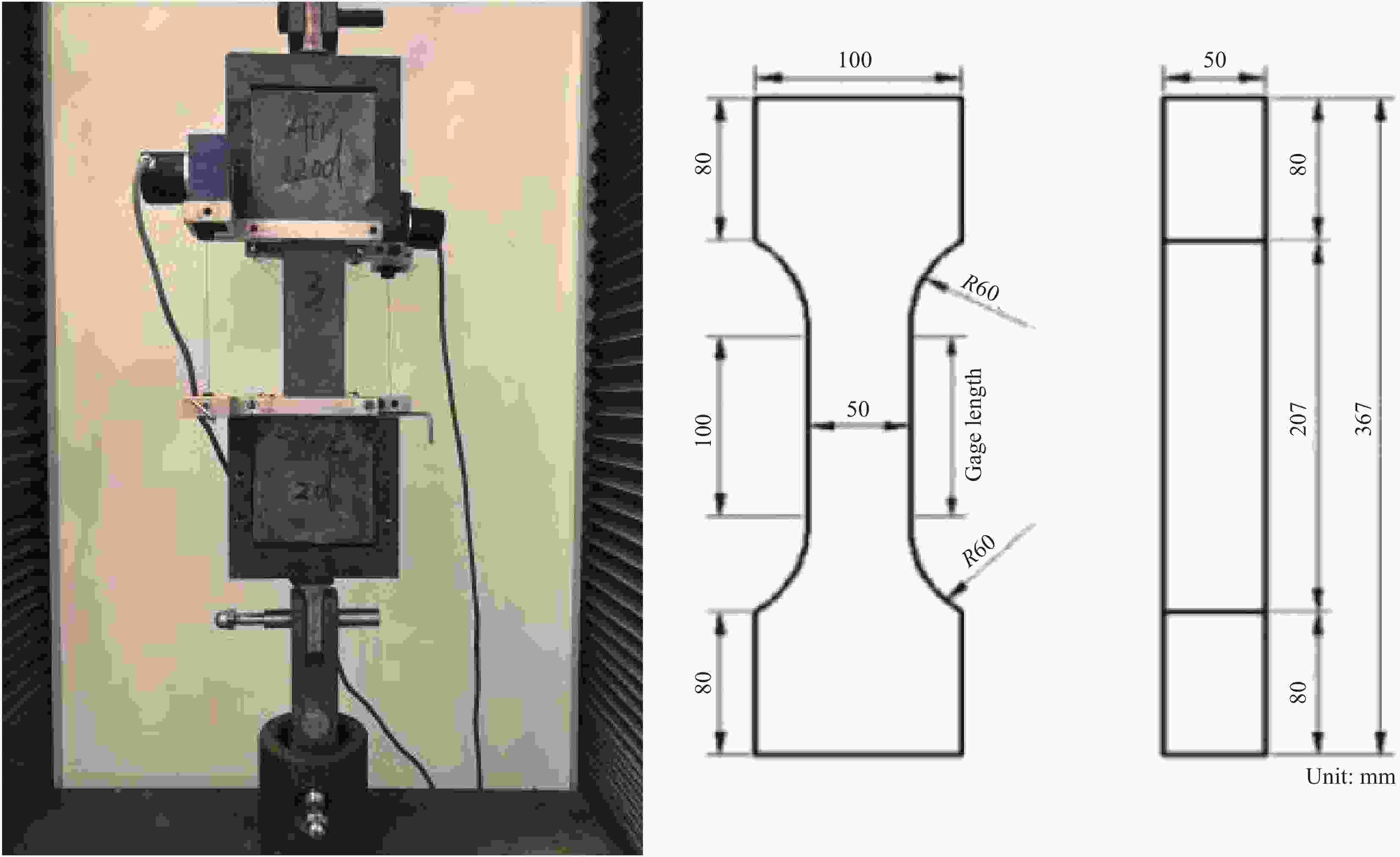

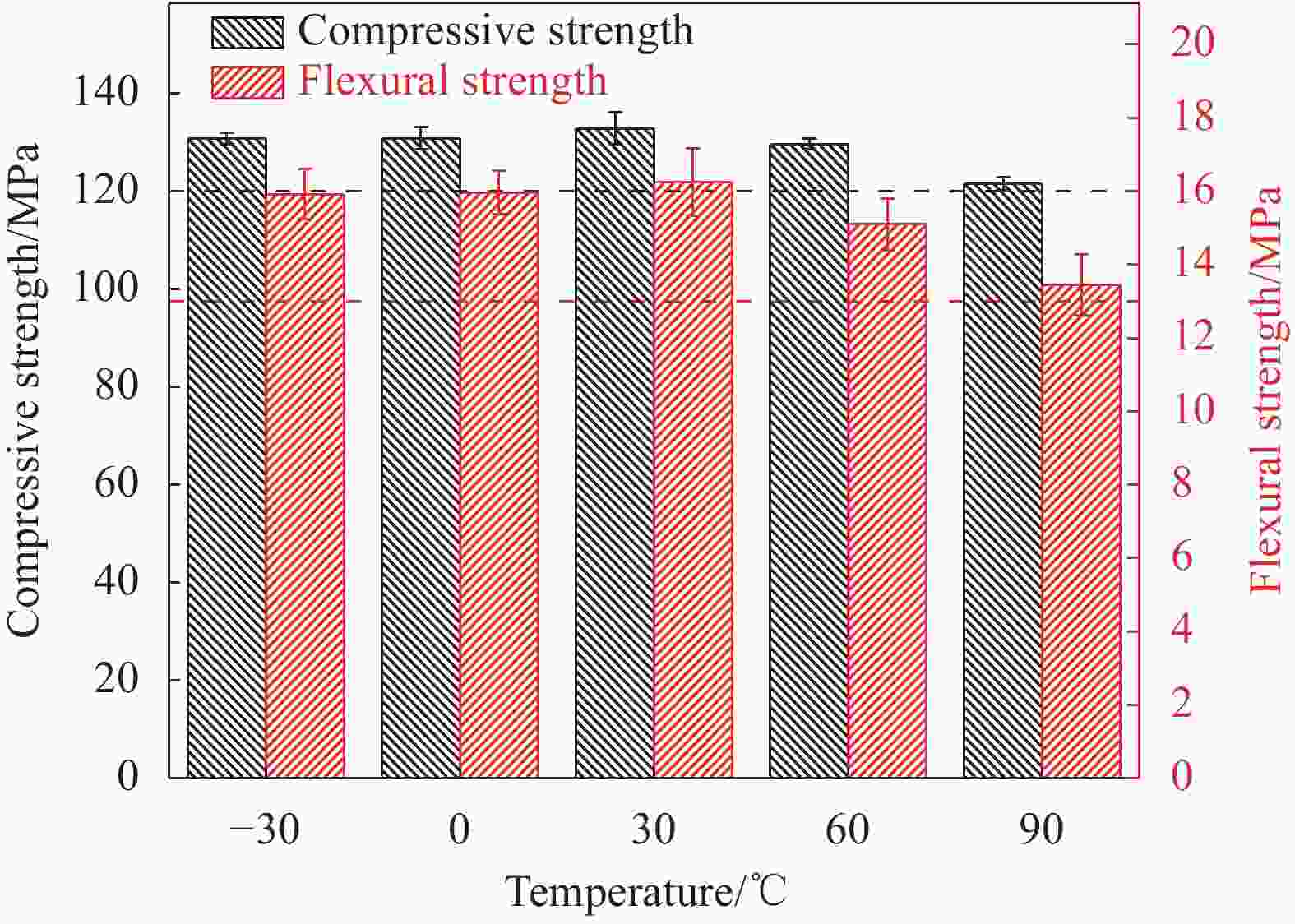

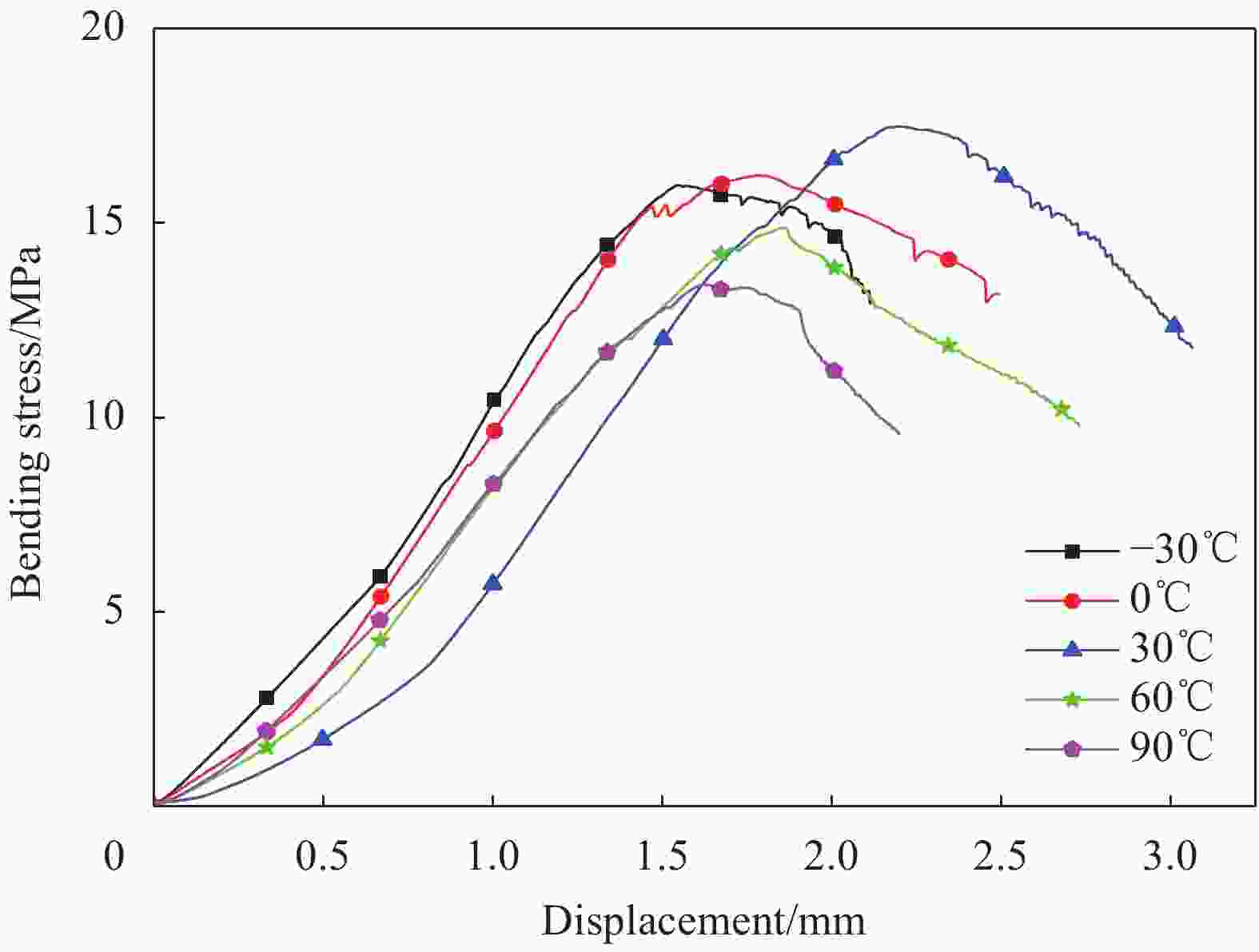

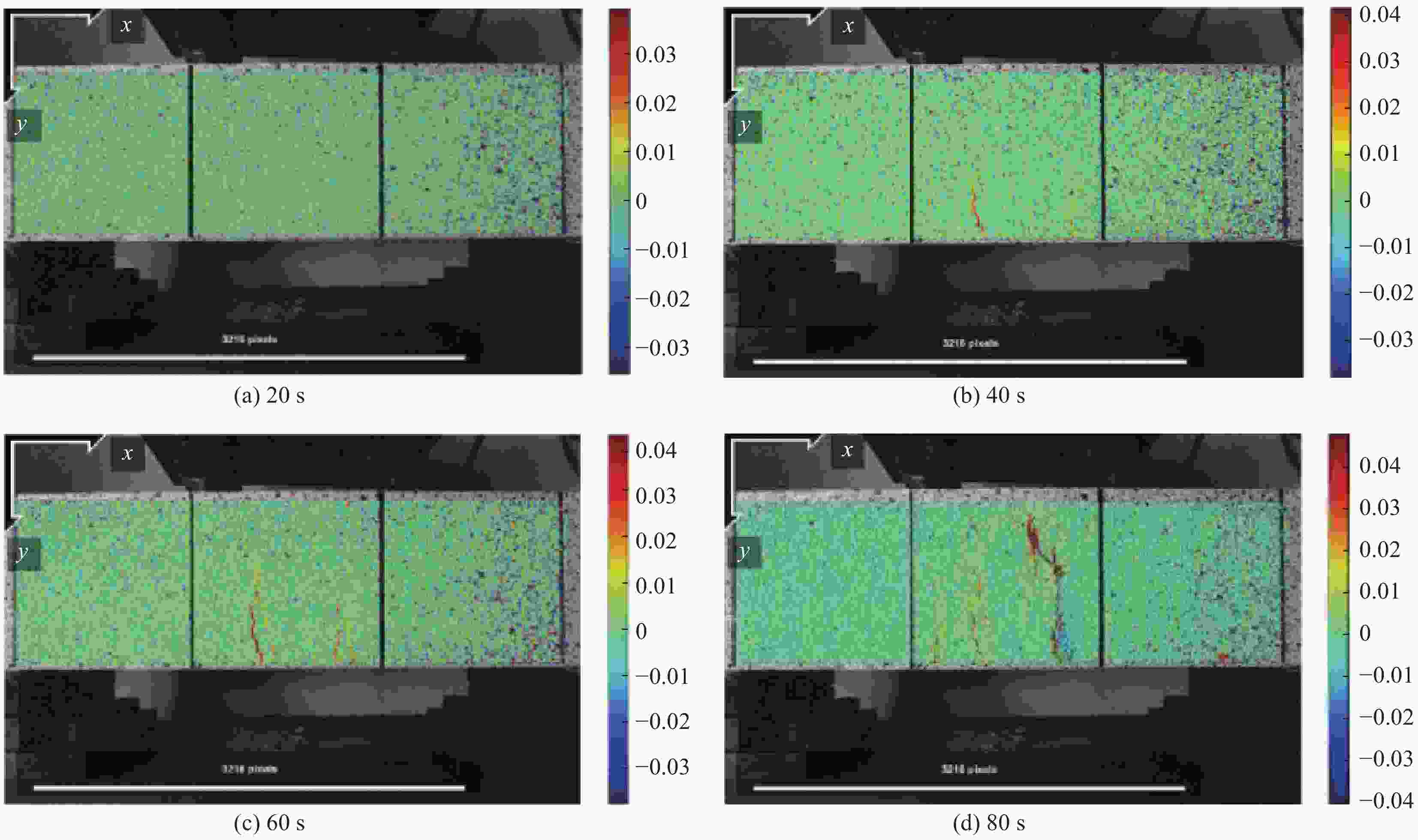

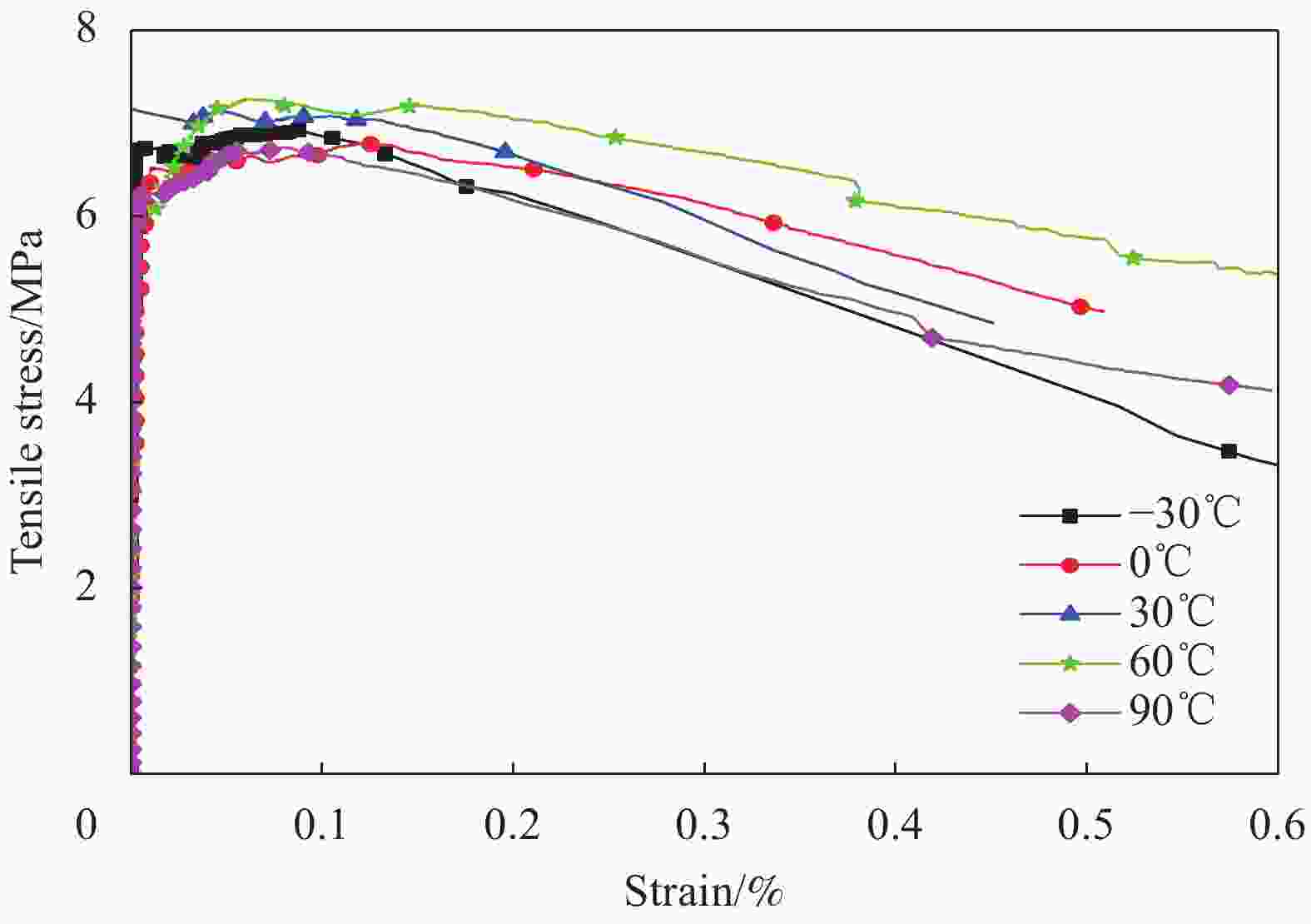

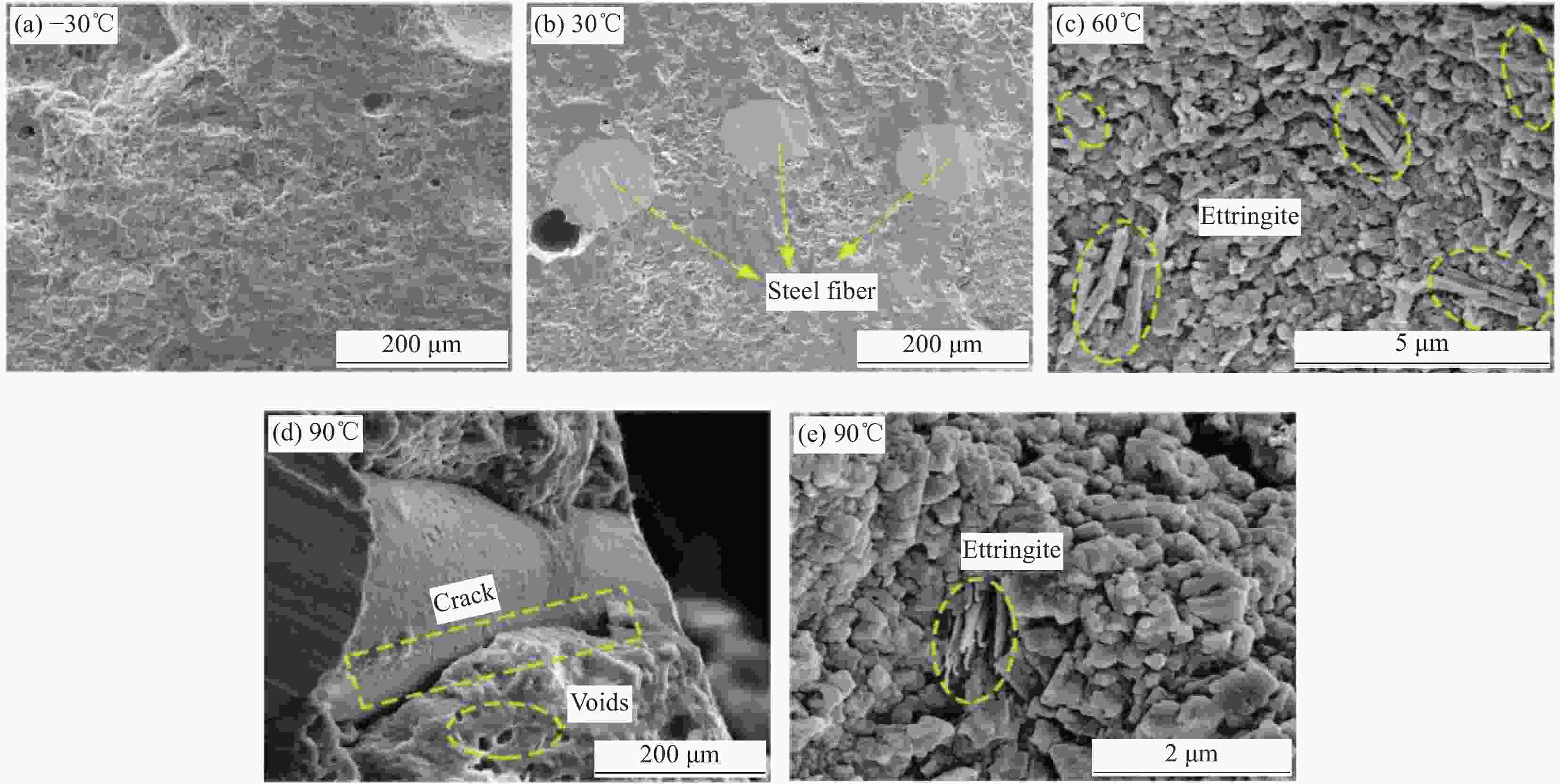

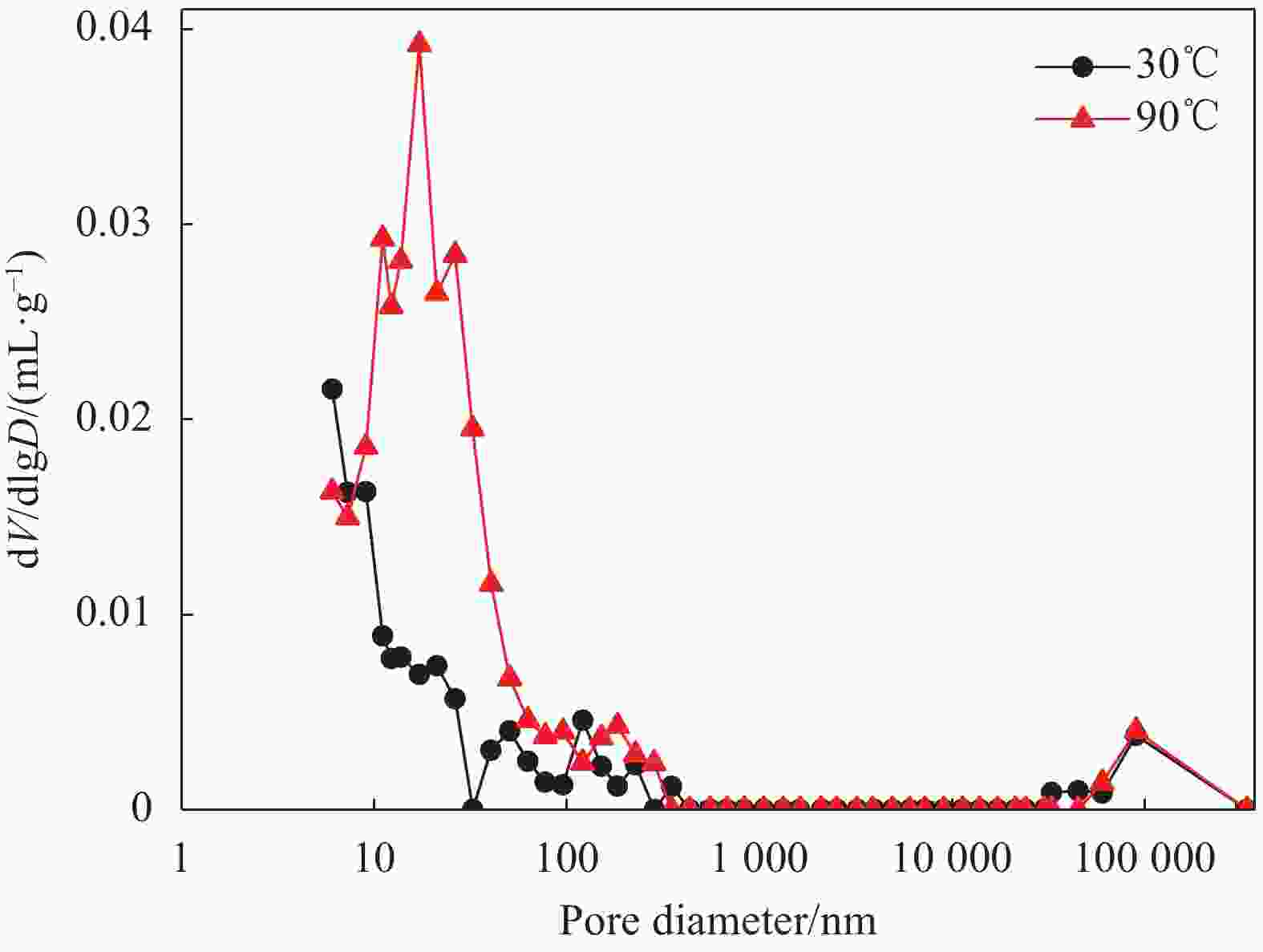

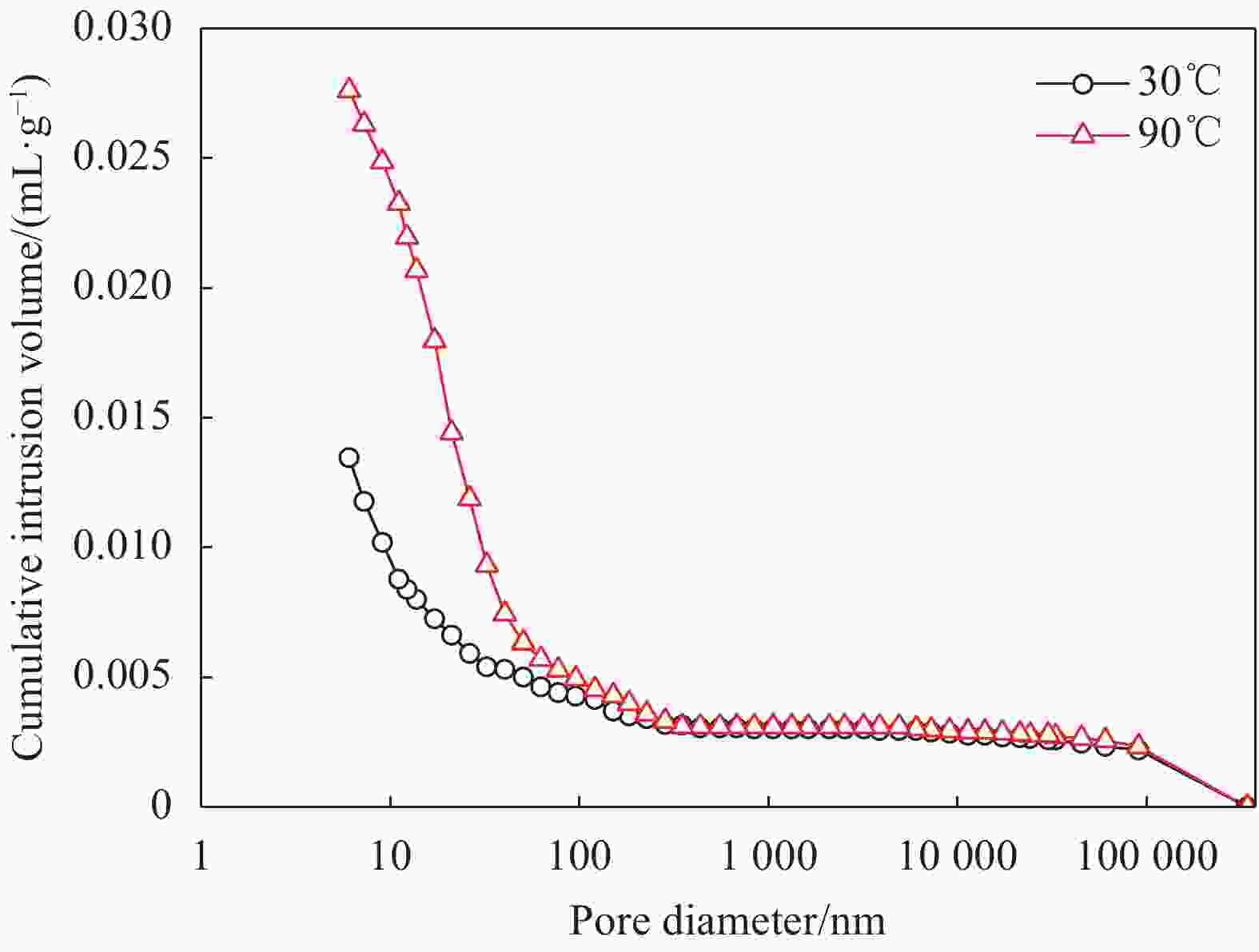

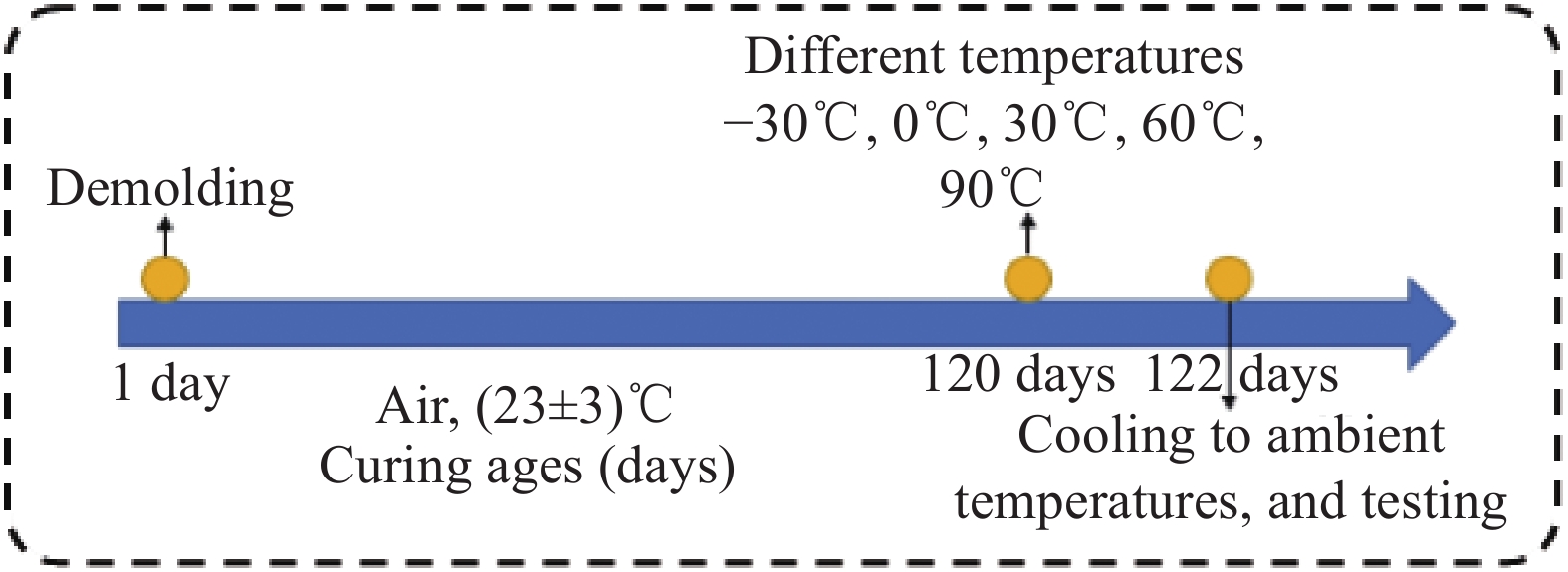

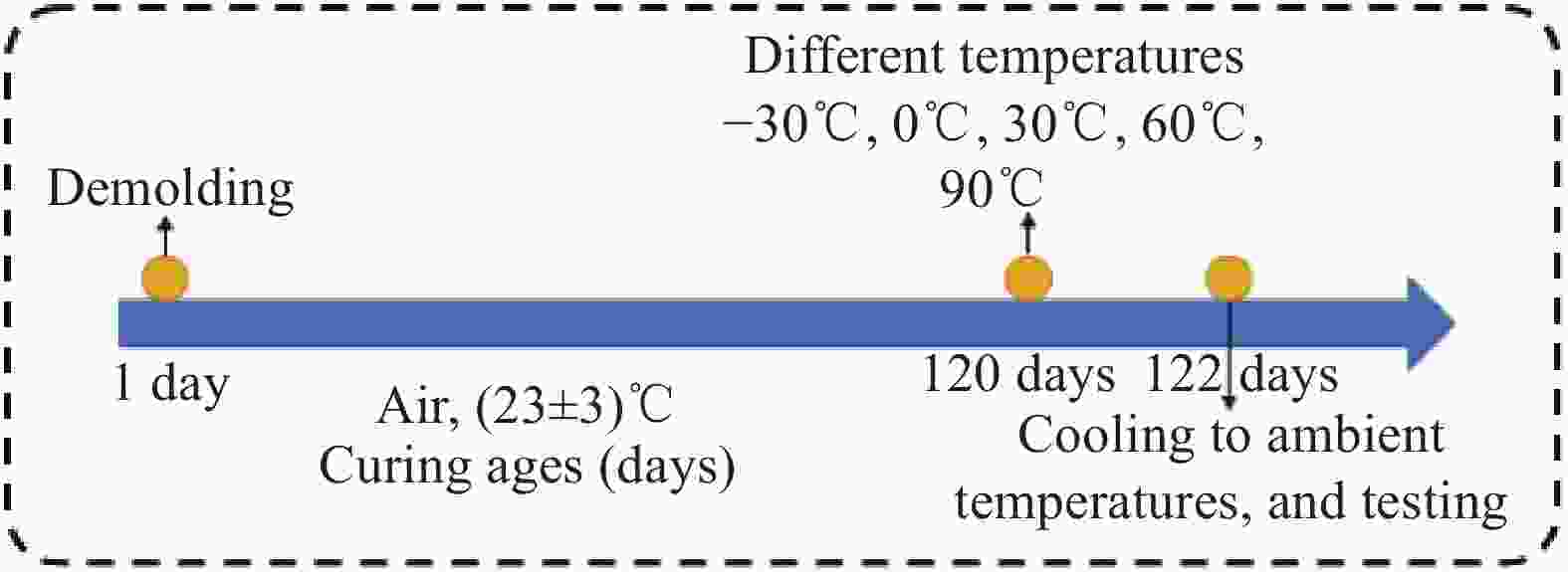

Abstract: Four-point bending, uniaxial compressive and tensile tests were employed to explore the effects of the change of ambient temperatures (−30℃、0℃、30℃、60℃、90℃) on the mechanical properties of the ultra-high performance concrete (UHPC). The propagation of cracks during bending process was monitored by a digital image correlation (DIC) technology, and SEM and mercury intrusion porosimetry (MIP) were conducted to analyze the microstructure. The results show that the bending, compressive and tensile strengths of UHPC are within the range of 13.4-16.3 MPa, 121.5-133 MPa and 6.6-7.0 MPa, respectively, after subjected to different ambient change of temperatures. The tensile strain keeps almost consistent around 0.2%. Compared with standard temperature (30℃), the low temperature has little impact on the mechanical properties of UHPC, while the properties decrease with the temperature increasing, nevertheless, still at a higher level. The flexural strength and uniaxial strength present approximately linear relationship with proportionality coefficient of 2.3 at different temperatures. The matrix of UHPC at 30℃ is relatively denser, and thus possesses optimal mechanical properties. -

表 1 超高性能混凝土(UHPC)材料配合比

Table 1. Mix design proportion of ultra-high performance concrete (UHPC)

wt% Cement Silica fume Sand Water Superplasticizers Steel fiber 35.4 7.1 42.5 7.8 0.2 7.0 表 2 UHPC在不同环境温度变化下的力学性能

Table 2. Mechanical properties of UHPC at different ambient temperatures

Temperature/℃ −30 0 30 60 90 ff-test/MPa 15.9 15.9 16.3 15.1 13.8 σt-test/MPa 6.8 6.9 7.0 6.7 6.6 σt-theoretic/MPa 10.1 10.1 11.7 9.5 7.8 ff-test/σt-test 2.3 2.3 2.3 2.3 2.1 表 3 不同环境温度作用下UHPC的孔结构参数

Table 3. Pore structure parameters of the UHPC subjected to different ambient temperatures

Temperature/℃ Porosity/% Total pore space/

(mL·g−1)Total pore specific

surface area/(m2·g−1)Most probable

pore/nmAverage probable

pore/nm30℃ 3.1324 0.0135 3.234 6.0469 16.6 90℃ 6.3647 0.0276 5.631 11.0392 19.6 -

[1] 梁兴文, 胡翱翔, 于婧, 等. 钢纤维对超高性能混凝土抗弯力学性能的影响[J]. 复合材料学报, 2018, 35(3):722-731.LIANG Xingwen, HU Aoxiang, YU Jing, et al. Influence of steel fiber on the flexural mechanical properties of ultra-high performance concrete[J]. Acta Materiae Compositae Sinica,2018,35(3):722-731(in Chinese). [2] 朋改非, 杨娟, 石云兴, 等. 超高性能混凝土抗高温爆裂性能试验研究[J]. 建筑材料学报, 2017, 20(2):229-233. doi: 10.3969/j.issn.1007-9629.2017.02.012PENG Gaifei, YANG Juan, SHI Yunxing, et al. Experimental study on high temperature burst resistance of ultra-high performance concrete[J]. Journal of Building Materials,2017,20(2):229-233(in Chinese). doi: 10.3969/j.issn.1007-9629.2017.02.012 [3] 杨娟, 朋改非. 纤维对超高性能混凝土残余强度及高温爆裂性能的影响[J]. 复合材料学报, 2016, 33(12):2931-2940.YANG Juan, PENG Gaifei. Effect of fiber on residual strength and explosives palling behavior of ultra-high-performance concrete exposed to high temperature[J]. Acta Materiae Compositae Sinica,2016,33(12):2931-2940(in Chinese). [4] 朋改非, 杨娟, 石云兴. 超高性能混凝土高温后残余力学性能试验研究[J]. 土木工程学报, 2017, 50(4):73-79.PENG Gaifei, YANG Juan, SHI Yunxing. Experimental study on residual mechanical properties of ultra-high performance concrete after high temperature[J]. China Civil Engineering Journal,2017,50(4):73-79(in Chinese). [5] HUANG H H, WANG R, GAO X J. Improvement effect of fiber alignment on resistance to elevated temperature of ultra-high performance concrete[J]. Composites Part B: Engineering,2019,177(15):107454. [6] HOU X M, ABID M, ZHENG W Z, et al. Evaluation of residual mechanical properties of steel fiber-reinforced reactive powder concrete after exposure to high temperature using nondestructive testing[J]. Proceia Engineering,2017,210:588-596. doi: 10.1016/j.proeng.2017.11.118 [7] AHMAD S, HAKEEM I, AZAD A K. Effect of curing, fiber content and exposures on compressive strength and elasticity of UHPC[J]. Advance in Cement Research,2015,27(4):233-239. doi: 10.1680/adcr.13.00090 [8] KIM M J, KIM S, LEE S K, et al. Mechanical properties of ultra-high-performance fiber-reinforced concrete at cryogenic temperatures[J]. Construction Building Materials,2017,157:498-508. doi: 10.1016/j.conbuildmat.2017.09.099 [9] KIM S, KIM M J, YOO D Y, et al. Effect of cryogenic temperature on the flexural and cracking behaviors of ultra-high-performance fiber-reinforced concrete[J]. Cryogenics,2018,93:75-85. doi: 10.1016/j.cryogenics.2018.06.002 [10] KIM M J, YOO D Y, KIM S, et al. Effects of fiber geometry and cryogenic condition on mechanical properties of ultra-high-performance fiber-reinforced concrete[J]. Cement and Concrete Research,2018,107:30-40. doi: 10.1016/j.cemconres.2018.02.003 [11] KIM S, YOO D Y, KIM M J, et al. Self-healing capability of ultra-high-performance fiber-reinforced concrete after exposure to cryogenic temperature[J]. Cement and Concrete Composites,2019,104:103335. doi: 10.1016/j.cemconcomp.2019.103335 [12] 牛旭婧, 乜颖, 朋改非, 等. 养护制度对超高性能混凝土抗高温爆裂性能的影响[J]. 硅酸盐学报, 2020, 48(8):1-11.NIU Xujing, NIE Ying, PENG Gaifei, et al. Effect of curing system on high temperature blowout resistance of ultra high performance concrete[J]. Journal of the Chinese Ceramic Society,2020,48(8):1-11(in Chinese). [13] 刘柯柯. 混杂纤维混凝土的环境温度作用、抗冻、氯盐渗透性试验研究[D]. 上海: 同济大学, 2019.LIU Keke. Experimental research on environmental temperature impact, frost resistance and chloride penetration of hybrid fiber reinforced concrete[D]. Shanghai: Tongji University, 2019(in Chinese). [14] 中国建筑科学研究院. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003.China Academy of Building Research. Standard for test method of mechanical properties on ordinary concrete: GB/T 50081—2002[S]. Beijing: China Architecture & Building Press, 2003(in Chinese). [15] LIU S F, SUN W, LIN W, et al. Preparation and durability of a high performance concrete with natural ultra-fine particles[J]. Journal of The Chinese Ceramic Society, 2003(11): 1080-1085. [16] 阎培渝, 覃肖, 杨文言. 大体积补偿收缩混凝土中钙矾石的分解与二次生成[J]. 硅酸盐学报, 2000, 28(4):21-26.YAN Peiyu, QIN Xiao, YANG Wenyan. Decomposition and secondary formation of ettringite in mass compensated shrinkage concrete[J]. Journal of the Chinese Ceramic Society,2000,28(4):21-26(in Chinese). [17] 钱觉时, 余金城, 孙化强, 等. 钙矾石的形成与作用[J]. 硅酸盐学报, 2017, 45(11):1569-1581.QIAN Jueshi, YU Jincheng, SUN Huaqiang, et al. Formation and action of ettringite[J]. Journal of the Chinese Ceramic Society,2017,45(11):1569-1581(in Chinese). [18] CHEN H J, YU Y L, TANG C W. Mechanical properties of ultra-high performance concrete before and after exposure to high temperatures[J]. Materials,2020,13(3):770. doi: 10.3390/ma13030770 [19] 张哲. 钢—配筋UHPC组合桥面结构弯曲受拉性能研究[D]. 长沙: 湖南大学, 2016.ZHANG Zhe. Bending behaviors composite bridge deck system composed of OSD and reinforced UHPC layer[D]. Changsha: Hunan University, 2016(in Chinese). [20] PYO S, WILLE K, EL-TAWIL S, et al. Strain rate dependent properties of ultra high performance fiber reinforced concrete (UHP-FRC) under tension[J]. Cement and Concrete Composites,2015,56:15-24. doi: 10.1016/j.cemconcomp.2014.10.002 [21] 申鼎宇. 超高性能混凝土弯拉基本性能研究[D]. 长沙: 湖南大学, 2017.SHEN Dingyu. The basic research on the flexural properties of ultrahigh performance concrete[D]. Changsha: Hunan University, 2017(in Chinese). [22] GRAYBEAL B A, BABY F. Development of direct tension test method for ultra-high-performance fiber-reinforced concrete[J]. ACI Materials Journal, 2013, 110(2): 177-186. [23] 管品武, 涂雅筝, 张普, 等. 超高性能混凝土单轴拉压本构关系研究[J]. 复合材料学报, 2019, 36(5):1295-1305.GUAN Pinwu, TU Yazheng, ZHANG Pu, et al. A review on constitutive relationship of ultra-high performance concrete under uniaxial compression and tension[J]. Acta Materiae Compositae Sinica,2019,36(5):1295-1305(in Chinese). [24] GRAYBEAL B A. Material property characterization of ultra-high performance concrete[M]. McLean: Department ofTransportation, Federal Highway Administration, 2006. [25] 高绪明. 钢纤维对超高性能混凝土性能影响的研究[D]. 湖南: 湖南大学, 2013.GAO Xuming. Research on the performance of UHPC with steel fiber[D]. Changsha: Hunan University, 2013(in Chinese). -

下载:

下载: